Patents

Literature

361results about How to "Expand smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

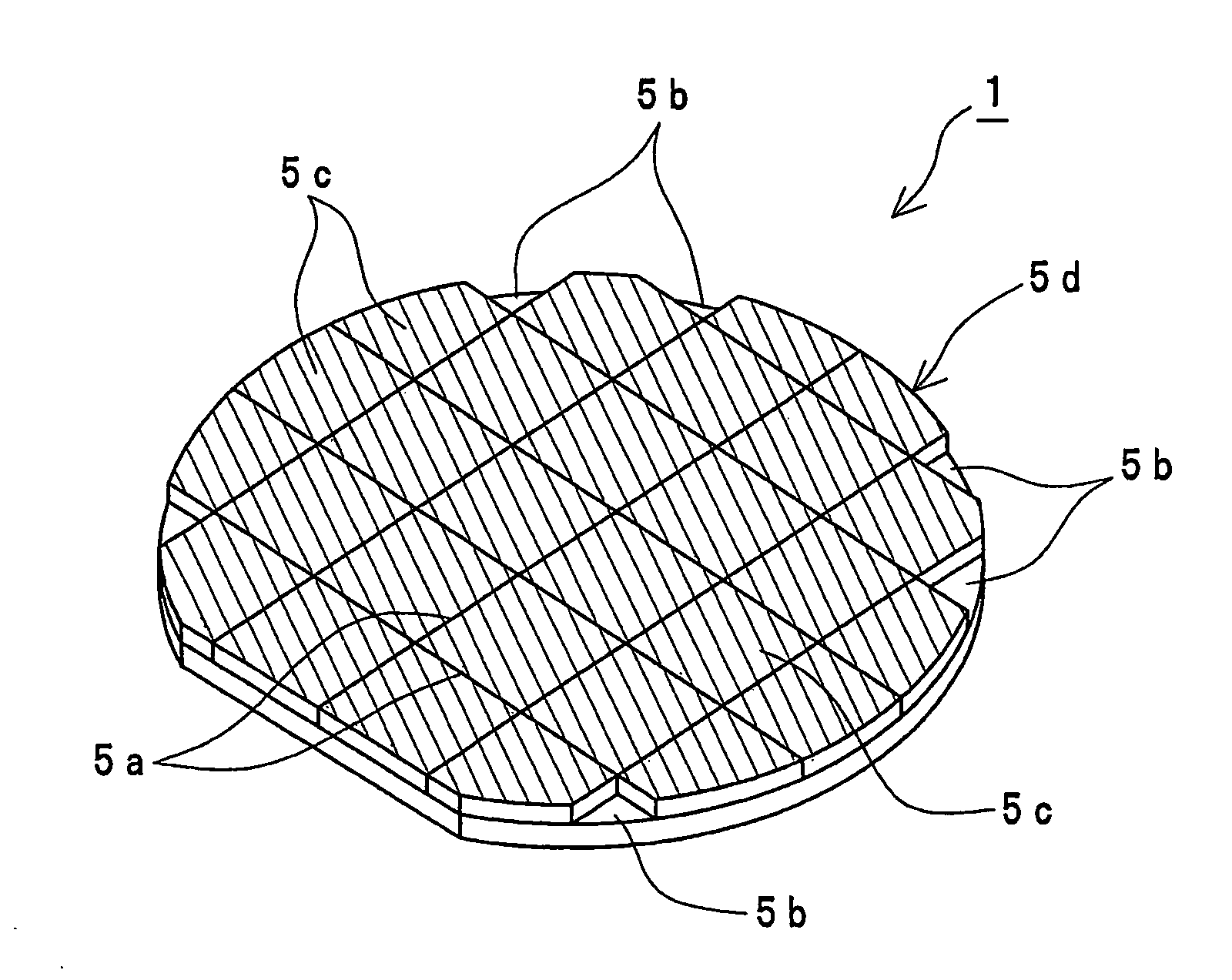

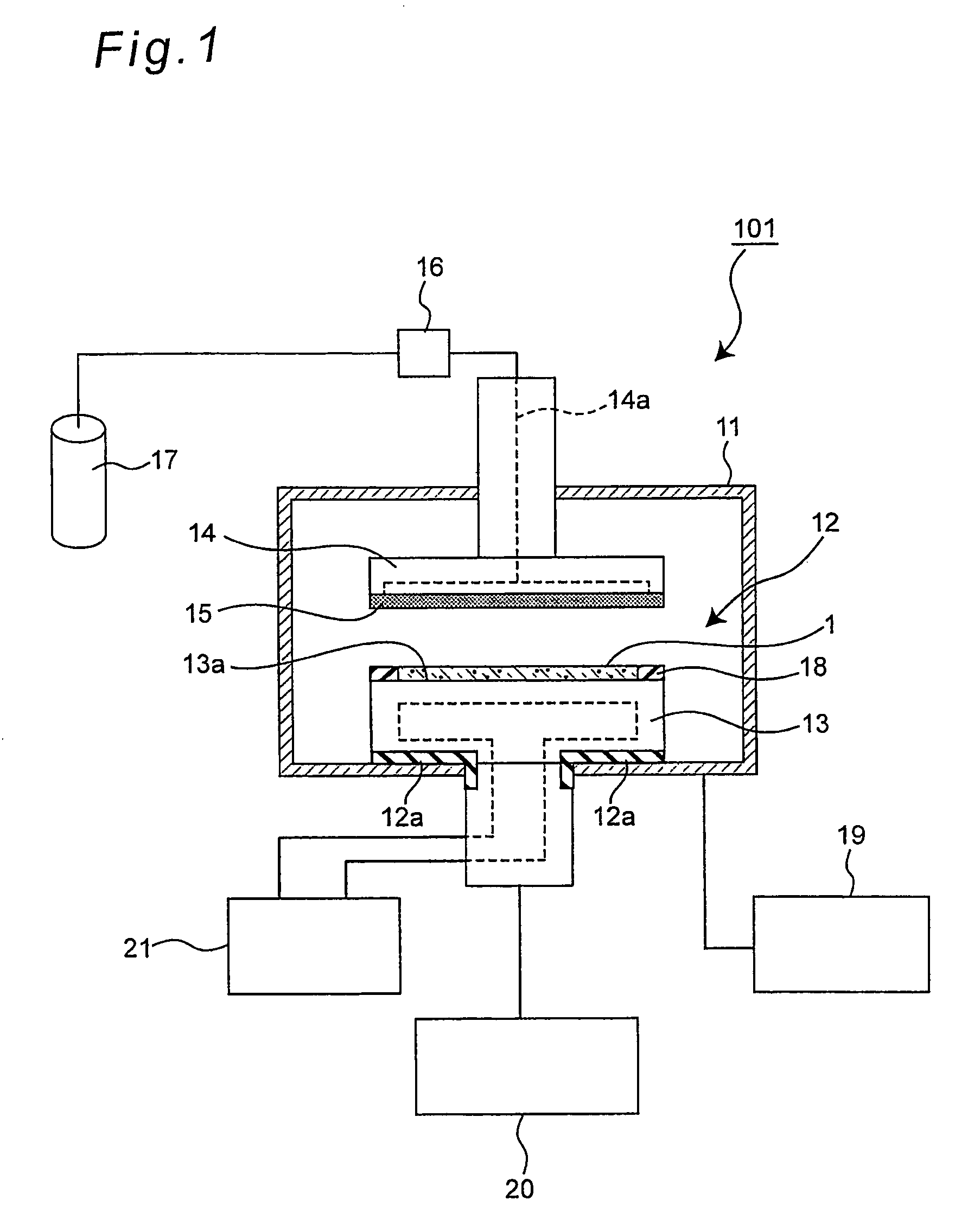

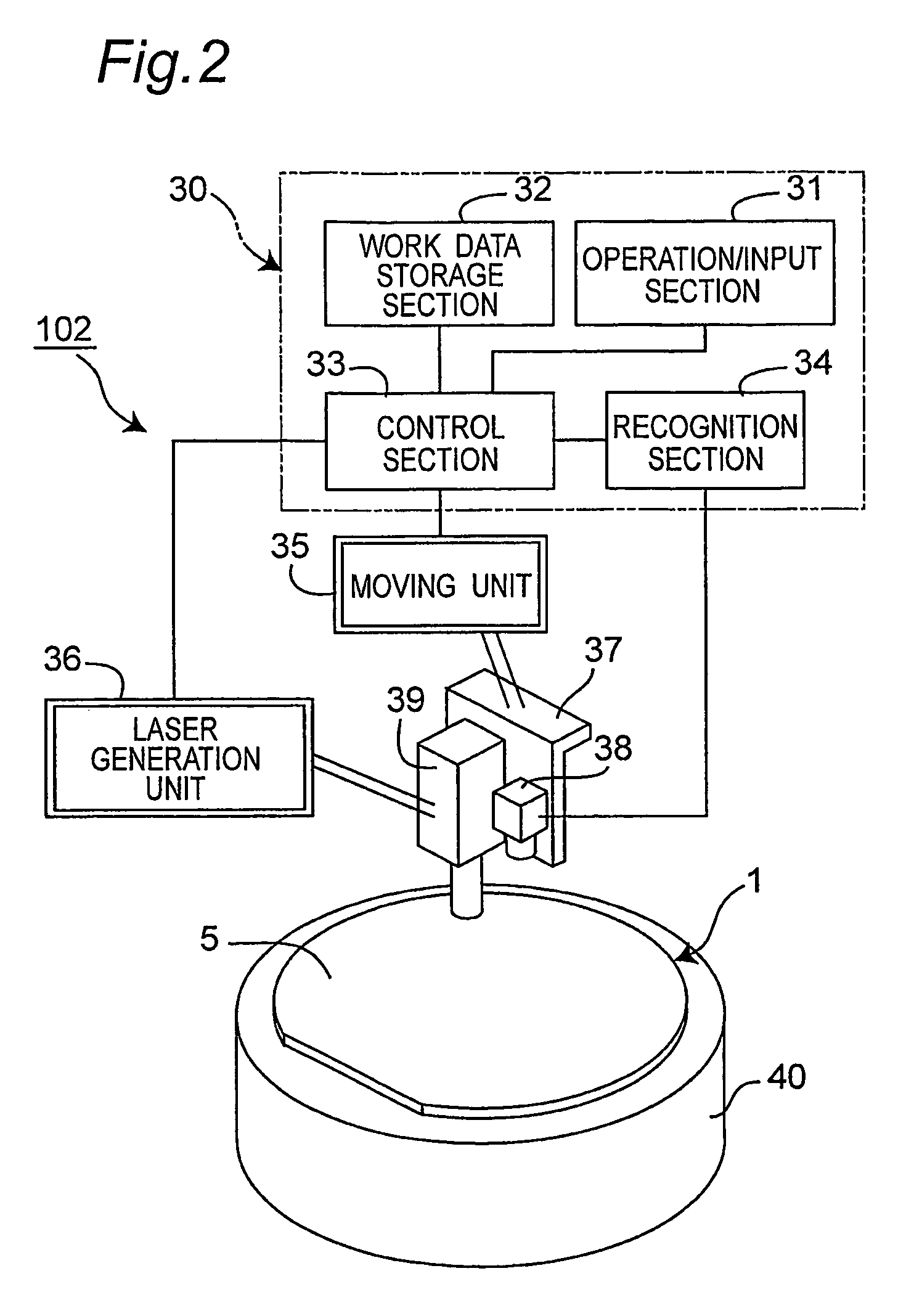

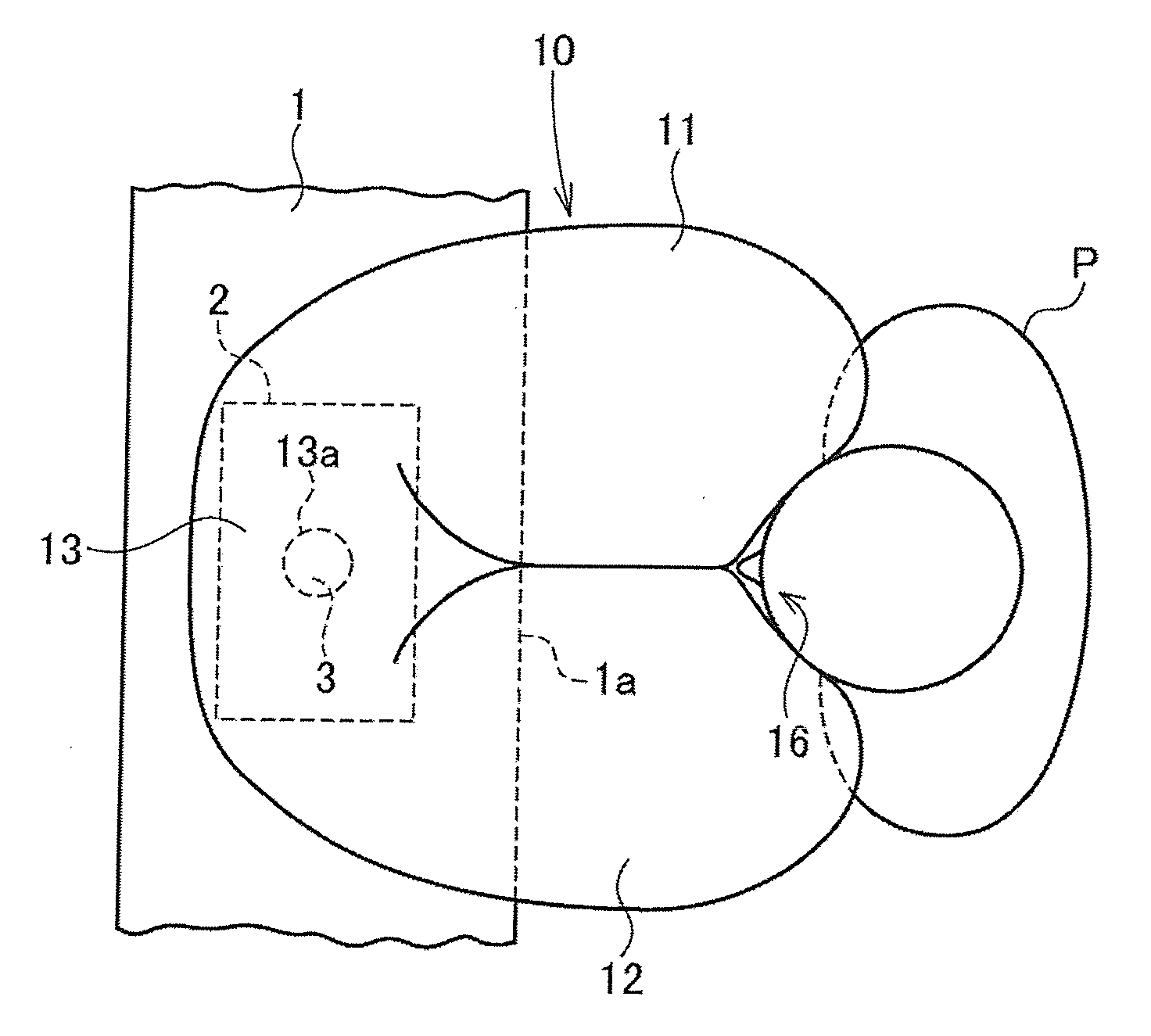

Method for dividing semiconductor wafer and manufacturing method for semiconductor devices

ActiveUS7927973B2Formation of comparatively small pieces in the semiconductor wafer can be preventedInhibition formationSemiconductor/solid-state device manufacturingSplit linesEngineering

In a semiconductor wafer including a plurality of imaginary-divided-regions which are partitioned by imaginary-dividing-lines that are respectively arranged in a grid-like arrangement on the semiconductor wafer and a circumferential line that is the outer periphery outline of the semiconductor wafer, a mask is placed so as to expose an entirety of surfaces of the wafer corresponding to respective removal-regions. The removal-regions are regions in approximately triangular form partitioned by the circumferential line of the wafer and the imaginary-dividing-lines. Then, plasma etching is performed on a mask placement-side surface of the wafer, by which the semiconductor wafer is divided into the individual semiconductor devices along dividing lines while portions corresponding to the removal-regions of the wafer are removed.

Owner:PANASONIC CORP

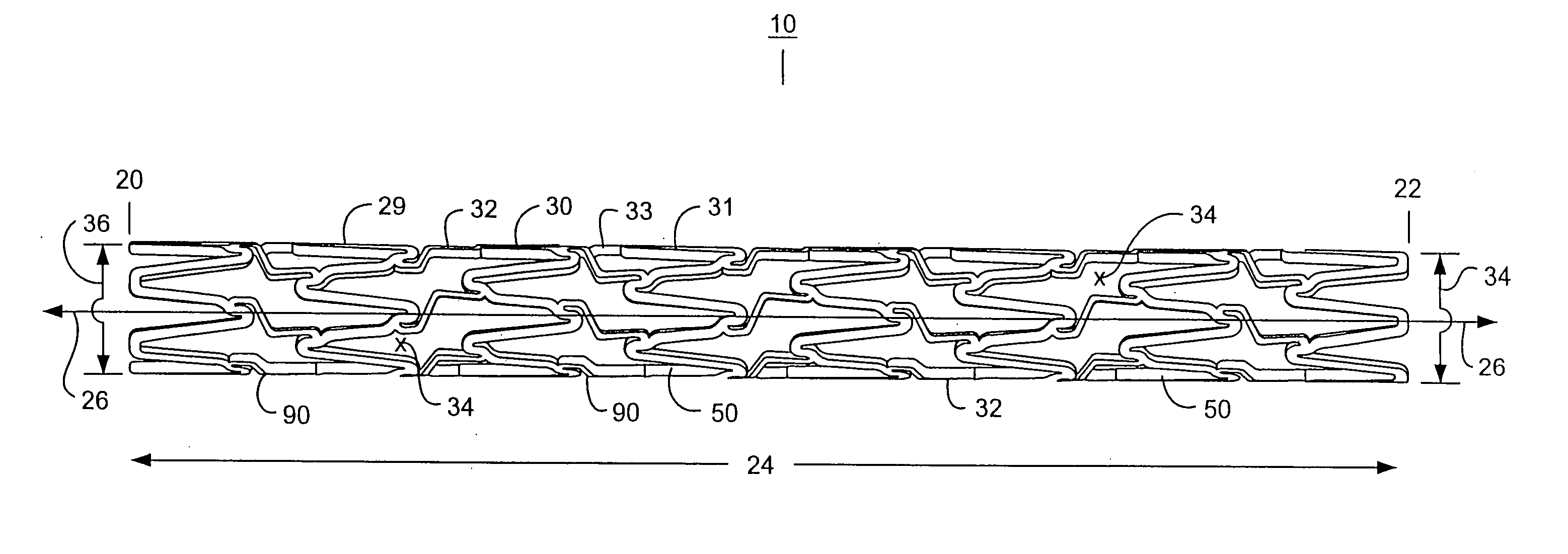

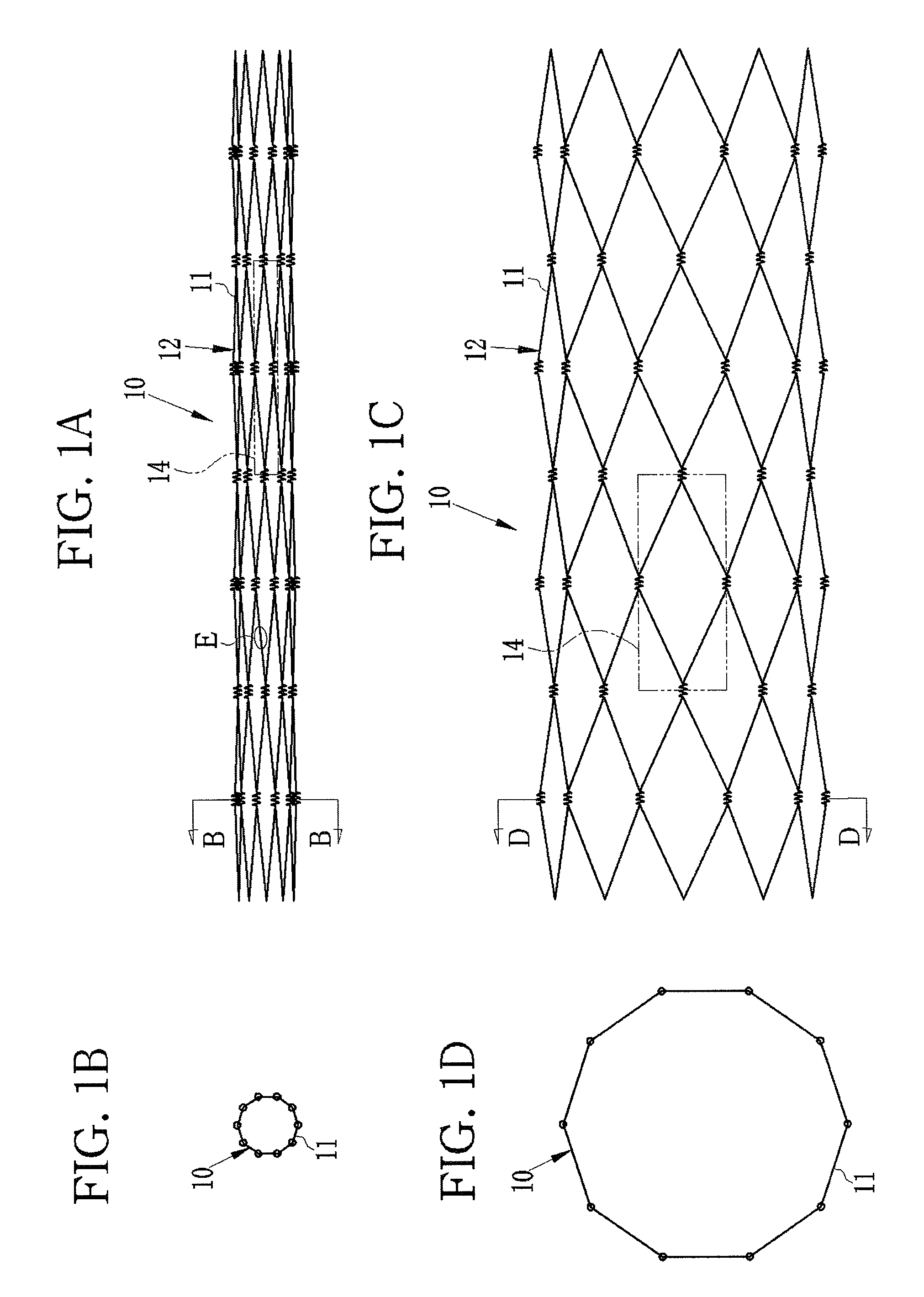

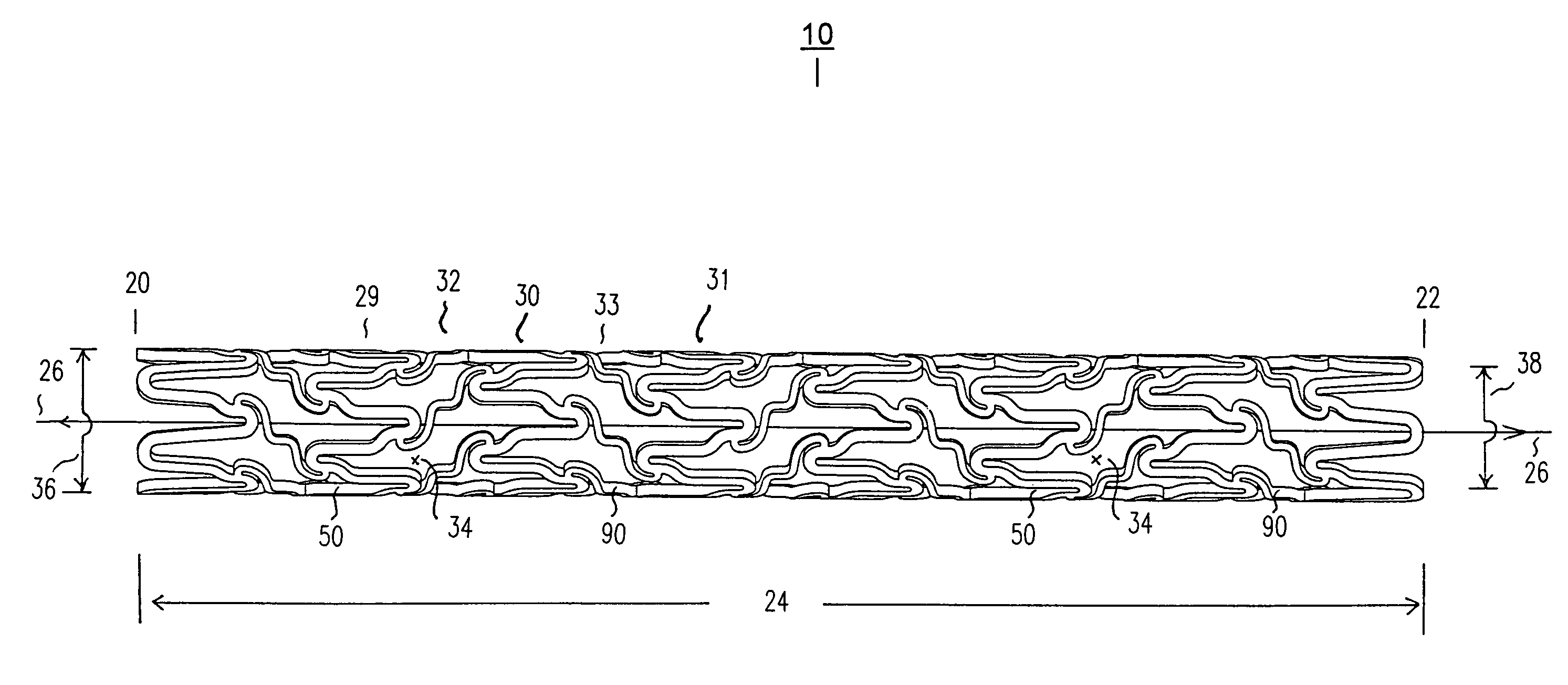

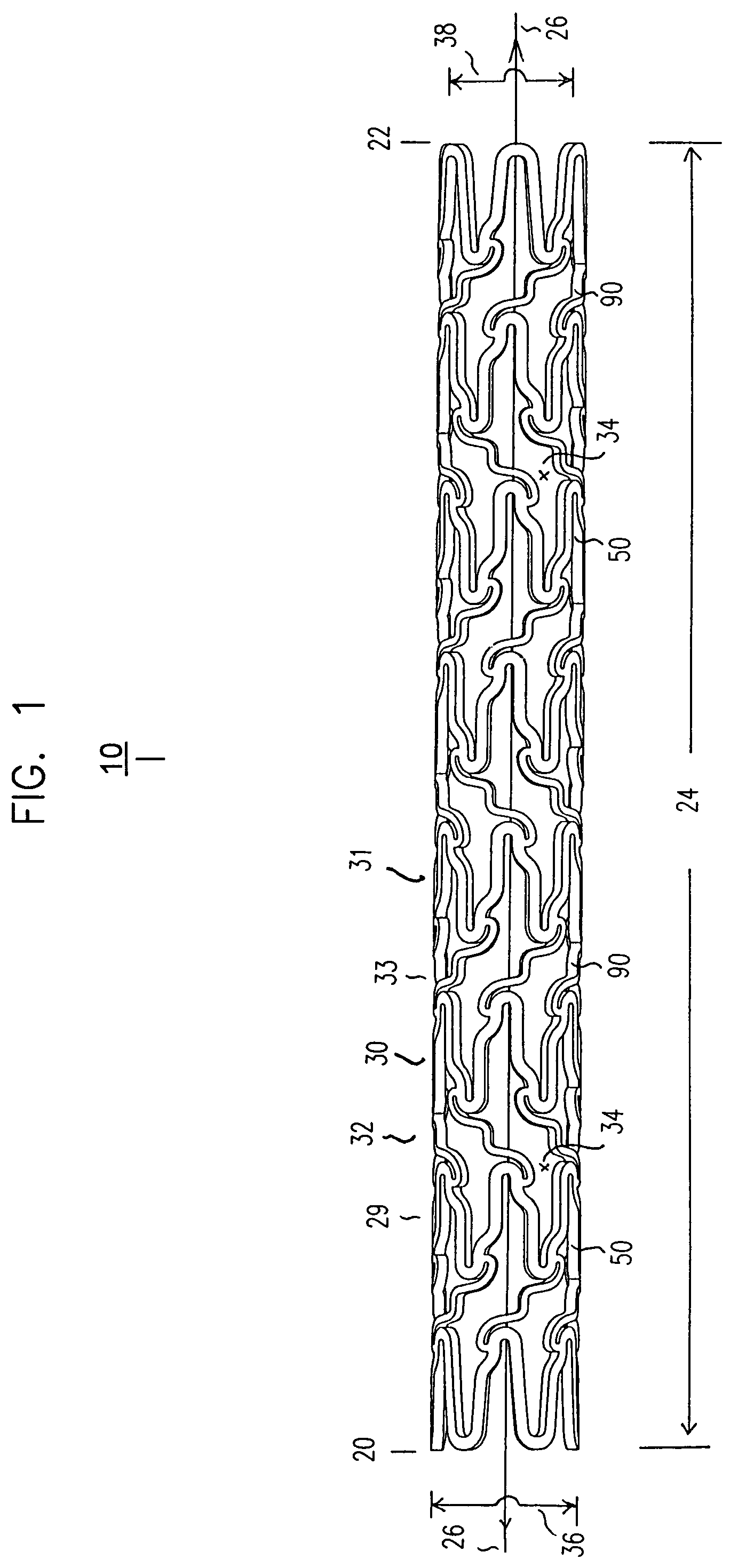

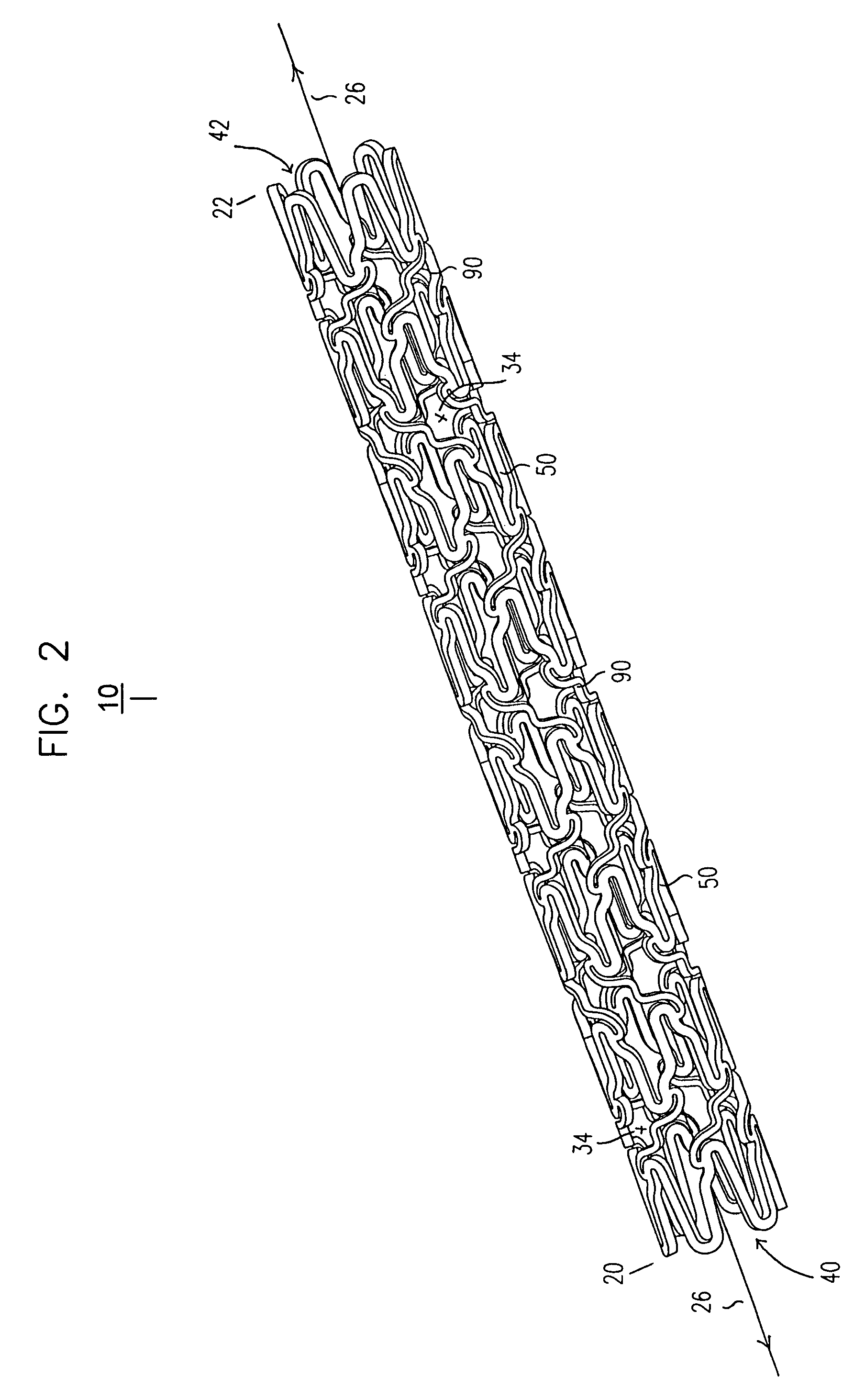

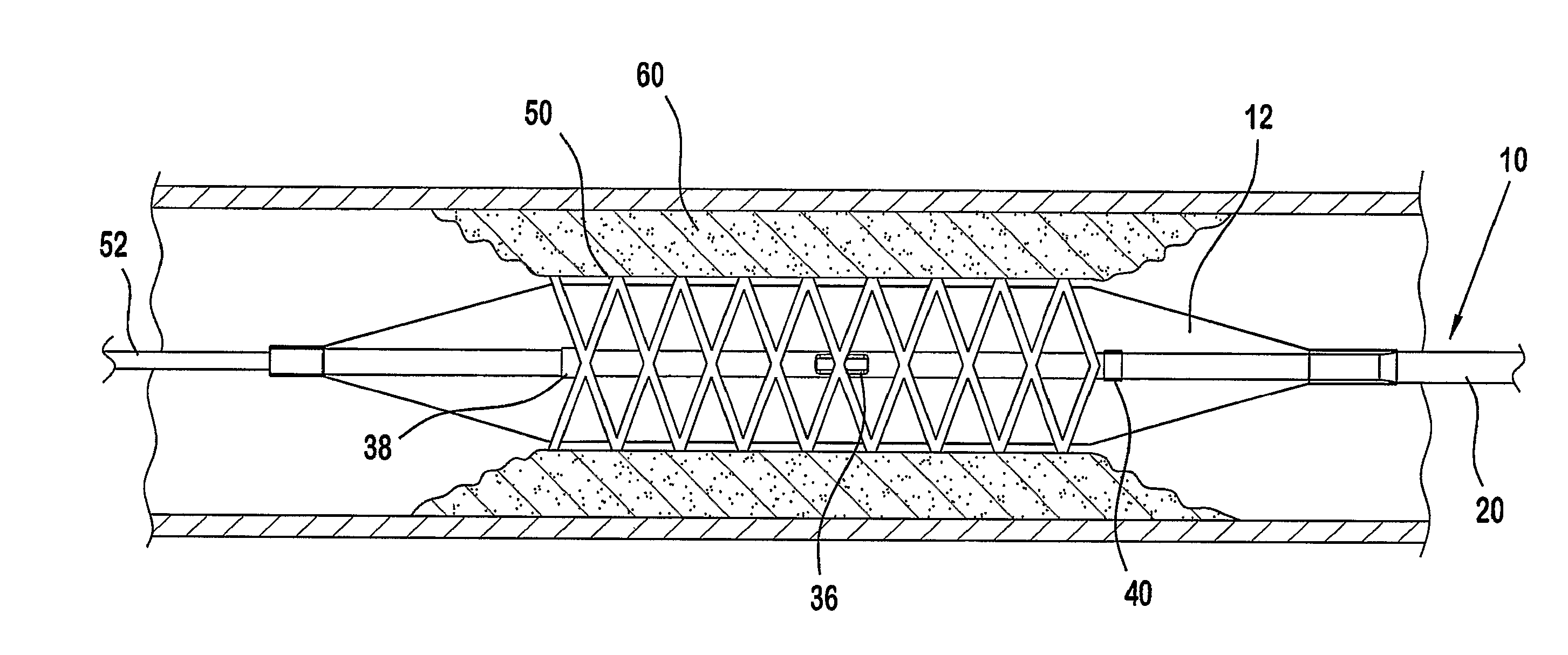

Intravascular stent and assembly

InactiveUS20040133271A1Maximum possible flexibility and conformabilityOptimal metal fractionStentsSurgeryVascular lumenIntravascular stent

Various intravascular stents, such as intracoronary stents, include improved expansion and connecting strut designs. Such stents can be both very flexible and fully cover vessel surface inside the vascular lumen, and be well designed for both the delivery phase and the deployed phase of the stent life cycle.

