Patents

Literature

31 results about "Propelling nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A propelling nozzle is a nozzle that converts the internal energy of a working gas into propulsive force; it is the nozzle, which forms a jet, that separates a gas turbine, being gas generator, from a jet engine.

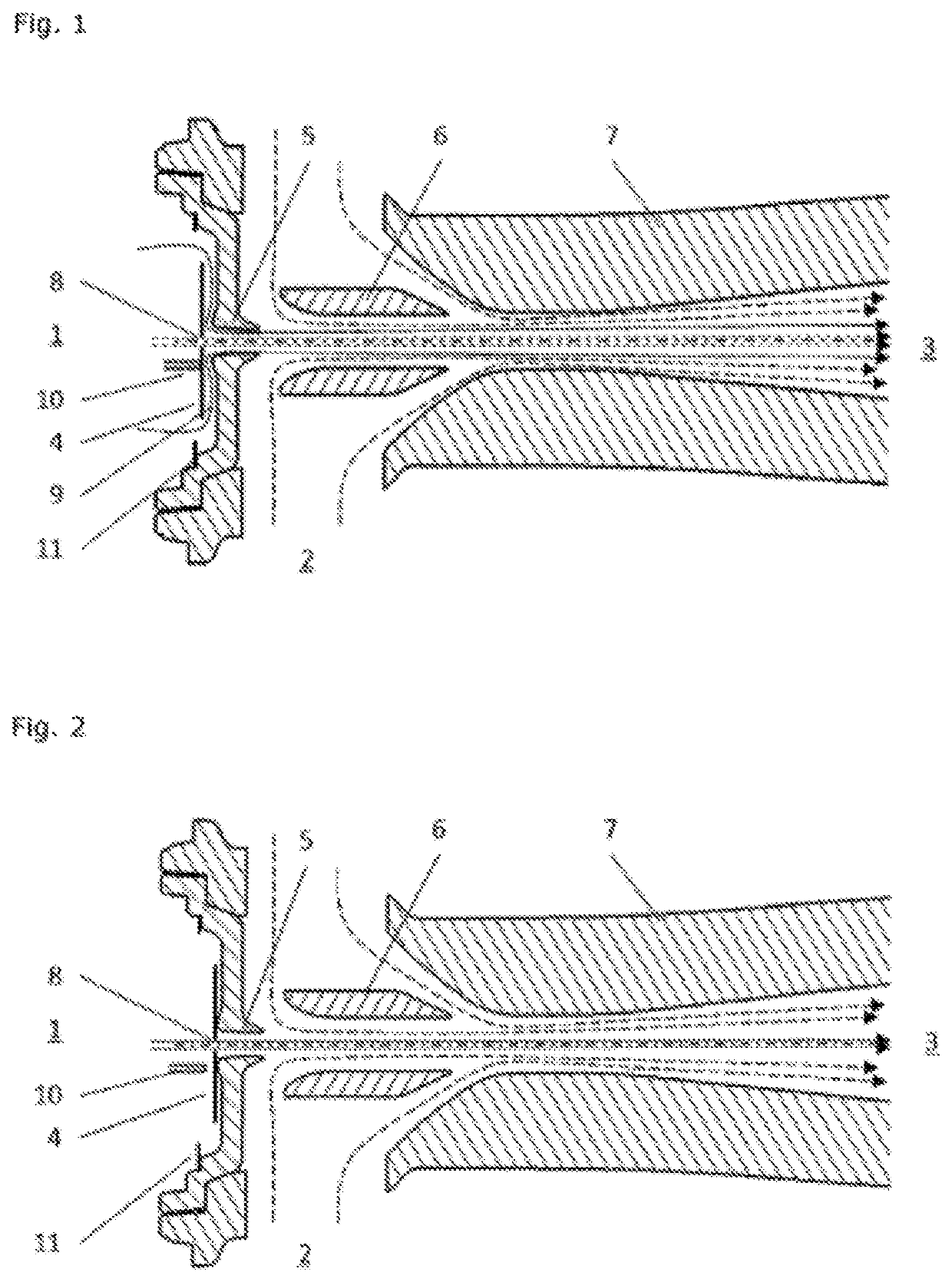

Method for mixing a liquid in a sealed container with a fine-particle solid, container of this type, ejector jet and use of a jet of this type

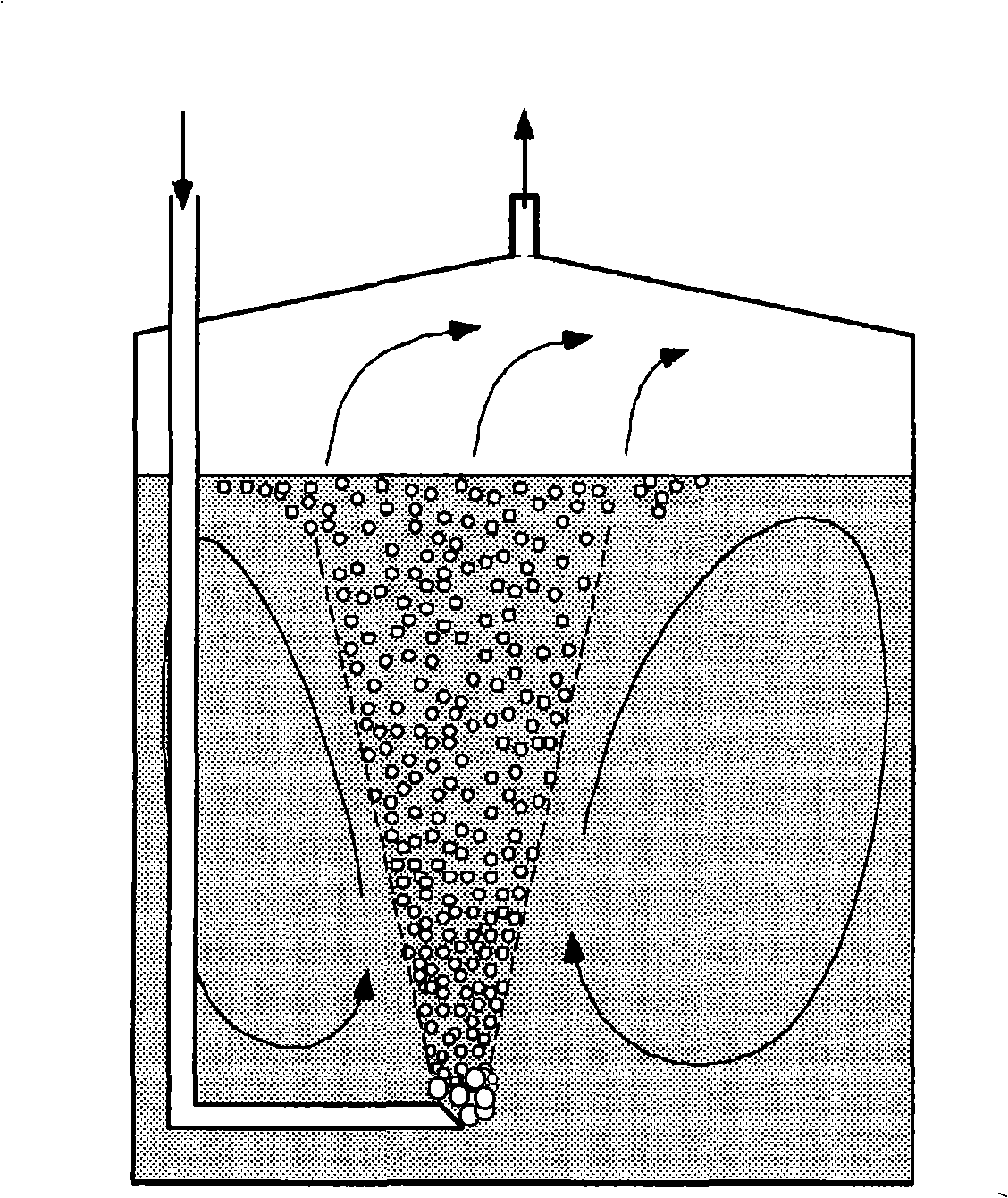

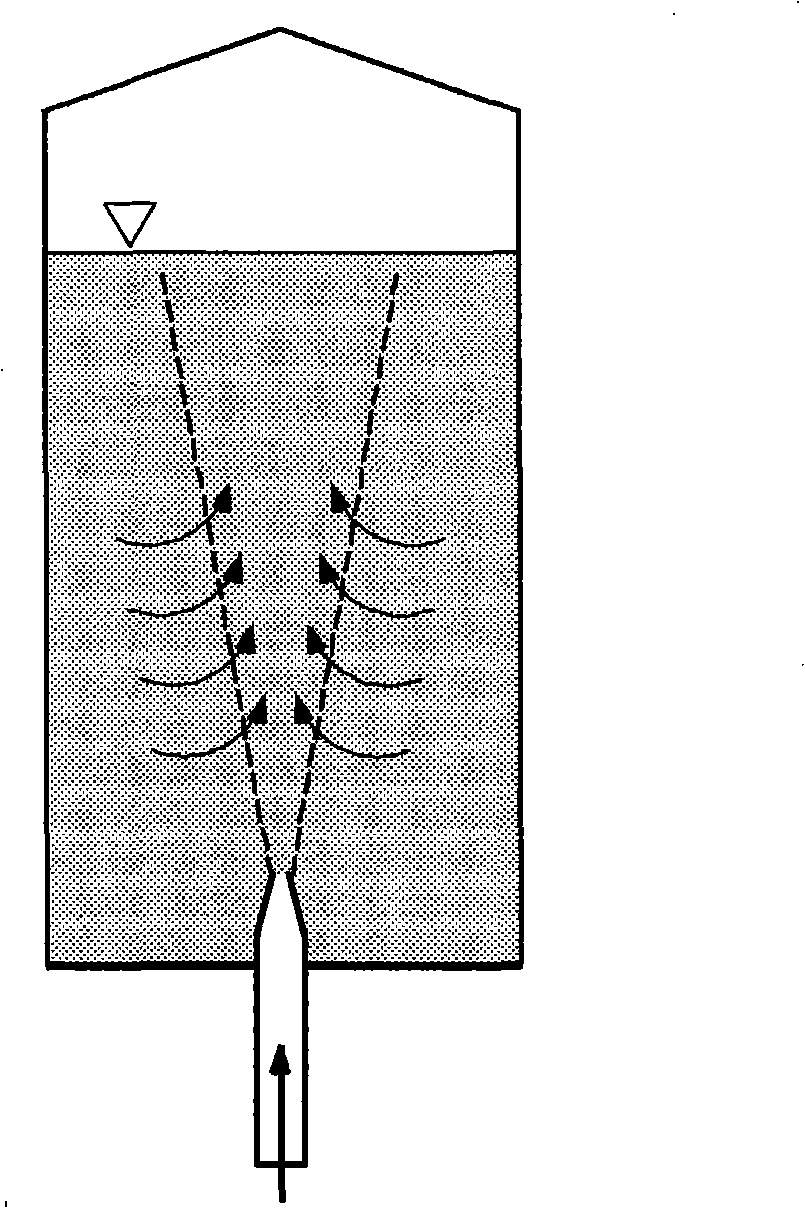

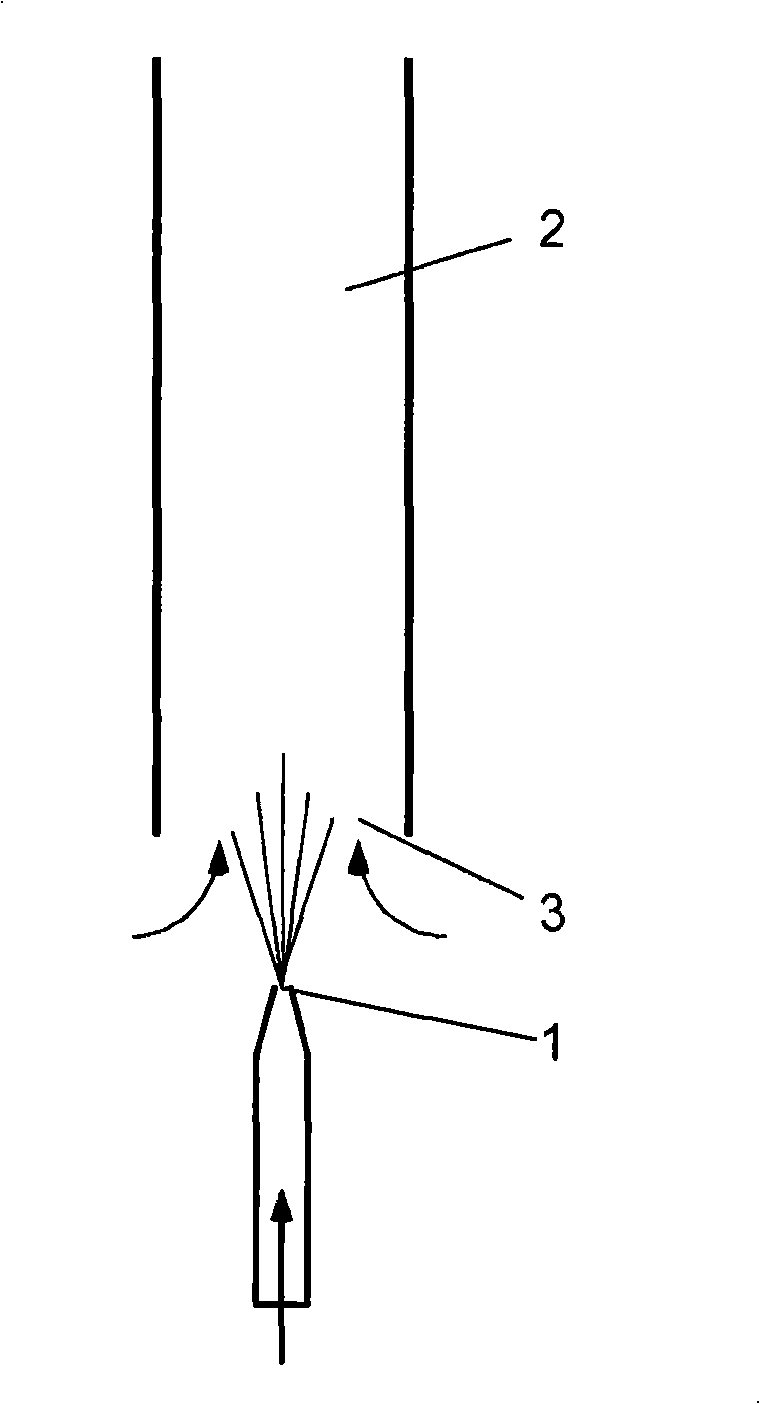

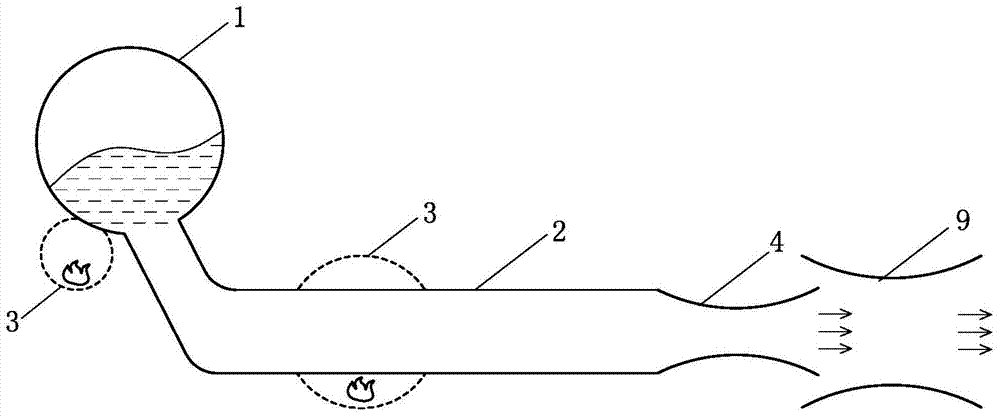

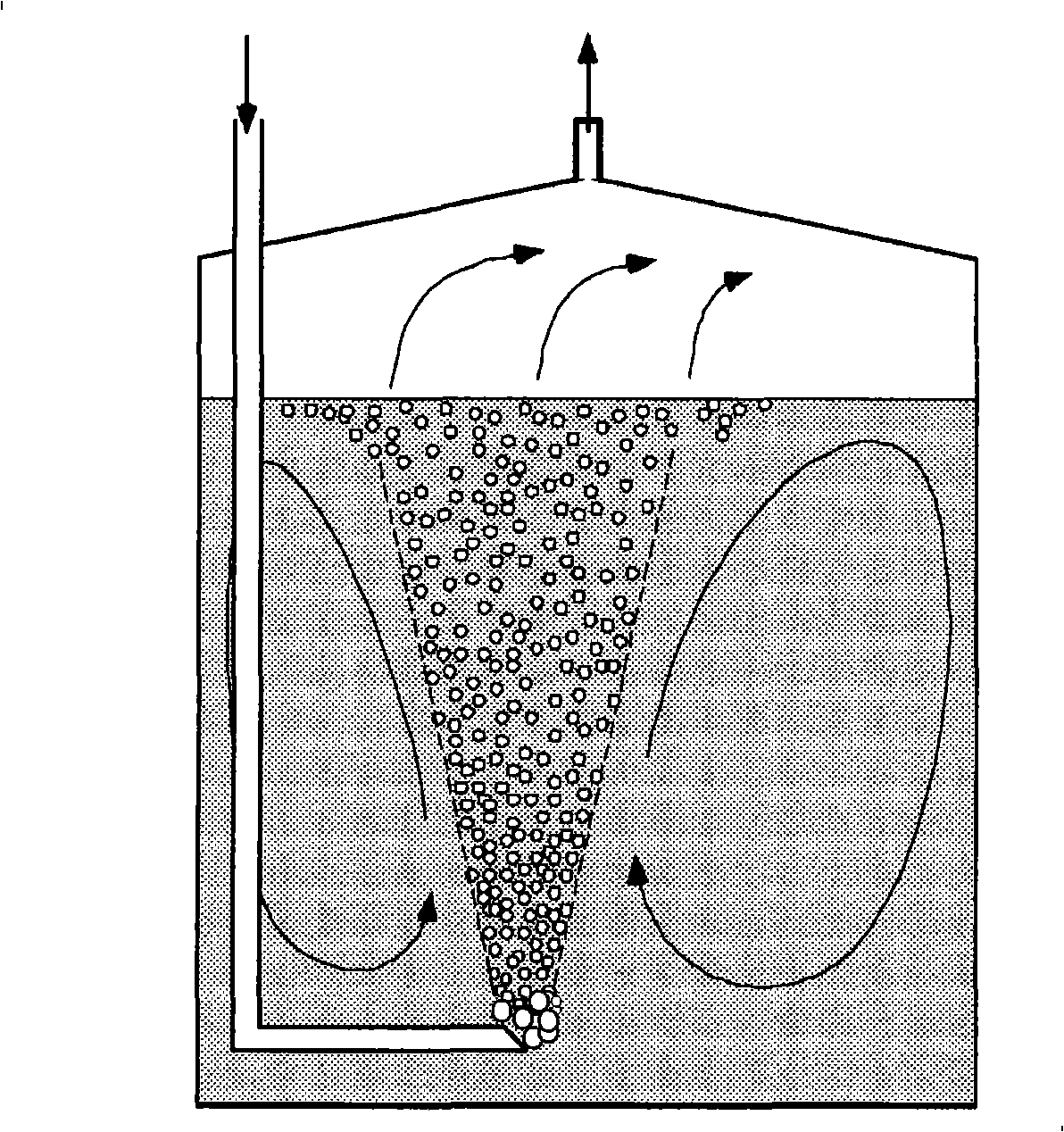

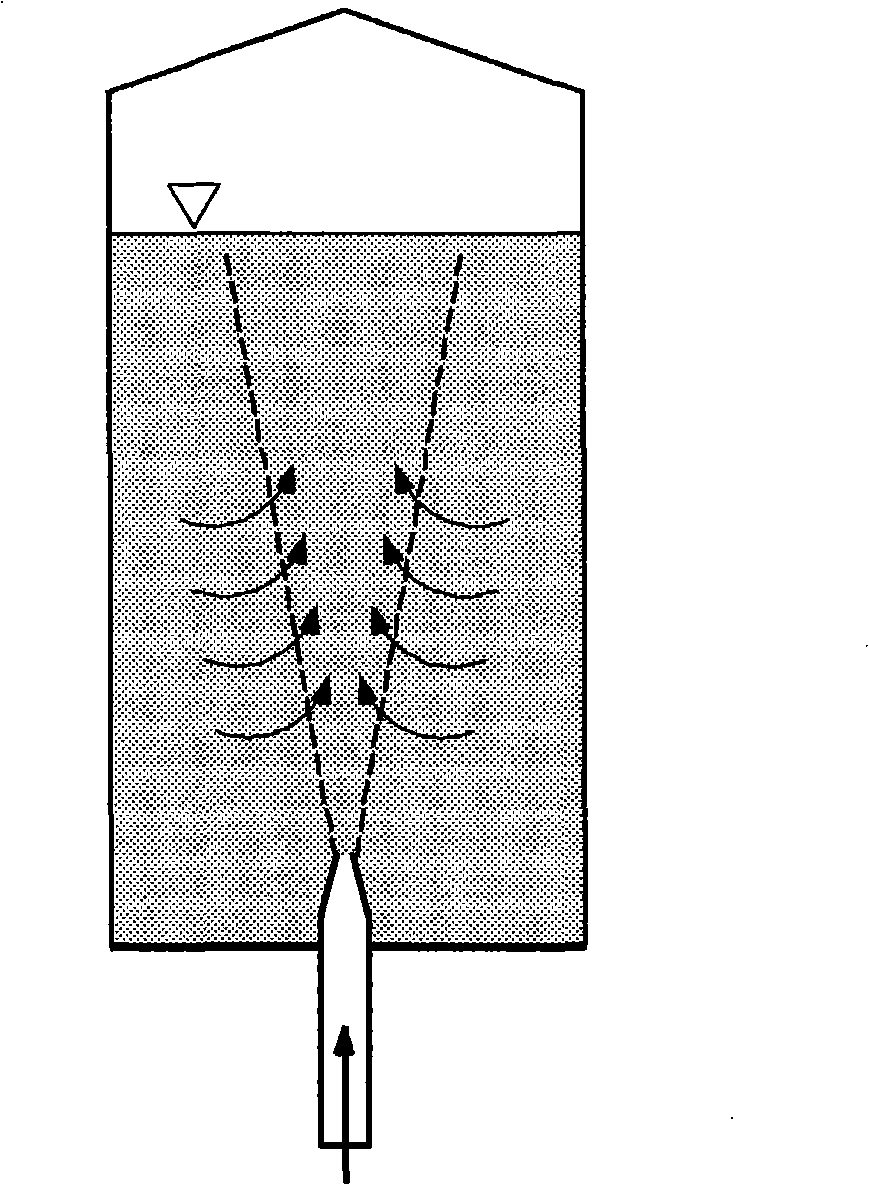

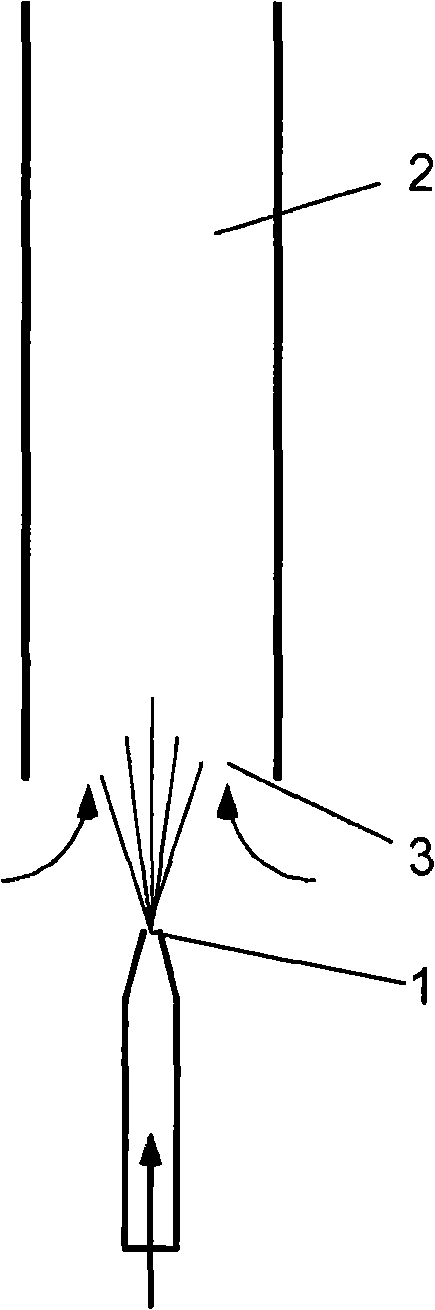

The invention relates to a method and a device for mixing a liquid in a substantially sealed container or a mixture of a liquid and a fine-particle solid, said liquid or mixture only partially filling the internal volume of the container that can be occupied by a fluidic phase and the remaining available internal volume of the container being filled by a gaseous phase. According to the invention,the essentially same liquid or mixture is fed to the container in the form of a propelled stream of a suction device that is situated in the liquid or mixture in the container. In its simplest form, the method according to the invention is implemented by means of an ejector (i.e. according to water jet pump principles) embodied as the suction device. The propelled stream is pumped through a propelling nozzle, which is fitted into the ejector in such a way that gas is sucked from the gaseous phase during the passage of the stream through the nozzle, e.g. by means of a riser tube that projects into the gaseous phase of the container, and is released in the form of dispersed gas bubbles, together with the propelled stream, into the liquid content of the storage container.

