High-power high-current choking winding

A choke coil, high current technology, applied in the direction of transformer/inductor coil/winding/connection, inductor with magnetic core, transformer/inductor core, etc. and other problems, to achieve the effect of easy insertion and welding, easy penetration and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

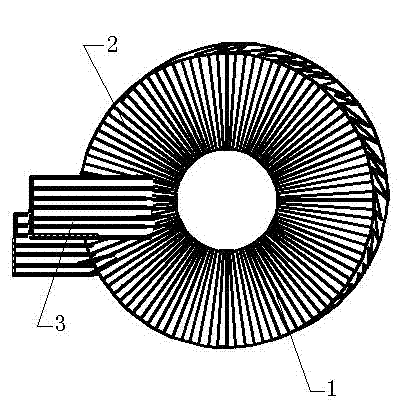

[0011] Such as figure 1 Shown is a high-power and high-current choke coil, including a ring-shaped magnetizer 1 and a coil winding wrapped around the ring-shaped magnetizer. The coil winding is formed by twisting more than three enameled wires 2; the lead-out part 3 of the coil winding is each strand The enameled wires 2 are arranged in parallel and connected to form a flat plate; the outer surface of the ring magnet is coated with an insulating layer.

[0012] The above is only a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also possible. It should be regarded as the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com