Owner:BOSTON SCI SCIMED INC

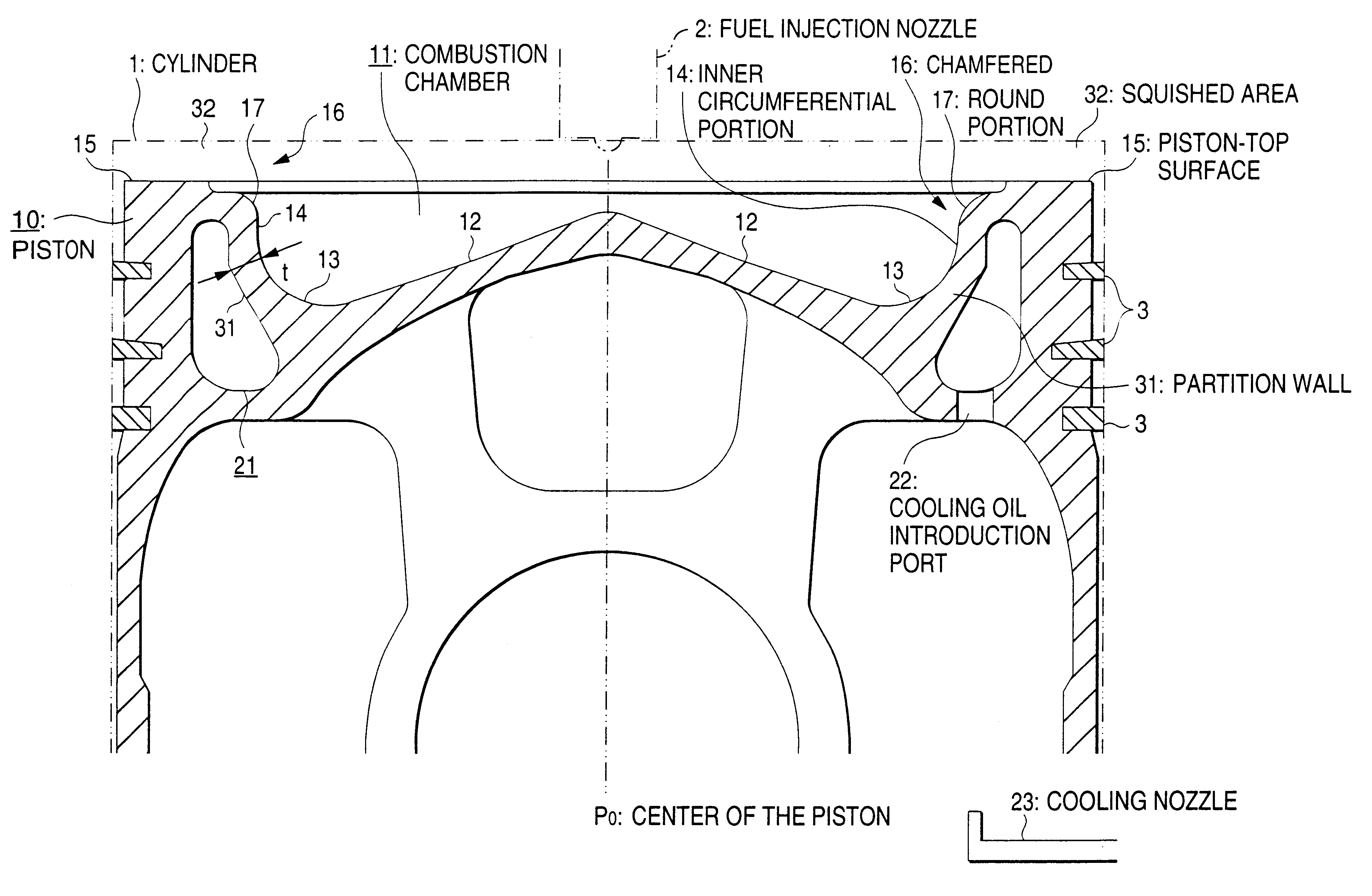

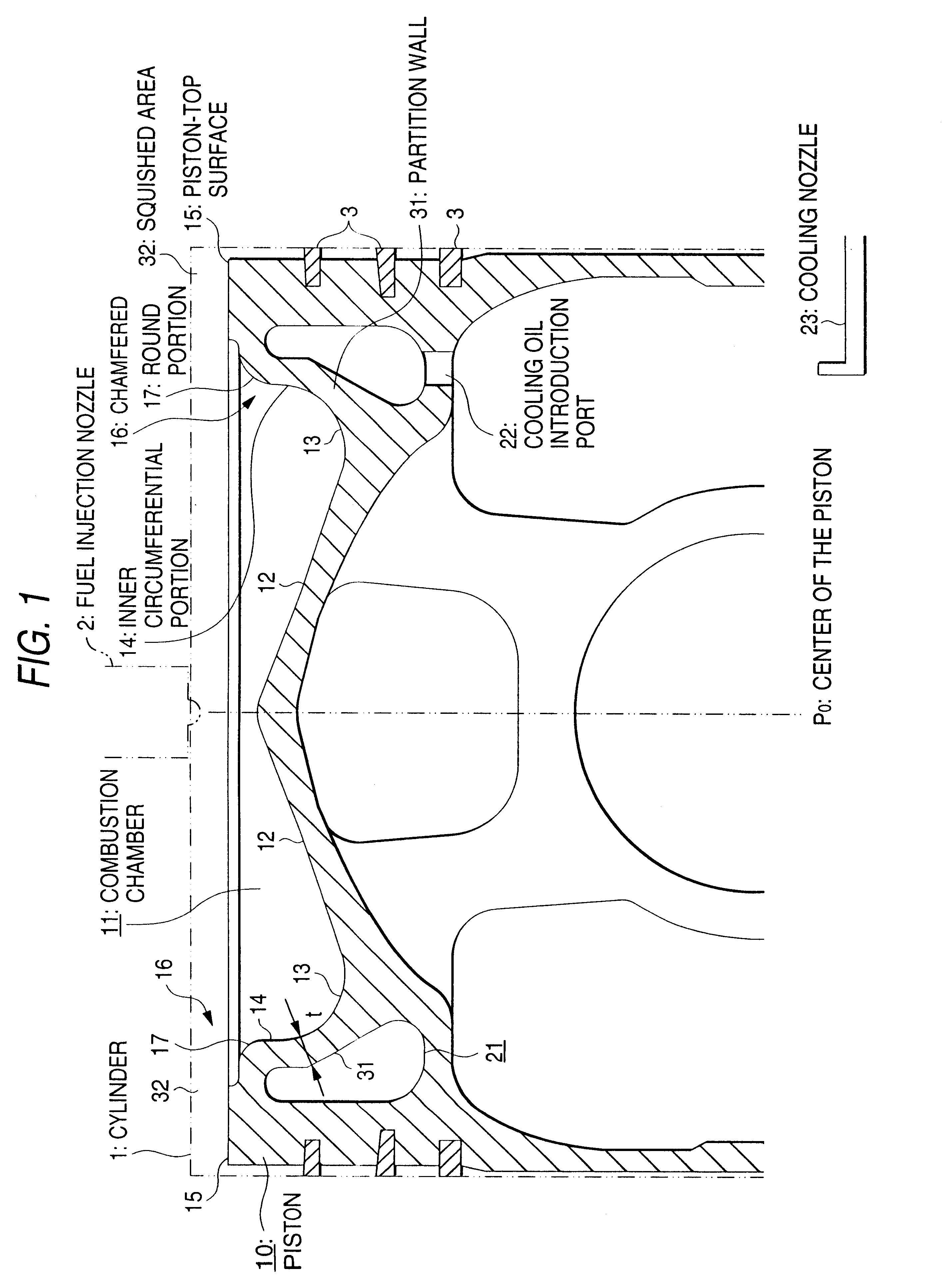

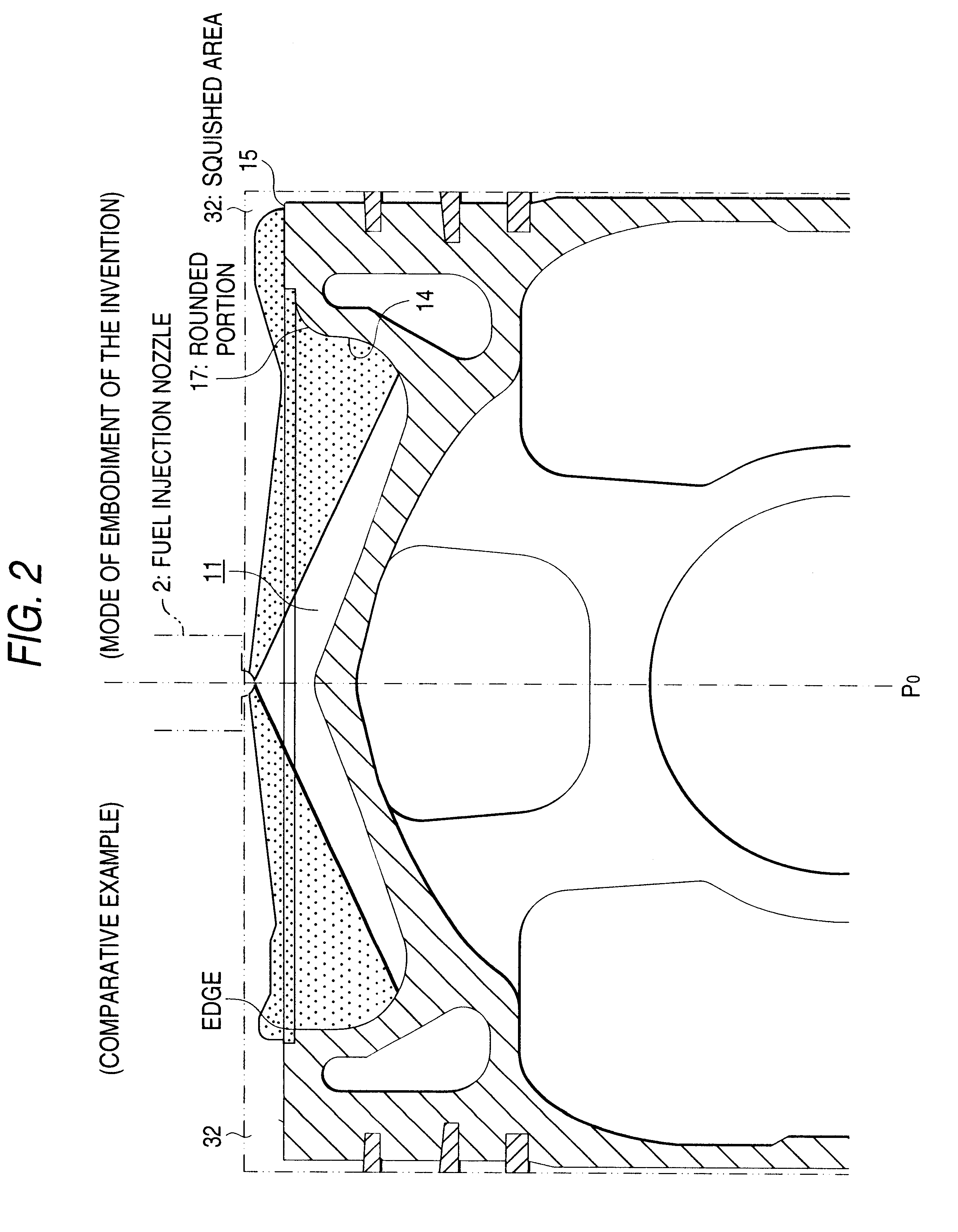

Piston for internal combustion engines

InactiveUS6314933B1Low temperature resistanceIncreased durabilityInternal combustion piston enginesAir coolingCombustion chamberReciprocating motion

A piston for internal combustion engines, capable of being manufactured easily and improving the durability of a combustion chamber, moved reciprocatingly in a cylinder of an internal combustion engine, and provided in a top surface thereof with a combustion chamber formed by recessing the same top surface, and in an outer circumferential wall of the combustion chamber with a cooling cavity the inner diameter of a lower portion of an inner circumferential surface of which is set smaller than that of an upper portion thereof, wherein a cross-sectionally angular portion defined by an upper edge portion, at which the combustion chamber is opened in the interior of a cylinder, of an inner circumferential surface of the combustion chamber and a piston-top surface is chamfered greatly in conformity with the cross-sectional shape of the upper portion of the inner circumferential surface of the cooling cavity to such an extent that the thickness of an upper portion of an inner circumferential wall of the cooling cavity does not greatly vary.

Owner:KOMATSU LTD

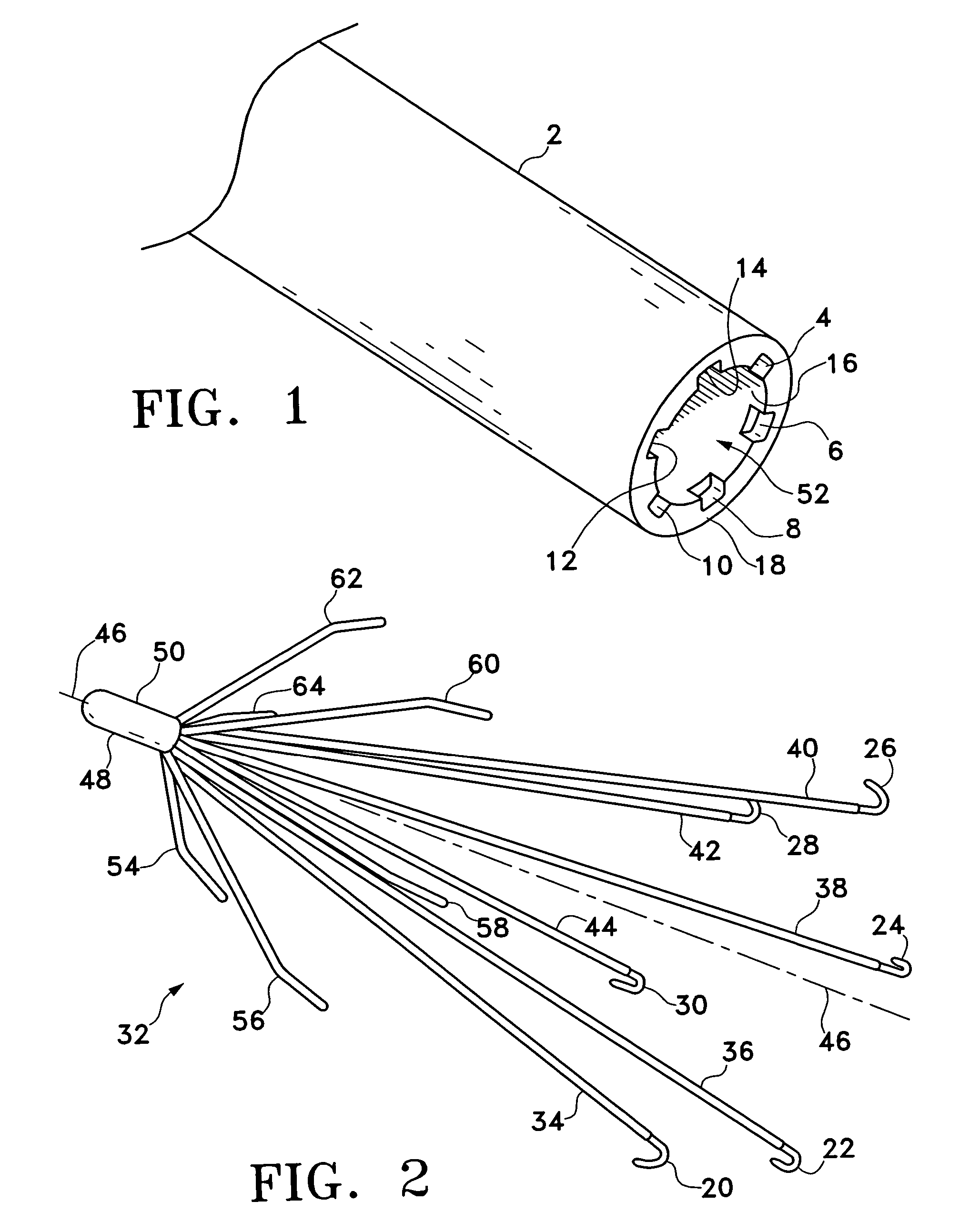

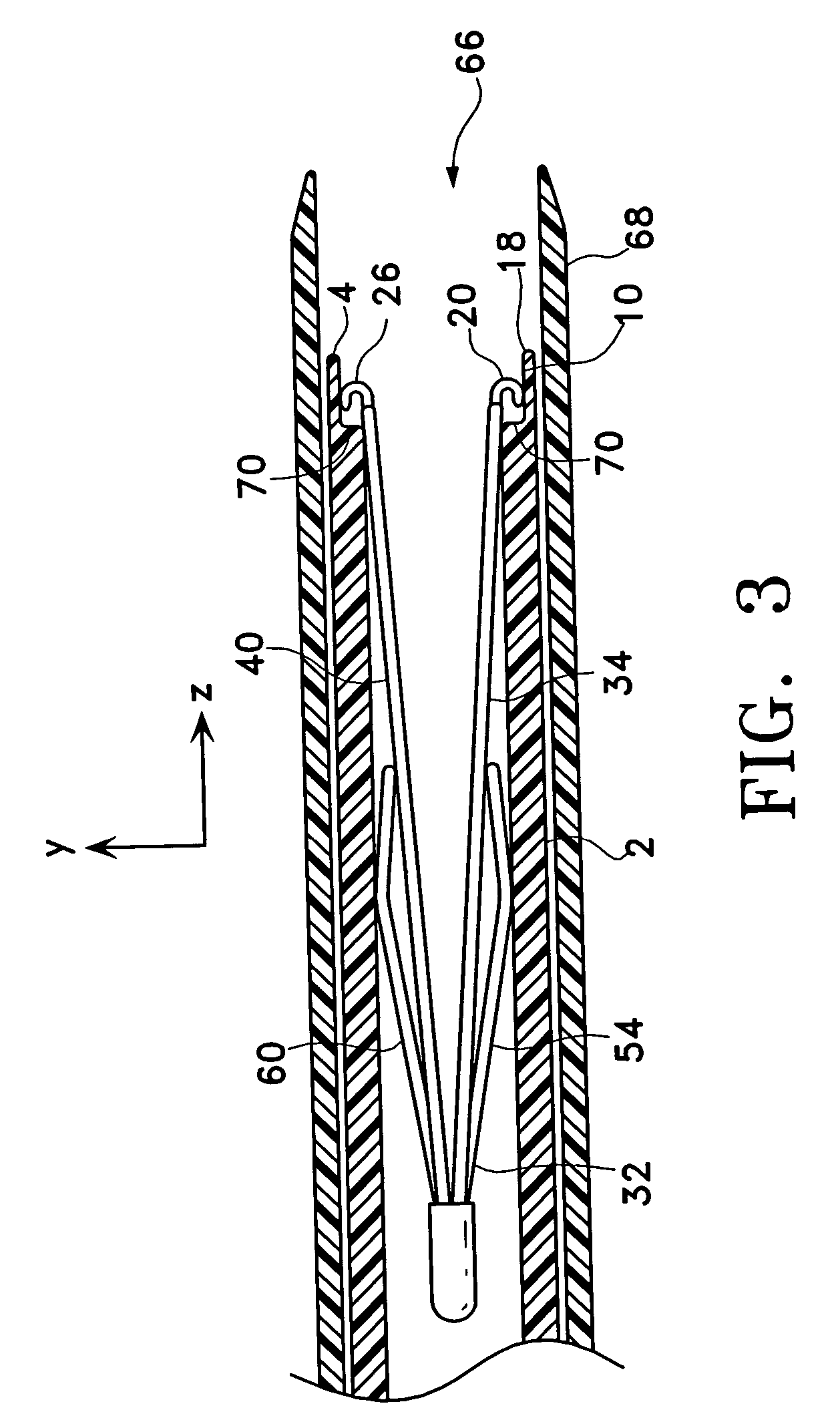

Filter delivery system

A filter delivery device for implanting a vessel filter within a blood vessel of a patient's body. The filter delivery device includes a mechanism for preventing hooks and / or legs on a vessel filter from entangling with each other while the vessel filter is loaded within the delivery device. In one variation, the filter delivery device includes a delivery catheter with grooves at the distal end lumen opening. When a vessel filter with radially expanding legs is compressed and inserted into the distal end of the delivery catheter, the hooks on the distal end of the legs are received and separated by the corresponding grooves on the delivery catheter. In another variation, a pusher rod, with a receptacle for receiving the hooks, is positioned within a delivery catheter to prevent the entanglement of the hooks and / or legs of a filter loaded within the delivery catheter.

Owner:CR BARD INC

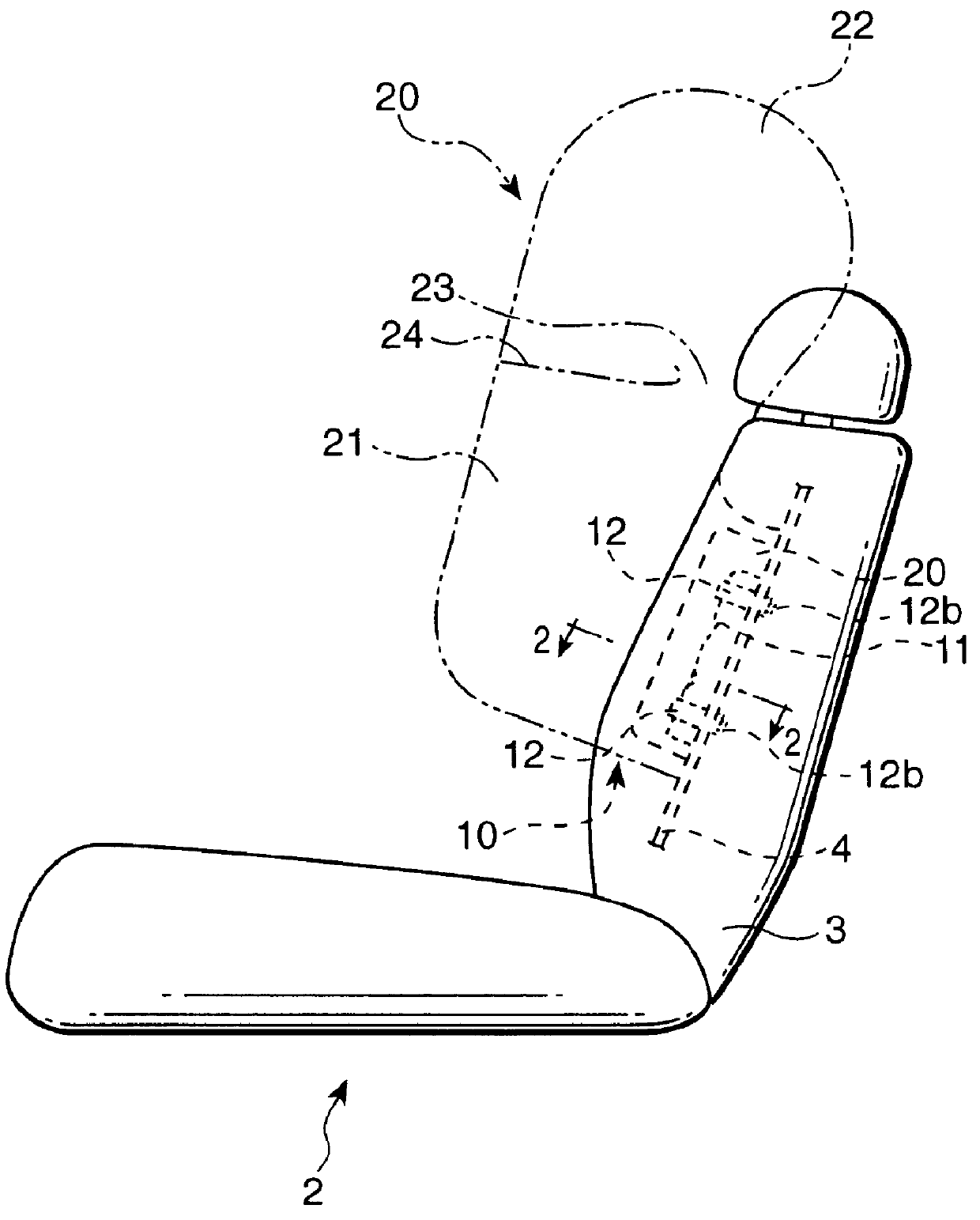

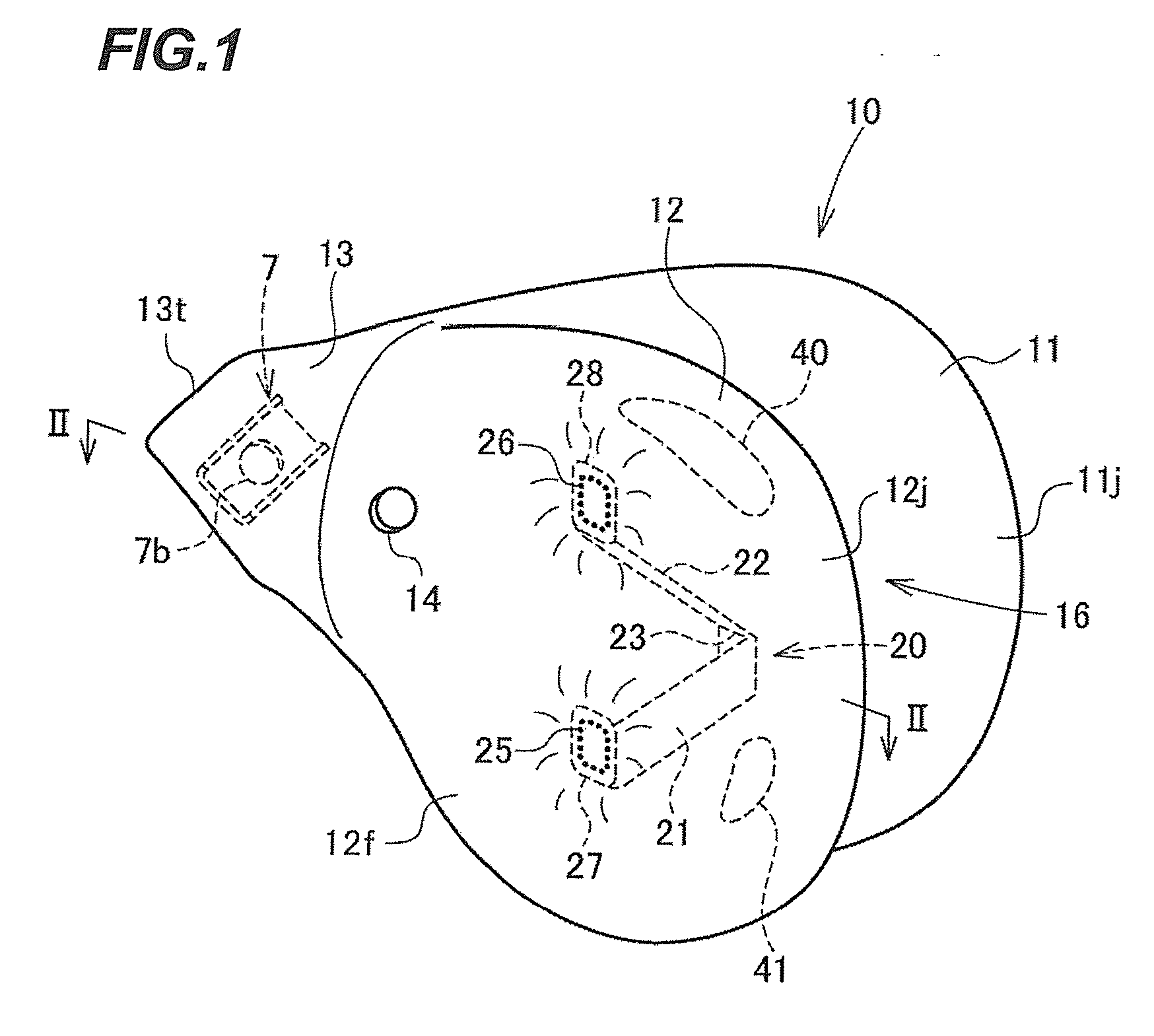

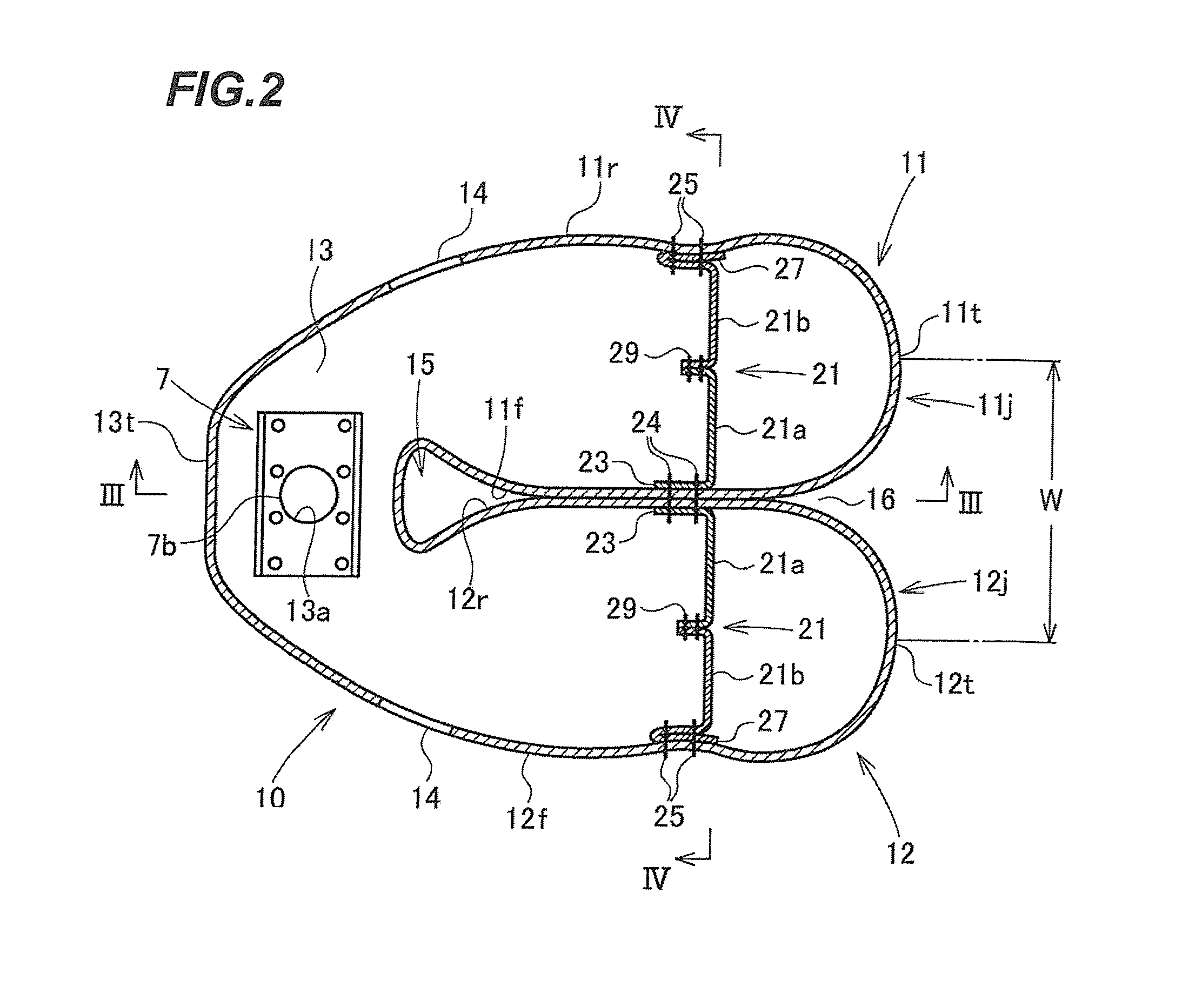

Air bag for protecting passenger from side collision which has uniform inflation characteristics

InactiveUS6062594AUpper chamber can be expanded smoothlyExpand smoothlyPedestrian/occupant safety arrangementInternal pressureEngineering

Owner:TOYODA GOSEI CO LTD

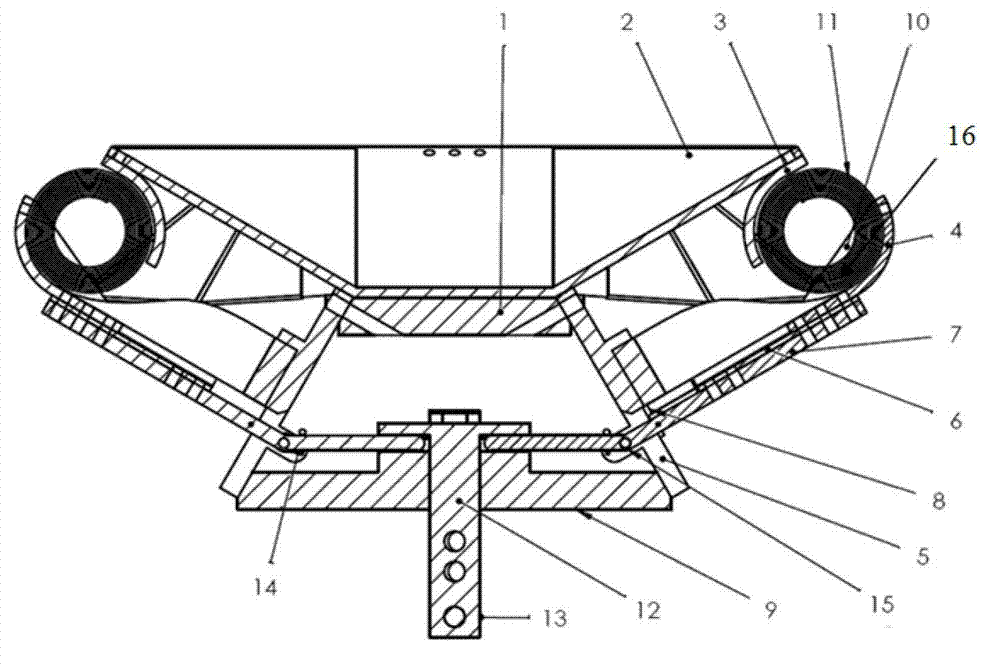

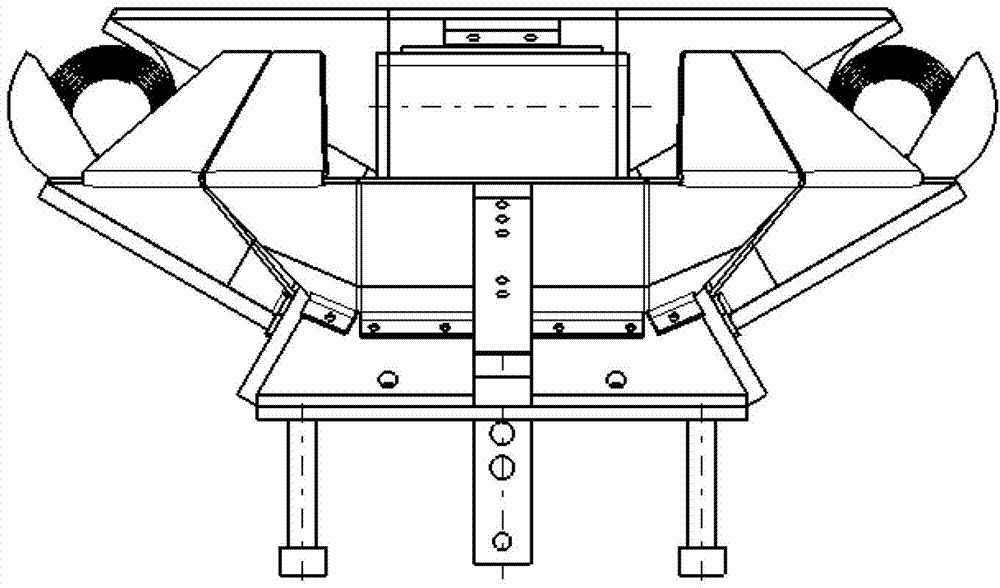

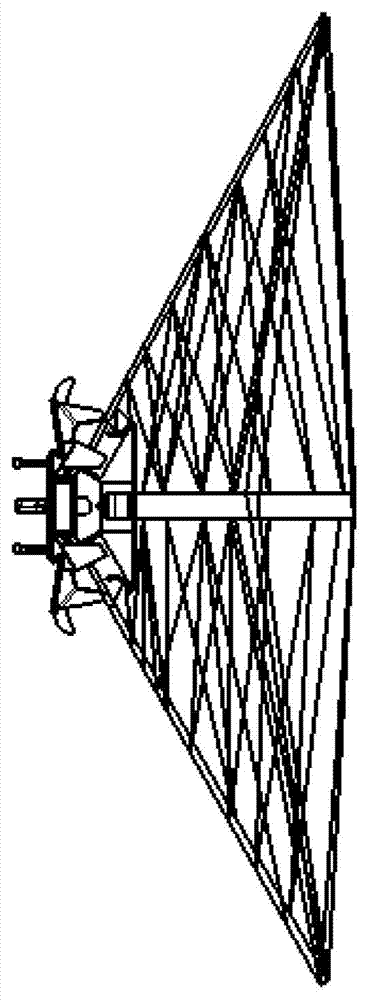

Rope net type space debris capturing and cleaning system

The invention discloses a rope net type space debris capturing and cleaning system which comprises a transmission subsystem and a fly net subsystem. The transmission subsystem comprises a transmitter, a net cabin, a net cabin cover ejecting device, a buffer device, a tying rope tension control device and a tying rope cutter, and the fly net subsystem comprises a rope net and four mass blocks; a net cabin cover can be ejected out of an outlet of the net cabin, and the rope net can be driven by the net cabin cover to be drawn out of the net cabin; the transmitter works at the moment when the fly net and a tying rope are straightened, the sides of the rope net are driven by four mass blocks according to preset transmitting opening angles, so that the rope net can fly out and is opened simultaneously until the rope net is fully opened, an object is netted after the rope net reaches the objective position, a port of the rope net is tightened under the control of the mass bocks, and the object can be completely captured; after the tying rope draws the captured object aircraft away from an orbit, the tying rope cutter cuts off the tying rope, and the object aircraft can be separated from a satellite platform. The rope net type space debris capturing and cleaning system has the advantages that a secondary transmission mode is adopted, so that twining and knotting can be prevented in rope net spreading procedures; the mass blocks are pushed to be synchronously transmitted, so that a millisecond-level synchronous transmission effect can be realized, and the shape of the rope net can be controlled advantageously.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

