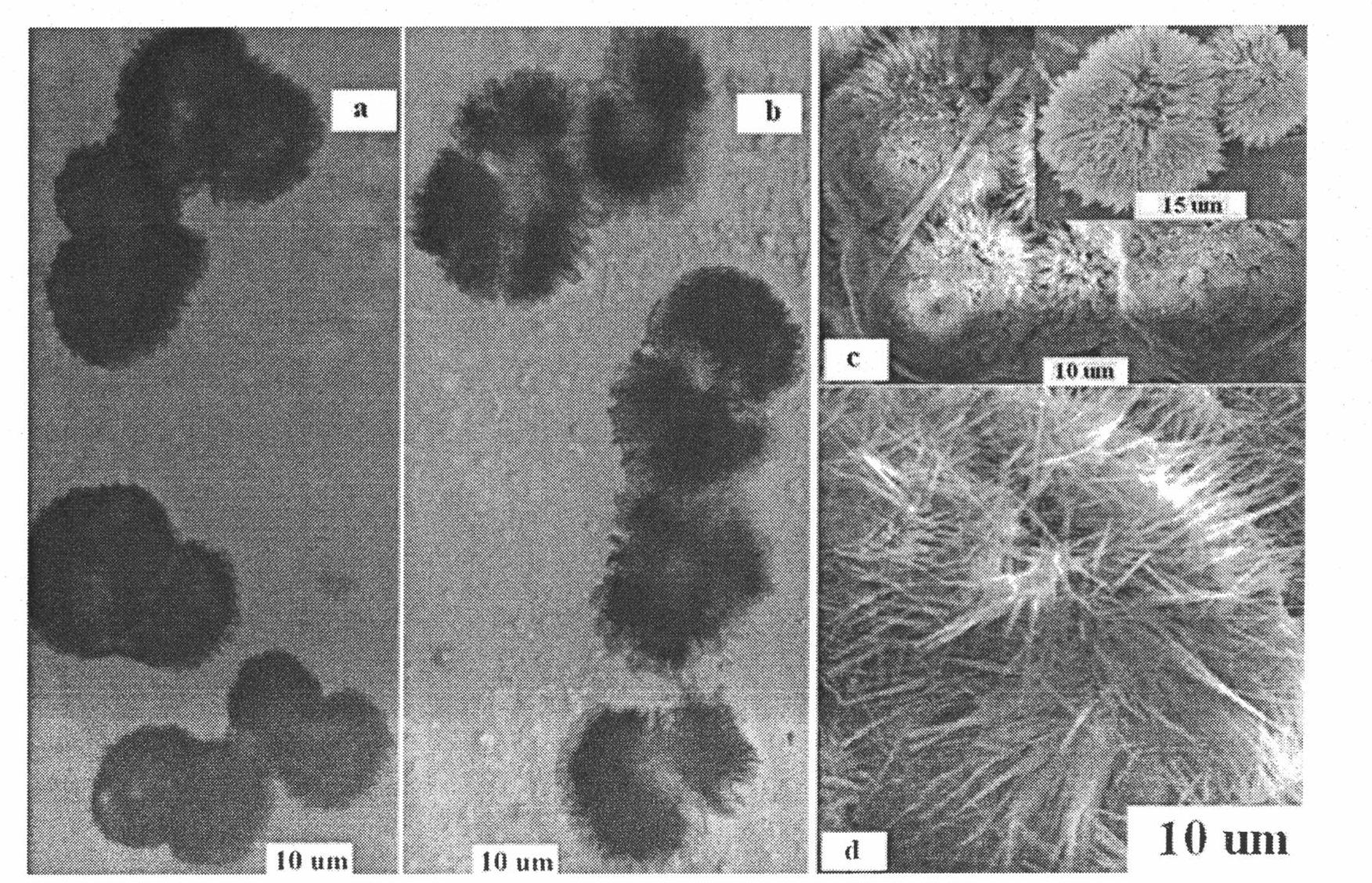

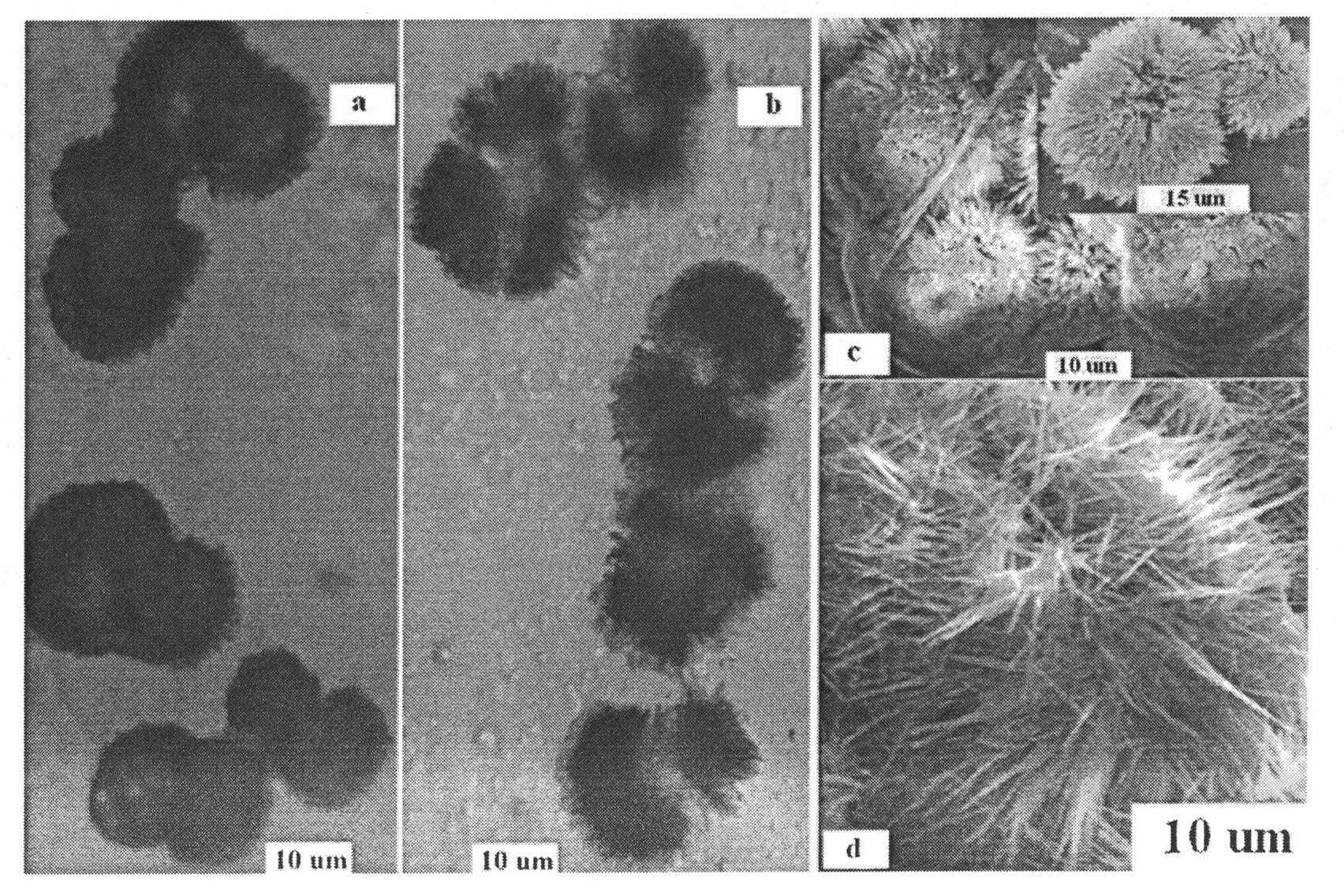

Preparation method of hedgehog SiO2 hollow microsphere

A hollow microsphere and hedgehog technology, which is applied in the field of preparation of hedgehog-shaped SiO2 hollow microspheres, can solve the problems that the silica hollow microspheres cannot be satisfied, the types of block copolymers are limited, and the synthesis of copolymers is not easy. Easy to tune, wide application value, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of block polymer polyacrylic acid ethyl cinnamate 53-block-(polyacrylic acid 94-copolymerization-polystyrene 258)

