Patents

Literature

433results about How to "Easy to control the length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

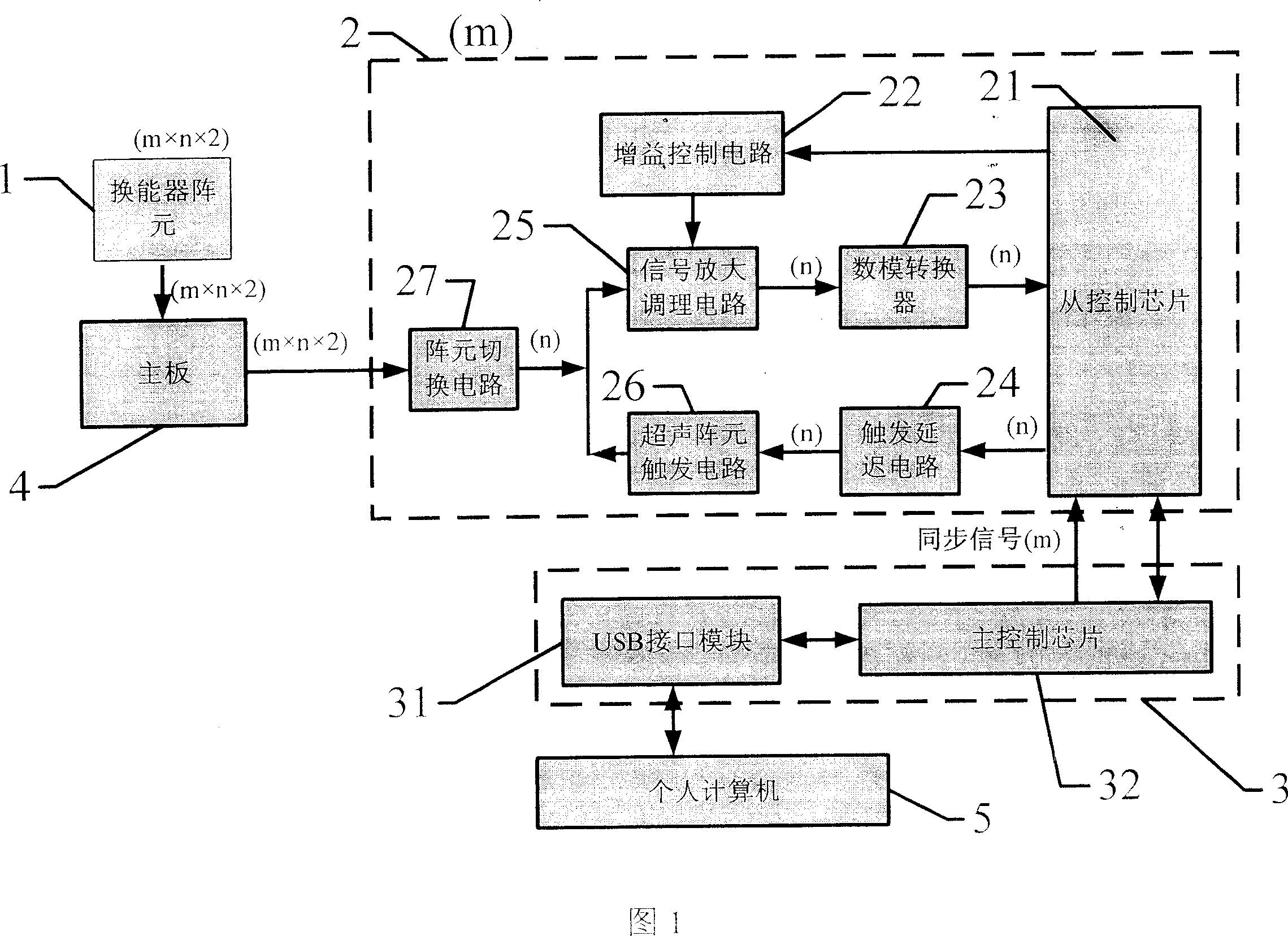

Ultrasonic phased array inspection instrument

ActiveCN101017154AImprove accuracyImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationArray element

This invention provides one supersonic phase control array test device, which comprises supersonic phase control array detector, supersonic trigger and receive board, main control board and computer, which comprises the following steps: the supersonic trigger and receive board first generates supersonic wave according to the parameter trigger; supersonic echo signal order is through array element switch circuit, signal amplification adjust circuit, A / D converter, digital echo data from control chip inner memory unit; under control board coordination, the echo data are through data to send high speed data transmission module to personal computer to get test result.

Owner:HARBIN INST OF TECH

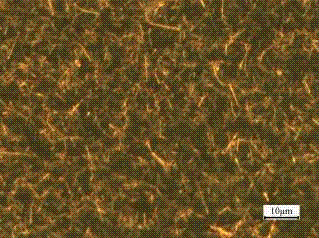

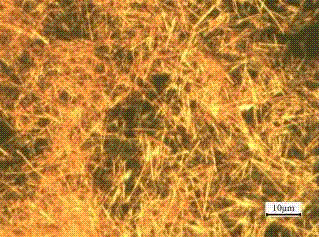

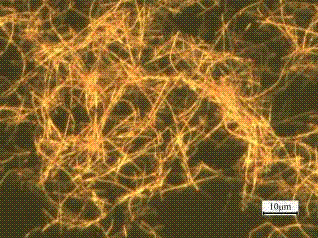

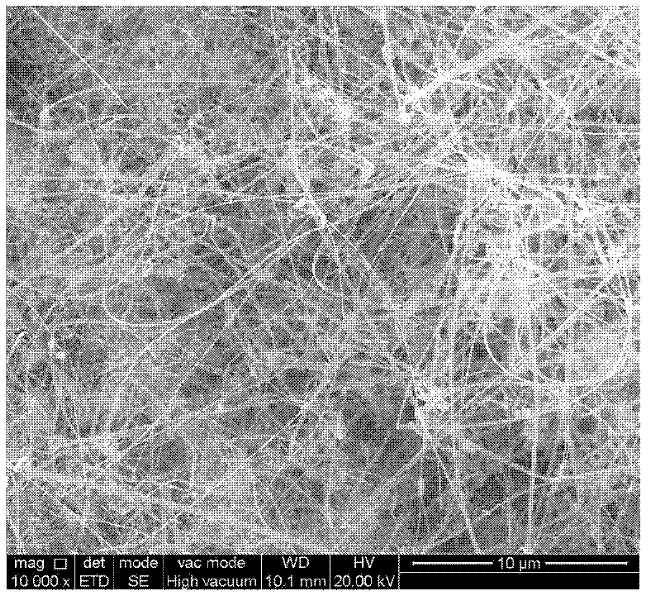

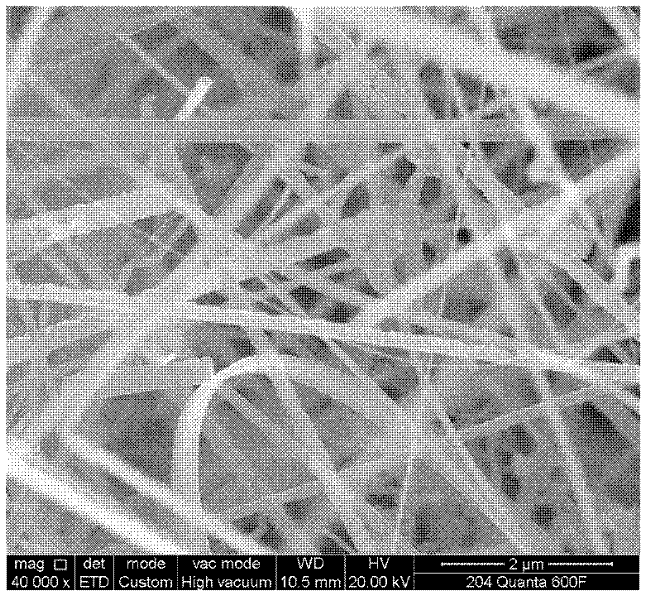

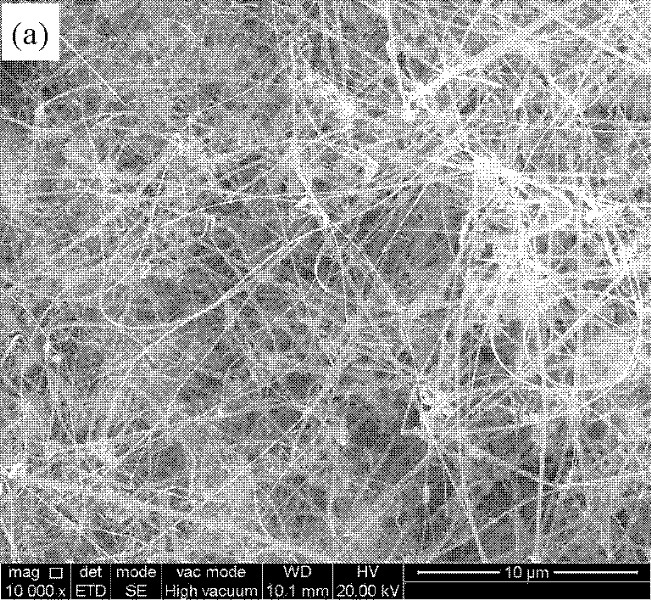

Controllable preparation method of monocrystal copper nanowires

InactiveCN102251278AFlat surfaceUniform radial thicknessPolycrystalline material growthFrom normal temperature solutionsDivalent metalIon

The invention relates to a preparation method of copper nanowires and in particular relates to a controllable preparation method of high-yield monocrystal copper nanowires in a liquid-phase reduction manner. The controllable preparation method comprises the steps: firstly, mixing a divalent metal copper salt solution and ethylenediamine, and heating in a water bath to form a single and stable copper ion chelate compound; mixing a strong base solution with hydrazine hydrate, and preparing a reducing agent in the water bath at the same temperature; then transferring the two mixture solutions into a reaction vessel, fully stirring to reach a uniform state, covering well, and placing in the water bath at the same temperature for heating reaction to prepare the copper nanowires; and fishing out flaky copper nanowires floating on the upper layer of the solution, washing the flaky copper nanowires with deionized water and absolute ethyl alcohol in sequence three times, and drying at room temperature under an Ar gas protection condition to prepare the copper nanowires. The controllable preparation method provided by the invention has the advantages of simple process, low cost and high yield, and the prepared copper nanowires are of monocrystal structures, and have relatively smooth surfaces, uniform radial thickness, and controllable and more uniform length and diameter.