Owner:BASF AG

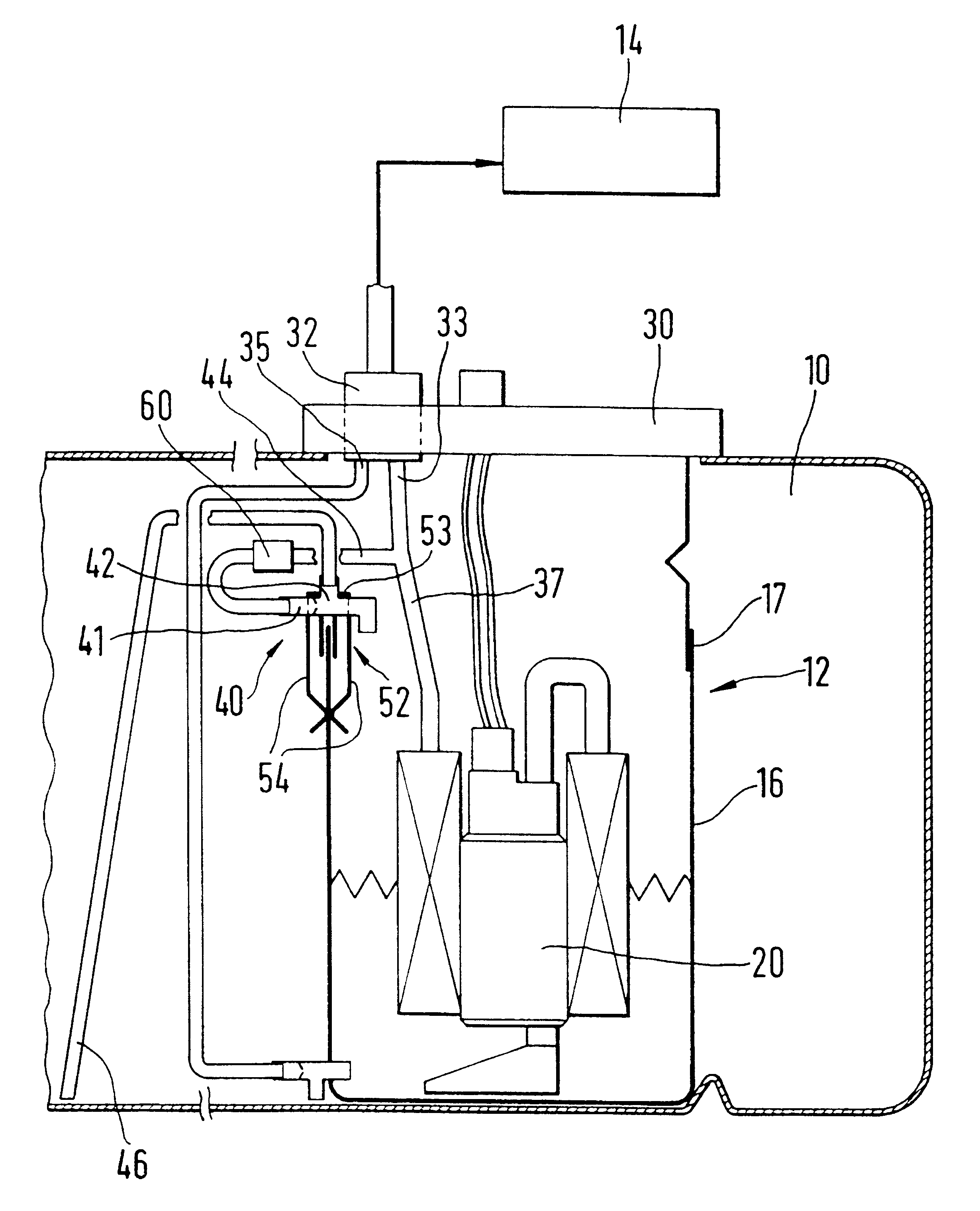

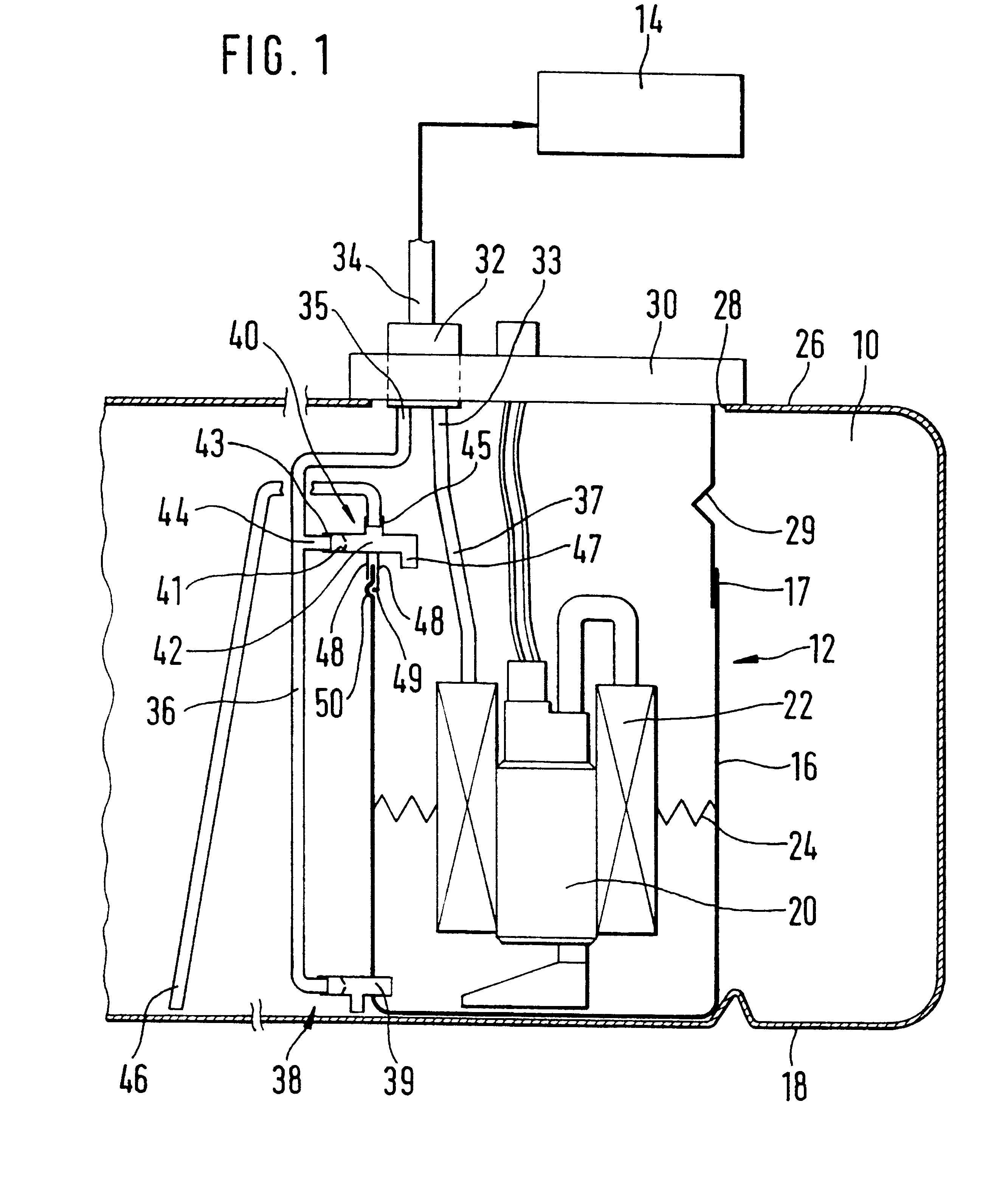

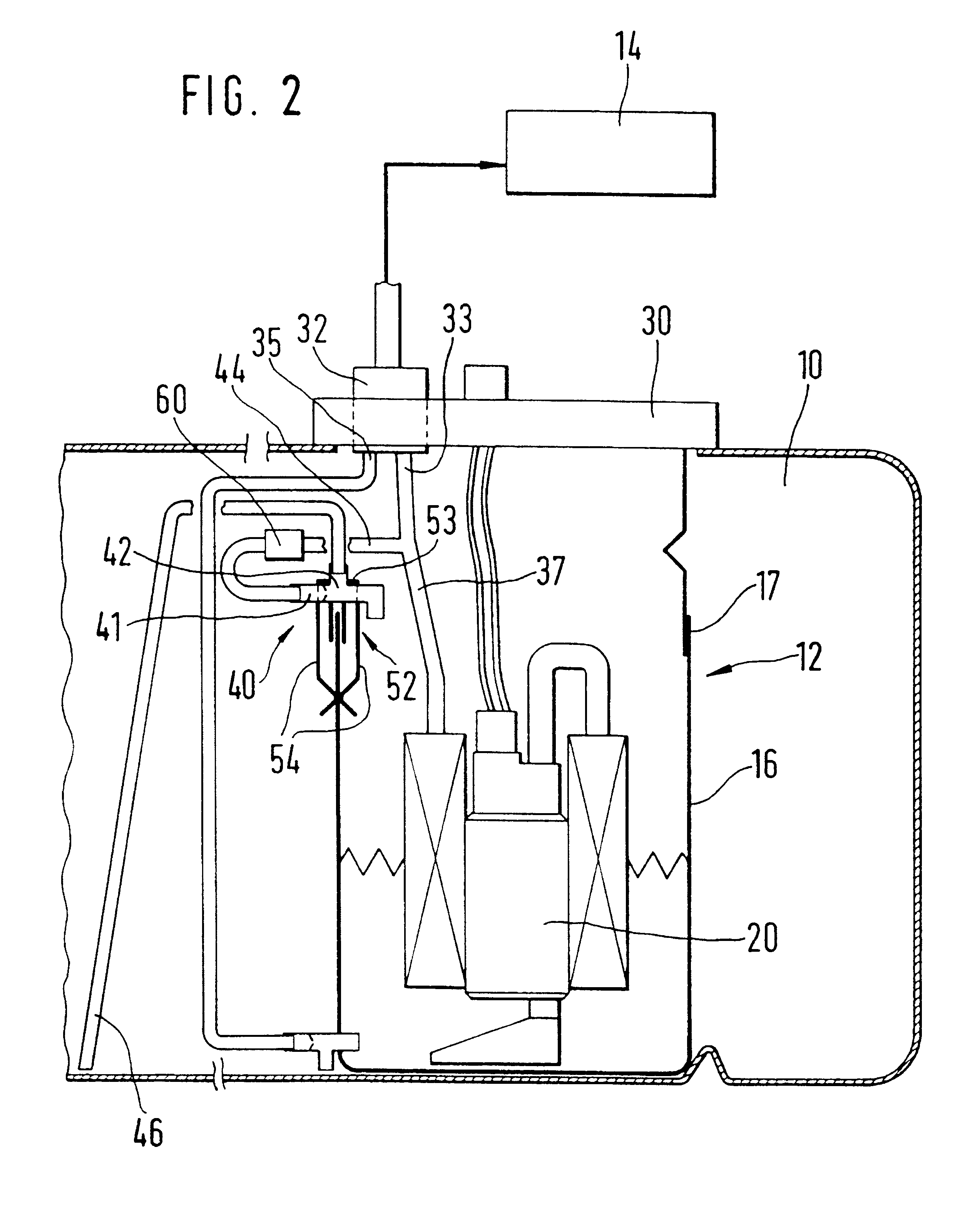

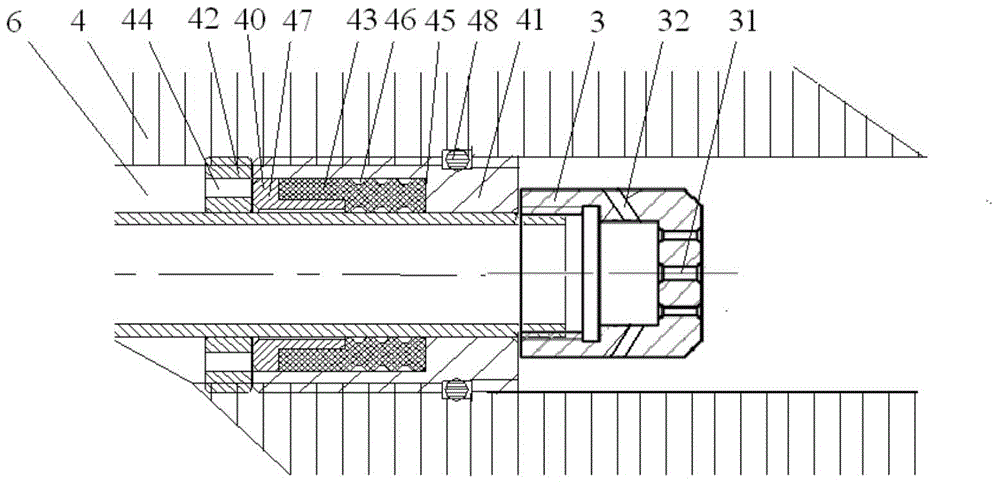

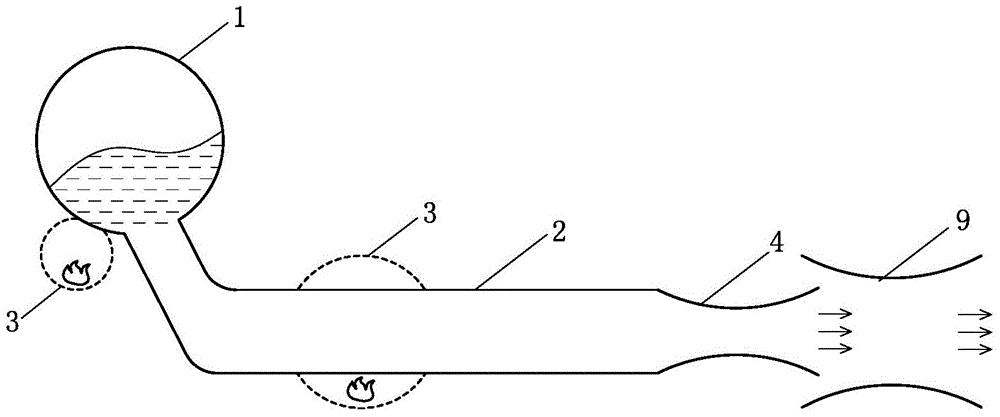

Fuel delivery device

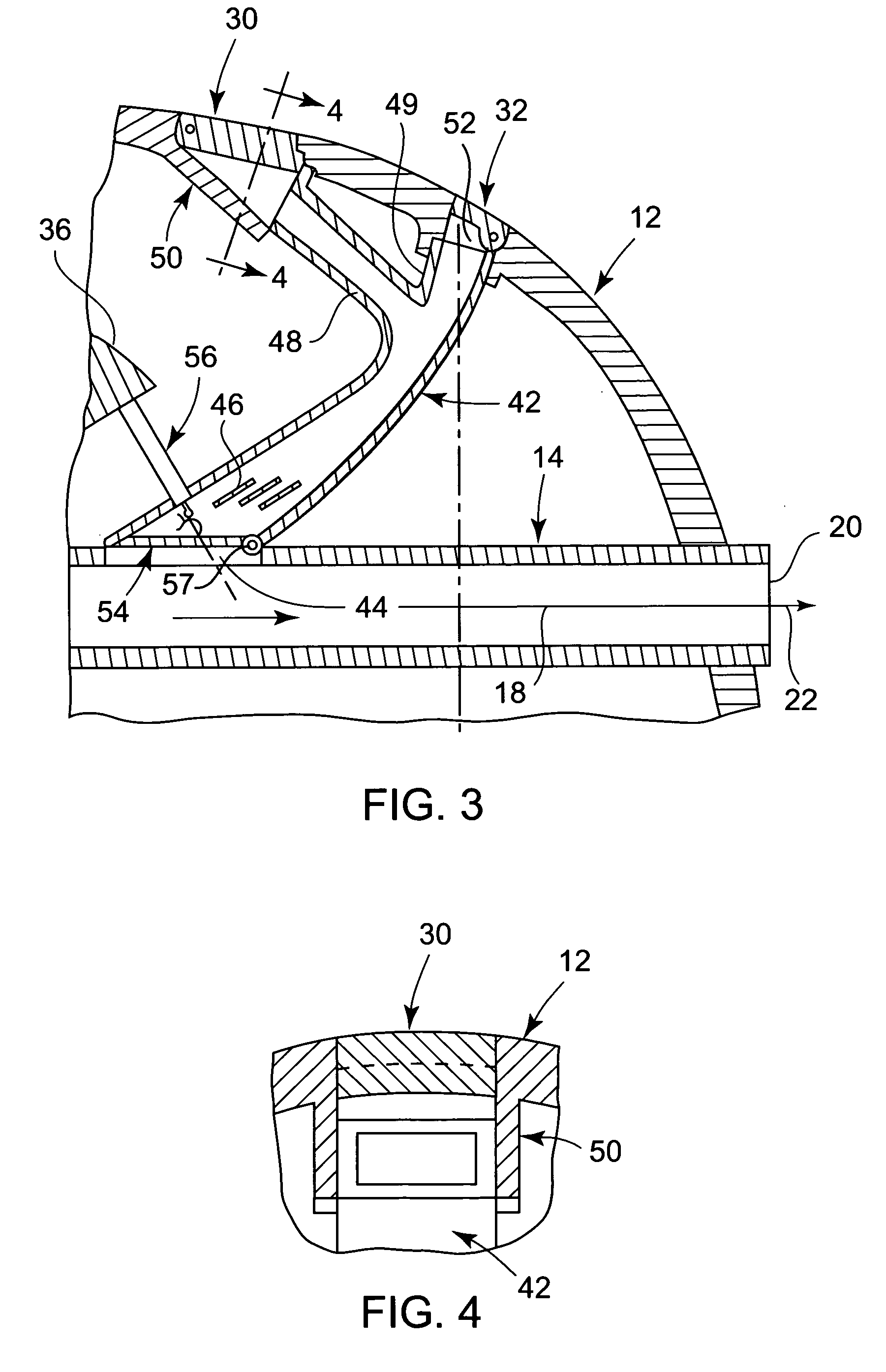

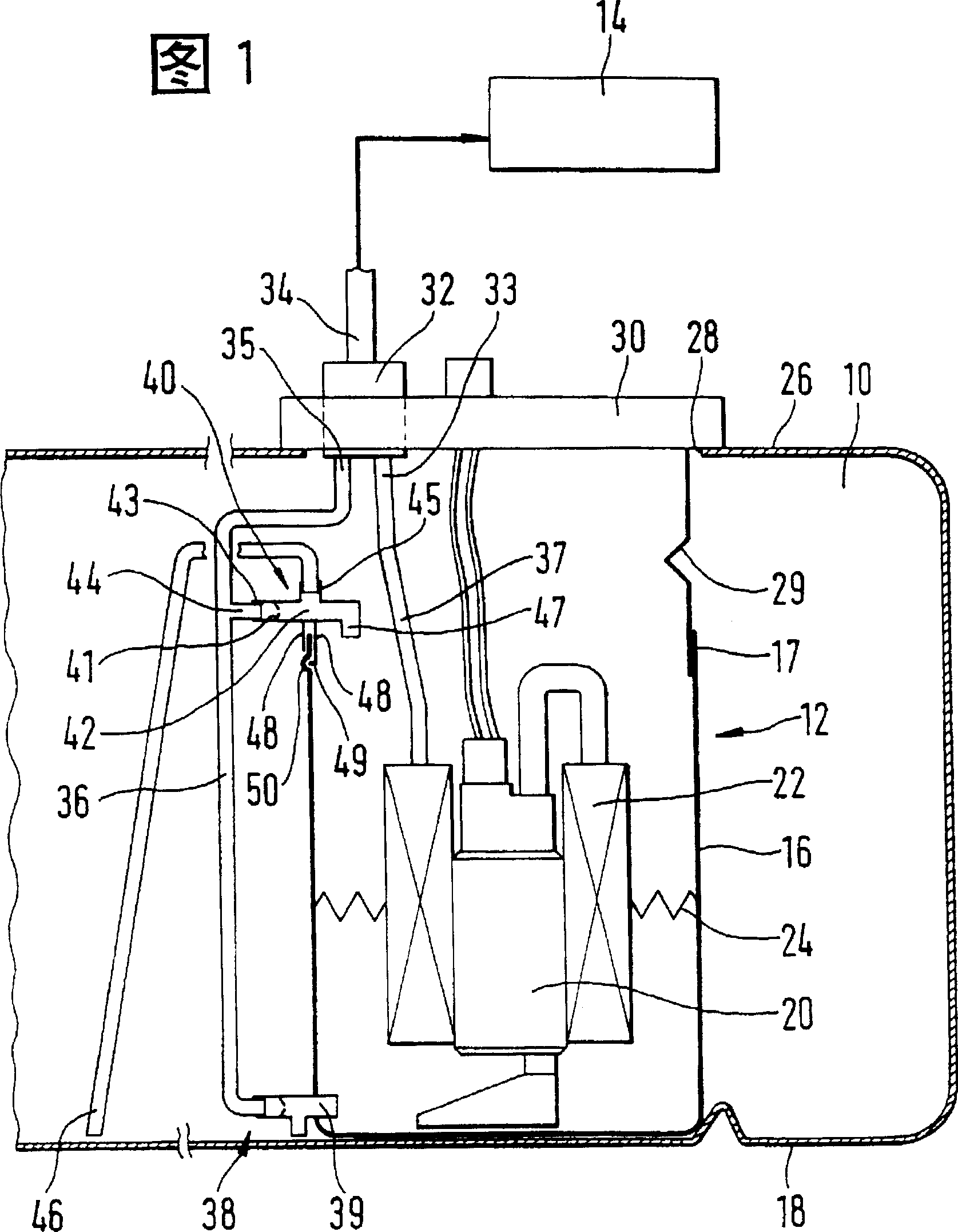

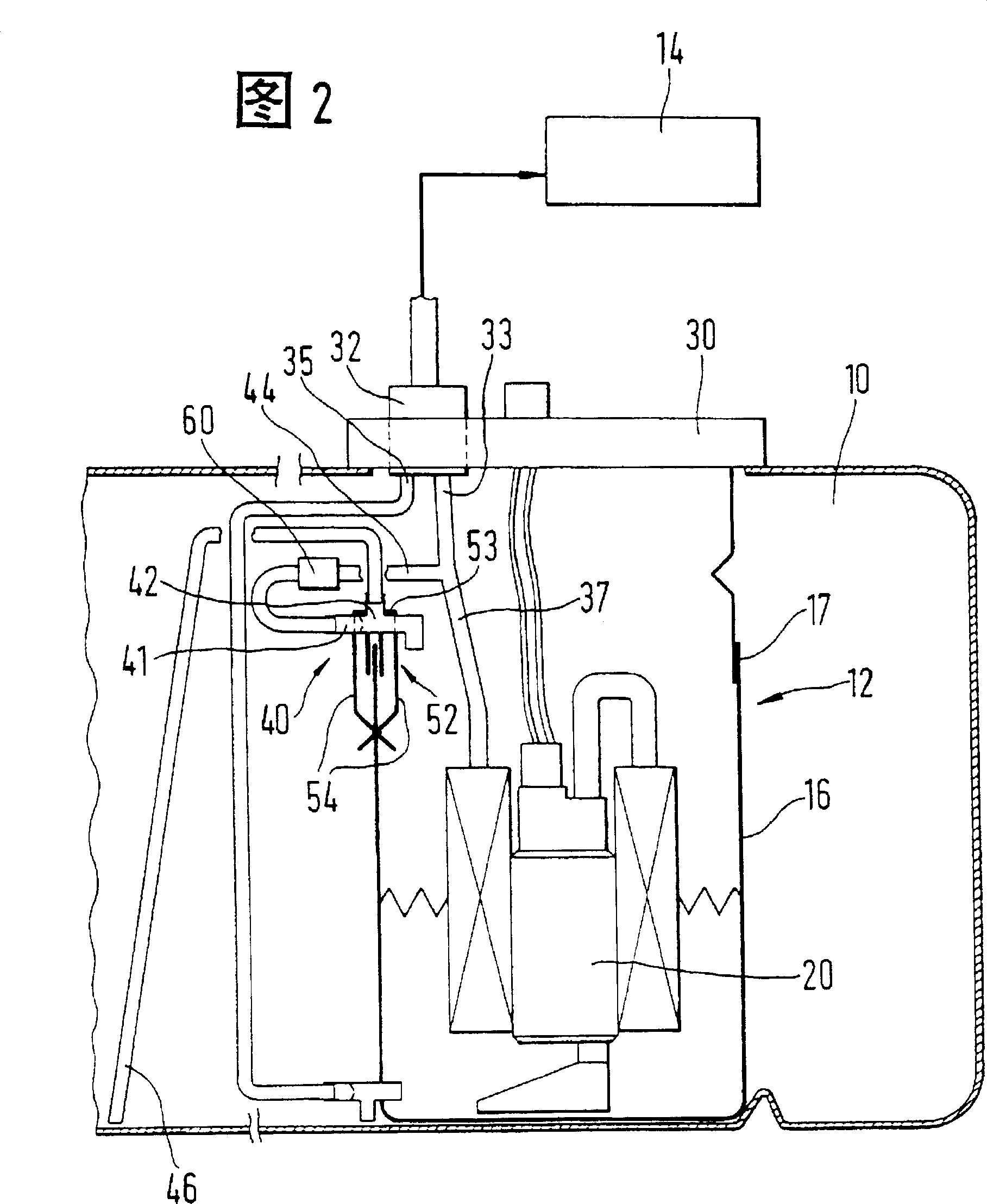

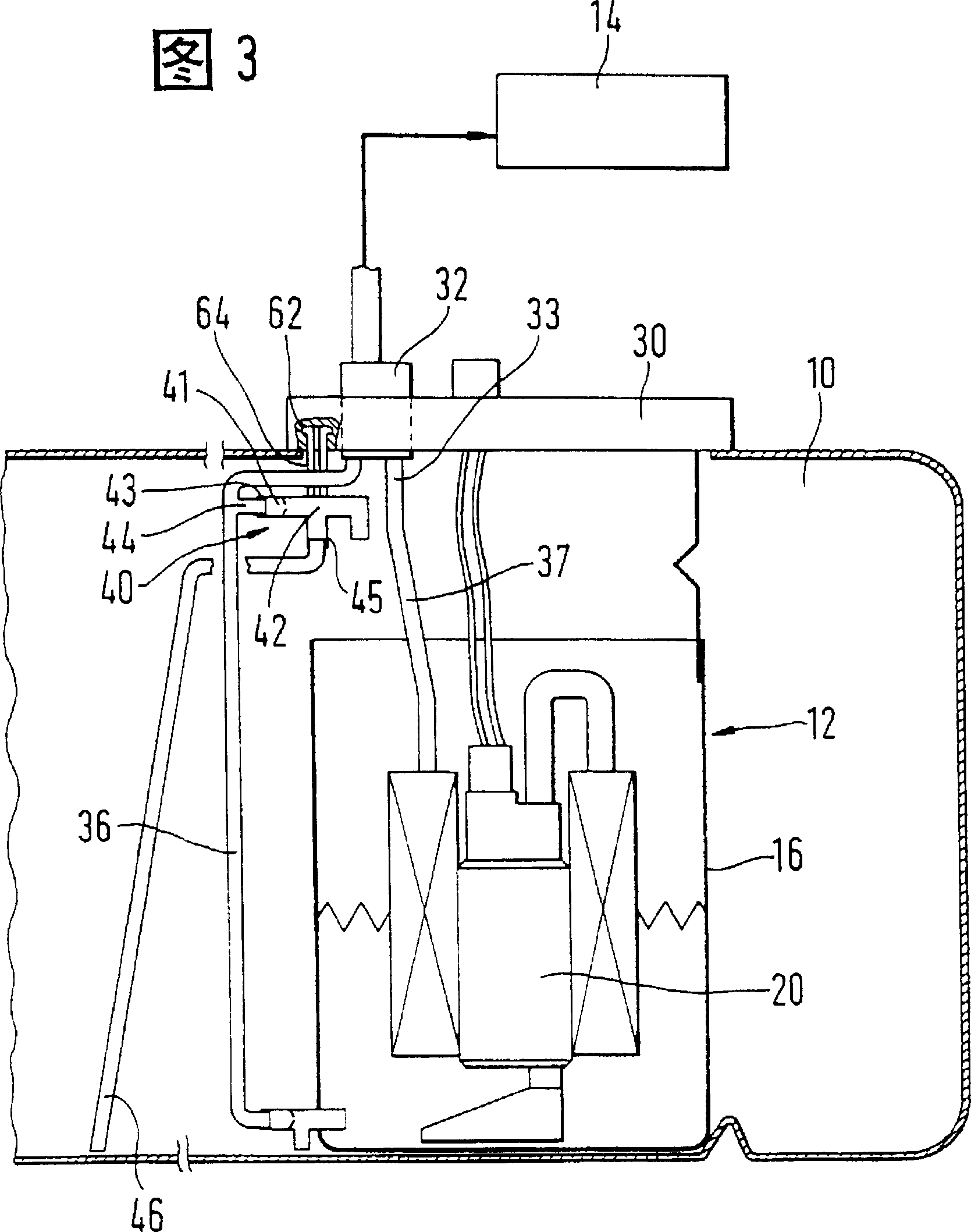

The fuel delivery device (12) has a receptacle (16) arranged in a storage tank (10) and a delivery unit (20) delivering fuel from the receptacle (16) to the internal combustion engine (14) of a motor vehicle. Further, there is provided at least one suction jet pump (40) which delivers fuel from the storage tank (10) into the receptacle (16). The suction jet pump (40) is fastened to an upper edge area (17) of the receptacle (16) as a separate constructional unit. The suction jet pump (40) is formed by a constructional unit having a propelling nozzle (41), a connection (43) for a propelling line (44), which connection (43) opens into the propelling nozzle (41), a mixing pipe (42) following the propelling nozzle (41), and a connection (45) for a suction line (46), which connection (45) opens into the mixing pipe (42). Two walls (48) located at a distance from one another project downward from the constructional unit (40), and the constructional unit (40) is mounted on the edge (17) of the receptacle (16) from the top, wherein the edge (17) of the receptacle (16) is introduced between the two walls (48). The suction line (46) connected to the suction jet pump (40) opens into the storage tank (10) remote of the receptacle (16).

Owner:ROBERT BOSCH GMBH

Maneuvering of submerged waterjet propelled sea craft

The stern hull portion of a sea craft through which main exit flow channels extend to projecting jet propulsion nozzles, is provided with facilities for controlled maneuvering of the sea craft, including steering, stopping, negative thrust backing and docking without substantial hydrodynamic loading and with facilitated installation. Such maneuvering control facilities include a secondary flow channel extending from each of the main exit flow channels having two angularly related subchannel branches for pressurized water outflow through gated openings in the hull from which propulsion jets emerge under maneuvering control. Either control of a subchannel diverting flapper, or by use of selective closure gates and a flow diverting flap within the main exit flow channel, maneuvering may be effected in response to inflow through inlet openings in the hull of water that is pressurized before supply to the main exit flow channels.

Owner:NAVY DEPT OF

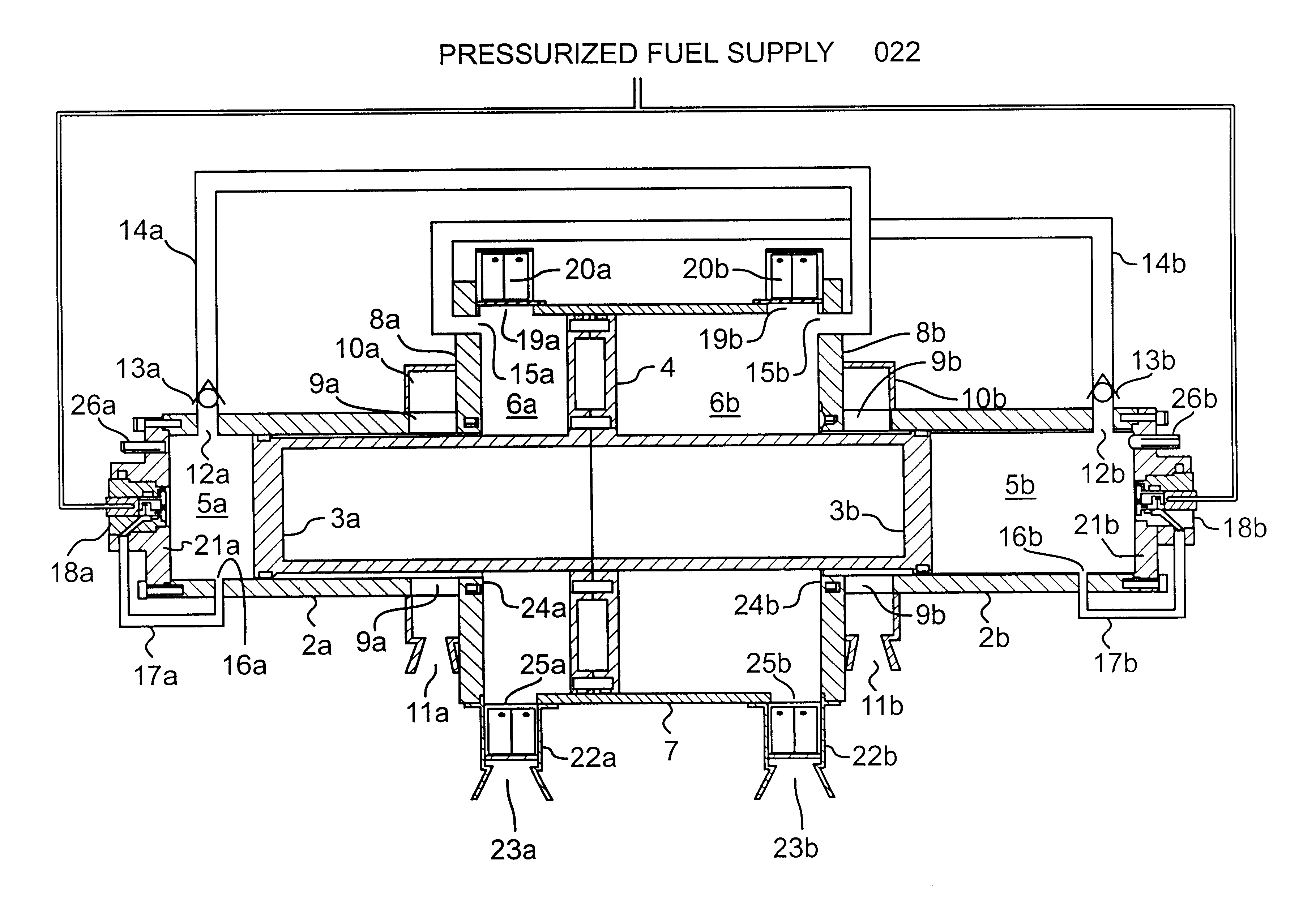

Free piston engine and self-actuated fuel injector therefor

A simple propulsion engine utilizing unheated atmospheric air as the propellant, and driven by a single cycle (unicycle) engine with internal combustion cylinder and free piston is disclosed. A plain piston is slidably displaceable in an elongated cylinder containing cylinder heads on opposite ends. The piston receives a combustive impulse at each end of its stroke. The cylinder also has exhaust / inlet ports and propulsive nozzles at each end with relevant valves and actuators to effect the requisite timing of the combustion, air induction, and propulsion functions. During the piston's traverse of the elongated cylinder's midsection, air is induced into the expanding volume of the moving piston / cylinder chamber while air is compressed and expelled through the nozzle of the decreasing volume chamber, producing usable thrust. The large amounts of atmospheric air induced provides inherent internal cooling and exhaust scavenging of the propulsion engine. The preferred embodiment combines a free piston with an annularly arranged thrust piston to divide a dual-diameter cylinder into two combustion chambers and two thrust chambers. Scavenge feeder lines connected the thrust chambers to the combustion chambers via check valves provide exhaust scavenging, additional thrust output through exhaust nozzles, and feeding of fresh air into the combustion chambers. Also, pressure-actuated fuel injectors utilize pressure changes in respective combustion chambers to inject fuel at the appropriate time. The fuel injector includes an intensifier piston and pintle to raise the fuel pressure.

