Graphene nano-belts, preparation method of graphene nano-belts, and application of graphene nano-belts in transparent electrodes

A graphene nanoribbon and graphene thin film technology, applied in nanotechnology, chemical instruments and methods, optics, etc., can solve the problems of cumbersome preparation process, high price, difficulty in preparing long-length graphene nanoribbon, etc. Simple, low-cost, shape-controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

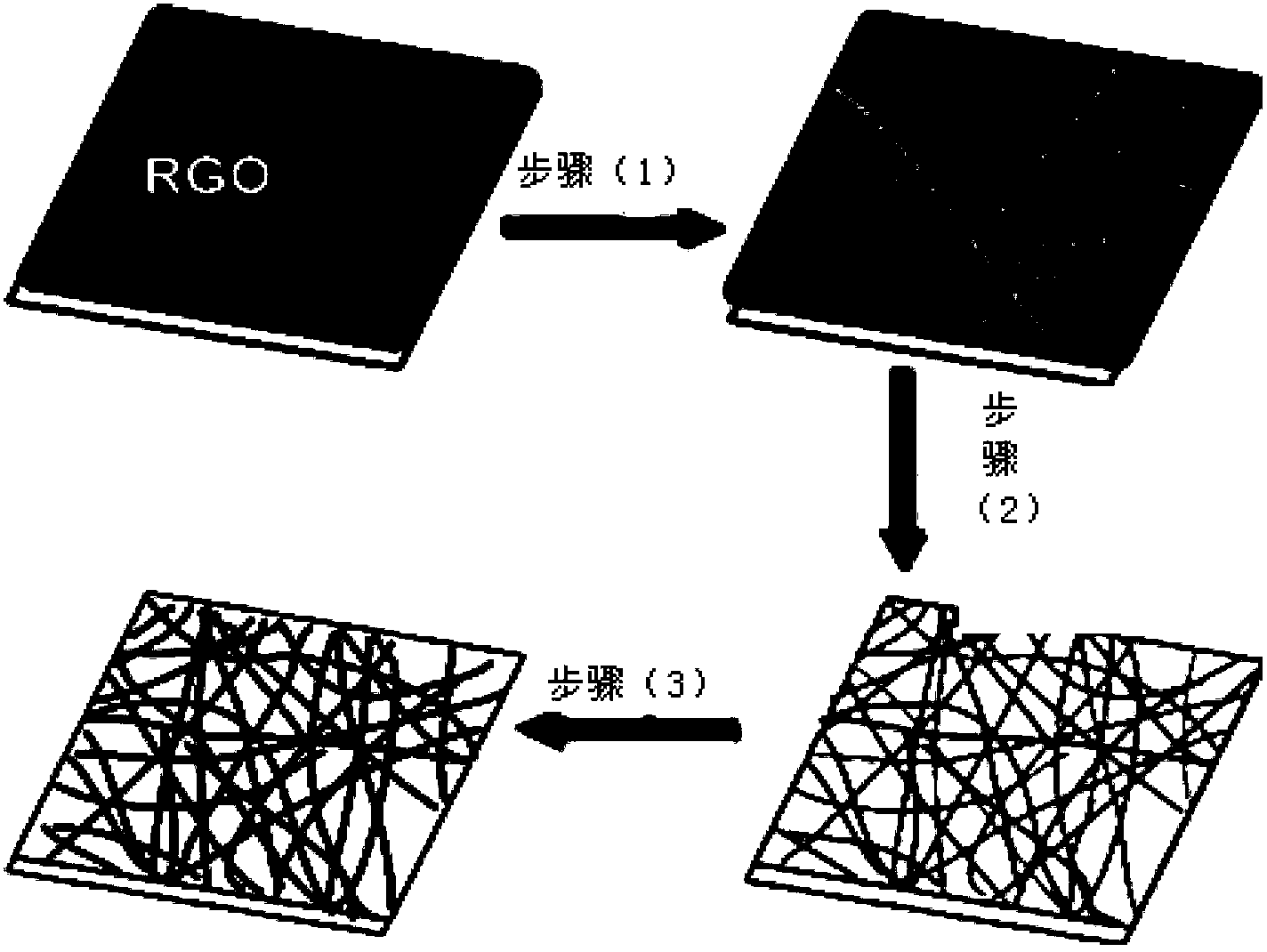

[0012] The invention provides a method for preparing a graphene nanoribbon, which comprises the following steps: (1) depositing a solution or melt containing a spinnable polymer on a graphene film by electrospinning to form a mask; (2) ) Etching away the graphene on the graphene film not covered by the mask; (3) removing the mask to form graphene nanobelts.

[0013] According to the present invention, the spinnable macromolecules can be any macromolecules capable of forming a mask on a graphene film by micro and / or nano wires by electrospinning technology, such as polyacrylonitrile, polyvinyl alcohol, poly One or more of vinylpyrrolidone, polystyrene and polylactic acid, preferably one or more of polyvinyl alcohol, polyacrylonitrile and polyvinylpyrrolidone.

[0014] According to the present invention, preferably, the method further includes dispersing one or more of inorganic substances, inorganic nanoparticles, and organometallic compounds in the solution or melt of the spin...

Embodiment 1

[0044] The graphite oxide solution of configuration 0.5mg / L, adopts the method for spin-coating of homogenizer to load graphite oxide thin film on the surface of quartz plate, and spin-coating speed is 4000 revs / min, and spin-coats 3 times, the graphene thin film that will obtain, in Treated at 1100°C under the protection of hydrogen.

[0045] At 60°C, polyvinyl alcohol was dissolved in twice-distilled water to prepare an aqueous solution of polyvinyl alcohol with a concentration of 10 wt%. Then carry out electrospinning, wherein the amount of solution is 1mL, the nozzle diameter of the glass tube is 0.33mm, and the nozzle of the glass tube is inclined at 35.9 degrees with the horizontal line, the voltage of the high-voltage power supply is 15kV, the receiving substrate is aluminum foil, and the spinning nozzle The distance from the receiving substrate is 10 cm, the quartz plate loaded with graphene film is placed on the receiving substrate aluminum foil, and the power is turn...

Embodiment 2

[0047] Prepare graphene nanobelts according to the same method as Example 1, the difference is that polyvinyl alcohol is first dissolved in double distilled water, and then nickel acetate is dispersed in this polyvinyl alcohol solution, wherein, by mass ratio , Nickel acetate: polyvinyl alcohol = 1:1, prepared as an aqueous solution of polyvinyl alcohol containing nickel acetate at a concentration of 10wt%. As a result, graphene nanoribbons with a length of 3 mm, a width of 150 nm, and a thickness of 30 nm were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com