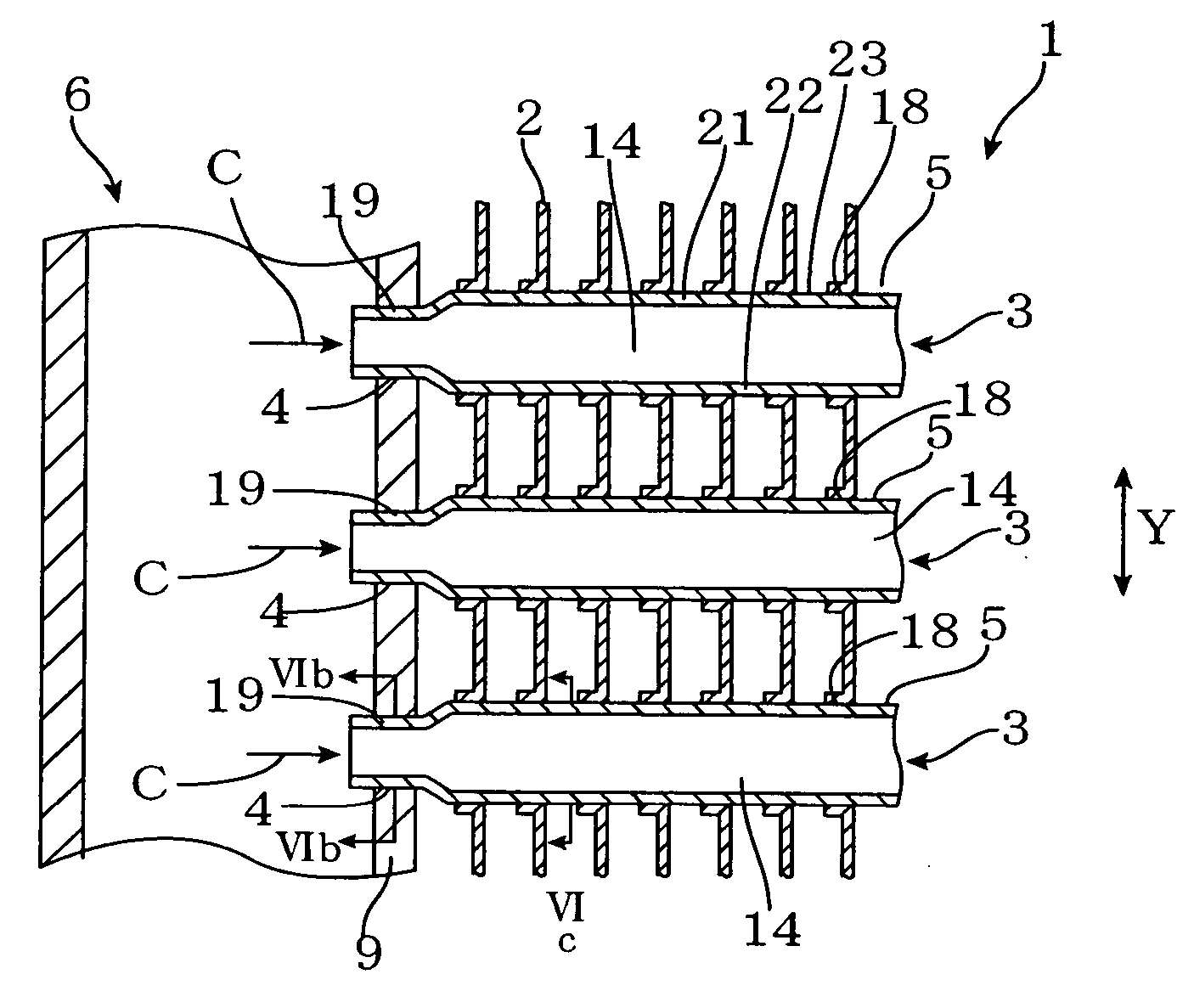

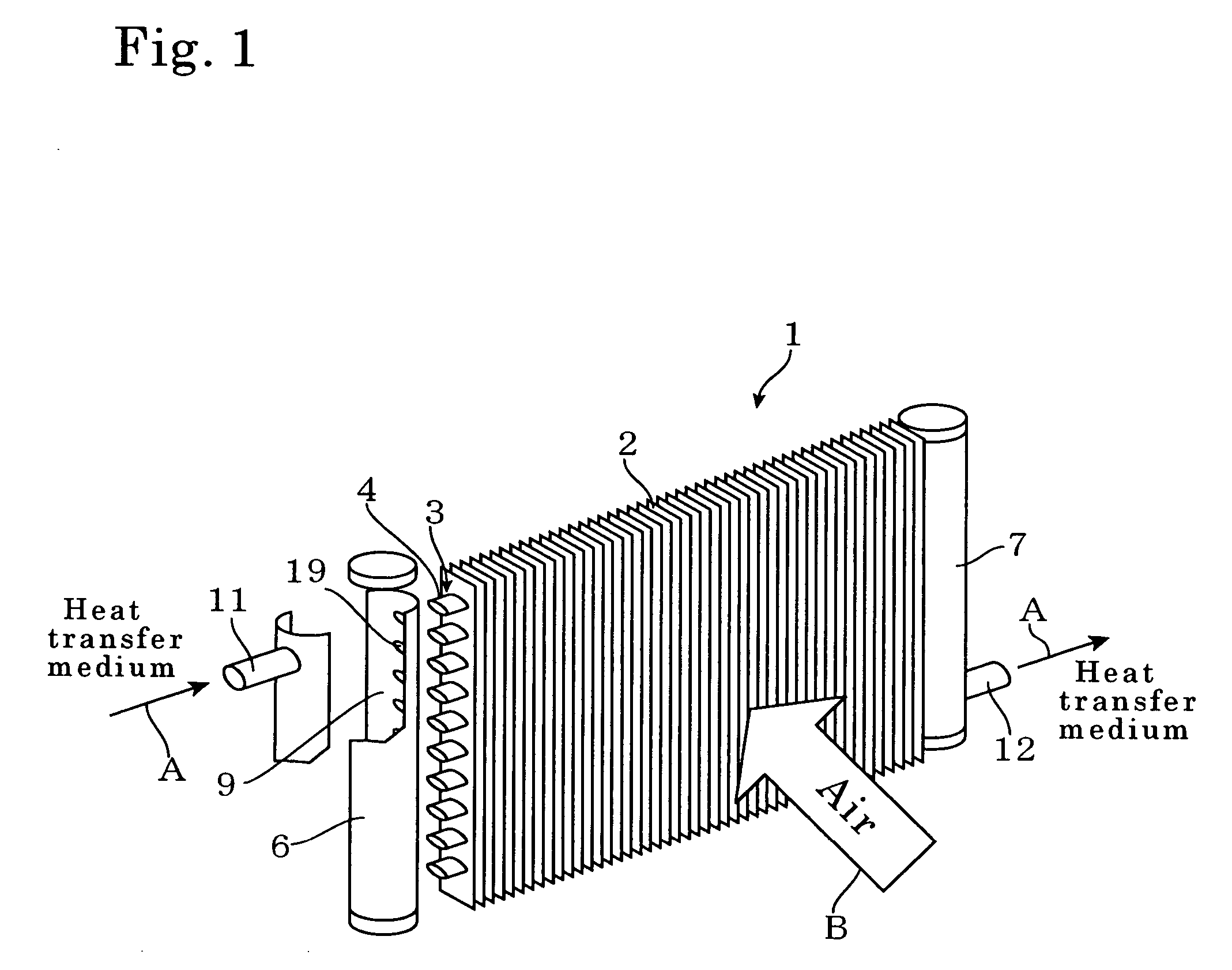

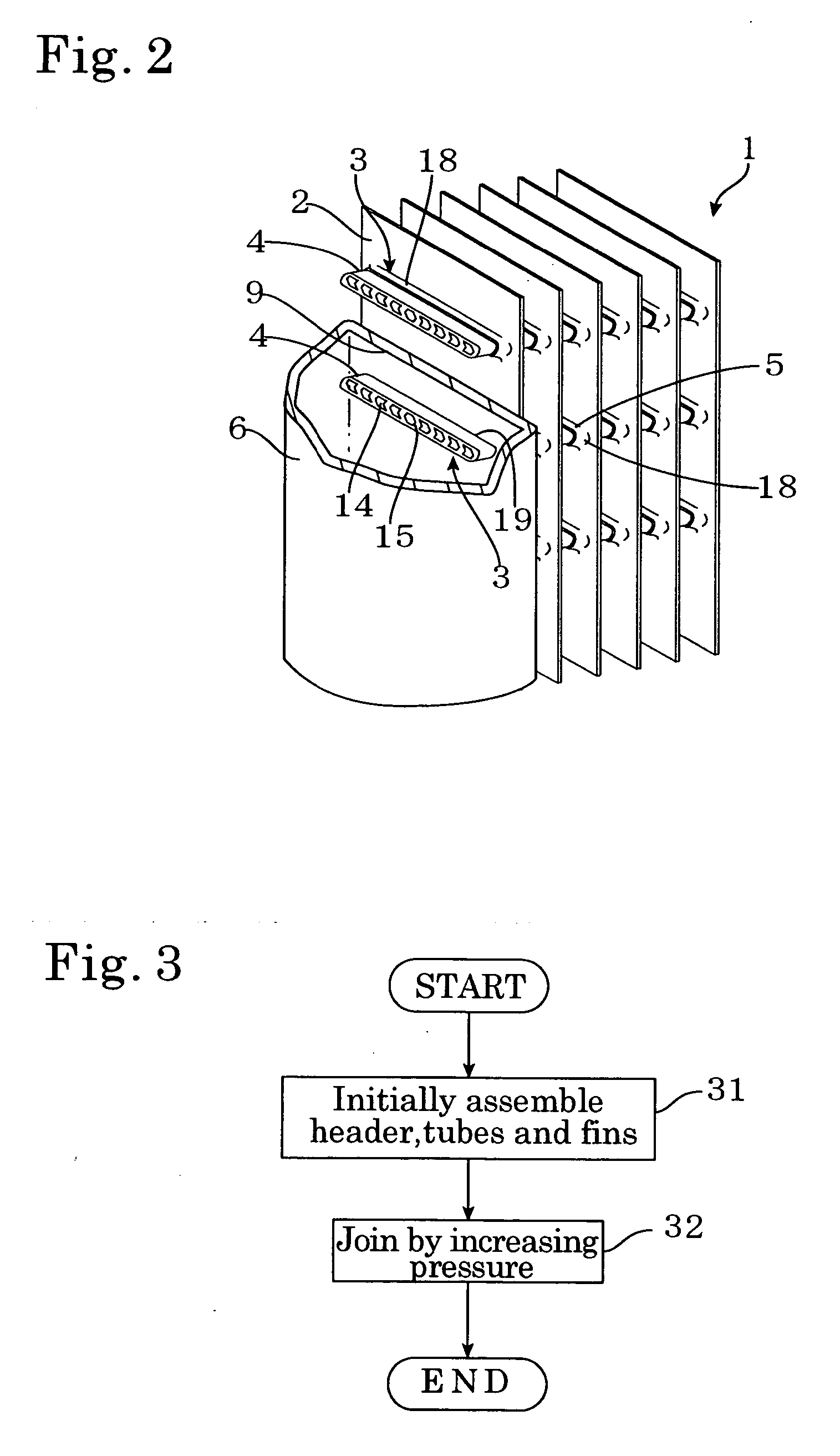

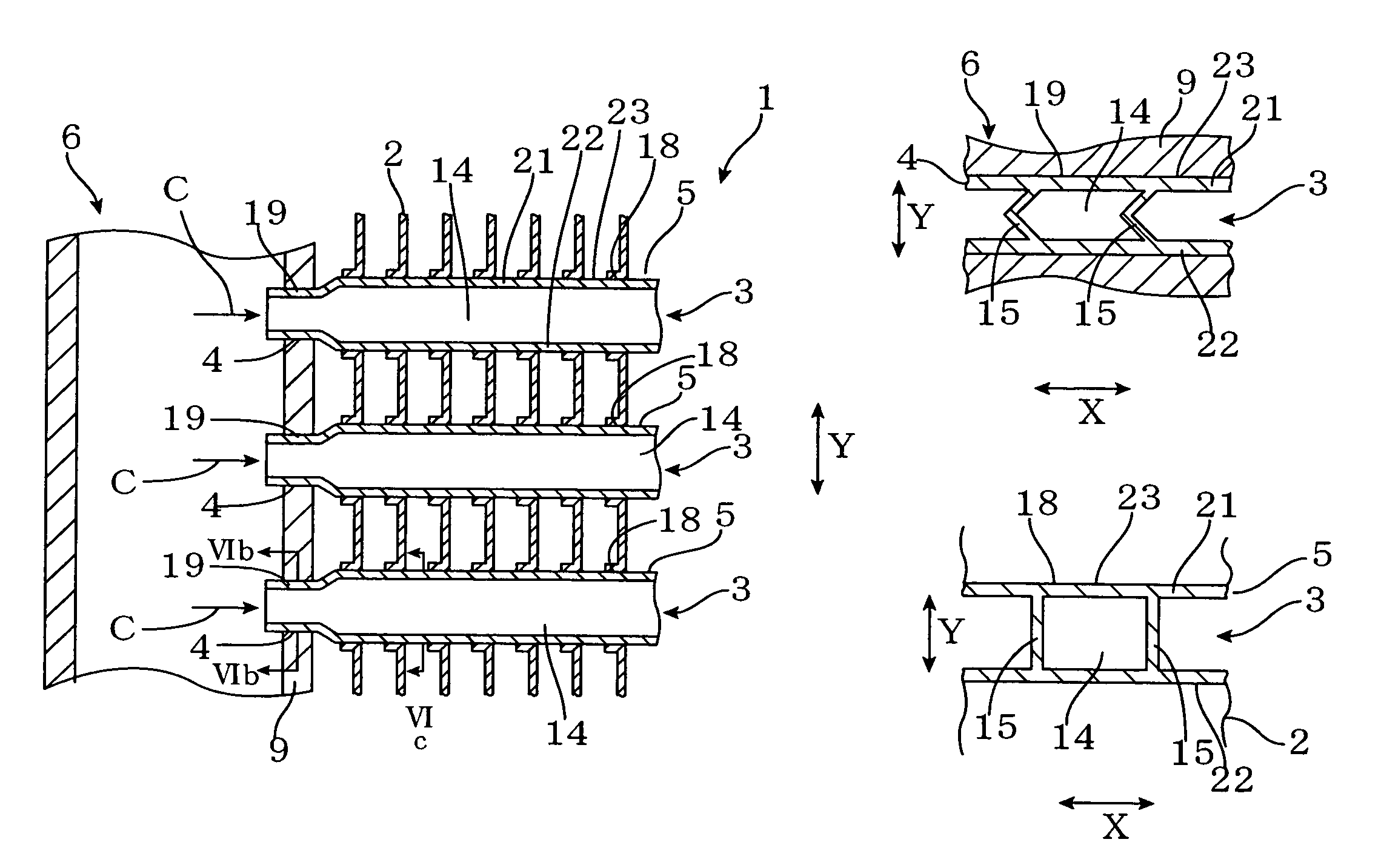

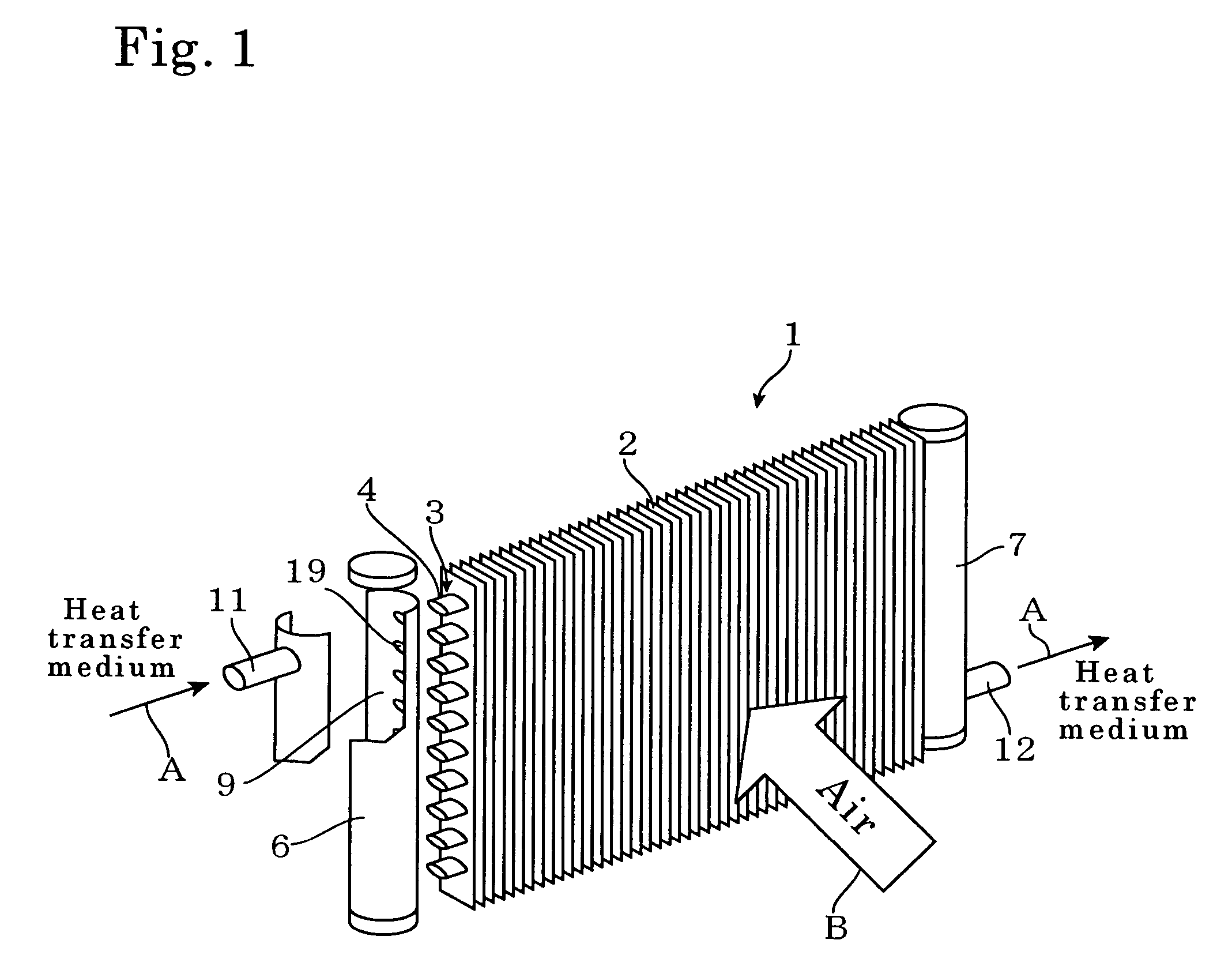

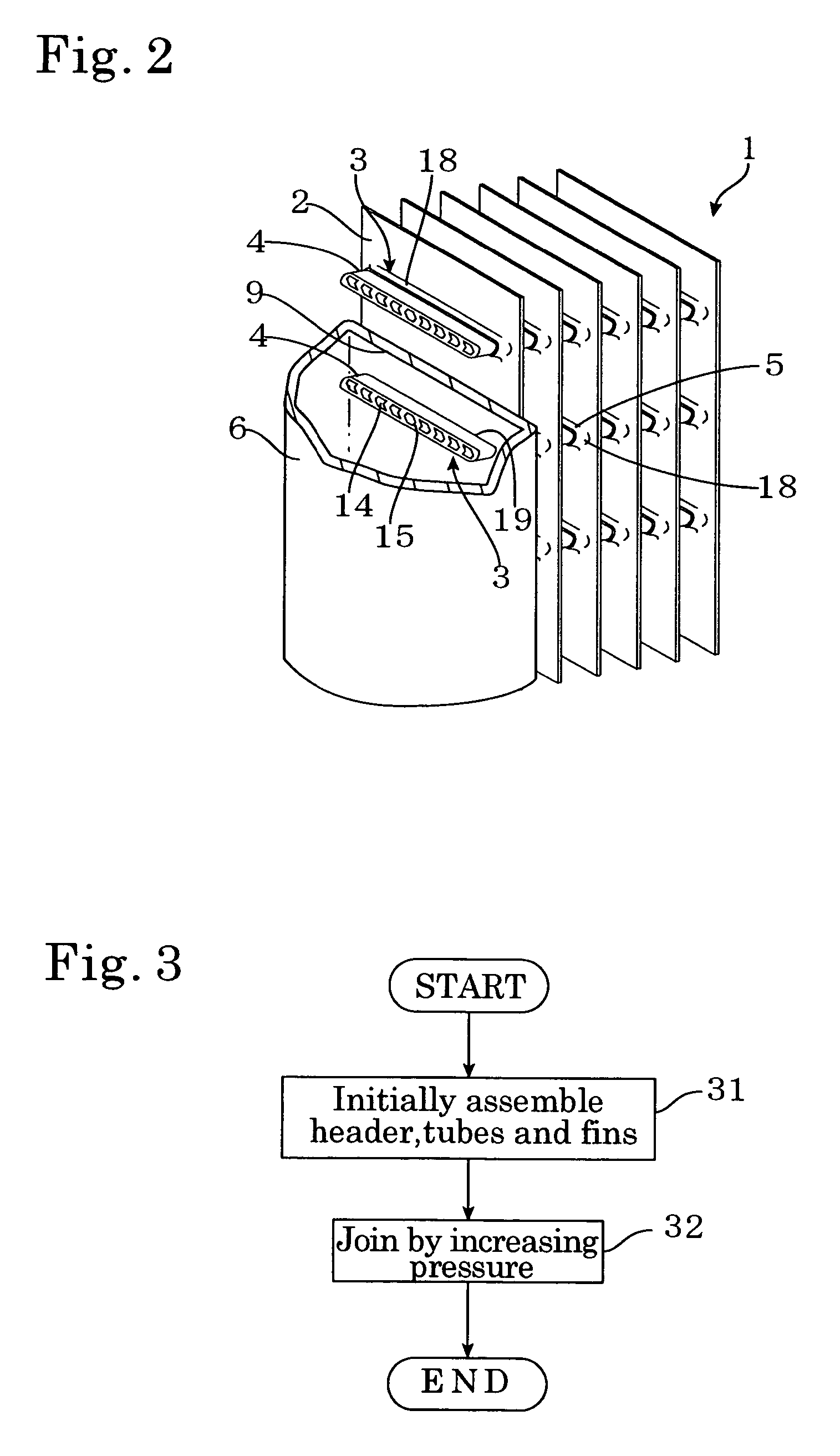

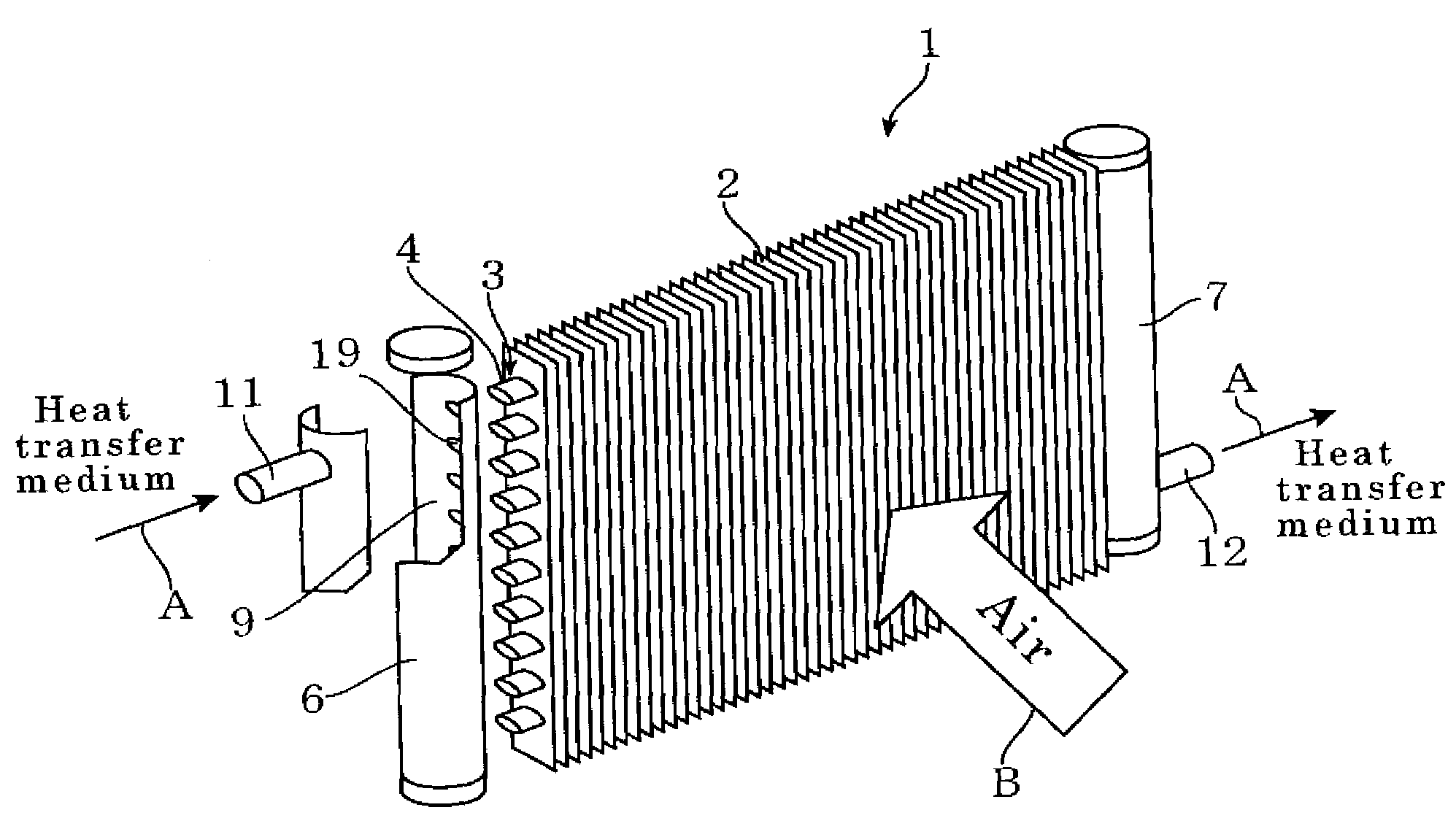

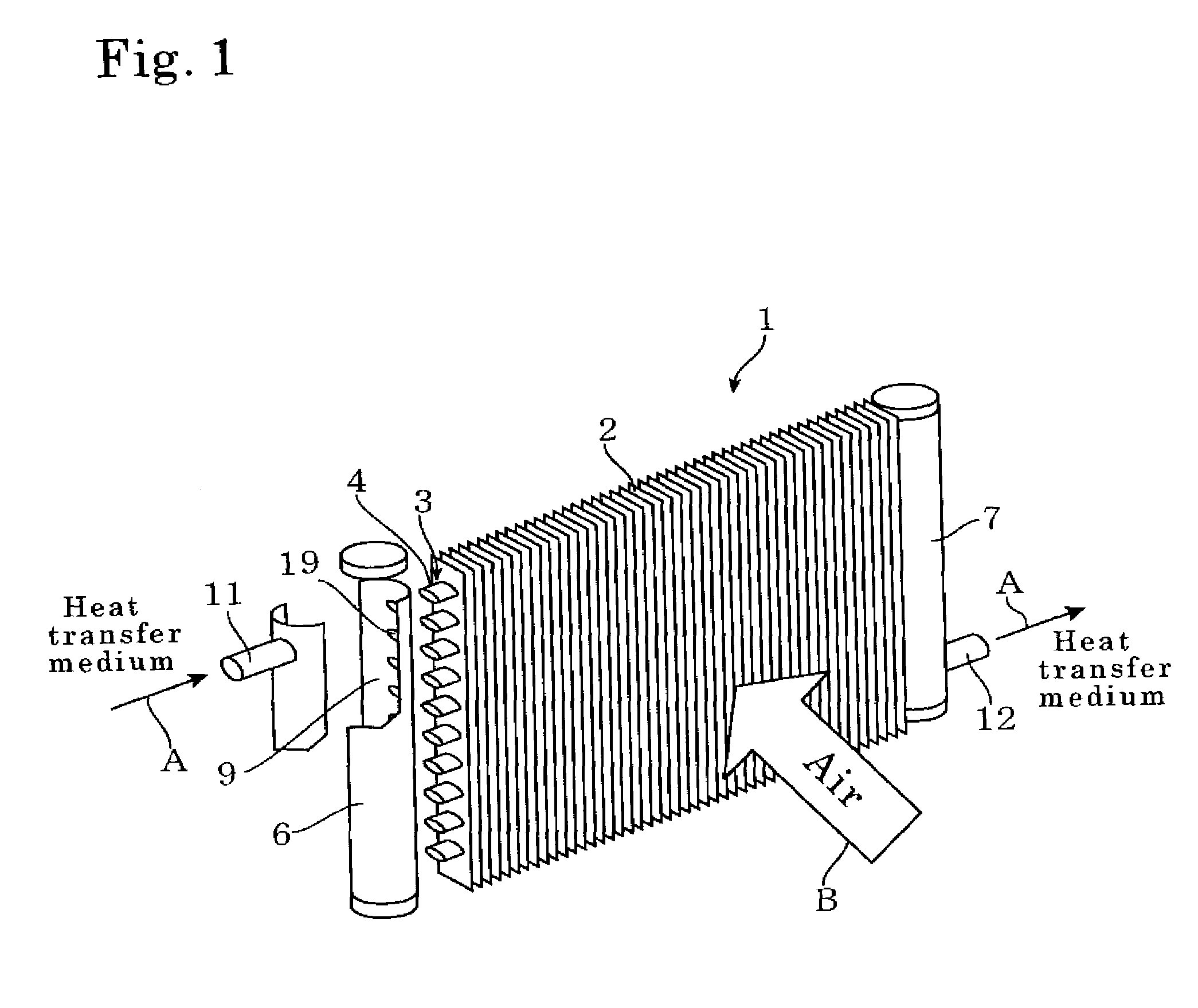

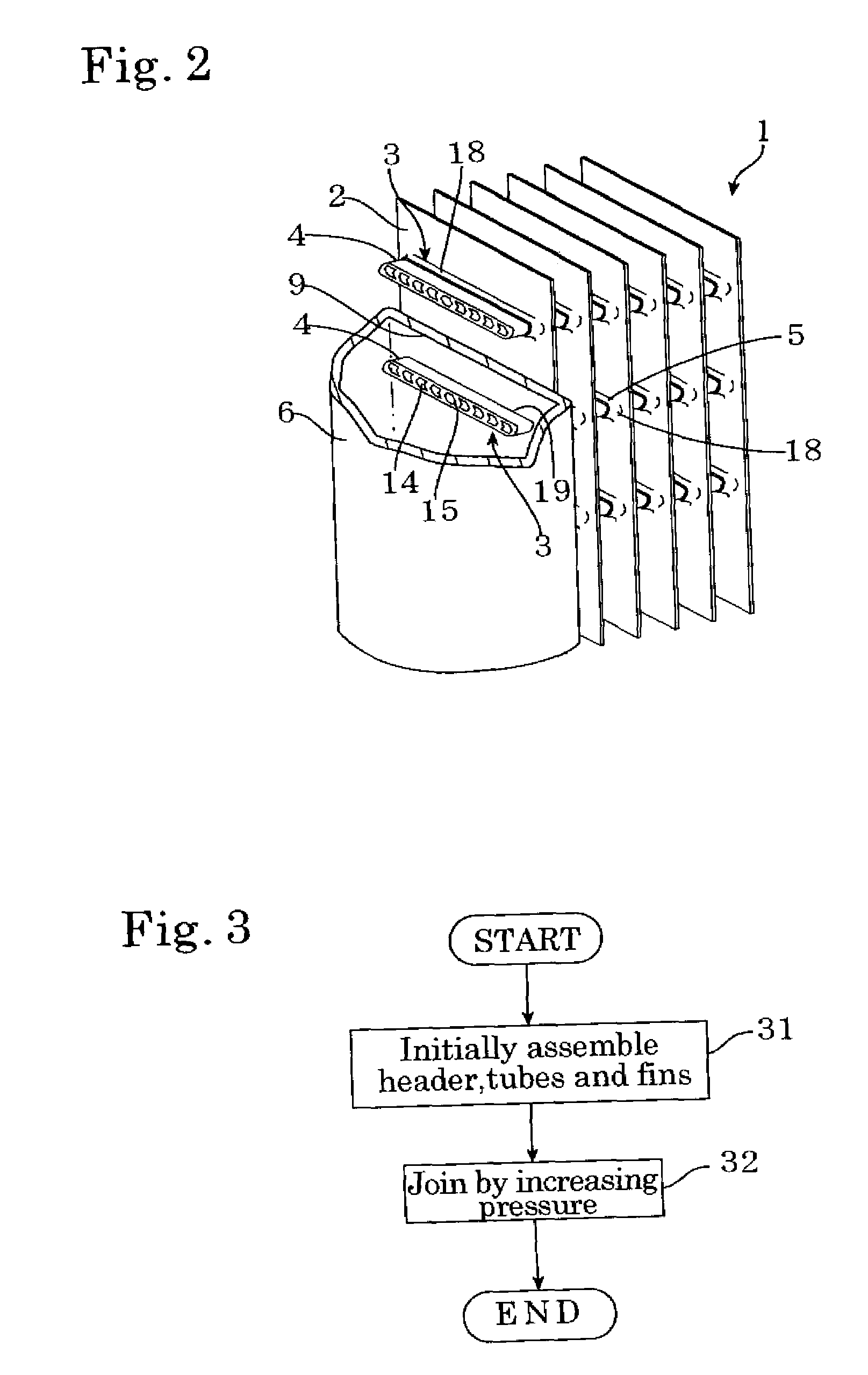

Heat exchanger and method of manufacturing the same

InactiveUS20050061494A1Increase internal pressureAdd partsStationary conduit assembliesHeat exchanger casingsInternal pressureEngineering

There is provided a method of manufacturing a heat exchanger, including a first step of mounting an end part of flat tube to a header, assembling the flat tube and fins, and sealing a part where the header and the end part is attached, and a second step of increasing an internal pressure of the flat tube to expand other part of flat tubes aside from the end parts with respect to the end part of the tube in order to make the fins and the other part of the flat tube in contact each other. According to this method of manufacturing, in the second step, the other part of the flat tube that passes through the fins is expanded, so that it is possible to mechanically join the flat tube and the fins, and a plate fin-type heat exchanger with high strength and heat exchange efficiency can be easily provided.