Owner:ALEXIUS RICHARD C +1

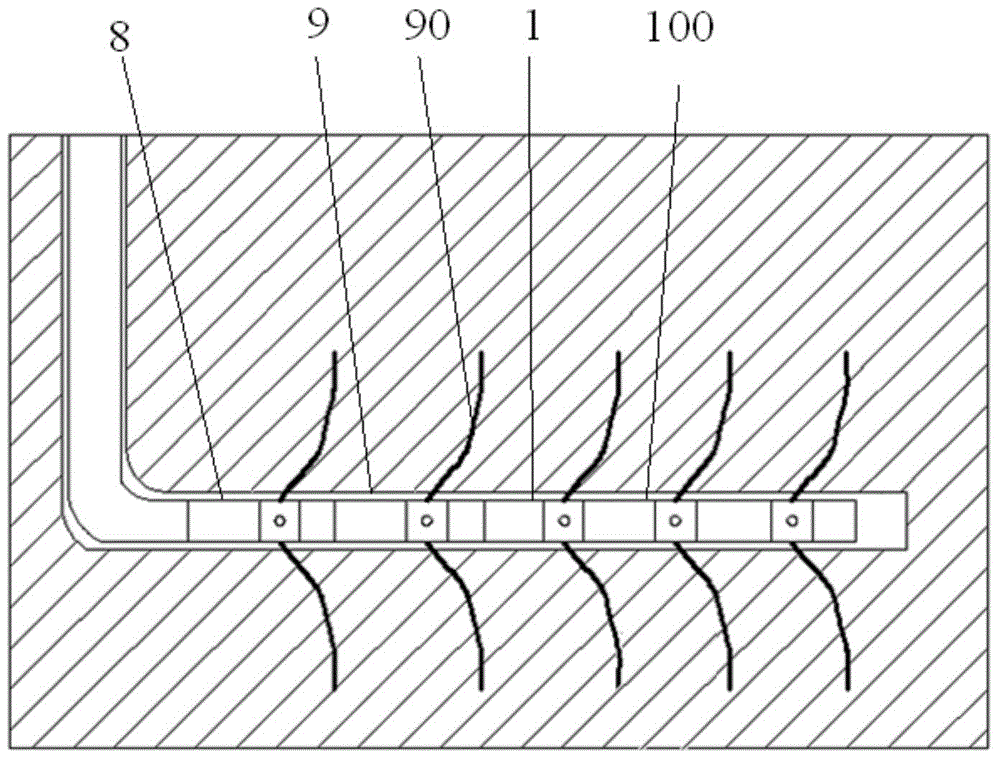

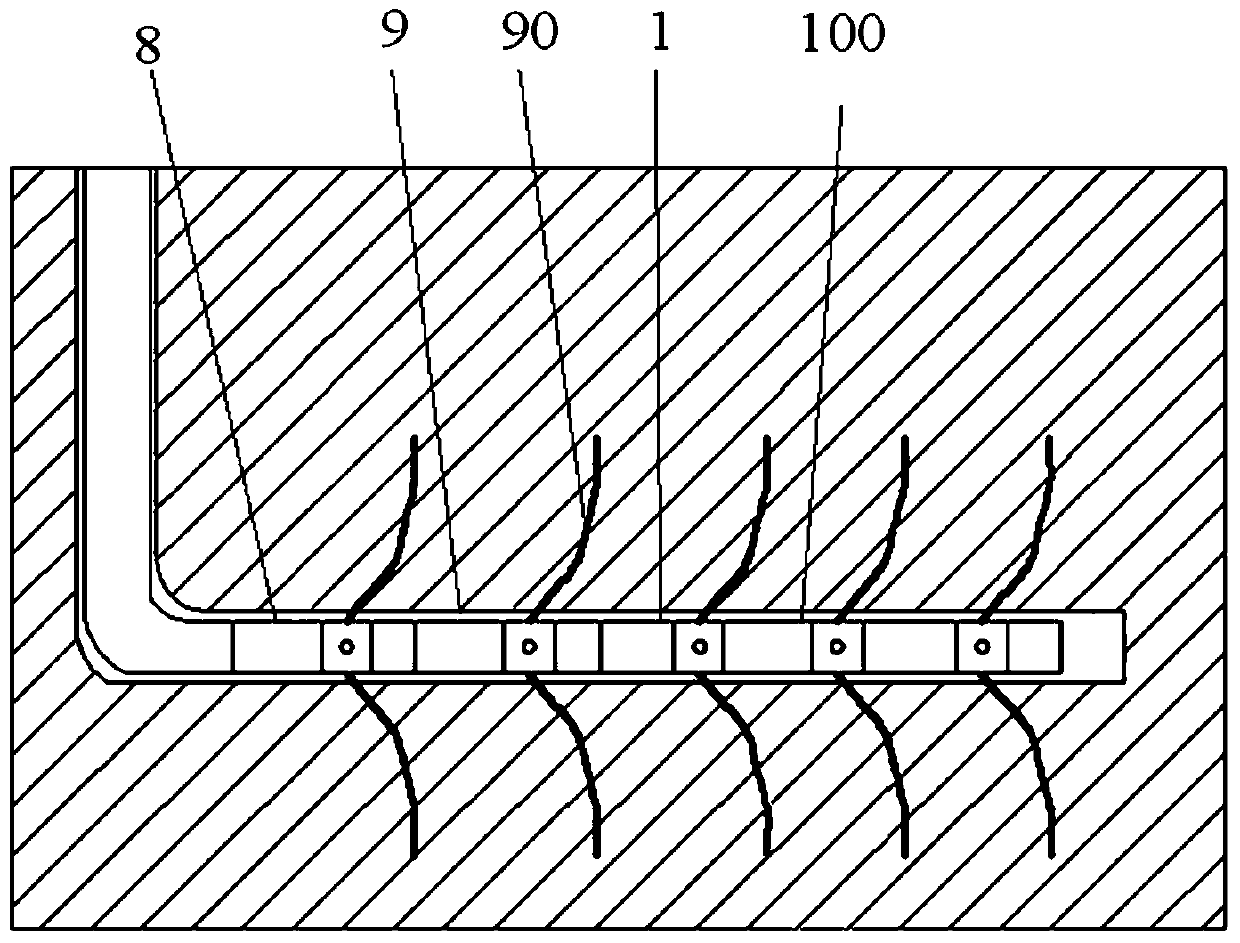

Oil gas exploitation apparatus and method

ActiveCN105443085AImprove effectivenessImprove controllabilityFluid removalHigh effectivenessPropelling nozzle

The invention relates to an oil gas exploitation apparatus and method. The apparatus includes at least an exploitation unit, a needle tubing, and a self-propelled nozzle arranged at a second end of the needle tubing. The exploitation unit includes a jet pipe nipple and an adjusting pipe nipple detachably connected to the jet pipe nipple, wherein penetrating installation holes are arranged on a sidewall of the jet pipe nipple, and the adjusting pipe nipple is provided with oil holes for the oil gas flowing from a stratum into an inner cavity of the exploitation unit. In the original state, a first end of the needle tubing is arranged in the inner cavity of the exploitation apparatus. The second end of the needle tubing is inserted in the installation holes. During a process for pumping the liquid to the exploitation apparatus, the needle tubing extends in a storage stratum so as to form an exploitation pore passage. In the oil gas exploitation process, the oil gas exploitation apparatus has high effectiveness for the reconstruction of the storage stratum and good oil gas output.

Owner:CHINA PETROLEUM & CHEM CORP +1

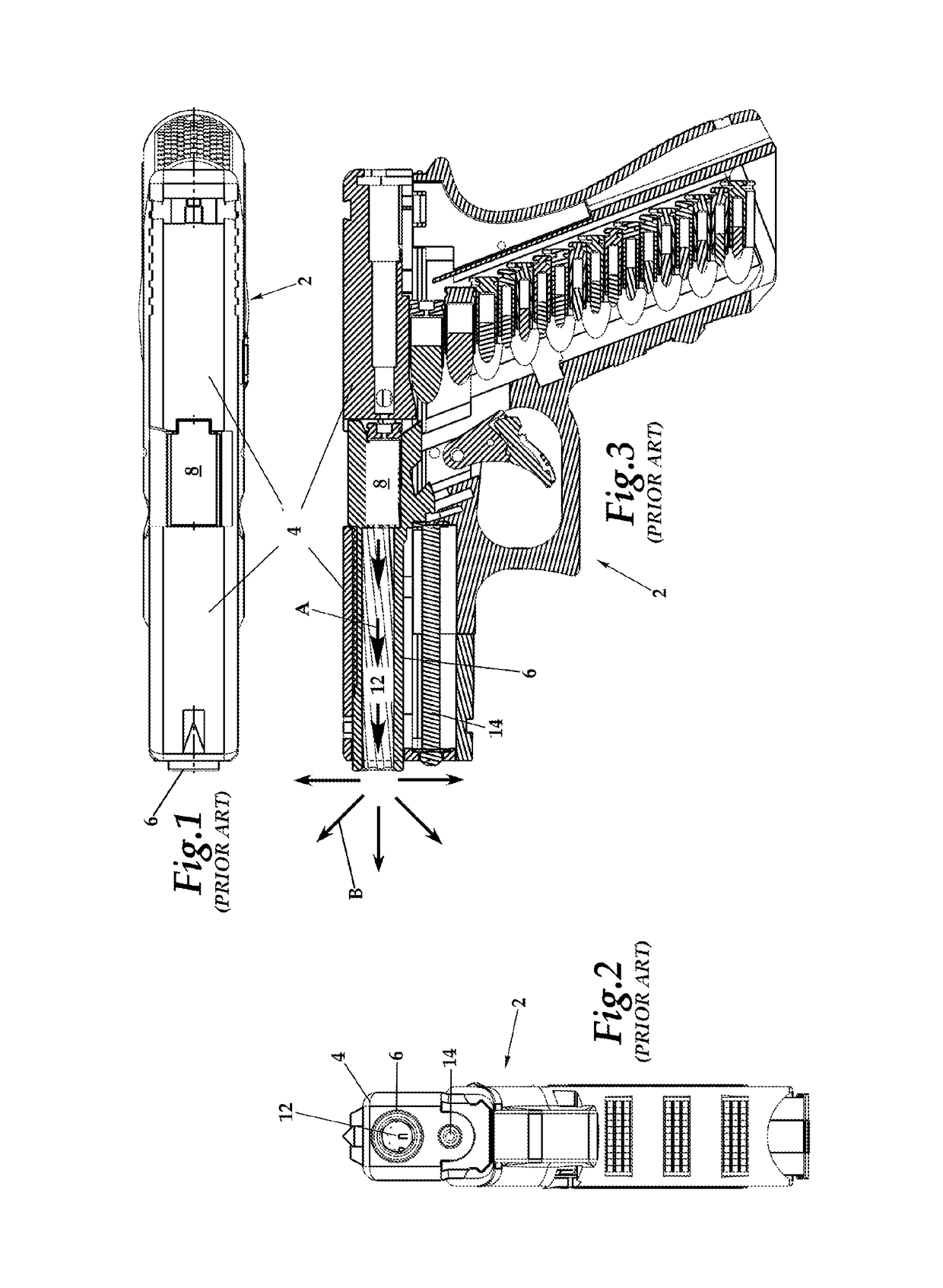

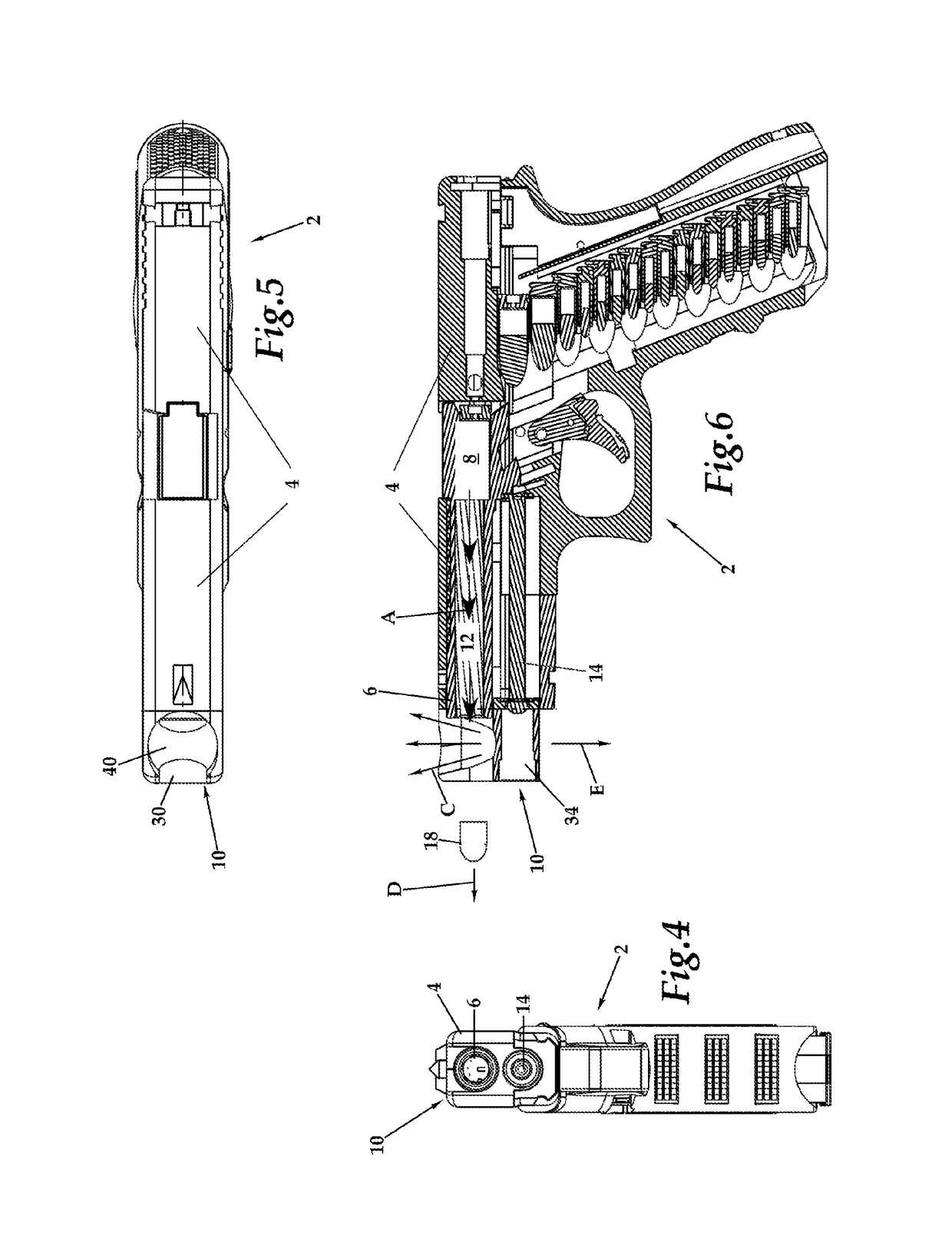

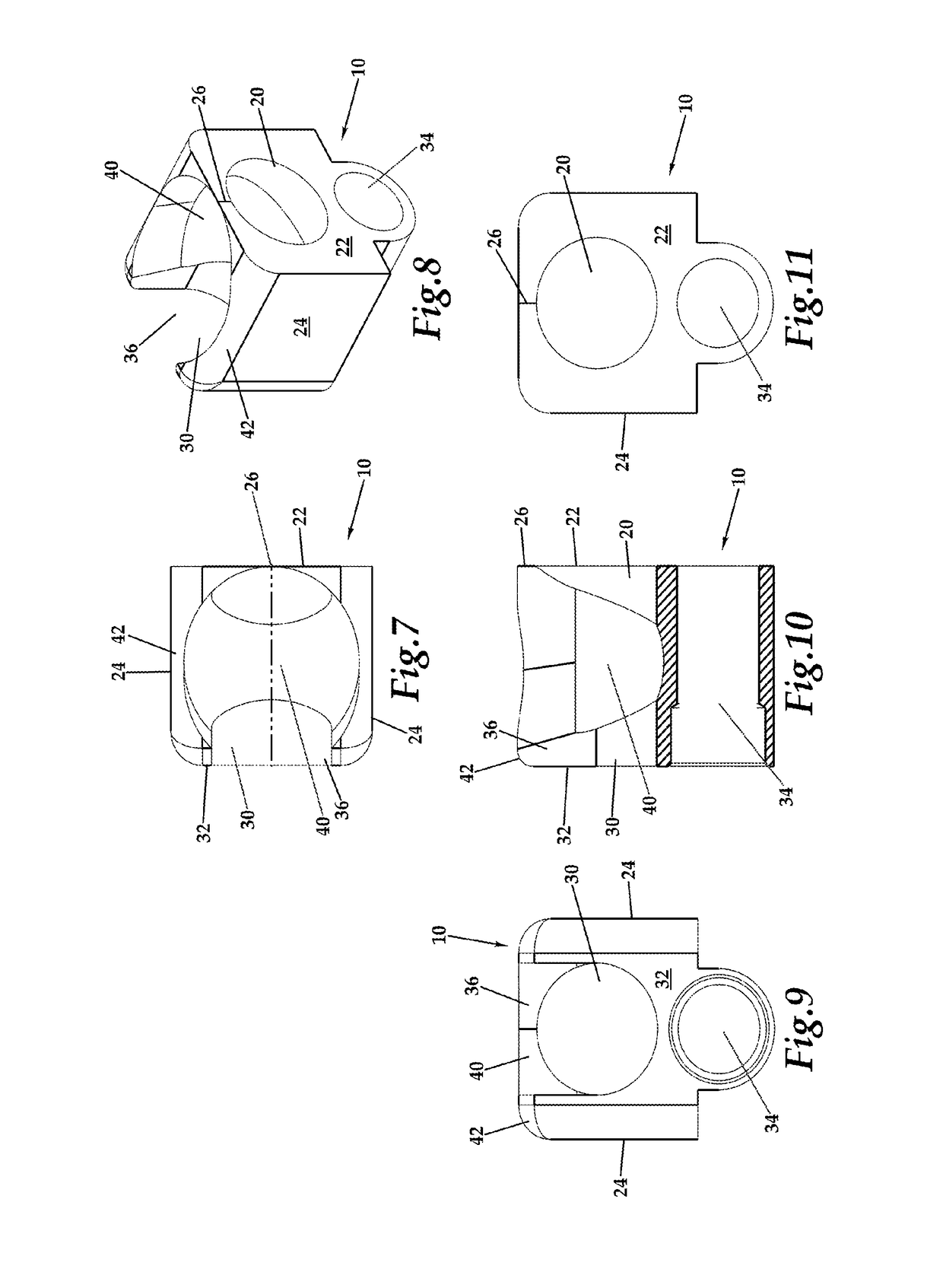

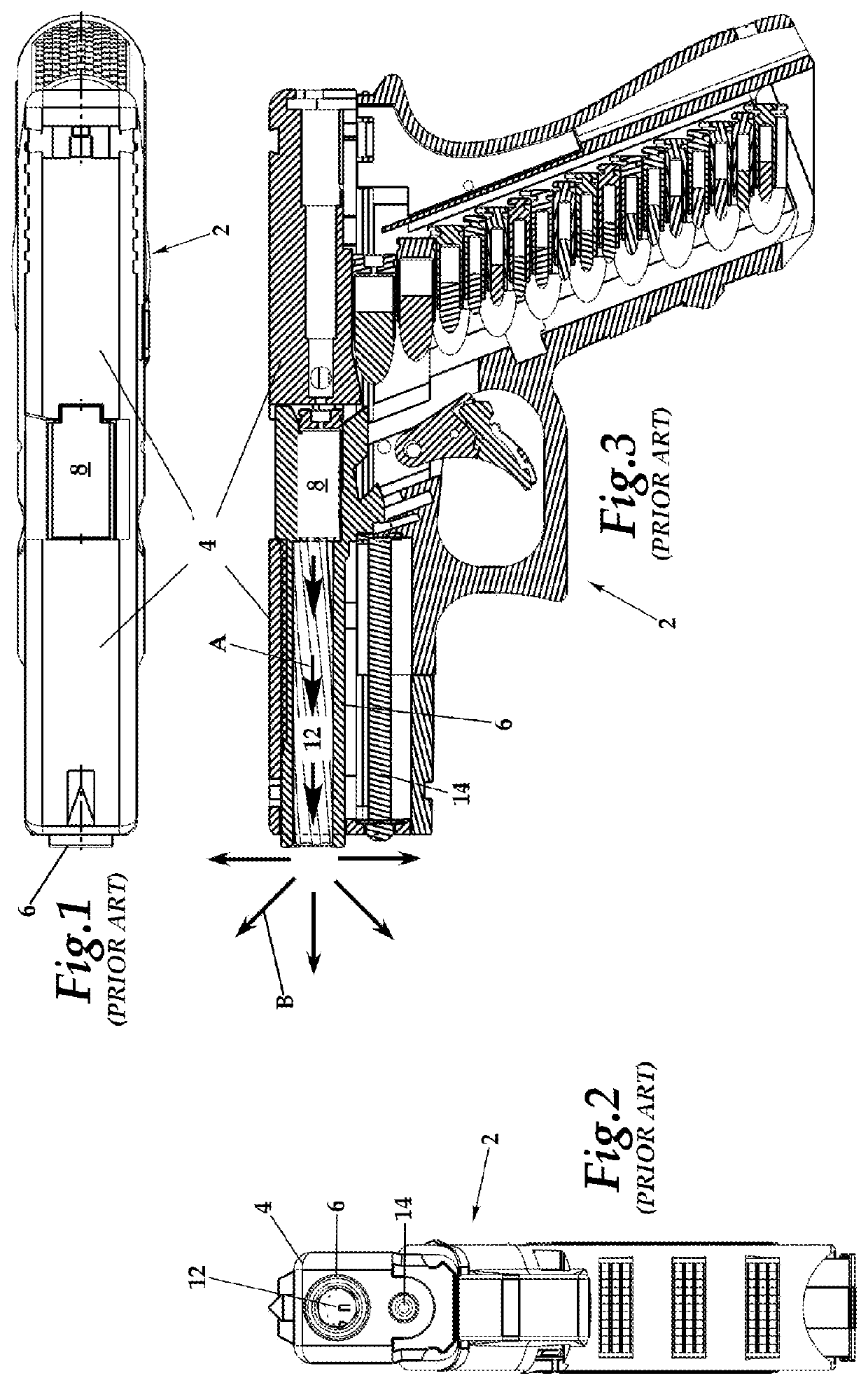

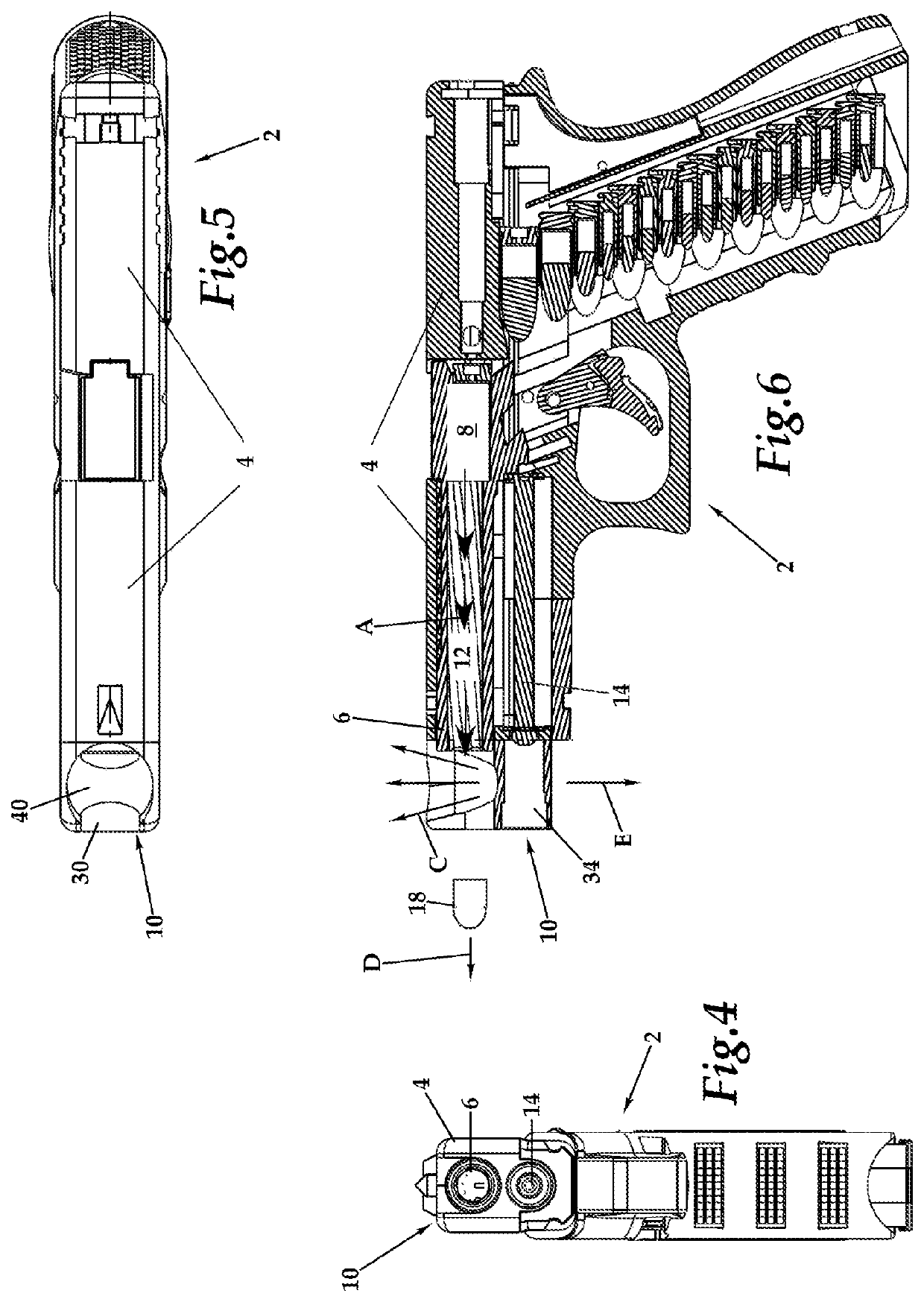

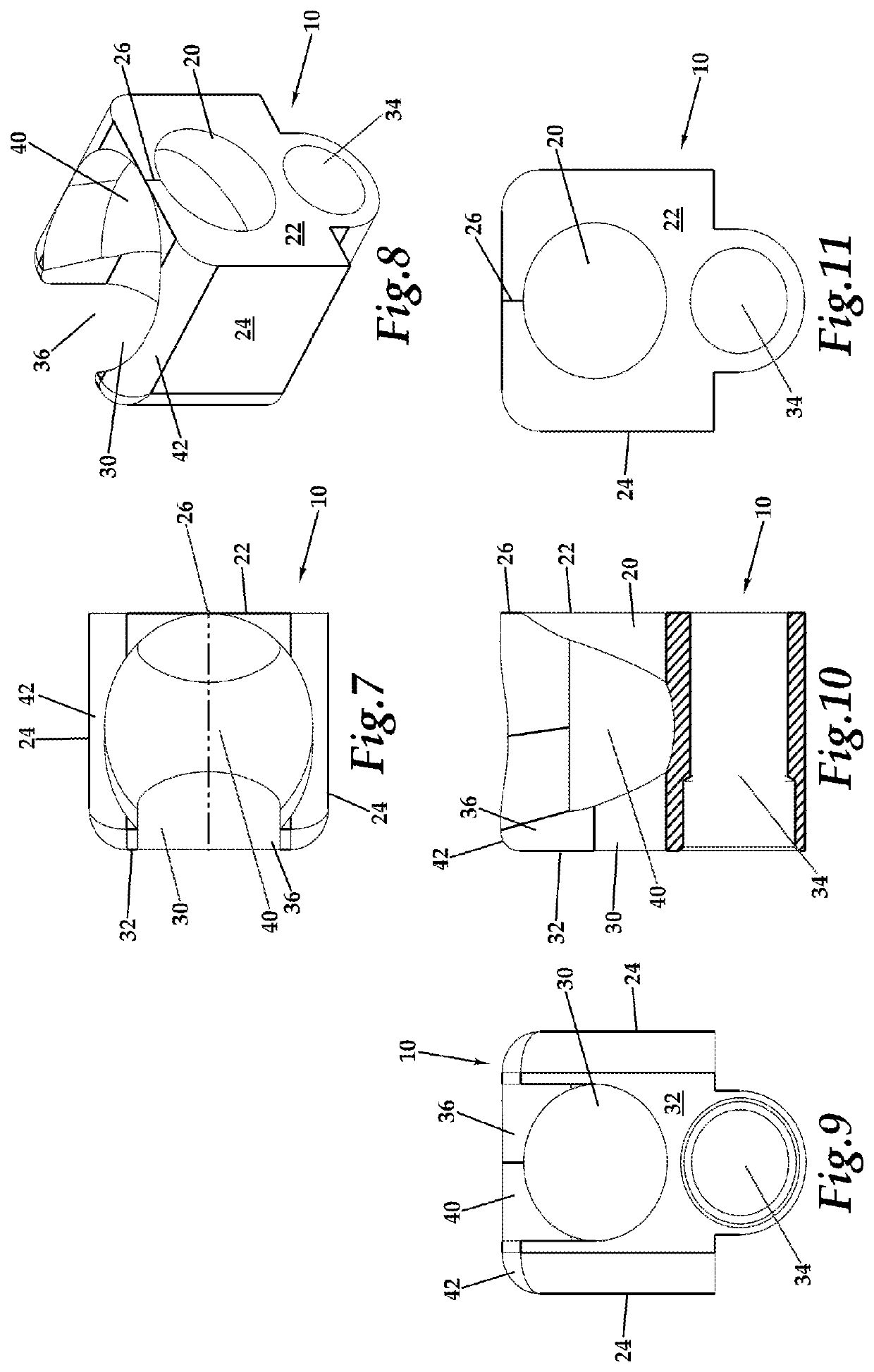

Muzzle brake with propelling nozzle for recoil control

The muzzle brake attaches to a distal end of the barrel of a firearm, typically a handgun, either built into the firearm or as an accessory attachable to the firearm. The muzzle brake includes a propelling nozzle in the form of a central chamber aligned with proximal and distal openings aligned with a barrel of the firearm. This propelling nozzle extends upward, generally expanding in cross-section, to a rim where it opens above the firearm near a distal end of the barrel. The shape of the propelling nozzle (or series of nozzles) is preferably selected to optimize downward reactive force when expanding gases discharged from firearm discharge expand upward out of the propelling nozzle. A downward reactive force is thus created which counteracts recoil of the firearm.

