Rope net type space debris capturing and cleaning system

A space debris and removal system technology, applied in space navigation equipment, tools, transportation and packaging, etc., can solve the problems of difficult to precisely control the launch synchronization, difficult to avoid the interference penetration of the net rope, and the center offset of the rope net, etc. Platform measurement and control requirements are low, the action distance is long, and the effect of avoiding entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

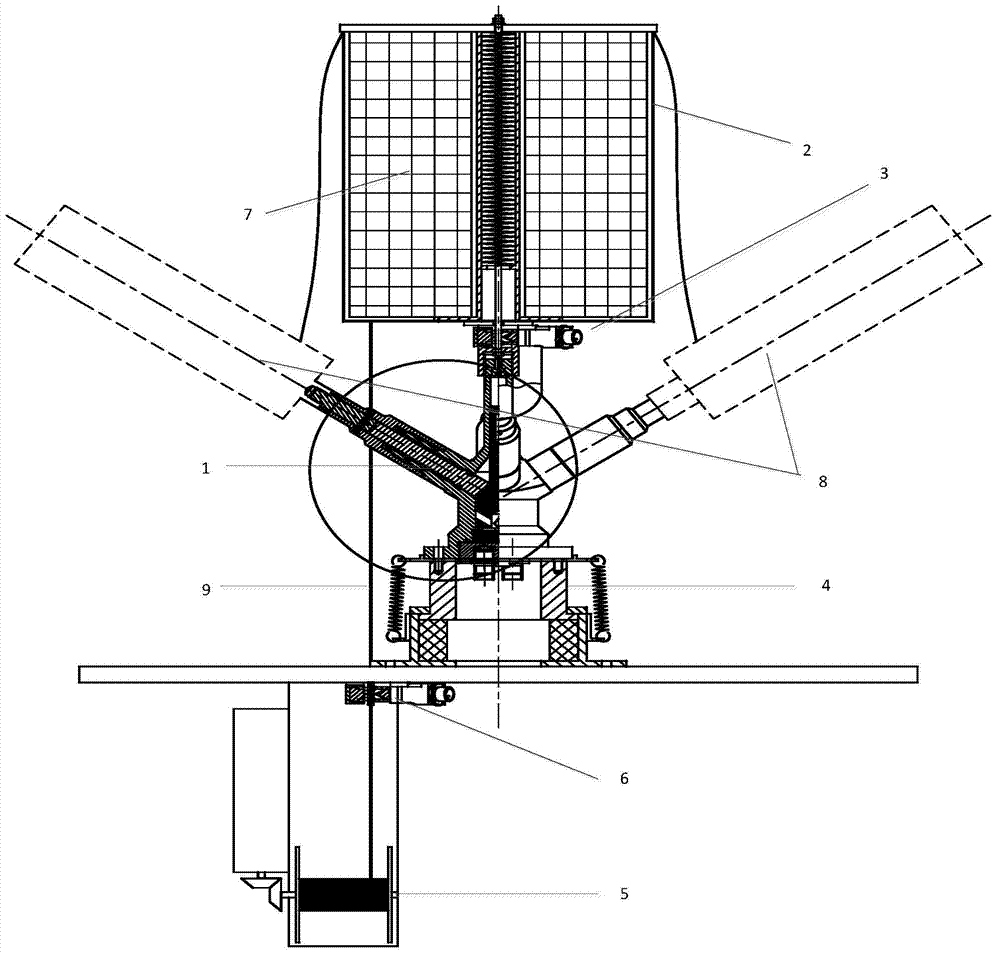

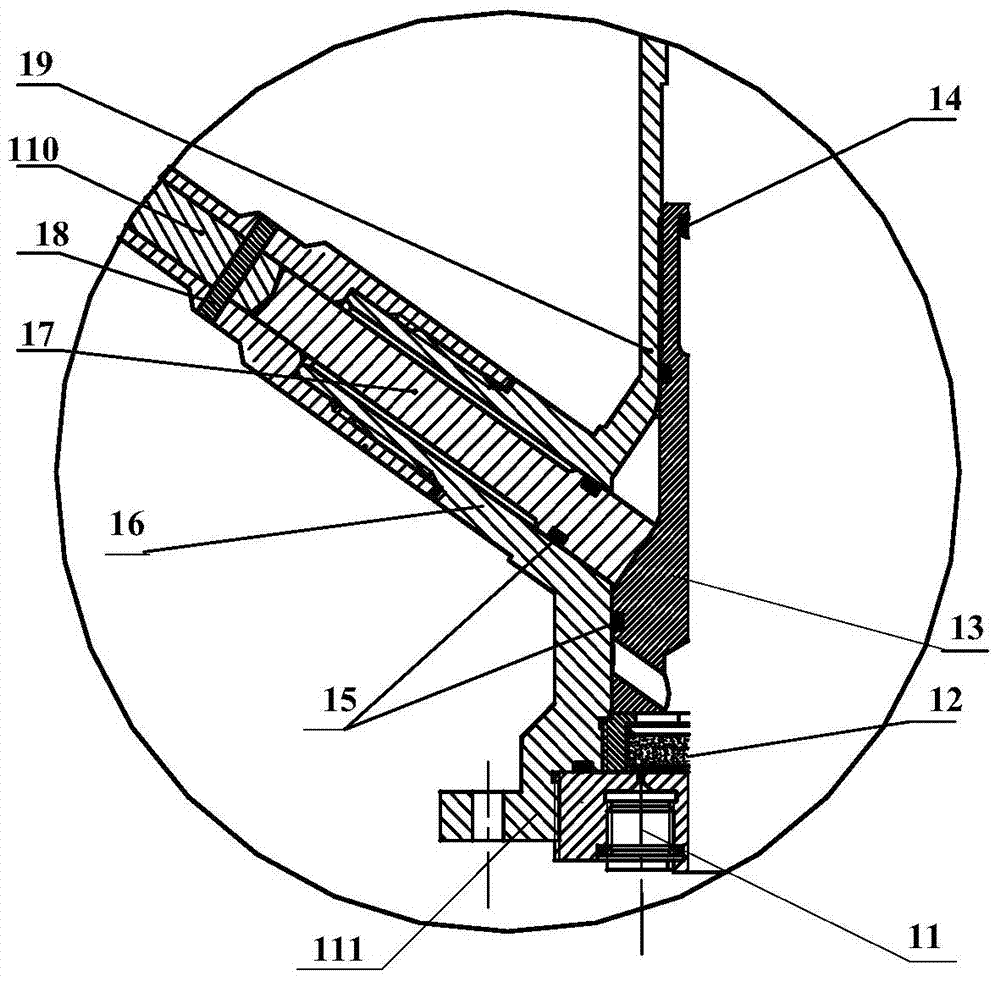

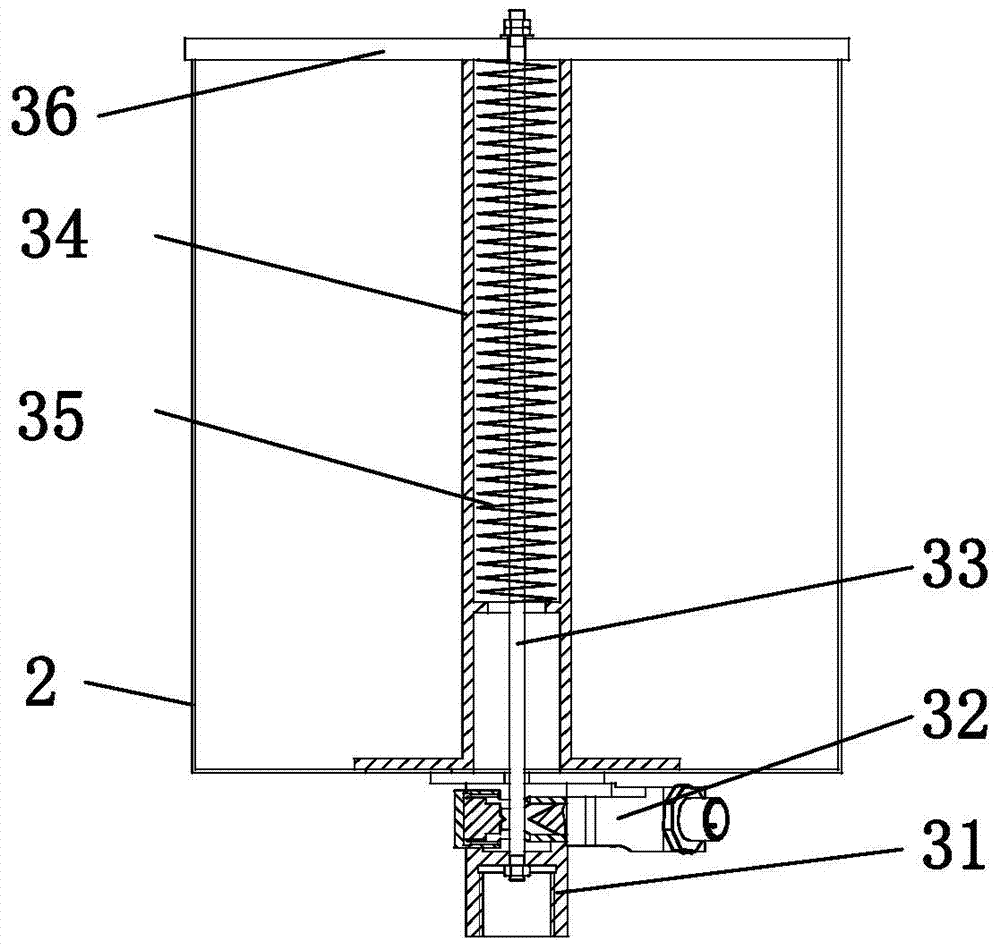

[0061] Such as figure 1As shown, the rope net type space debris capture and removal system is characterized in that it includes: a launching subsystem and a flying net subsystem, and the launching subsystem includes a launcher 1, a net cabin 2, a net hatch cover ejection device 3, and a buffer device 4. The tether tension control device 5 and the tether cutter 6, the flying net subsystem includes the rope net 7 and the mass block 8; when the satellite finds the target aircraft, the satellite autonomously controls the work of the net hatch cover ejection device 3, and the net cabin The cover is ejected from the outlet of the net cabin 2, and the rope net is pulled out from the net cabin 2 in reverse order under the drive of the net cabin cover. As the rope net 7 is pulled out, the rope net 7 and the tether tension control device 5 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com