Owner:CHANGZHOU UNIV

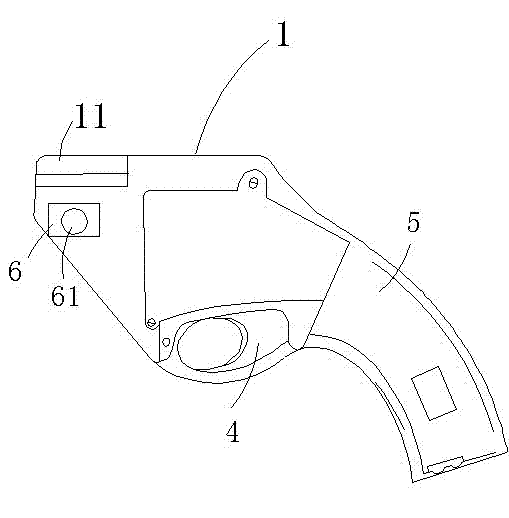

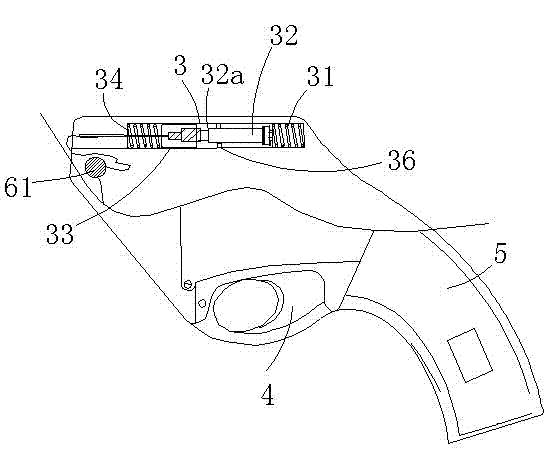

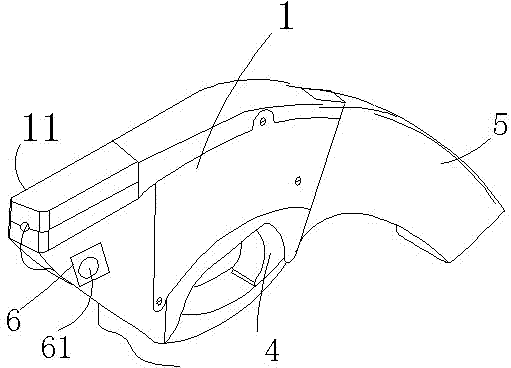

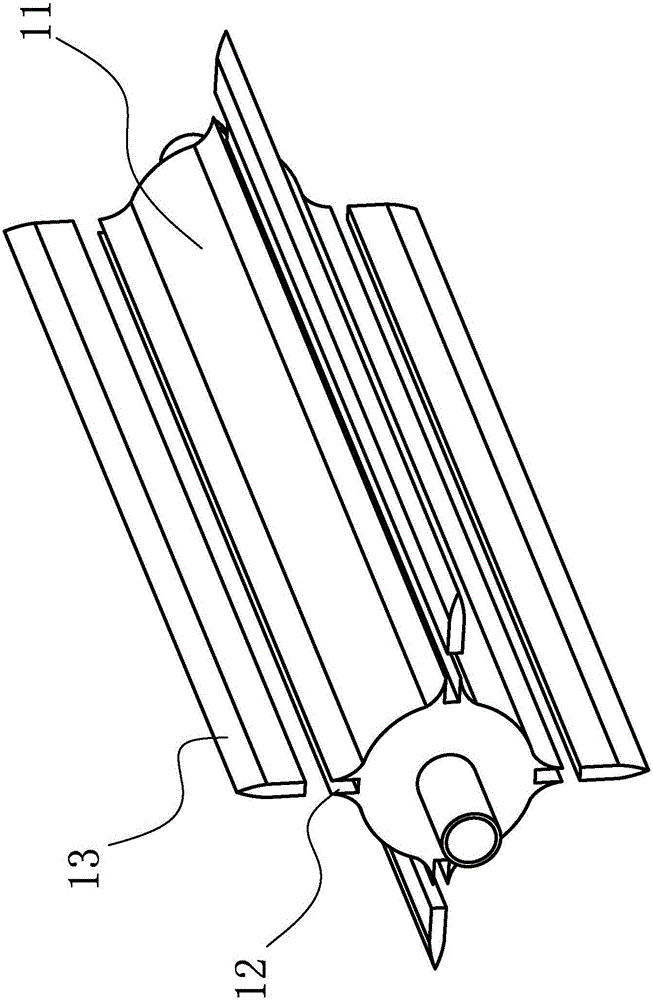

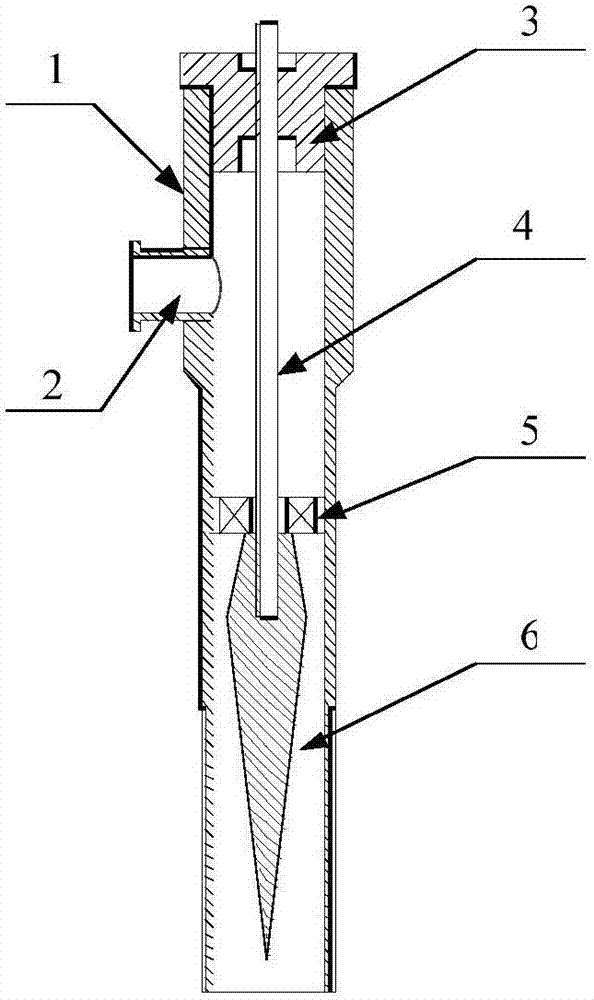

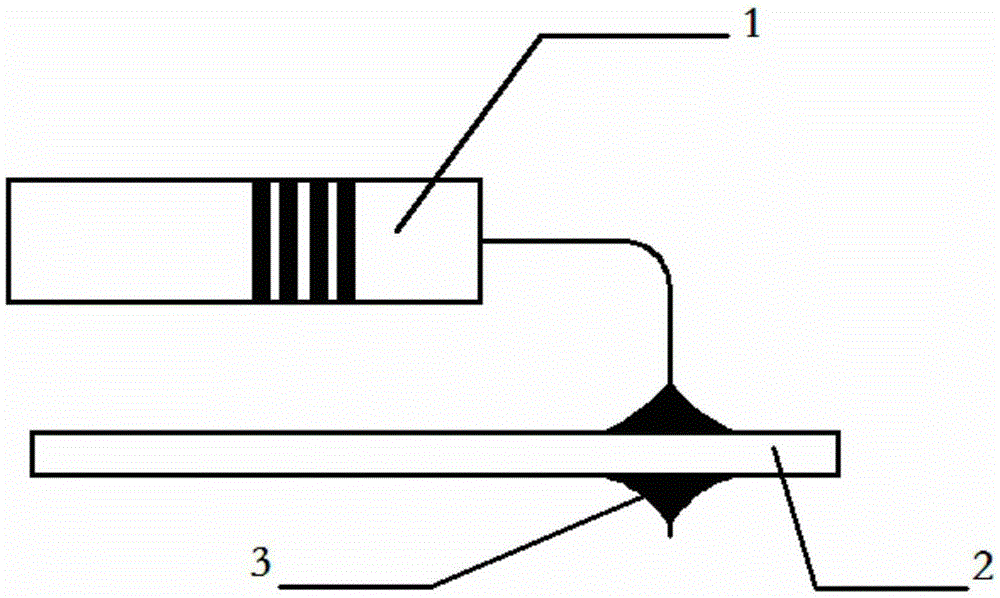

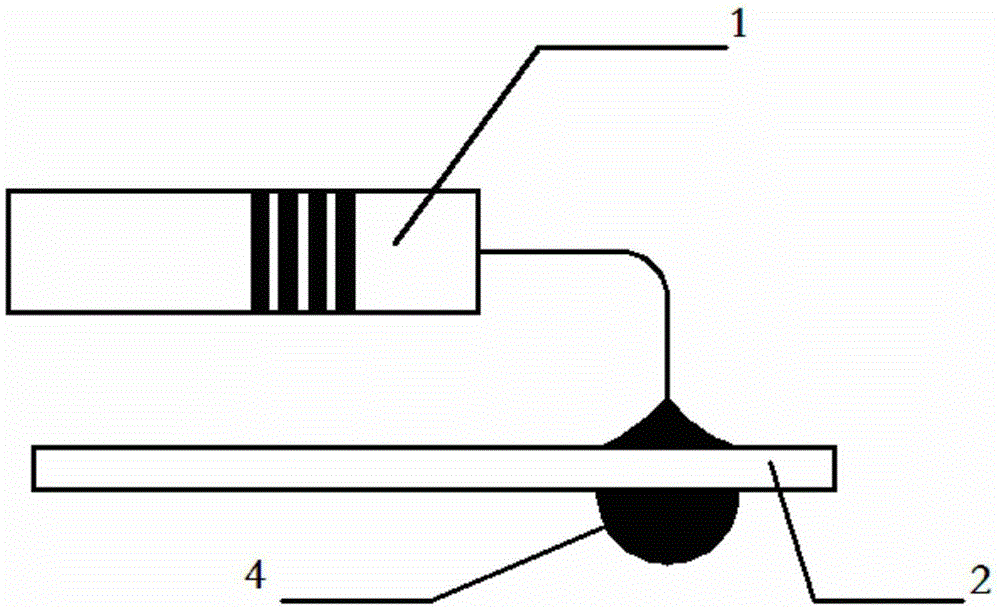

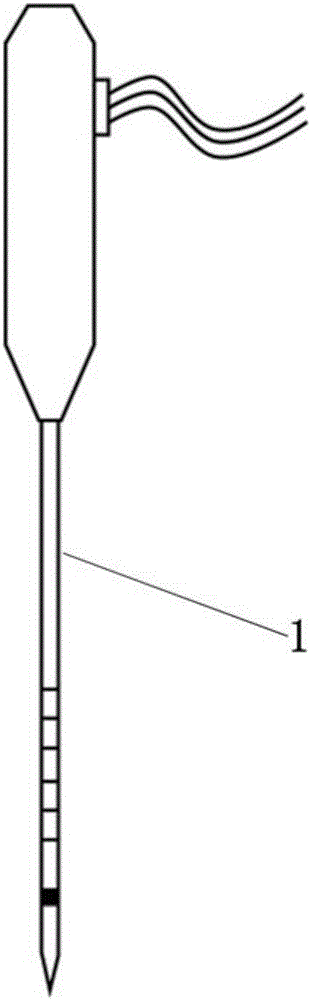

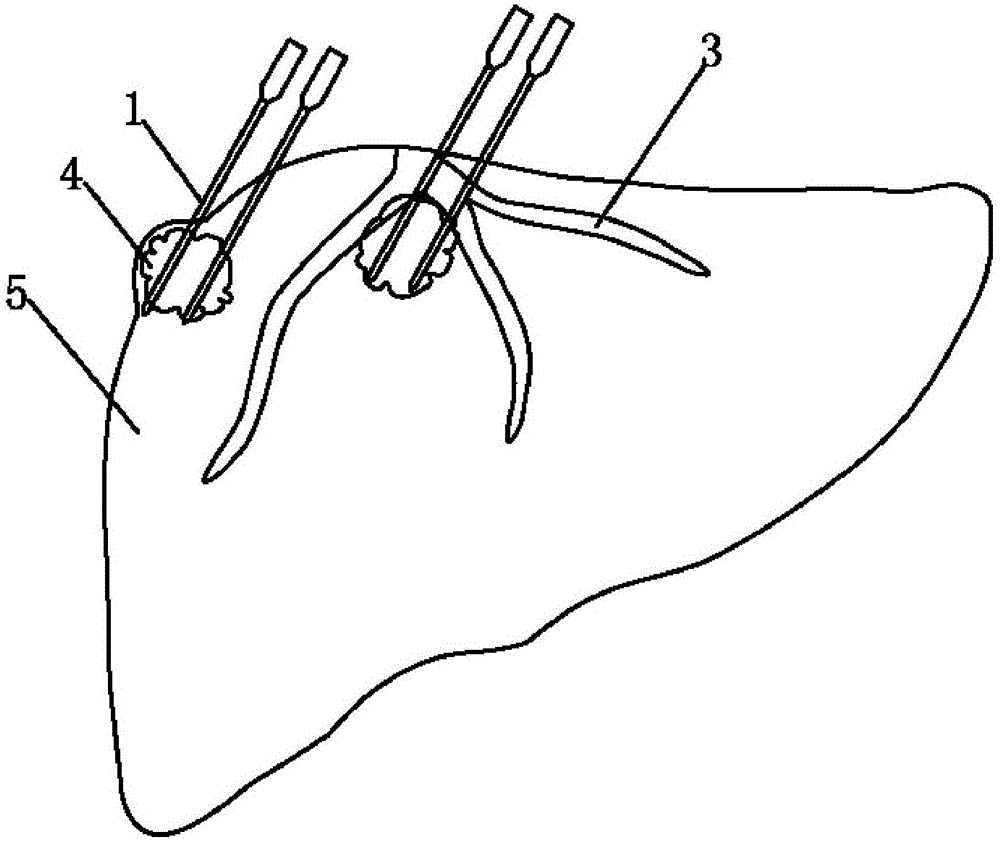

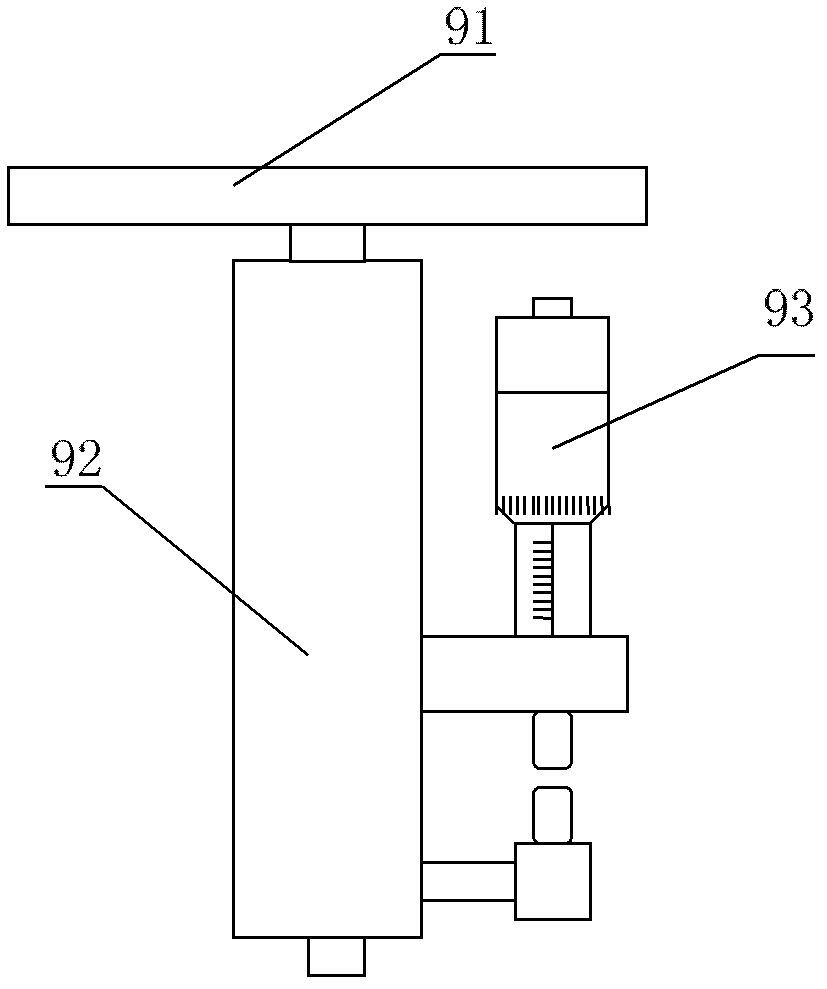

Bovine left abomasal displacement operative reduction apparatus with reduction needle transmitting range setting function

InactiveCN103690269BEasy to control the lengthLimit launch distanceSurgical veterinarySurvival probabilitySurgery

The invention discloses a bovine left abomasal displacement operative reduction apparatus with a reduction needle transmitting range setting function. The bovine left abomasal displacement operative reduction apparatus comprises a reduction needle transmitting device and a reduction needle with a line binding hole. The outer edge of the reduction needle transmitting device is smooth, the reduction needle transmitting device comprises a transmitting tube, an ejection portion and a trigger, the ejection portion is positioned at the rear of the transmitting tube and is communicated with the transmitting tube, the reduction needle is straight, the rear end of the reduction needle is arranged in the ejection portion, the other portion of the reduction needle is positioned in the transmitting tube, and the line binding hole is positioned on a needle body in the transmitting tube; the reduction needle transmitting device is further provide with a suture line position lock, and the length of a suture line is locked by the suture line position lock, so that the transmitting range of the reduction needle can be controlled. The bovine left abomasal displacement operative reduction apparatus has the advantages that the traditional double-side incision operation can be simplified onto single-side incision operation, so that the survival probability of seriously ill cattle can be effectively increased; the reduction needle further can be effectively protected, the transmitting distance of the reduction needle can be controlled, accordingly, accidents can be reduced, and the success rate of operation can be increased.

Owner:广州市九新生物科技有限公司

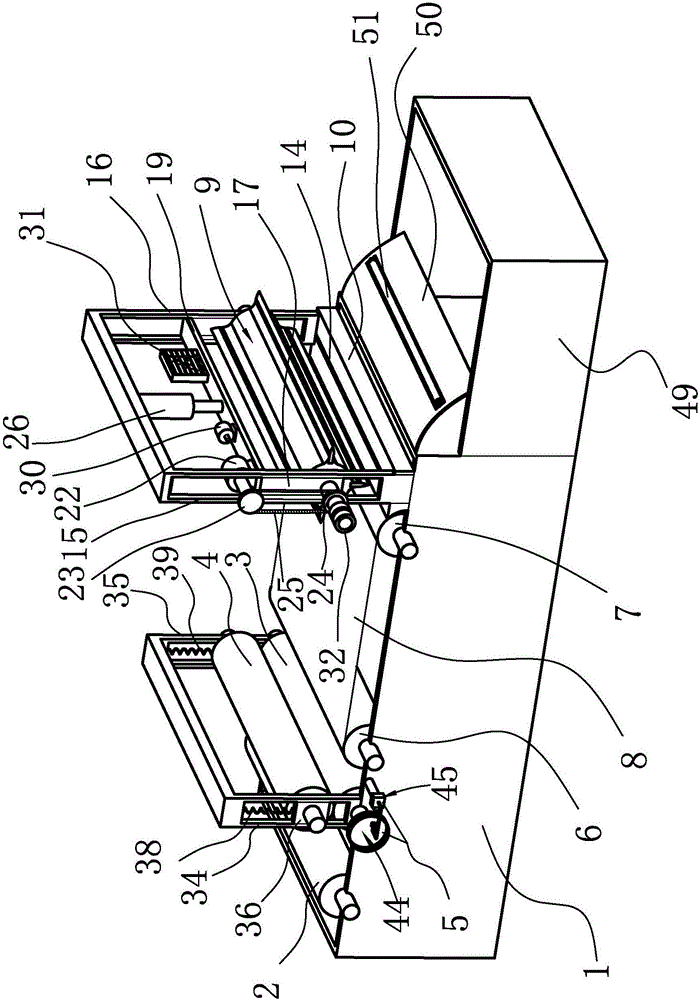

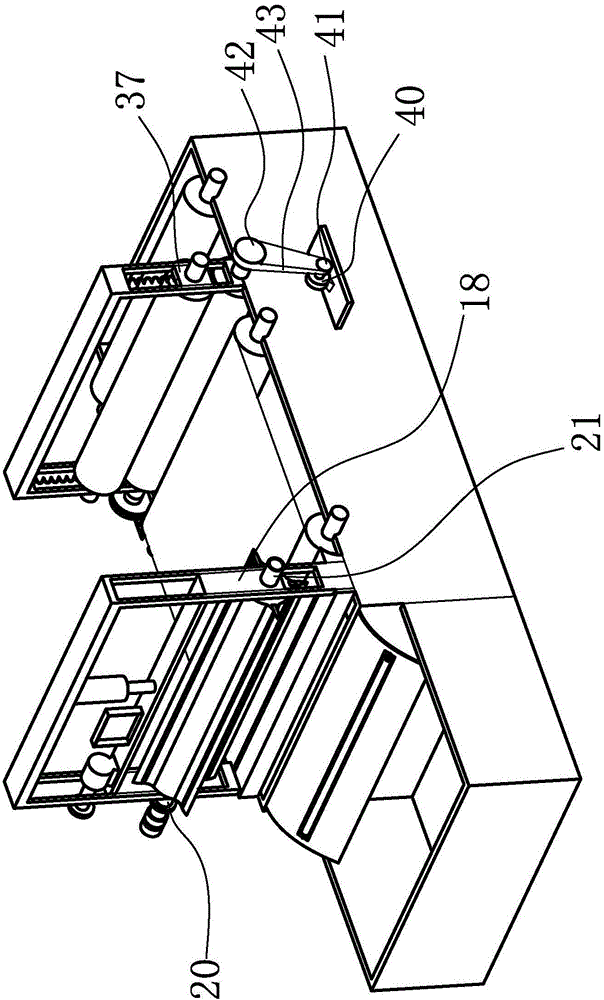

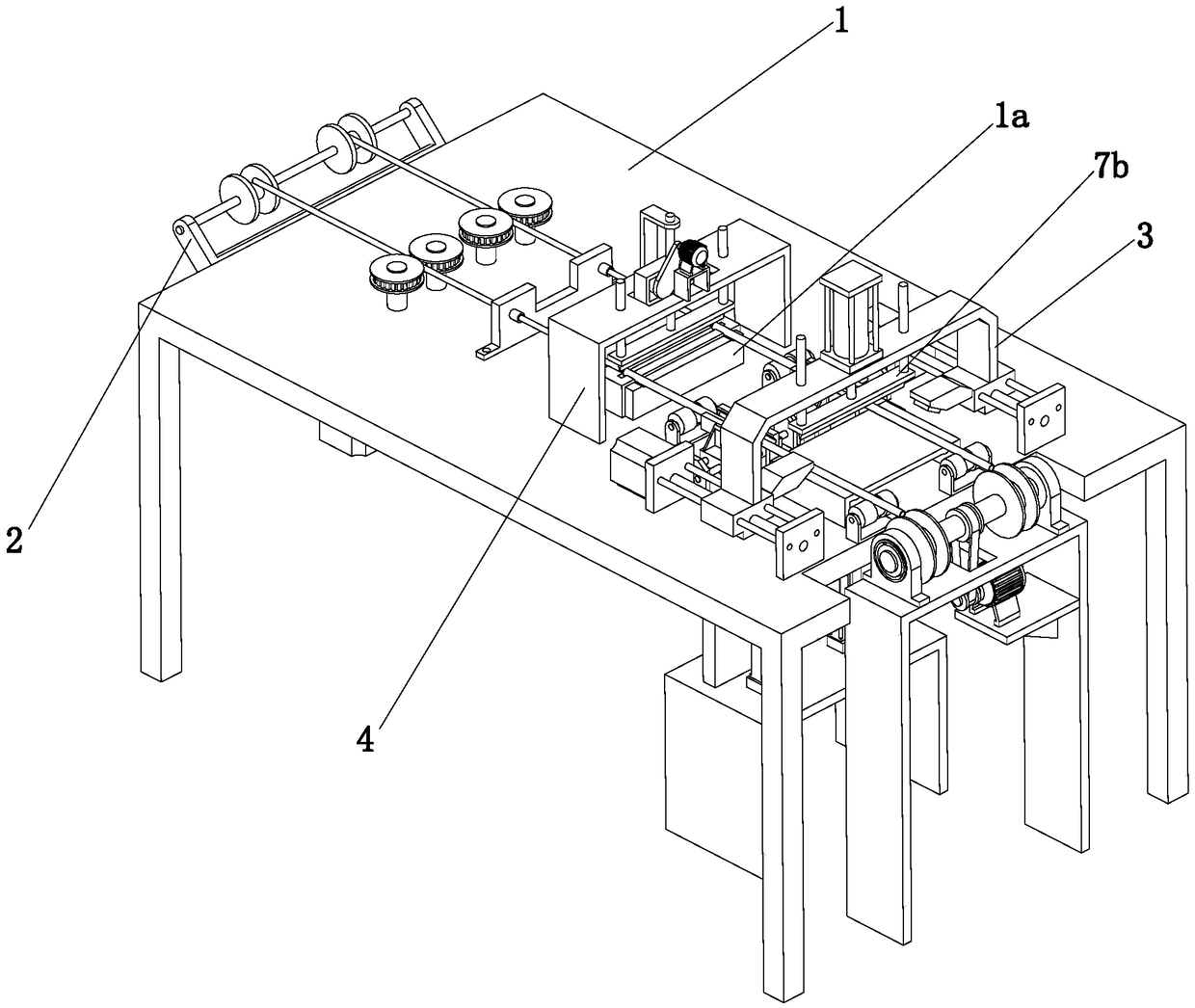

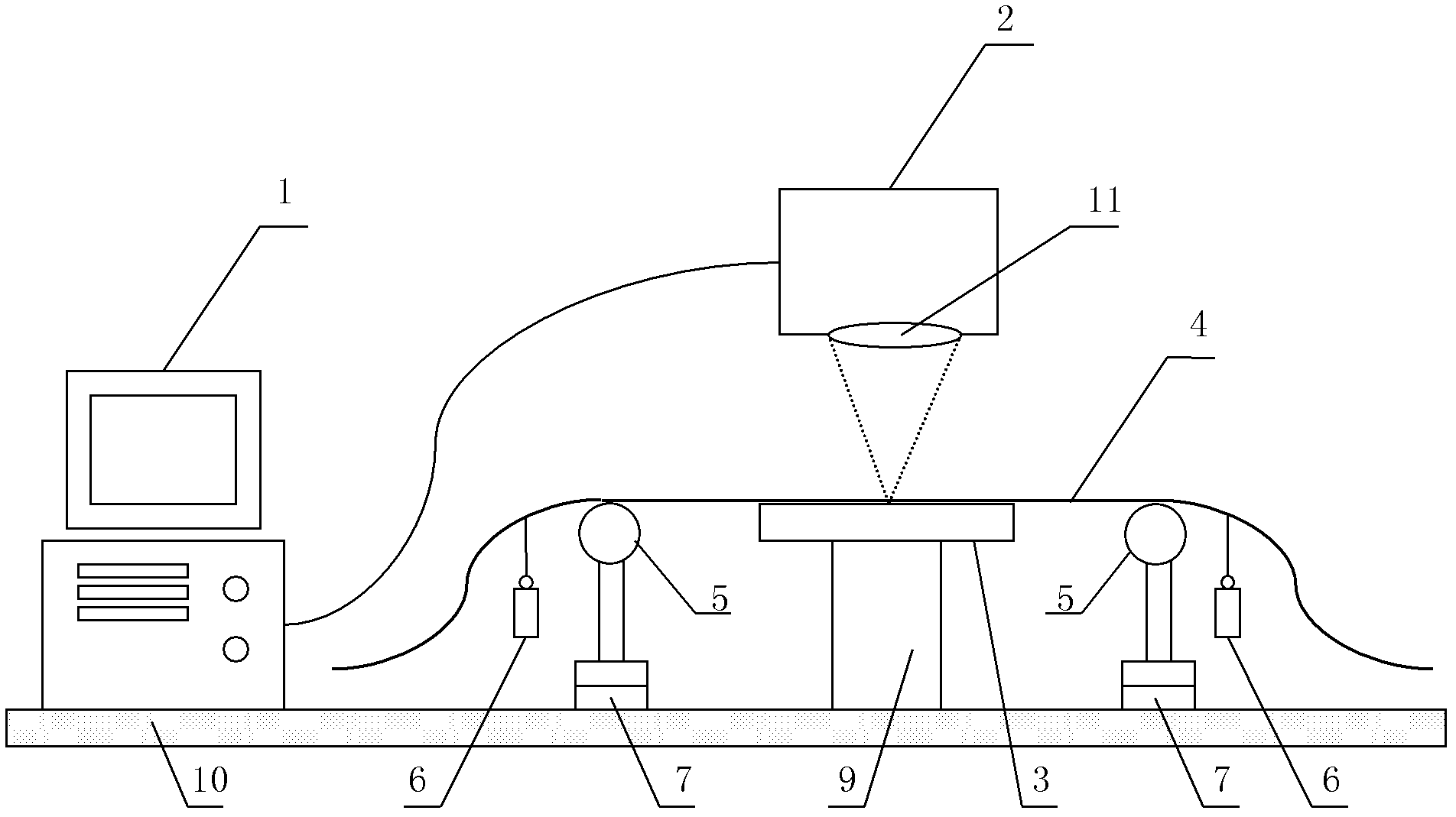

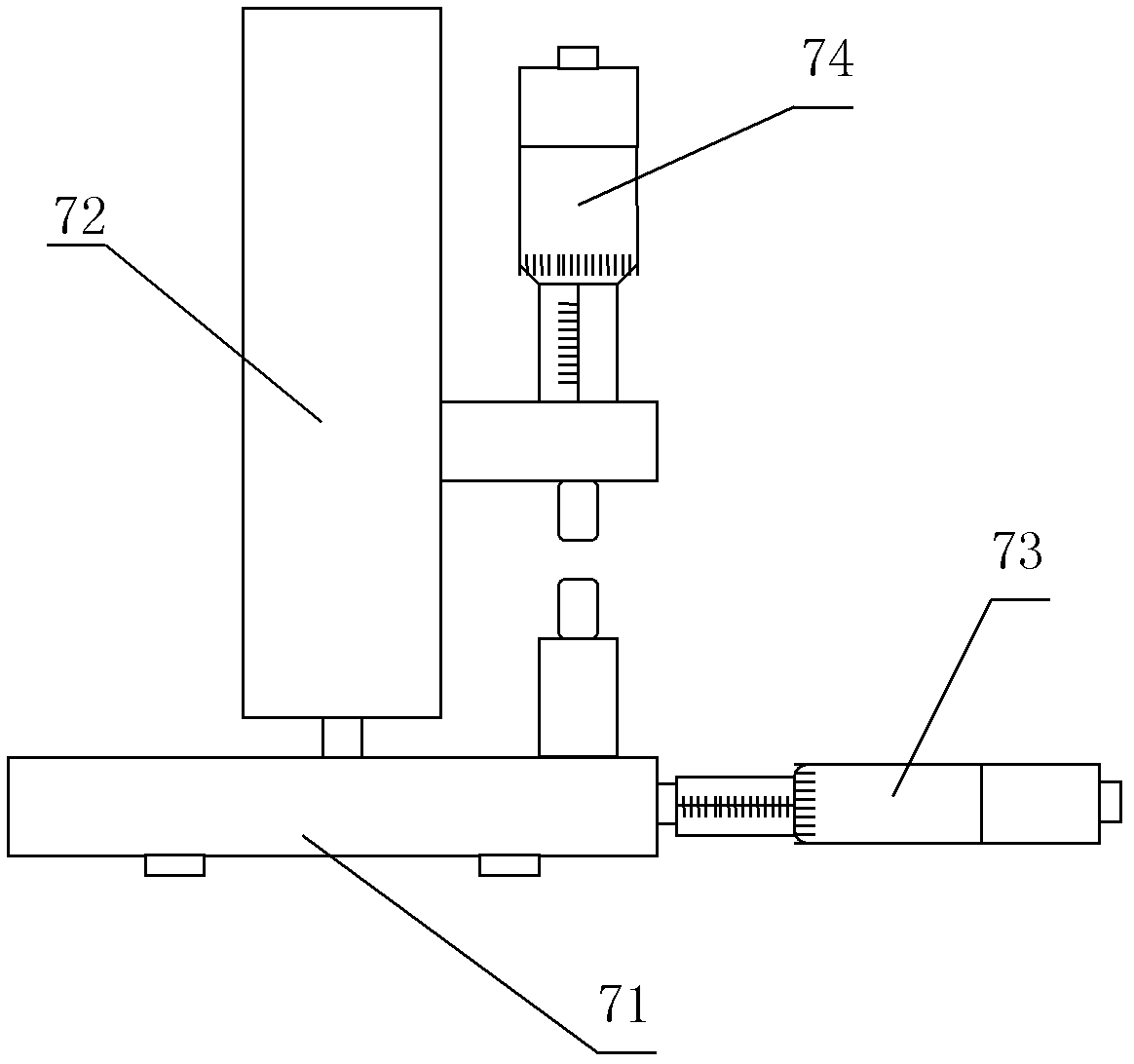

Pipe cutting device

InactiveCN105710911ARealize directional and quantitative movementEasy to control the lengthMetal working apparatusHydraulic cylinderControl engineering

The invention discloses a pipe cutting device which comprises a base and a cross beam arranged on the base. The cross beam is provided with a cutting unit. A motor is arranged on the base. A rotating shaft of the motor is provided with a screw rod. A fixing shaft is arranged below the screw rod. A tray is arranged on the screw rod. The screw rod and the fixing shaft are sleeved with the tray. Two oppositely-arranged hydraulic cylinders are arranged on the tray. A positioning buckle is arranged on a telescopic rod of each of the two hydraulic cylinders. The lower end of each positioning buckle is fixedly connected to the corresponding hydraulic cylinder. The upper end of each positioning buckle is in a semicircular shape. A round structure is formed between the positioning buckles on the two hydraulic cylinders. The problems in the prior art can be solved, the screw rod is used for driving the tray to move to drive a pipe to move, cutting with a designated length is conveniently achieved, and meanwhile due to the adopted positioning buckle structures, the pipe can be fixed.