Owner:PRICE DONALD H

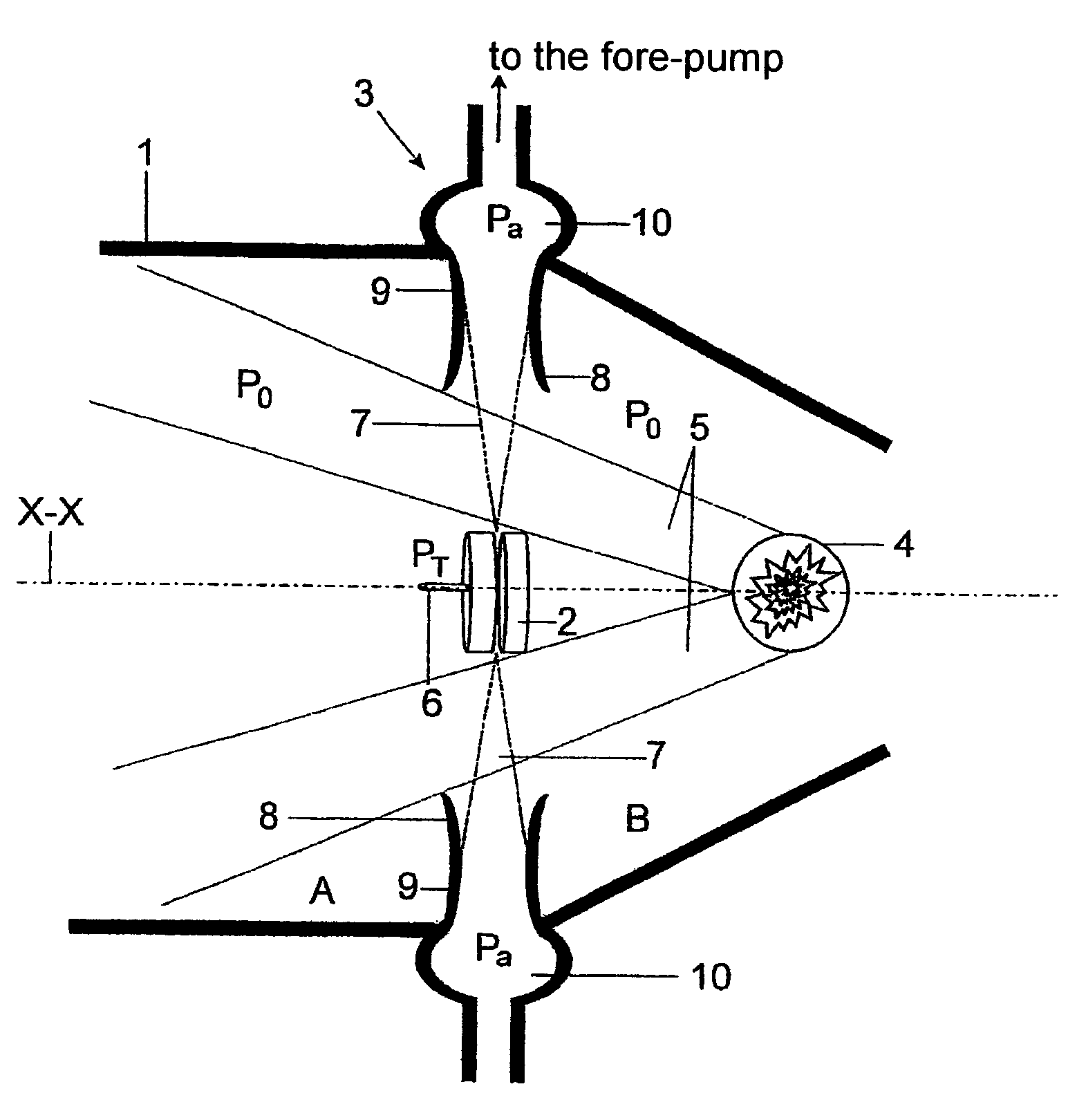

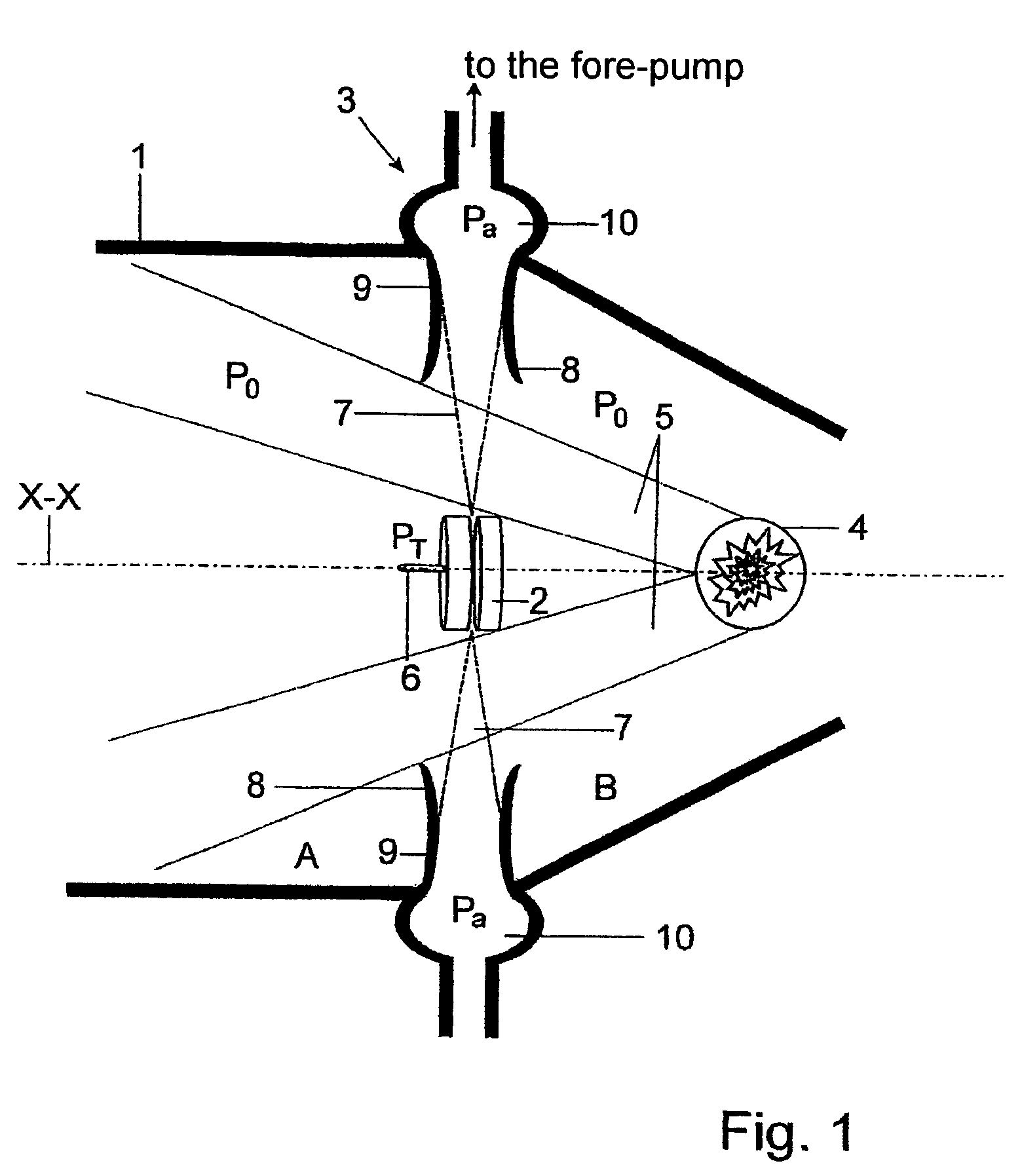

Plasma radiation source and device for creating a gas curtain for plasma radiation sources

InactiveUS7328885B2Inhibition effectImprove conversion efficiencyElectric arc lampsSemiconductor/solid-state device manufacturingSpray nozzleVacuum pump

A plasma radiation source is improved in such a way that the lifetime of the optics which is limited by the influence of debris is appreciably increased. A gas curtain through which the radiation proceeding from a source region in a vacuum chamber is emitted at a defined solid angle for debris suppression along an axis of the mean propagation direction of the radiation exits as a radially directed supersonic gas jet from a propulsion nozzle of a gas jet vacuum pump, which propulsion nozzle is arranged on the axis. The gas curtain is directed to an annular mixing nozzle that is arranged coaxial to the axis and is guided out of the vacuum chamber by a diffuser. This makes it possible to use source arrangements having an optimal conversion efficiency but extensive debris.

Owner:USHIO DENKI KK

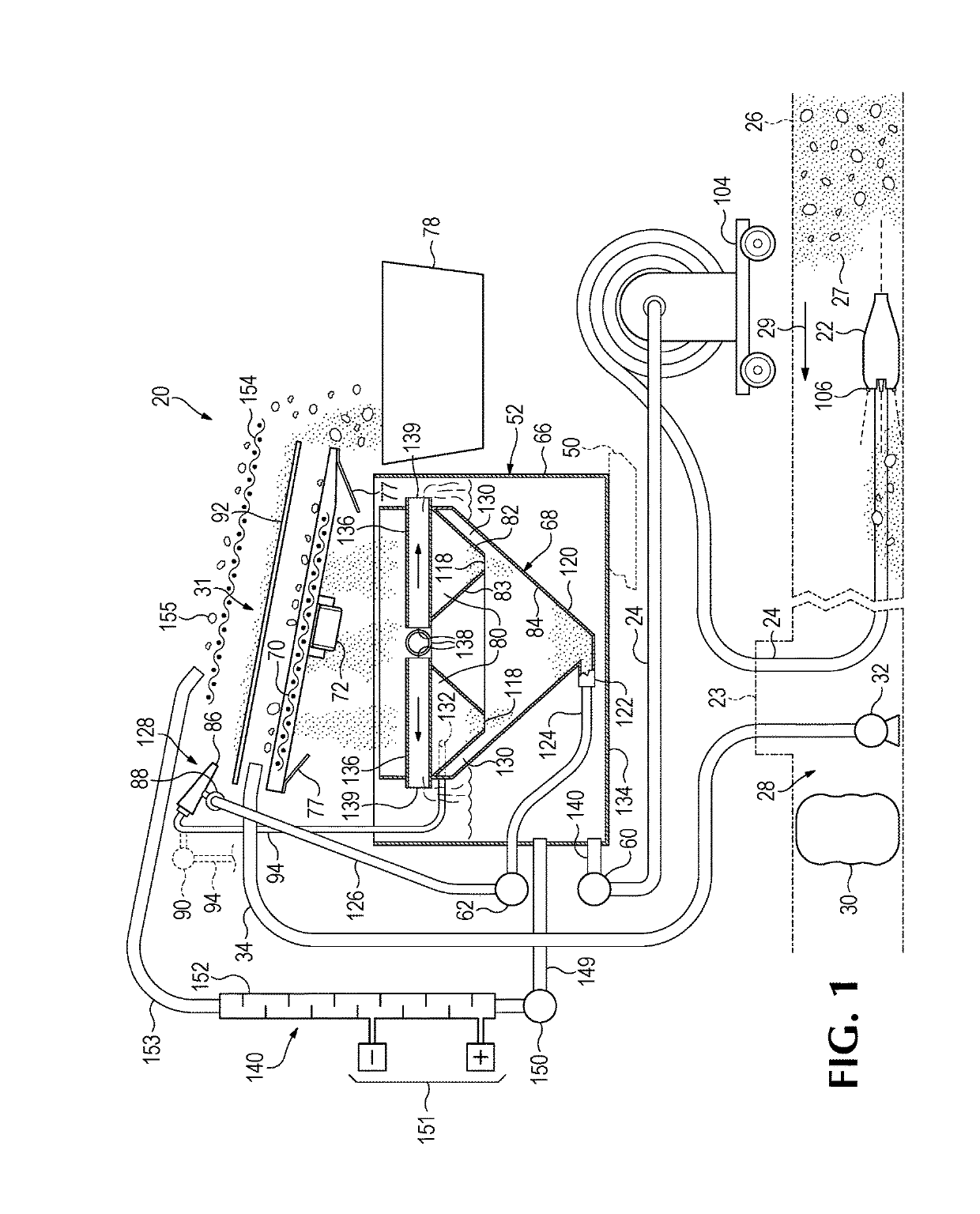

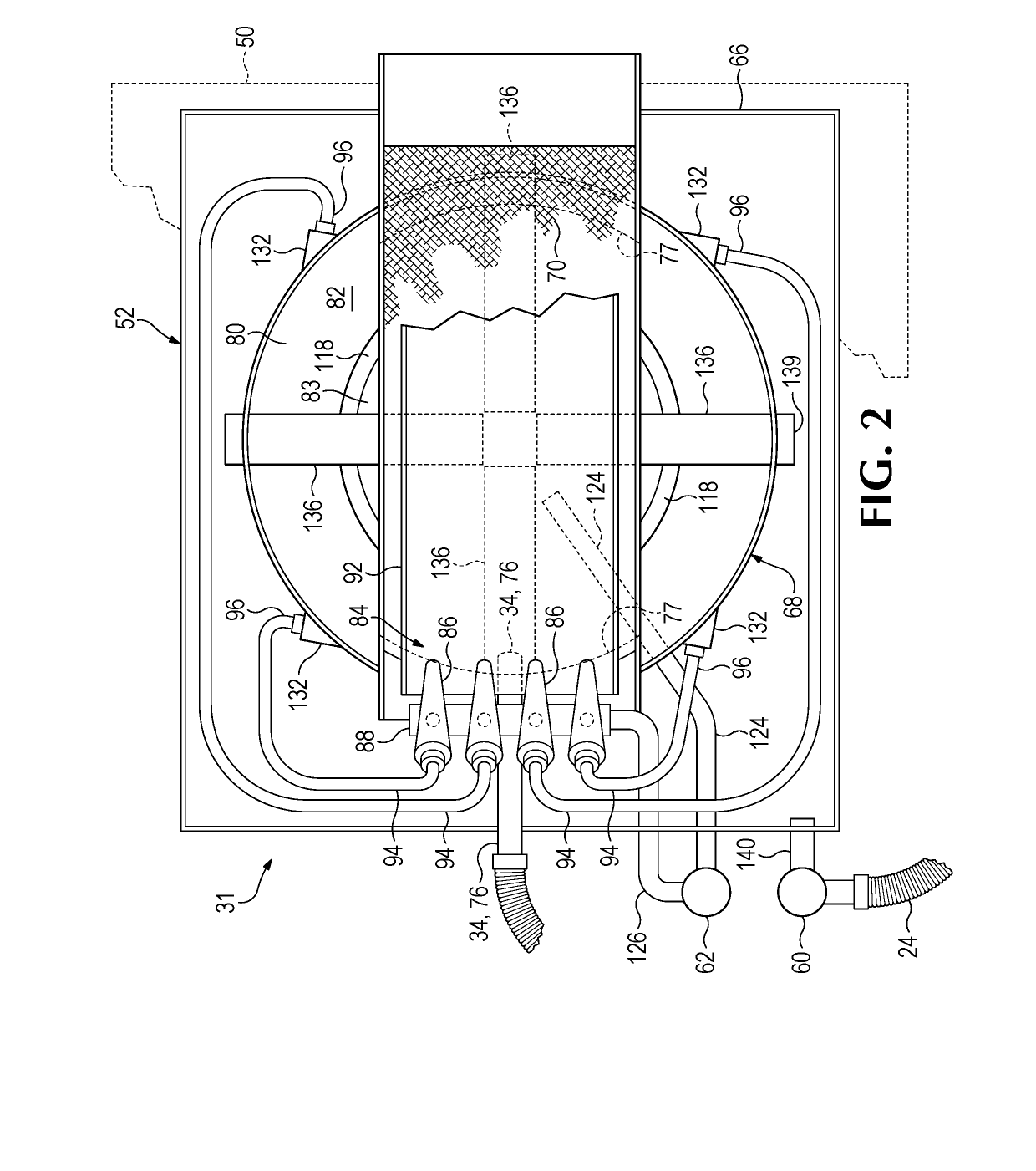

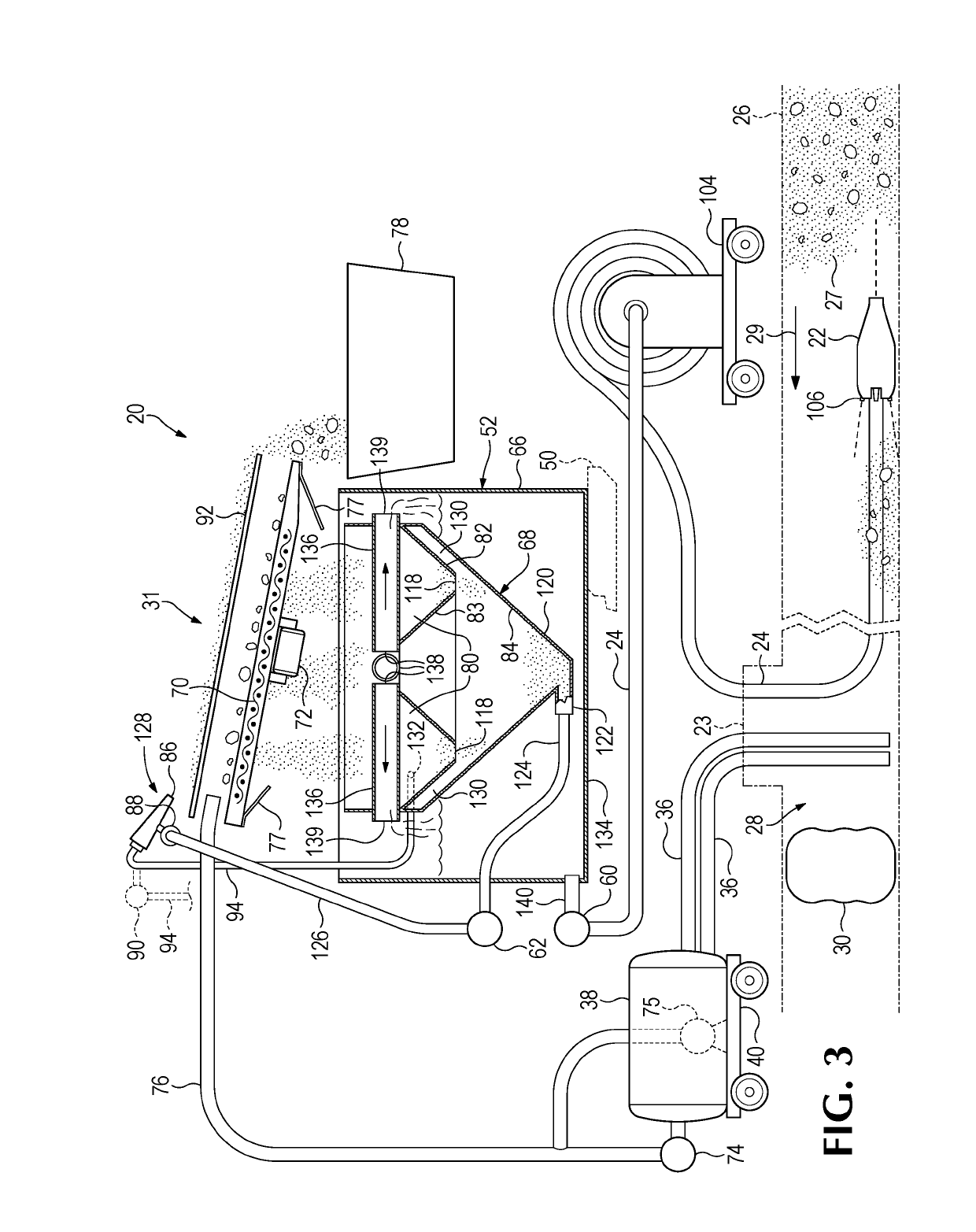

Method and apparatus for cleaning large pipes, such as storm drain conduits

ActiveUS20190271143A1Reduce wasteIncrease gravityTreatment involving filtrationCleaning using liquidsHigh concentrationWater flow

Apparatus and a method for cleaning accumulated sediment from storm drain conduits and other large-diameter conduits. A nozzle assembly is arranged to deliver a high-volume flow of water at a pressure high enough to loosen sediment from the interior of a conduit and to propel the nozzle assembly and an associated nozzle feed hose upstream within a conduit being cleaned. Water from the nozzle assembly flushes the sediment downstream and is then collected, partially cleaned, and reused in the nozzle assembly. Mud and clay may be left in the water to increase its specific gravity and viscosity. A self-contained portable and mobile system includes a tank and apparatus for removal of high concentrations of entrained or suspended solids, and a pump and conduits for delivering a high-volume flow of water, containing quantities of suspended solids, to the nozzle assembly.

Owner:IWASAKI HIGBEE JEFFREY L

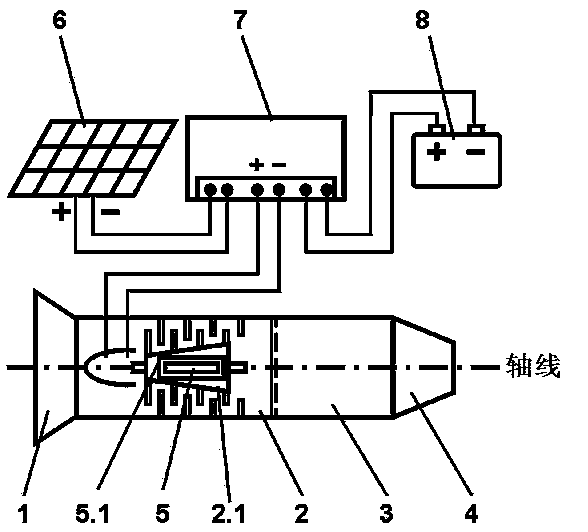

Electric drive jet engine

InactiveCN103807052AReduce manufacturing difficultyReduce maintenance difficultyBatteries circuit arrangementsElectric powerCombustion chamberGas compressor

The invention relates to an electric drive jet engine and belongs to the field of aero-engines. The electric drive jet engine is characterized by comprising a gas inlet, a gas compressor, a combustion chamber, a propelling nozzle, and a power system, wherein a motor is installed in the gas compressor to drive the gas compressor, a rotor of the motor and a rotor of the gas compressor are coaxial, the power system comprises a solar cell, an accumulator and a power controller, the solar cell and the accumulator are respectively connected with the power controller through a circuit, the solar cell converts the solar energy into electric energy, the accumulator is used for storing the electric energy, and the power controller inputs the electric energy into the motor in the gas compressor through the circuit. The electric drive jet engine has the advantages that 1) no turbine is used, 2) the motor is used to drive the gas compressor; and 3) the solar cell and the accumulator are used together to supply electric energy.