Owner:DENSO AIRCOOL CORP

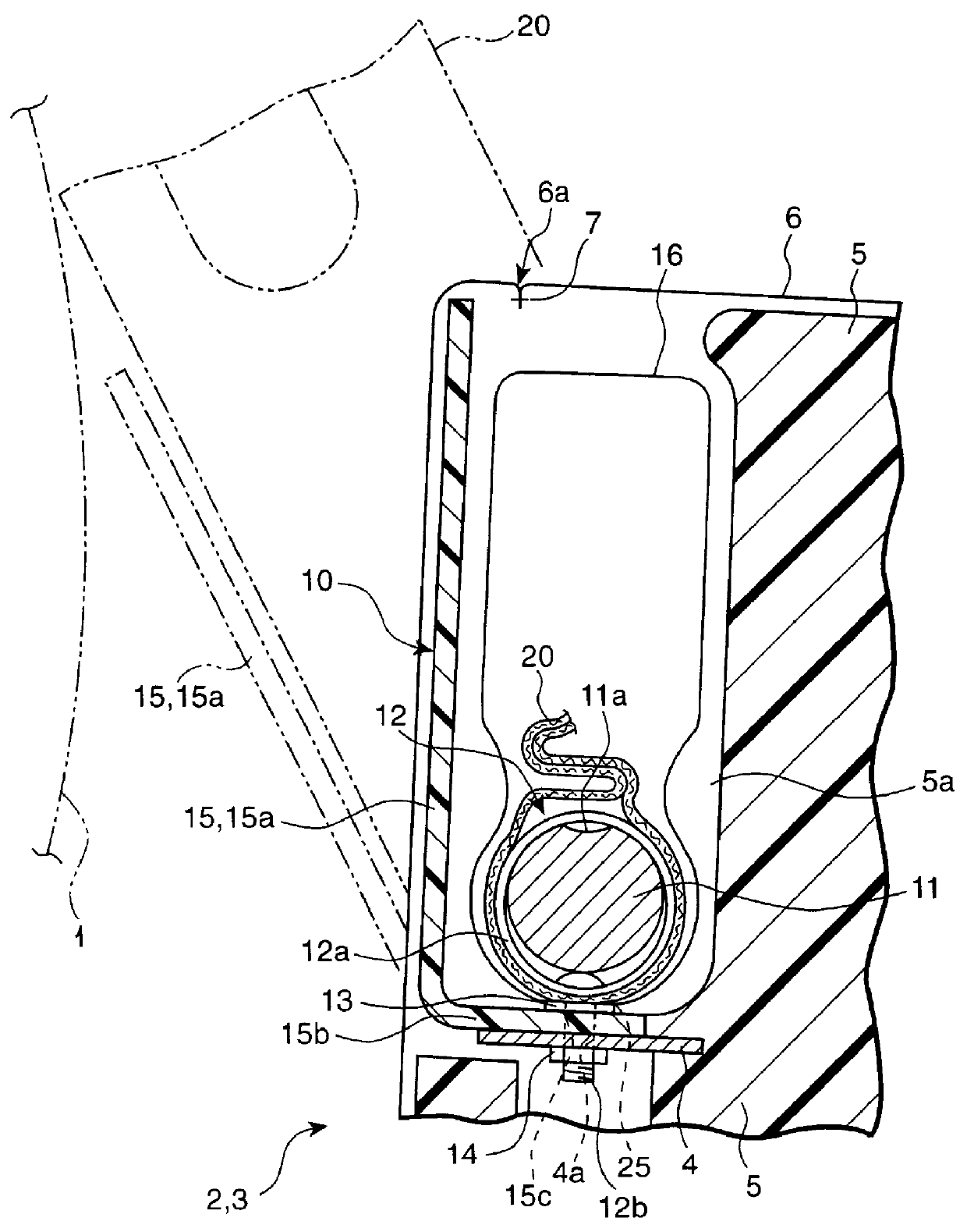

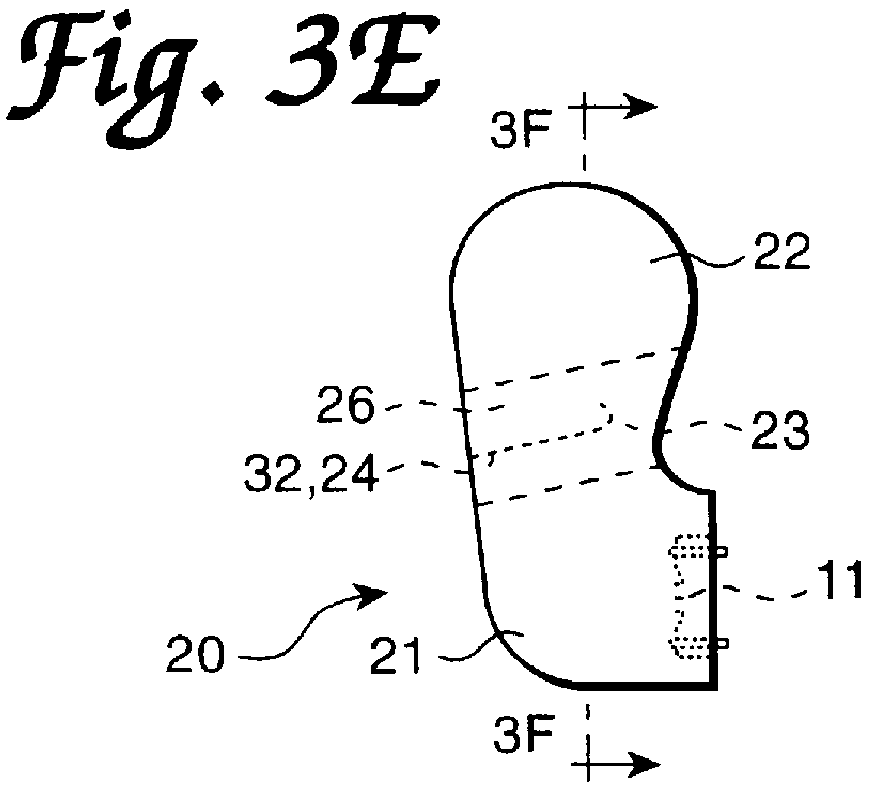

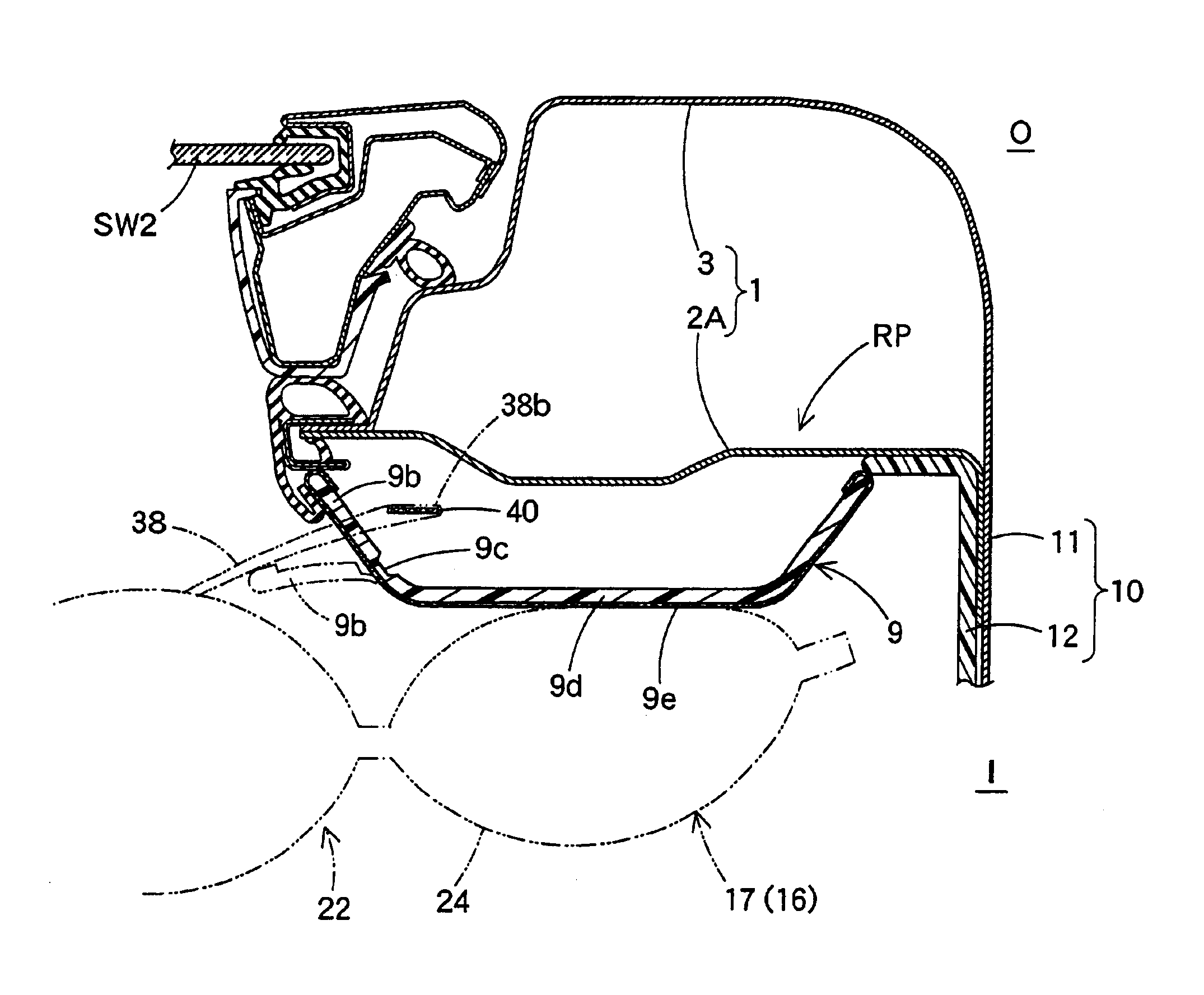

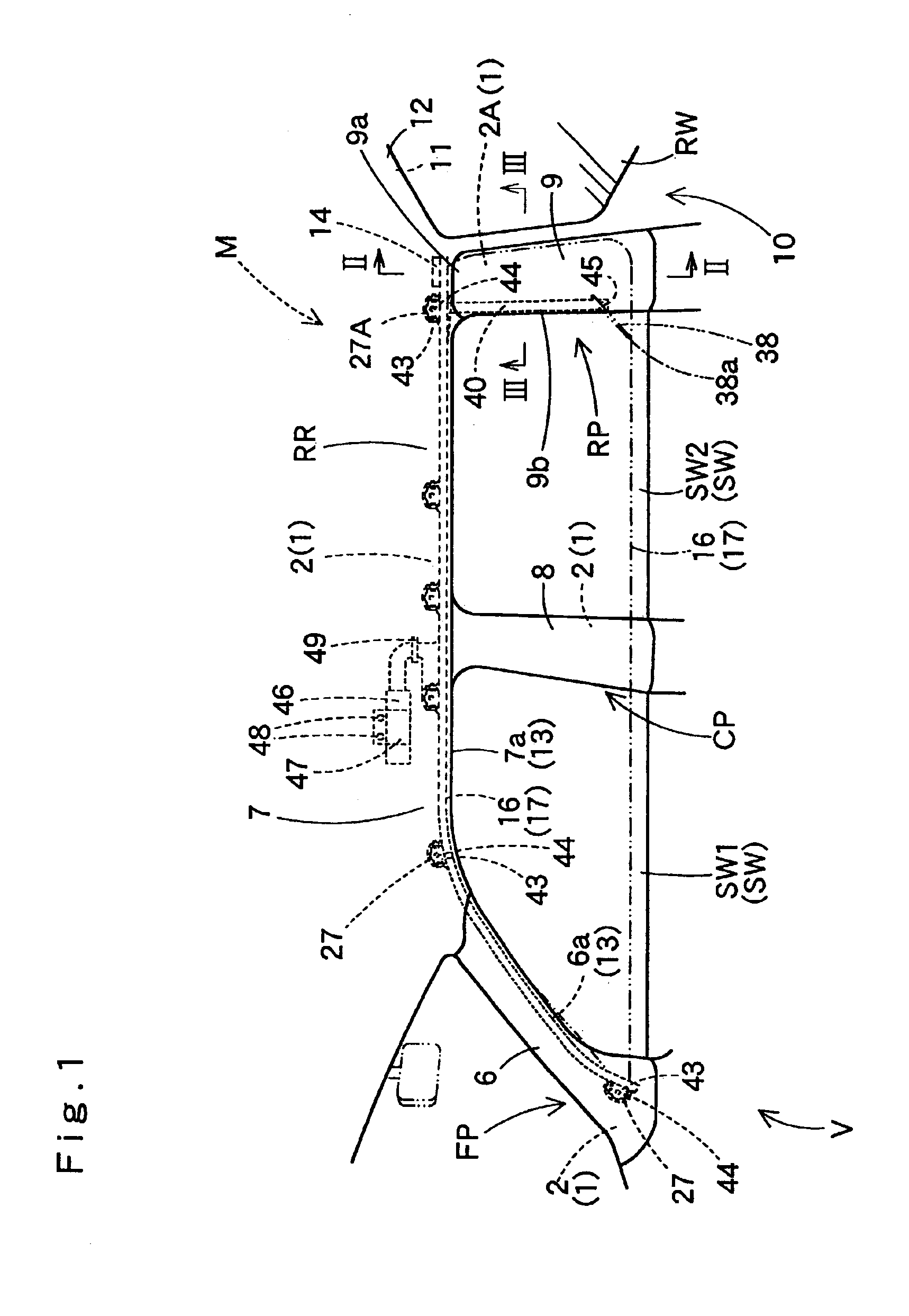

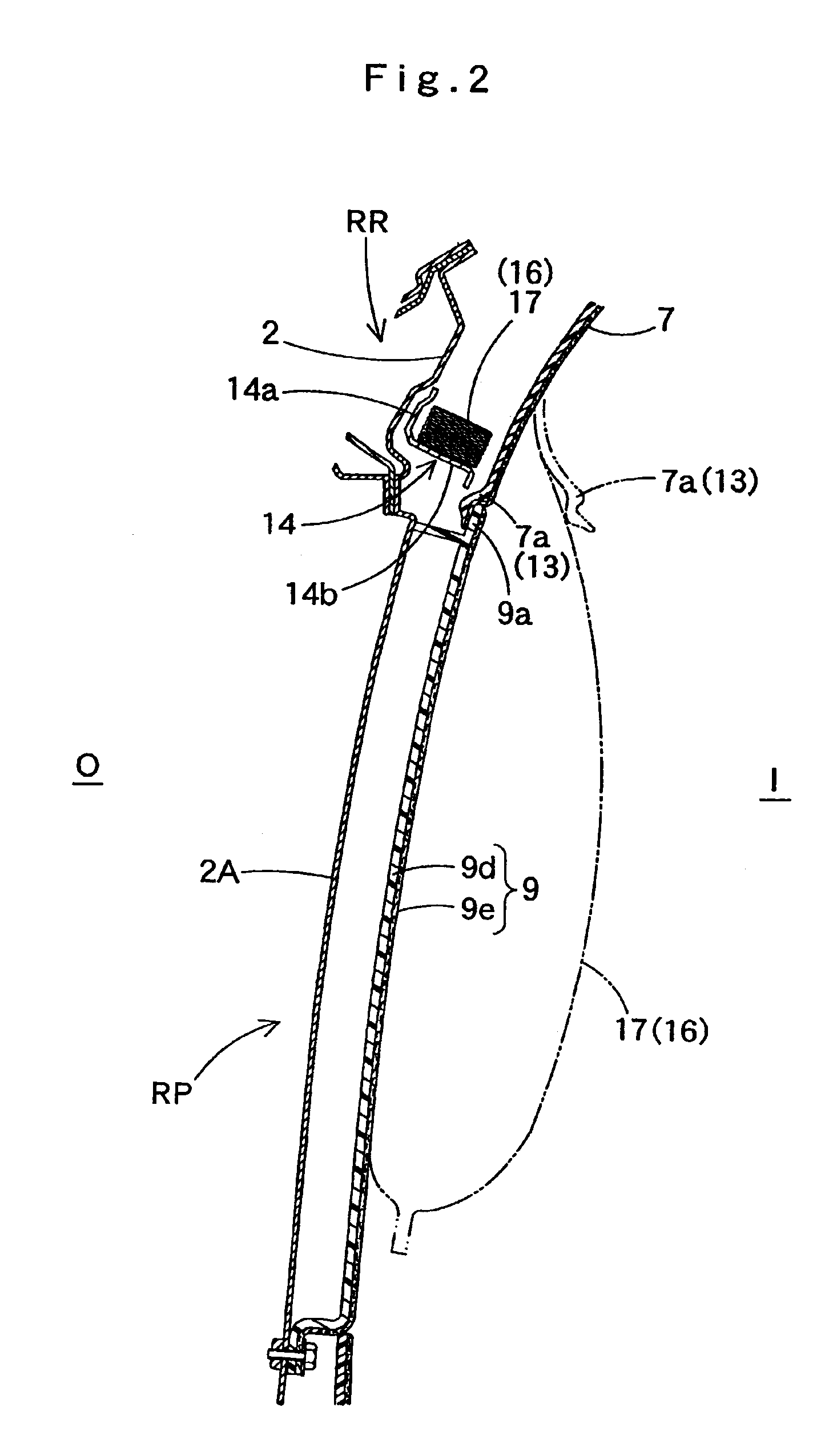

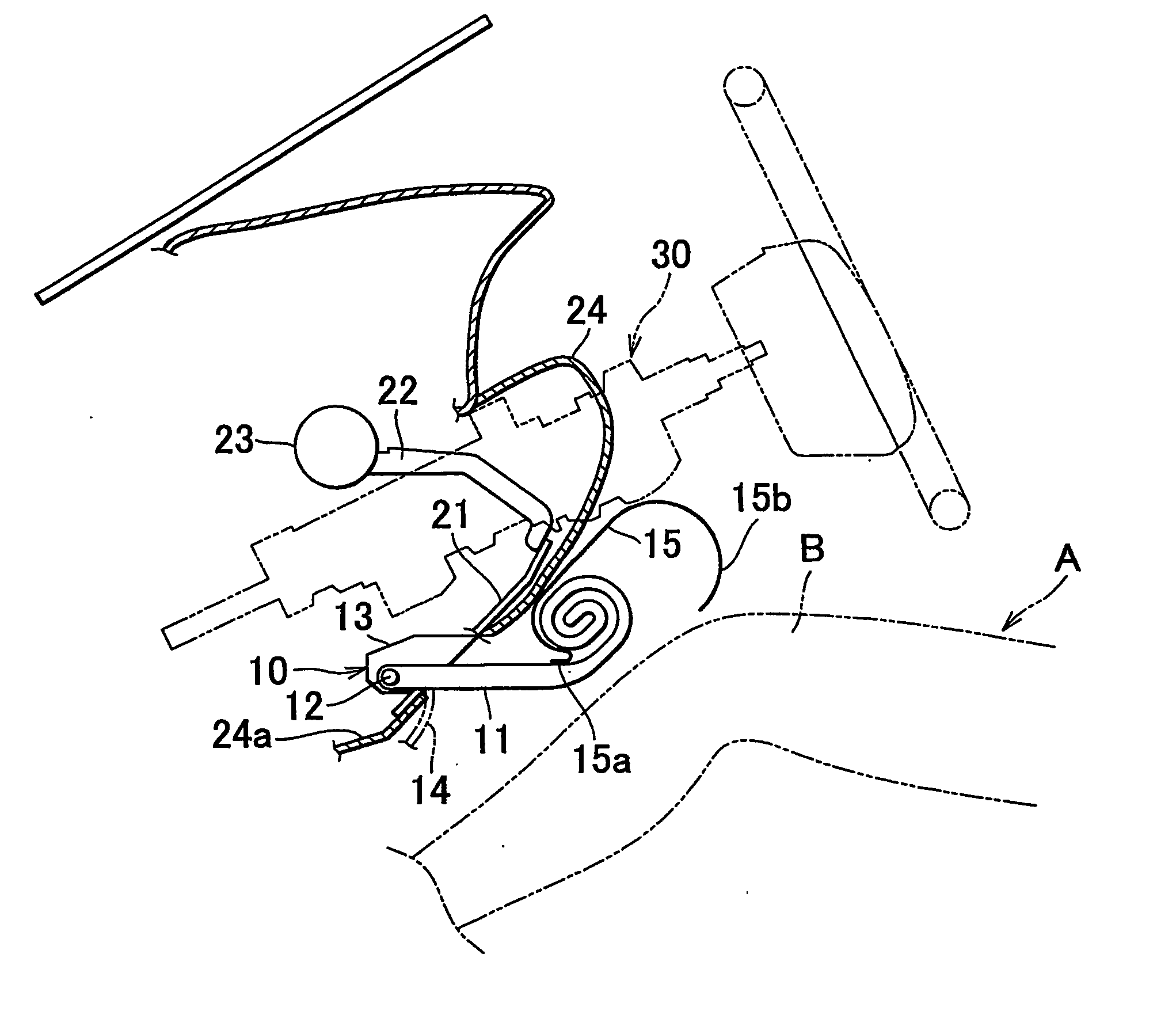

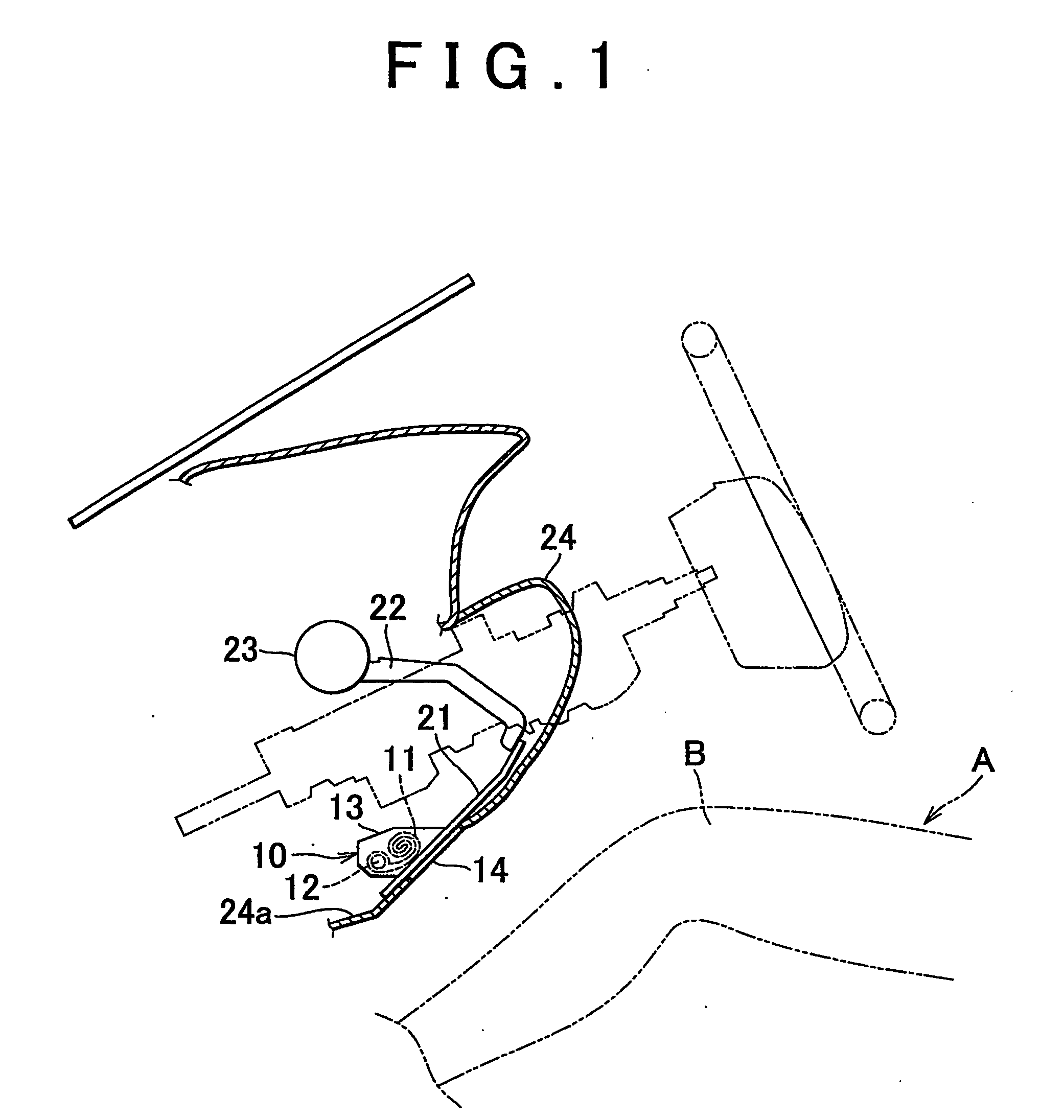

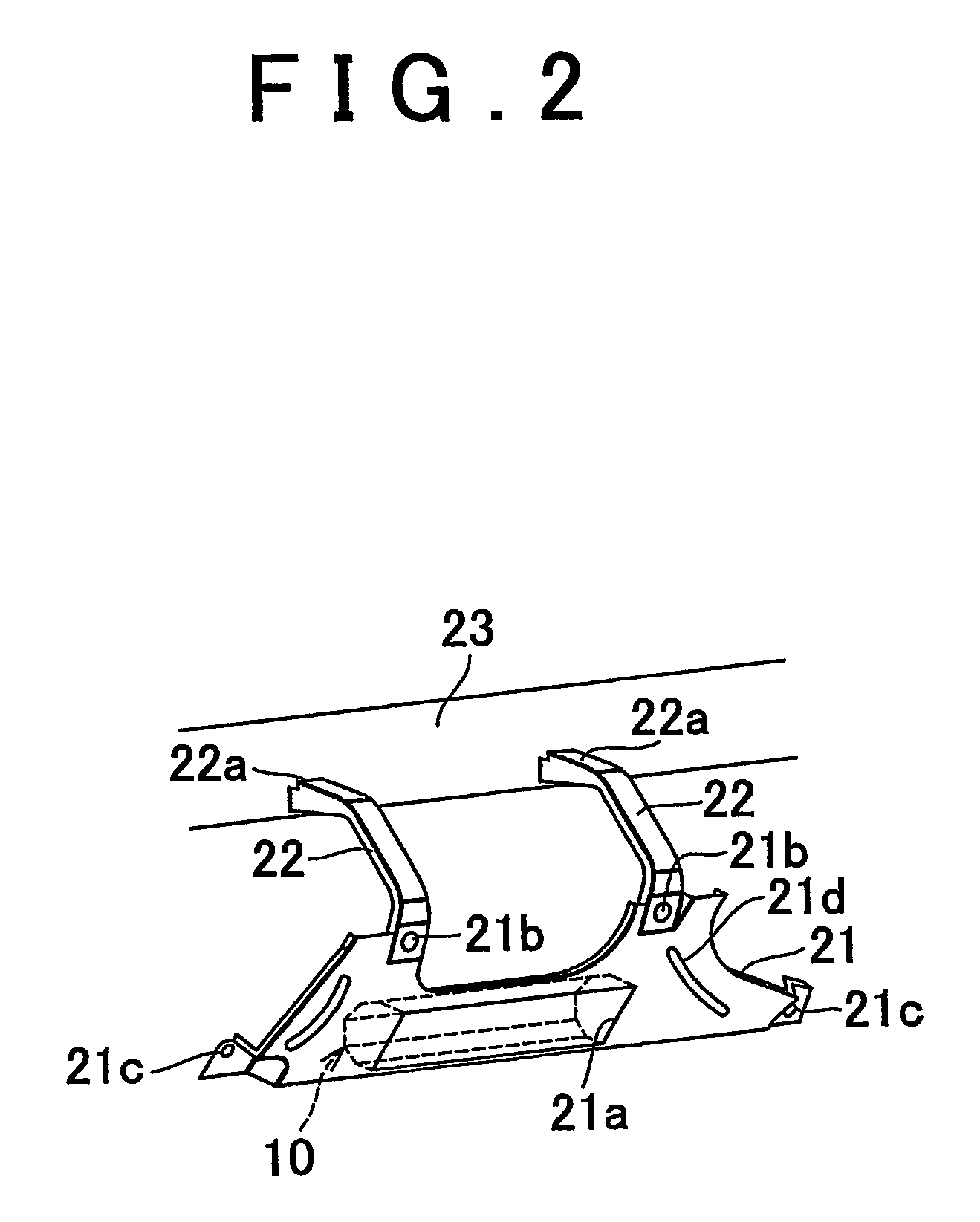

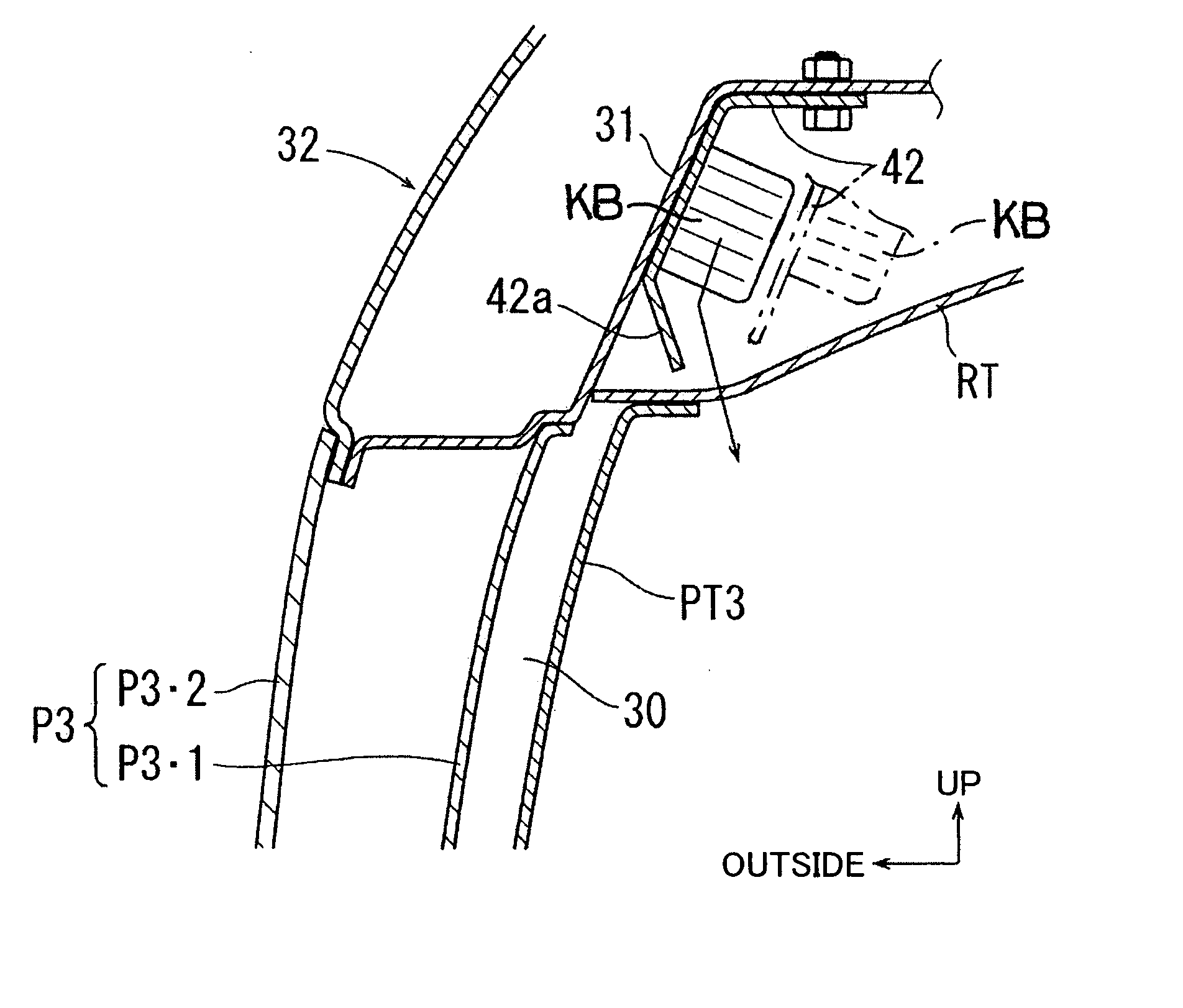

Head protecting airbag device

InactiveUS6866293B2Expand smoothlyEvenly inflatedPedestrian/occupant safety arrangementEngineeringAirbag

A head protecting airbag device of the invention is provided with an airbag which expands to cover the vehicular interior sides of a window and a pillar garnish. Near the front or rear edge of an inner panel, a guide member is so arranged in the vertical direction that its vehicular interior side is covered by the edge portion of the pillar garnish. A flexible connection member, which is slidably connected to the guide member, is connected to a portion of the airbag toward the center of the window. Moreover, the connection member pushes open the edge portion of the pillar garnish toward the vehicular interior side as the connection member slides downward along the guide member when the airbag expands.

Owner:TOYODA GOSEI CO LTD

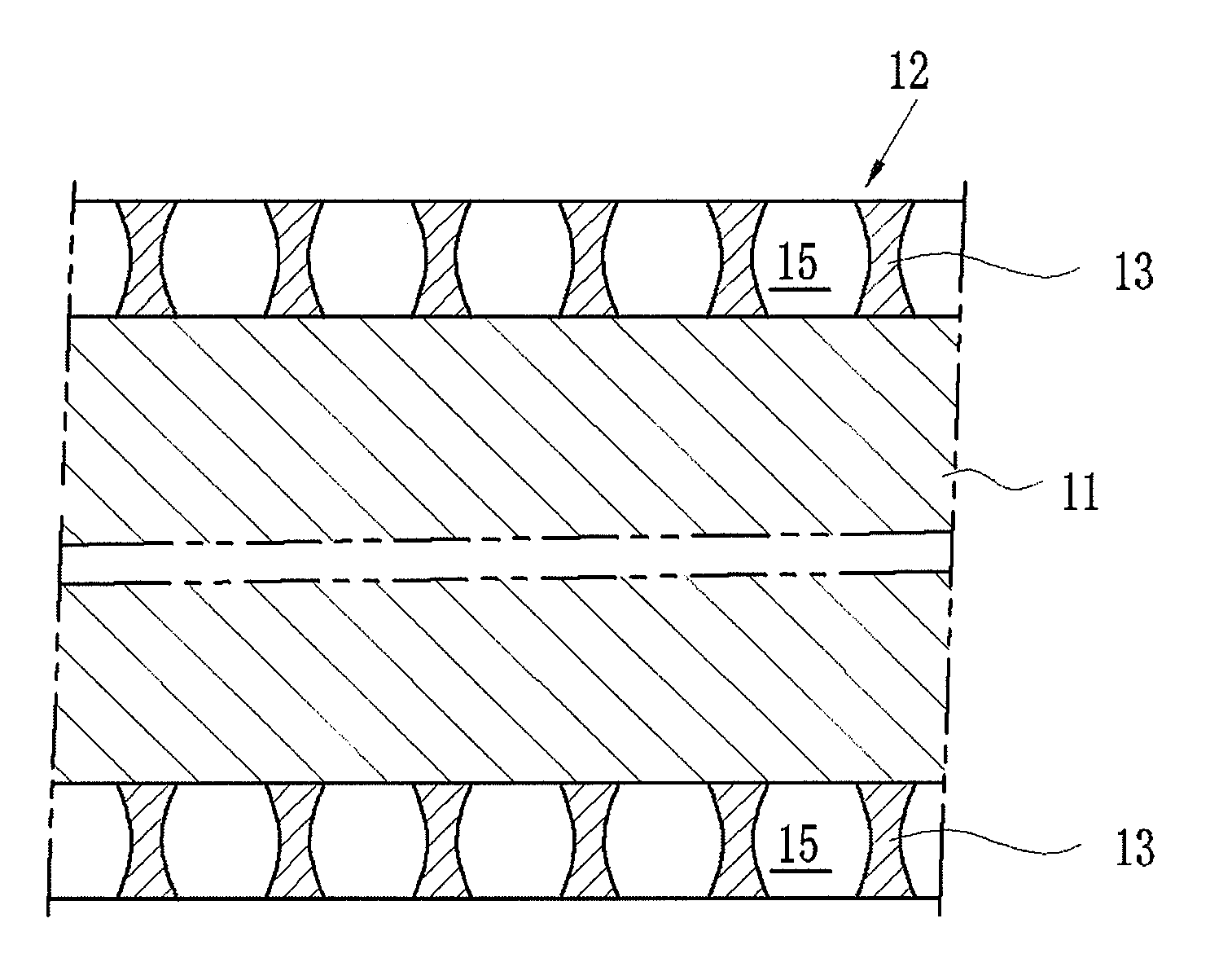

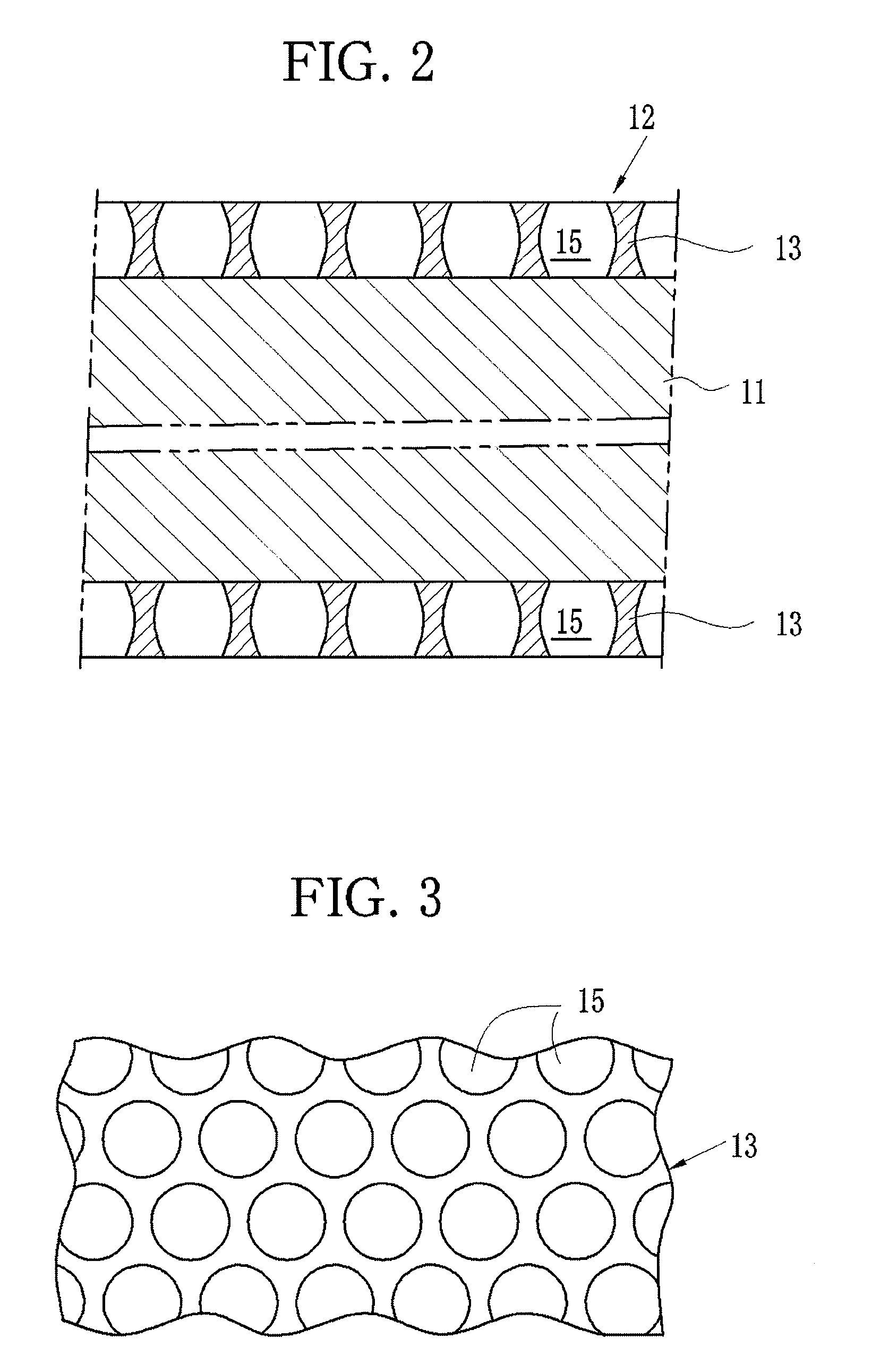

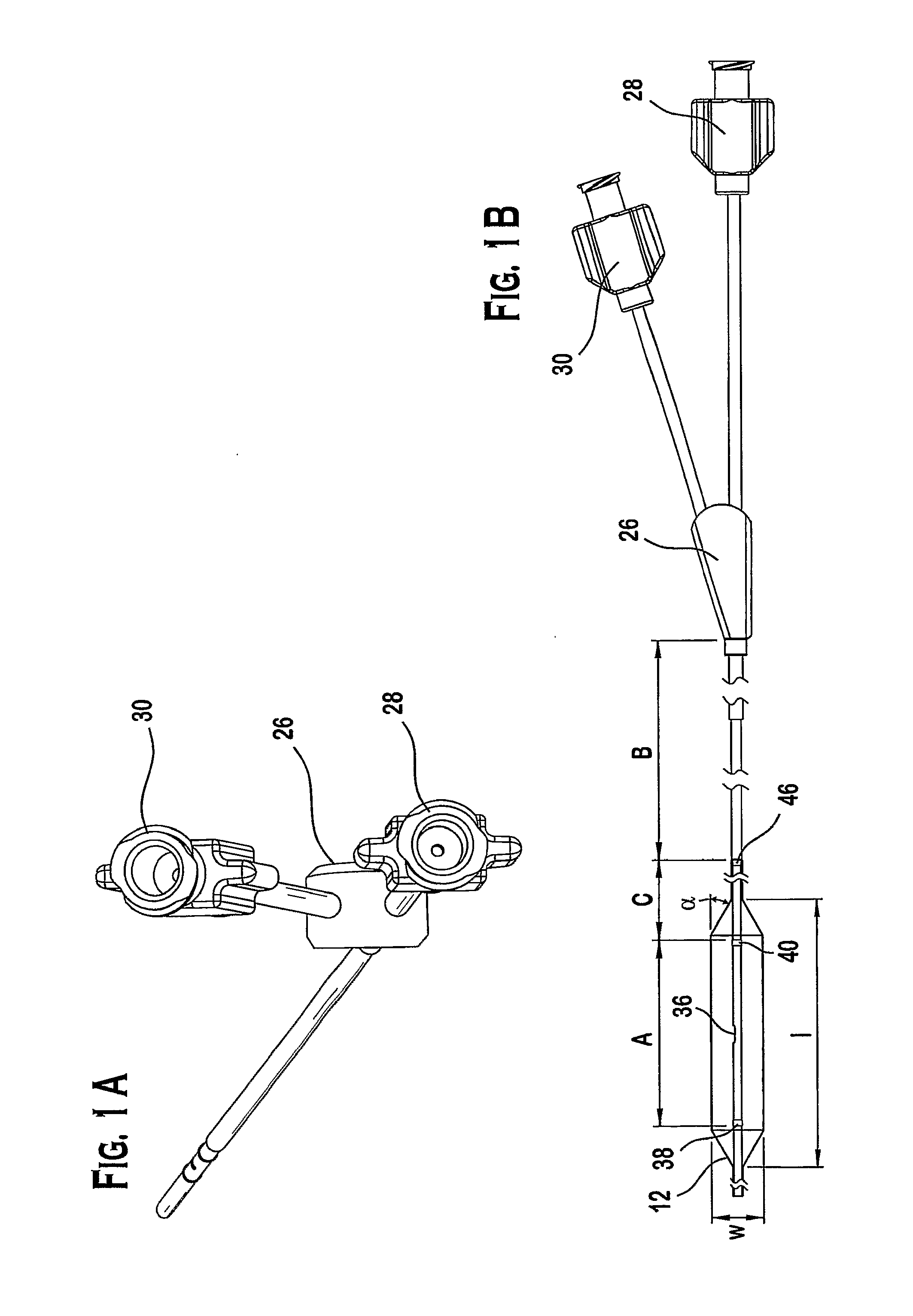

Stent with porous membrane and manufacturing method thereof

InactiveUS20100070026A1Restrict collapseControl deformationStentsMembranesPorous membranePolymer solution

A dipping bath contains a polymer solution. Stent body members are dipped into the polymer solution. The polymer solution forms membrane on the surface of the stent body member. Humid atmosphere is created around the stent body members with the membrane to condense water vapor into water droplets on the surface of the membrane. After growing the water droplets to water drops, a solvent is evaporated, and the water drops penetrate into the membrane. Then, the water drops are evaporated with leaving pores in the membrane. The water drops function as templates.

Owner:FUJIFILM CORP

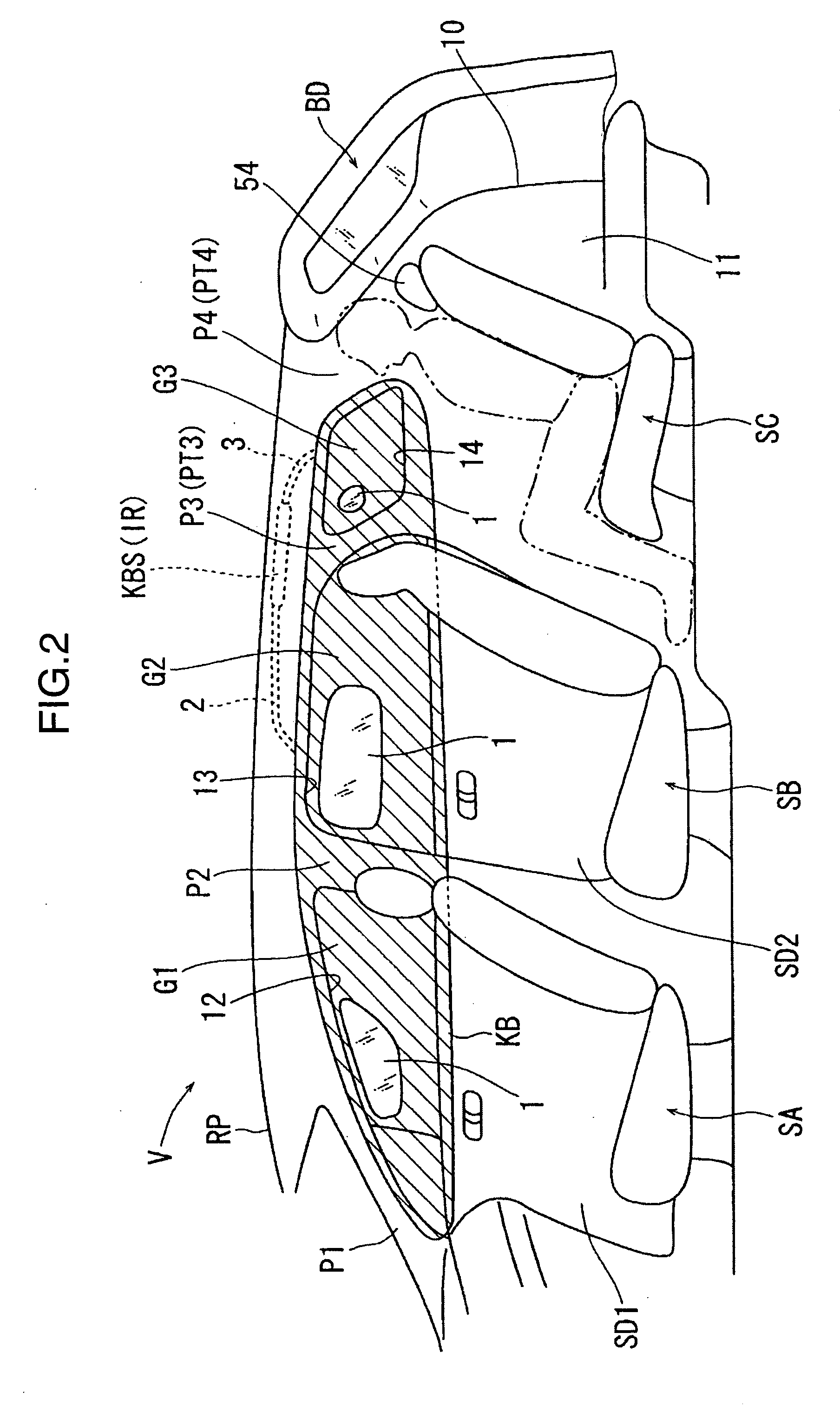

Knee protection apparatus for vehicle occupant

InactiveUS20060071459A1Reduce chanceIncrease equipment costPedestrian/occupant safety arrangementEngineeringAirbag

