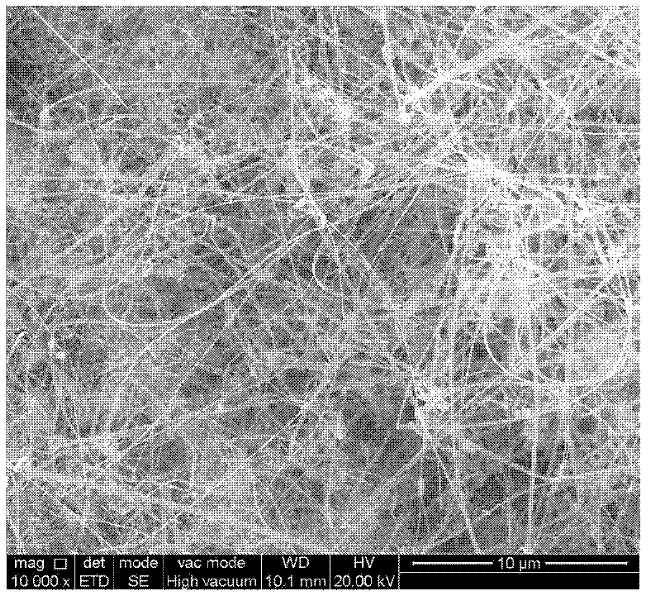

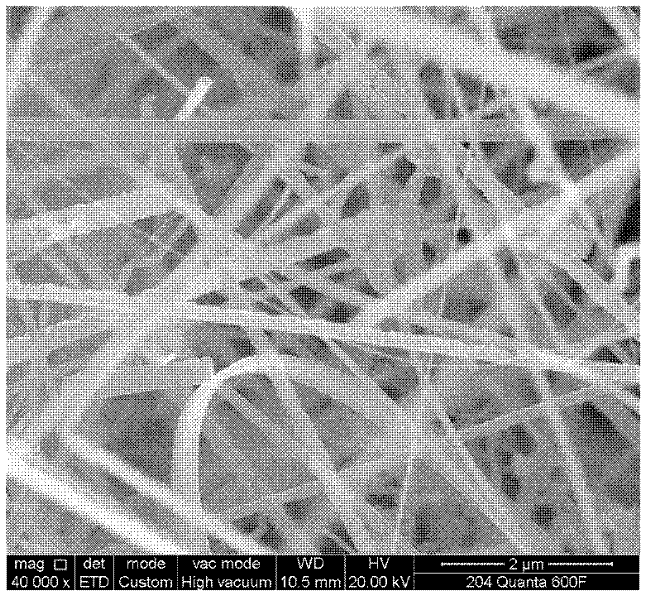

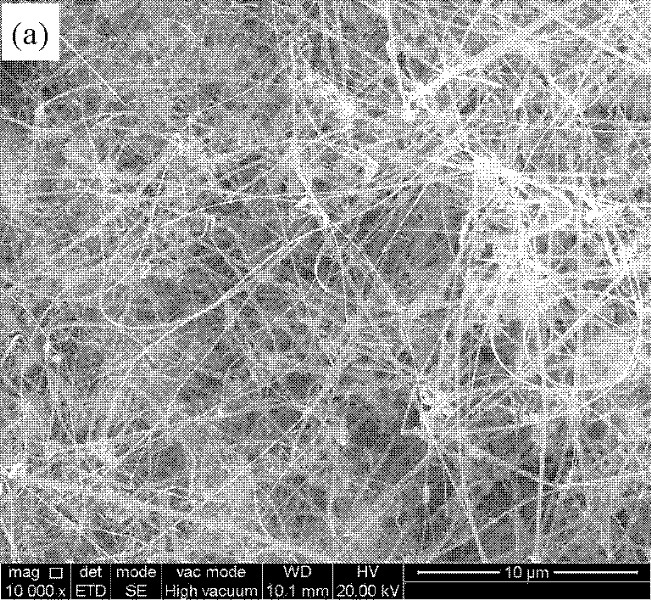

Method for preparing SiC nanometre wires and nanometre belts

A nanobelt and nanowire technology, which is applied in the field of preparing SiC nanowires and nanobelts, can solve the problems of SiC nanowires and nanobelts with complex preparation process, impure products, and difficult control, and achieve environmental protection and large-scale production. The effect of low production cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The block graphite was washed with absolute ethanol and dried in an oven for later use.

[0026] Weigh 75g of Si powder, 15g of SiC powder, 15g of C powder, 10g of Al 2 o 3 pink. Place in a turpentine ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 4 hours to obtain a mixed powder.

[0027] Put half of the mixed powder into the graphite crucible, put the prepared block graphite, then put the other half of the mixed powder, shake the crucible slightly to make the powder evenly embed the block graphite, and then put the graphite crucible Put graphite into the hot-press vacuum reaction furnace with graphite as the heating element. After evacuating for 30 minutes, make the vacuum degree reach -0.09MPa, keep the vacuum for 30 minutes, and observe whether the indication of the vacuum gauge changes. If there is no change, it means that the system is well seal...

Embodiment 2

[0030] The block graphite was washed with absolute ethanol and dried in an oven for later use.

[0031] Weigh 78g of Si powder, 10g of SiC powder, 11g of C powder, 6g of Al 2 o 3 pink. Place in a turpentine ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 3 hours to obtain a mixed powder.

[0032] Put half of the above mixed powder into the graphite crucible, put the prepared block graphite, then put the other half of the sintered material, shake the crucible slightly to make the mixed powder evenly embed the block graphite, and then put the graphite crucible Put graphite into a hot-pressed vacuum reaction furnace with graphite as a heating element. After evacuating for 30 minutes, make the vacuum degree reach -0.09MPa, keep the vacuum for 30 minutes, and observe whether the indication of the vacuum gauge changes. If there is no change, it means that the syste...

Embodiment 3

[0035] The block graphite was washed with absolute ethanol and dried in an oven for later use.

[0036] Weigh 85g of Si powder, 5g of SiC powder, 7g of C powder, 3g of Al 2 o 3 pink. Place in a turpentine ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 2 hours to obtain a mixed powder.

[0037] Put half of the above mixed powder into the graphite crucible, put the prepared block graphite, then put the other half of the embedding material, shake the crucible slightly to make the mixed powder evenly embed the block graphite, and then put the graphite The crucible is placed in a hot-press vacuum reactor with graphite as a heating element. After evacuating for 30 minutes, make the vacuum degree reach -0.09MPa, keep the vacuum for 30 minutes, and observe whether the indication of the vacuum gauge changes. If there is no change, it means that the system is well sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com