Owner:任新庄

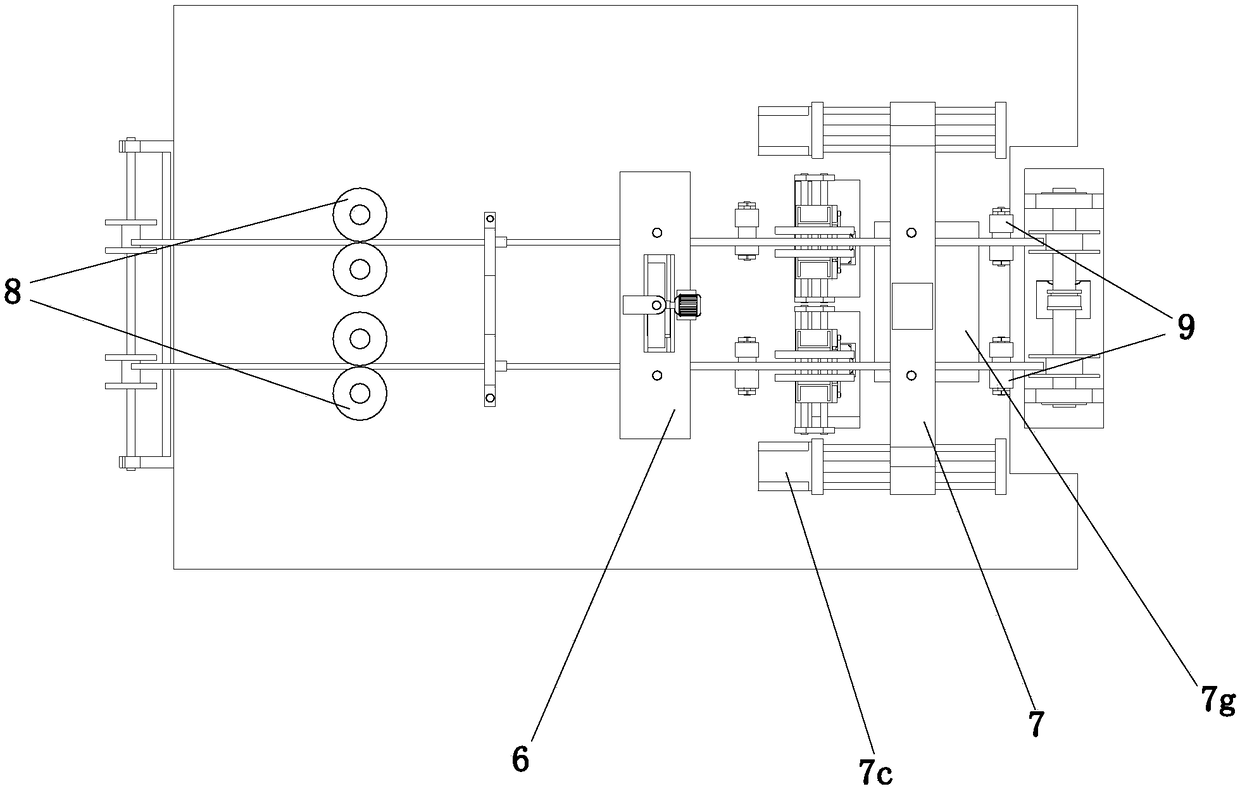

Improved decorative film cutting machine

ActiveCN106078869AEasy to usePrevent the blade from overheatingMetal working apparatusArticle deliveryTransfer mechanismEngineering

The invention provides an improved decorative film cutting machine and belongs to the technical field of machines. By the adoption of the improved decorative film cutting machine, the problem that an existing decorative film cutting machine generates heat in the working process, and accordingly a cut product is poor in quality is solved. The improved decorative film cutting machine comprises a machine case. The machine case is provided with an inner cavity. An opening communicating with the inner cavity is formed in the top of the machine case. A containing groove used for rotatably containing a coiled decorative film is formed in one end of the top of the machine case. The improved decorative film cutting machine is characterized by comprising a conveying mechanism, a transferring mechanism, a cutting mechanism and a storage mechanism, wherein the storage mechanism is used for collecting the cut decorative film. The improved decorative film cutting machine has the advantages that a cutter can be effectively cooled, and the decorative film is prevented from being burnt.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

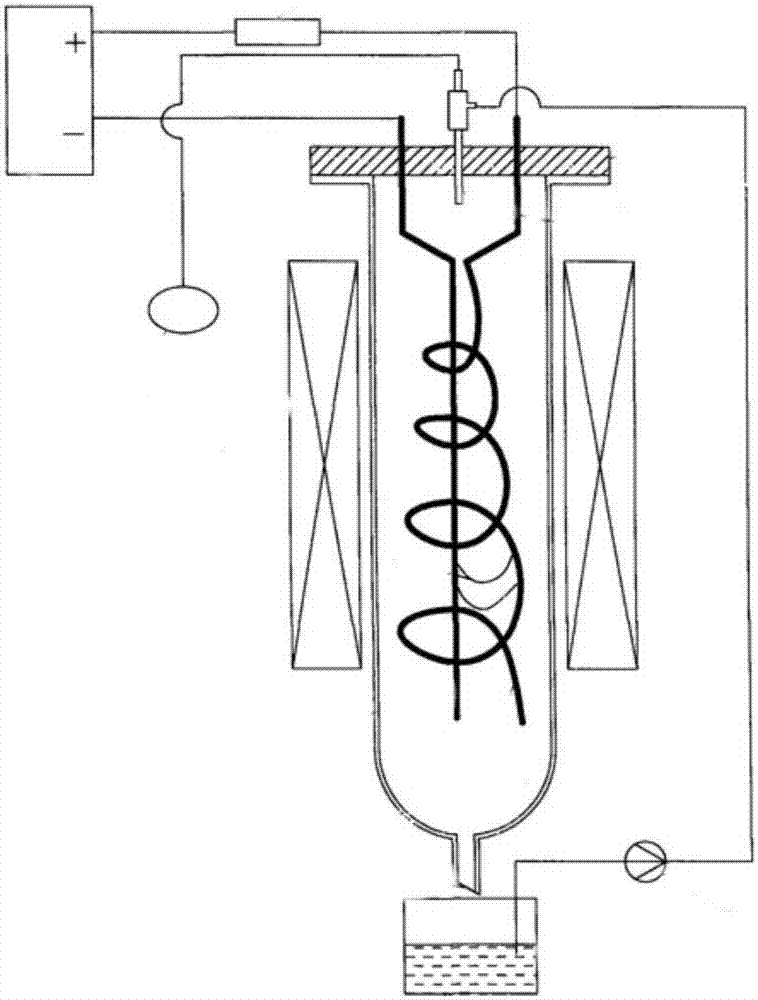

Preparation method of polyacrylonitrile carbon fiber with evenly distributed copolymerization sequence

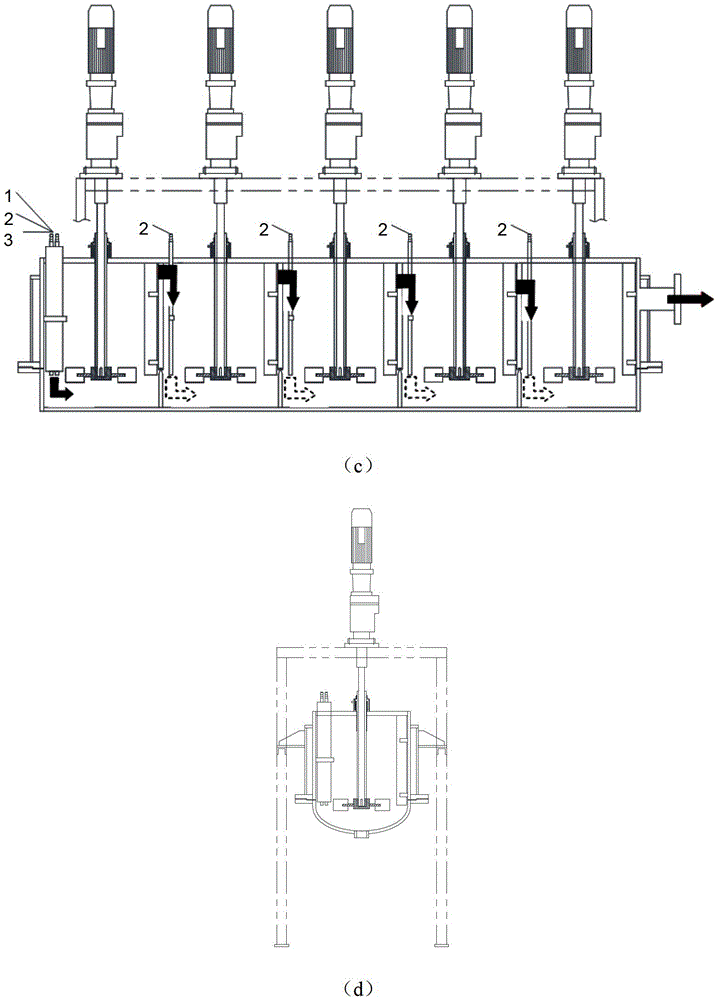

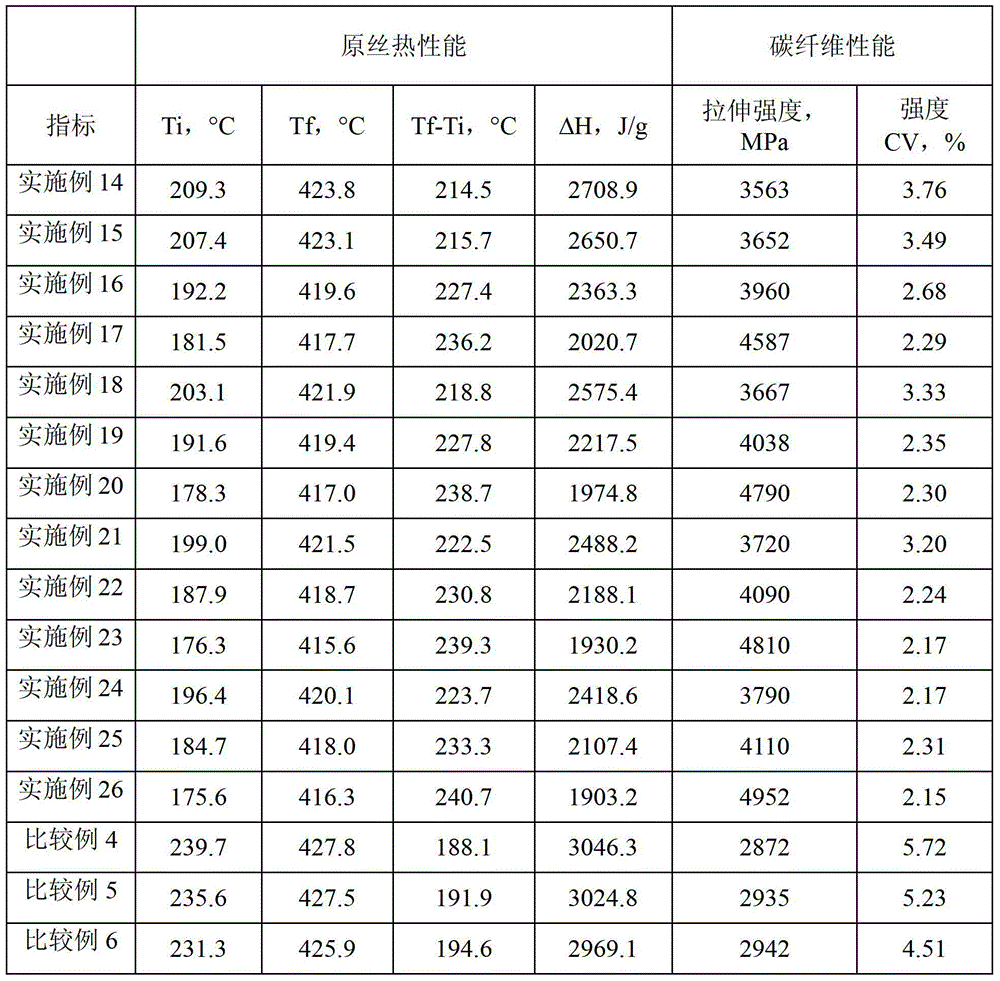

ActiveCN104372445AAggregation continuousUniform polymerizationArtificial filament heat treatmentFibre chemical featuresCarbon fibersPAN copolymer

The invention relates to a preparation method of a polyacrylonitrile carbon fiber with an evenly distributed copolymerization sequence. The preparation method comprises the following steps: determining the number of serially connected reactors; determining the ratio of fed materials of different areas in the third co-monomer zone; carrying out precipitation polymerization by taking water as the medium, drying so as to obtain polyacrylonitrile powder; dissolving the polyacrylonitrile powder to prepare a spinning solution, removing the bubbles from the solution, filtering, spraying, and curing to form primary fibers, washing and subjecting the primary fibers to a post treatment so as to obtain polyacrylonitrile-based carbon precursor fibers; and finally subjecting the precursor fibers to pre-oxidation, carbonation, and a post treatment so as to obtain the high performance carbon fiber. The preparation method adopts multi-grade serially-connected stirred tank polymerization reactors, and raw materials are supplemented in the third co-monomer zone according to a certain ratio in different areas so as to obtain a PAN copolymer with evenly distributed copolymerization sequence. Because the distribution uniformity of the copolymerization sequence of polyacrylonitrile precursor fibers is high, the possibility that fibers with a shell-core structure appear during the pre-oxidation process is small. Moreover, the diffusion of oxygen gas in the radical direction of fibers is also promoted, thus the pre-oxidation reactions can be stably carried out and the heat dissipation can be controlled so as to obtain carbon fiber with an excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

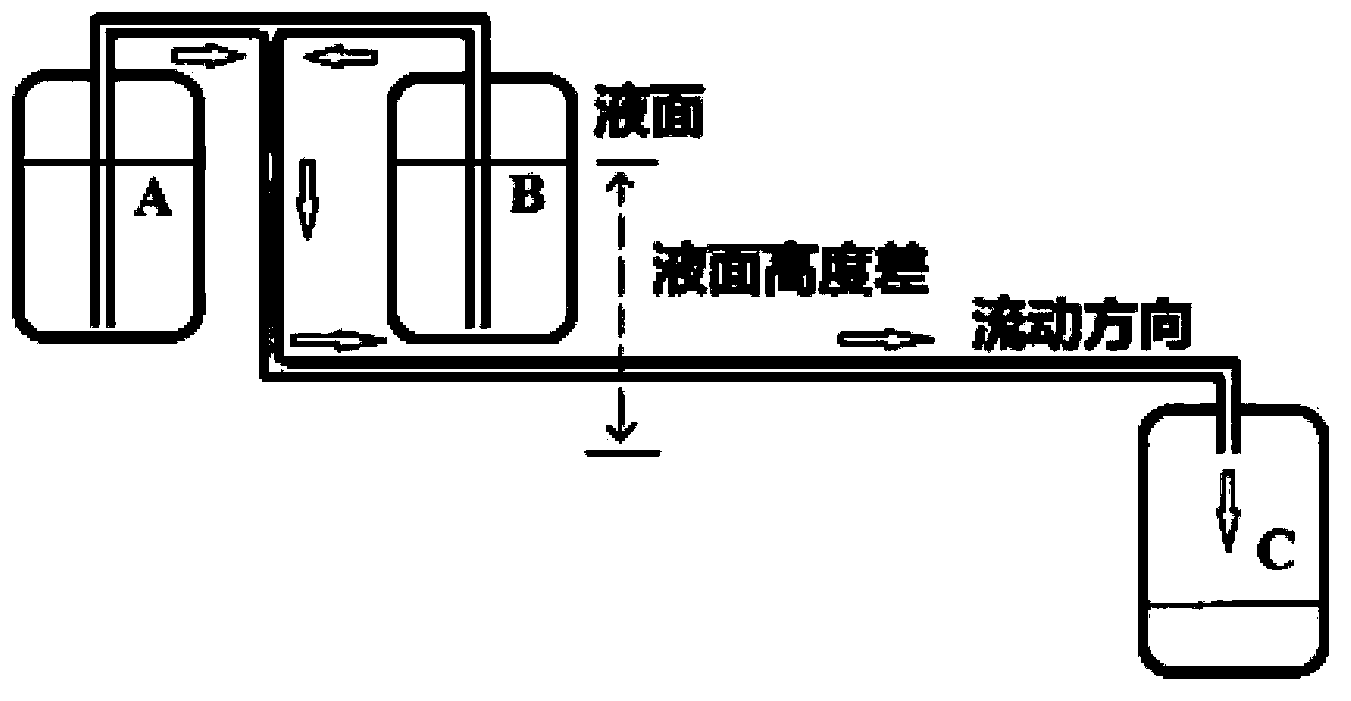

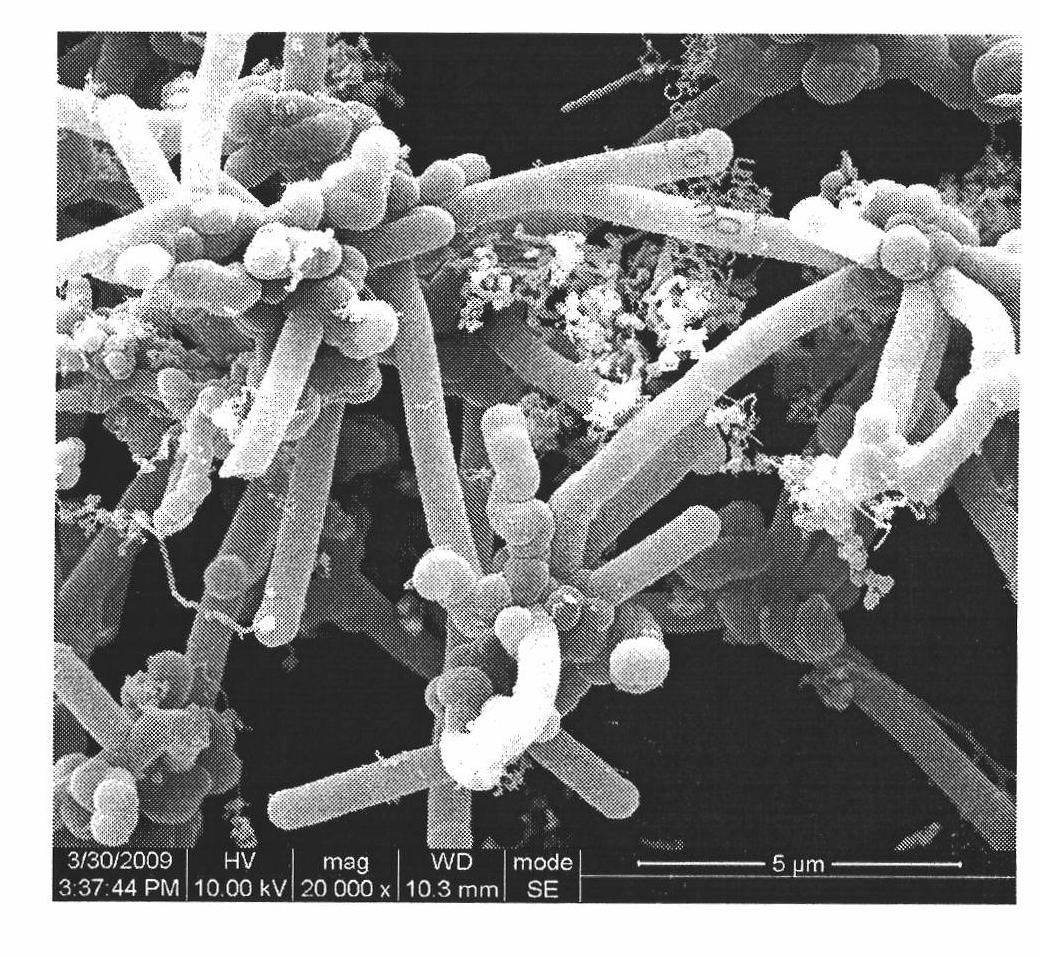

Preparation method of polyaniline nanometer fiber

The invention relates to a preparation method of a polyaniline nanometer fiber. The method comprises the following steps: dissolving a phenylamine monomer and a monomer initiator in acidic solutions containing dopants respectively; respectively loading the resulting solutions in a container A and a container B, wherein the liquid levels in the container A and the container B are consistent; introducing the solutions inside the container A and the container B into a reaction tube, controlling the free flow speeds of the reaction liquids inside the reaction tube, and collecting the reaction products by using a container C containing an inhibitor solution, wherein in the free flow process, the phenylamine is subjected to a polymerization reaction at room temperature or in an ice water environment, and the molar ratio of the phenylamine monomer to the monomer initiator is 1: (0.1-5); and after the flow is finished, causing the reaction products inside the container C to stand still, and then carrying out washing, centrifugation, and drying to obtain the polyaniline nanometer fiber. The preparation method provided by the invention is simple and easy to operate and low in cost; no template needs to be used; the whole process is mainly carried out in a water phase and tedious posttreatment is not needed; the preparation method is high in production efficiency, capable of realizing batch preparation and suitable for industrialized production.

Owner:DONGHUA UNIV

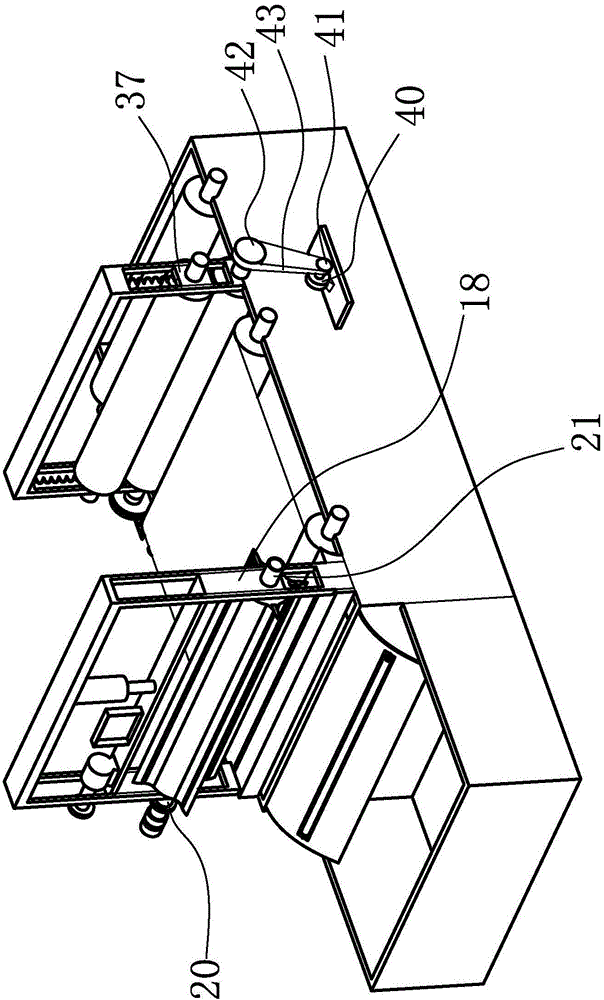

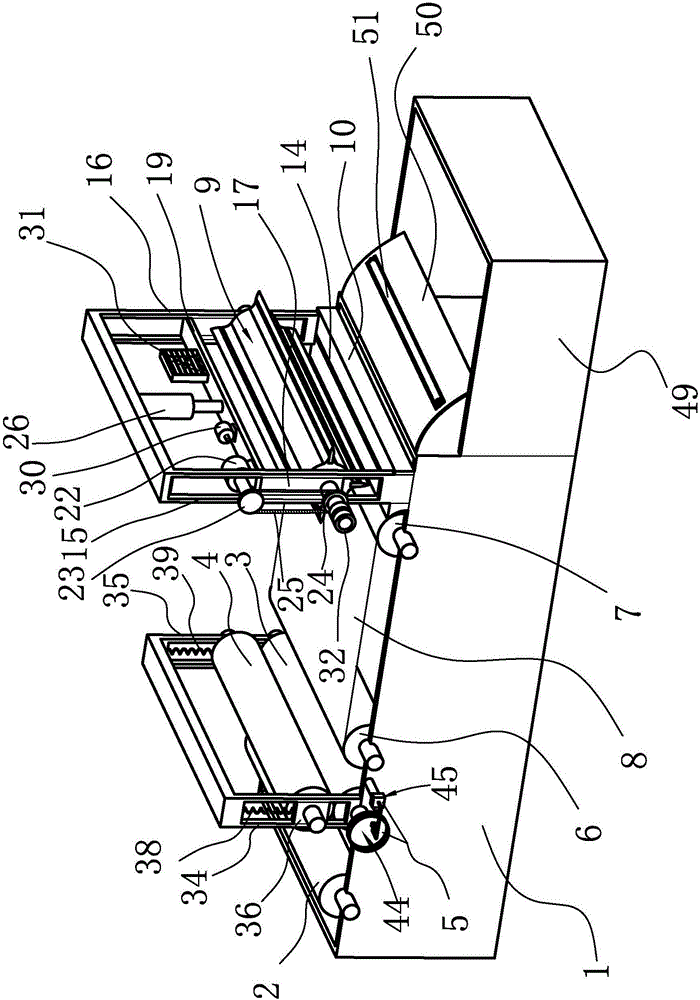

Decorative film cutting machine

ActiveCN106182117AEasy to control the lengthEasy to useMetal working apparatusArticle feedersEngineeringMechanical engineering