[0038] Weigh 0.075g polyethyl cinnamate 53-intercalated-(tert-butyl acrylate 94-copolymerization-polystyrene 258), put it into a 50mL single-neck round bottom flask, add 10mL solvent dichloromethane, 2mL of trifluoroacetic acid, protected from light and hydrolyzed for 24 hours, to obtain polyacrylic acid ethyl cinnamate 53-intercalated-(polyacrylic acid 94-copolymerization-polystyrene 258), spin concentration to remove solvent and trifluoroacetic acid, and add a certain amount of dichloromethane, at room temperature to make it volatilize, the obtained sample is the block polymer polyacrylic acid ethyl cinnamate 53-block-(polyacrylic acid 94-copolymerization-polystyrene 258) in a refrigerator after vacuum drying for 24h save.

[0039] (2) SiO 2 Preparation of hollow microspheres

[0040] Take 0.002g polyacrylic acid ethyl cinnamate 53-int...

Embodiment 2

[0042] (1) Block polymer polyacrylic acid ethyl cinnamate 53-block-(polyacrylic acid 58-co-poly-poly-tert-butyl acrylate 36-co-polystyrene 258) (referred to as PCEA53-b-P(AA58-co-tBA36 Preparation of -co-Sty258))

[0043] Weigh 0.025g of polyethyl cinnamate 53-intercalated-(tert-butyl acrylate 94-co-polystyrene 258) (referred to as PCEA53-b-P(tBA94-co-Sty258) and put it into a 50mL single-necked round Add 10mL of dichloromethane and 2mL of trifluoroacetic acid into a bottom flask, and hydrolyze for 5 hours in the dark to obtain polyacrylic acid ethyl cinnamate 53-intercalated-(polyacrylic acid 58-copolymerized-polyacrylic acid tert-butyl ester 36-copolymerized-polyacrylic acid Styrene 258) (referred to as PCEA53-b-P (AA58-co-tBA36-co-Sty258)), rotary concentration to remove solvent and trifluoroacetic acid, a certain amount of dichloromethane was added to it, and it was volatilized at room temperature, and the obtained The sample PCEA53-b-P (AA58-co-tBA36-co-Sty258) was vacuu...

Embodiment 3

[0047] (1) Preparation of block polymer polyacrylic acid ethyl cinnamate 53-block-(polyacrylic acid 94-copolymerization-polystyrene 258) (referred to as PCEA53-b-P(AA94-co-Sty258)

[0048] Weigh 0.050g polyethyl cinnamate 53-intercalated-(tert-butyl acrylate 94-co-polystyrene 258) (referred to as PCEA53-b-P(tBA94-co-Sty258)), put it into a 50mL single Add 10mL of dichloromethane and 2mL of trifluoroacetic acid into a round-bottomed flask, and hydrolyze in the dark for 24 hours to obtain polyacrylic acid ethyl cinnamate 53-intercalated-(polyacrylic acid 94-copolymerized-polystyrene 258), (PCEA53 -b-P(AA94-co-Sty258)), spin concentration to remove solvent and trifluoroacetic acid, add a certain amount of dichloromethane to it, and make it volatilize at room temperature, the resulting sample is PCEA53-b-P(AA94-co-Sty258 ) after vacuum drying for 24 h and stored in the refrigerator.

[0049] (2) SiO 2 Preparation of hollow microspheres

[0050] Take 0.005g polyacrylic acid ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com