Method for directly forming polypyrrole nano line on electrode surface

A polypyrrole nanowire and electrode surface technology, which is applied in the direction of electrolytic organic production, electrolytic process, electrolytic components, etc., can solve the problems of low yield and achieve the effects of high yield, short time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

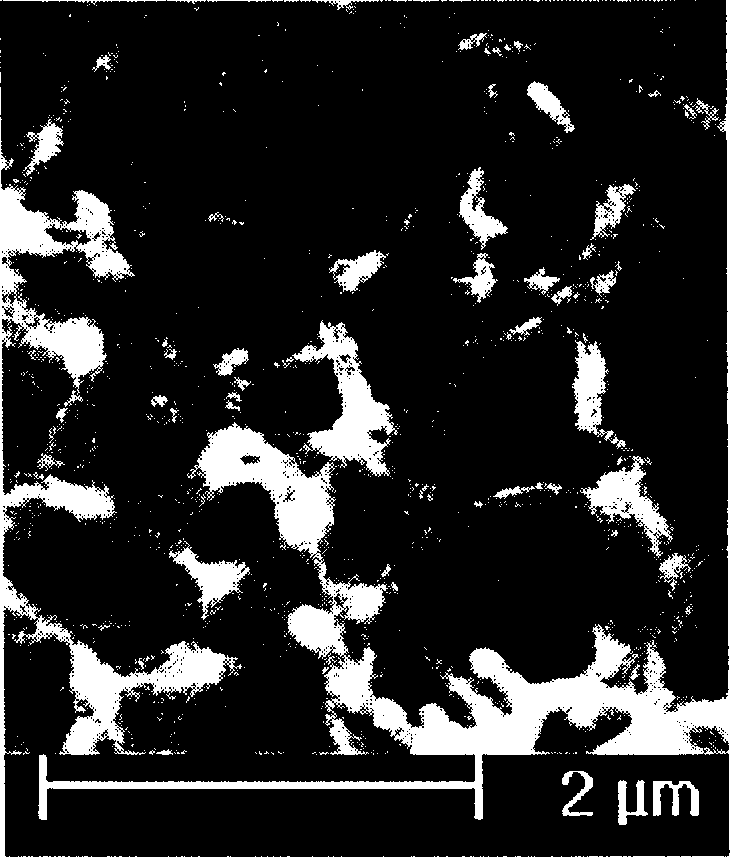

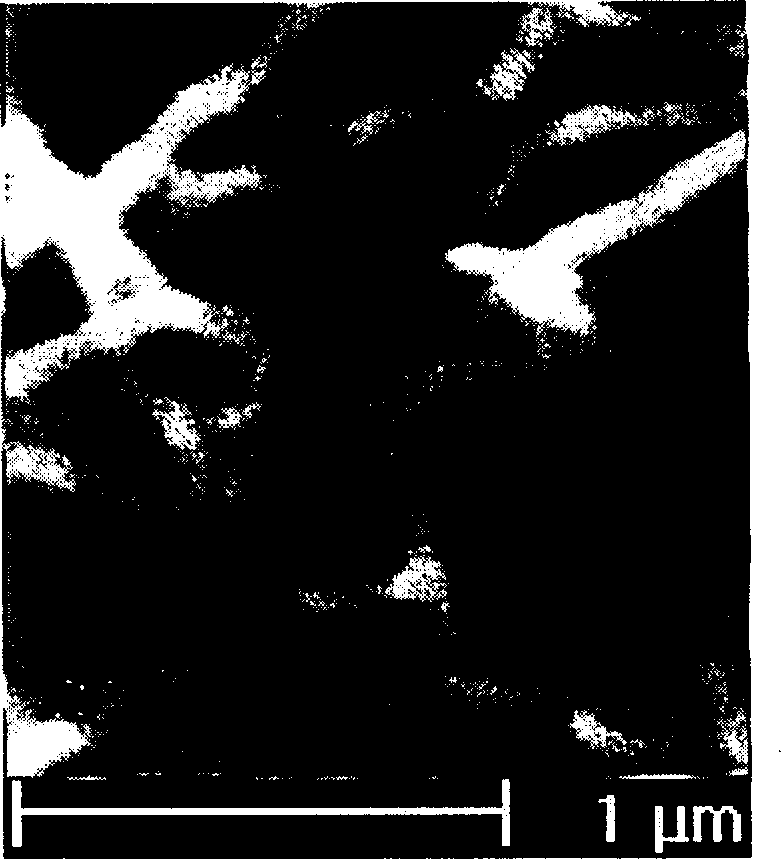

[0015] The electrolyte composition is 0.2mol L -1 Phosphate buffer solution with a pH of 6.86, containing 0.4% polyacrylic acid in the buffer solution, 0.10mol L -1 Lithium perchlorate and 0.15mol L -1 pyrrole. Then, take 0.00V as the start potential, 0.85V as the end potential, and scan for 20 cycles at a scanning speed of 25mv / s; or electrolytically polymerize at a constant potential of 0.85V for 100 seconds.

Embodiment 2

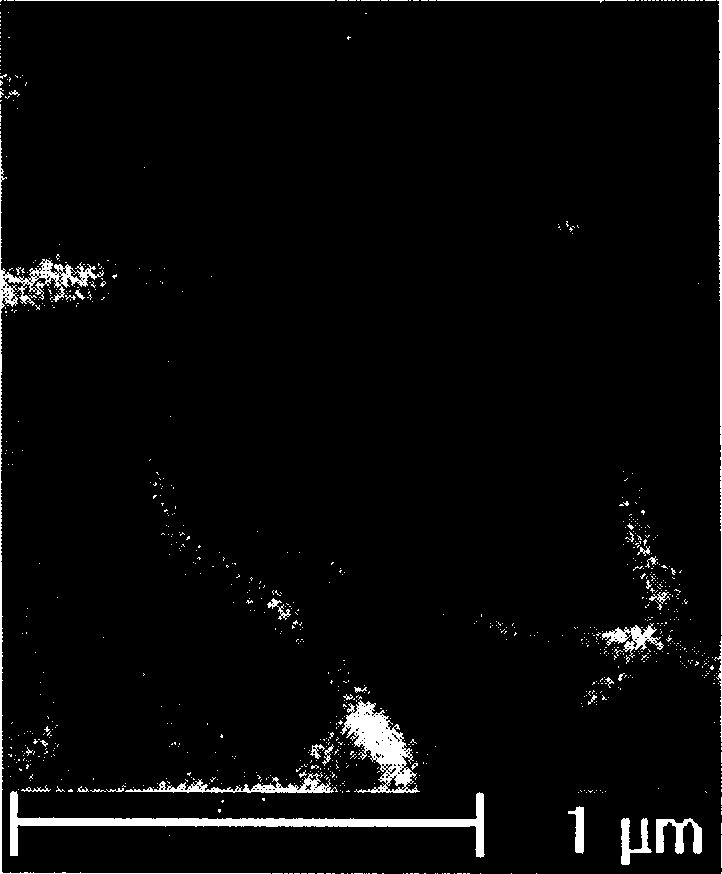

[0017] The electrolyte composition is 0.2mol L -1 EDTA buffer solution with a pH of 9.00, in the buffer solution, 0.10mol·L -1 Lithium perchlorate and 0.15mol L -1 pyrrole. Then, take 0.00V as the start potential, 0.85V as the end potential, and scan for 20 cycles at a scanning speed of 25mv / s; or electrolytically polymerize at a constant potential of 0.85V for 100 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com