The invention provides a decorative film cutting machine, belongs to the technical field of machinery and solves the problem of poor quality of cut products due to the fact that existing decorative film cutting machines can produce heat in working processes. The decorative film cutting machine comprises a machine case, wherein the machine case comprises an inner cavity; an opening communicating with the inner cavity is formed in the top of the machine case; an accommodating groove for rotationally arranging a rolled decorative film is formed in one end of the top of the machine case; and the decorative film cutting machine is characterized by further comprising a conveying mechanism, a transmission mechanism, a cutting mechanism and a storage mechanism for collecting the cut decorative film. The machine has the advantages that a cutter can be cooled effectively, the decorative film is prevented from being scalded and the like.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

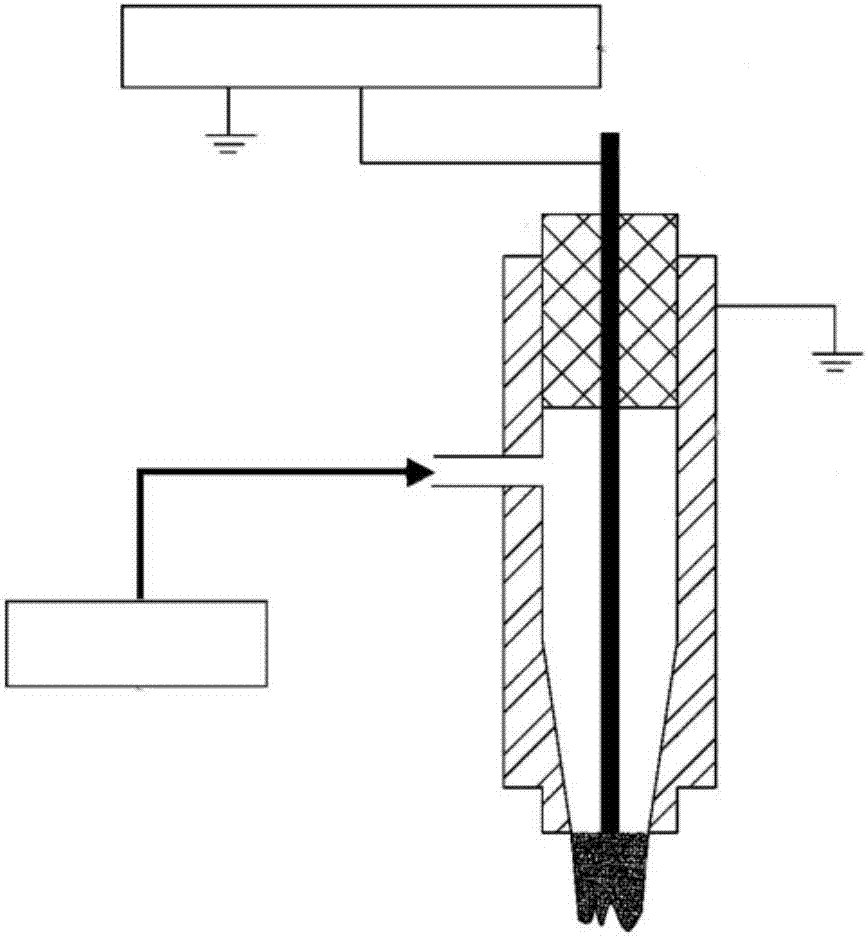

Aeroengine combustor rotational sliding arc plasma combustion-supporting actuator

InactiveCN107420199AImprove combustion efficiencyIncreased range of stable combustionGas turbine plantsJet propulsion plantsCycloneCombustion chamber

The invention discloses an aeroengine combustor rotational sliding arc plasma combustion-supporting actuator. An axial flow cyclone is arranged at the middle section in an anode shell; a cathode cone electrode is arranged below a round hole type axial flow cyclone; the lower end of a cathode electrode rod penetrates through a center hole of the round hole type axial flow cyclone and is charged into a center blind hole formed in the upper end surface of the cathode cone electrode; the upper end of the cathode electrode rod is charged into a center hole formed in an electrode mounting isolation seat; the electrode mounting isolation seat is fixed at the end of a large diameter section of an inner hole of the anode shell; and an air inlet nozzle which is connected with an engine gas supply device in a sealing manner is installed on the outer circumferential surface of the large diameter section of the anode shell. The aeroengine combustor rotational sliding arc plasma combustion-supporting actuator is capable of improving the combustion efficiency of an aeroengine combustor and the uniformity of an outlet of the combustor and expanding the stable combustion range of the combustor, overcomes the deficiency that the existing plasma combustion-supporting technology is not suitable for being used in a high-temperature and high-pressure environment of the aeroengine combustor and has the characteristics of capability of producing a great amount of active particles, small size, simple structure, strong universality and the like.

Owner:AIR FORCE UNIV PLA

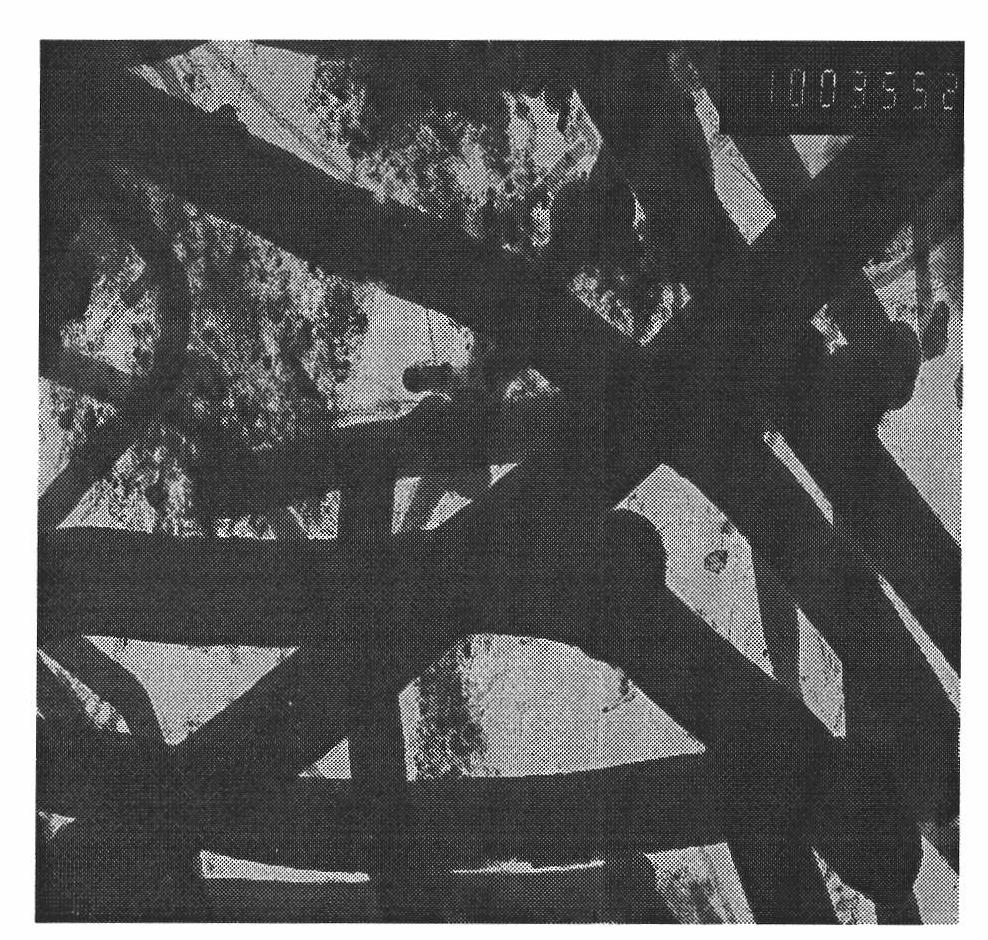

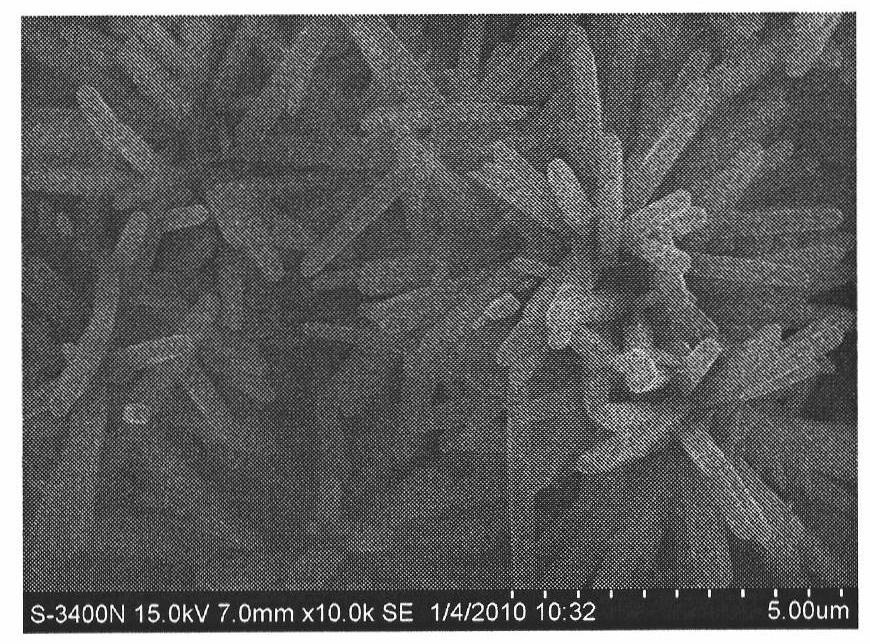

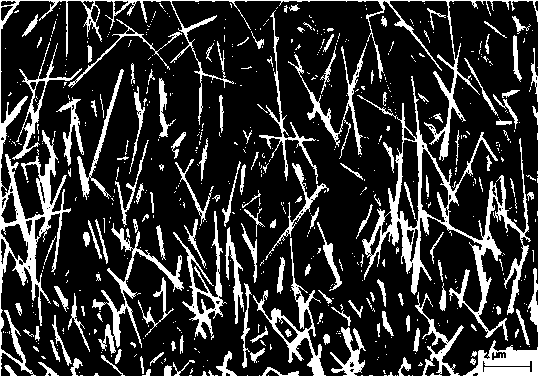

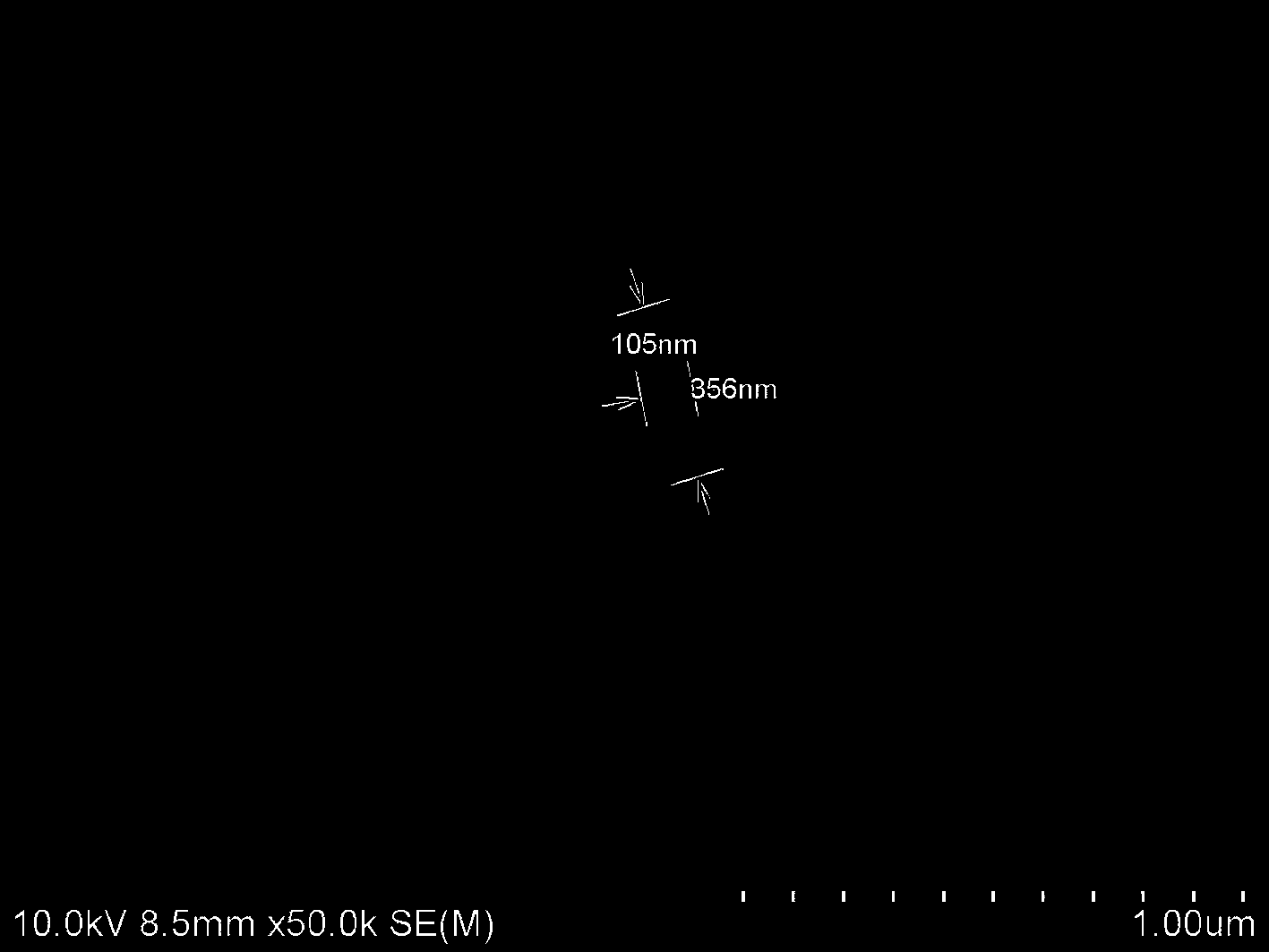

SiC nano-wire and preparing method thereof

Disclosed are a SiC nanowire and the preparation method which relates to nanowires and preparation methods and solves the problems that the existing SiC nanowire is of complex preparation technology, difficult control, high cost and environmental pollution. The SiC nanowire of the invention adopts industrial silicon powder and graphite powder and is made through atmosphere sintering from the mixture of 50 to 75 percent of industrial silicon powder and 25 to 50 percent of graphite powder according to the mass percentage. The preparation method of the invention is that, first, industrial silicon powder and graphite powder are evenly mixed are put into a graphite crucible; second, the graphite crucible is placed into an atmosphere sintering furnace for vacuum pumping; third, argon gas in pumped into the atmosphere sintering furnace; fourth, the graphite crucible and the argon gas are sintering in the atmosphere sintering furnace with the furnace cooling to room temperature in order to produce SiC fibers. Industrial silicon powder and graphite powder are selected in the invention as raw materials, so that the cost is reduced while the technology is simple and easy to operate. No environmental pollution is caused in the process of the reaction. The product is single-crystal phase beta -SiC fibers with uniform thickness, wherein, the diameter is mainly between 30 to 150 nanometers, the length is controllable, and the longest can reach mm-magnitude.

Owner:HARBIN INST OF TECH

Method for preparing carbon nano tube with great inside diameter and controllable length

InactiveCN101927995ACarbon source solventCarbon source solvent environmental protectionCarbon nanotubeCarbon source

The invention discloses a method for preparing a carbon nano tube with great inside diameter and controllable length. Mixed liquid of dimethyl benzene and ethanol is used as a carbon source, a mixture of dicyclopentadienyl iron and dicyclopentadienyl nickel is used as a catalyst, nitrogen or hydrogen is used as a carrier gas, a mixture of sulfur and thiophane is used as an additive, and the carbon nano tube with great inside diameter and controllable length is prepared in a horizontal electric furnace at 950 to 1,100 DEG C by adopting a floating catalysis method. A proper amount of dicyclopentadienyl nickel is added into the dicyclopentadienyl iron to form iron-nickel alloy nano granules so as to regulate the carbon settling speed of the catalyst, enlarge the inside diameter of the carbon tube and shorten the length of the carbon tube. The method has the advantages of convenient and simple operation, low cost, no pollution and simple equipment, and realizes low-cost batch preparation.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

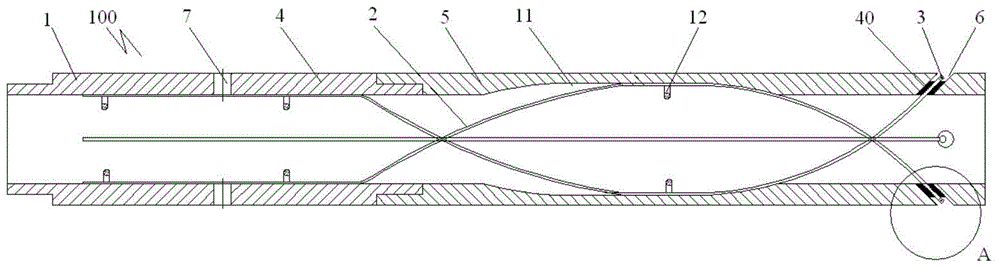

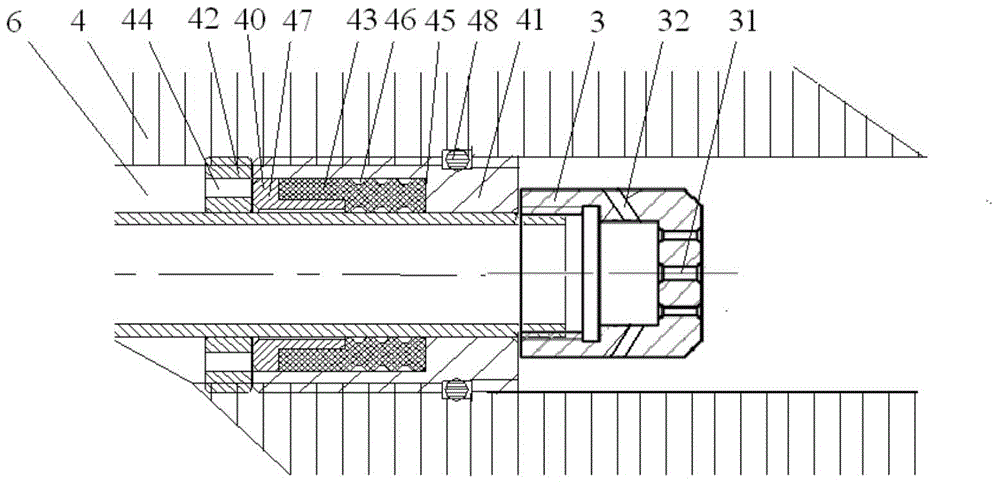

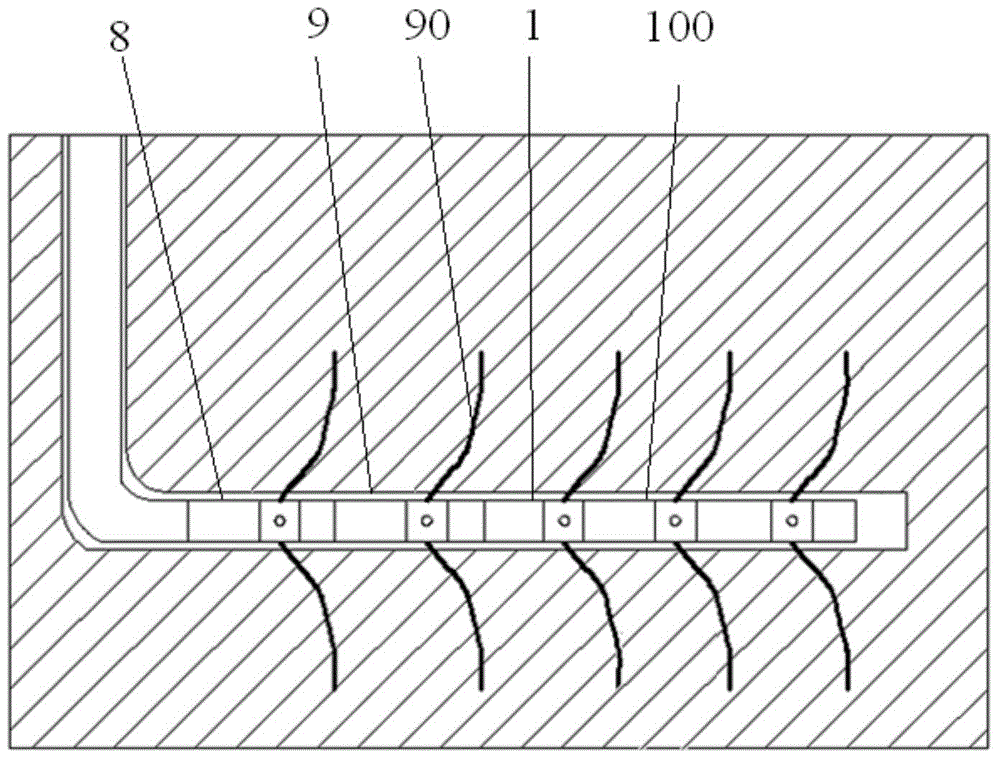

Device and system for locally delivering therapeutic agents

The invention discloses a device for locally delivering therapeutic agents, which comprises a main body catheter, an injection catheter and an operating handle, wherein a head electrode and a plurality of ring electrodes are arranged on a bendable section of the main body catheter; the head electrode is connected with the ring electrodes through a lead; the other end of the lead is connected witha connecting tail line jack on the operating handle; and a magnetic field sensor is fixed on the head electrode and is connected with the connecting tail line jack on the operating handle through a lead thereon. The invention also discloses a system. The head electrode and the ring electrodes are arranged on the bendable section for collecting electric signals, and a doctor distinguishes a pathological area of a patient according to the signals. Due to the arrangement, the device is compatible with magnetic positioning equipment and electrical positioning equipment, a three-dimensional geometrical model and a three-dimensional potential model are established, and a therapeutic part is accurately determined. According to a bending control piece on the operating handle, bidirectional bending is realized, and the therapeutic part is convenient and accurate to select.