Owner:TOYOTA JIDOSHA KK

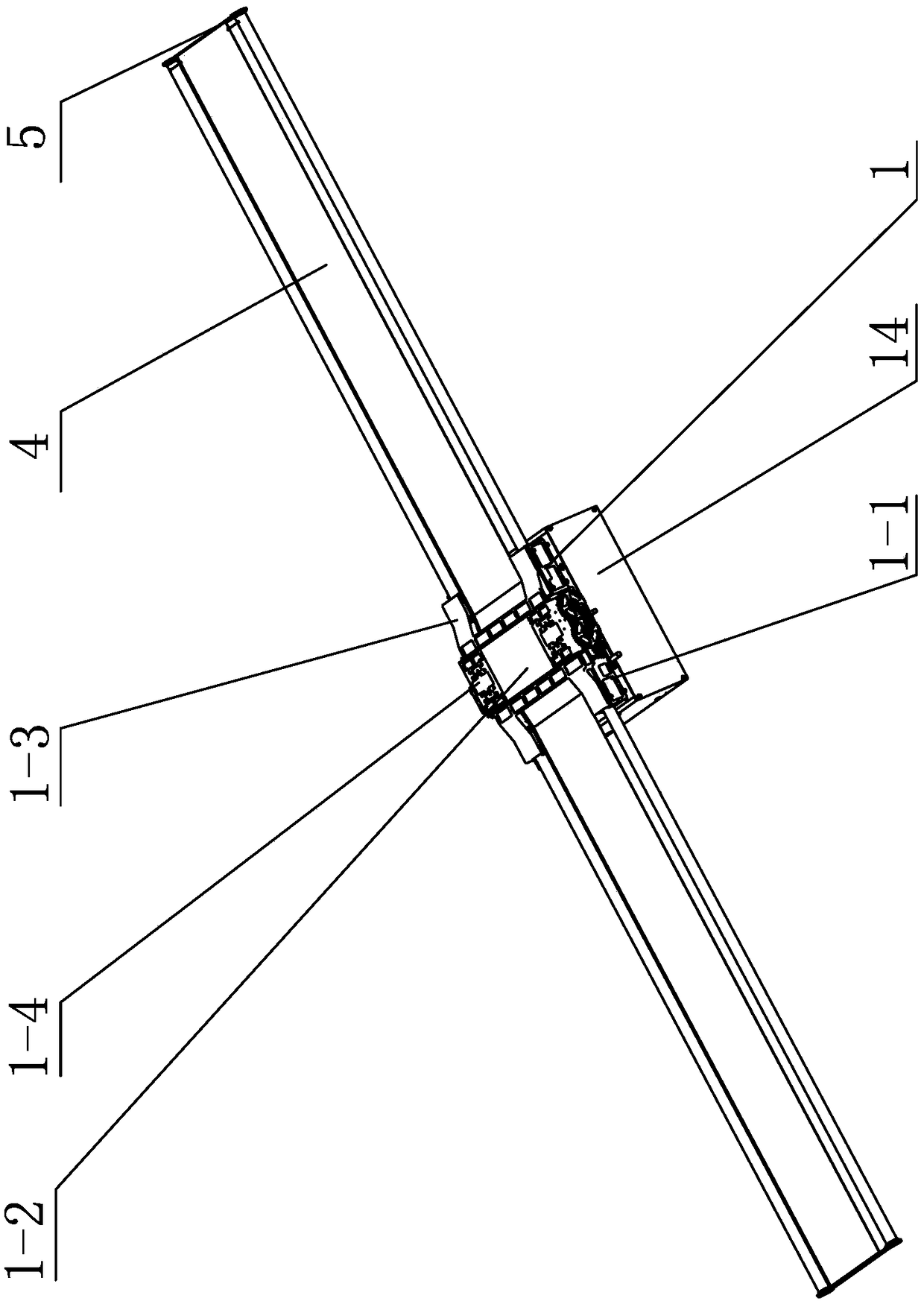

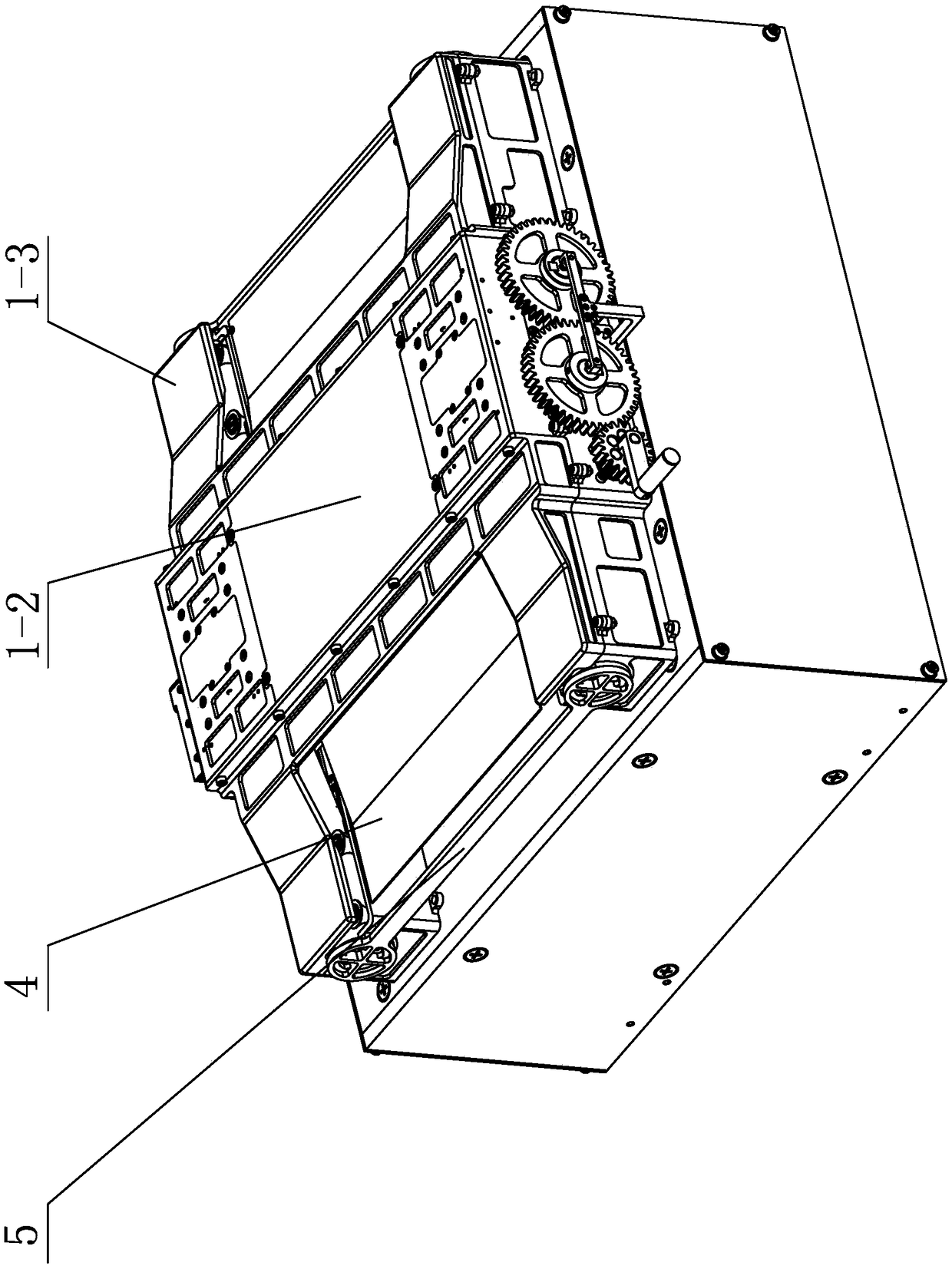

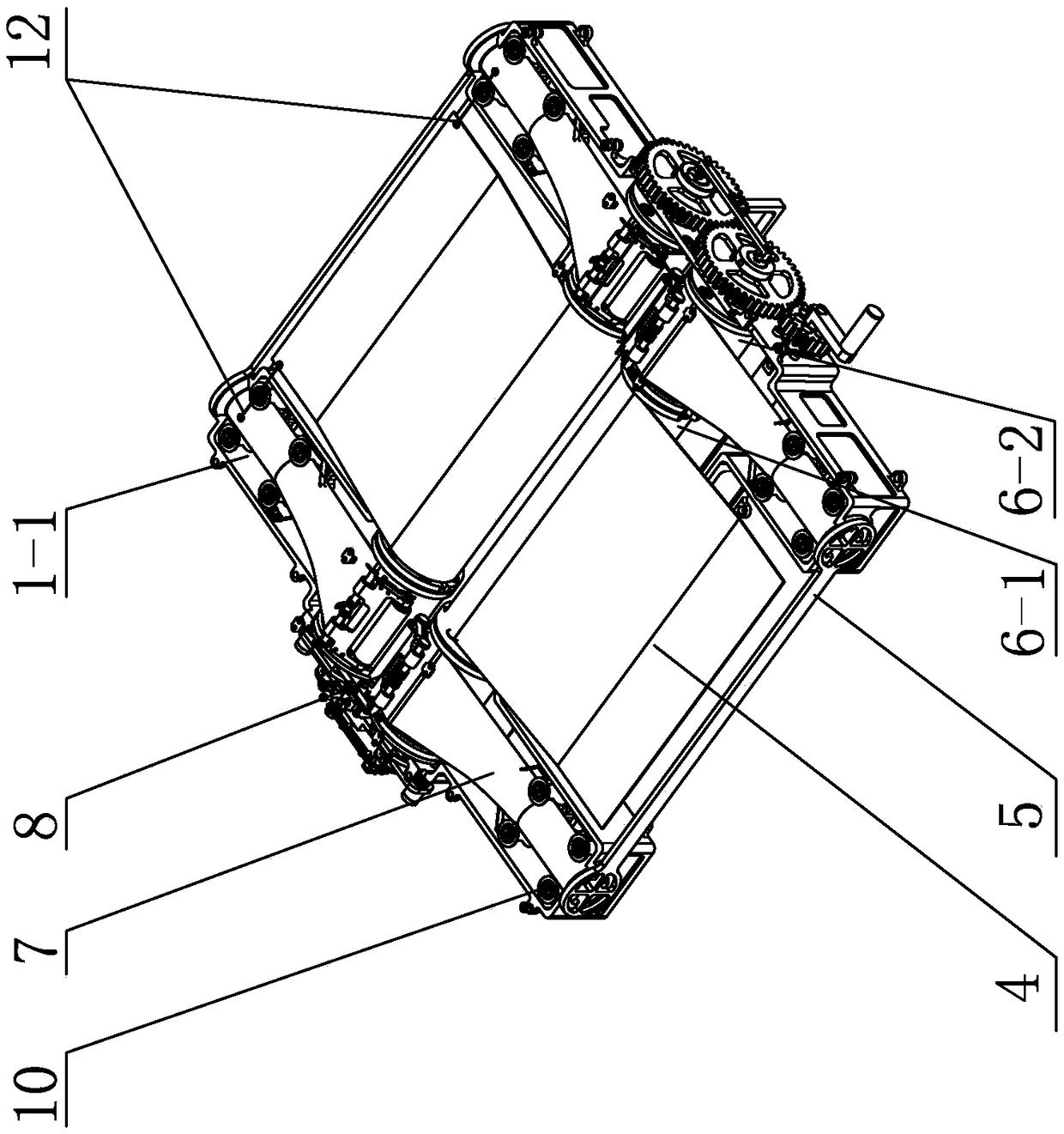

Rope net unfolding device based on thin-wall type stretching arm

InactiveCN102756811ANo need to consume energyRelease stabilityCosmonautic vehiclesCosmonautic partsStrain energyEngineering

The invention discloses a rope net unfolding device based on a thin-wall type stretching arm, which is used for ontrack cleaning of space debris. The device does not need to be driven by external power, and a net body structure is driven to unfold by strain energy stored by the thin-wall type stretching arm, so as to capture the space debris. Through adoption of a thin-wall structure, the stretching arm has high flexibility and light weight, the stretching arm stretches out and contracts back to store strain energy and to enable the mechanism to achieve a high magnification ratio. Due to the design that the stretching arm drives the net body structure to unfold, the unfolding process of the net body structure has good controllability; and due to the design of a press plate and a limiting pin, the unfolding synchronism is ensured.

Owner:BEIHANG UNIV

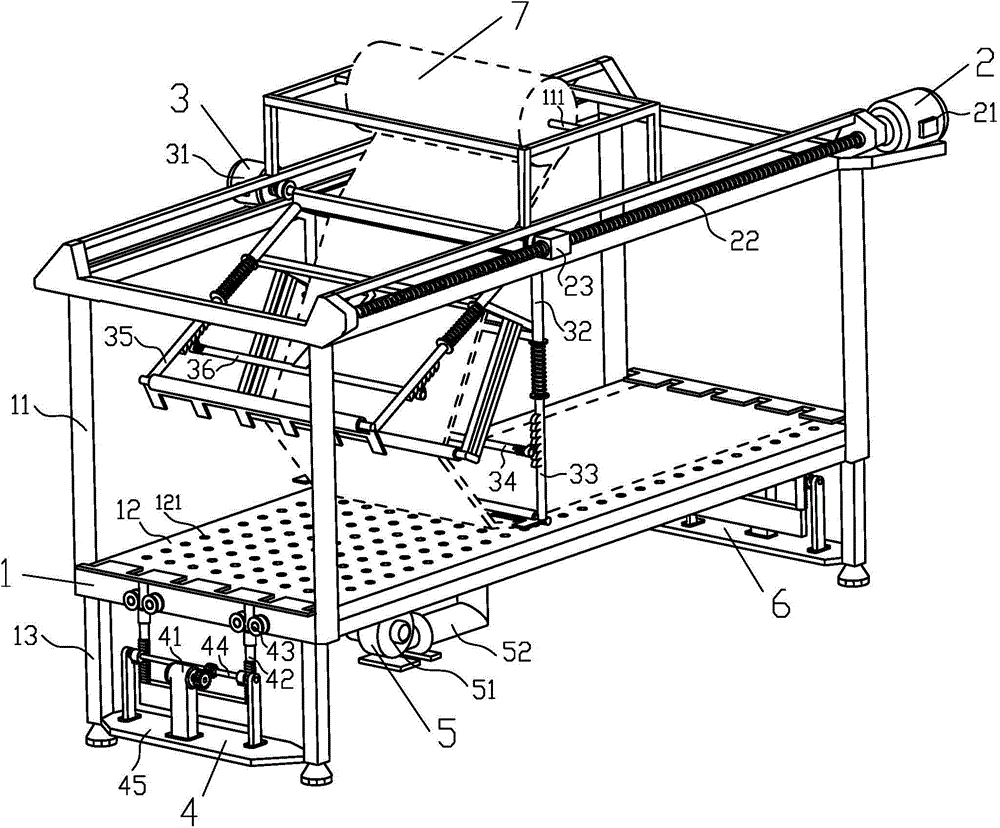

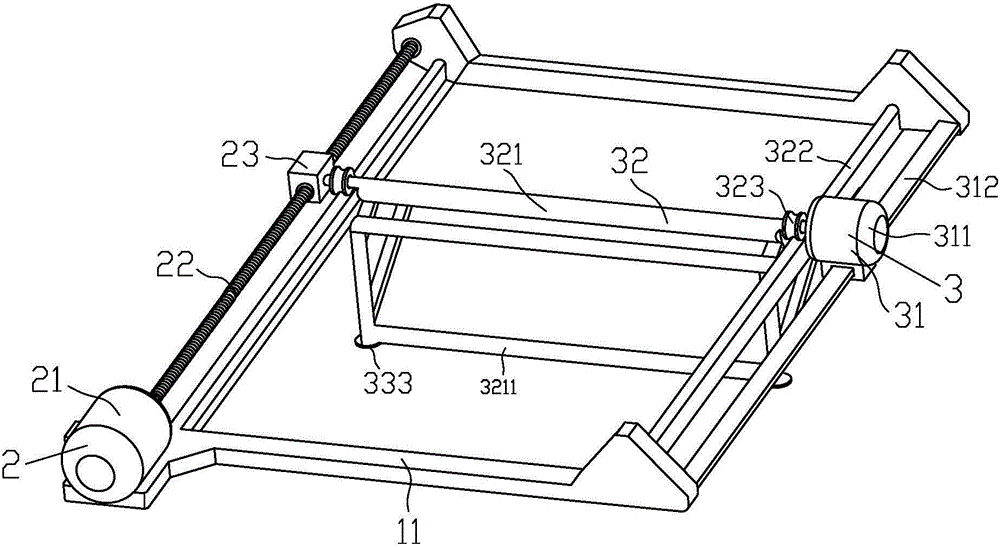

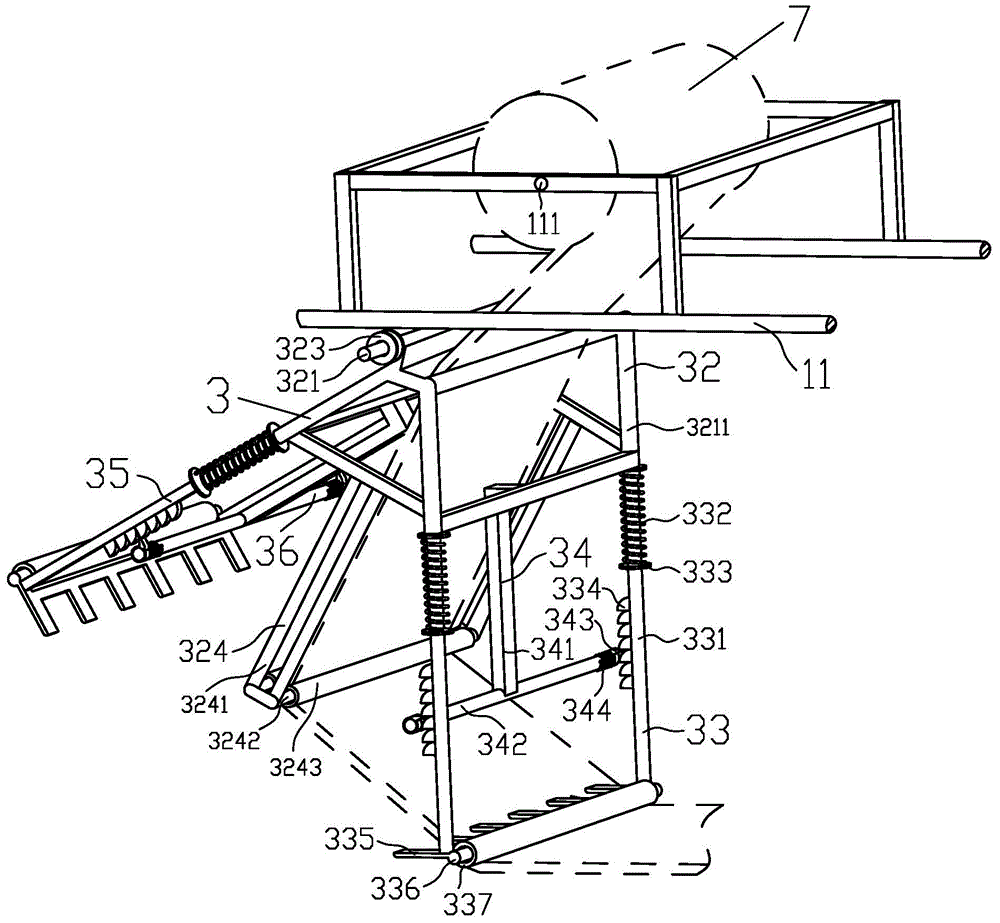

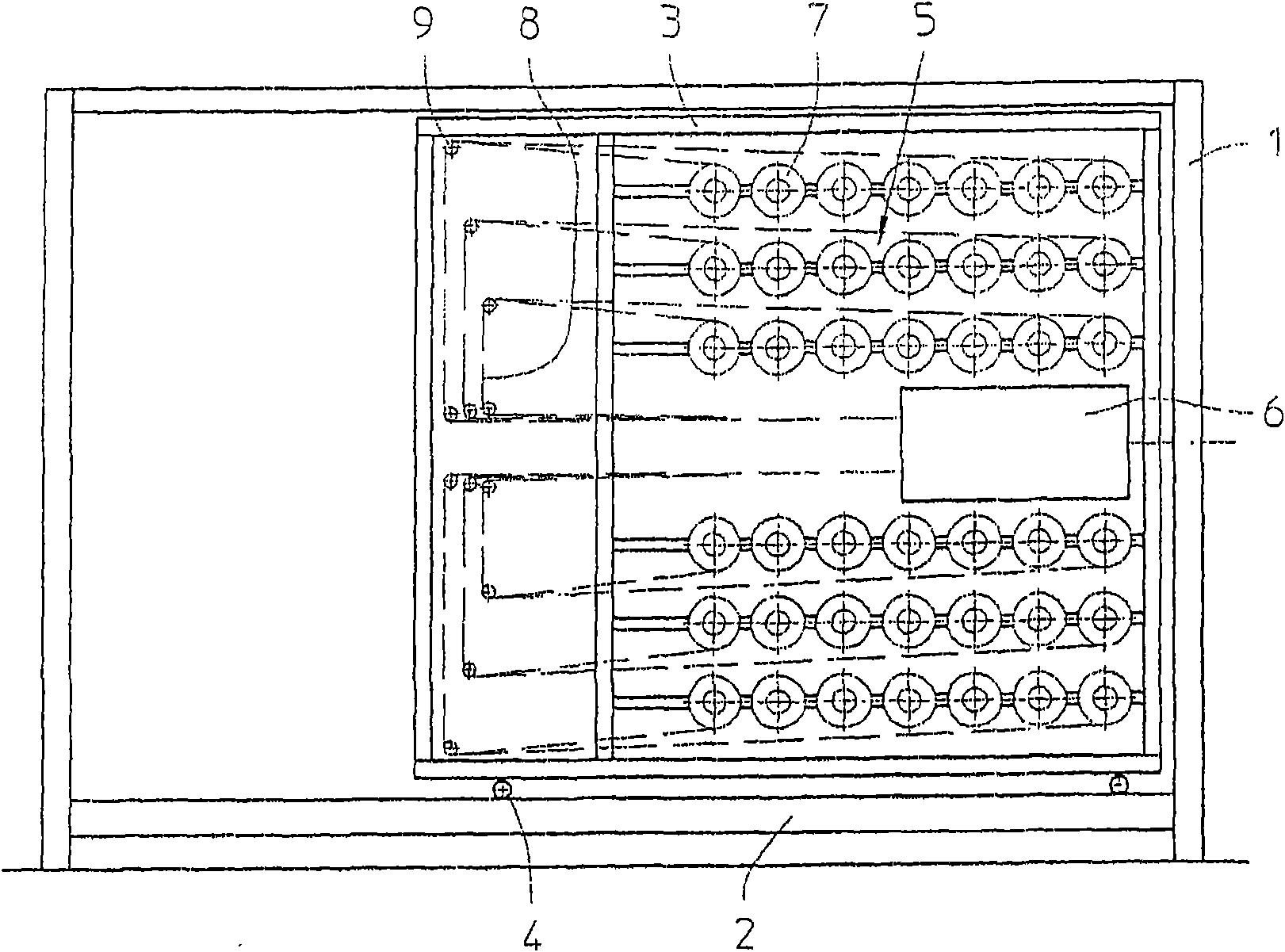

Automatic spreading machine

InactiveCN104876053AReduce the impactSave human effortUnfolding thin materialsWebs handlingSelf lockingEngineering

The invention discloses an automatic spreading machine which is composed of a workbench, a spreading device, a cloth laying device, a left cloth pressing device, an adsorption device and a right cloth pressing device. The workbench is composed of a supporting frame, a cloth laying platform and adjustable table legs. The spreading device is composed of a spreading motor, a lead screw and a movable sliding block. The cloth laying device is composed of a cloth laying driving device, a spreading connecting frame, a right cloth laying ascending mechanism, a right self-locking mechanism, a left cloth laying ascending mechanism and a left self-locking mechanism. The left cloth pressing device is composed of a cloth pressing driving device, a lifting mechanism, a pressing rod guide device, a cloth pressing transmission device and a cloth pressing supporting plate. The adsorption device is composed of an adsorption air pump and an air pipe. Cloth can be pulled out and flatly laid on the cloth laying platform with all the layers closely attached, and no wrinkle exists. Every time one layer of cloth is laid, cloth spreading and laying can be carried out in a reciprocating mode without breaking the cloth. According to the automatic spreading machine, manpower is saved, and cloth laying efficiency and quality are improved.

Owner:ANHUI UNIV OF SCI & TECH

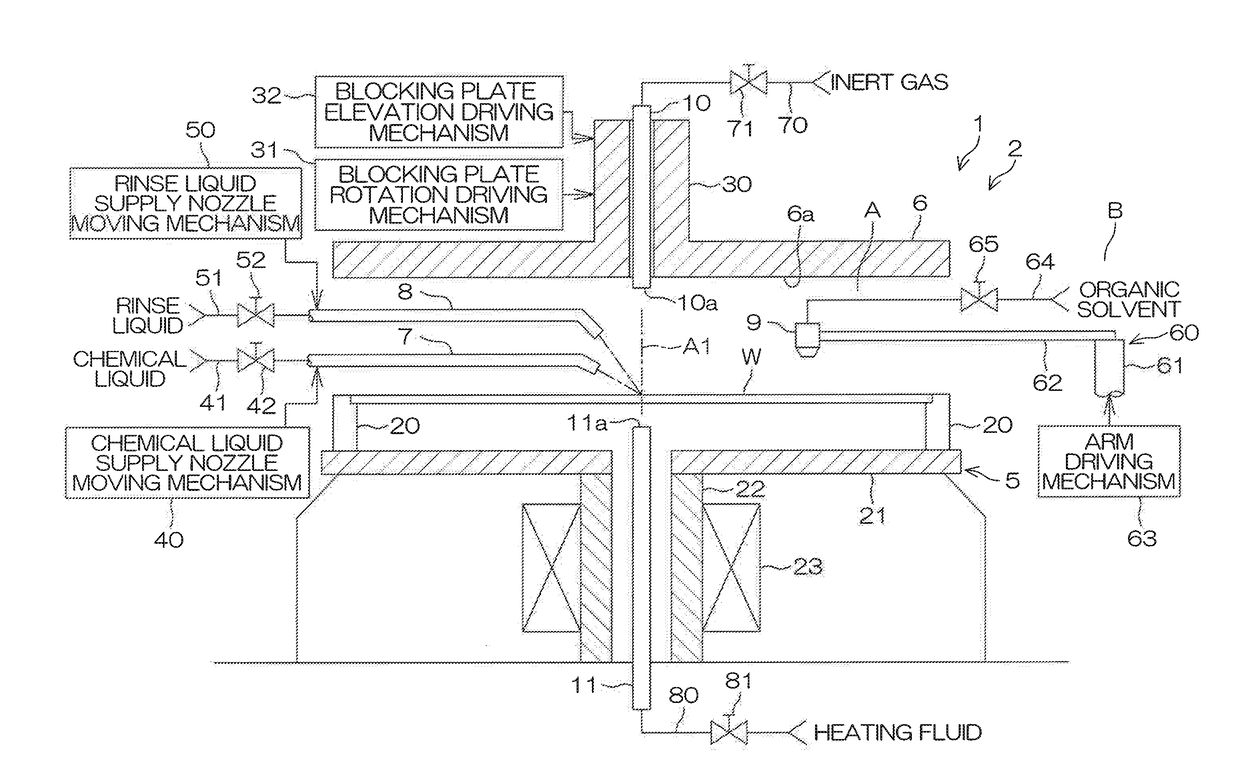

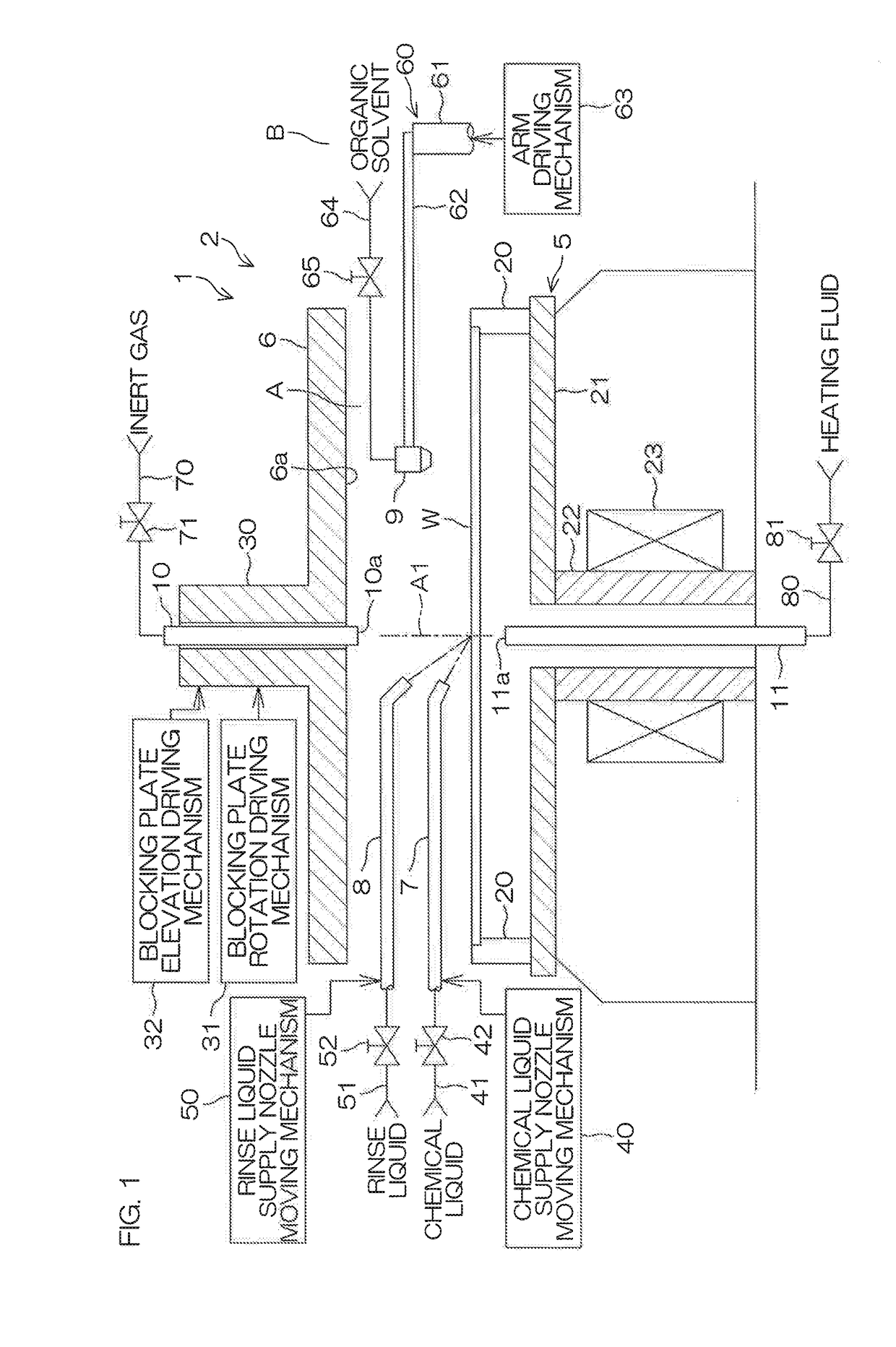

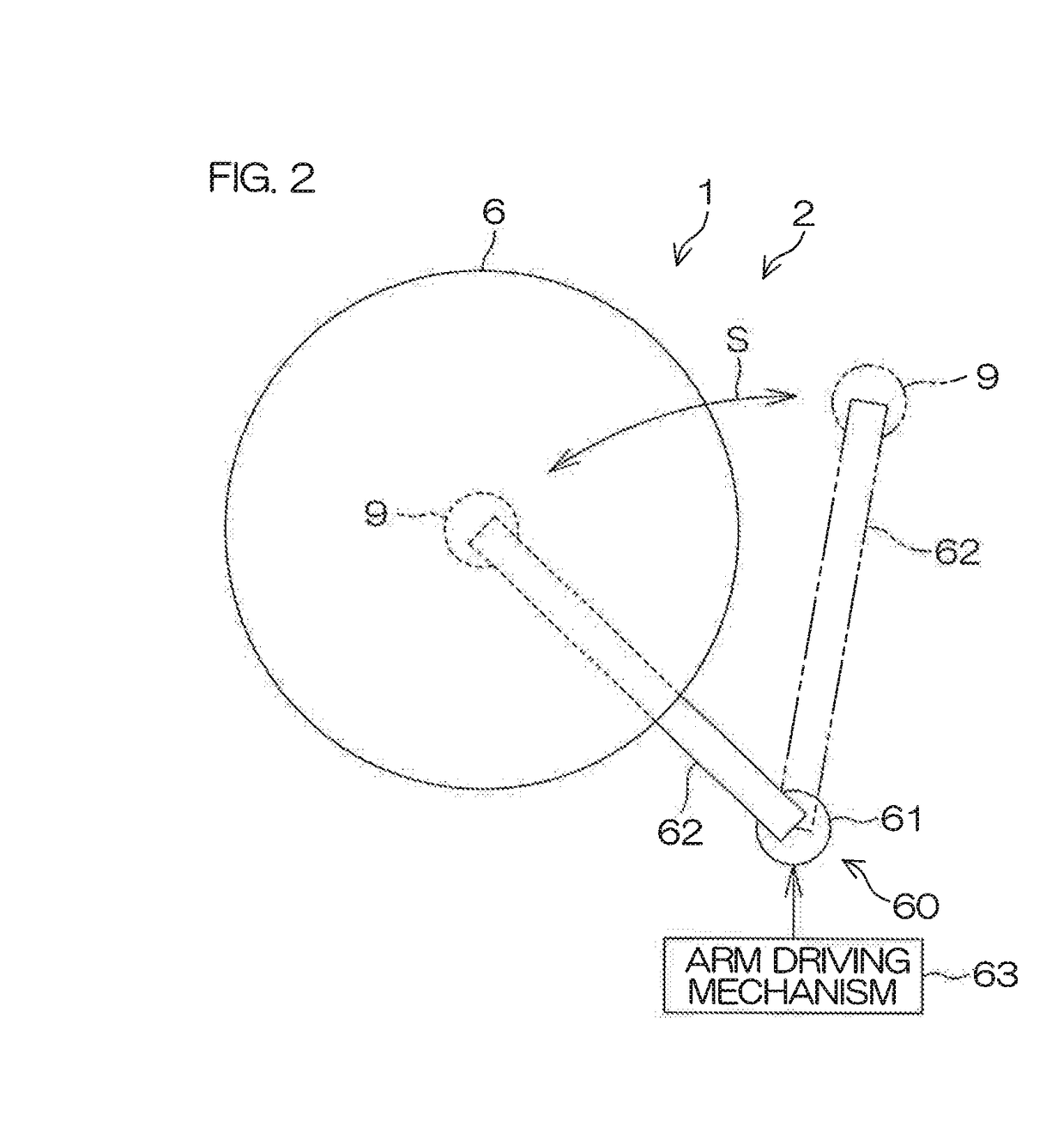

Substrate processing apparatus and substrate processing method

ActiveUS20170186599A1Expand smoothlyDry fastSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The controller is programmed to cause a low-surface-tension liquid supply unit to supply a liquid film of a low-surface-tension liquid to a front surface of a substrate so as to form a liquid film of the low-surface-tension liquid. The controller is programmed to control the substrate rotating unit and the inert gas supply unit so that an inert gas is supplied toward the rotational center position while rotating the substrate, thereby forming an opening spreading from the rotational center position to be formed in the liquid film, and enlarging the opening in a direction away from the rotational center position, and to control the landing-position changing unit to change the landing position of the low-surface-tension liquid to at least two positions except the rotational center position in accordance with enlargement of the opening so that the landing position is placed outside the peripheral edge of the opening.

Owner:DAINIPPON SCREEN MTG CO LTD

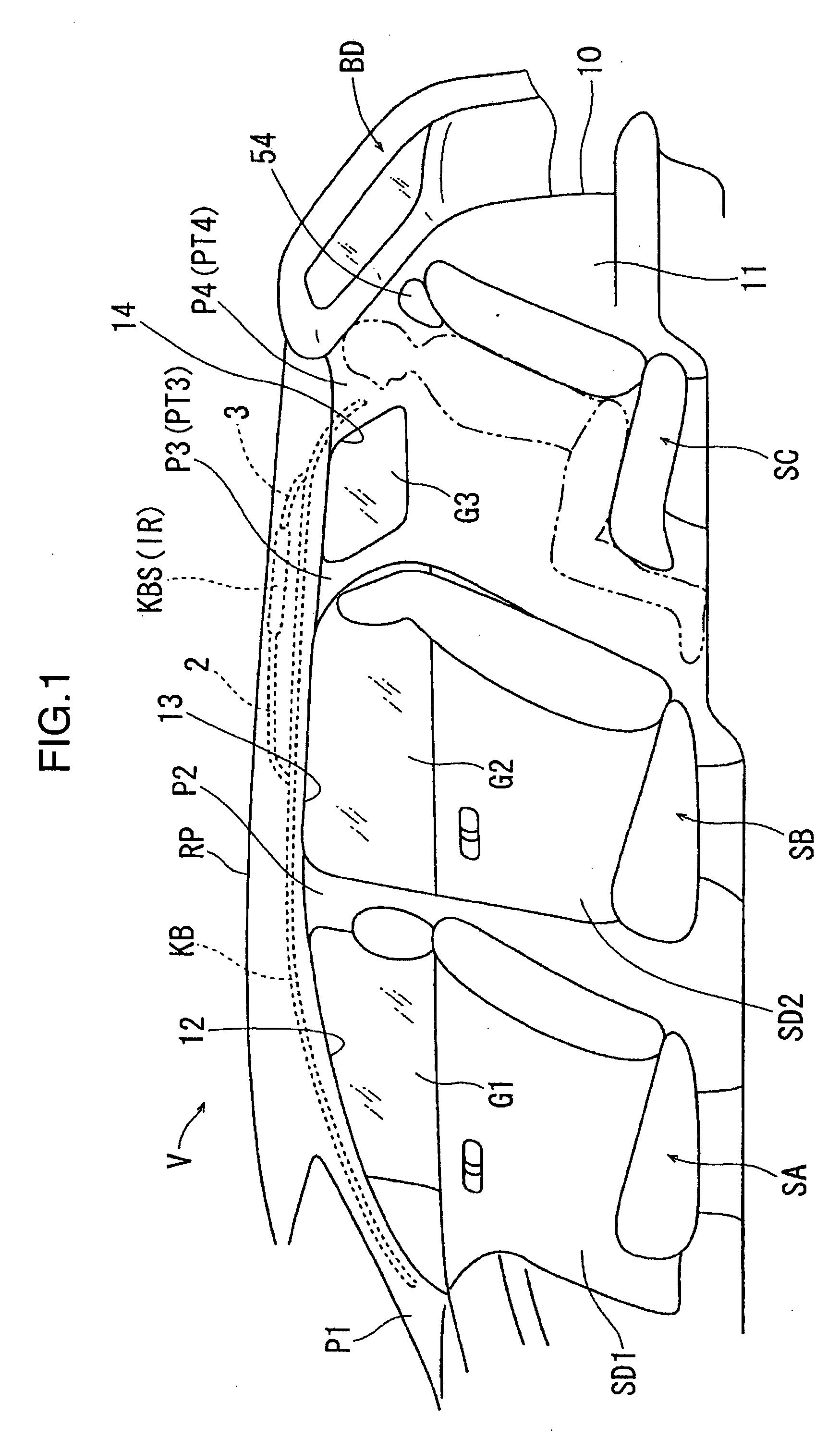

Head protecting airbag device

InactiveUS7077425B2Expand smoothlyQuick upgradePedestrian/occupant safety arrangementEngineeringAirbag deployment

Owner:TOYODA GOSEI CO LTD

Intravascular stent and assembly

InactiveUS7766956B2Maximum possible flexibility and conformabilityOptimal metal fractionStentsSurgeryVascular lumenIntravascular stent

Owner:BOSTON SCI SCIMED INC

Heat exchanger and method of manufacturing the same

InactiveUS7500515B2Increase internal pressureAdd partsMetal-working apparatusStationary conduit assembliesInternal pressureEngineering

There is provided a method of manufacturing a heat exchanger, including a first step of mounting an end part of flat tube to a header, assembling the flat tube and fins, and sealing a part where the header and the end part is attached, and a second step of increasing an internal pressure of the flat tube to expand other part of flat tubes aside from the end parts with respect to the end part of the tube in order to make the fins and the other part of the flat tube in contact each other. According to this method of manufacturing, in the second step, the other part of the flat tube that passes through the fins is expanded, so that it is possible to mechanically join the flat tube and the fins, and a plate fin-type heat exchanger with high strength and heat exchange efficiency can be easily provided.

Owner:DENSO AIRCOOL CORP

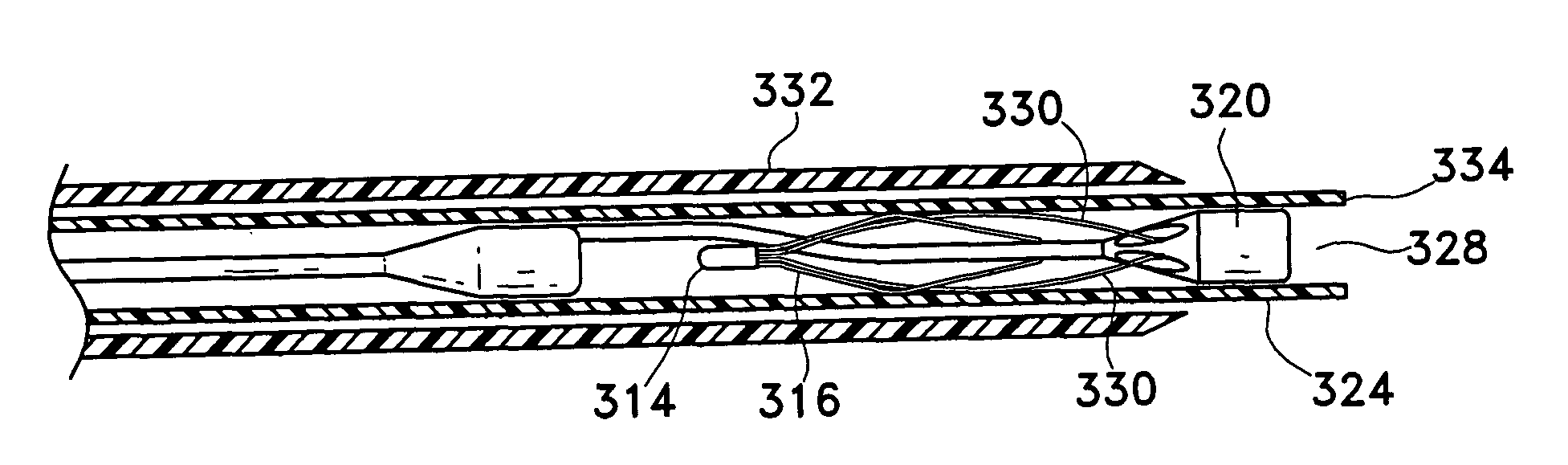

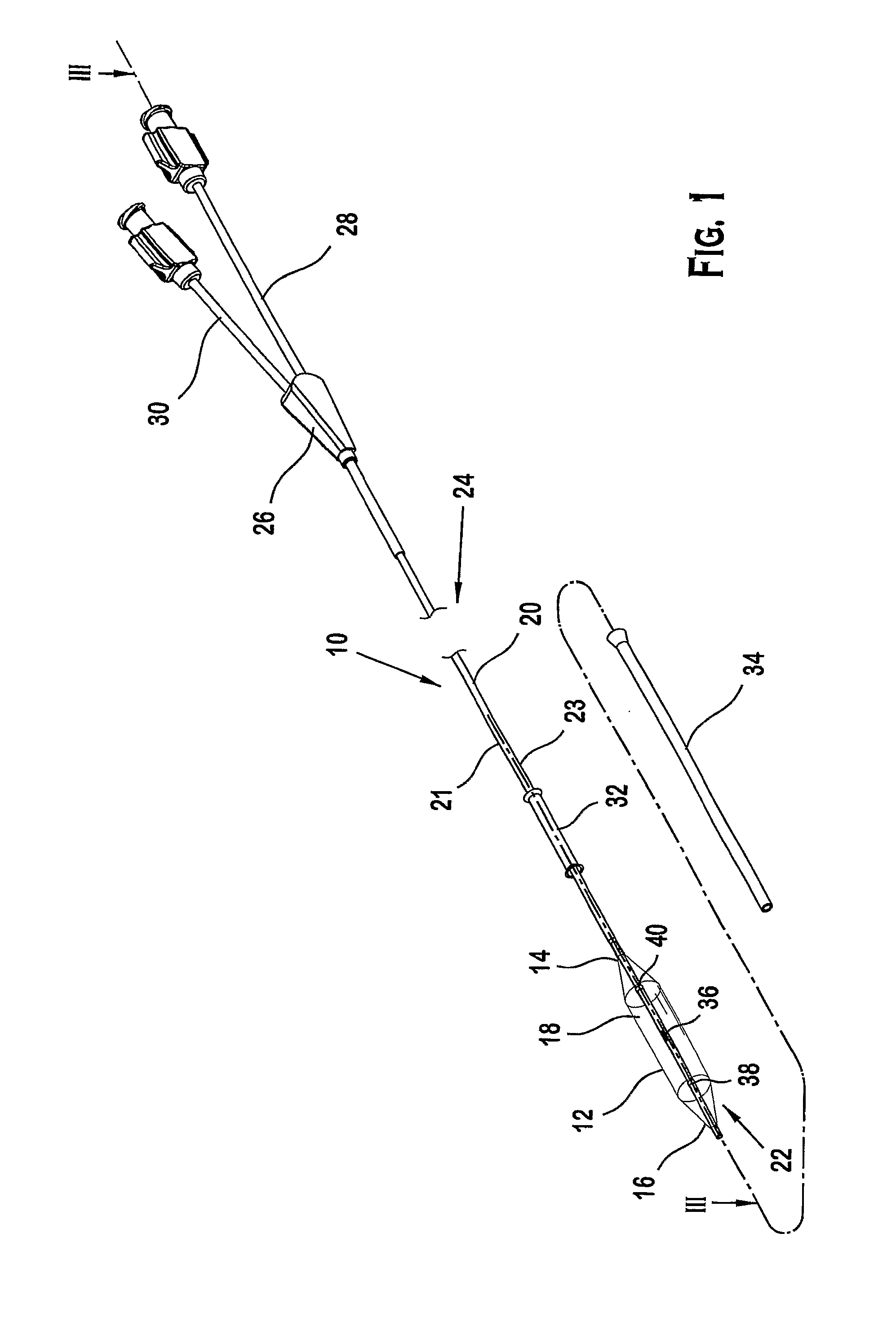

Balloon catheter with centralized vent hole

InactiveUS20090312827A1Expand smoothlyLimit stent migrationBalloon catheterSurgeryInsertion stentBalloon catheter

A system and method providing a catheter assembly for engaging a stenosis. The assembly includes a catheter defining a first lumen and a second lumen spaced apart and disposed about a longitudinal axis. The catheter includes an opening in communication with the first lumen to define a flow path having an angle incident to the longitudinal axis. A first marker; and a second marker disposed on the catheter are spaced equidistantly from the opening. The assembly includes a balloon having a first end and a second end each sealed about the catheter and equidistantly from the opening to define a holding volume therebetween. The opening is disposed within the holding volume thereby placing the first lumen in sealed fluid communication with the holding volume. In a preferred embodiment, the catheter assembly includes a stent disposed about the balloon, and the balloon is configured to engage the stent with a stenosis.