Owner:邱世军

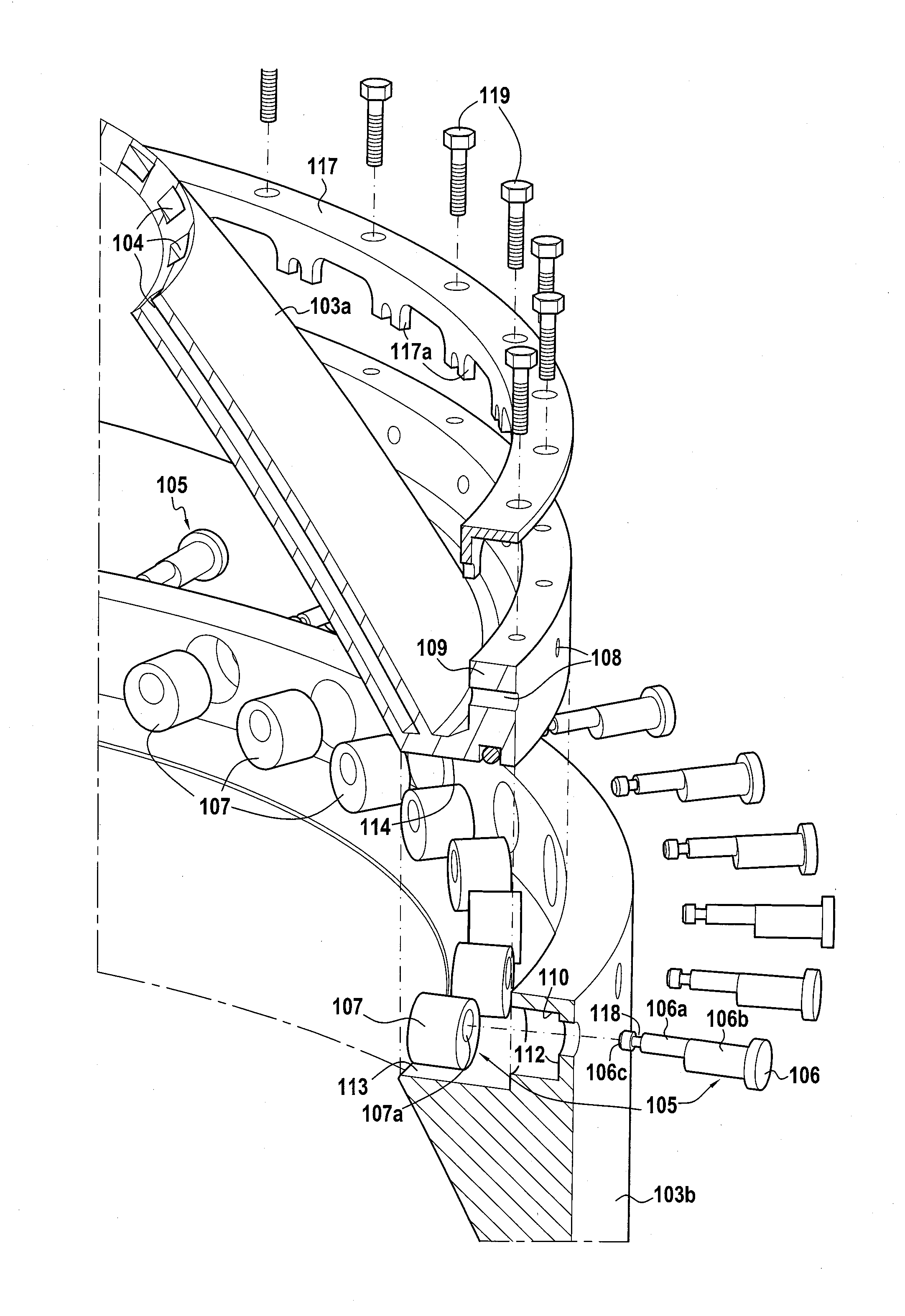

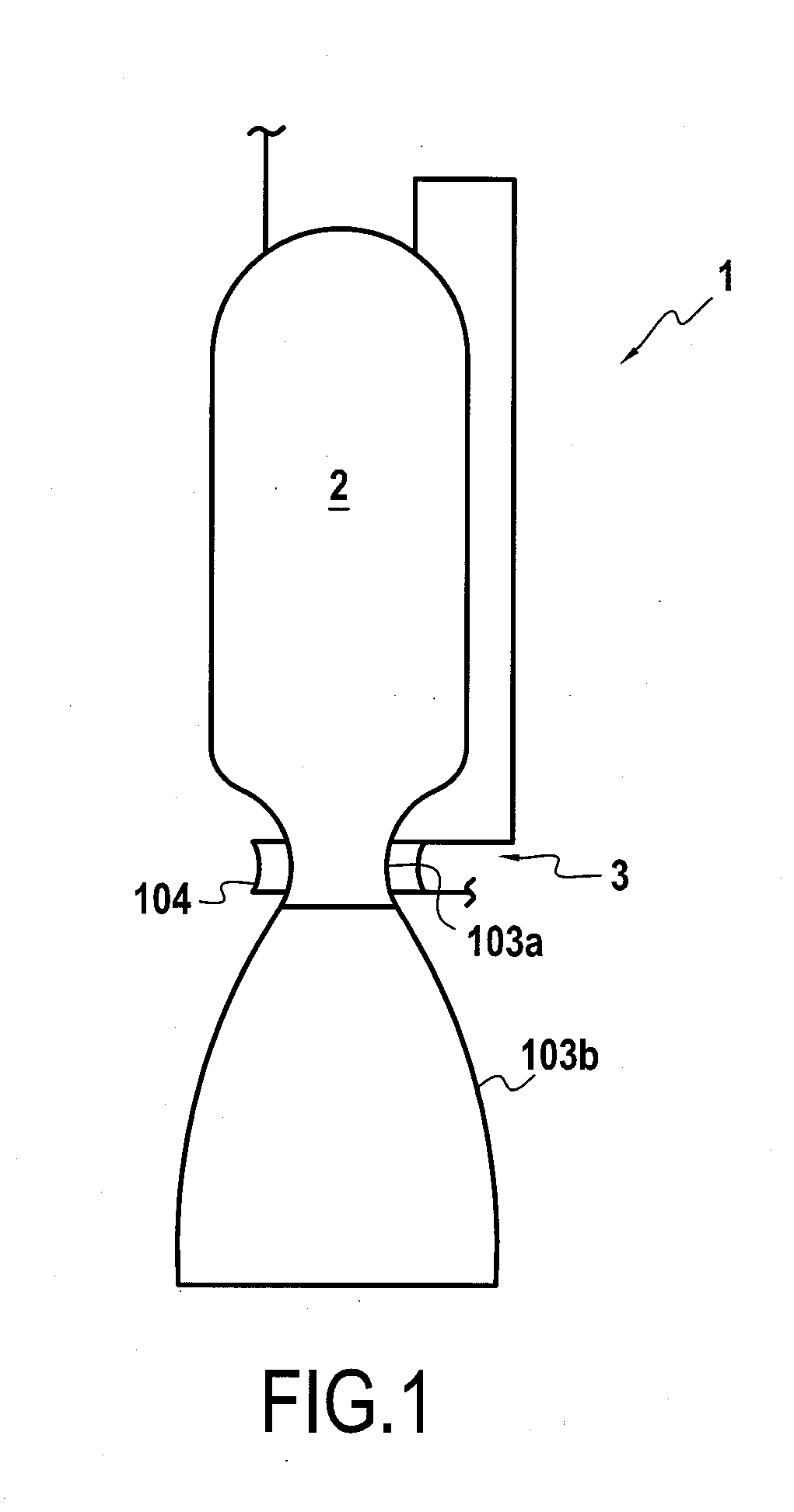

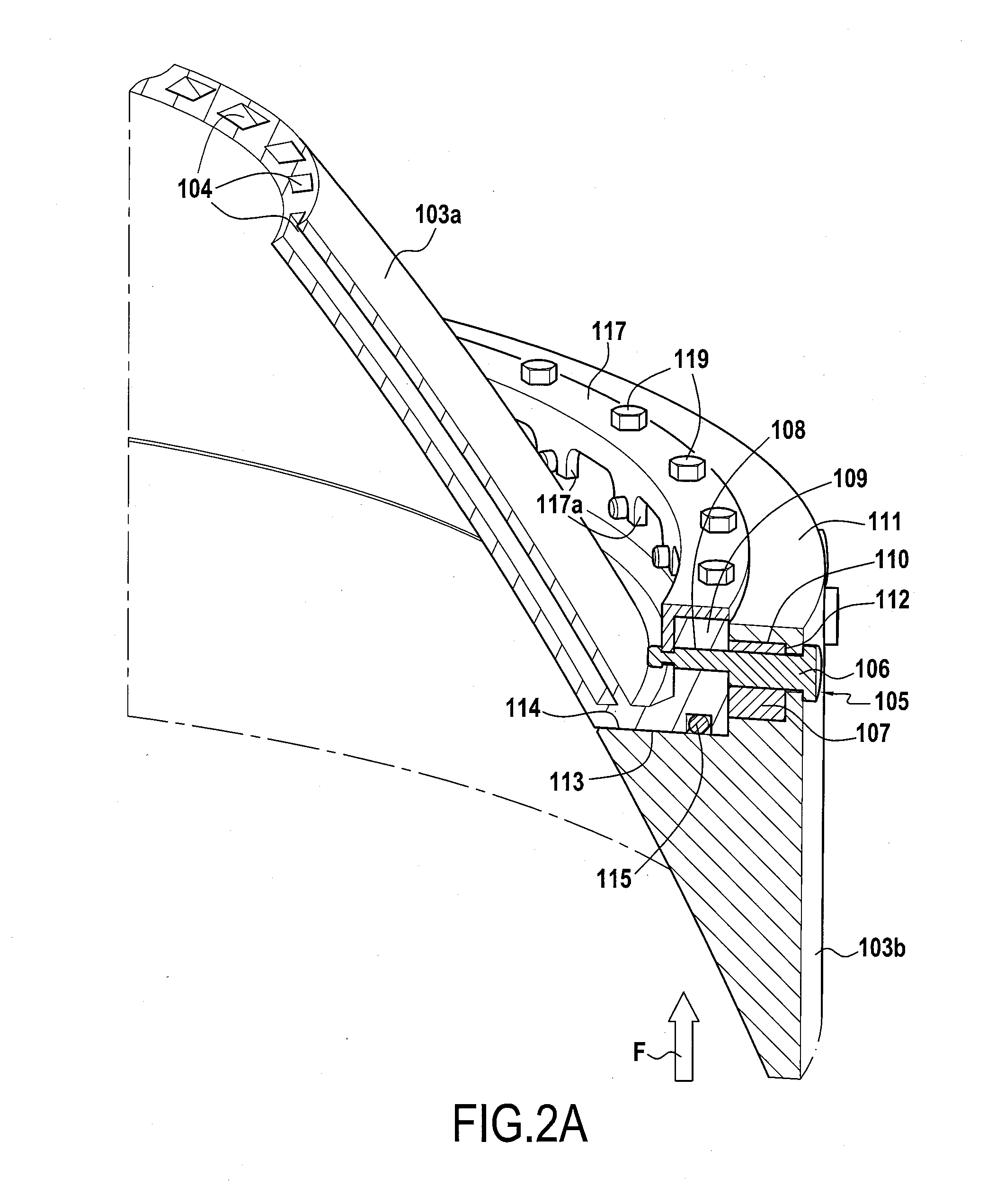

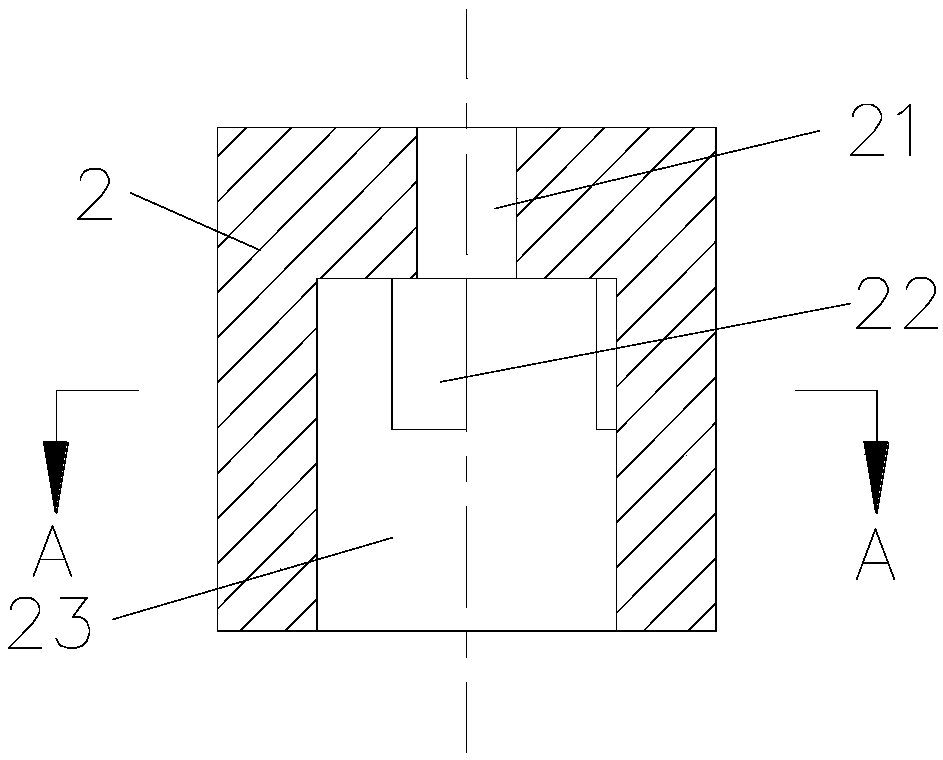

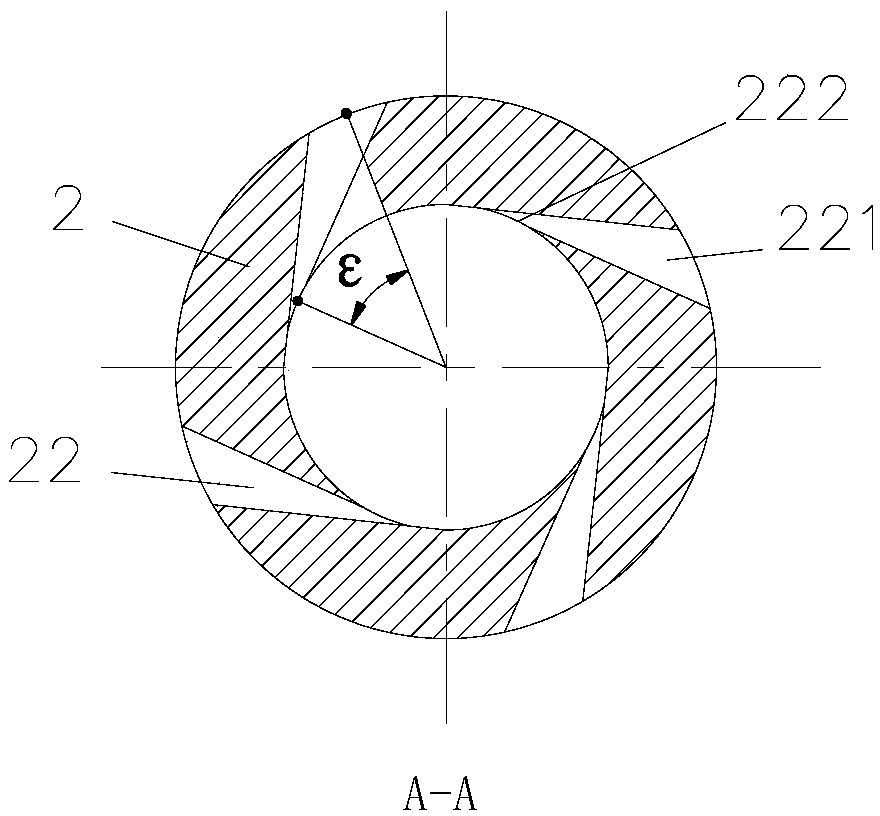

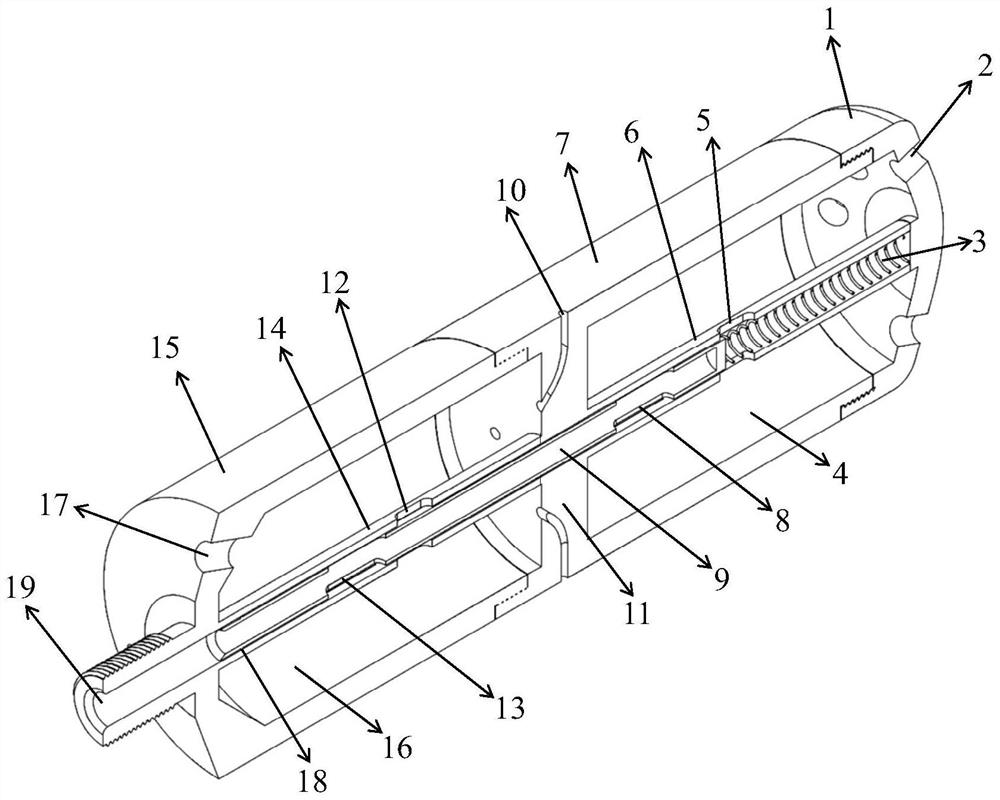

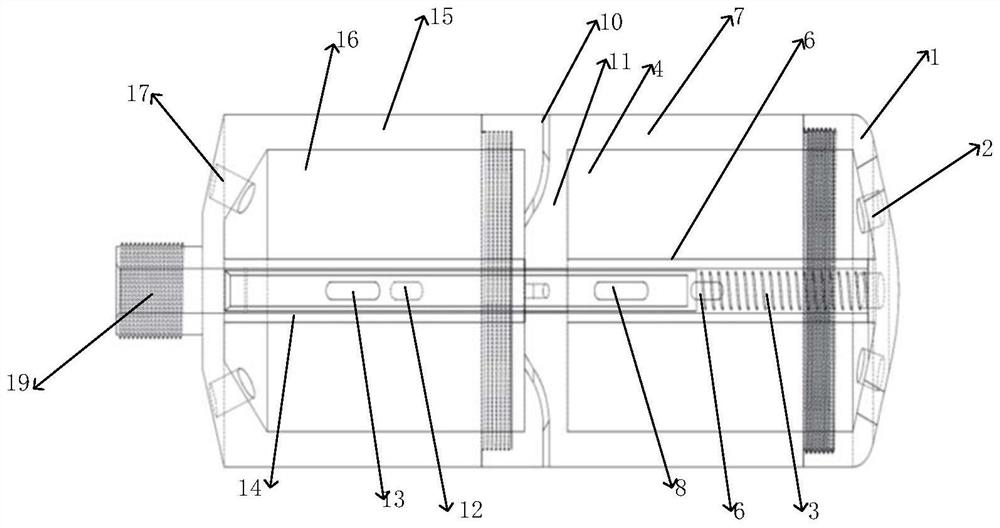

Device for connecting two segments of a propelling nozzle

InactiveUS20160169155A1Reliable mechanical connectionAvoid large gradientEngine manufactureEngine fuctionsEngineeringPropelling nozzle

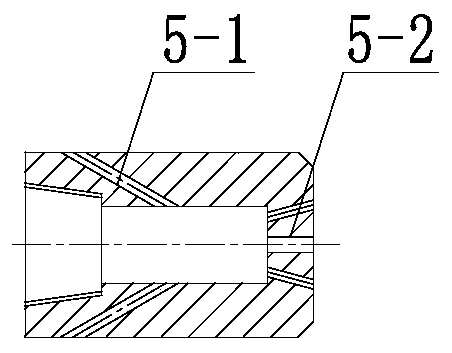

The invention relates to the field of propulsion nozzles, and in particular to a device (105) for connecting together first and second segments (103a, 103b) of a propulsion nozzle that are made of thermally dissimilar materials. The device (105) comprises at least one pin (106) and an eccentric bushing (107). The pin (106) presents both a first axisymmetric surface (106a) that is to be housed in a radial orifice (108) of the first nozzle segment (103a) and also a second axisymmetric surface (106b) that is eccentric relative to said first axisymmetric surface (106a).

Owner:ARIANEGRP SAS

Self-rotating high-pressure water jet adjustable drilling device

ActiveCN107605403AEfficient formationEffective stimulationConstructionsLiquid/gas jet drillingPropellerHigh pressure water

A self-rotating high-pressure water jet adjustable drilling device comprises a high-pressure pipe, a fixed shell, a rotating body and a rotating spraying head. The fixed shell comprises a cylindricalbody, the high-pressure pipe is arranged at the rear end of the cylindrical body, and a first propeller is mounted on the high-pressure pipe. The high-pressure pipe is fixed trough a second propellermounted at the rear end of the fixed shell, the rotating body is rotatably located in the fixed shell, and the rear portion of the rotating body is elastically supported to the fixed shell through a spring. The front portion of the rotating body is connected with the rotating spraying head provided with a breaking cutting nozzle set for front-end breaking operation. A first propulsion nozzle set is mounted on the first propeller, a second propulsion nozzle set is mounted on the second propeller, high-pressure fluid is broken through propulsion nozzle sets at the rotating spraying head, and thepropulsion nozzle sets drive the fixed shell and the rotating spraying head to move forwards, so that automatic propulsion drilling is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