Owner:MICROPORT SINICA CO LTD

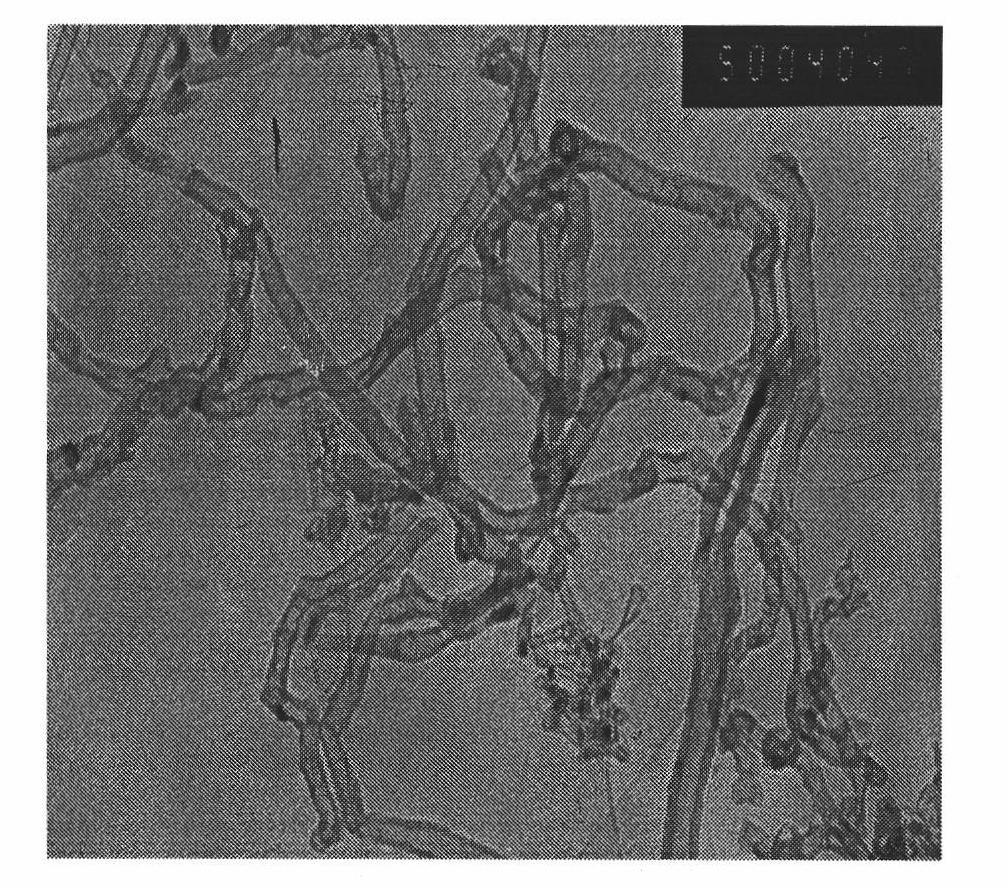

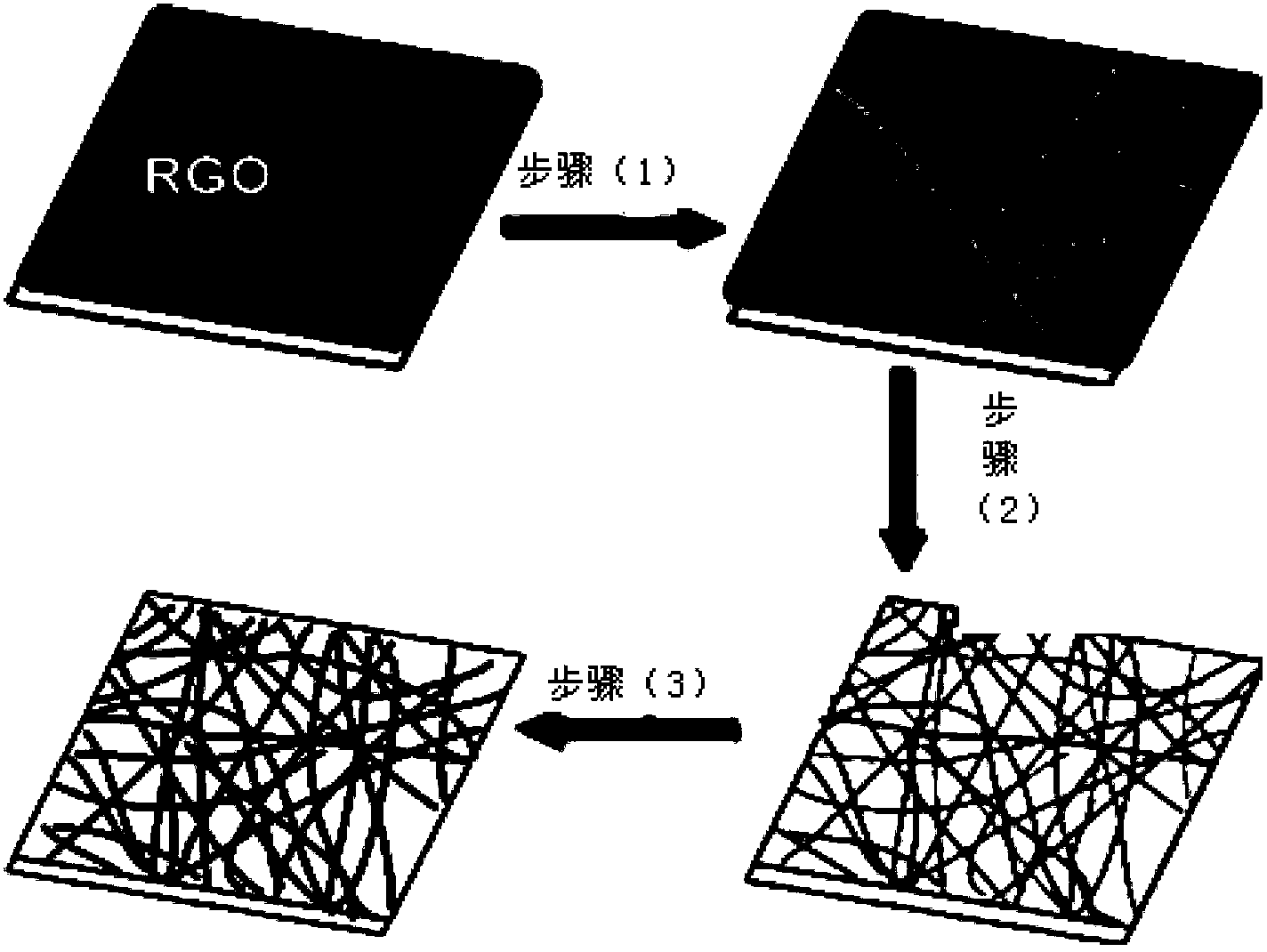

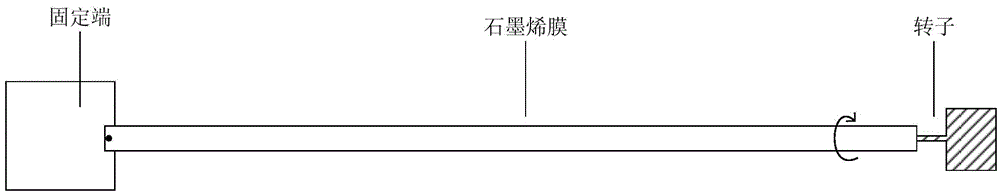

Graphene nano-belts, preparation method of graphene nano-belts, and application of graphene nano-belts in transparent electrodes

InactiveCN103848415AEasy to control the lengthThickness is easy to controlCarbon compoundsNanotechnologyGraphene nanoribbonsElectrospinning

The present invention provides a graphene nano-belt preparation method, which comprises: (1) depositing a spinnable polymer-containing solution or melt on a graphene film through electrostatic spinning to form a mask; (2) etching away the graphene being not covered with the mask; and (3) removing the mask to form the graphene nano-belts. The present invention further provides the graphene nano-belts prepared through the preparation method, and an application of the graphene nano-belts in transparent electrodes. According to the present invention, the method has advantages of simple process, low cost, easy large-scale preparation and the like, and the graphene nano-belts prepared through the preparation method has characteristics of controllable length, controllable width, controllable thickness and controllable shape.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing SiC nanometre wires and nanometre belts

ActiveCN102491331AEasy to makeEfficient preparationCarbon compoundsNanotechnologyComposite ceramicNanometre

The invention relates to a method for preparing SiC nanometre wires and nanometre belts. The method comprises the following step of: preparing the SiC nanometre wires and nanometre belts on a Si-Sic composite ceramic matrix by a two-step method combining reaction sintering with in-situ reaction. A plurality of high-purity SiC nanometre wires and nanometre belts can be prepared in the method with low cost, simplicity and high efficiency, so that the problems such as a complicated preparation process, high cost, difficult control, impurity of prepared products, and the like, of the SiC nanometre wires and nanometre belts in the prior art are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

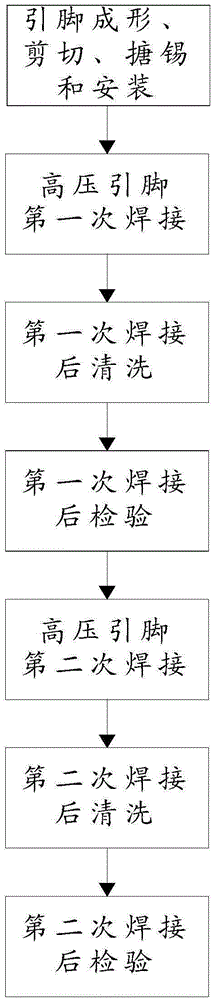

High-reliability installation method for high-voltage welding spots

ActiveCN105252094APromote formationImprove reliabilitySoldering apparatusMetal working apparatusHigh pressureCapacitor

The invention discloses a high-reliability installation method for high-voltage welding spots. The high-reliability installation method is suitable for welding spots which are formed through welding of pins of 100-500 V plug-in mounting resistors, capacitors, diodes, connectors, TO package MOS tubes and other plug-in mounting devices and through hole bonding pads on printed boards, and welding spots which are formed through welding of wires and through hole pads on printed boards. According to the high-reliability installation method, before installation, forming and shearing of through hole element pins or wires are conducted, the length of the part, extending out from a welding face of a printed board, of a pin is optimally controlled, forming of a high-voltage welding spot can be better facilitated, and reliability of the welding spot is further improved; meanwhile, a high-voltage welding spot is formed through secondary welding, the surface of the welding spot formed through secondary welding is rounder, more smooth and free of pulling points, and the low-air-pressure discharging phenomenon can be easily prevented; and in addition, checking is conducted after two times of welding, it is ensured that the installed welding spots can resist low-air-pressure discharging, hot vacuum, vibration, impacts and other severe environment conditions, and installation reliability is ensured.

Owner:BEIJING SATELLITE MFG FACTORY

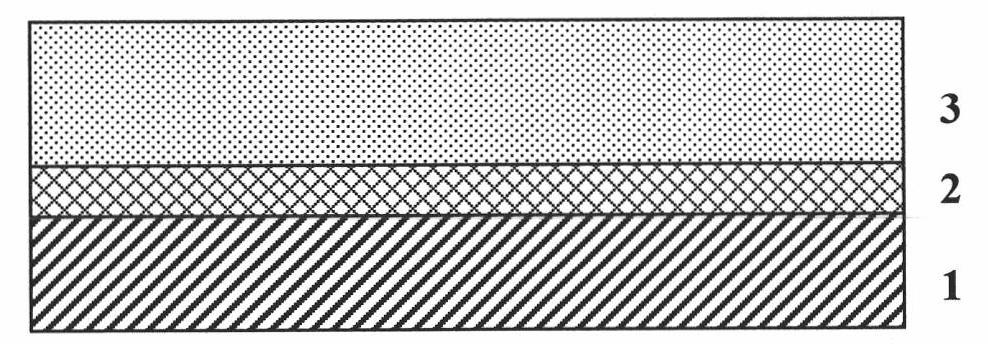

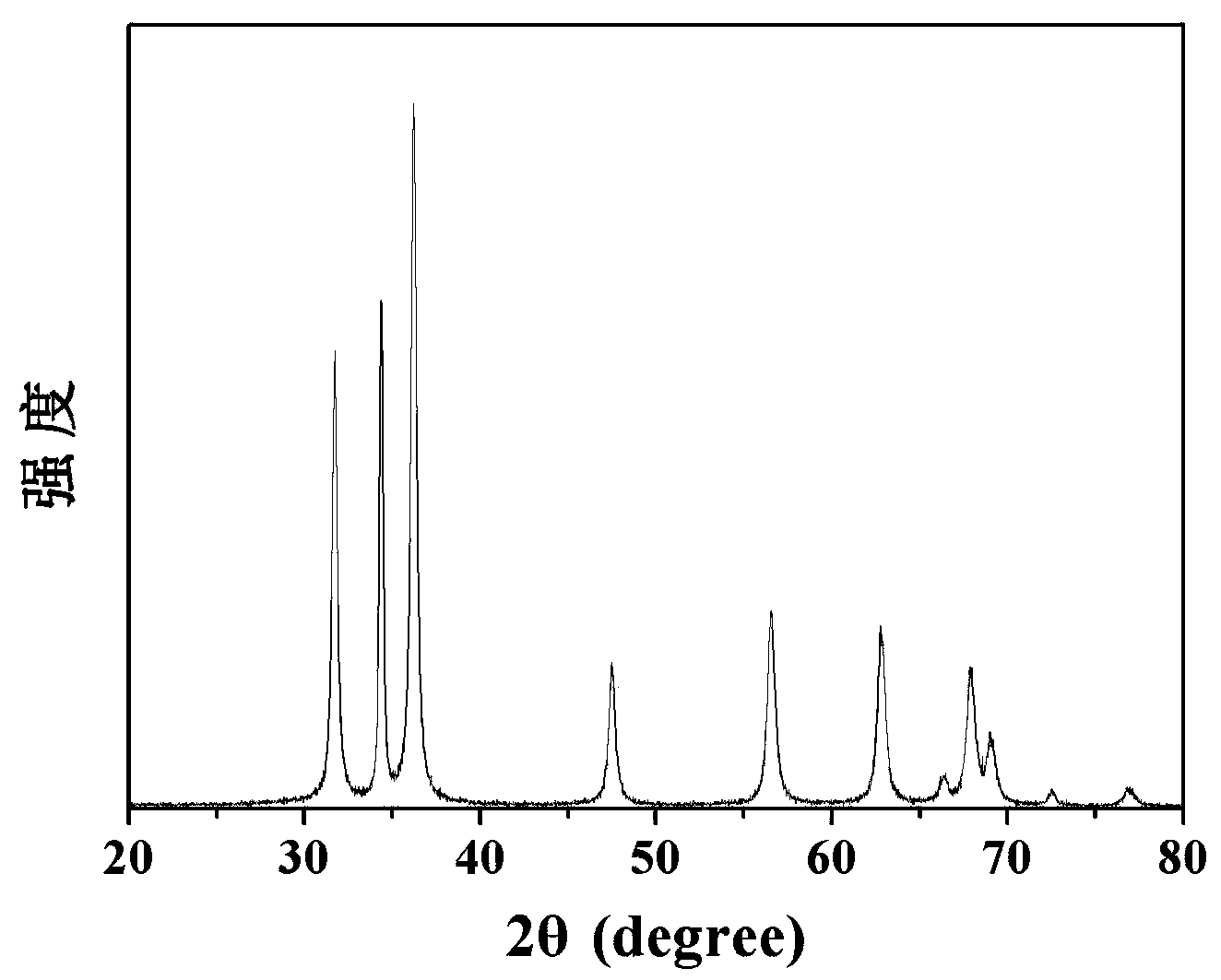

Titanium dioxide nanoflower film photoanode and preparation method thereof

InactiveCN101916670AImprove photoelectric conversion efficiencyImprove light capture efficiencyLight-sensitive devicesSolid-state devicesTin dioxideTransportation capacity

The invention discloses a titanium dioxide (TiO2) nanoflower film photoanode and a preparation method thereof. The photoandoe consists of common glass, a fluorine (F) doped tin dioxide (SnO2) transparent conductive film and a TiO2 nanoflower film. The preparation method comprises the following step of: directly synthesizing the TiO2 nanoflower film serving as the photoanode of a dye-sensitized solar cell on a FTO glass substrate by taking a mixture of concentrated hydrochloric acid, deionized water, toluene and butyl titanate as a reaction precursor and by hydro-thermal synthesis technology, wherein the shape of nanoflowers and the diameter and the length of nanorods consisting of the nanoflowers can be controlled by changing the ratio of the concentrated hydrochloric acid to the deionized water to the toluene and the concentration of the butyl titanate in the reaction precursor. By using higher light utilization efficiency and excellent electron transfer characteristic of TiO2 nanowires, the photoanode has the advantages of ensuring higher light trapping efficiency of electrodes, improving the transportation capacity of photon-generated carriers, reducing the recombination process of the photon-generated carriers, and consequently improving the photoelectric conversion efficiency of the dye-sensitized solar cells.

Owner:GUANGDONG UNIV OF TECH

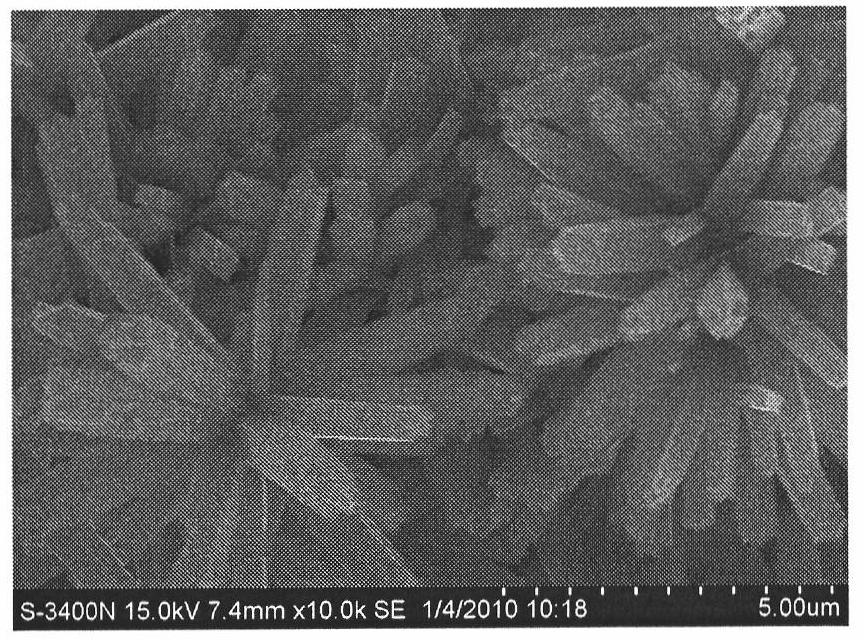

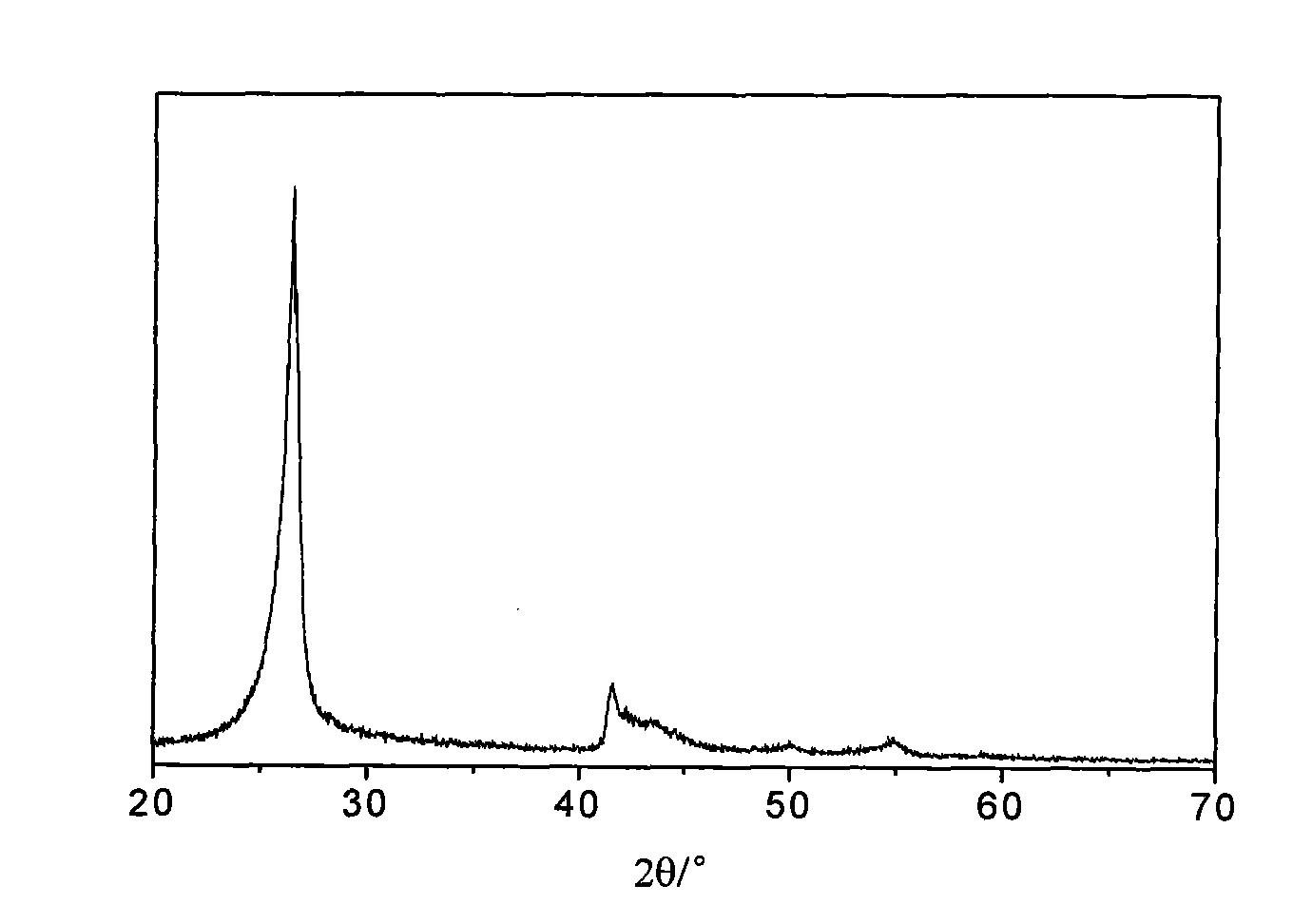

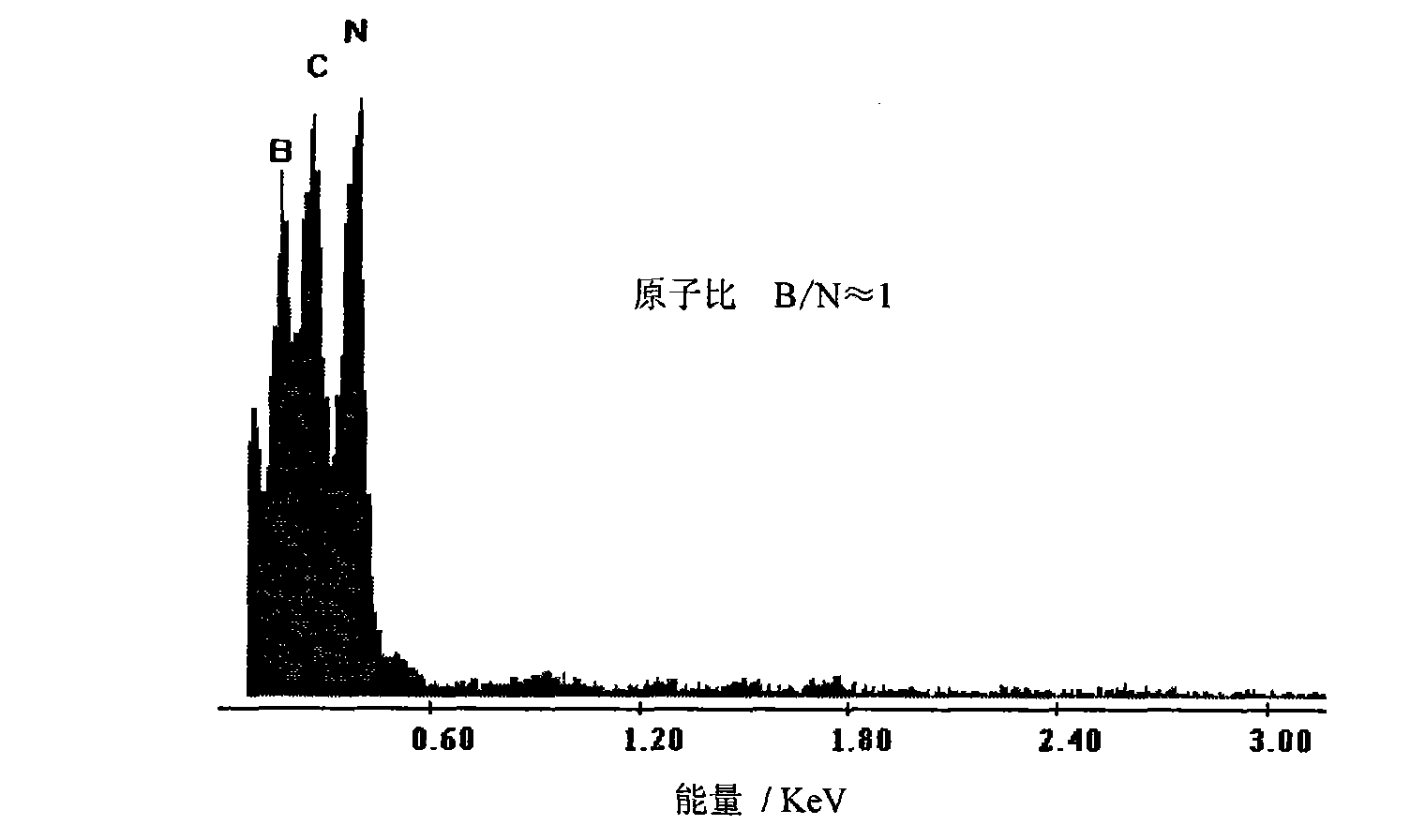

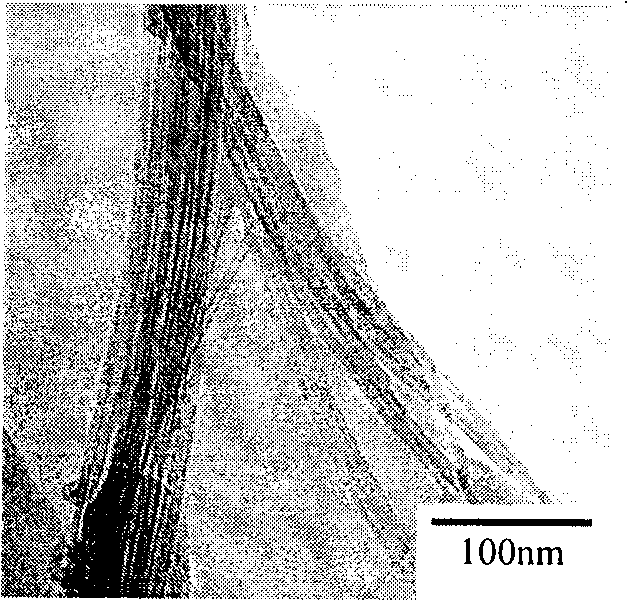

Preparation method of boron nitride nano tube with controllable dimension

InactiveCN101633498AHigh yieldEasy to purifyNanostructure manufactureNitrogen compoundsBoron nitrideNitrogen gas