Owner:CR BARD INC

Passenger-side airbag folded body and passenger-side airbag apparatus

ActiveUS20120126515A1Reduce the applied forceEasy to unfoldPedestrian/occupant safety arrangementEngineeringAirbag

There is provided a passenger-side airbag folded body in which an inflator opening is provided at a base end of an airbag and a vent hole is provided at each of right and left side surfaces of the airbag. Right and left end parts of the airbag are folded along vertical fold lines, thereby providing a vertically long primary folded body. The primary folded body is folded along lateral fold lines, thereby providing the passenger-side airbag folded body serving as a final folded body, and the vent holes are exposed at right and left end faces of the final folded body.

Owner:JOYSON SAFETY SYST JAPAN GK

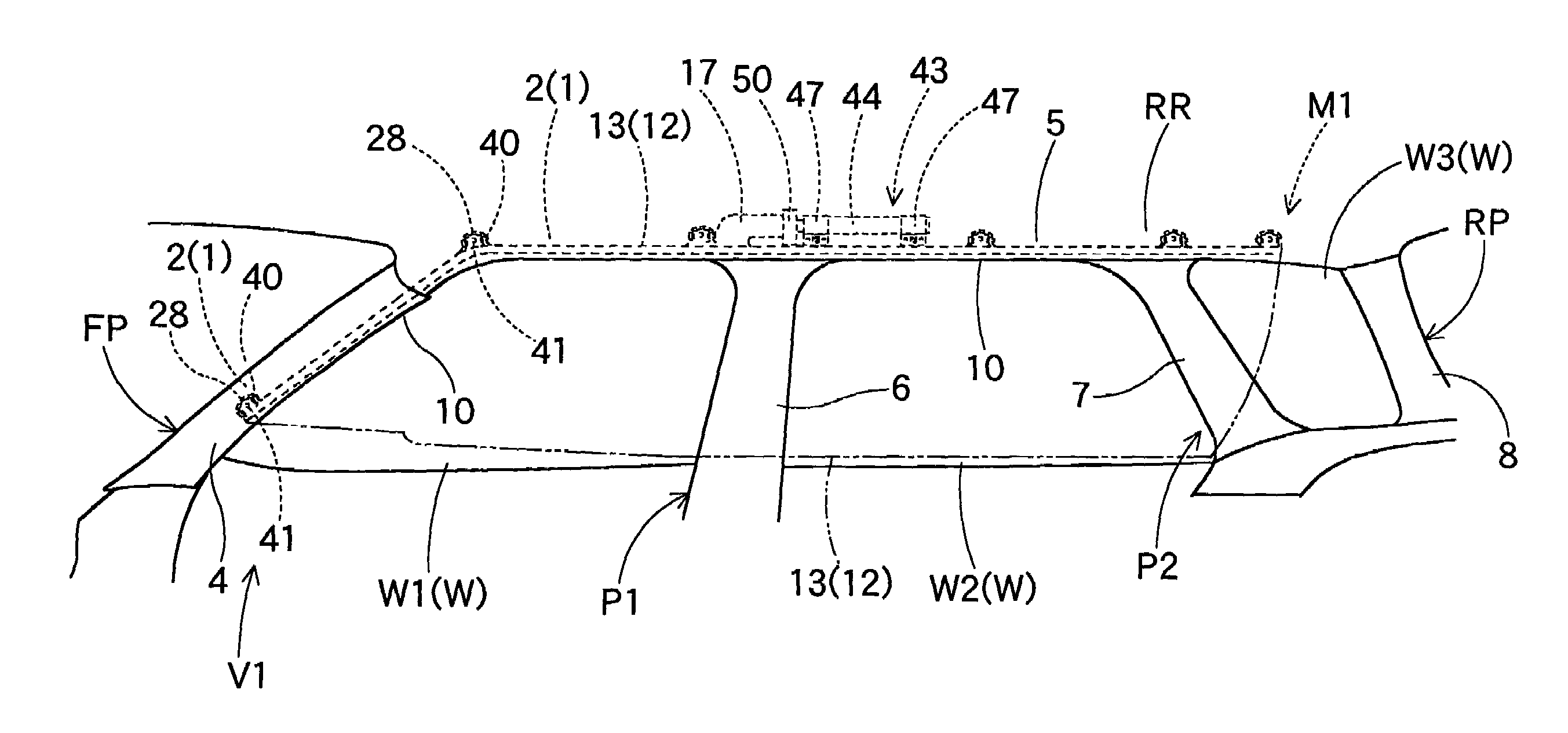

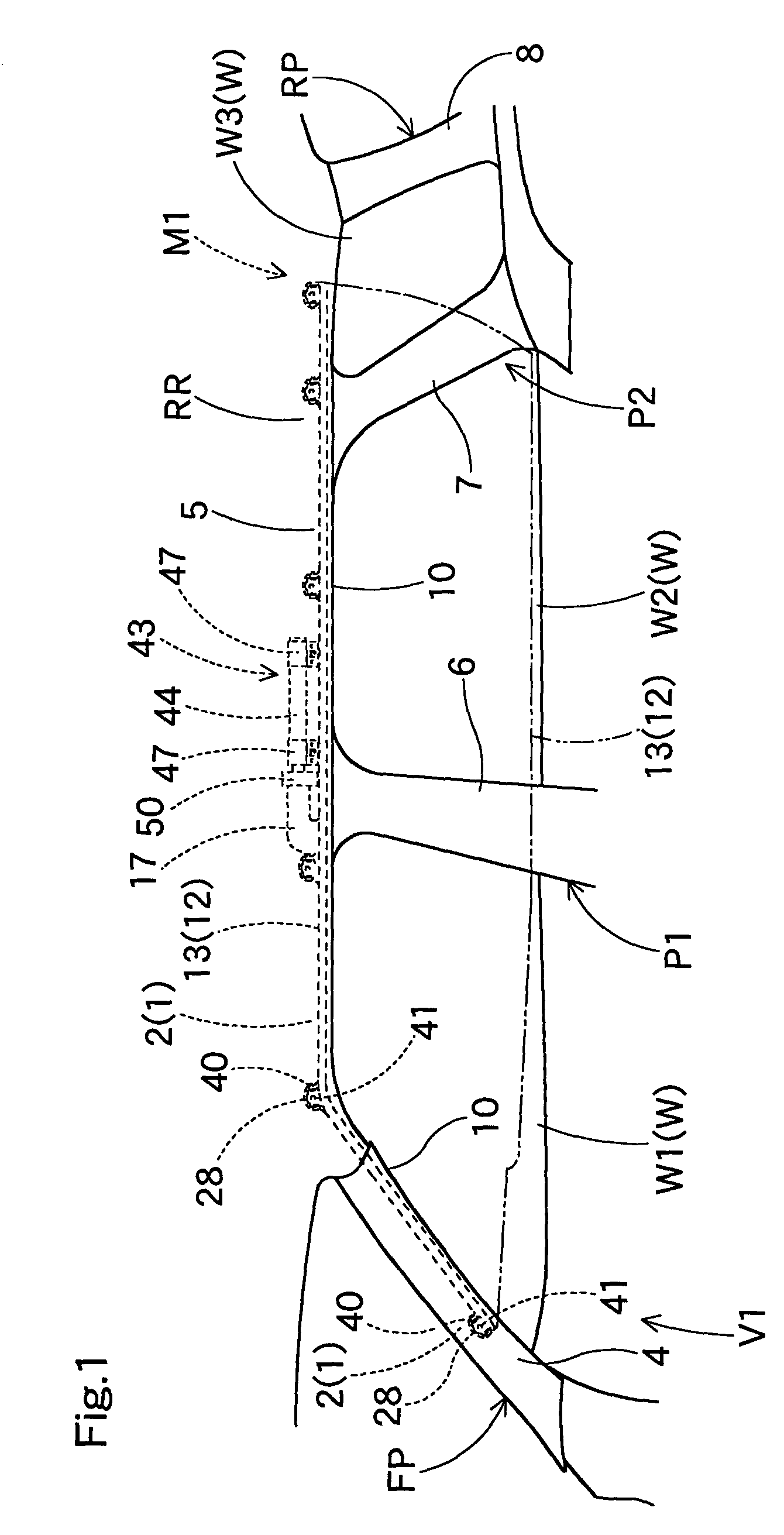

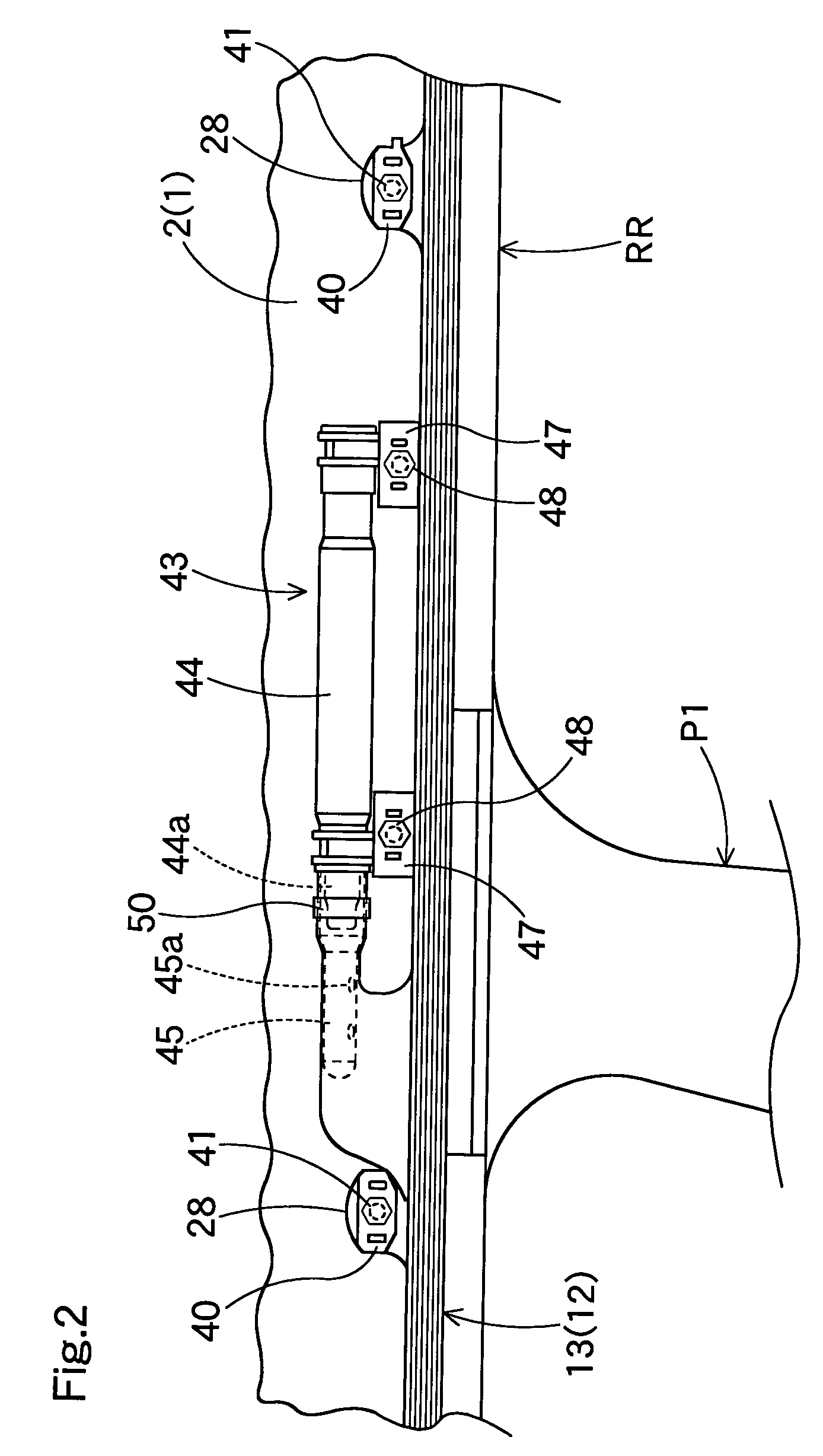

Rear structure of vehicle provided with curtain air bag apparatus

ActiveUS20070210561A1Expand smoothlyEvenly deployedPedestrian/occupant safety arrangementEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

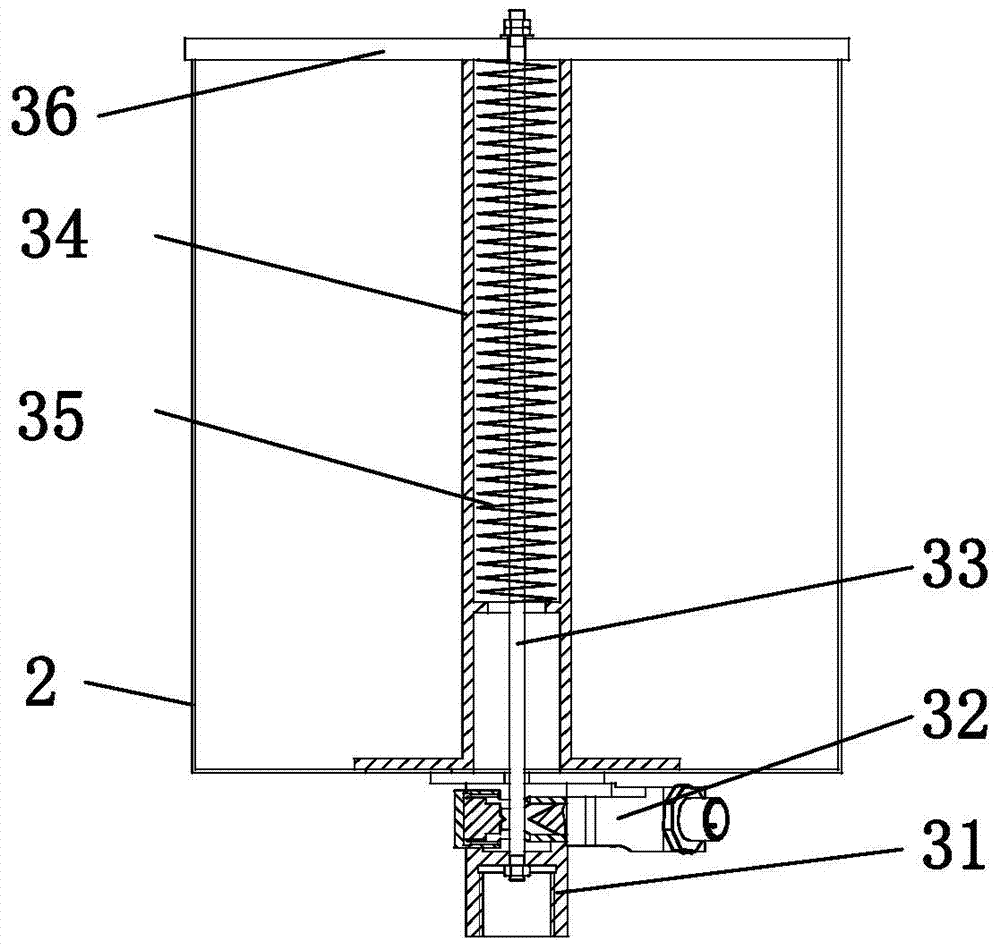

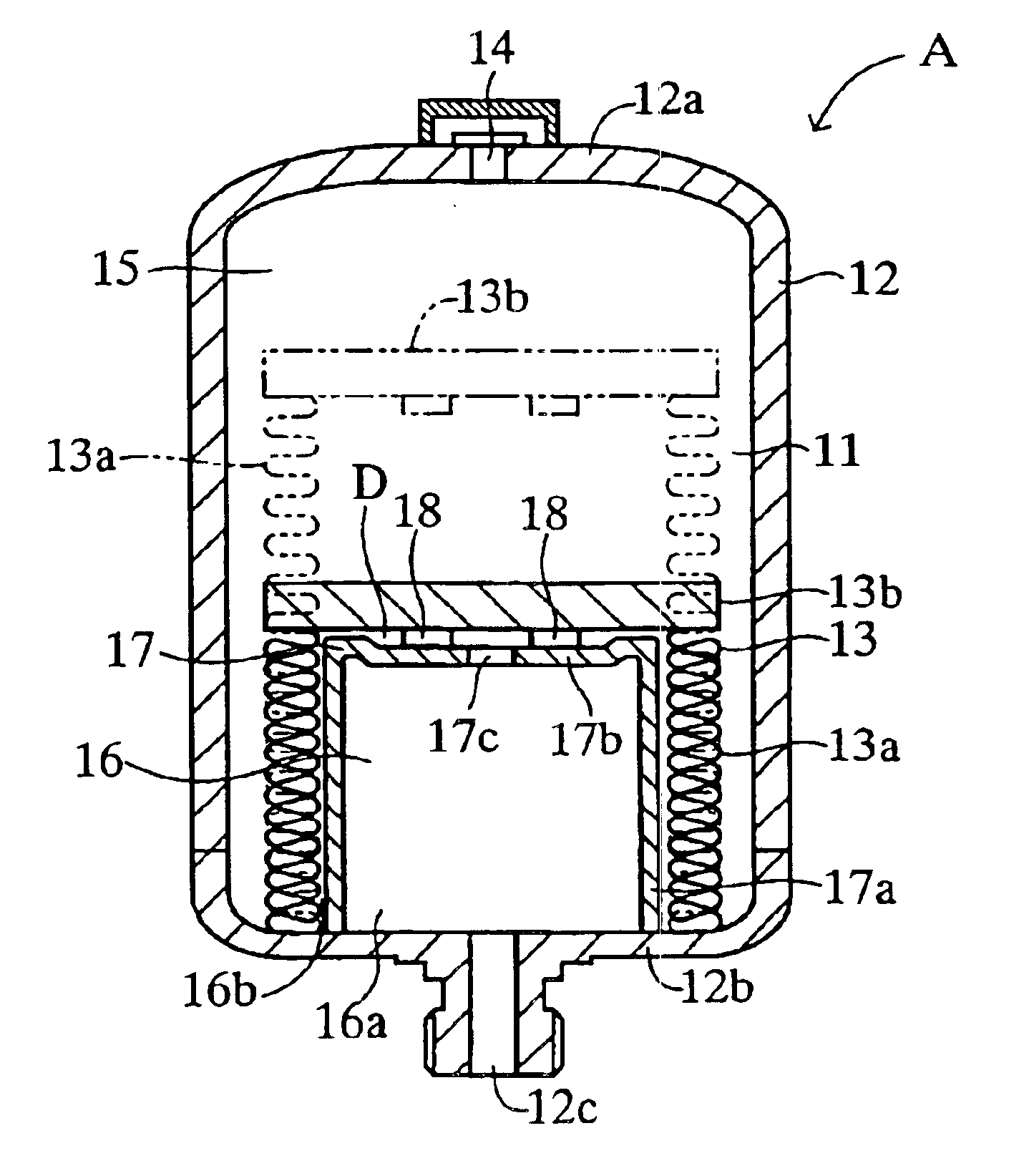

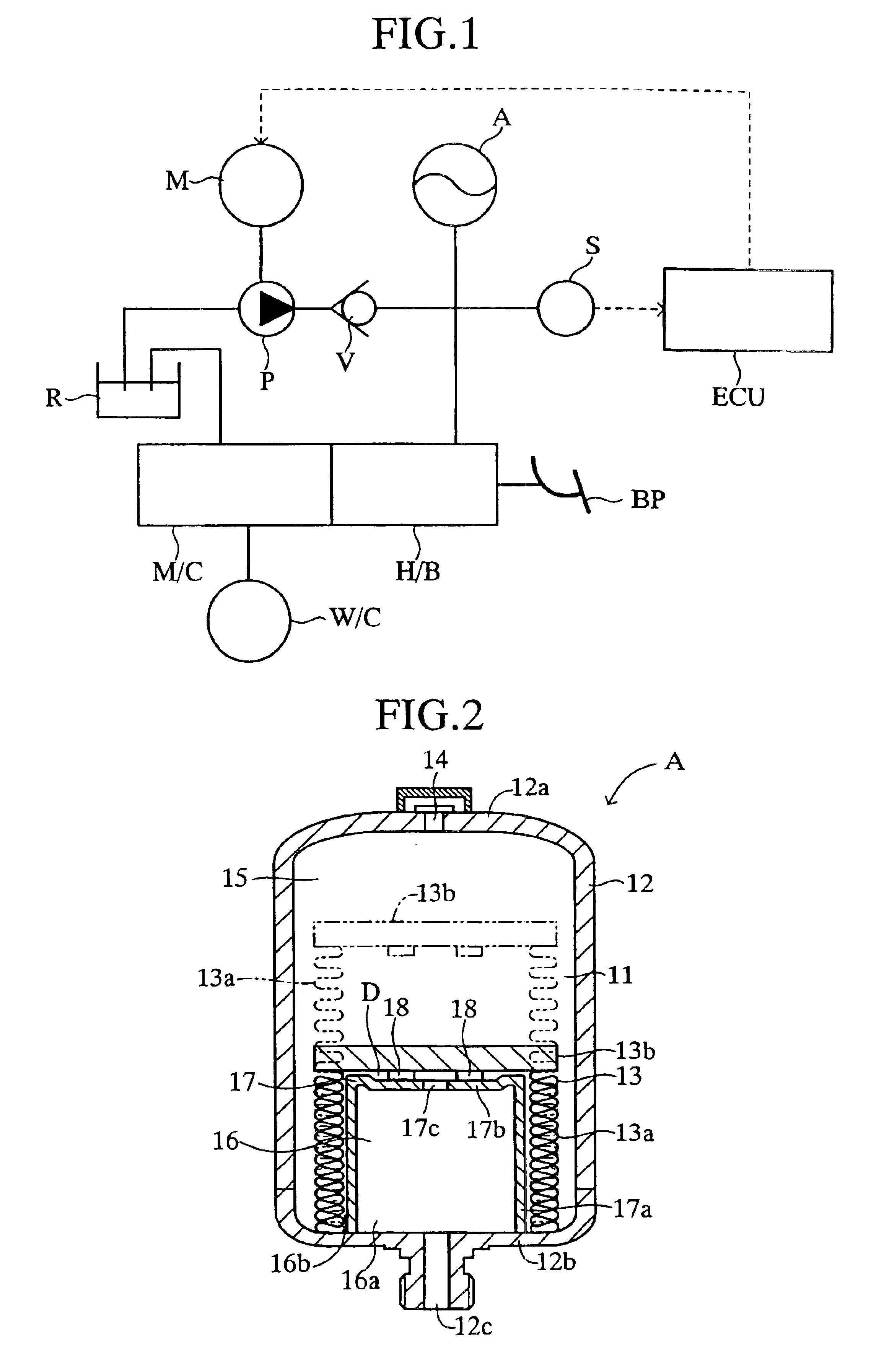

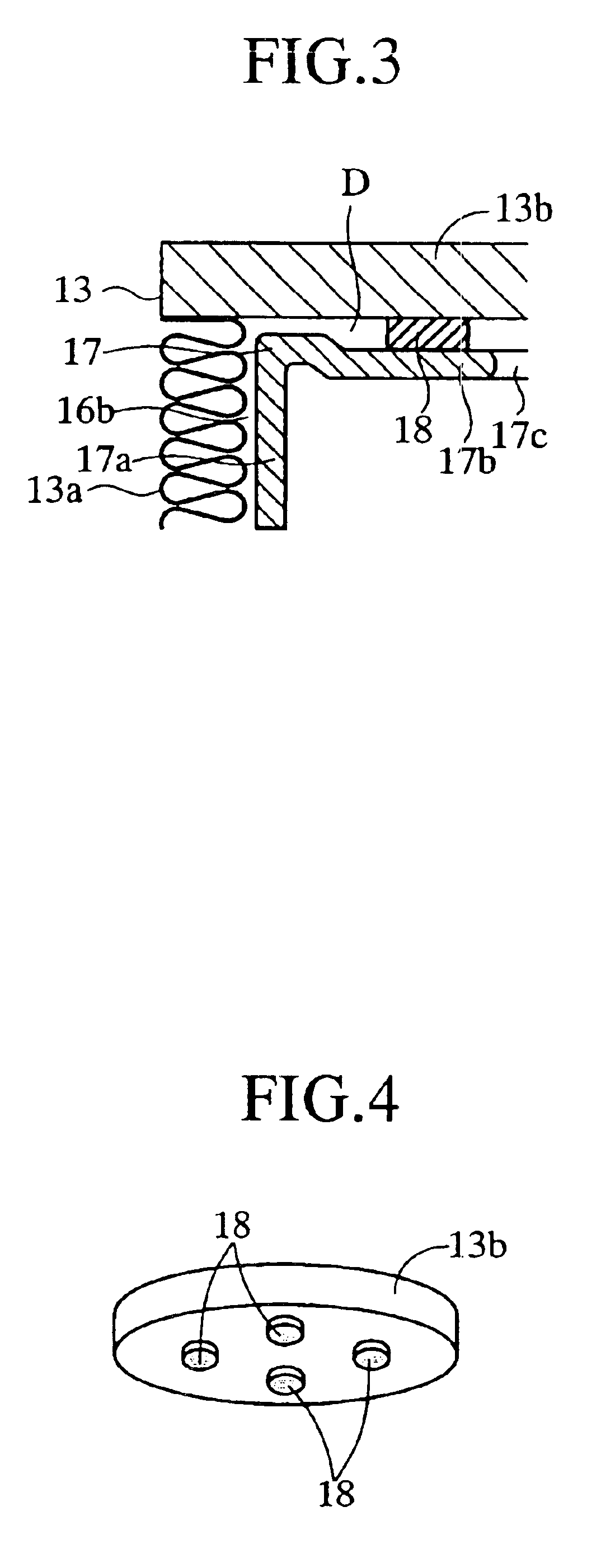

Metal bellows accumulator

InactiveUS6871670B2Compact manufacturingReliably accumulatingAccumulator installationsPipe elementsProduct gasGas chamber

In a metal bellows accumulator, a metallic bellows unit is disposed within a pressure space defined in a main shell, and one end of the metallic bellows unit is fixedly secured to one end wall of the main shell. The metallic bellows unit sections the pressure space into an outer chamber serving as a gas chamber in which a pressurized gas is enclosed, and an inner chamber serving as a liquid chamber communicating with a liquid port formed in the end wall of the main shell. A stopper (auxiliary shell) for limiting collapsing movement of the metallic bellows unit is disposed within the liquid chamber and has a communication passage hole. The liquid port always communicates with a liquid chamber to which an inner circumferential surface of a bellows portion of the metallic bellows unit is exposed via the communication passage hole.

Owner:ADVICS CO LTD

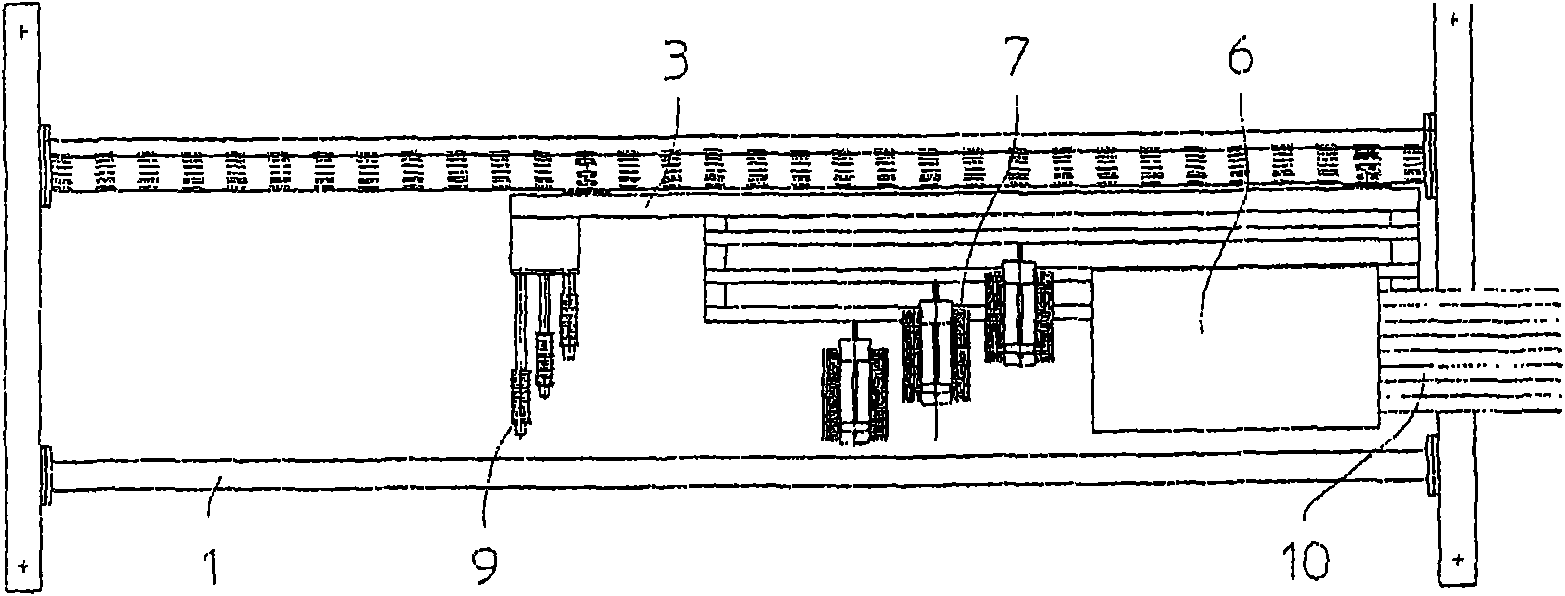

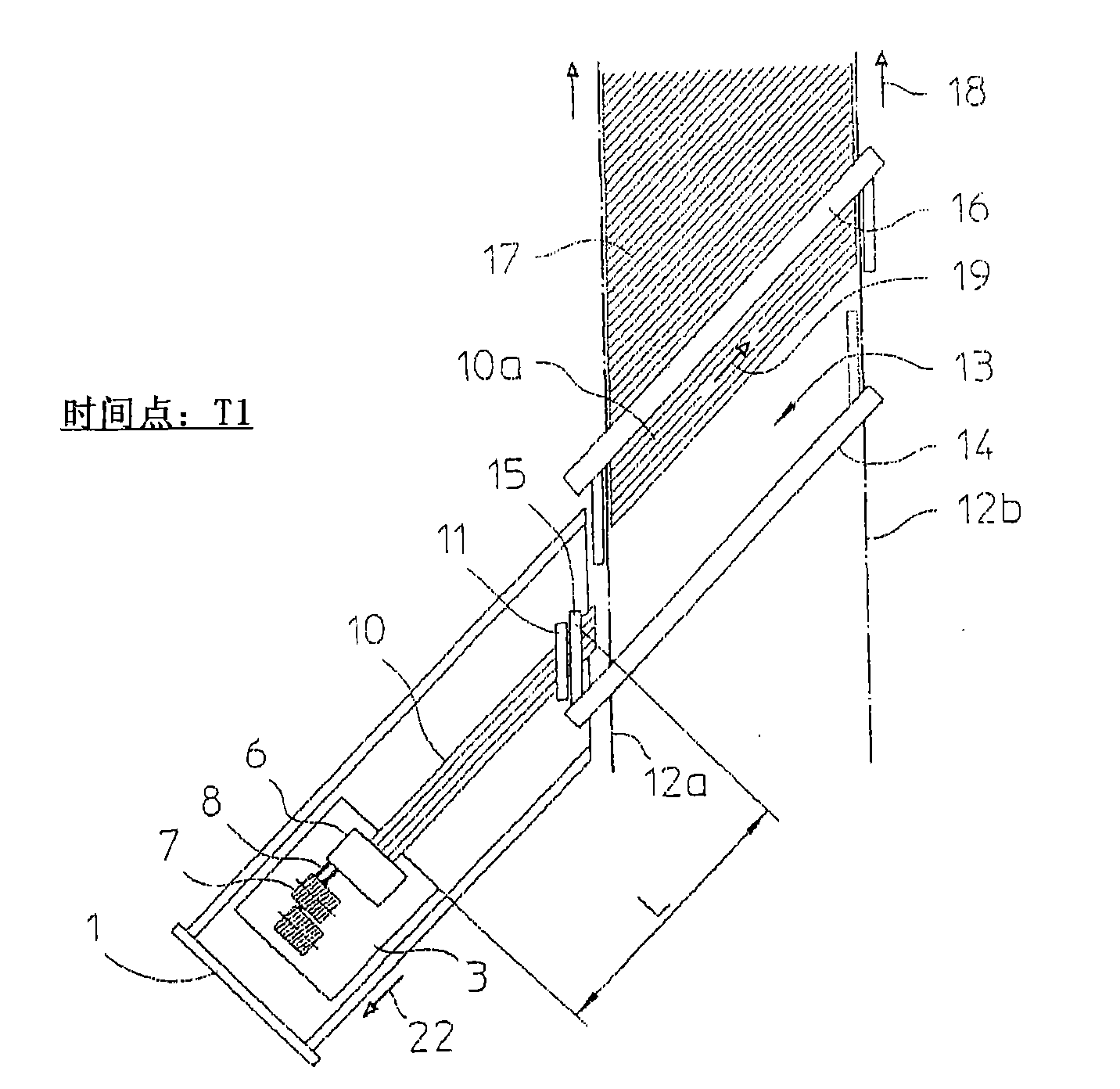

Method and device for creating a unidirectional fibre layer, method for manufacturing a multi-axial layed fabric and a multi-axial machine as well as a method for manufacturing a woven cloth and weavi

A unidirectional fiber layer (17) which has a form of fiber strip (10a) that is cut in a certain length is laid between two conveying chains along the conveying direction (18). The unidirectional fiber layer is fixed on a fixing device on the conveying chains (12a, b). A spool (7) provides the fibers (8) used for lying and forms a common yarn creel. The spool (7) traverses an expanding device (6)and forms a broadened fiber beam (10). The fiber (8) in the fiber beam is parallel with each other. The fiber beam (10) is divided to single fiber beam segments (10a) and is layed by a laying device which operates intermittently with different speeds. The yarn creel with the spool (7), and the expanding device (6) are positioned on a common moving vehicle (3) together. The moving vehicle can movecontrollably in a laying direction (19) repeatedly. Through the motion of the moving vehicle (3), a fiber base with length of L is formed for compensating the irregular motion of the laying device (13). Therefore the fiber (8) positioned on the moving vehicle (3) can leave the spool (7) and traverse the expanding device (6) with a same speed. Therefore the unidirectional fiber layer (17) uniformly with a yarn tension same in all single fibers (8) and a high quality.