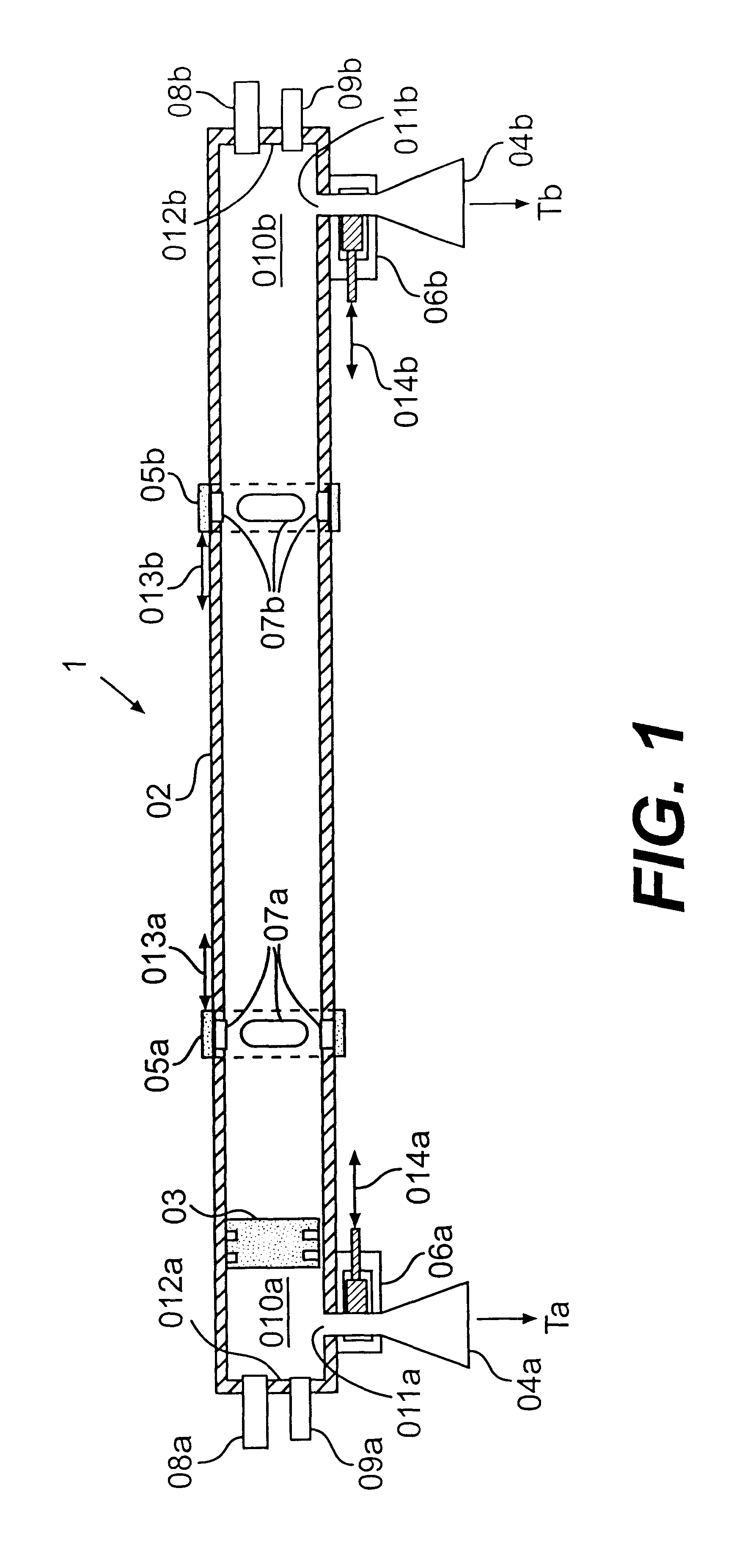

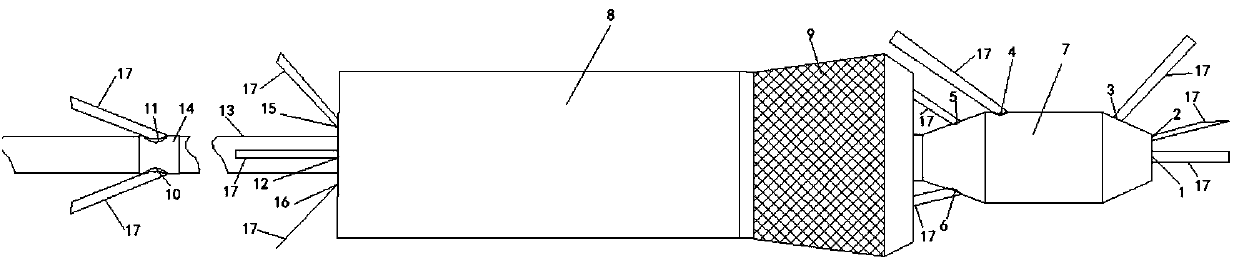

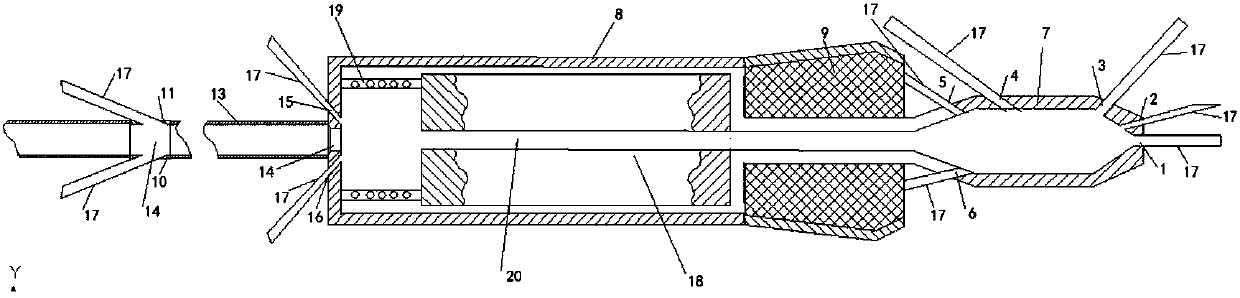

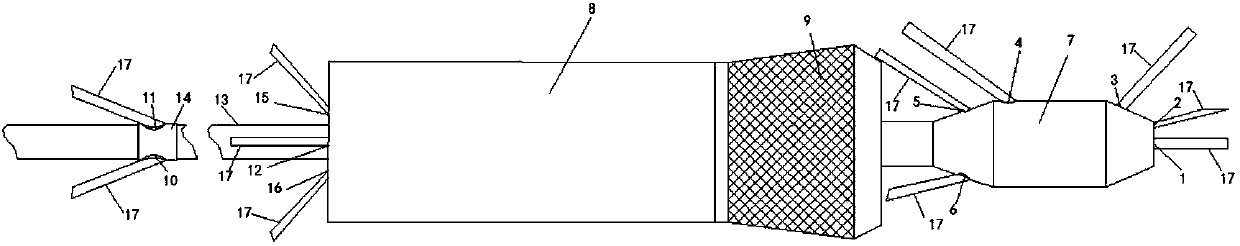

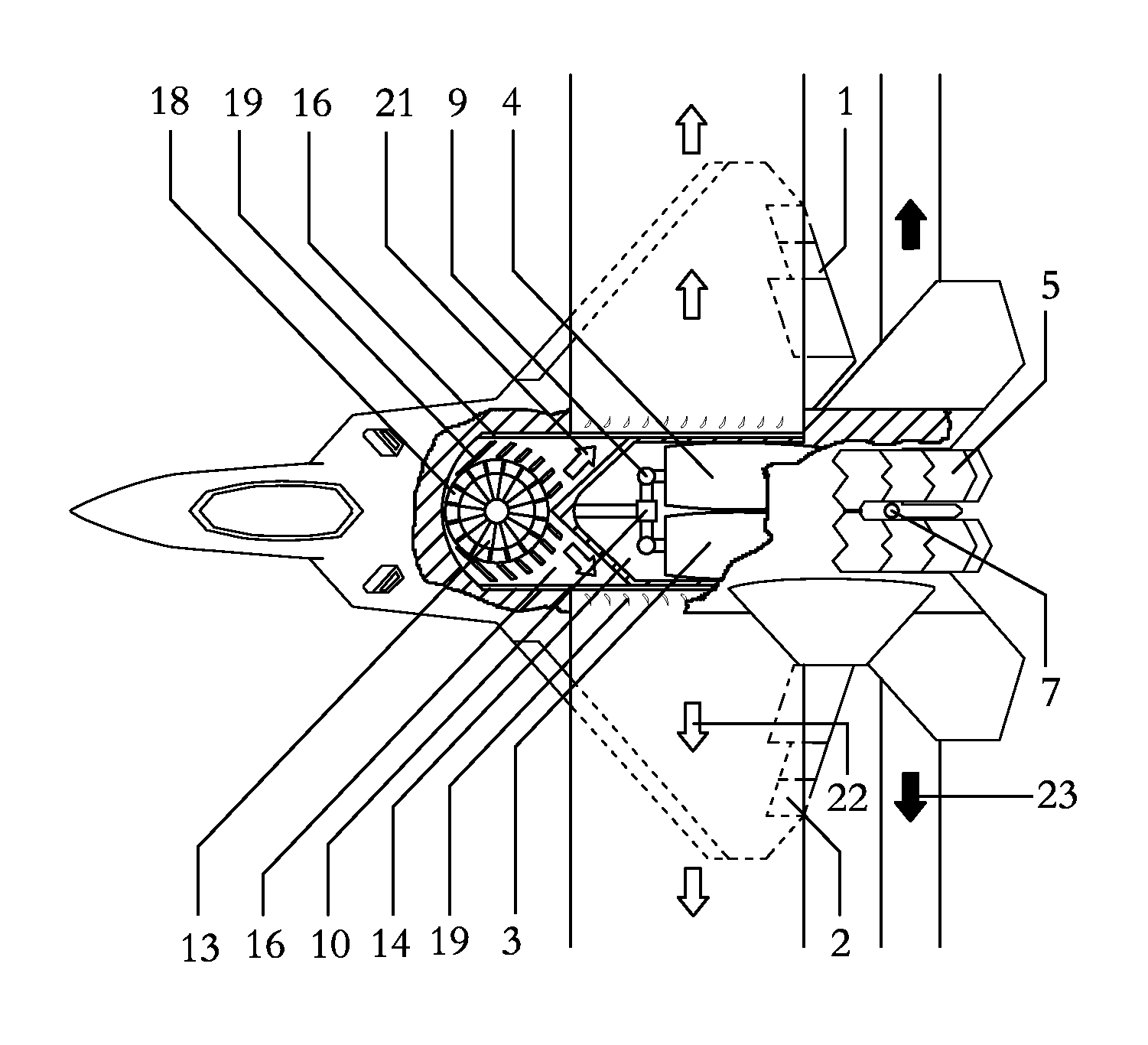

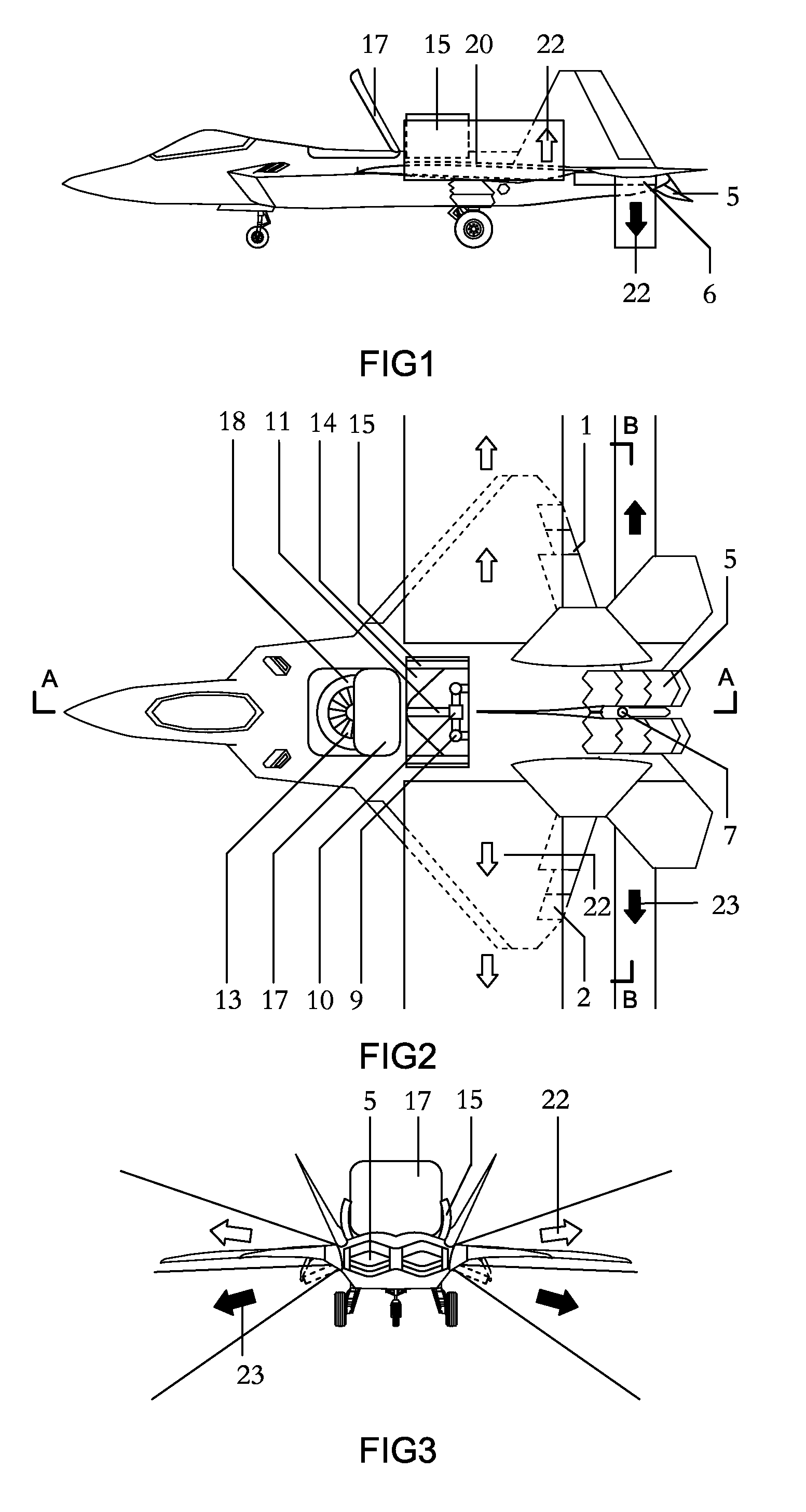

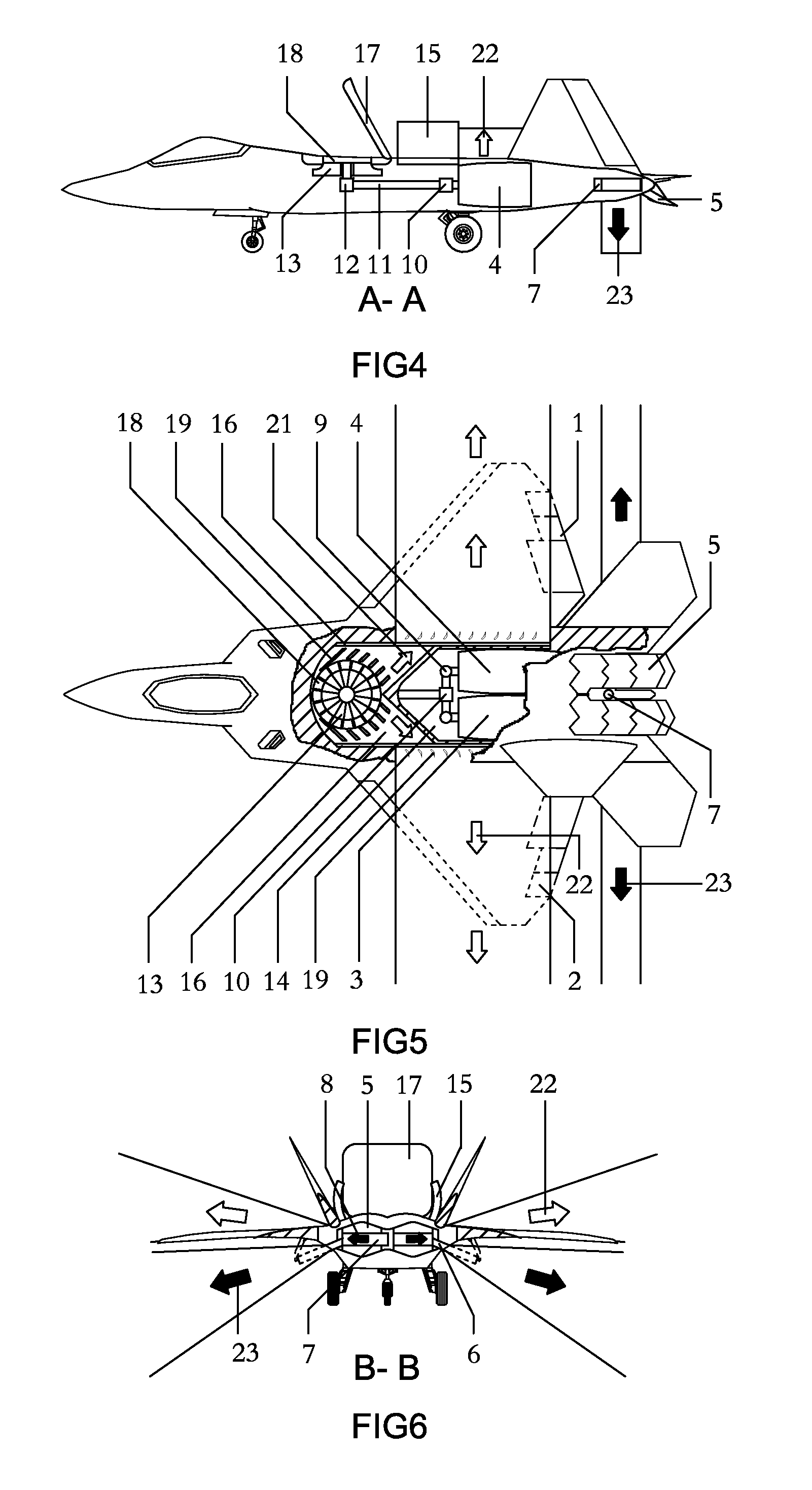

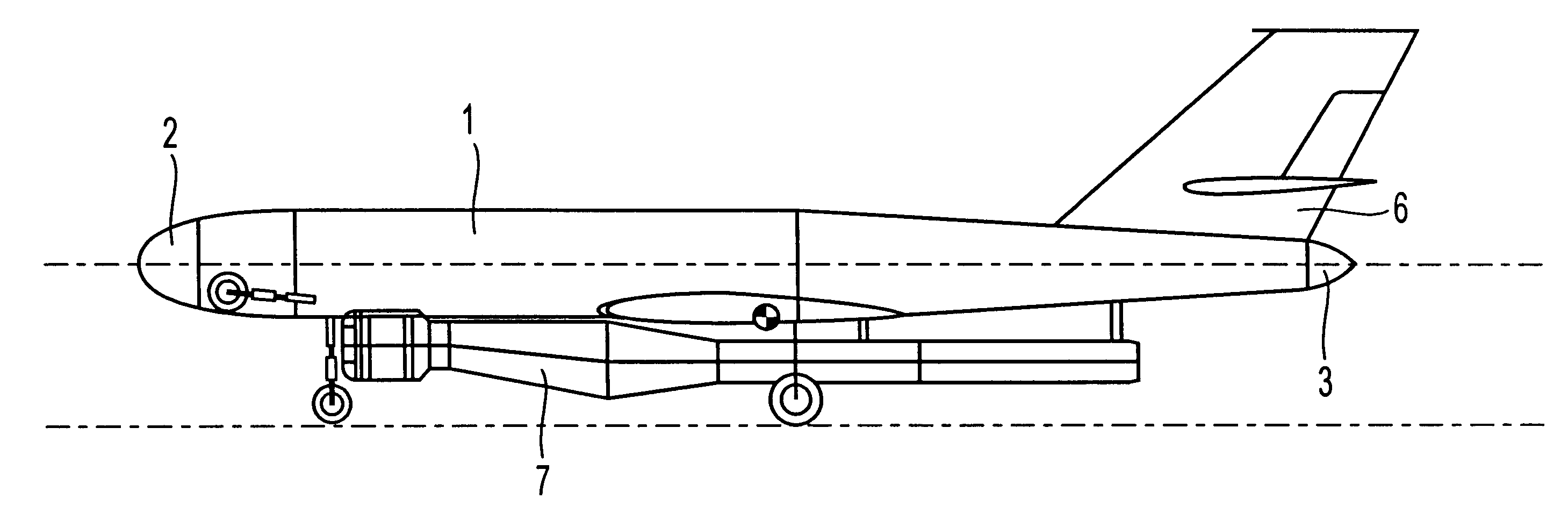

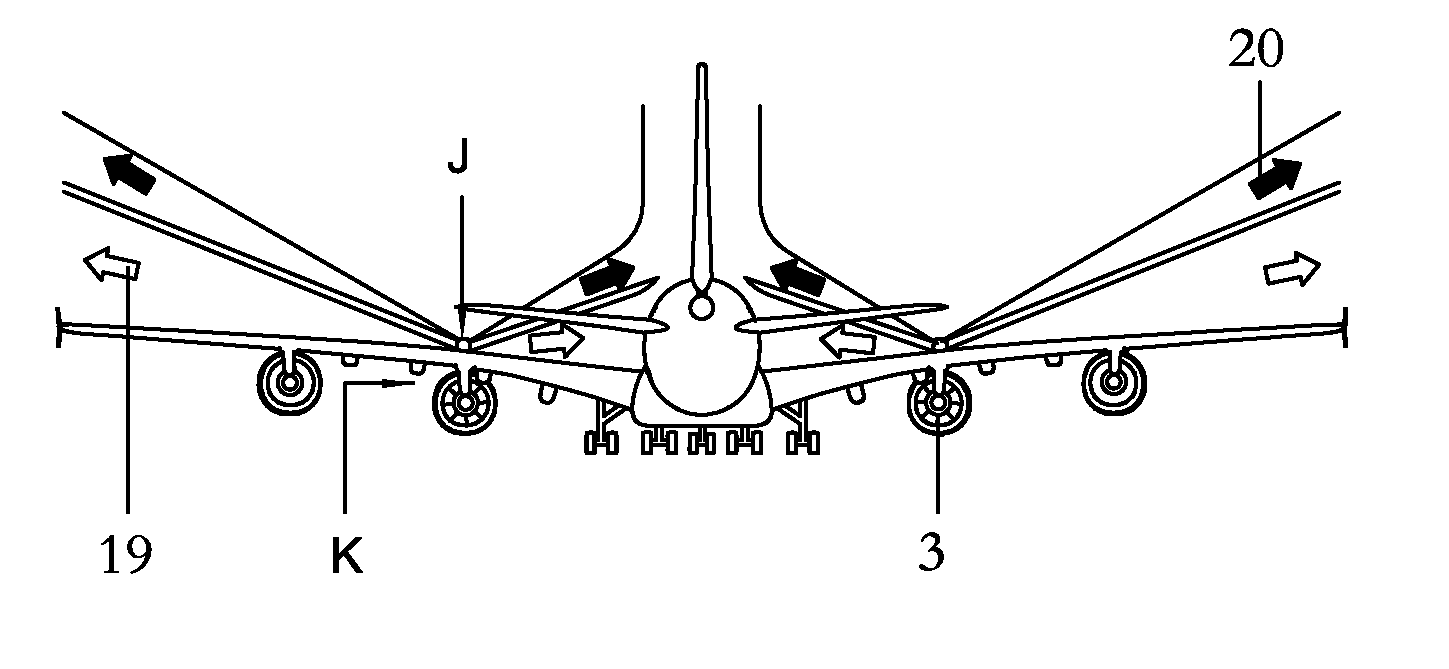

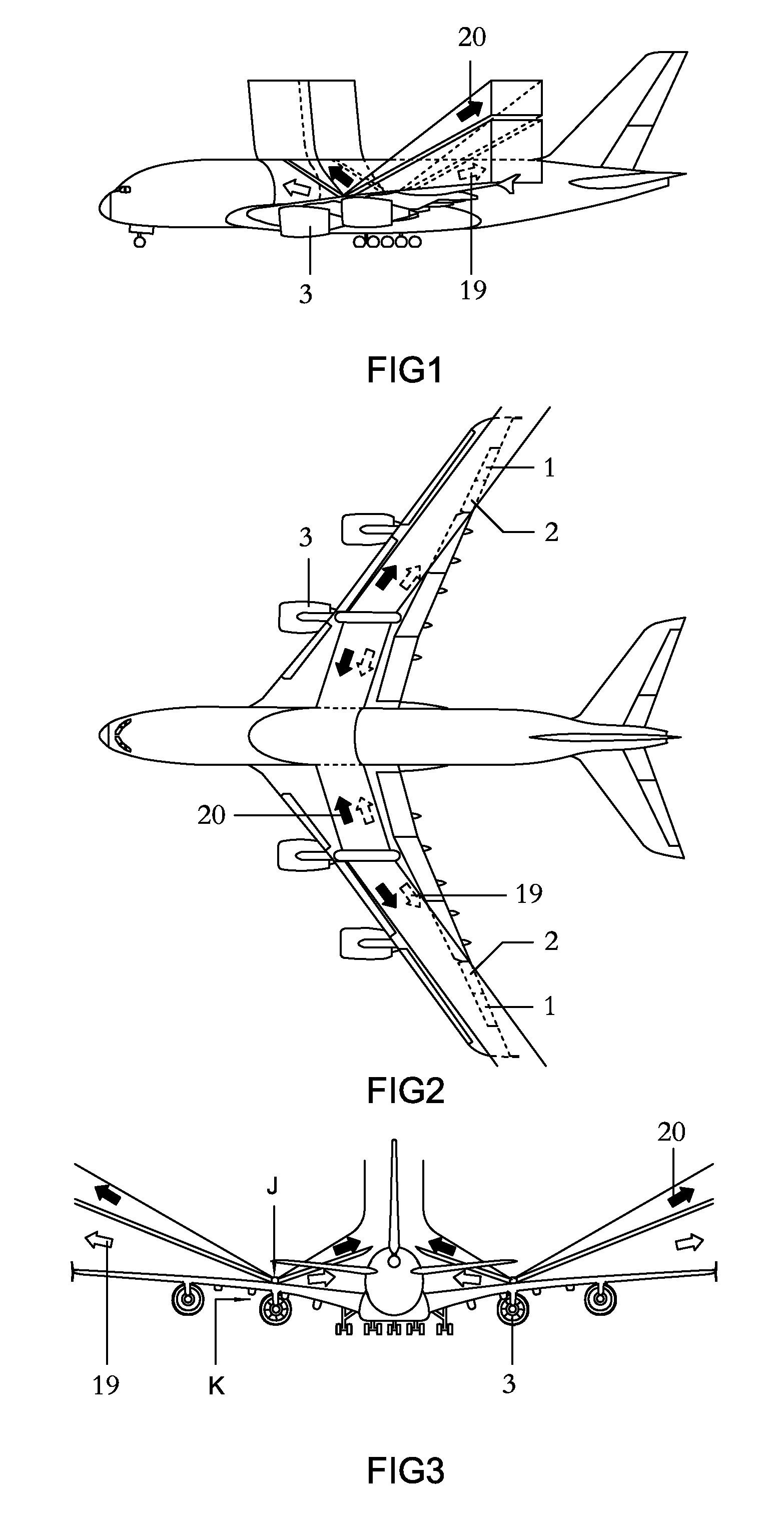

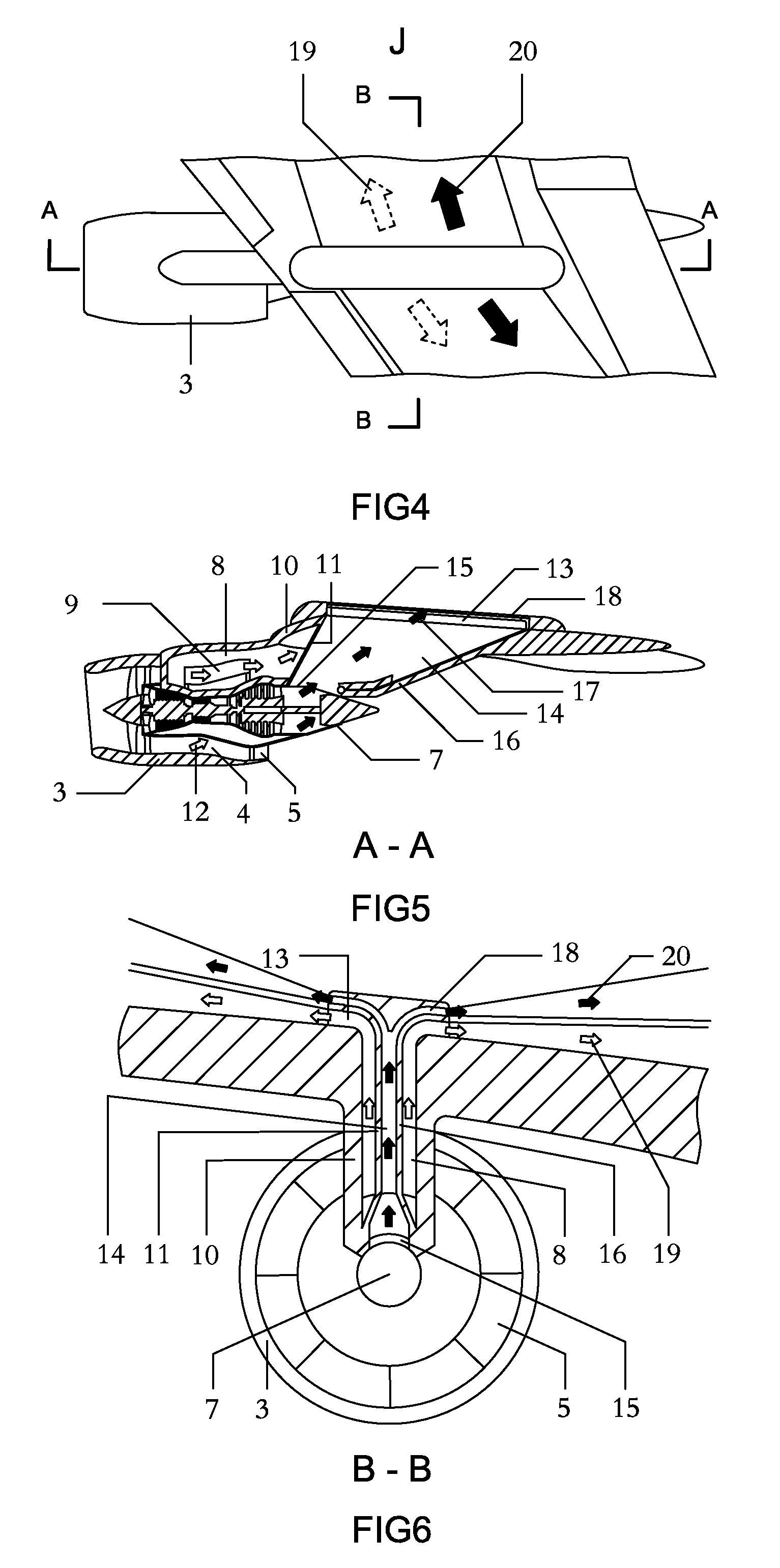

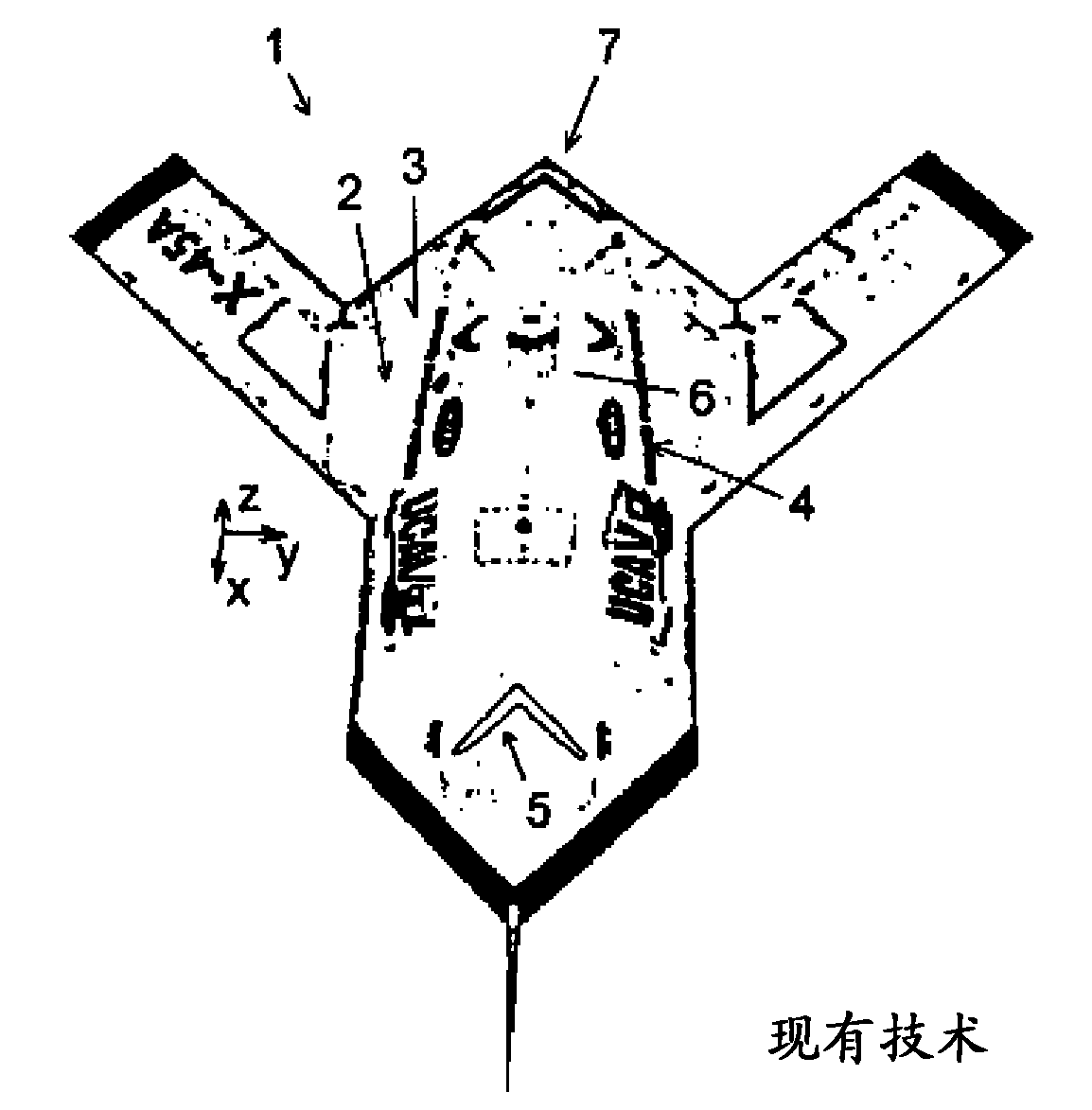

VTOL aircraft with a thrust-to-weight ratio smaller than 0.08

InactiveUS20150336665A1Generating most lift efficiently.Aircraft navigation controlJet type power plantsImpellerDrive shaft

VTOL aircraft with a thrust-to-weight ratio smaller than 0.08, during vertical take-off / landing, obtains most vertical lift, besides traditional small vertical lift by high-temp bypass slot outlet (6) directing, under its opening, the closing of the tail of the power-off jet engine (3) by the valve (7) in tail cone, the closing and the stretching of the propelling nozzle (5), high-temp air (8) to spout out along the inclined downward direction of the wingspan, by a centrifugal impeller (13) accelerating, under the connecting of the transmission shaft (11) with a jet engine (4), and the opening of the cabin doors (15, 17) of the inlet (18) of the low-temp duct (16) and the auxiliary engine's inlet (14), low-temp air (21) to flow through the low-temp duct (21) and flow over the upper surface of the wing but not burn up it along the wingspan direction, thereby generating most vertical lift and enabling ailerons (1, 2) to control balances of the aircraft.

Owner:JING CHEN LI

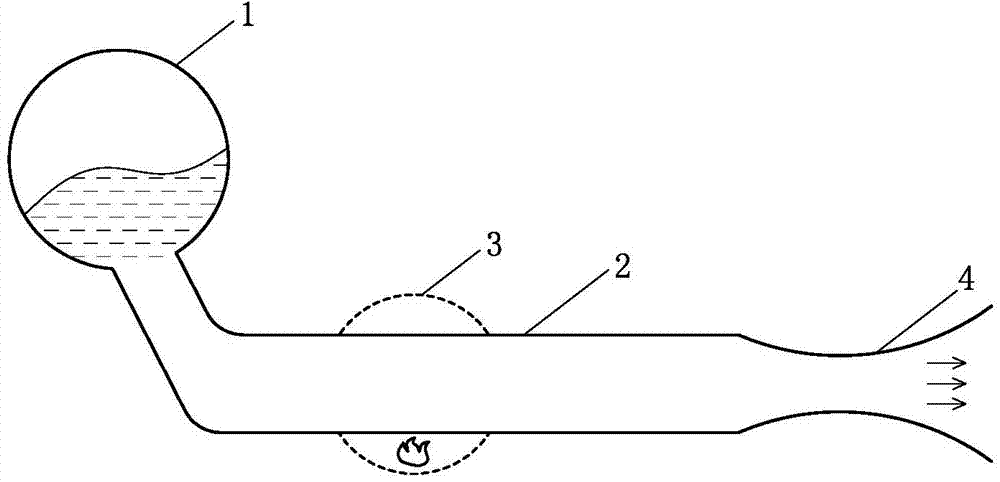

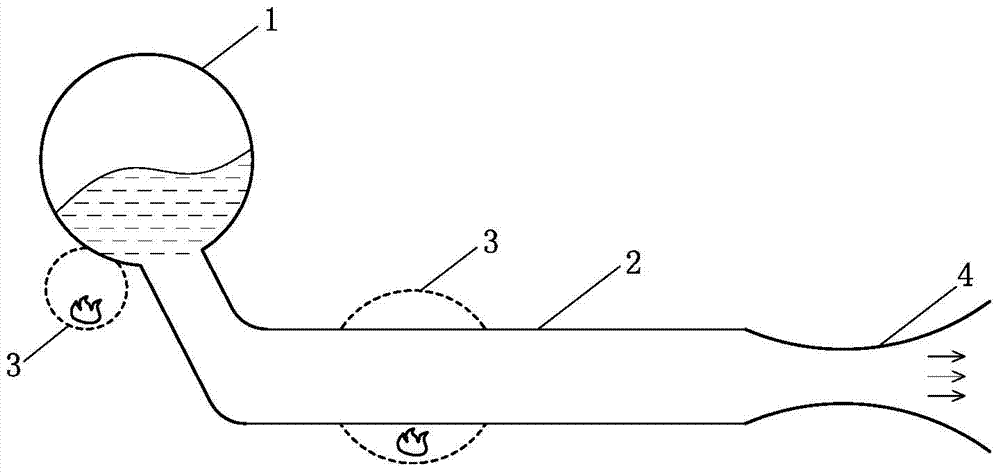

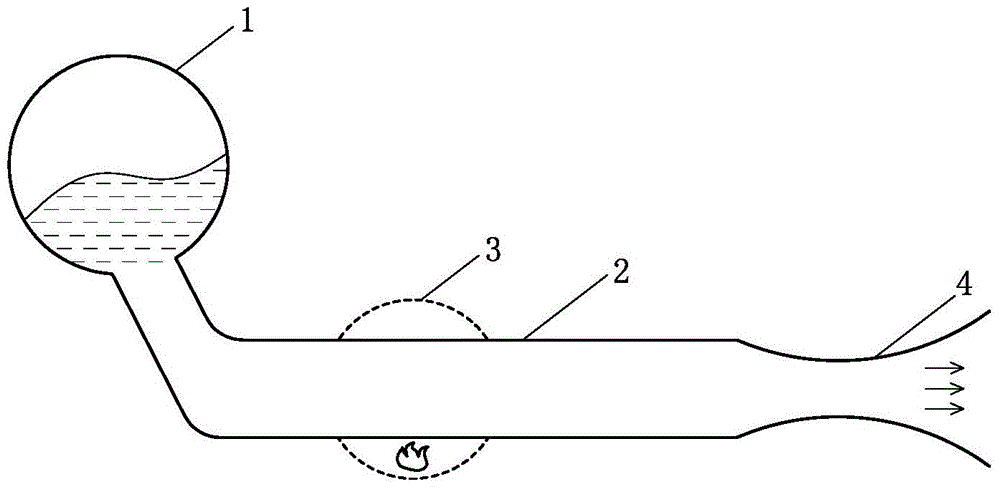

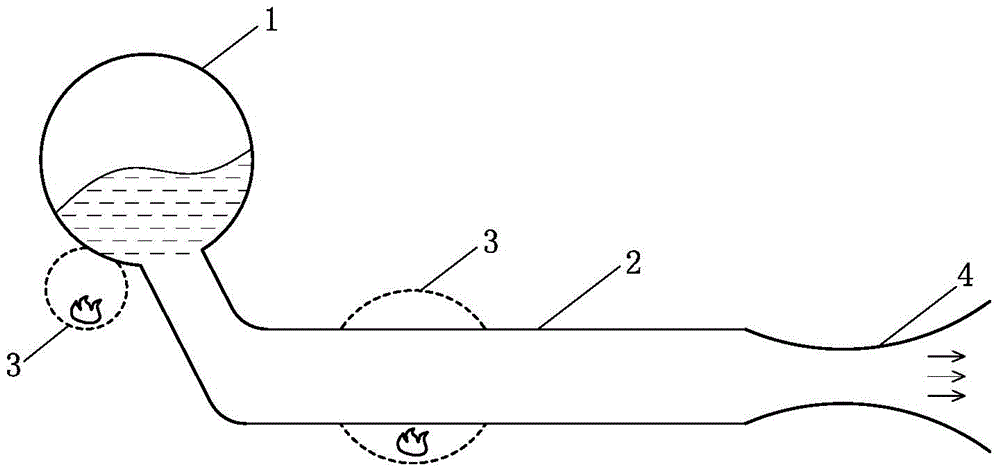

External combustion propelling engine

ActiveCN103939236AReduce volumeImprove power densityJet propulsion plantsCombustion chamberFlight vehicle

The invention discloses an external combustion propelling engine. The external combustion propelling engine comprises a liquid working medium pressure-bearing storage tank, a working medium heating fluid channel, a combustion chamber and a propelling nozzle. The bearing capacity of the liquid working medium pressure-bearing storage tank is larger than 2MPa. The combustion chamber transfers heat to the working medium heating fluid channel. The working medium heating fluid channel is communicated with the propelling nozzle. The propelling nozzle outputs power. The liquid working medium pressure-bearing storage tank is communicated with the working medium heating fluid channel in an automatically flowing mode. The combustion chamber transfers heat to the liquid working medium pressure-bearing storage tank or the pressure-bearing storage tank is communicated with the working medium heating fluid channel and the combustion chamber transfers heat to the liquid working medium pressure-bearing storage tank. The external combustion propelling engine is small in size, high in power density, low in manufacturing cost and capable of being used as an engine of aircrafts such as a target drone.

Owner:JIANGSU ETERN

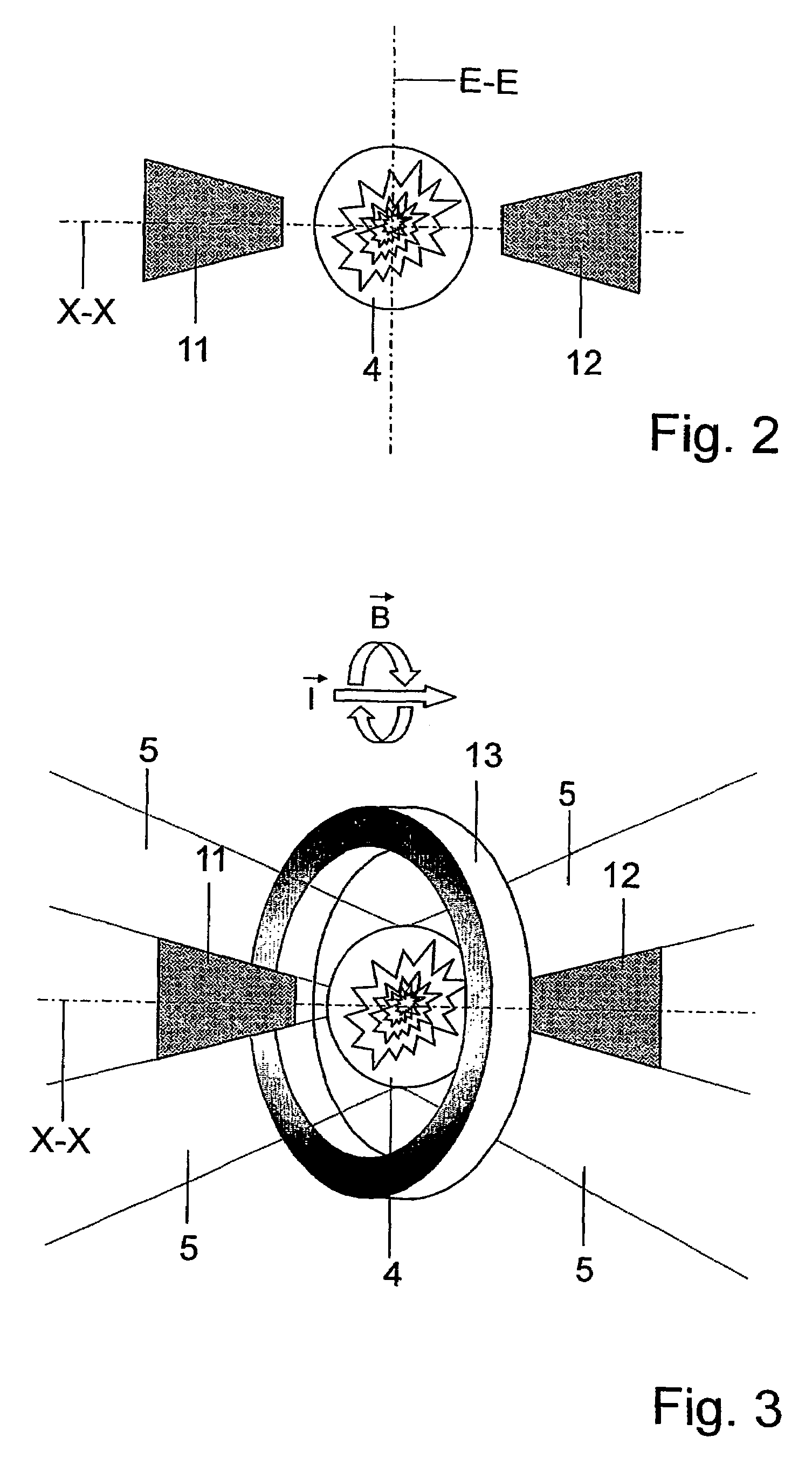

Self-propelled infrared emission aerial target

A self-propelled infrared emission aerial target has an aircraft- or a missile-shaped body and a nose, wings and / or control surfaces, a system for feeding fuel and oxidizer to a combustion chamber in which combustion gases are produced and for supplying the combustion gases to a propulsion nozzle, and an infrared radiation emitter. The target has at least one conduit connecting the combustion chamber or propulsion nozzle of the propulsion system to a nose, wing and / or control surface of the target, or to an outside element attached thereto.

Owner:DOE PASCAL +3

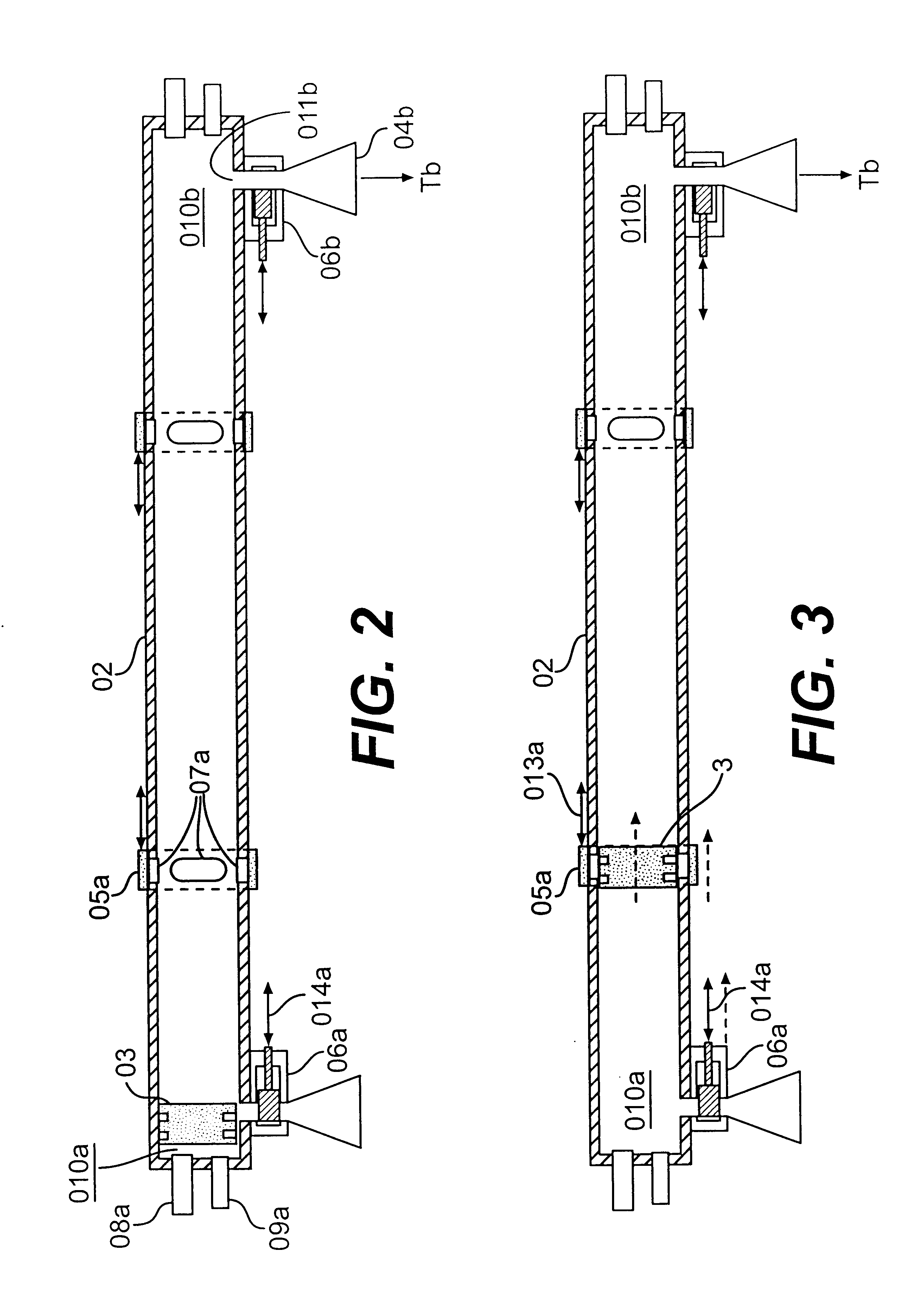

VTOL aircraft with a thrust-to-weight ratio smaller than 0.1

InactiveUS20150298805A1Generating lift efficiently.Aircraft navigation controlJet type power plantsWingspanTurbofan

VTOL aircraft with a thrust-to-weight ratio smaller than 0.1, during vertical take-off / landing, obtains another vertical lift, besides traditional vertical lift generated by low-temp bypass duct directing, under the closing of the propelling nozzle (7) of low-temp duct (6) of a turbofan engine and the opening of the inlet (14) of the low-temp bypass duct (15), the low-temp air (18) from the low-temp duct (6) to flow, in form of low-temp planar jet (20), over the upper surface of the wing along the wingspan, by high-temp bypass duct (15) directing, under the closing of the propelling nozzle (5) of high-temp duct (4) of the turbofan engine and the opening of the inlet (8) of the high-temp bypass duct (9), the high-temp air (18) from the high-temp duct (4) to flow, in form of high-temp planar jet (13), above the low-temp planar jet (20) but not burn up the wing along the wingspan and enables the ailerons (1, 2) to control the balances more efficiently.