The invention belongs to the field of inorganic nano material. The prior preparation method of a boron nitride nano tube has the problems of low production rate, high cost, complicated technology, difficult dimension control and the like. The preparation method comprises the steps: putting boron and a catalyst on the basis of weight ratio of 1 to (0.01 to 0.05) into a plastic bottle; using a nonaqueous solvent as a medium; ball-milling the boron and the catalyst for 8 to 24 hours; sieving the boron and the catalyst in a screen of 100 meshes after drying; heating a sieved mixture under the protection of argon gas; stopping leading the argon gas and leading nitrogen gas or the mixed gas of ammonia gas and the nitrogen gas when the temperature reaches 1000 DEG C to 1300 DEG C; keeping the temperature for 0.5 to 5 hours; reducing the temperature to room temperature after the constant temperature is finished; adding an obtained product to nitric acid for ultrasonic processing; removing the remained catalyst; and obtaining the boron nitride nano tube. The preparation method has the advantages of low cost, simple preparation technology, good repeatability and easy control and amplification of reaction; and the obtained boron nitride nano tube has the advantages of high production efficiency, easy purification, controllable tube diameter, controllable length and the like.

Owner:BEIJING UNIV OF TECH

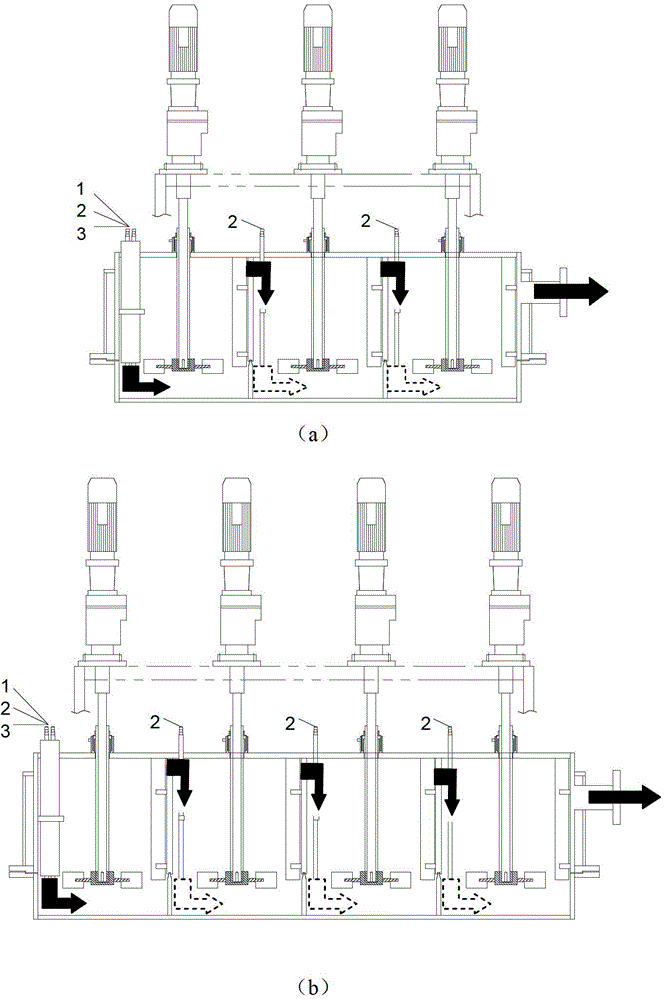

Oil gas exploitation apparatus and method

ActiveCN105443085AImprove effectivenessImprove controllabilityFluid removalHigh effectivenessPropelling nozzle

The invention relates to an oil gas exploitation apparatus and method. The apparatus includes at least an exploitation unit, a needle tubing, and a self-propelled nozzle arranged at a second end of the needle tubing. The exploitation unit includes a jet pipe nipple and an adjusting pipe nipple detachably connected to the jet pipe nipple, wherein penetrating installation holes are arranged on a sidewall of the jet pipe nipple, and the adjusting pipe nipple is provided with oil holes for the oil gas flowing from a stratum into an inner cavity of the exploitation unit. In the original state, a first end of the needle tubing is arranged in the inner cavity of the exploitation apparatus. The second end of the needle tubing is inserted in the installation holes. During a process for pumping the liquid to the exploitation apparatus, the needle tubing extends in a storage stratum so as to form an exploitation pore passage. In the oil gas exploitation process, the oil gas exploitation apparatus has high effectiveness for the reconstruction of the storage stratum and good oil gas output.

Owner:CHINA PETROLEUM & CHEM CORP +1

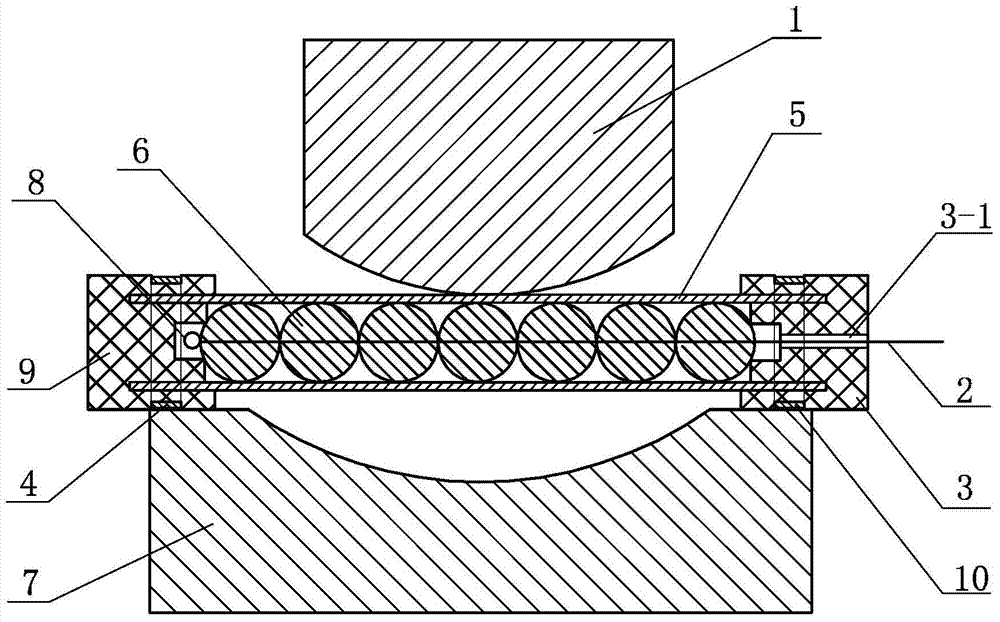

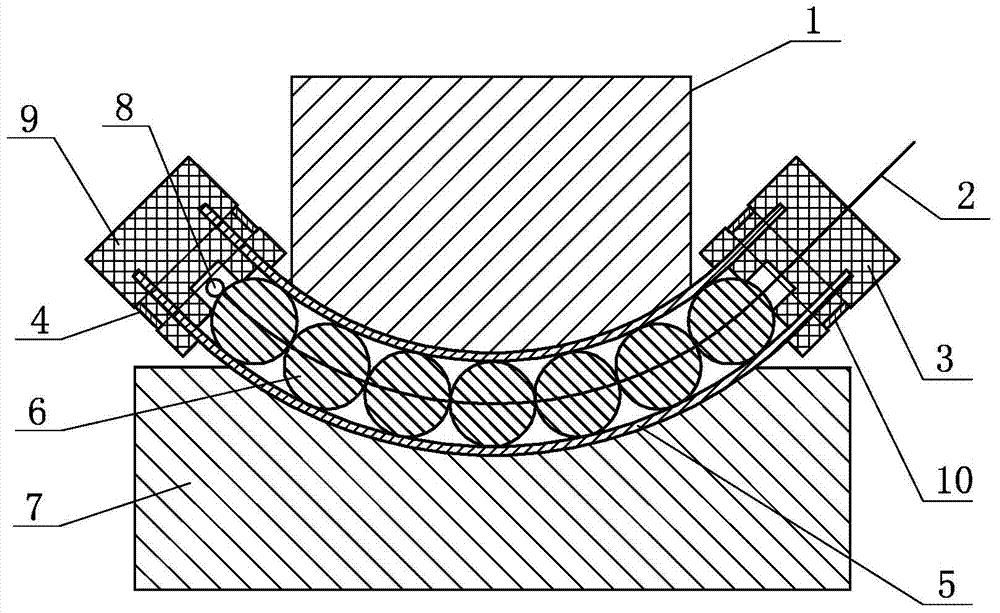

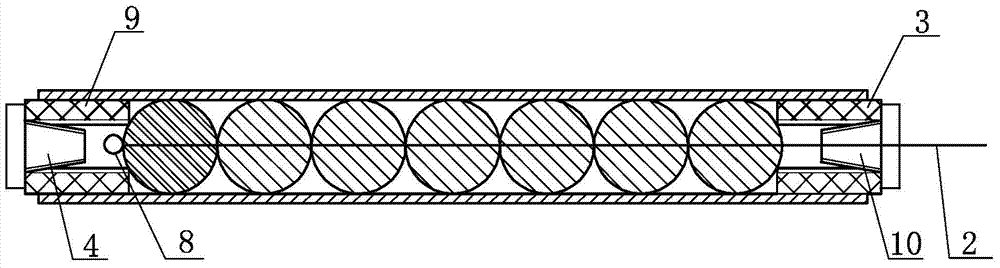

Bending method of pipes with flexible chained-ball mandrel

InactiveCN103752666AThere is no problem of mutual interferenceUniform deformationEngineeringMachine press

The invention relates to a pipe bending method, in particular to a bending method of pipes with a flexible chained-ball mandrel and solves the problem that high bending degree in the existing process of bending pipes having a mandrel causes mutual interference. The method includes: 1, threading a plurality of balls with a rope having a restraint ring at one end; 2, inserting a combined flexible chained-ball mandrel into a pipe to be bent; 3, placing a first rubber plug into one end of the pipe to be bent, fastening the first rubber plug through a first fastener, placing a second rubber plug into the other end of the pipe to be bent, and fastening the second rubber plug through a second fastener; 4, placing the pipe to be bent, onto a female die, and driving a male die to move down by a press until the pipe to be bent is bent; 5, after bending, loosening the first fastener, the second fastener, the first rubber plug and the second rubber plug to obtain a bent pipe. The bending method of pipes with one flexible chained-ball mandrel is applicable to pipe bending.

Owner:HARBIN UNIV OF SCI & TECH

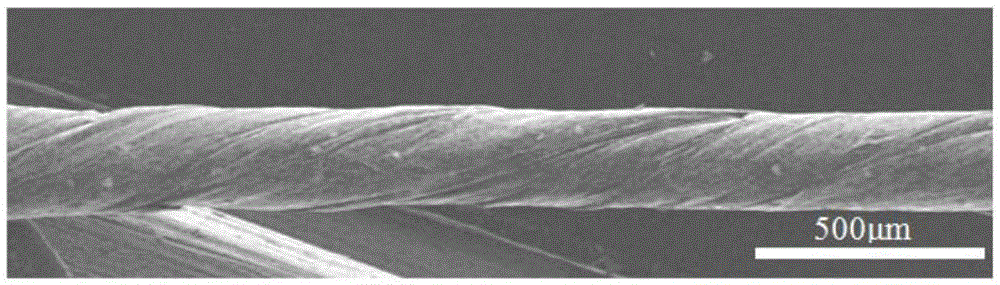

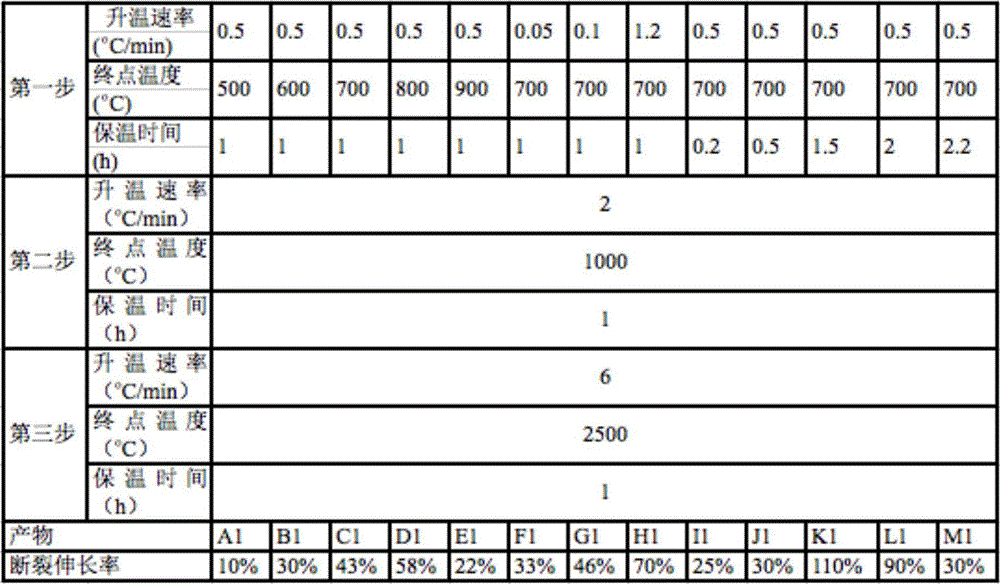

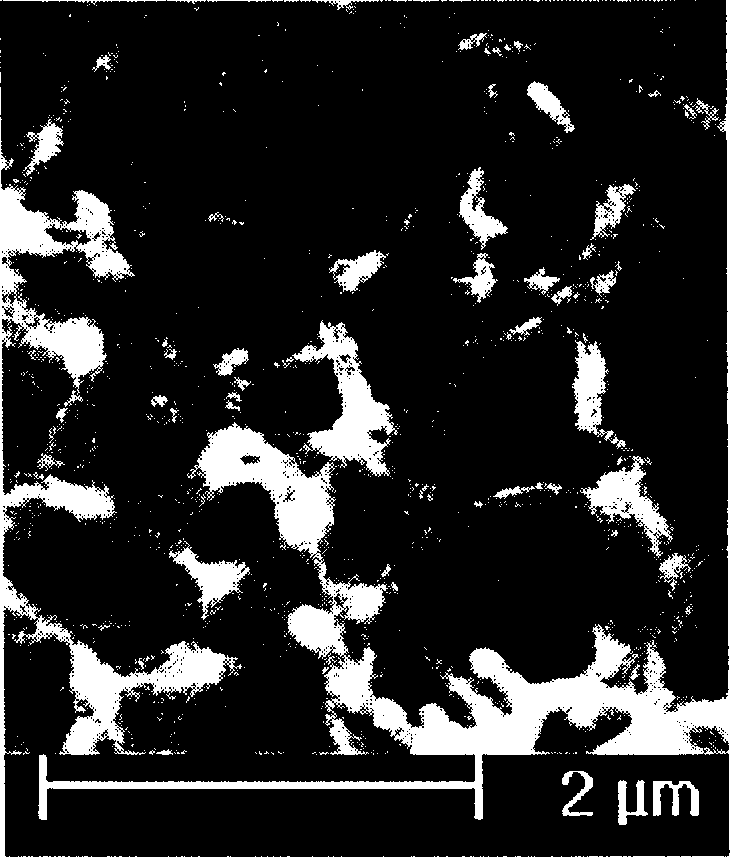

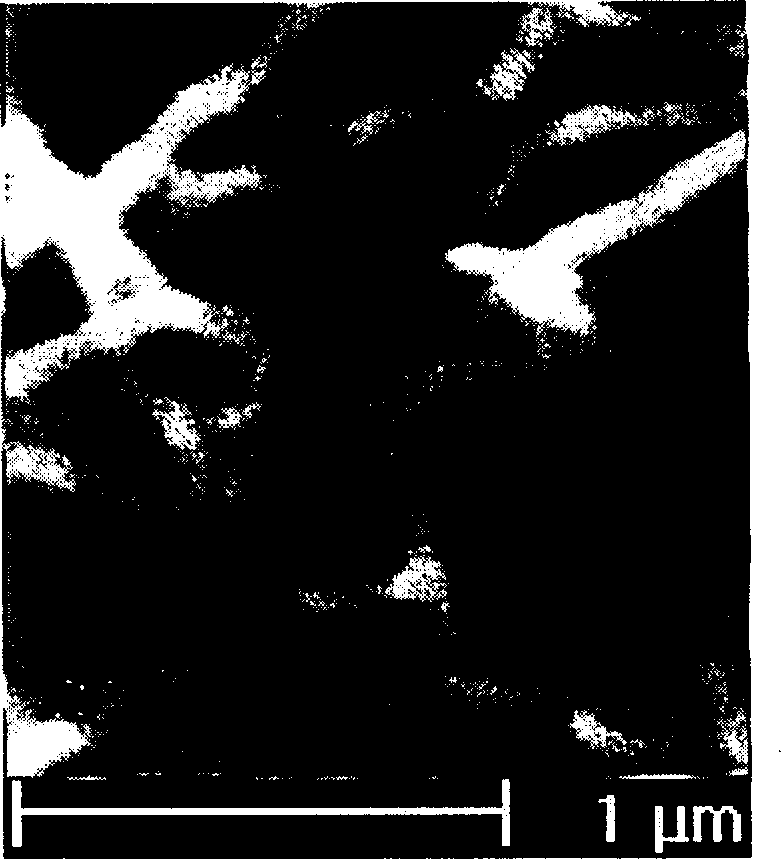

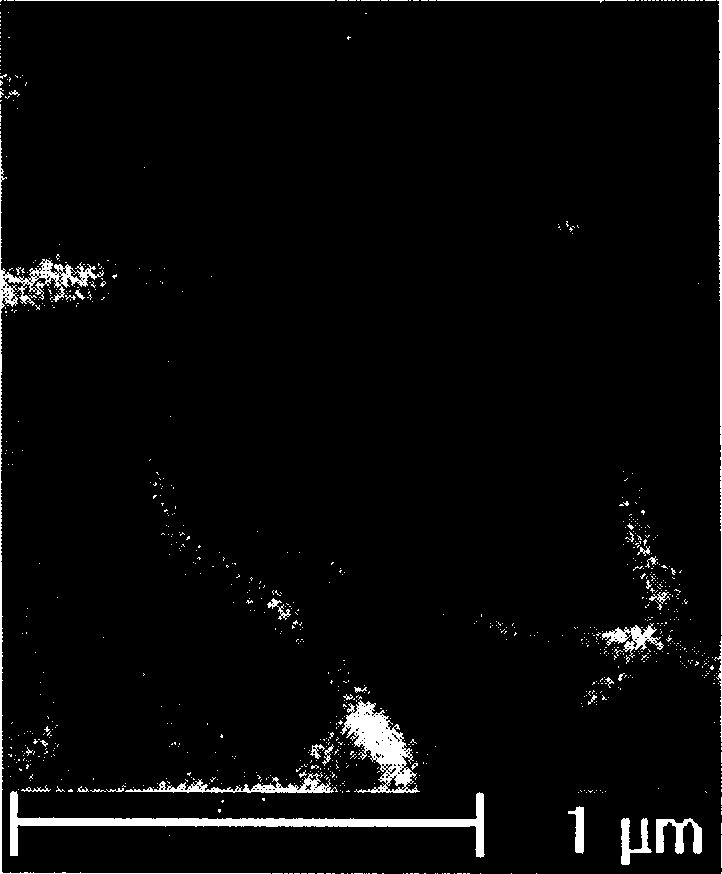

Super stretchable high-conductivity graphene fiber and preparation method thereof

The invention discloses a super stretchable high-conductivity graphene fiber and a preparation method thereof. The method comprises the steps that the temperature of a graphene oxide film is firstly raised to 500 DEG C to 800 DEG C at the rate of 0.1 DEG C / min to 1 DEG C / min, and heat preservation is carried out for 0.5 h to 2 h; then the temperature is raised to 1,000 DEG C to 1,300 DEG C at the rate of 1 DEG C / min to 3 DEG C / min, and heat preservation is carried out for 0.5 h to 3 h; the temperature is raised to 2,000 DEG C to 3,000 DEG C at the rate of 5 DEG C / min to 8 DEG C / min, and heat preservation is carried out for 0.5 h to 4 h; the graphene oxide film is wound, the super stretchable high-conductivity graphene fiber is obtained, the elongation at break ranges from 30% to 220%, and the conductivity is 1-2.36*106 S / m. The preparation method is simple in process, graphene fibers of different diameters and lengths can be obtained, the problem that a traditional graphene fiber is broken and is prone to be pulled to be broken is solved, the conductivity is excellent, and industrial prospects are achieved.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

Method for directly forming polypyrrole nano line on electrode surface

InactiveCN1465748AShorten the timeHigh yieldElectrolysis componentsElectrolytic organic productionPyrroleVolt-ampere

The method for directly forming polypyrrole nano wire on the surface of electrode includes the following steps: making pyrrole, polyanion dopant or high-valence anion dopant and supporting electrolyte into electrolyte, adopting composite electrode and utilizing constant potential method or circulation volt-ampere method to make the above-mentioned electrolyte undergo the process of electrolytic polymerization, and utilizing the control of pyrrole concentration, dopant concentration and supporting electrolyte solution concentration to attain the goal of directly forming polypyrrole nano wire with different length and diameter on the surface of the electrode. The diameter of nano wire can be 50 nano.

