Ultrasonic phased array inspection instrument

An ultrasonic phased array and testing instrument technology, applied in instruments, scientific instruments, analyzing solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of low technical level of testing equipment, and achieve the effect of improving accuracy and testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

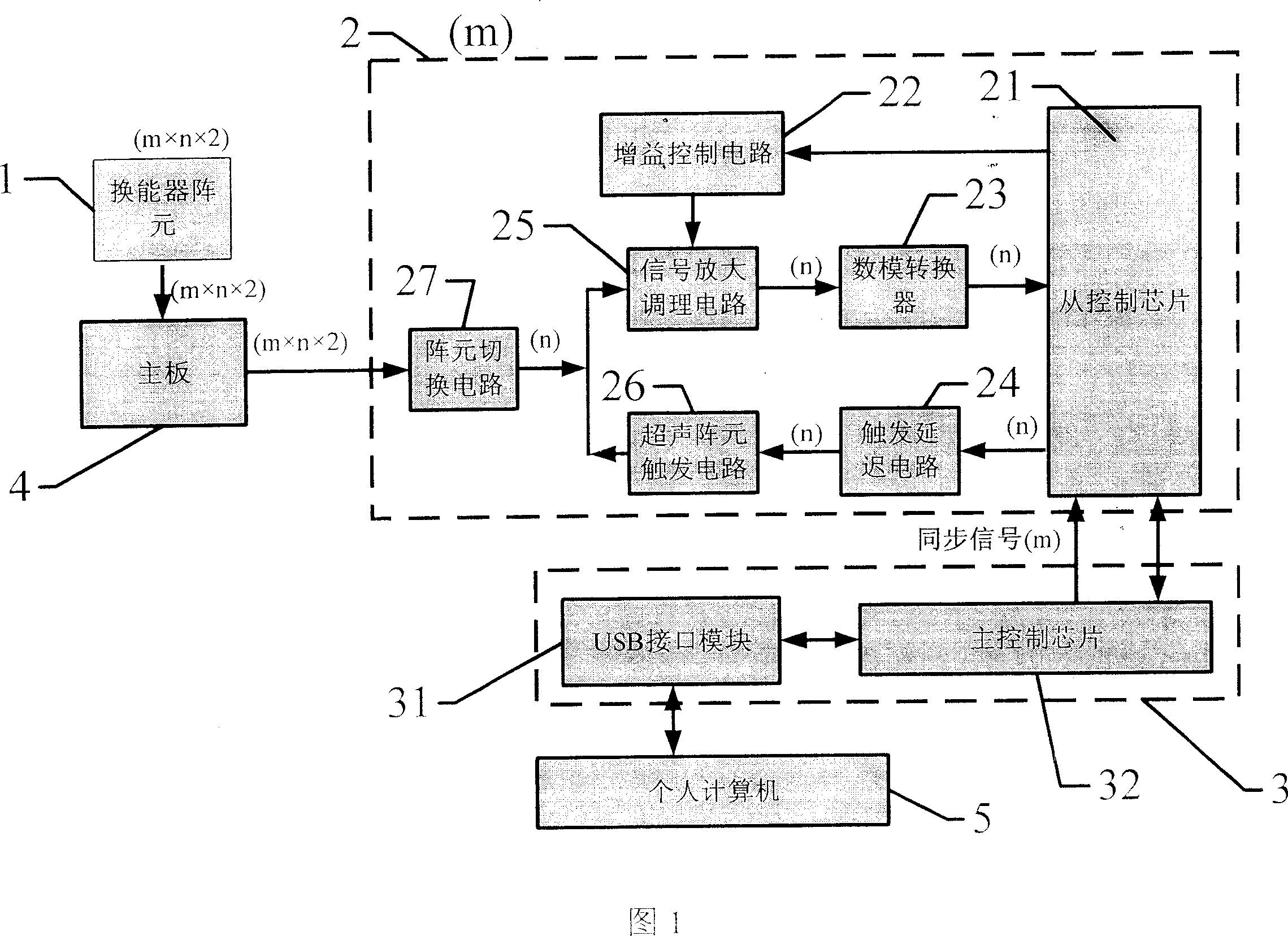

[0015] Referring to Fig. 1, the composition of the ultrasonic phased array detection instrument includes: ultrasonic phased array probe part 1, ultrasonic triggering / receiving board part 2, main control board part 3, main board part 4 and computer 5.

[0016] In conjunction with Fig. 1, the described ultrasonic triggering / receiving board part 2 is composed of a slave control chip part 21, a gain control circuit part 22, a digital-to-analog converter part 23, a trigger delay circuit part 24, a signal amplification conditioning circuit part 25, an ultrasonic array element The trigger circuit part 26 and the element switching circuit part 27. This embodiment adopts 8 ultrasonic triggering / receiving boards, and each ultrasonic triggering / receiving board can trigger and receive 4 array element signals at the same time, and can be extended to 8 array element signals thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com