Owner:JING CHEN LI

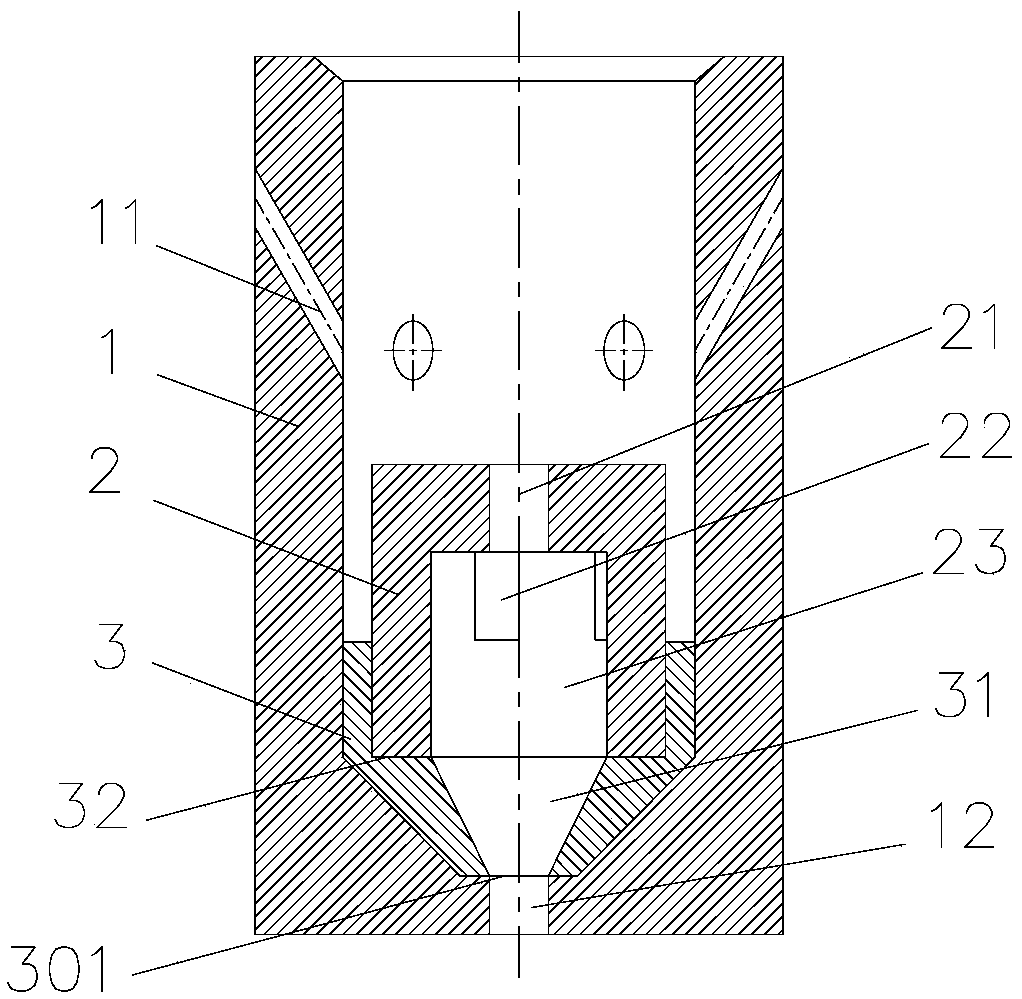

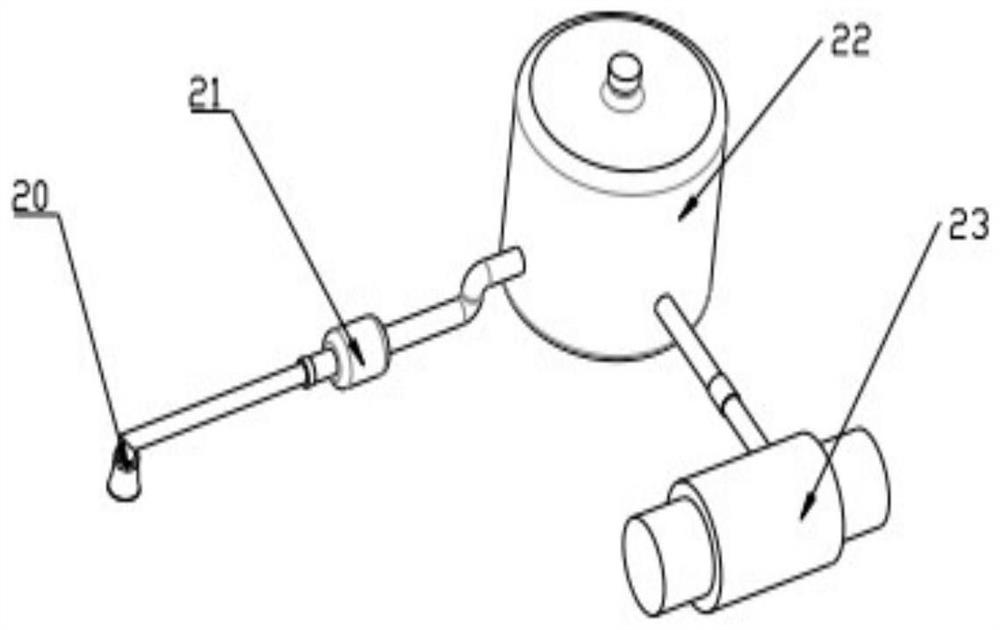

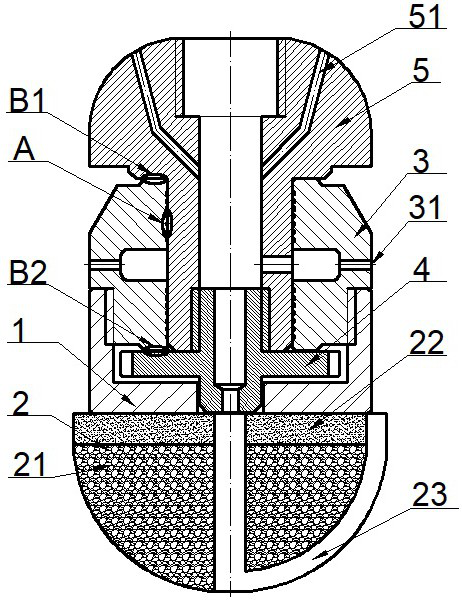

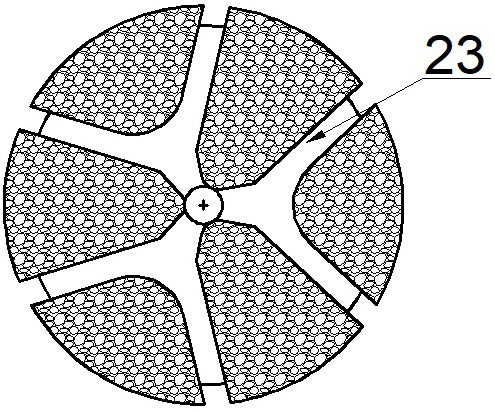

Cut-in direct-rotation mixed jet self-propelled nozzle

InactiveCN111042735APlunge groove short runnerReduce contact timeLiquid/gas jet drillingMixed flowJet flow

The invention discloses a cut-in direct-rotation mixed jet self-propelled nozzle, and belongs to the technical field of oilfield oil production engineering. The nozzle comprises a flow mixing body, and a flow mixing cavity, a central hole communicating with the flow mixing cavity and at least two cut-in grooves communicating with the flow mixing cavity are formed in the flow mixing body; and the central hole is used for forming a liquid straight flow in the flow mixing cavity, the cut-in grooves are used for forming a liquid swirling flow in the flow mixing cavity, and the two jet flows form adirect-rotation mixed jet flow in the flow mixing cavity. The invention aims to provide the cut-in direct-rotation mixed jet self-propelled nozzle, which can break the rock in a reliable structure and a direct-rotation mixed jet mode, and improve the rock breaking efficiency while prolonging the service life of the nozzle.

Owner:SOUTHWEST PETROLEUM UNIV +1

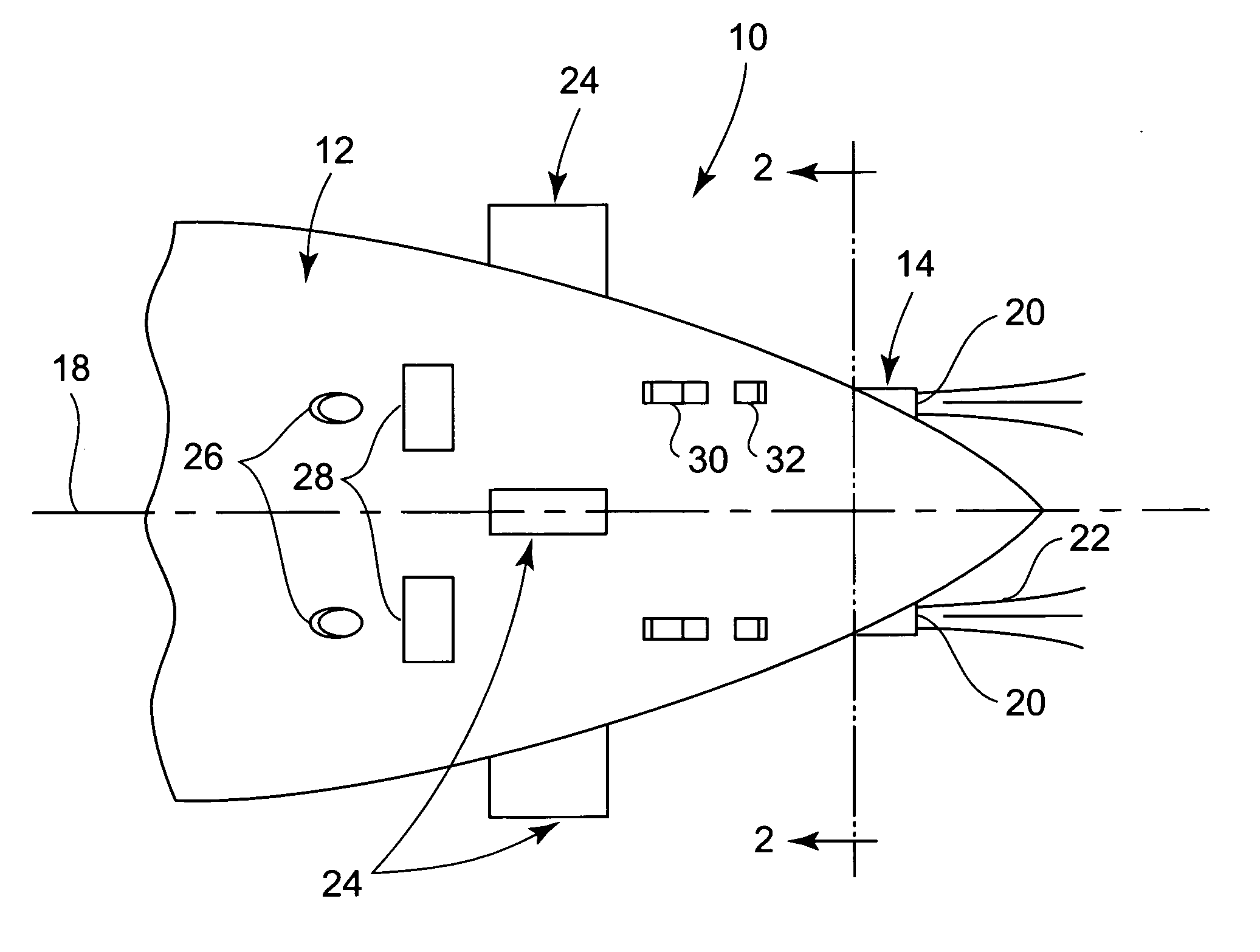

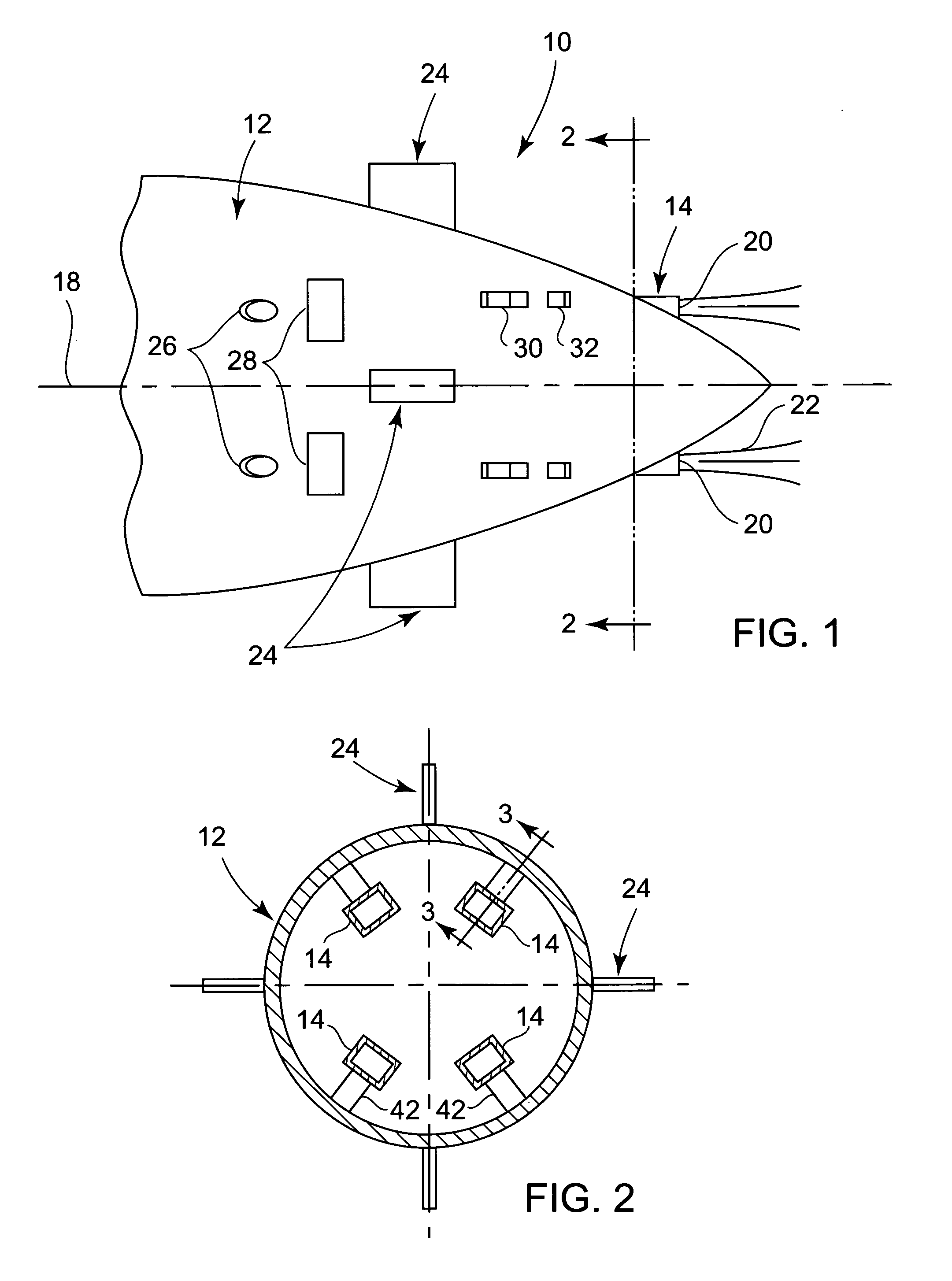

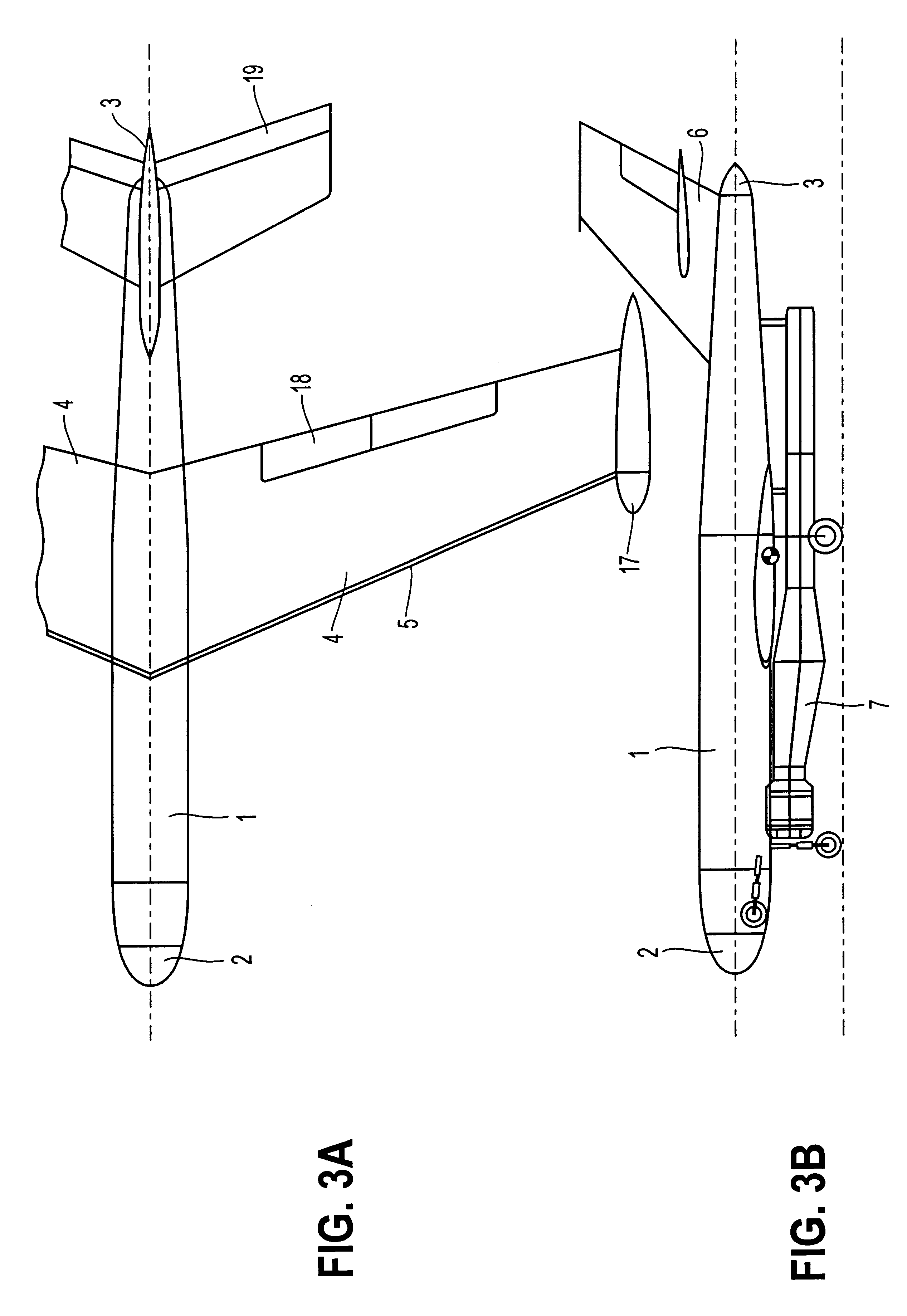

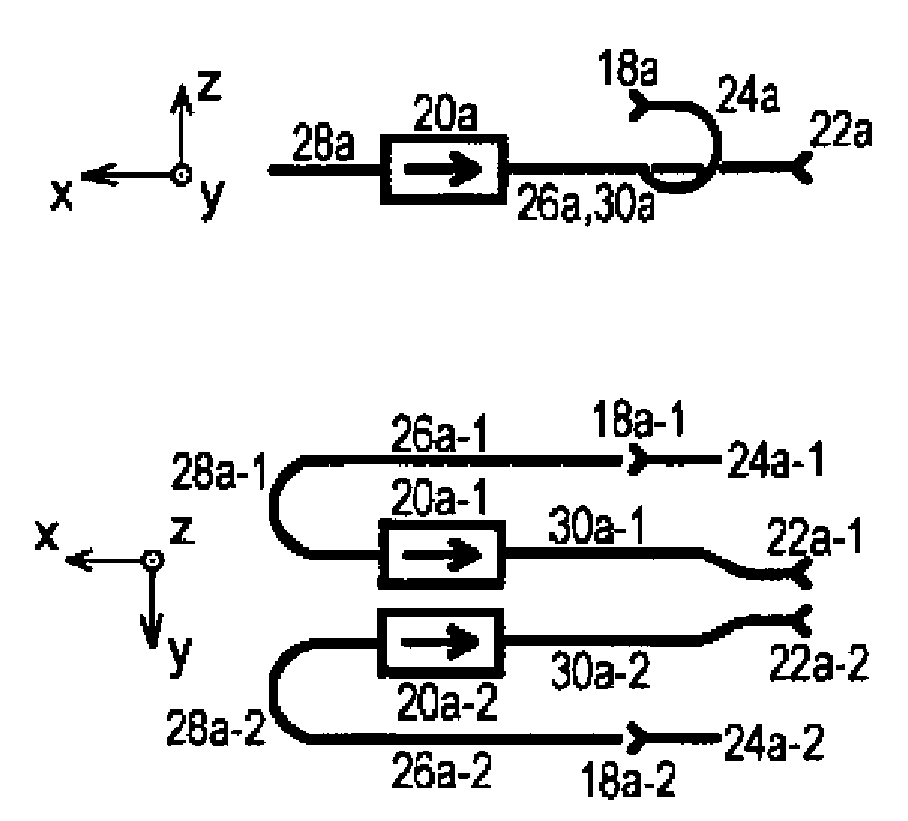

Driven aircraft, in particular an aircraft designed as a flying wing and/or having a low radar signature

ActiveCN103038132AAlleviating the problem of unstable yaw momentsAll-wing aircraftJet type power plantsFlapping wingFlight direction

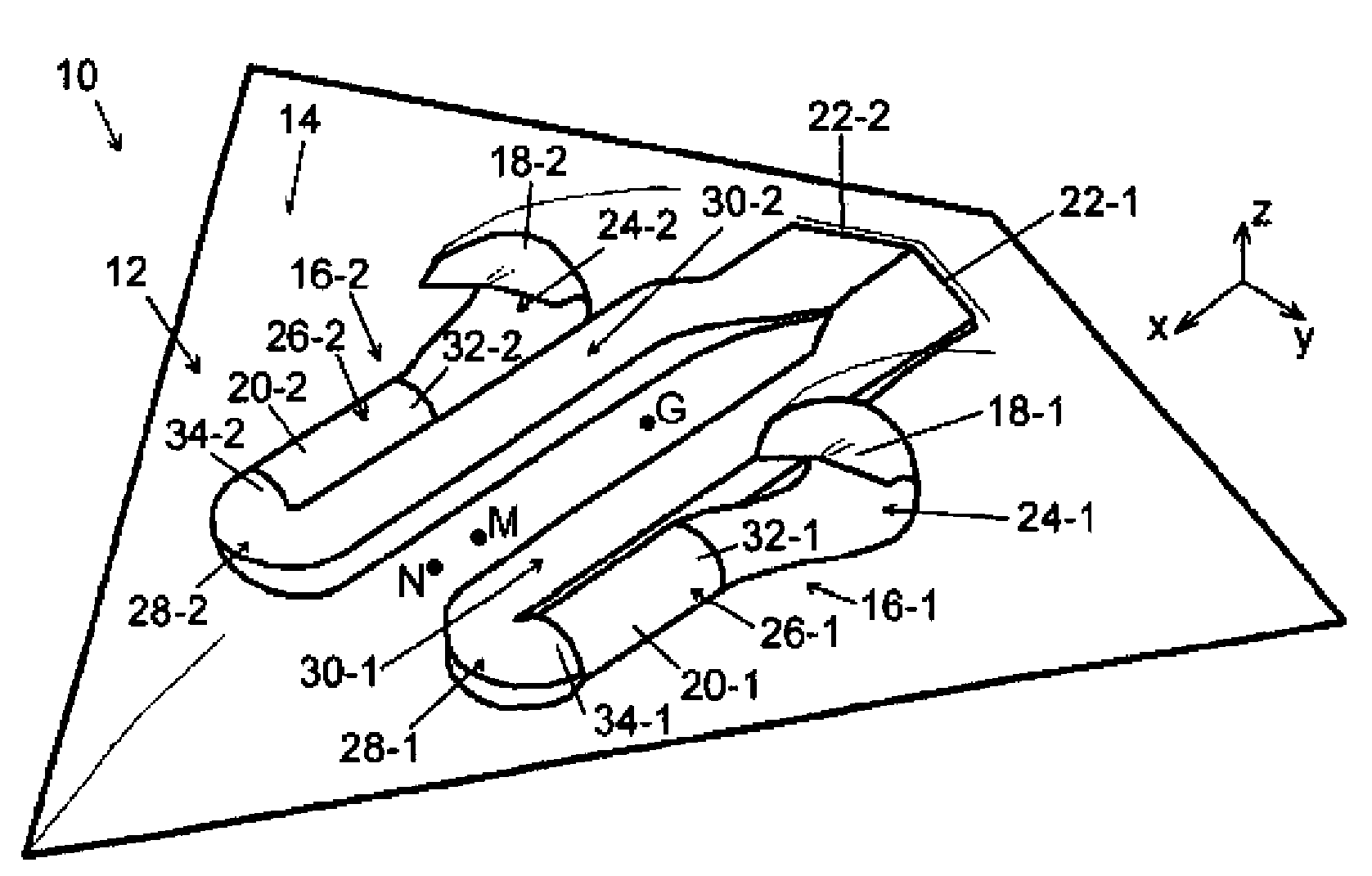

The invention relates to an aircraft (10), comprising a fuselage body, a wing body (12), and at least one drive flow passage (16), which extends from an air inlet (18) directed forward (+x) on the body surface (14) via a jet engine (20) through the body (12) to a propelling nozzle (22) that opens toward the rear (-x) on the body surface (14).; In order to enable greater design freedom in regard to the shape of the body (12), in particular in the manner of a flying wing having improved flight properties compared to known aircrafts, and / or to achieve an extreme reduction in the radar signature of the aircraft (10), at least one part of the jet engine (20), in particular the entire jet engine (20), is arranged upstream of the air inlet (18) as viewed in the flying direction (+x) of the aircraft (10) and the drive flow passage (16) has curvature sections (24, 28) designed and arranged suitably therefor.

Owner:AIRBUS DEFENCE & SPACE GMBH

Method for mixing a liquid in a sealed container with a fine-particle solid, container of this type, ejector jet and use of a jet of this type

The invention relates to a method and a device for mixing a liquid in a substantially sealed container or a mixture of a liquid and a fine-particle solid, said liquid or mixture only partially filling the internal volume of the container that can be occupied by a fluidic phase and the remaining available internal volume of the container being filled by a gaseous phase. According to the invention,the essentially same liquid or mixture is fed to the container in the form of a propelled stream of a suction device that is situated in the liquid or mixture in the container. In its simplest form, the method according to the invention is implemented by means of an ejector (i.e. according to water jet pump principles) embodied as the suction device. The propelled stream is pumped through a propelling nozzle, which is fitted into the ejector in such a way that gas is sucked from the gaseous phase during the passage of the stream through the nozzle, e.g. by means of a riser tube that projects into the gaseous phase of the container, and is released in the form of dispersed gas bubbles, together with the propelled stream, into the liquid content of the storage container.

Owner:BASF SE

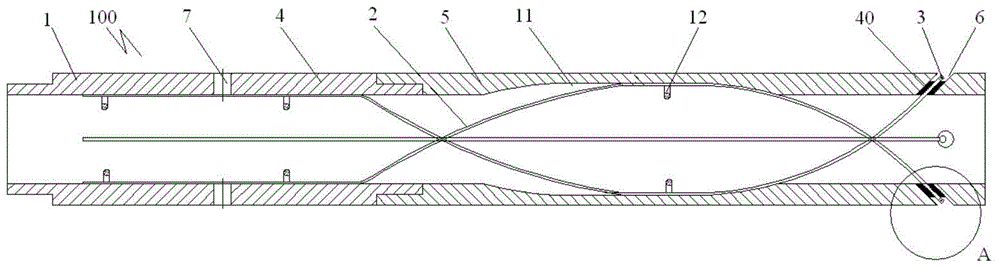

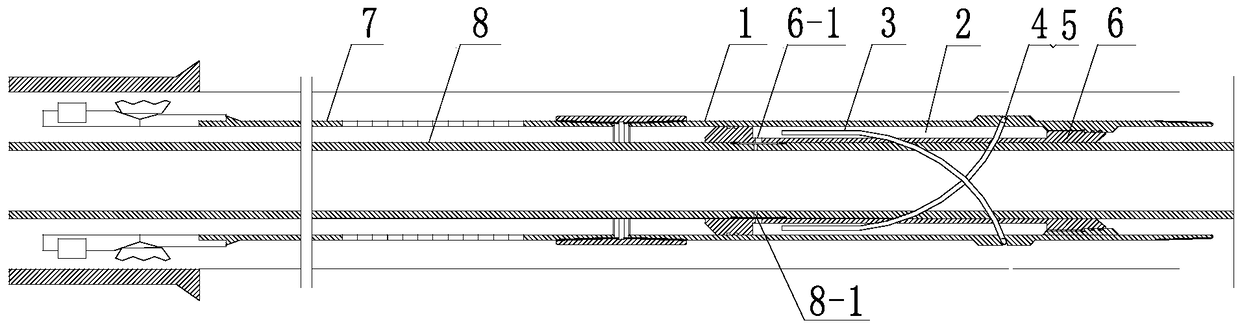

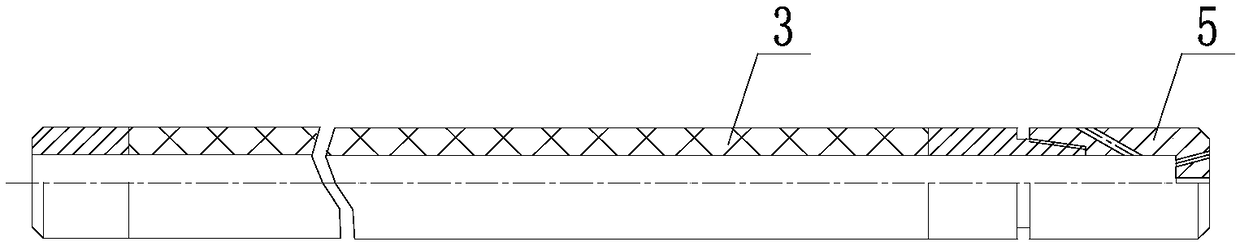

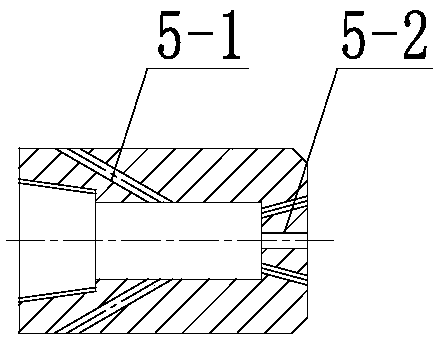

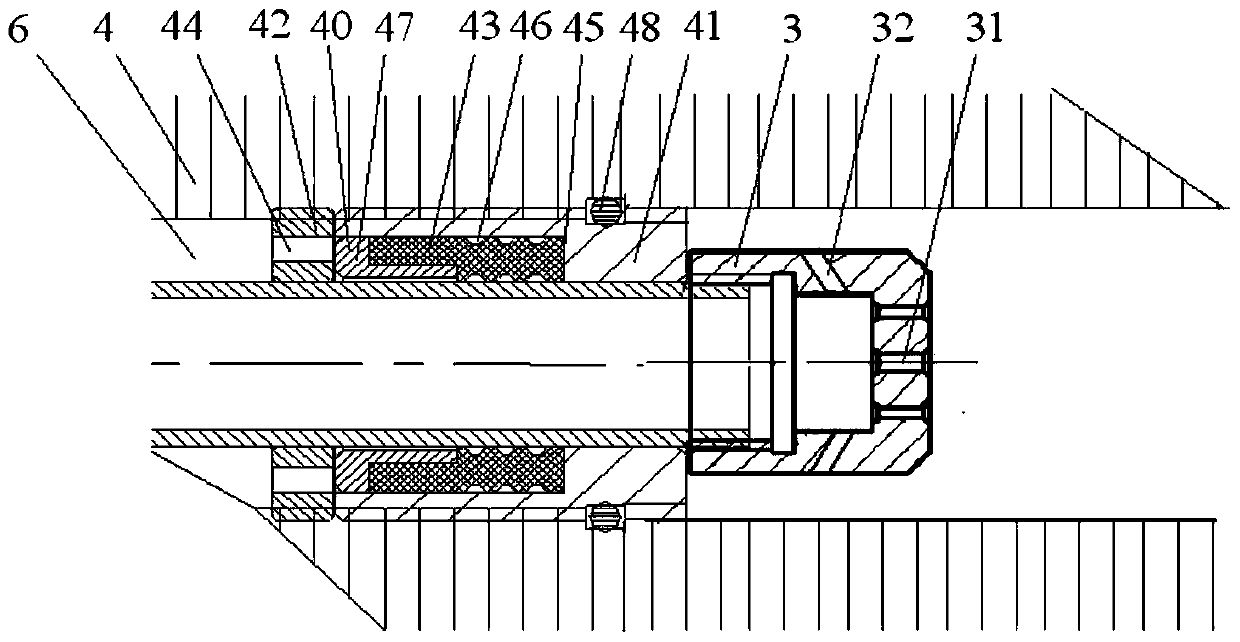

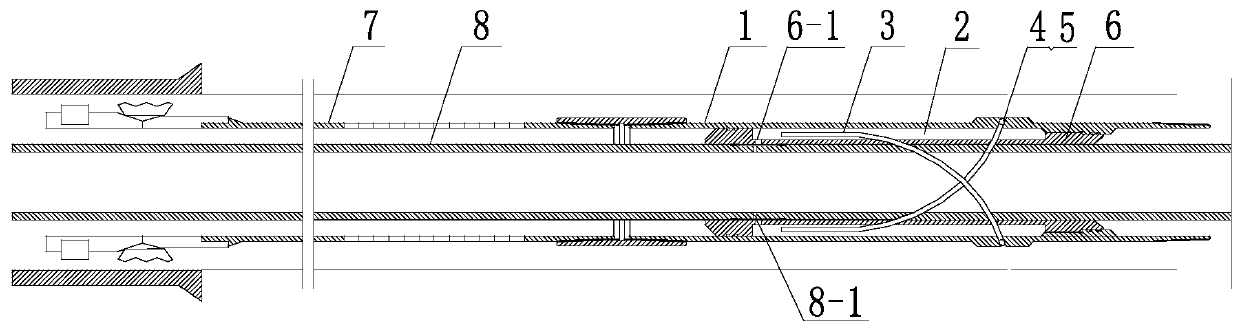

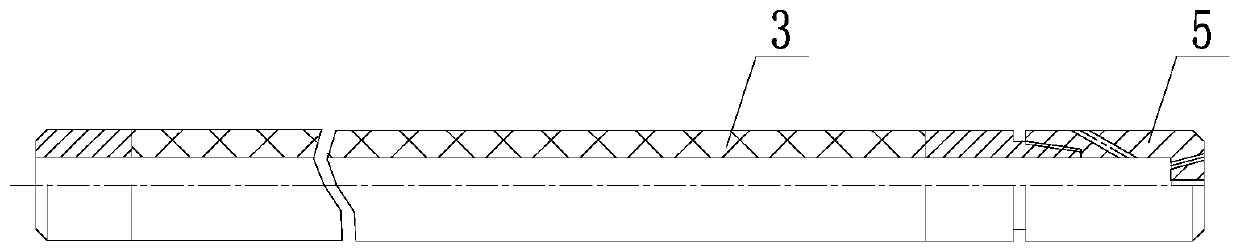

Spraying self-propelled multi-branch slim-hole completing tool and operation method

ActiveCN108729859ADepth is easy to controlSimple construction workLiquid/gas jet drillingFluid removalLine tubingEngineering

The invention discloses a spraying self-propelled multi-branch slim-hole completing tool. The tool comprises a spraying short joint connected with the lower end of a completing pipe string, a liner pipe in sealed connection with the spraying short joint is arranged inside the spraying short joint, an annular space with upper and lower sealed portions is formed between the liner pipe and the spraying short joint, a pressure transfer hole communicated with the annular space is formed in the liner pipe, a plurality of branch slim pipelines evenly distributed in the peripheral direction are arranged inside the annular space, inlets of the branch slim pipelines are formed inside the annular space, the outlets of the branch slim pipelines penetrate through the side wall of the spraying short joint, the branch slim pipelines are connected with the side wall of the spraying short joint through a pipeline sealing joint, and self-propelled nozzles are connected to the outlets of the branch slimpipelines. The invention further discloses an operation method of the spraying self-propelled multi-branch slim-hole completing tool. The tool has the advantages that the processing radius is large, the slim hole depth is controllable, and field operation is easy and reliable.