Owner:TIANJIN UNIV

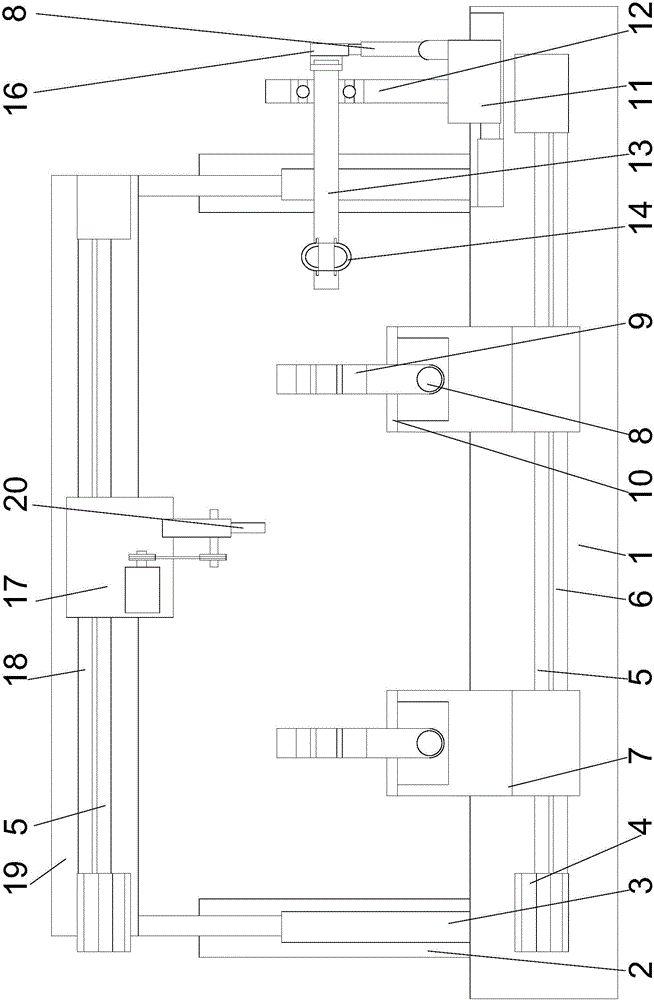

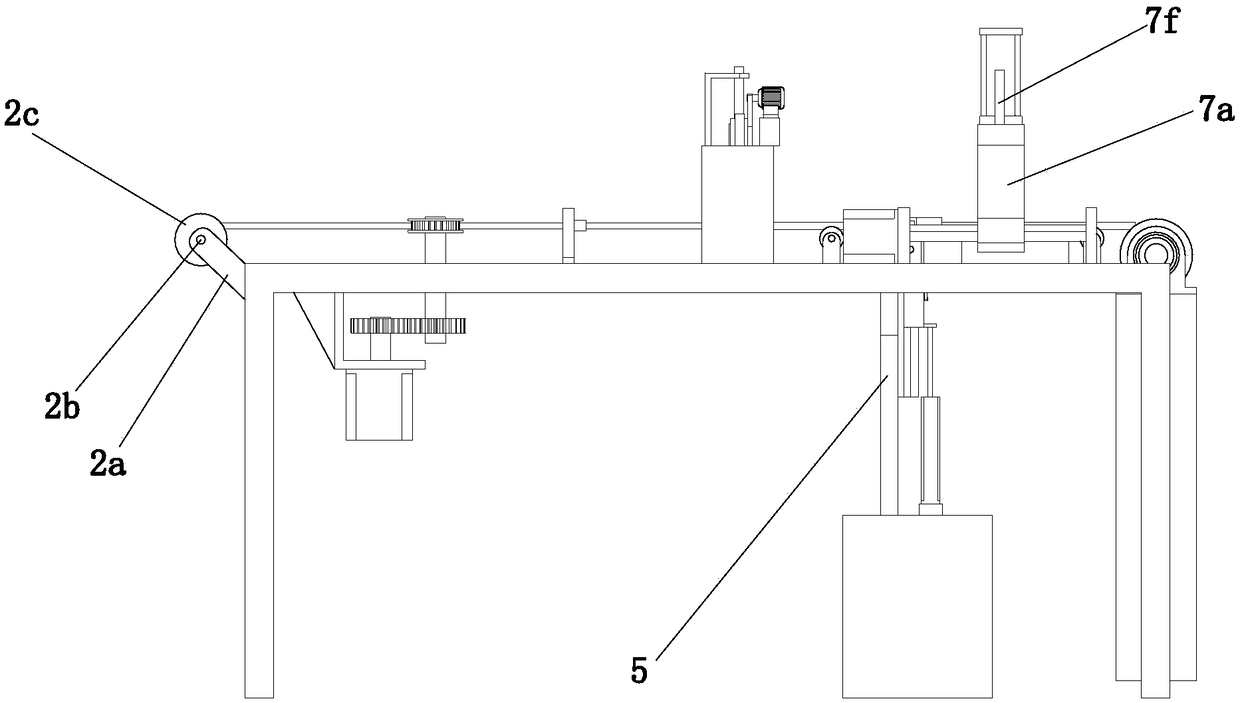

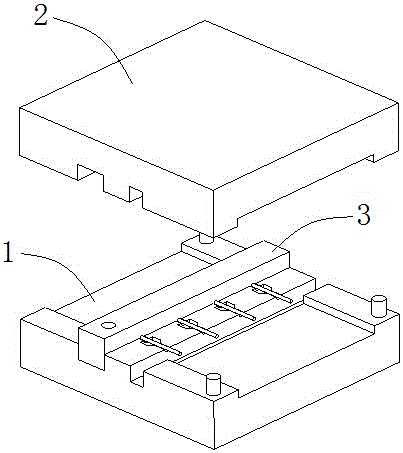

Automatic heat-shrinkable tubing threading and roasting machine

ActiveCN109435225AReduce laborEasy to control the lengthLine/current collector detailsMetal working apparatusEngineeringAutomation

The invention discloses an automatic heat-shrinkable tubing threading and roasting machine and belongs to the technical field of wire rod processing. The automatic heat-shrinkable tubing threading androasting machine comprises a worktable, a wire rod feeding mechanism, a heat-shrinkable tubing feeding mechanism, a packaged cutting mechanism and a heat-shrinkable tubing limiting mechanism. A bushing rack is arranged on the top of the worktable, two conduit grooves are formed in the top of the bushing rack, a limiting ring is arranged in each conduit groove, and the packaged cutting mechanism comprises a left cutting assembly and a packaged cutting assembly. The automatic heat-shrinkable tubing threading and roasting machine has the beneficial effects that the automatic heat-shrinkable tubing threading and roasting machine is high in degree of automation, can achieve the feeding operation of the wire rod and the heat-shrinkable tubing; the to-be-cut wire rod and the eat-shrinkable tubing sleeved o the wire rod can be pre-limited through the eat-shrinkable tubing limiting mechanism; the packaged right end of the wire rod can be cut in a proper position by the packaged cutting mechanism, so that a user can control the length of the eat-shrinkable tubing with high precision.

Owner:山东金博防腐材料有限公司

Manufacture method for earphone wires

ActiveCN106142442AReduce the difficulty of operationEasy to control the lengthDomestic articlesCoatingsIndustrial engineering

The invention discloses a manufacture method for earphone wires. The manufacture method comprises the following steps: a, a wire is cut according to dimension requirement, and one end of the wire is welded on an earphone plug; b, the welded earphone plug is sequentially subjected to inner mould injection and outer mould injection; c, stripping is performed from the middle part of the wire to an end which is far away from the earphone plug, and a core wire is divided into two strands according to requirement; e, the two strands of the core wires are separately inserted into a sleeve pipe; then the sleeve pipe and the stripped part of the middle part of the wire are sequentially subjected to middle buckle inner mould injection and middle buckle outer mould injection; and before the core wires are inserted in the sleeve pipe, a step d is performed, namely a tail baffle is injected at one end of the sleeve pipe, and then the sleeve pipe is cut from the tail baffle according to a required dimension. By adopting the manufacture method, operation difficulty of workers can be lowered; the length of the earphone wire is conveniently controlled; the production efficiency and qualification rate of earphones are improved; cost is lowered; and the like.

Owner:CHONGQING XIALANG TECH CO LTD

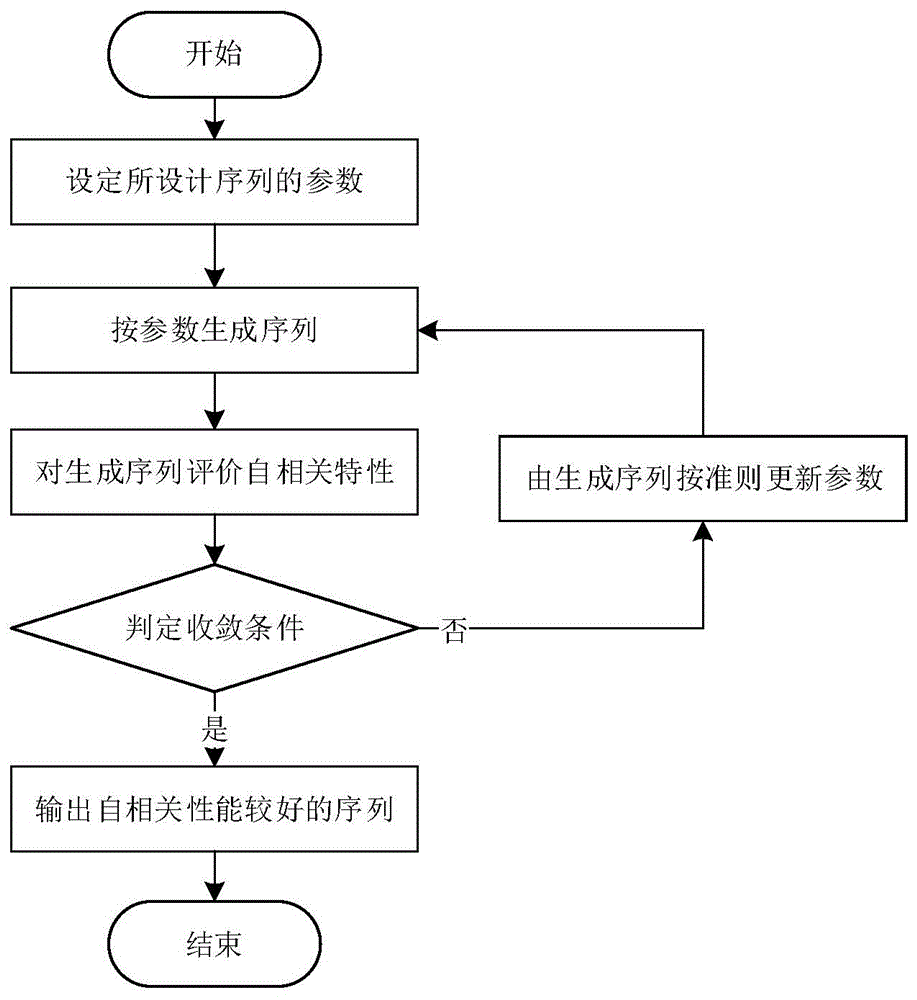

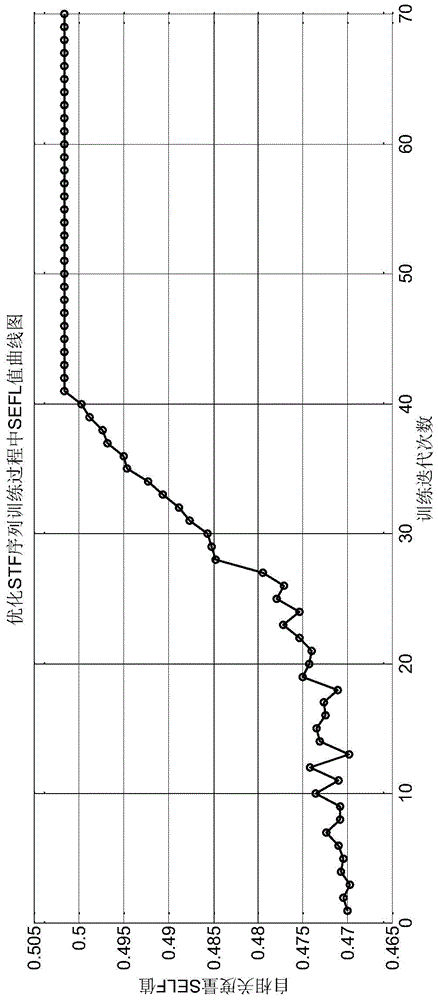

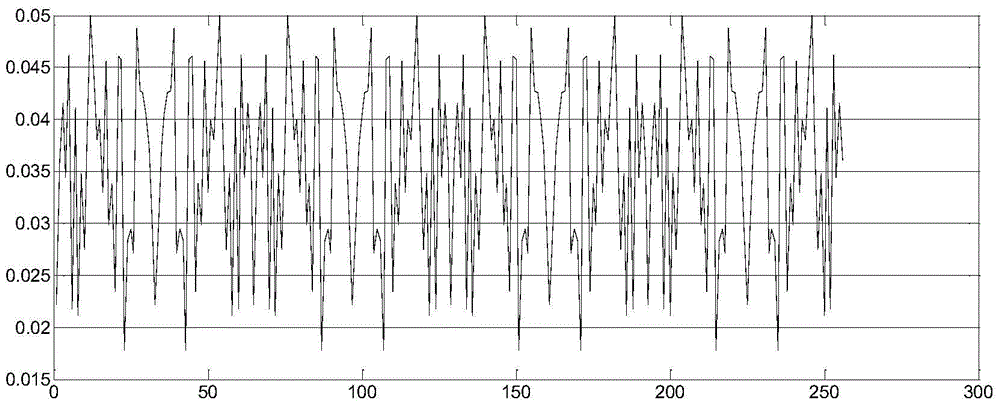

Short training field design method used for wireless local area network communication system

InactiveCN105162745AEasy to control the lengthControl lengthMulti-frequency code systemsWave shapeLocal area network

The invention discloses a short training sequence design method used for a wireless local area network communication system. First, related parameters of a field to be designed are determined. Then multiple times of iteration are performed. In one time of iteration, fields, which are the sums of a plurality of elements obeying a Bernoulli distribution of predetermined probability density parameters, of determined lengths and configuration, are generated according to the parameters, and the generated fields are screened according to SELF of the fields and parameters for next iteration are updated. Finally, after the iteration is ended, the fields with good self-relevance and periodically repeated time domains are set as the designed short training fields. According to the invention, short training fields of any lengths can be designed. The fields only contains elements of (1+i), -(1+i) and 0 and has good self-relevance and periodically repeated time domains and wave shapes. According to the invention, on the condition that specific values are assigned to specific positions of the fields, the fields with good wave shapes can also be obtained, so that application scene and application range are increased further. The invention can be applied but is no limited to the design of short training fields for OFDM systems.

Owner:ZTE WAVETONE SCI & TECH

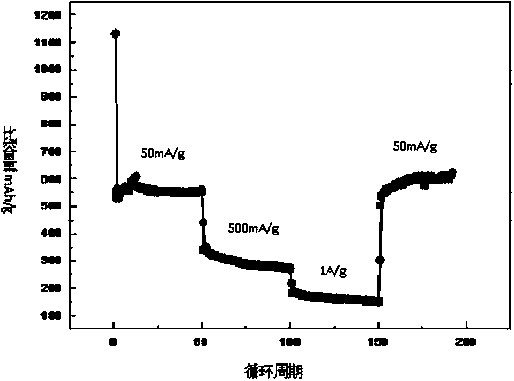

Preparation method of copper oxide nanowires and application of copper oxide nanowires in negative electrode of lithium ion battery

InactiveCN103482674AEasy to control diameterEasy to control the lengthCell electrodesNanotechnologyNanowireCopper oxide

A mixture of copper oxide nanowires and cuprous oxide is firstly prepared by a thermal oxidation method, then concentrated ammonia is utilized for post-processing the mixture, and pure one-dimensional copper oxide nanowires are obtained. When the one-dimensional copper oxide nanowires are used as a negative electrode material of a lithium ion battery, under a current density of 50 mA / g, the stable specific capacity of the electrode material is up to 550 mAh / g and is 1.5 times as much as that of a commercial carbon electrode. When the current density is gradually increased from 50 mA / g to 1 A / g and then returns to 50 mA / g, the capacity retention rate is 99%. The electrode material has excellent cycling stability and rate performance.