Owner:KARL MAYER TECH TEXTILIEN GMBH

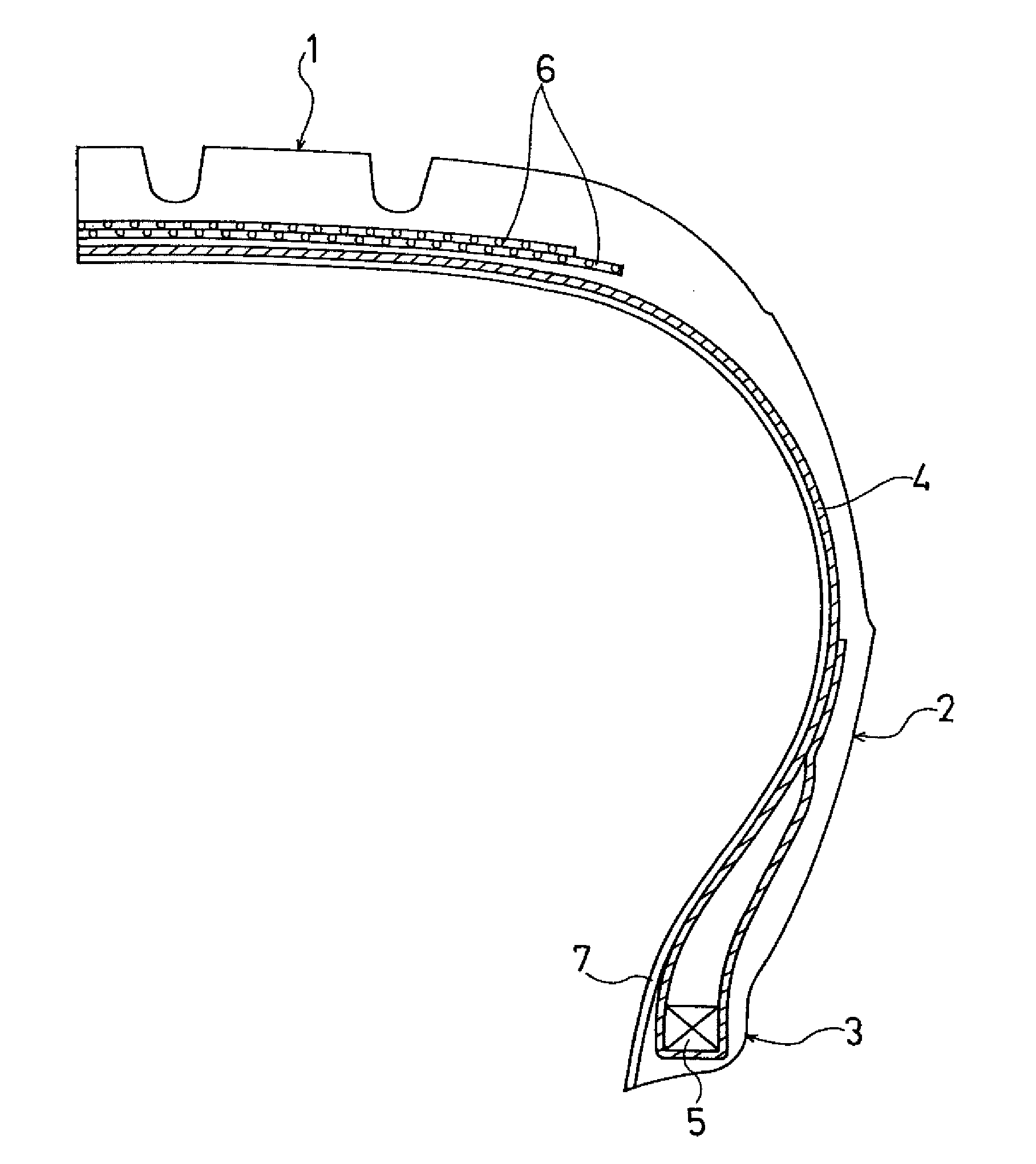

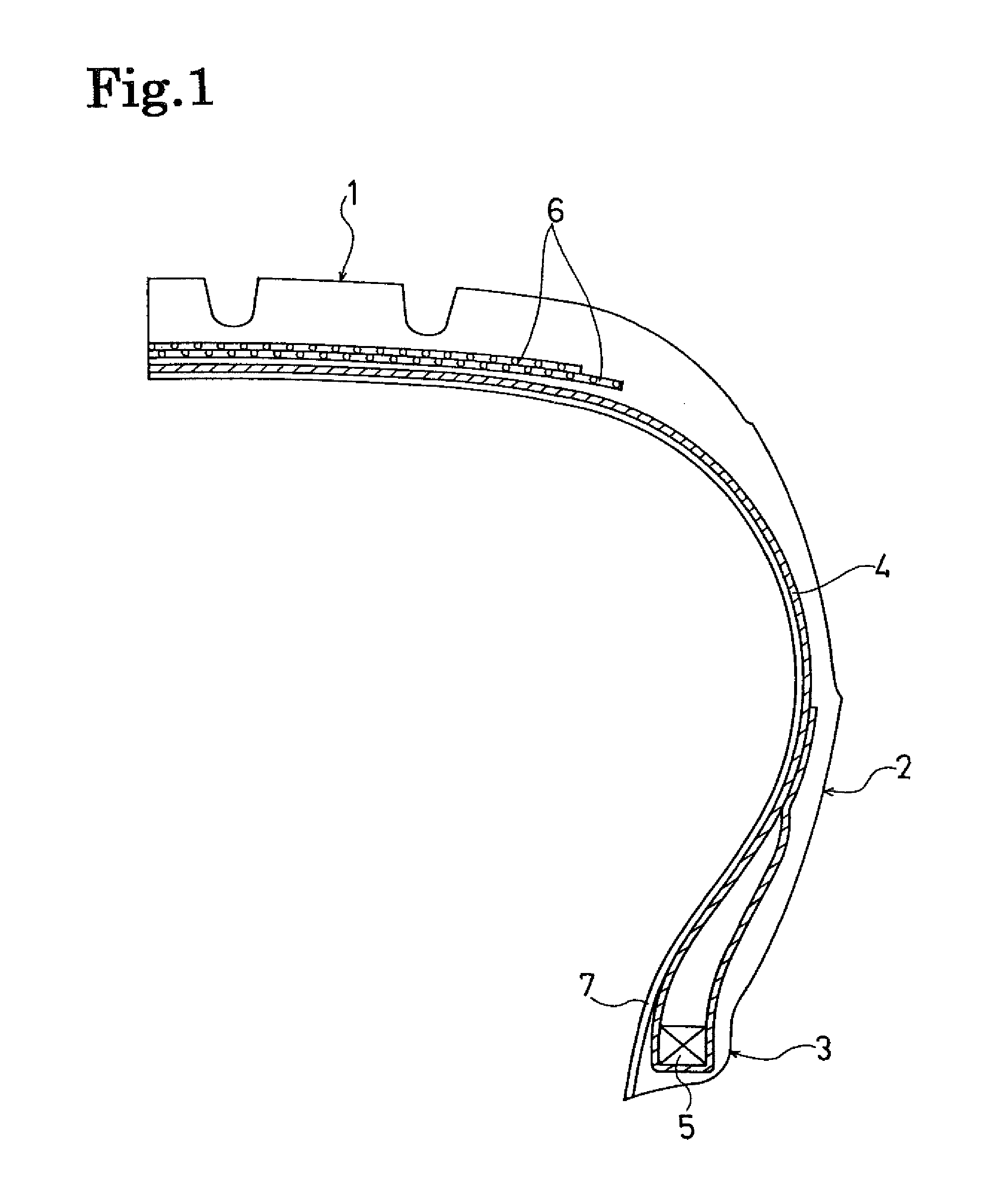

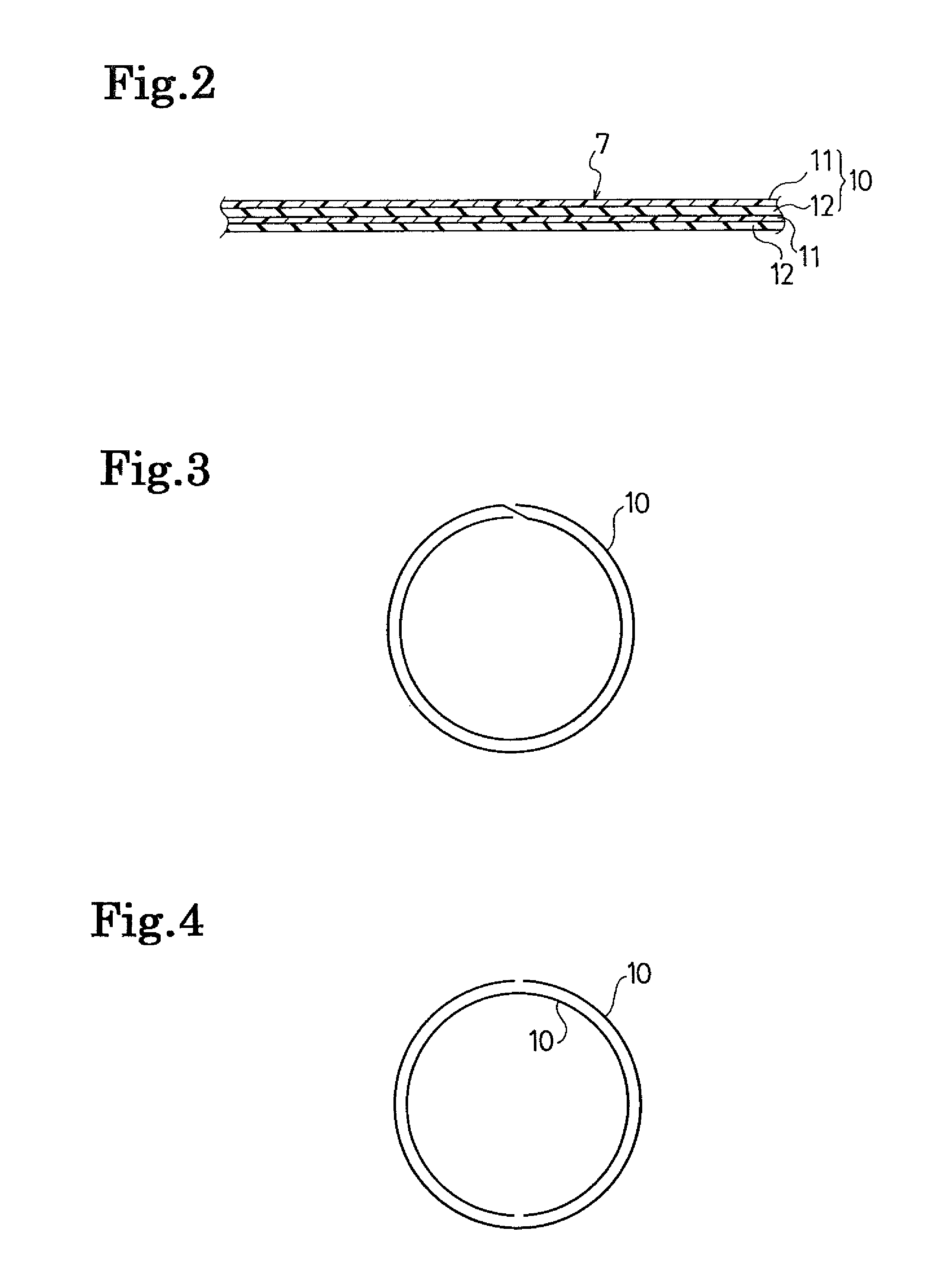

Pneumatic tire and process for producing the same

InactiveUS20100319829A1Satisfactory uniformityEven by forceWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

Provided are: a pneumatic tire capable of retaining a satisfactory uniformity even though the tire includes film layers superposed by winding a film layer in a circumferential direction of the tire multiple times; and a process for producing the same. The present invention is the pneumatic tire including the film layers of the thermoplastic resin or the thermoplastic elastomer composition made by blending the elastomer with the thermoplastic resin, which are superposed by winding the film layer in the circumferential direction of the tire multiple times, the tire wherein a rubber film is interposed between the film layers. The process for producing the pneumatic tire includes: preparing a laminated body in which the rubber layer is stuck to at least one surface of the film layer; interposing the rubber layer between the film layers by winding the laminated body in the circumferential direction of the tire multiple times; forming an uncured tire which includes the film layers and the rubber layers; and curing the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

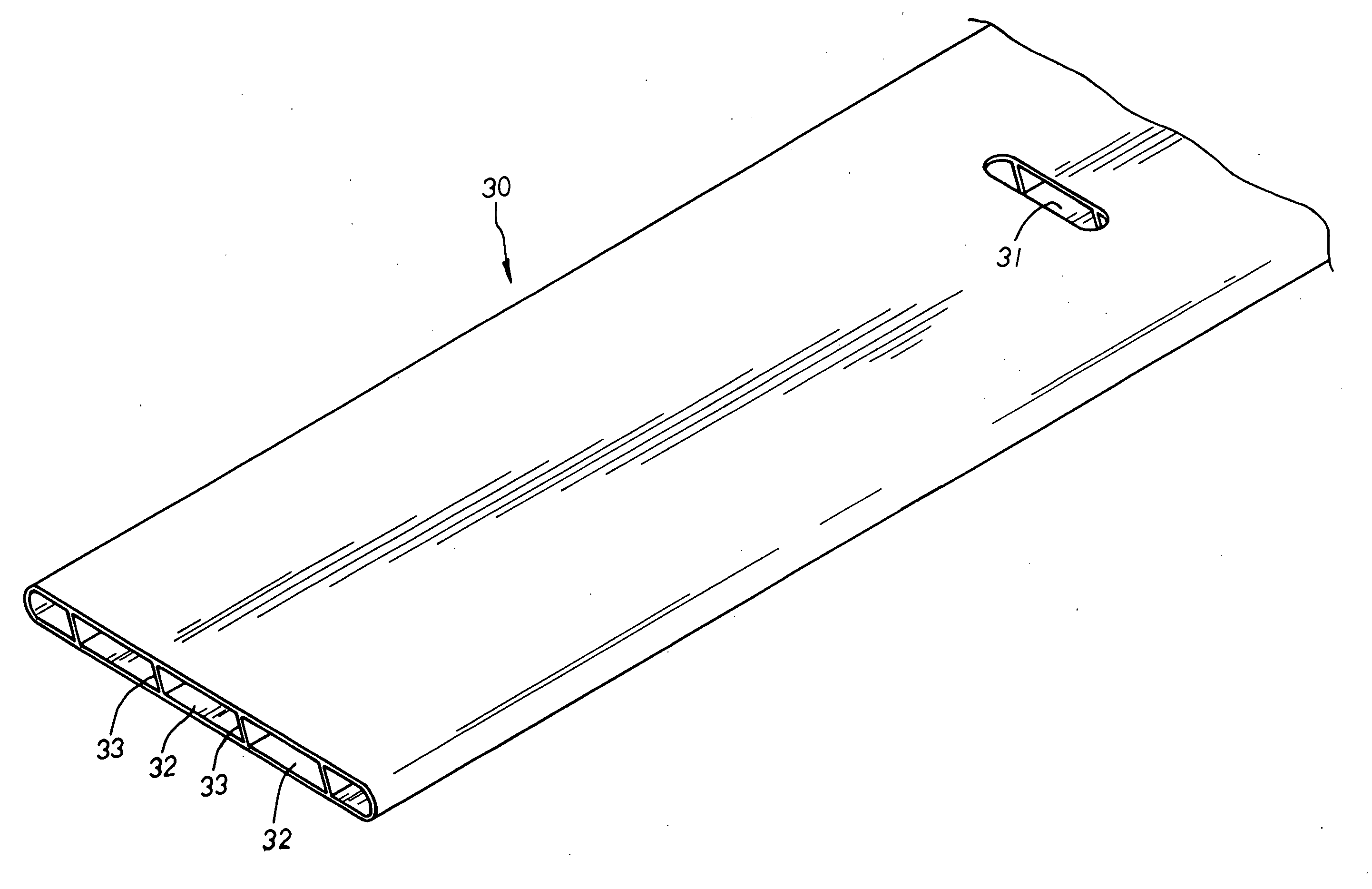

Heat exchanger and method for manufacturing the same

InactiveUS20090113711A1Increase pressureIncrease internal pressureMetal-working apparatusStationary conduit assembliesMechanical engineeringIndustrial engineering

There is provided a method of manufacturing a heat exchanger, including a first step of mounting an end part of flat tube to a header, assembling the flat tube and fins, and sealing a part where the header and the end part is attached, and a second step of increasing an internal pressure of the flat tube to expand other part of flat tubes aside from the end parts with respect to the end part of the tube in order to make the fins and the other part of the flat tube in contact each other. According to this method of manufacturing, in the second step, the other part of the flat tube that passes through the fins is expanded, so that it is possible to mechanically join the flat tube and the fins, and a plate fin-type heat exchanger with high strength and heat exchange efficiency can be easily provided.

Owner:DENSO AIRCOOL CORP

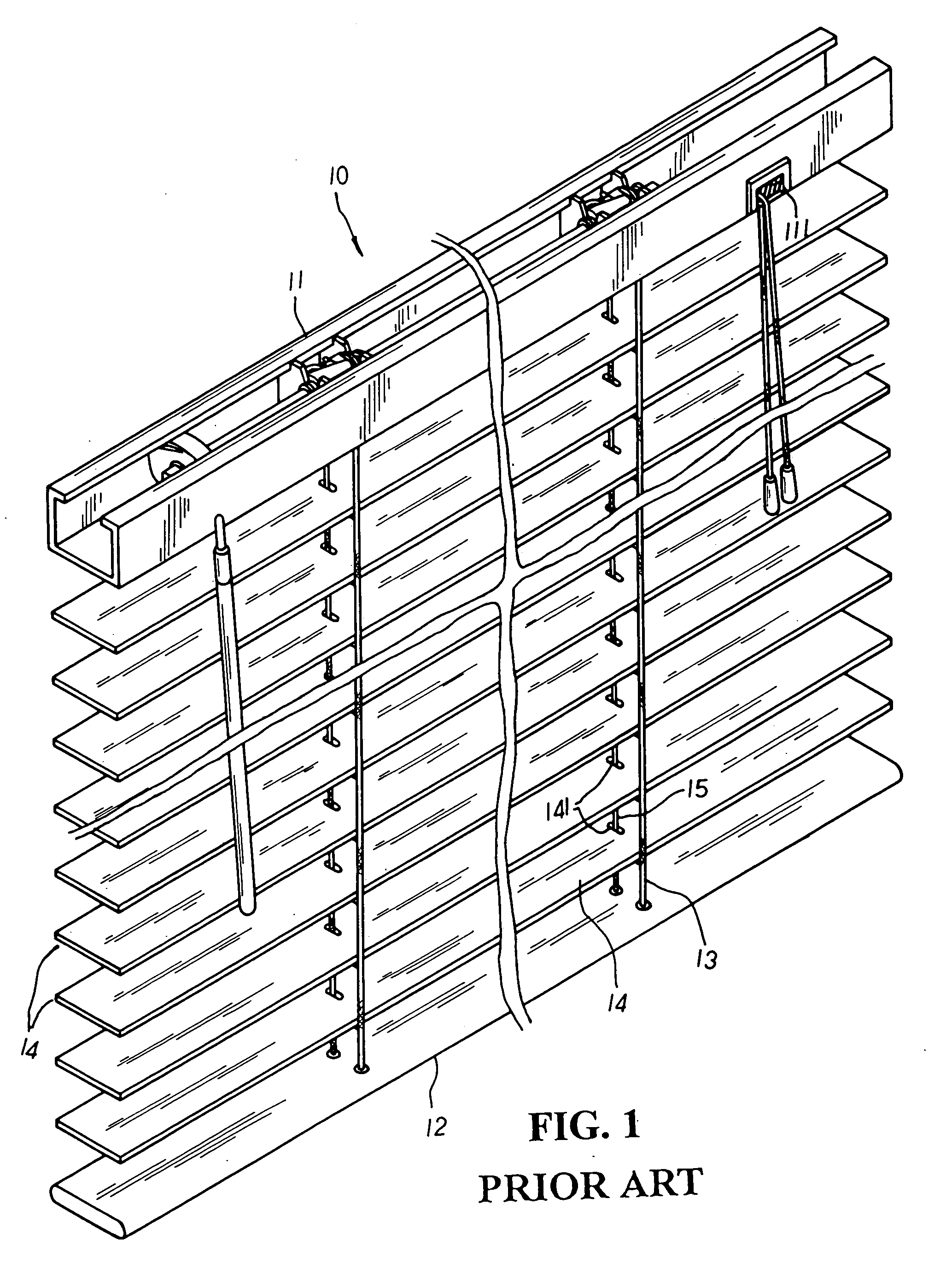

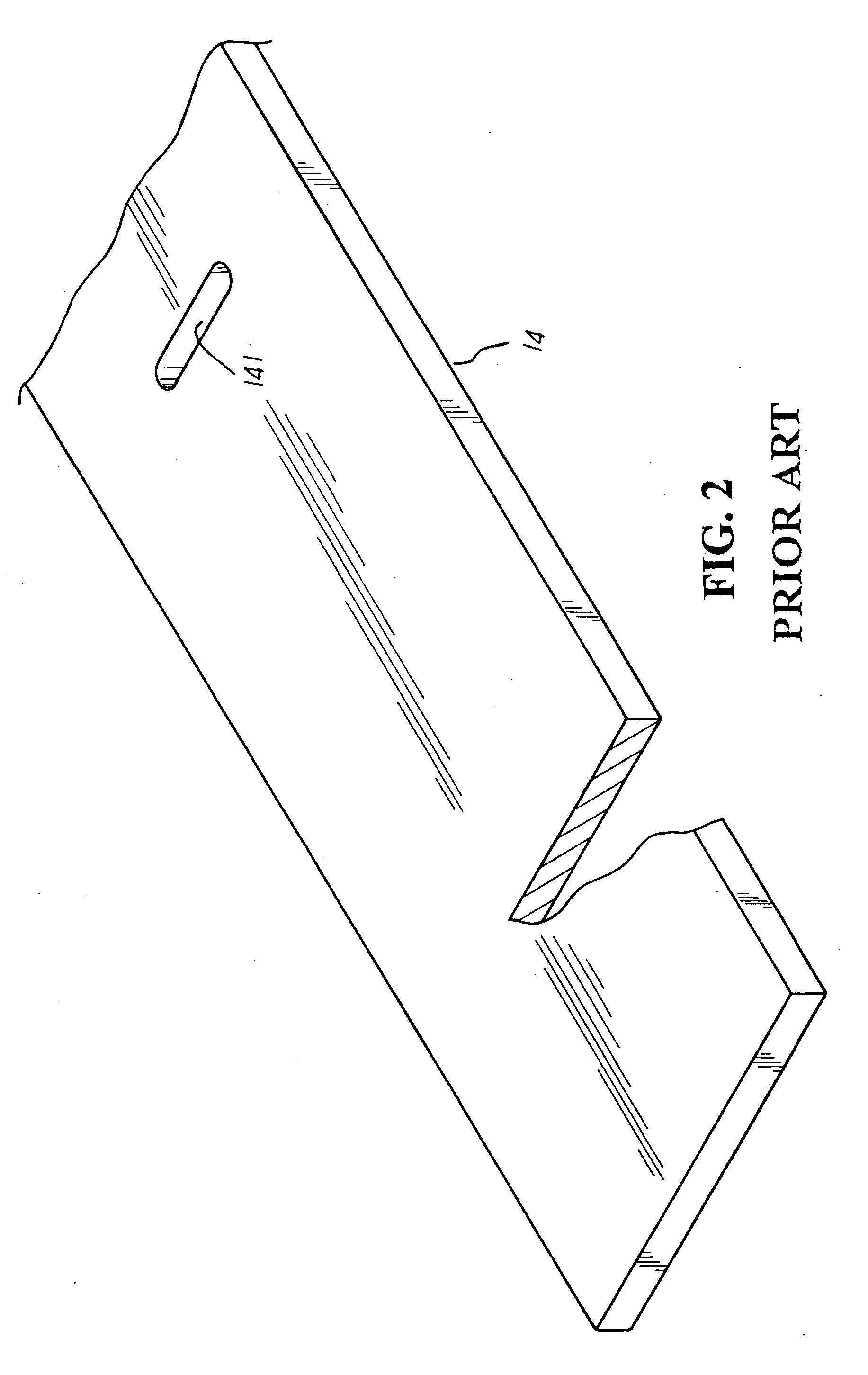

Slat structure for venetian blinds

InactiveUS20060060311A1Light weightEasy to transportLight protection screensWing framesEngineeringVenetian blinds

A slat structure for Venetian blinds includes a Venetian blind made up of rope ladders suspended between an upper and lower beams for supporting a plurality of blind slats located in an equal space thereto, and a pull cord led through cord-passage holes of the blind slats thereof respectively before wound around a pulley seat mounted at one end of the upper beam to hang downwards there-from so as to raise or lower the blind slats thereby wherein each blind slat is made in a hollow shape with a ventilation hole formed at the inner side thereof for better heat dissipation and insulation effects thereby, and the ventilation hole thereof has a plurality of vertically-extending support guide ribs properly disposed therein and integrally connected with the upper and lower inner walls thereof so as to provide a reinforcing support effect thereby. The walls defining the ventilation hole and the support guide ribs thereof are made in thin plates, which makes the Venetian blind lighter in weight for easier transportation and effortless assembly thereof. Besides, the ventilation hole and the support guide ribs thereof are integrally made as a whole, facilitating a simpler and speedier processing thereof to reduce the cost of production for more competitive power on the market as well as maintaining a neat and smooth surface of the blind slats without the sediment of dirt accumulated thereto so as to achieve the best using condition thereof.

Owner:CHING FENG BLINDS INC CO LTD

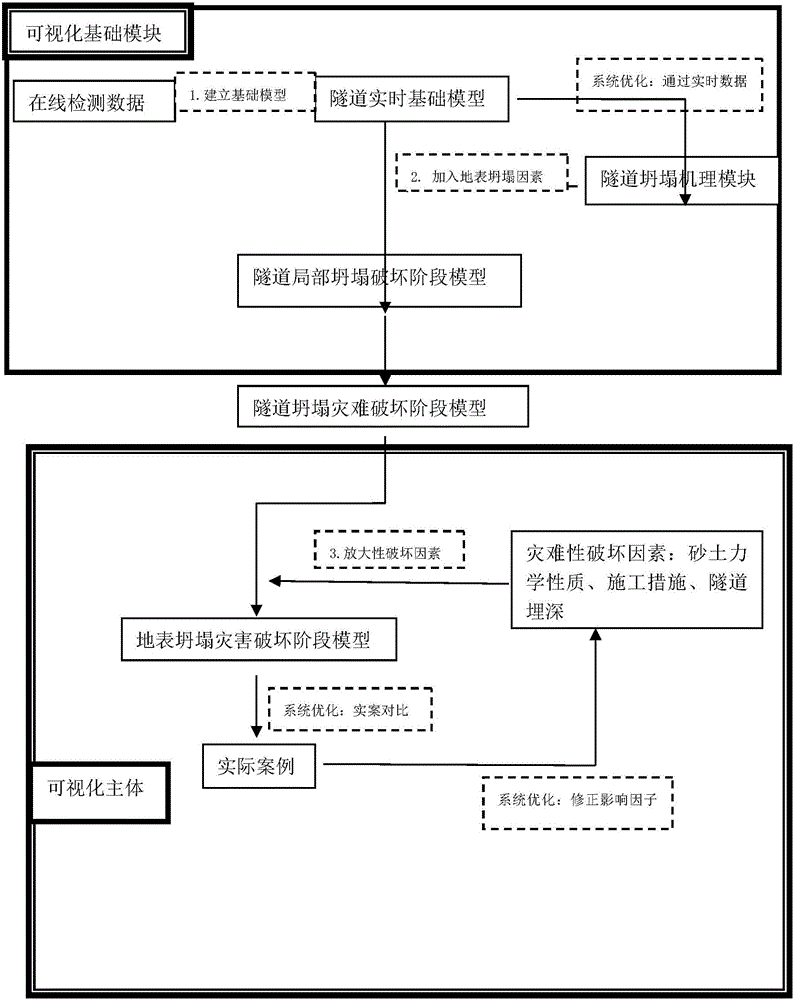

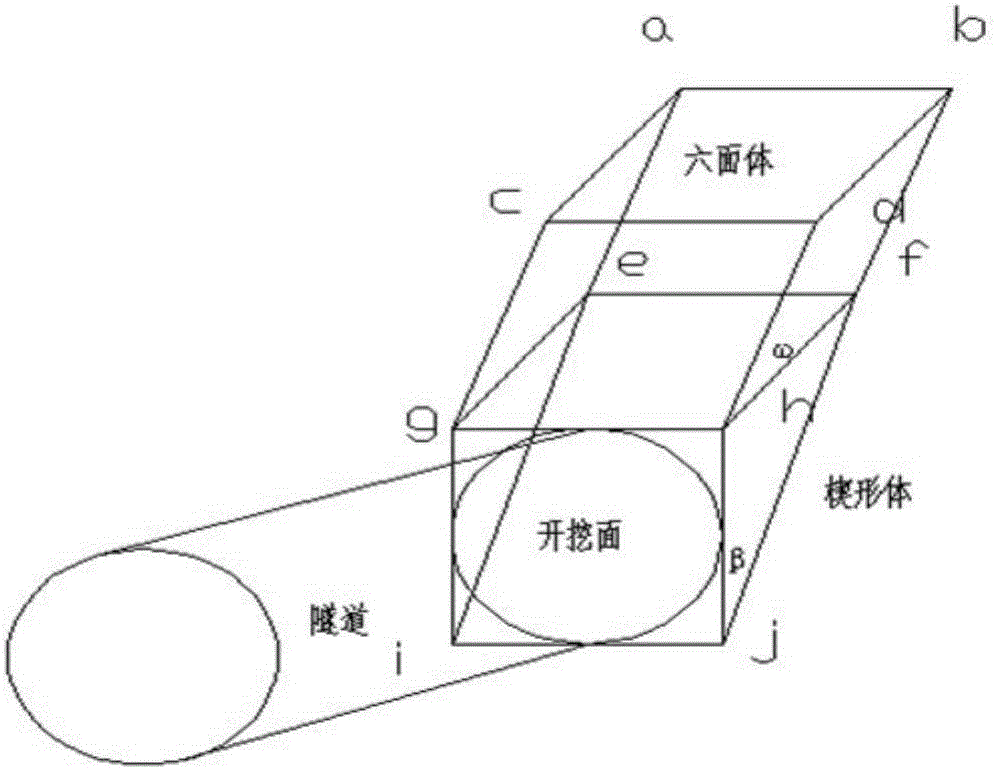

Method for demonstrating surface collapse disaster caused by subway tunnel construction

InactiveCN106652728AExpand smoothlyReduce lossesGeometric CADDesign optimisation/simulationAnimationEngineering

The invention belongs to the technical field of subway tunnel construction safety management and relates to a method for demonstrating a surface collapse disaster caused by subway tunnel construction. The method comprises analyzing the current situation of the surface collapse disaster frequently caused by the subway tunnel construction, summarizing the reason, the mechanism, and the process of the surface collapse disaster caused by the subway tunnel construction; constructing and visualizing of the evolution process and the damage degree of the surface collapse disaster caused by the subway tunnel construction by using a scenario construction concept and method. By means of the demonstration animation, people understand the evolution process of the subway collapse more visually and specifically, coordinate and plan the duties of respective parties in the disaster in advance so that professionals know how to quickly and effectively solve their own technical problems in cooperation in order to minimize the losses of the people due to the disaster within the shortest time.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

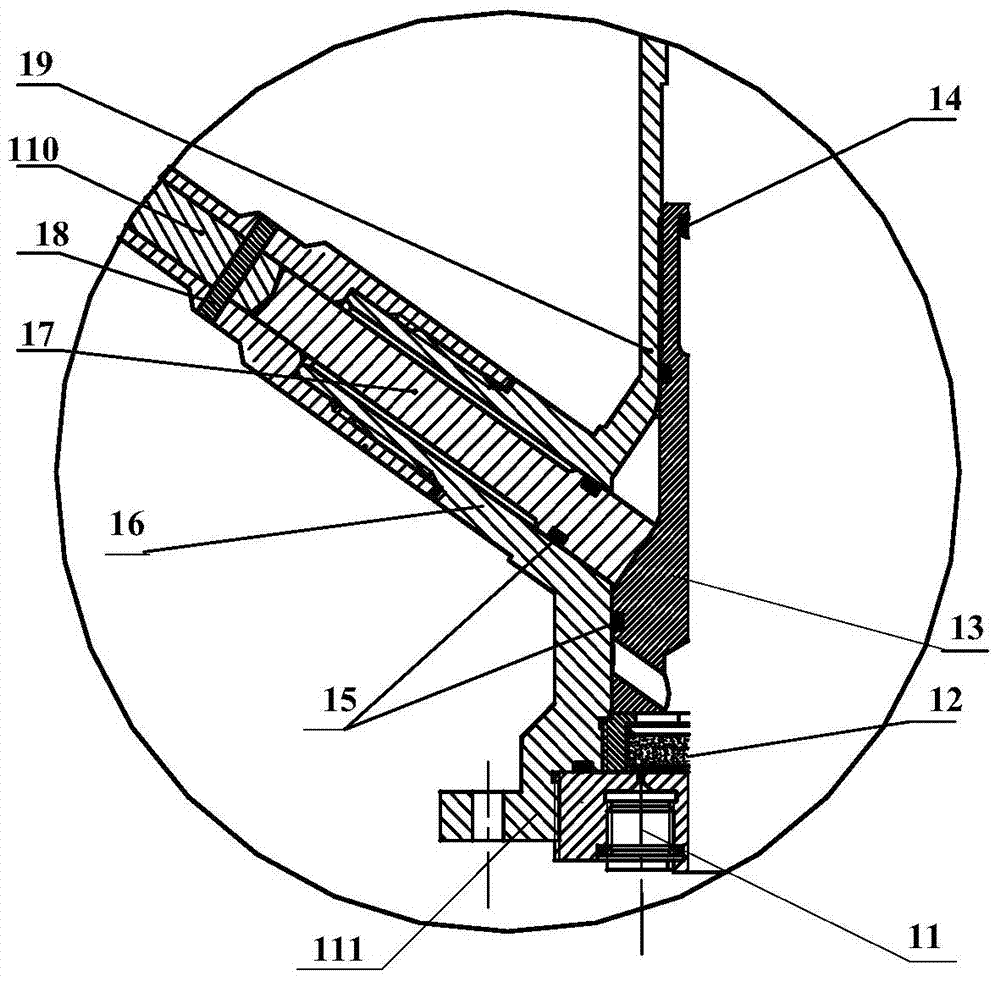

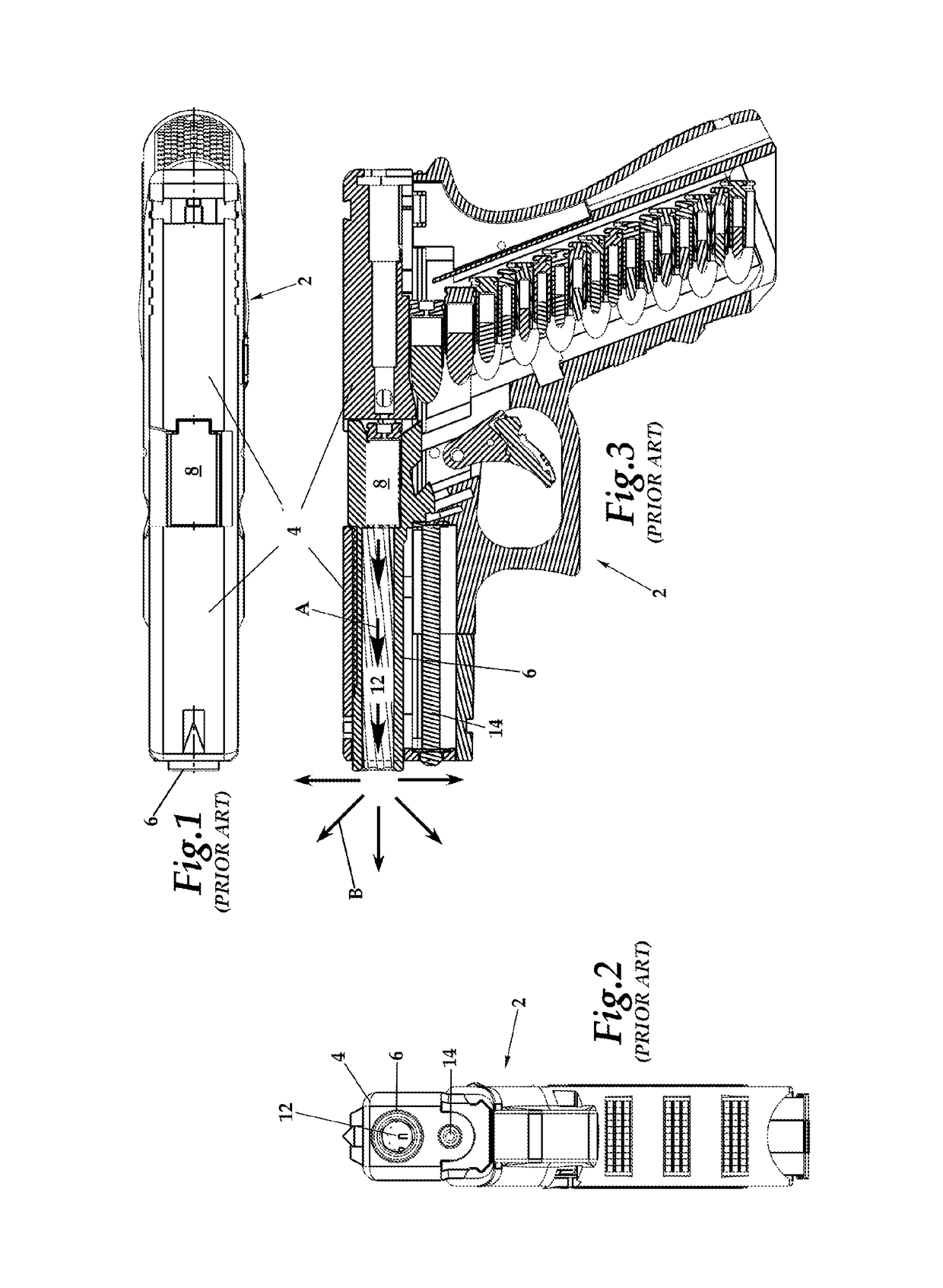

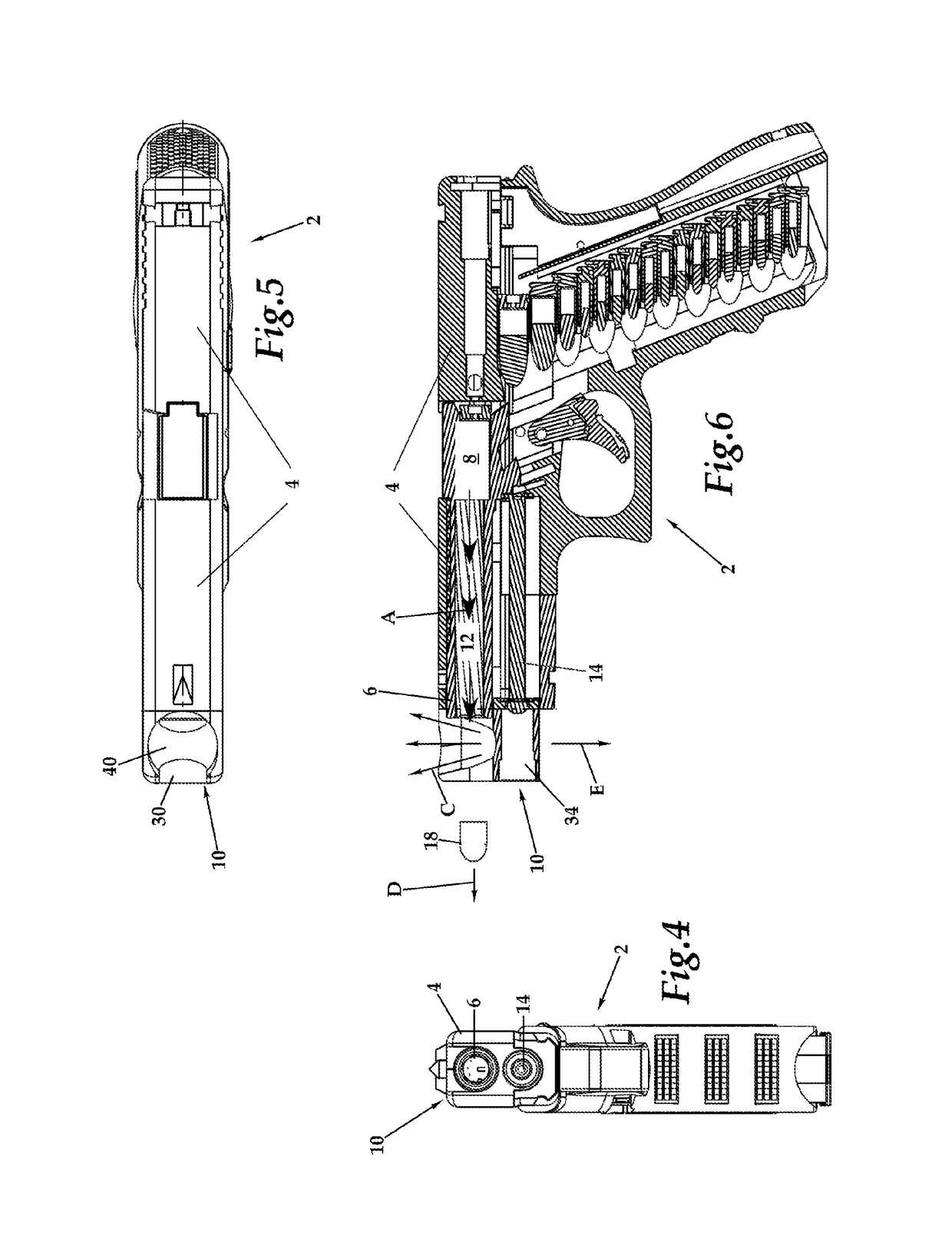

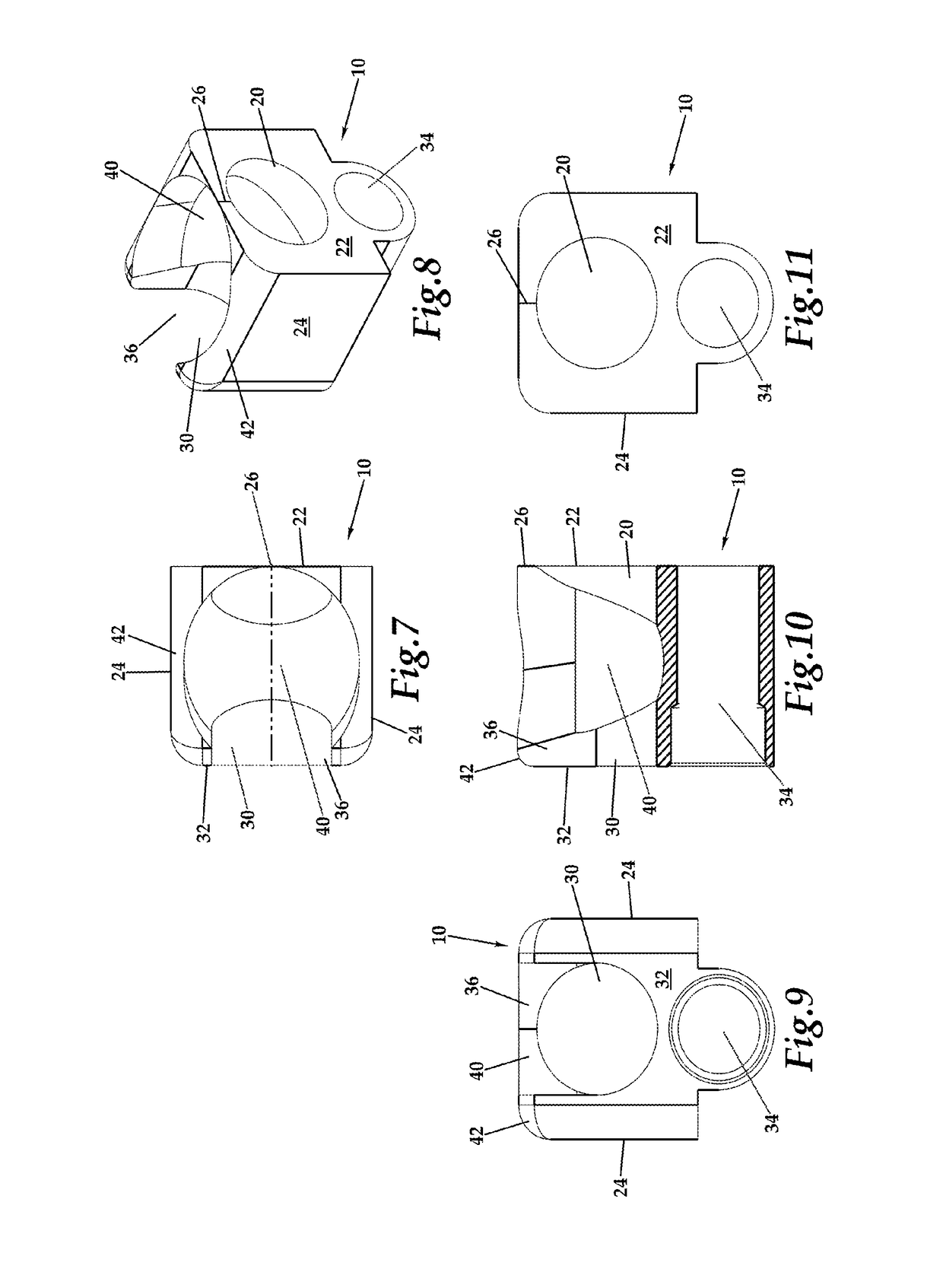

Muzzle brake with propelling nozzle for recoil control

The muzzle brake attaches to a distal end of the barrel of a firearm, typically a handgun, either built into the firearm or as an accessory attachable to the firearm. The muzzle brake includes a propelling nozzle in the form of a central chamber aligned with proximal and distal openings aligned with a barrel of the firearm. This propelling nozzle extends upward, generally expanding in cross-section, to a rim where it opens above the firearm near a distal end of the barrel. The shape of the propelling nozzle (or series of nozzles) is preferably selected to optimize downward reactive force when expanding gases discharged from firearm discharge expand upward out of the propelling nozzle. A downward reactive force is thus created which counteracts recoil of the firearm.