Owner:CHINA NAT OFFSHORE OIL CORP +1

External combustion propulsion engine

ActiveCN103939236BReduce volumeImprove power densityJet propulsion plantsExternal combustion engineProcess engineering

The invention discloses an external combustion propelling engine. The external combustion propelling engine comprises a liquid working medium pressure-bearing storage tank, a working medium heating fluid channel, a combustion chamber and a propelling nozzle. The bearing capacity of the liquid working medium pressure-bearing storage tank is larger than 2MPa. The combustion chamber transfers heat to the working medium heating fluid channel. The working medium heating fluid channel is communicated with the propelling nozzle. The propelling nozzle outputs power. The liquid working medium pressure-bearing storage tank is communicated with the working medium heating fluid channel in an automatically flowing mode. The combustion chamber transfers heat to the liquid working medium pressure-bearing storage tank or the pressure-bearing storage tank is communicated with the working medium heating fluid channel and the combustion chamber transfers heat to the liquid working medium pressure-bearing storage tank. The external combustion propelling engine is small in size, high in power density, low in manufacturing cost and capable of being used as an engine of aircrafts such as a target drone.

Owner:JIANGSU ETERN

An oil and gas extraction device and method

ActiveCN105443085BPosition is easy to controlEasy to control the lengthFluid removalThermodynamicsPropelling nozzle

The invention relates to an oil gas exploitation apparatus and method. The apparatus includes at least an exploitation unit, a needle tubing, and a self-propelled nozzle arranged at a second end of the needle tubing. The exploitation unit includes a jet pipe nipple and an adjusting pipe nipple detachably connected to the jet pipe nipple, wherein penetrating installation holes are arranged on a sidewall of the jet pipe nipple, and the adjusting pipe nipple is provided with oil holes for the oil gas flowing from a stratum into an inner cavity of the exploitation unit. In the original state, a first end of the needle tubing is arranged in the inner cavity of the exploitation apparatus. The second end of the needle tubing is inserted in the installation holes. During a process for pumping the liquid to the exploitation apparatus, the needle tubing extends in a storage stratum so as to form an exploitation pore passage. In the oil gas exploitation process, the oil gas exploitation apparatus has high effectiveness for the reconstruction of the storage stratum and good oil gas output.

Owner:CHINA PETROLEUM & CHEM CORP +1

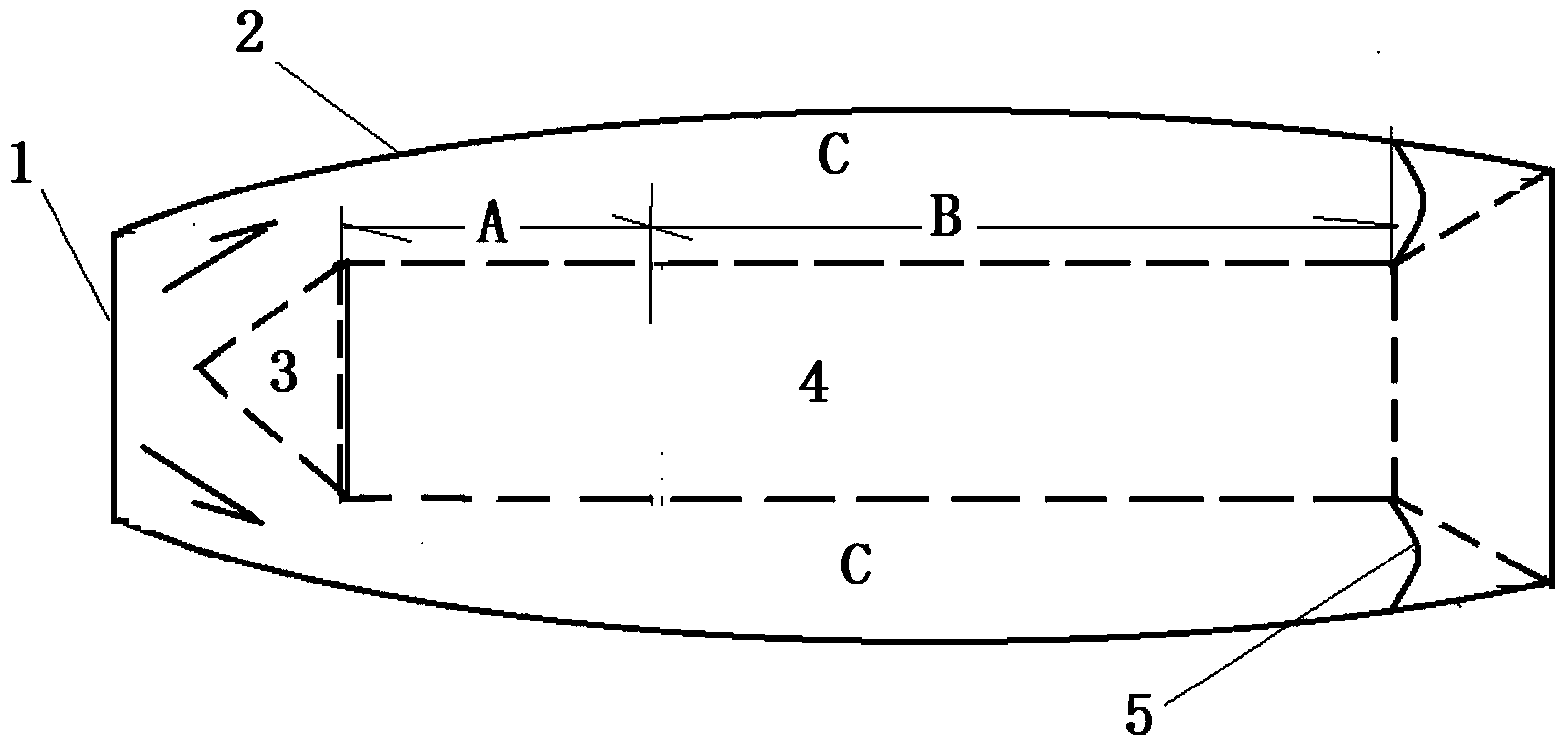

Airflow heat insulation airspace ramjet

InactiveCN104234869AKeep the advantagesPlay a role in energy savingRam jet enginesRamjetCombustion chamber

The invention provides an airflow heat insulation airspace ramjet comprising an air inlet passage (diffuser), an ignition device, a combustion chamber and a propelling nozzle. The airflow heat insulation airspace ramjet is characterized in that the propelling nozzle is composed of a shell (2) and an inner pipe (4), an air chamber (C) is formed between the shell (2) and the inner pipe (4), and an air inlet is arranged in the A-section of the inner pipe (4); when an aircraft flies, kinetic energy is converted into pressure energy in the process that head-on airflow passes through the air inlet passage, compressed air enters the combustion chamber to be mixed with fuel for constant-pressure combustion, and generated high-temperature combustion gas swells and accelerates in the inner pipe (4) prior to being discharged so as to generate thrust. The original advantages of the ramjet are retained, and meanwhile energy conservation and efficiency improvement are achieved.

Owner:吴润秀

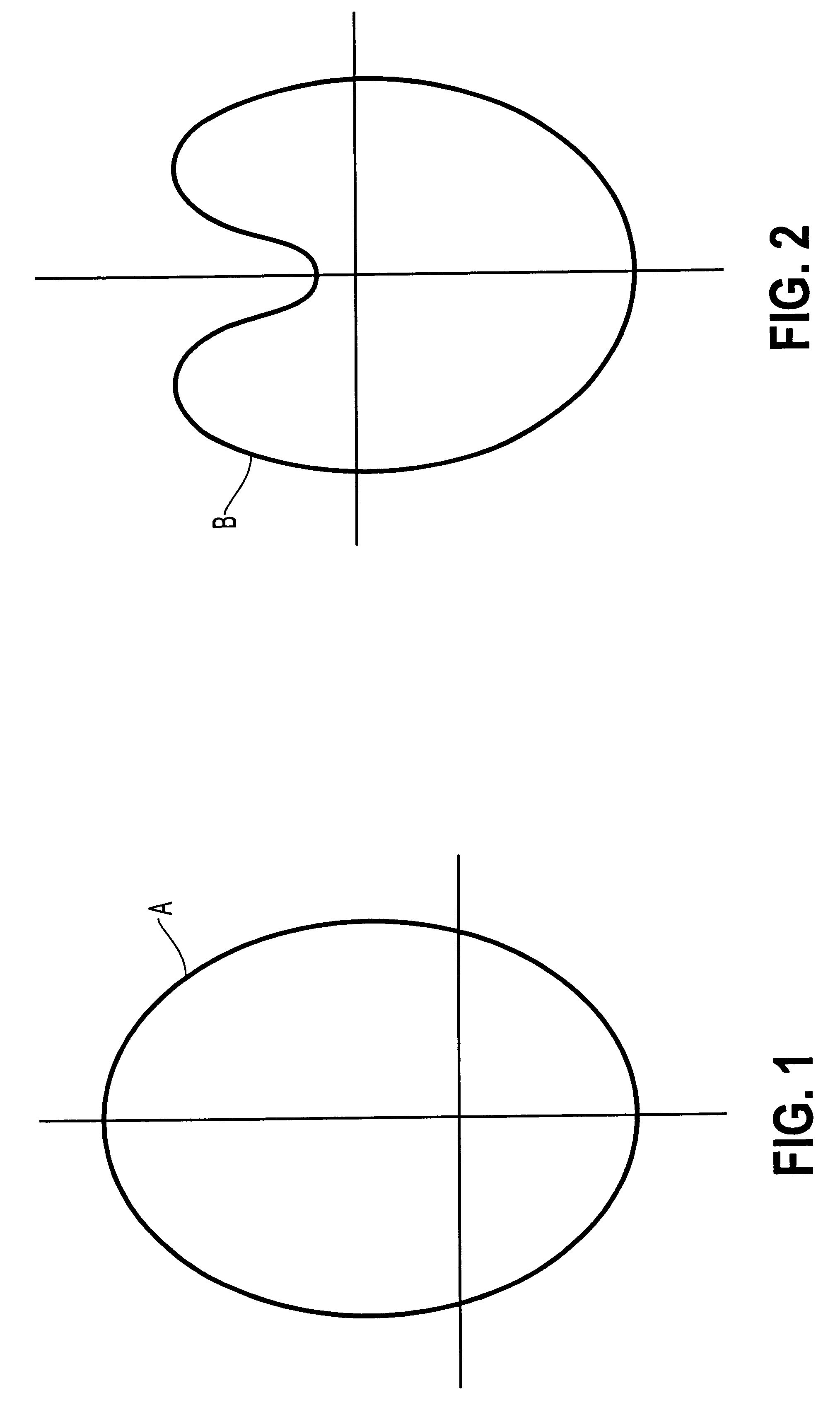

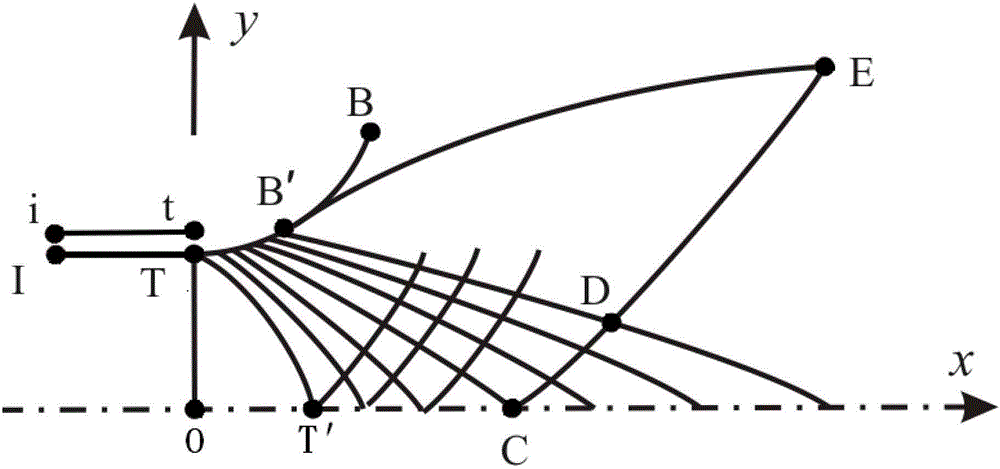

Supersonic non-uniform incoming flow maximum thrust nozzle and its wall surface determination method

ActiveCN103321779BImprove bindingIncrease thrustJet propulsion plantsMethod of characteristicsEngineering

The invention provides a supersonic non-uniform inflow maximum-thrust nozzle and a wall determination method therefor. The wall determination method for the supersonic non-uniform inflow maximum-thrust nozzle includes the steps of S1, determining an initial boundary of the supersonic non-uniform inflow maximum-thrust nozzle according to non-uniform inflow parameter; S2, determining a core area of the supersonic non-uniform inflow maximum-thrust nozzle according to the initial boundary by a method of characteristics; S3, performing iterative solution in the core area to determine wall profile of the supersonic non-uniform inflow maximum-thrust nozzle according to the principle of conservation of mass and the method of characteristics; and S4, determining the wall of the supersonic non-uniform inflow maximum-thrust nozzle according to the wall profile of the supersonic non-uniform inflow maximum-thrust nozzle. The supersonic non-uniform inflow maximum-thrust nozzle and the wall determination method therefor have the advantage that the maximum-thrust nozzle applicable to supersonic non-uniform inflows can be produced.

Owner:NAT UNIV OF DEFENSE TECH

Self-advancing and retreating type jet flow drill bit and drilling method

PendingCN114458157ASimple structureImprove reliabilityLiquid/gas jet drillingFluid removalEngineeringPipe

A drill bit end cover, a drill bit middle section and a drill bit rear section of the drill bit are sequentially in threaded connection, a coal breaking nozzle is in threaded connection with the drill bit end cover, a circumferential centralizing nozzle is in threaded connection with the drill bit middle section, and a propelling nozzle is in threaded connection with the drill bit rear section; the coal breaking pressure-bearing cavity and the propelling pressure-bearing cavity are separated through a pressure-bearing cavity baffle. The pressure adjusting spring is located in the coal breaking pressure-bearing cavity liquid inlet pipe. The coal breaking pressure-bearing cavity liquid inlet pipe is located at the axis of the coal breaking pressure-bearing cavity and welded to the drill bit middle section, and the propelling pressure-bearing cavity liquid inlet pipe is located at the axis of the propelling pressure-bearing cavity and welded to the drill bit rear section. The pressure regulating pipe is located in the propelling pressure-bearing cavity liquid inlet pipe and the coal breaking pressure-bearing cavity liquid inlet pipe, and the outer wall of the pressure regulating pipe and the inner walls of the propelling pressure-bearing cavity and the coal breaking pressure-bearing cavity liquid inlet pipe are sealed through gaps.

Owner:CHONGQING UNIV

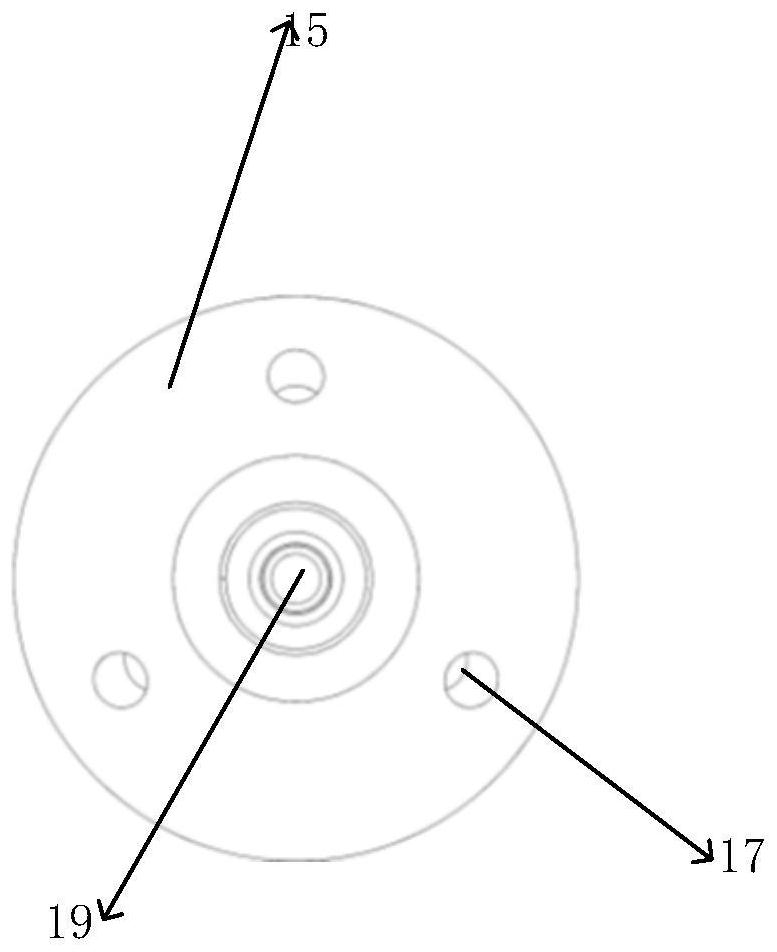

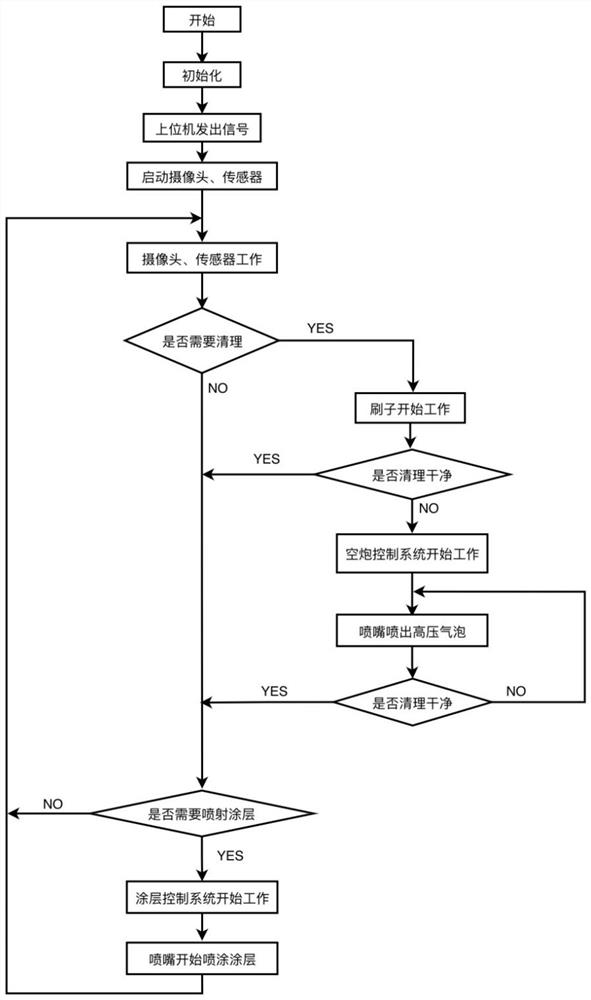

Underwater cleaning robot for outer wall of ship

PendingCN114516388AReduce lossAvoid corrosionVessel cleaningHullsMarine engineeringStructural engineering

The invention discloses an underwater cleaning robot for the outer wall of a ship. The underwater cleaning robot comprises a robot body; the cleaning brush assembly is mounted at the front end of the robot main body through a mechanical arm; the camera is used for shooting the cleaning range of the cleaning brush assembly; the cavitation bubble device is arranged in the robot main body and emits high-pressure cavitation bubbles to the cleaning range through a propelling nozzle mounted at the front end of the robot main body; the spraying assembly is used for spraying the cleaned area when the coating of the outer wall of the ship is damaged after cleaning is completed; the four permanent magnet universal wheel assemblies are arranged on the two sides of the bottom of the robot body correspondingly and used for being attracted to the outer wall of the ship and driving the robot body to move. The robot firstly adopts a cleaning brush and then adopts a cavitation device for cleaning, so that the loss of the outer wall coating of the ship can be reduced. And by arranging the spraying assembly, repairing and spraying can be conducted in time after the coating is lost, and seawater is prevented from corroding the damaged position of the coating.

Owner:SHANGHAI OCEAN UNIV

Hydraulic jet grouting drill bit

The invention relates to a hydraulic jet grouting drill bit. The hydraulic jet grouting drill bit is characterized in that the hydraulic jet grouting drill bit comprises a drill bit steel body, a jackscrew and a mandrel, a cutting blank block is arranged at one end of the drill bit steel body, the other end of the drill bit steel body is connected with a rotating body, and one end of the mandrel penetrates through a hollow part of the rotating body to be connected with the jackscrew. The jackscrew is arranged in the hollow part of the drill bit steel body, and a central hole of the jackscrew,a central hole of the mandrel and a central hole of the cutting blank block share the same central line. A rotational flow cavity is formed in the rotating body and communicates with the center hole of the mandrel, and one or more sets of eccentric rotating nozzles are further arranged on the rotating body and communicate with the rotational flow cavity. A plurality of propelling nozzles are further arranged at the tail of the drill bit and communicate with the central hole of the mandrel. High-pressure liquid flow is adopted as a driving source to generate rotating power, rear propelling force and front-end high-pressure jet flow, the jet flow rock breaking capacity is achieved, the drilling efficiency and the drilling depth can be improved, and extra large power system driving is not needed.

Owner:BEIJING INST OF EXPLORATION ENG

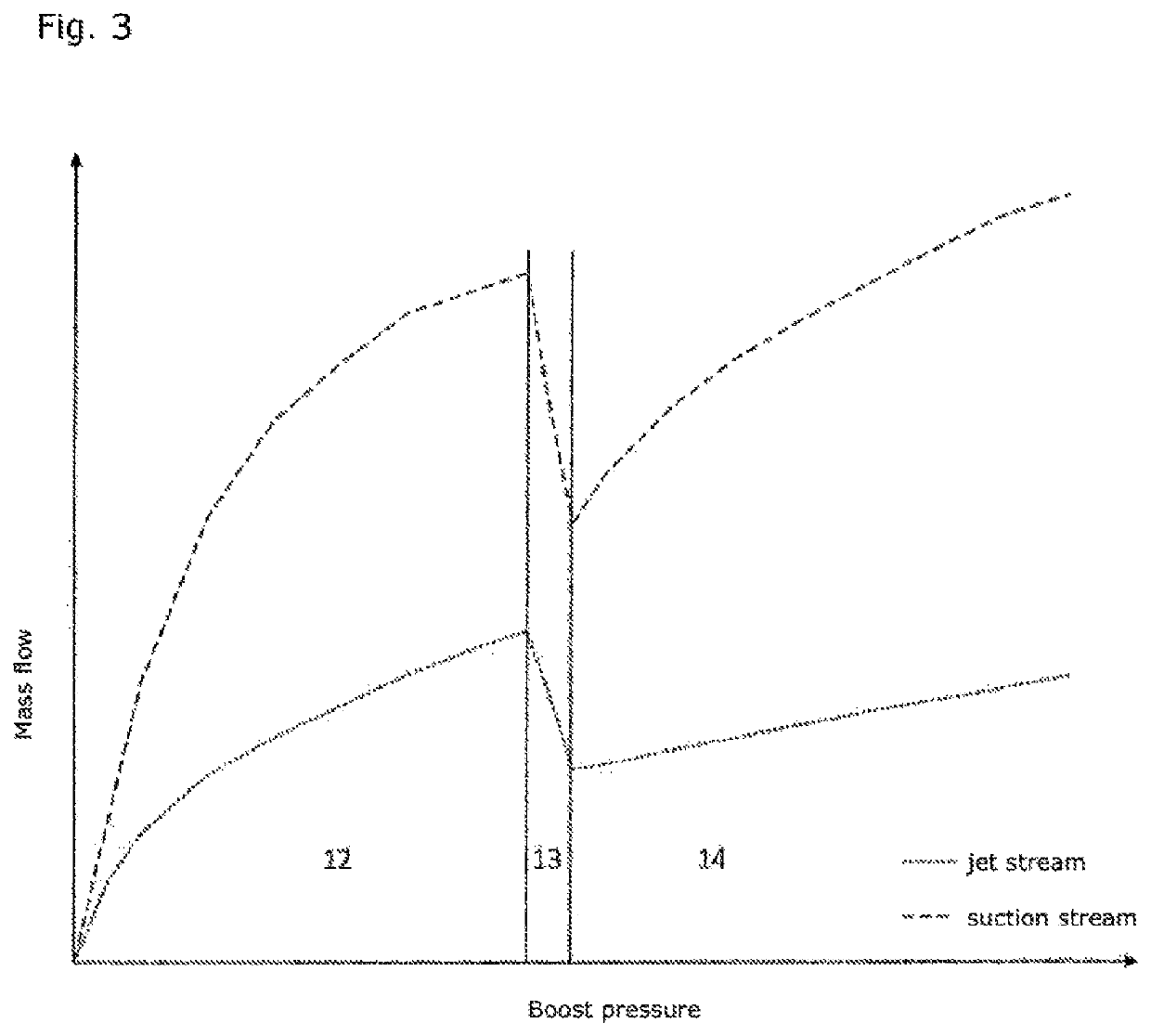

Switched suction jet pump

ActiveUS11022149B2Reduce nozzle cross-sectionCompact structureJet pumpsMachines/enginesSuction forceEngineering

The invention relates to a single-stage or multistage suction jet pump comprising a propelling nozzle (5), one or more suction nozzles (2), a diffuser (7), and a volume flow limiting valve in or directly in front of the propelling nozzle. The volume flow limiting valve has a valve element (4) in the overpressure region (1) of the suction jet pump, said valve element having an opening (8) with a cross-sectional area which is smaller than the cross-sectional area of the propelling nozzle (5). The valve element spans at least one additional gap opening (9) which first releases the cross-section of the gap opening (9) when the pressure difference between the overpressure region (1) and the suction region (2) increases and which switches in the event of a defined large pressure drop and the valve element (4) reduces or closes the cross-section of the gap opening (9) such that the volume flow flowing over the opening (8) is limited to a defined level even in the event of a further increasing pressure difference.

Owner:POLYTEC PLASTICS GERMANY

Muzzle brake with propelling nozzle for recoil control

Owner:PRICE DONALD H

A jet self-propelled multi-branch slimhole completion tool and its operation method

ActiveCN108729859BDepth is easy to controlSimple construction workLiquid/gas jet drillingFluid removalLine tubingStructural engineering

The invention discloses a spraying self-propelled multi-branch slim-hole completing tool. The tool comprises a spraying short joint connected with the lower end of a completing pipe string, a liner pipe in sealed connection with the spraying short joint is arranged inside the spraying short joint, an annular space with upper and lower sealed portions is formed between the liner pipe and the spraying short joint, a pressure transfer hole communicated with the annular space is formed in the liner pipe, a plurality of branch slim pipelines evenly distributed in the peripheral direction are arranged inside the annular space, inlets of the branch slim pipelines are formed inside the annular space, the outlets of the branch slim pipelines penetrate through the side wall of the spraying short joint, the branch slim pipelines are connected with the side wall of the spraying short joint through a pipeline sealing joint, and self-propelled nozzles are connected to the outlets of the branch slimpipelines. The invention further discloses an operation method of the spraying self-propelled multi-branch slim-hole completing tool. The tool has the advantages that the processing radius is large, the slim hole depth is controllable, and field operation is easy and reliable.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Fuel delivery device

The fuel delivery device (12) has a receptacle (16) arranged in a storage tank (10) and a delivery unit (20) delivering fuel from the receptacle (16) to the internal combustion engine (14) of a motor vehicle. Further, there is provided at least one suction jet pump (40) which delivers fuel from the storage tank (10) into the receptacle (16). The suction jet pump (40) is fastened to an upper edge area (17) of the receptacle (16) as a separate constructional unit. The suction jet pump (40) is formed by a constructional unit having a propelling nozzle (41), a connection (43) for a propelling line (44), which connection (43) opens into the propelling nozzle (41), a mixing pipe (42) following the propelling nozzle (41), and a connection (45) for a suction line (46), which connection (45) opens into the mixing pipe (42). Two walls (48) located at a distance from one another project downward from the constructional unit (40), and the constructional unit (40) is mounted on the edge (17) of the receptacle (16) from the top, wherein the edge (17) of the receptacle (16) is introduced between the two walls (48). The suction line (46) connected to the suction jet pump (40) opens into the storage tank (10) remote of the receptacle (16).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com