Owner:BEIJING UNIV OF CHEM TECH

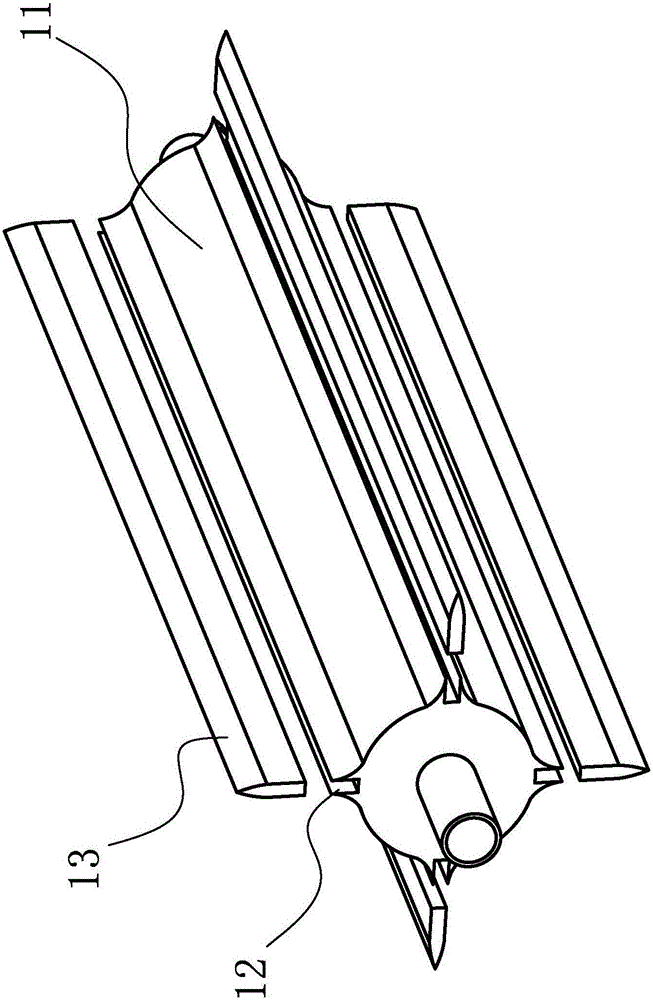

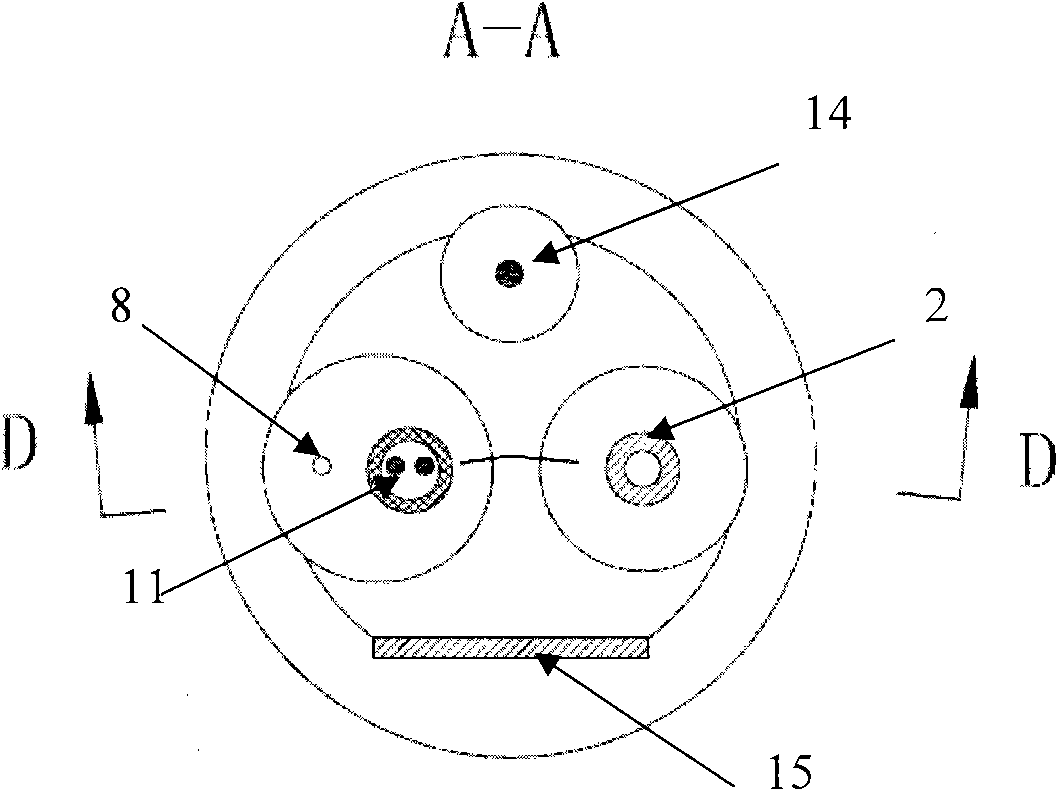

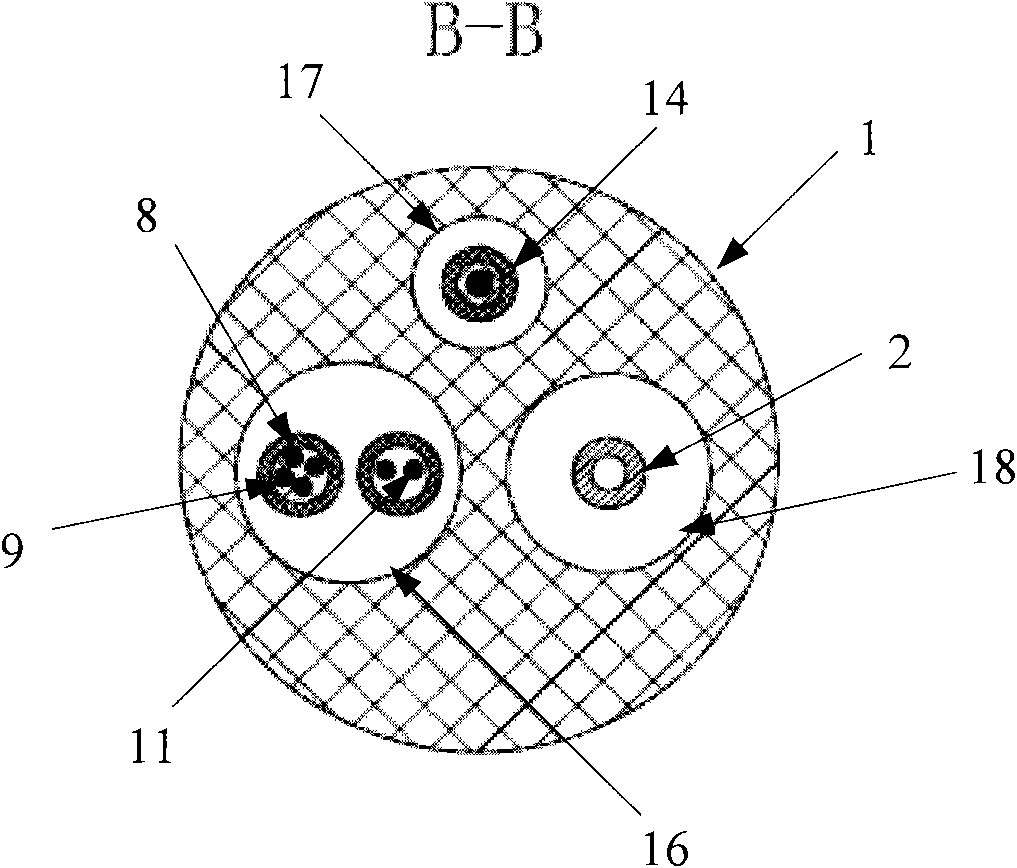

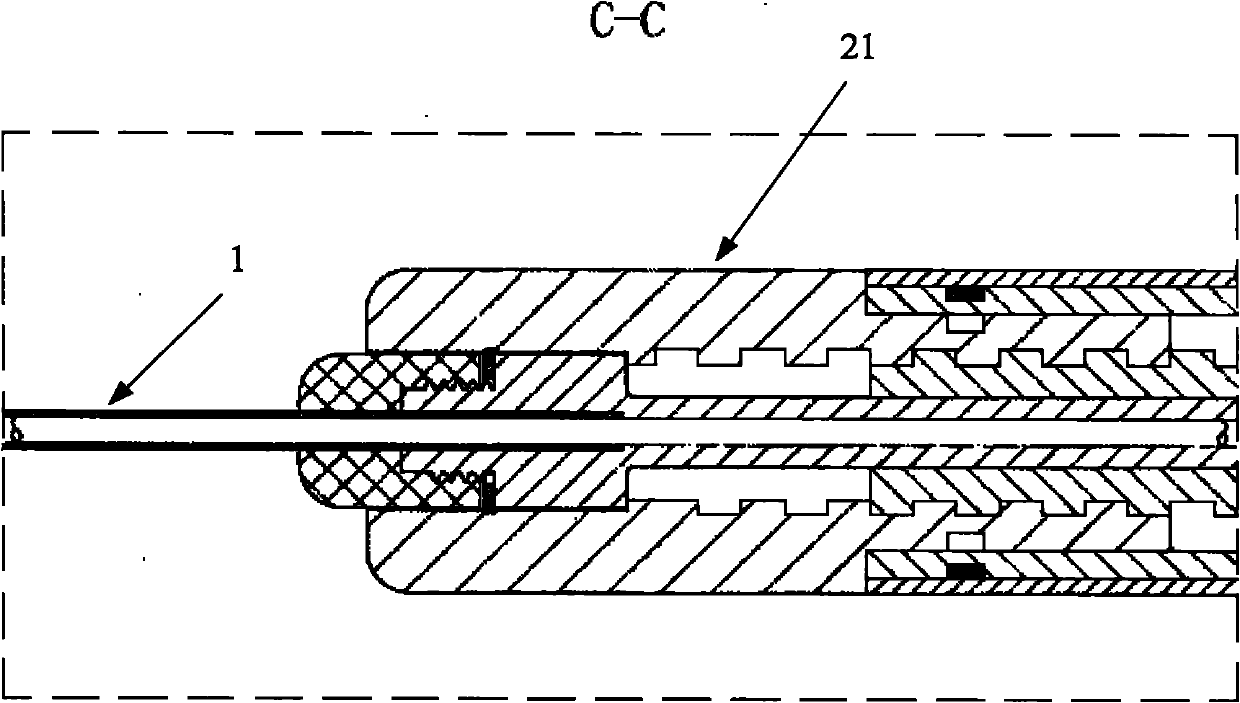

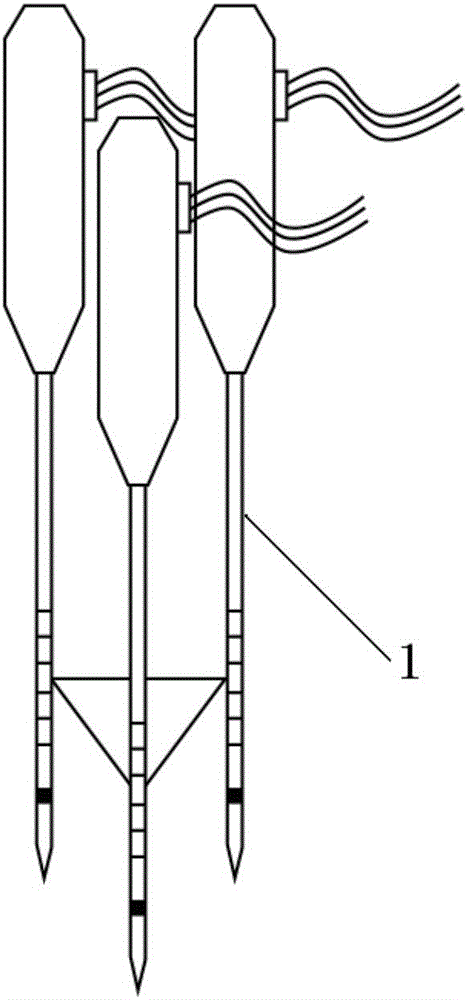

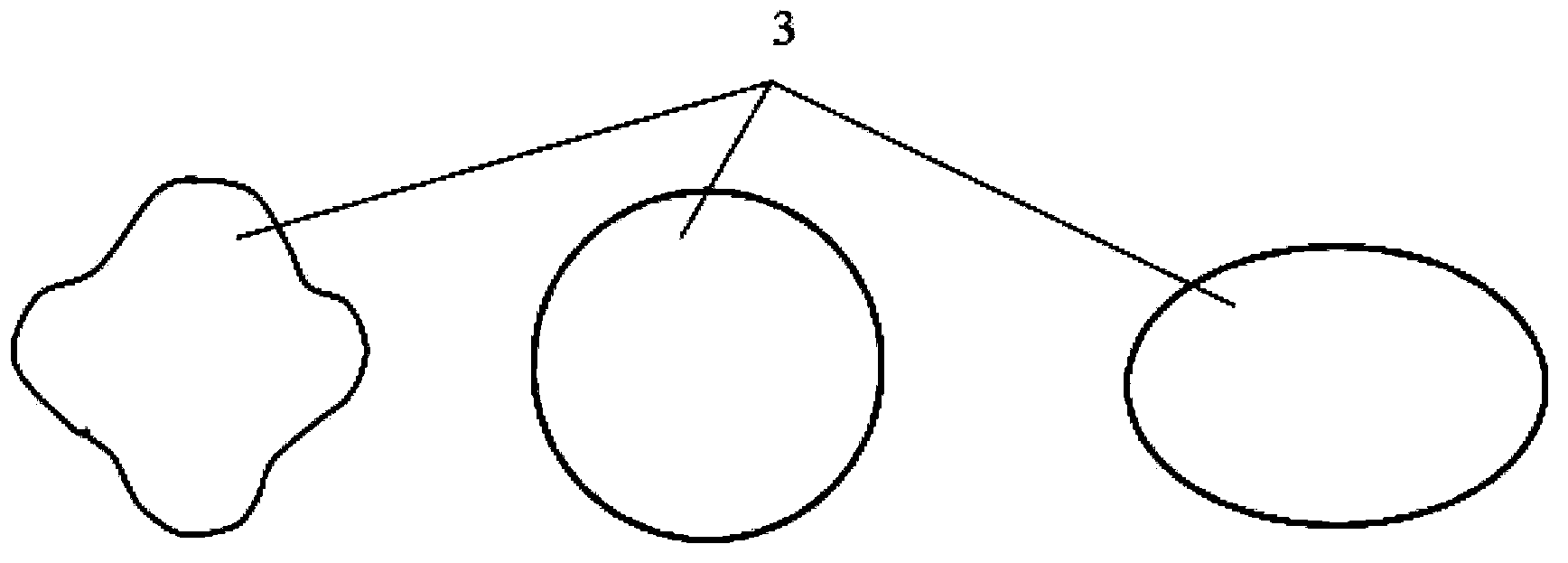

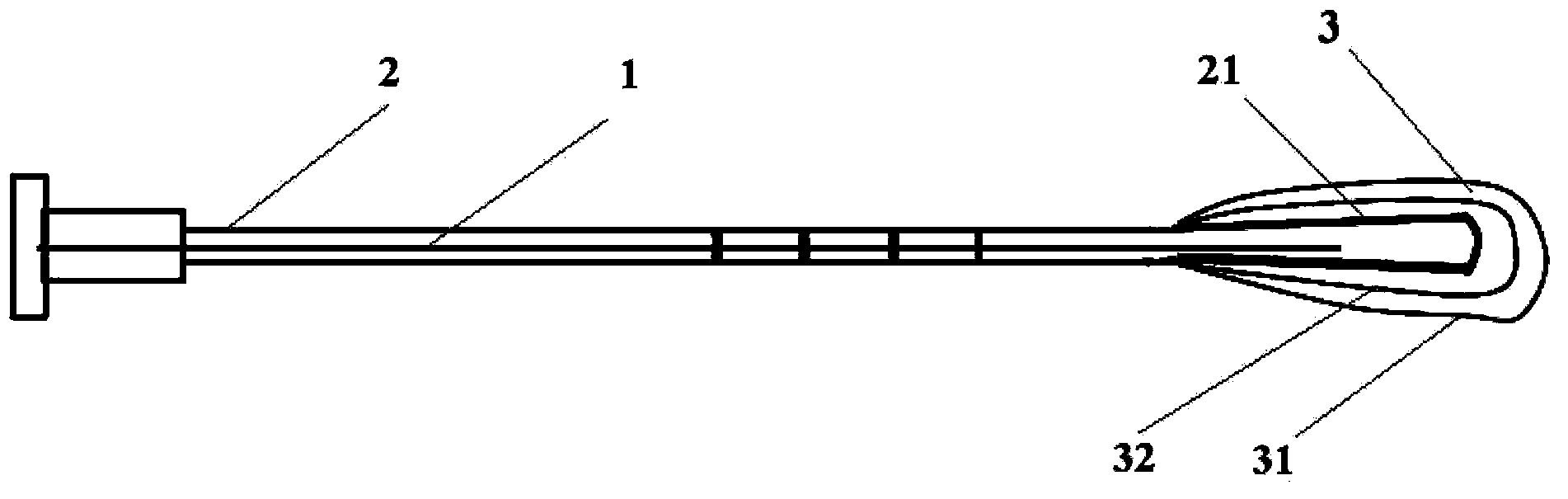

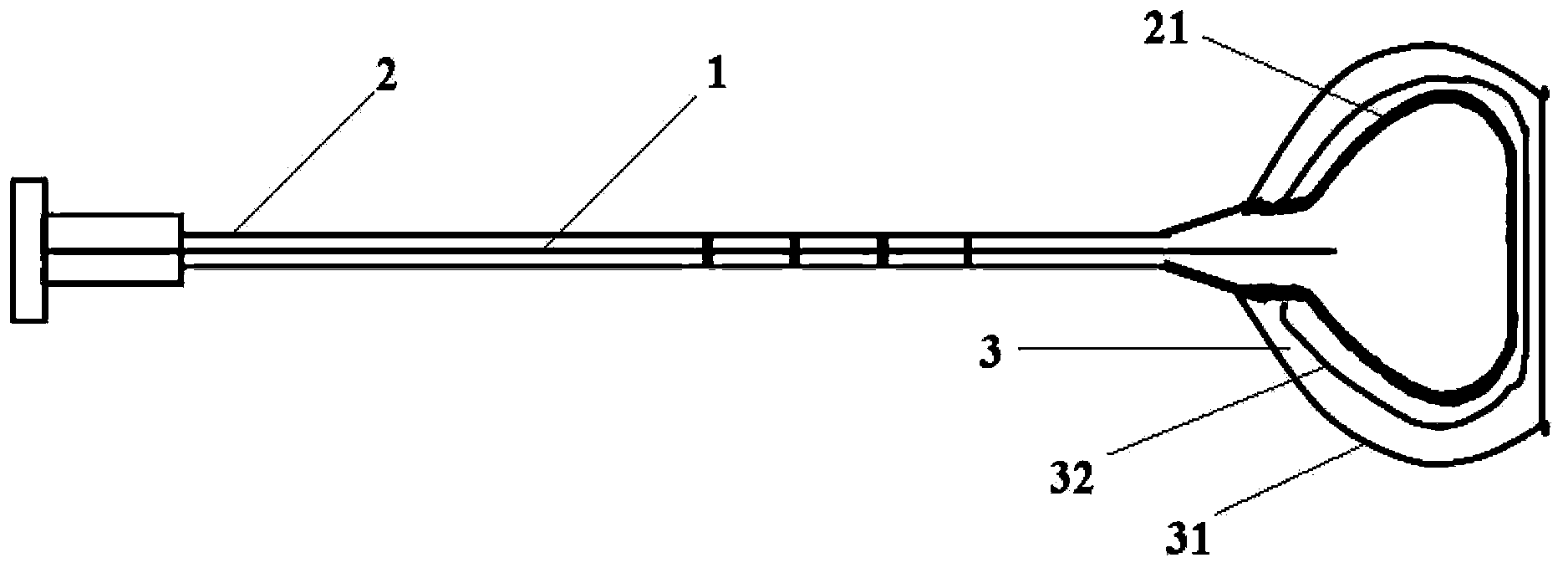

Multi-tip extension type radiofrequency ablation electrode needle

PendingCN106308927AEasy to control the number of needlesEasy to control the lengthSurgical needlesSurgical instruments for heatingRadiofrequency ablationBiomedical engineering

The invention provides a multi-tip extension type radiofrequency ablation electrode needle. The multi-tip extension type radiofrequency ablation electrode needle comprises a trocar, a handle part and a plurality of control slide blocks, wherein one end of the trocar is provided with a needle outlet; a plurality of electrode auxiliary needles are arranged in the trocar in a penetrating way, can respectively extend out of the needle outlet, and are outwards extended and bent; the electrode auxiliary needles are arranged in the trocar in the circumferential direction; the handle part is fixedly arranged at the other end of the trocar, a plurality of metal slide bars are arranged in the handle part and can slide, one end of each metal slide bar is connected with the corresponding electrode auxiliary needle, and the other end of each metal slide bar is connected with a radiofrequency treatment instrument; the control slide blocks are glidingly arranged on the circumferential wall of the handle part, and are connected with the metal slide bars. The multi-tip extension type radiofrequency ablation electrode needle has the advantages that the needle discharging number, direction and length can be controlled, the directional extension of the electrode auxiliary needles is realized, the electrode needle is suitable for thoroughly ablating tumors under large blood vessels or at the edges of organs, and the operation is simple and convenient.

Owner:BEIJING CANCER HOSPITAL PEKING UNIV CANCER HOSPITAL

Compound active amnion material, preparation method and application thereof and compound active amnion uterine cavity repair stent

ActiveCN103349798AStructure remains intactMaintain biological functionSurgeryMedical devicesSacculeMedicine

The invention provides a compound active amnion material, a preparation method and application thereof and a compound active amnion uterine cavity repair stent. The preparation method comprises the following steps: (1) providing a collagen sponge prepare liquid or a compound collagen sponge prepare liquid; (2) providing an amnion with both an epithelial layer and a basement membrane; (3) pouring and coating the prepared prepare liquid on the basement membrane of the amnion to enable the basement membrane and the prepare liquid to be subject to crosslinking, and then preparing the compound active amnion material through freeze drying. The compound active amnion material not only keeps the complete structure and the due biological function of the amnion but also endow the amnion with a certain rigidity, so that the compound active amnion material has stronger maneuverability in application after TCRA (Transcervical Resection Of Adhesions) operation; the compound active amnion uterine cavity repair stent integrates the compound active amnion material and a saccule at the front end of a pipe body, the saccule expands under the action of an external force to push out the compound active amnion material, and then the compound active amnion material is successfully attached to the inner wall of the uterine cavity; the stent is convenient to take out and prevents secondary damage.

Owner:JIANGXI RUIJI BIOTECH CO LTD

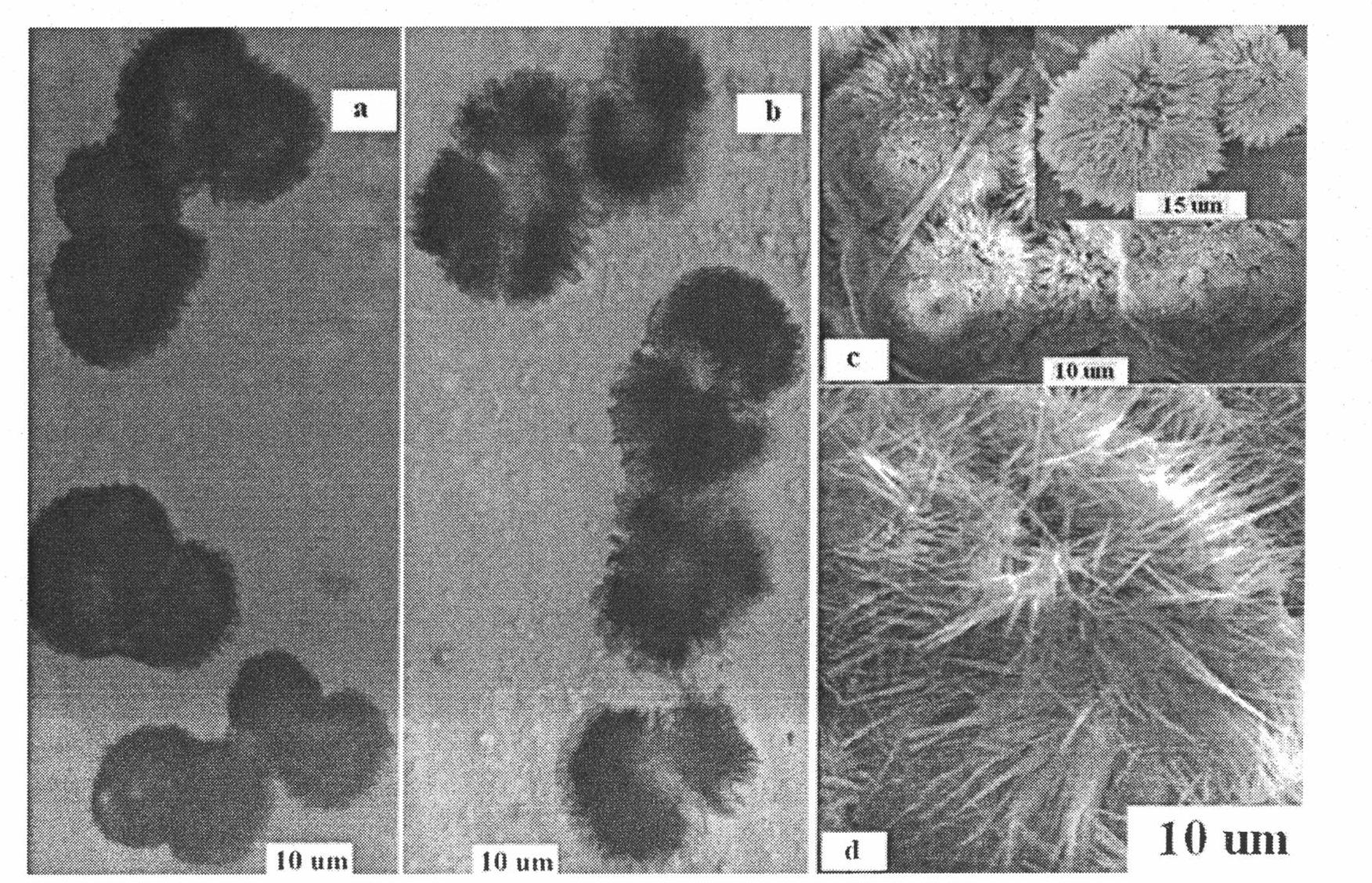

Preparation method of hedgehog SiO2 hollow microsphere

The invention discloses a hedgehog SiO2 hollow microsphere and preparation method thereof. Block polymer is taken as soft template; block polymer solution is added into organic solvent / water two-phase system, so as to form stable emulsion, co-guiding agent and silicon source are dissolved in organic solvent and mixed to be uniform, and the emulsion is added; under the conditions of faintly acid and alkalescence, silicon precursor is hydrolyzed and condensed; then drying and calcination subsequent treatment are carried out; and finally the hedgedog SiO2 hollow microsphere is obtained. The invention is easy to implement and is economic and practicable, the grain diameter distribution of the prepared hedgedog SiO2 hollow microsphere is uniform, and the cavity diameter and spinous density are adjustable.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Preparation method of zinc oxide nanorod

InactiveCN103359773AOvercoming the Difficulty of Poor Structural StabilitySolve problems such as small scale and long response timeMaterial nanotechnologyZinc oxides/hydroxidesGas detectorPotassium hydroxide

The invention discloses a preparation method of a zinc oxide nanorod. The preparation method comprises the following steps of: preparing a water solution of sodium hydroxide or potassium hydroxide; weighting cetyltrimethylammonium bromide according to the mole ratio of the cetyltrimethylammonium bromide to the sodium hydroxide of (0.001:1)-(1:1), and adding the cetyltrimethylammonium bromide into the water solution of the sodium hydroxide; weighting carbamide according to the mole ratio of the carbamide to the sodium hydroxide of 0.05:1 to 1:1, adding the carbamide into the prepared solution, and stirring the solution; weighting a zinc precursor according to the mole ratio of the zinc precursor to the sodium hydroxide of (0.03-3):1, and preparing a zinc precursor solution with the concentration of 0.3-1M; heating and stirring the solution; and centrifuging the solution to obtain white powder, and drying to obtain the zinc oxide nanorod. The method is simple in operation; the prepared ZnO rod is adjustable in size; the prepared ZnO rod is small in size so as to be large in special surface area and suitable for application in a photocatalyst and a gas sensor.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Device and method for manufacturing tapered optical fiber

InactiveCN102565947AAvoid physical damageReduce processing timeCoupling light guidesGalvanometerEngineering

The invention discloses a device and a method for manufacturing a tapered optical fiber. The device comprises an optical flat, a computer terminal, a carbon dioxide laser, a scanning galvanometer, a metal film plated reflector, a placing platform, two bi-dimensional accurate adjusting brackets, two optical fiber fixing parts and a plurality of pairs of weights. The placing platform is used for placing the metal film plated reflector, the two bi-dimensional accurate adjusting brackets are respectively arranged on two sides of the placing platform, the two optical fiber fixing parts are respectively fixed on the two bi-dimensional accurate adjusting brackets and are respectively used for fixing one of two ends of the processed optical fiber, the plurality of pairs of weights are used for suspending on the two ends of the processed optical fiber, the mirror surface of the reflector is right against an output end of the carbon dioxide laser, during usage, a portion to be processed with a coating layer removed in the processed optical fiber is enabled to tightly cling to the mirror surface of the reflector and is located on a focal plane of a focusing lens of the carbon dioxide laser, output laser spots of the carbon dioxide laser are controlled by the computer terminal, and the weights are quickly pulled after one scanning is completed to obtain the tapered optical fiber. Not onlythe processing time is shortened, but also physical damage to the optical fiber caused by long time action of the output laser spots on the optical fiber is avoided.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com