Owner:PRICE DONALD H

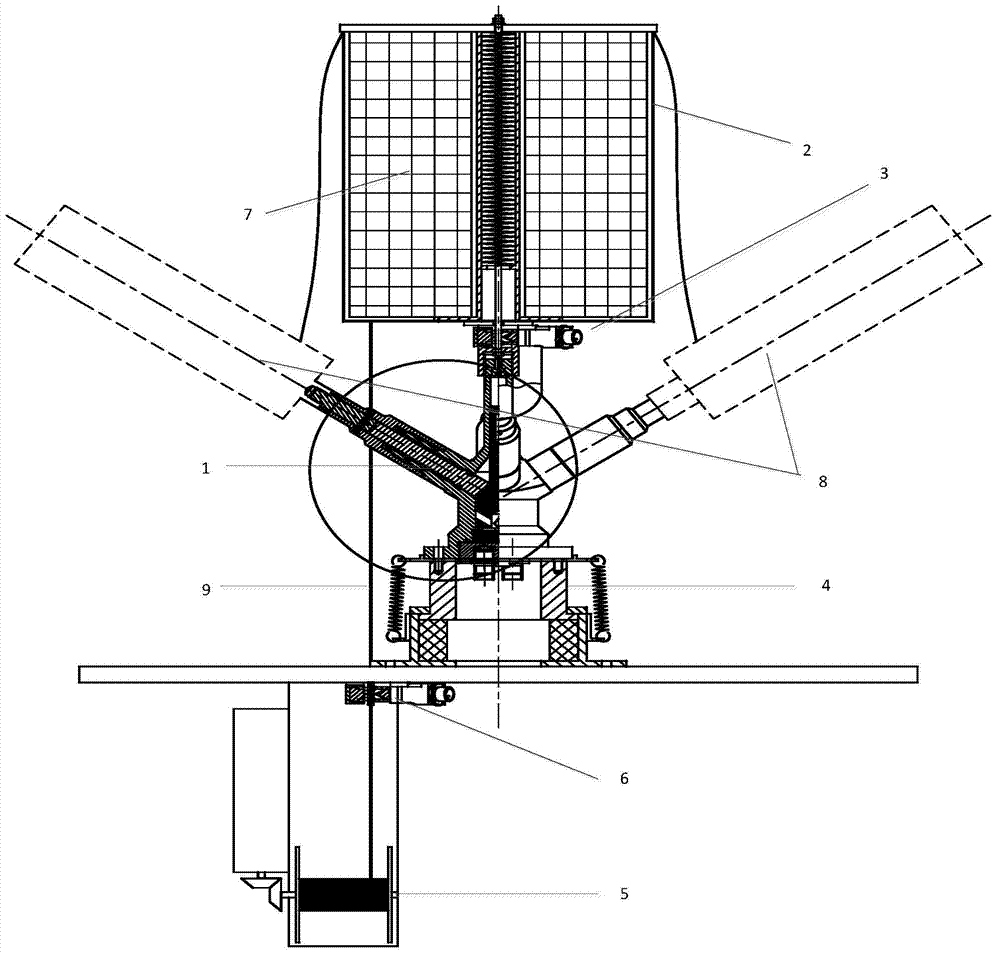

A flexible solar wing elastic stretching rod repetitive unfolding and retracting mechanism

ActiveCN109094821AReduce weightHigh specific powerCosmonautic vehiclesCosmonautic power supply systemsSpace powerBar pressing

The invention relates to a flexible solar wing elastic stretching rod repetitive unfolding and retracting mechanism, which relates to the field of aerospace space mechanism. The invention solves the problems of large folding envelope, heavy weight and low specific power of the prior rigid and semi-rigid solar wing which adopts the unilateral deployment mode. The two force transmission devices of the invention are fixed on the mounting base side by side, A deployment bar is arranged on both sides of the flexible solar blanket, A flexible solar blanket is connected to the deployment lever by a rope, At that end of the flexible solar blanket is wound up on a solar blanket take-up roll, At that end of the unwrap bar is wound up on the unwrapping bar take-up drum, A distal end of that deployment bar is press against the deployment bar retracting roll by a deployment bar pressing device, Four unfolding bar guides correspond to four unfolding bars one by one. An initial driving device is arranged inside the inner guide cylinder of the unfolding bar guide. An initial pressing and releasing device is installed at one end of the force transmission device of the unfolding roller, and an electric recovery driving device is installed at the other end of the force transmission device of the unfolding roller. A space power supply for a spacecraft is provided.

Owner:HARBIN INST OF TECH

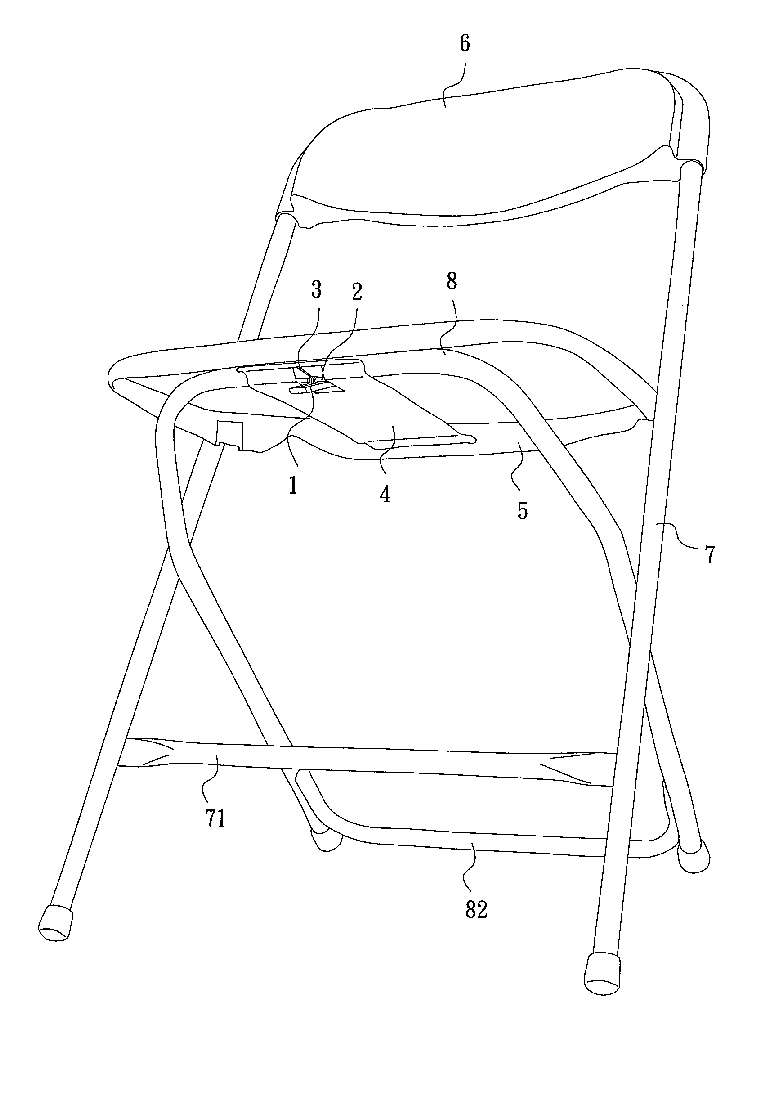

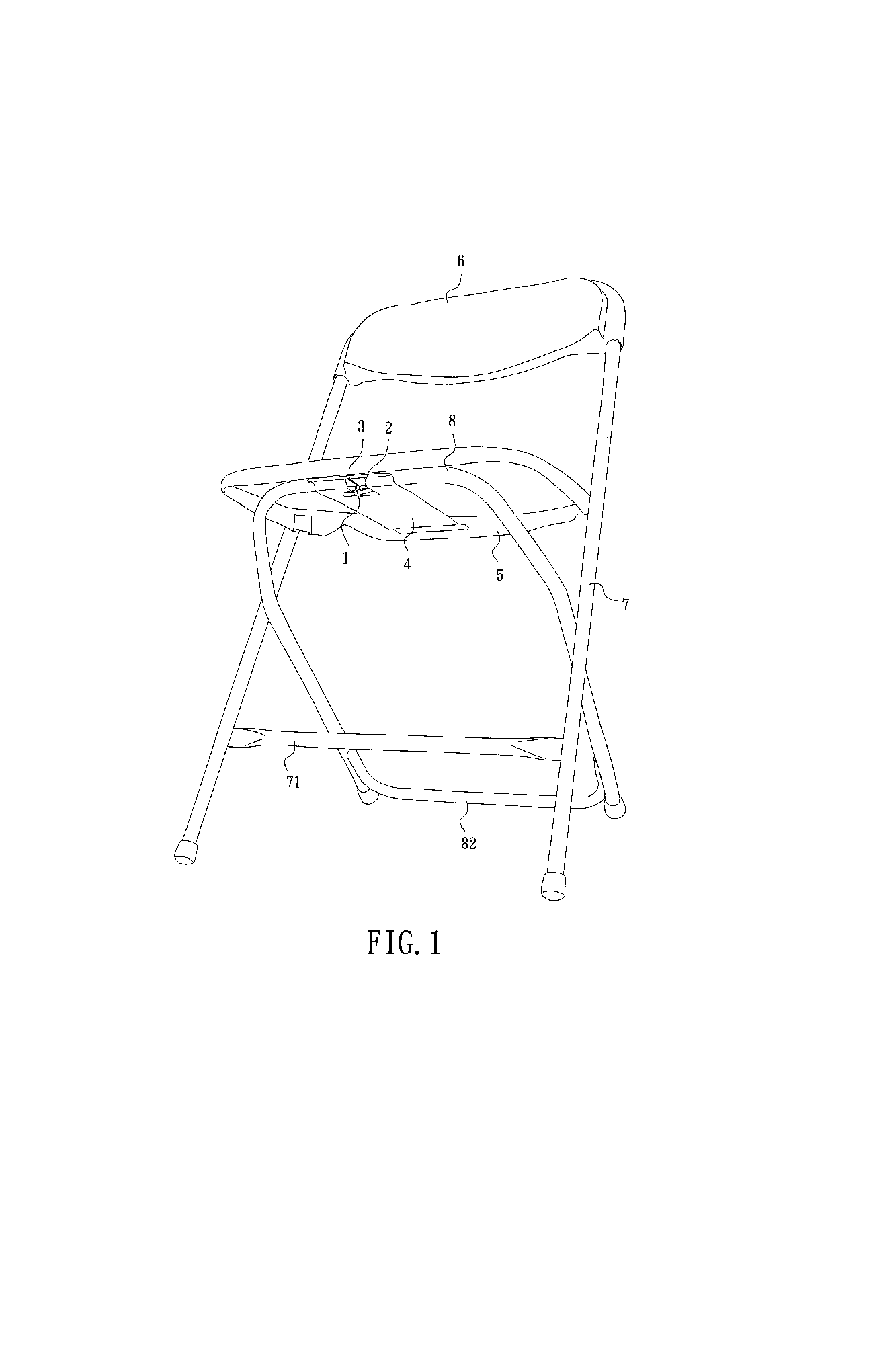

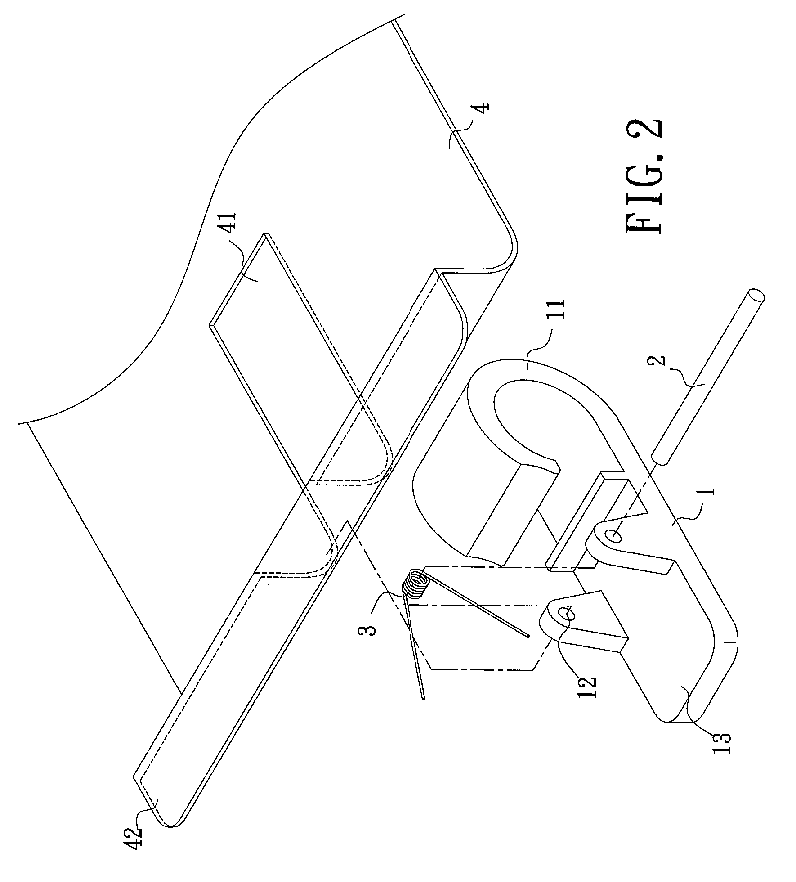

Folding chair with safety folding device

InactiveUS7331628B2Preventing an undesired folding of the folding chairSafely foldedFoldable chairDismountable chairsEngineeringTorsion spring

A folding chair with safety folding device comprises a safety hook, a pin, a torsion spring, a bottom cover, a seat, a back, a pair of front legs, a pair of rear legs, a front crossbar, a rear crossbar and a pivotal shaft. The safety hook is employed to position the pair of rear legs after the folding chair is unfolded, when the folding chair is being folded, the pair of rear legs can be released safely by pressing the safety hook, thus preventing an undesired pinching injury as a result of improper operation or impact.

Owner:LIN WEI CHI

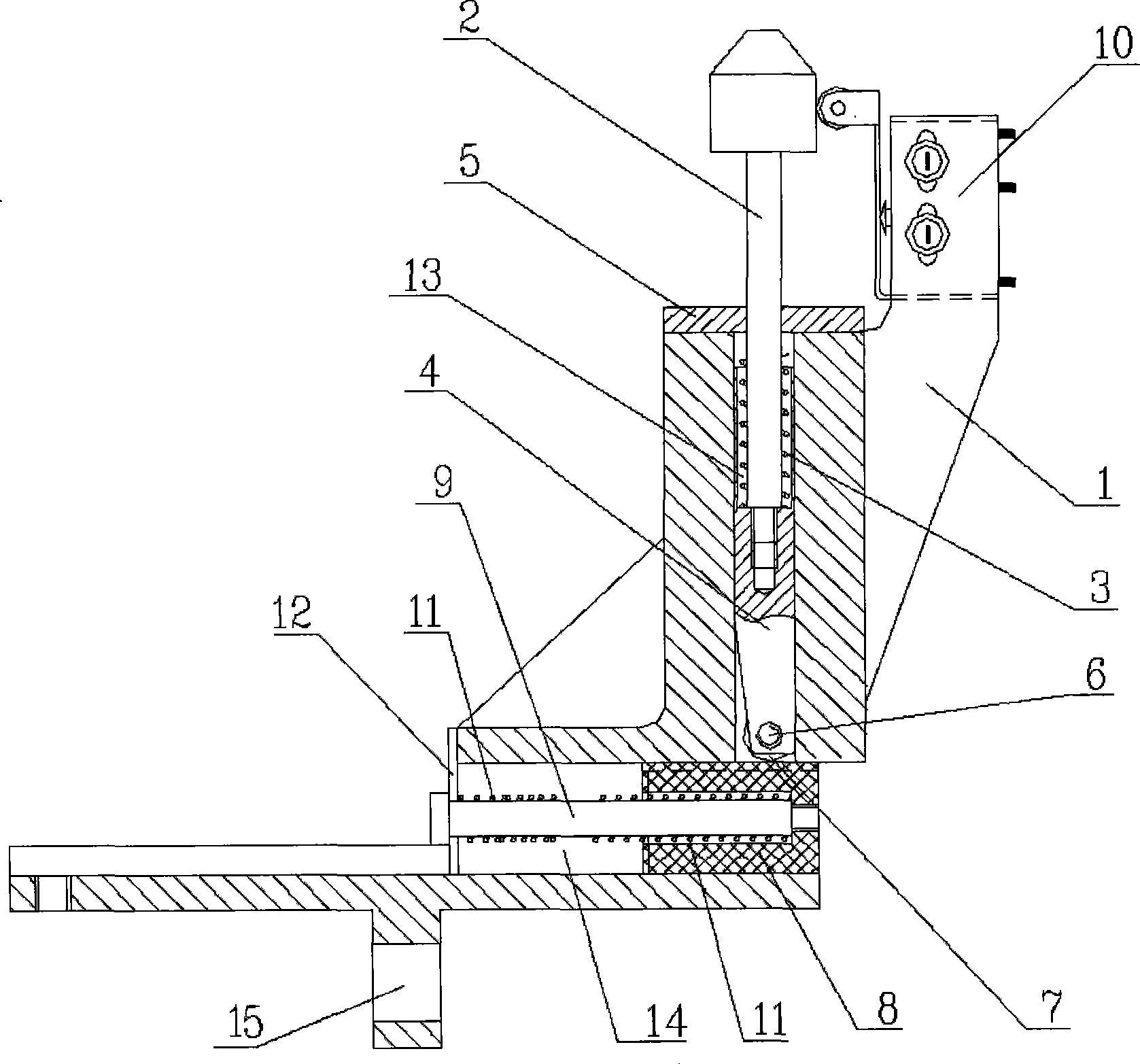

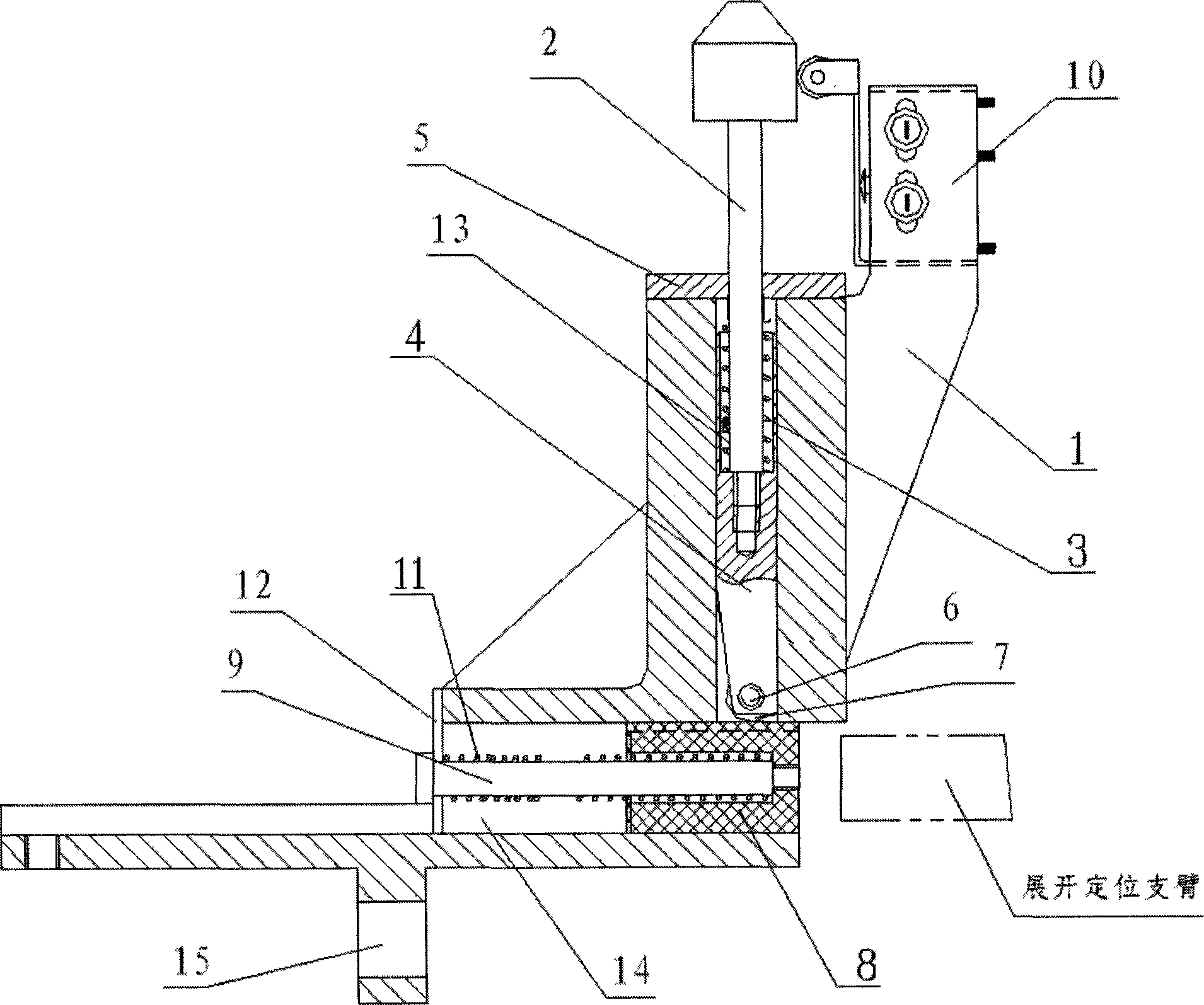

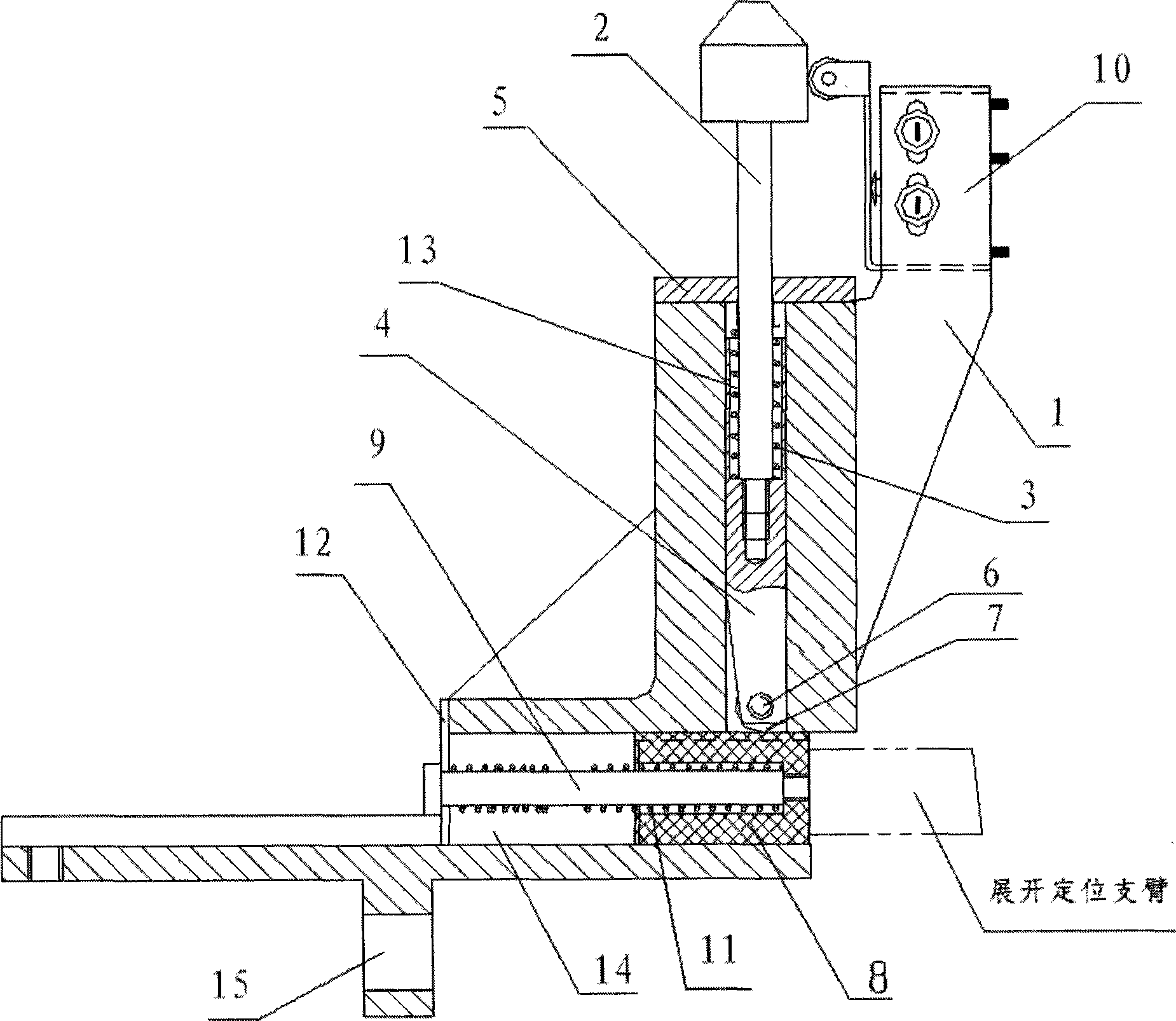

Expansion positioning mechanism for satellite antenna

ActiveCN101483267AAvoid foreign collisionsImprove securityCollapsable antennas meansAntenna supports/mountingsContact frictionSatellite

A satellite antenna expansion location mechanism comprises an expansion location mechanism frame, a location stop pin guide bar, a stop pin thrust spring, a location stop pin, a stop pin block cover board, a stop pin shaft, a stop pin roller, a sliding support plate, a guide bard, a sensitive switch, a sliding support plate thrust spring and a guide cover plate. The invention employs the sliding support plate instead of original sliding guide arc plate mounted inside the antenna support structure, and avoids external collisions in the antenna expansion process, and improves the safety. The invention can reduce a friction resistance during the antenna expansion process to make the antenna expansion more smoothly without contact friction force at the beginning of the antenna expansion. The antenna expansion location mechanism can be used for various satellite expansion antenna, specific and widely application fields.

Owner:中国航天科技集团公司第五研究院第五〇四研究所

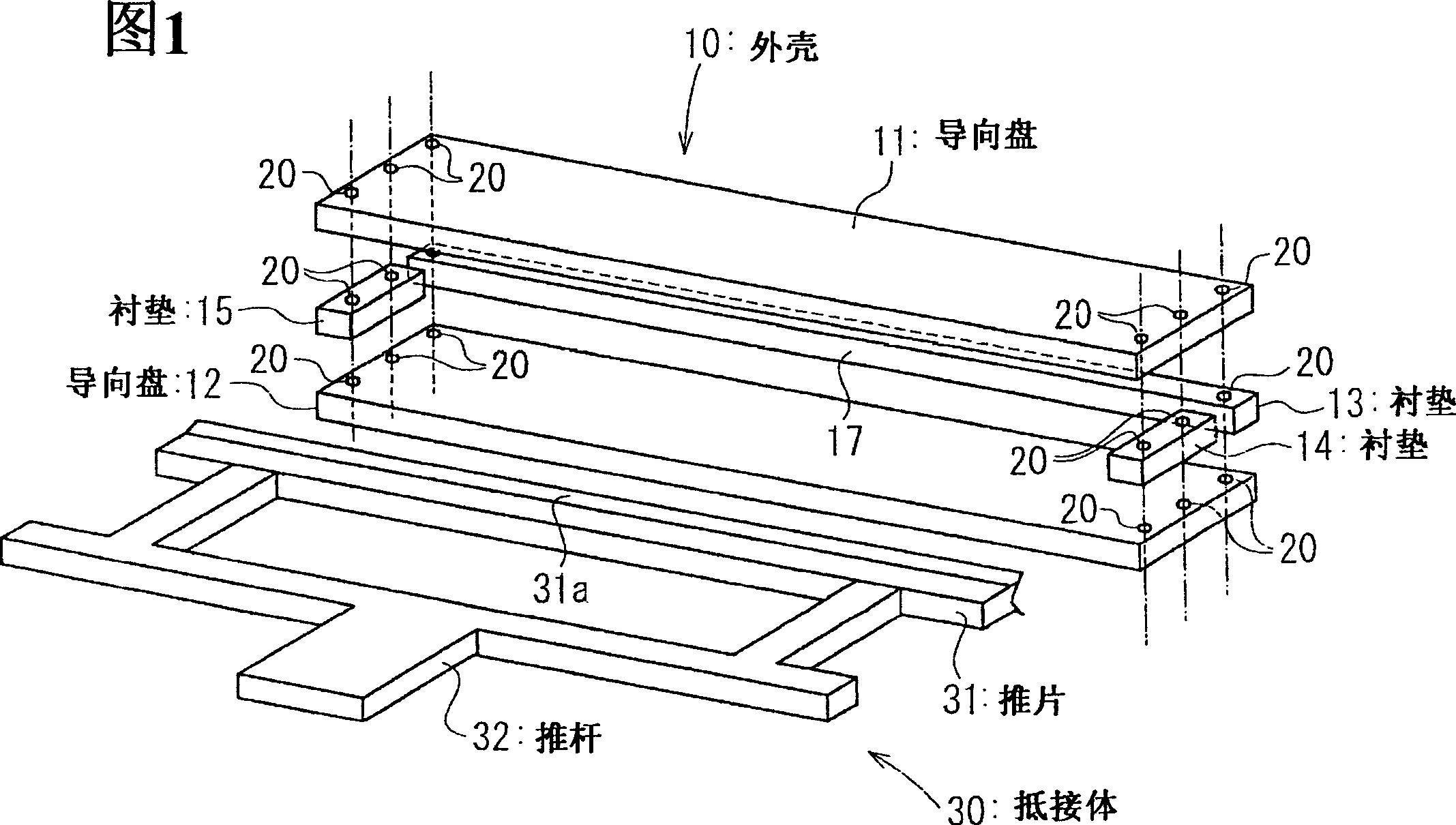

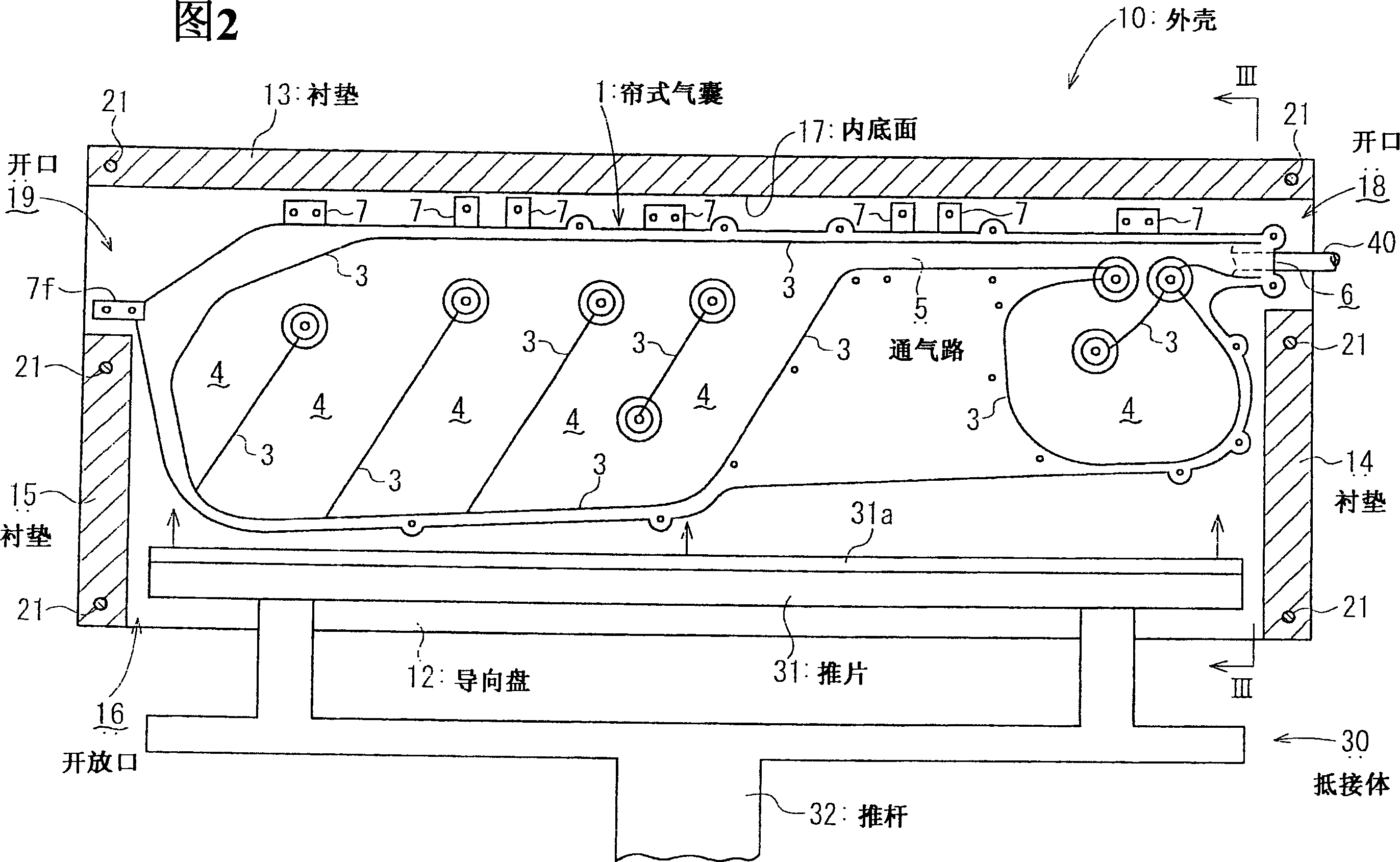

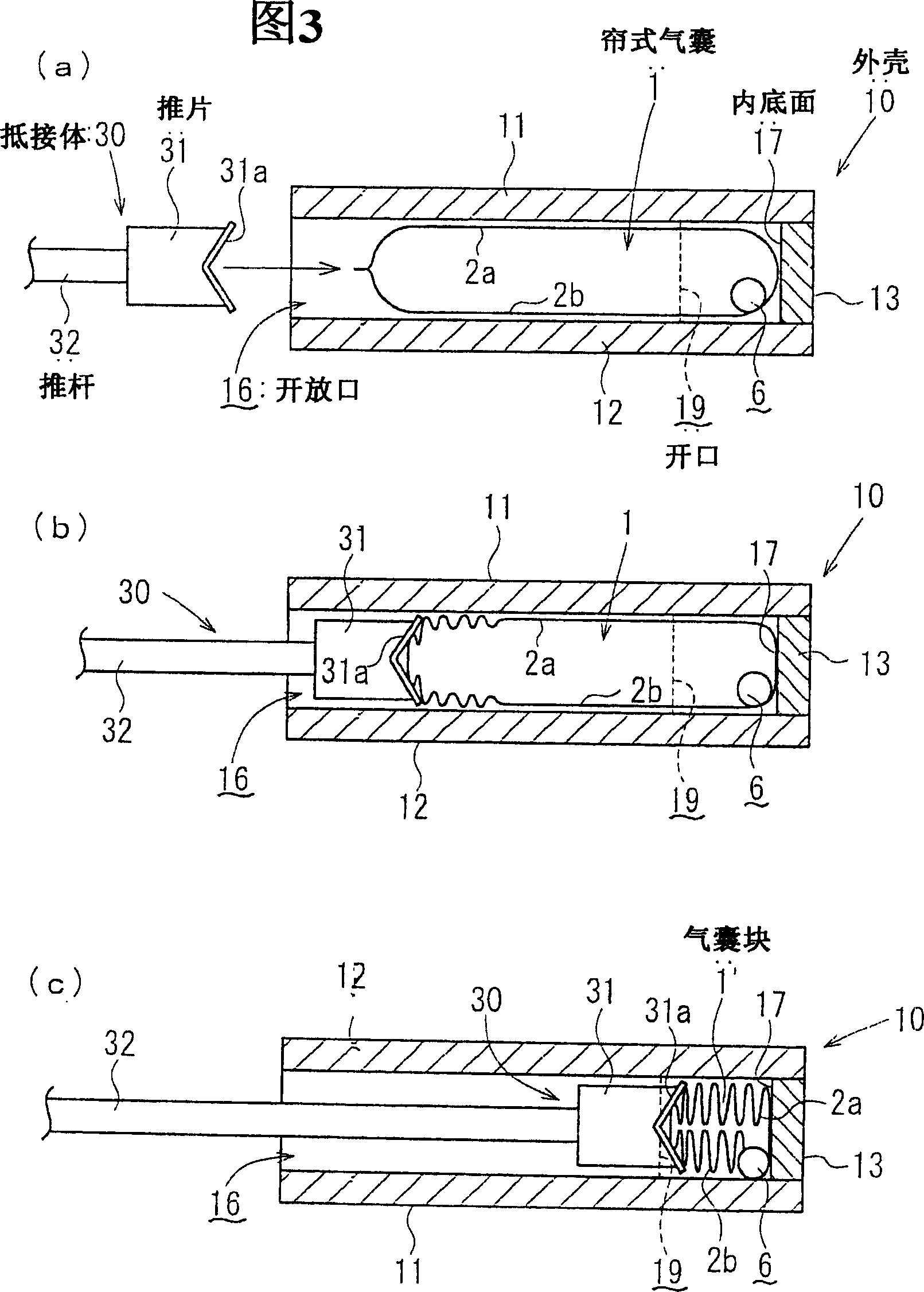

Airbag packet, production method therefor, and airbag device

InactiveCN1792679AUniform compressionExpand smoothlyBox making operationsPaper-makingEngineeringAirbag

The present invention provides a method of not folding the airbag regularly, but forming the airbag into a prescribed block shape only by compression. A curtain airbag (1) is housed in a casing (10) with its upper side arranged on the inner bottom surface (17) side and its lower side arranged on the opening (16) side. Air is fed into the curtain airbag (1) to inflate the curtain airbag (1). The curtain airbag (1) is compressed from the side of the opening (16) to the inner bottom surface (17) through the abutment body (30). At this time, the air in the curtain airbag (1) is discharged through the inflator opening (6). After the curtain airbag (1) is compressed into a predetermined small block shape, the airbag block (1') is taken out of the casing (10) while sliding along the inner bottom surface (17). After the airbag block (1') is taken out from the housing (10), the shape of the airbag block (1') is maintained by the shape-retaining member.

Owner:TAKATA CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com