Method and device for creating a unidirectional fibre layer, method for manufacturing a multi-axial layed fabric and a multi-axial machine as well as a method for manufacturing a woven cloth and weavi

A unidirectional fiber, laying device technology, used in looms, textiles, knitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

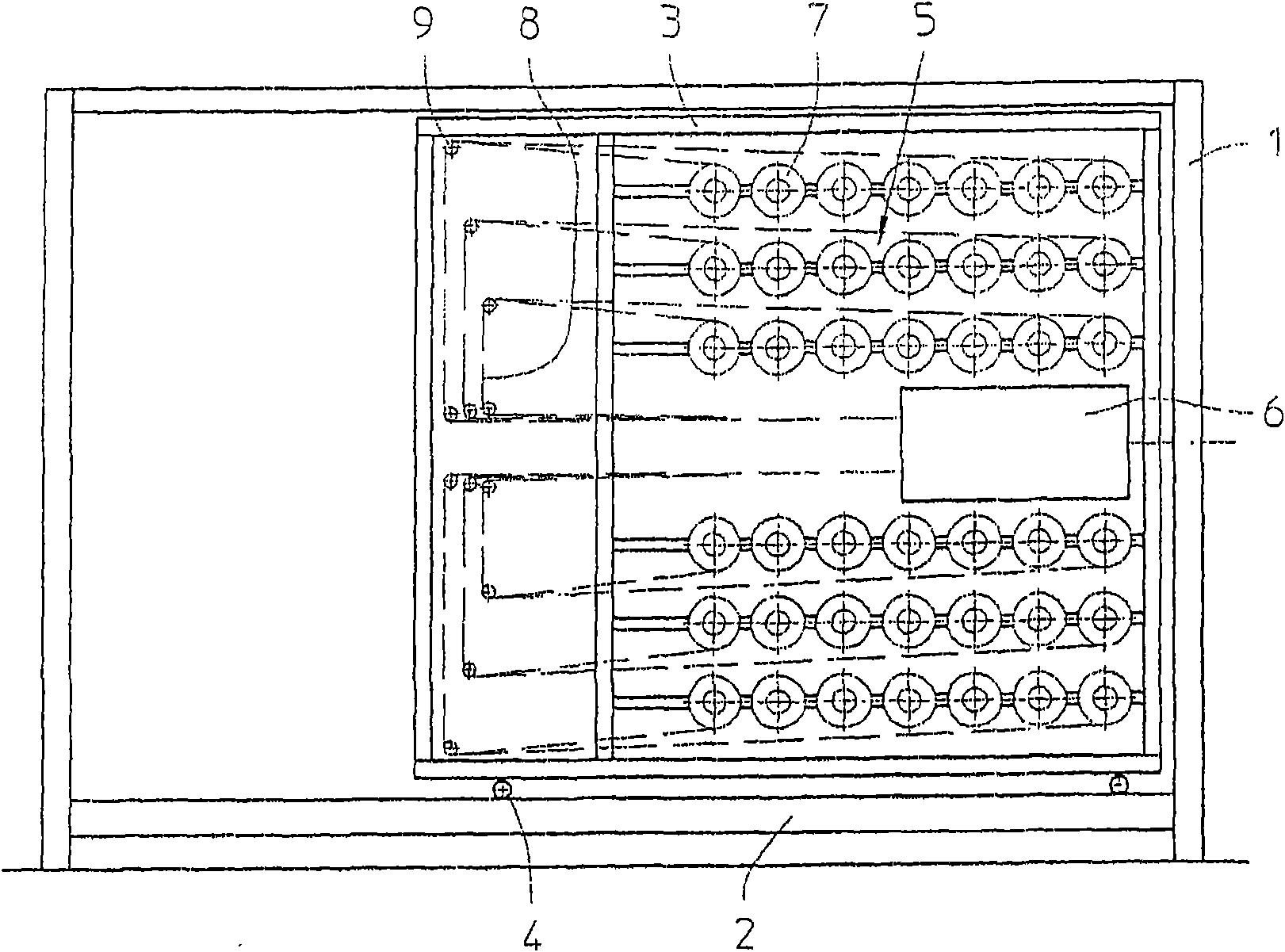

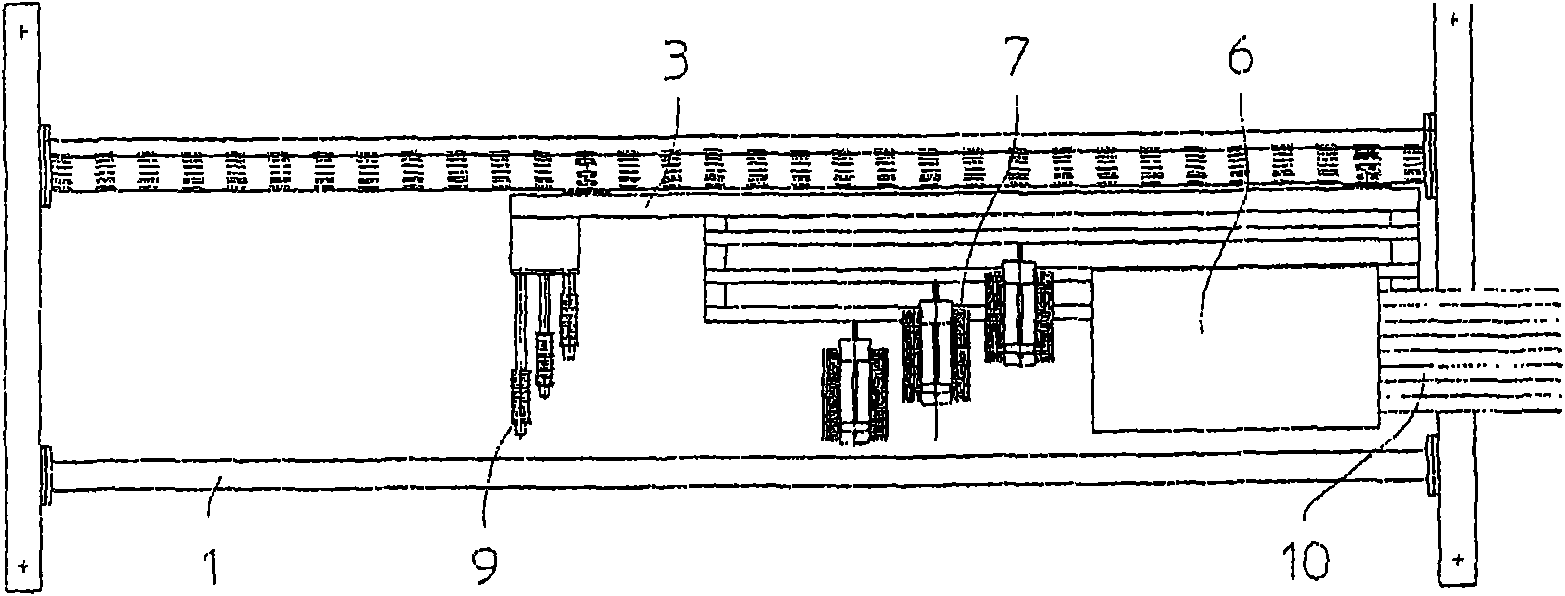

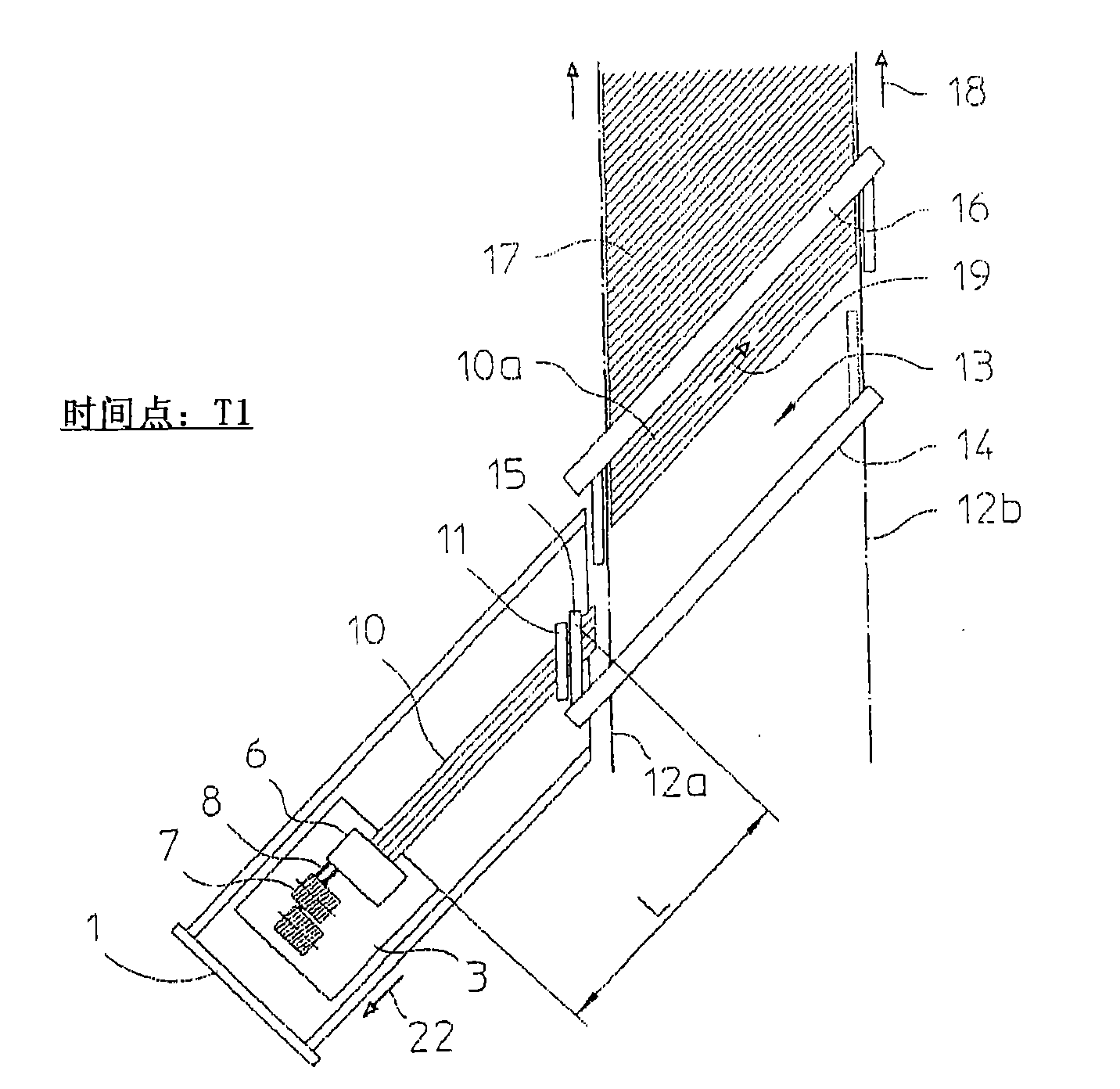

[0036] exist figure 1 The frame is marked with reference numeral 1, which can form a side structure on a multi-axial braiding machine, to which reference image 3 . The frame 1 has a track in the form of a guide rail 2 . On said rails is a moving element in the form of a trolley 3 which can be moved by means of pulleys 4 . The trolley 3 carries the creel 5 and the unrolling device 6 designed as a through element. The creel 5 consists of a large number of bobbins 7 on which are wound individual fibers 8 as yarn material, for example carbon fibers or nylon fibers.

[0037] The individual fibers 8 are drawn off from the bobbins 7 by deflection rollers 9 and guided through the spreading device 6 . The alignment criteria for the bobbins 7 and deflection guide rollers 9 is that the drawn individual fibers 8 cannot touch each other before entering the spreading device 6 . The bobbins 7 are equipped with brakes in order to be able to adjust and control the mechanical tension in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com