Self-rotating high-pressure water jet adjustable drilling device

A technology of high-pressure water jet and drilling device, which is applied in the direction of drilling with liquid/gas jets, construction, etc., can solve the problems of easy drilling of target rock layers, affecting the uniformity of drilling holes, affecting the drilling length, etc., and achieving the diameter of the drilling holes Controllable, well controlled wellbore diameter, and the effect of reducing drilling risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

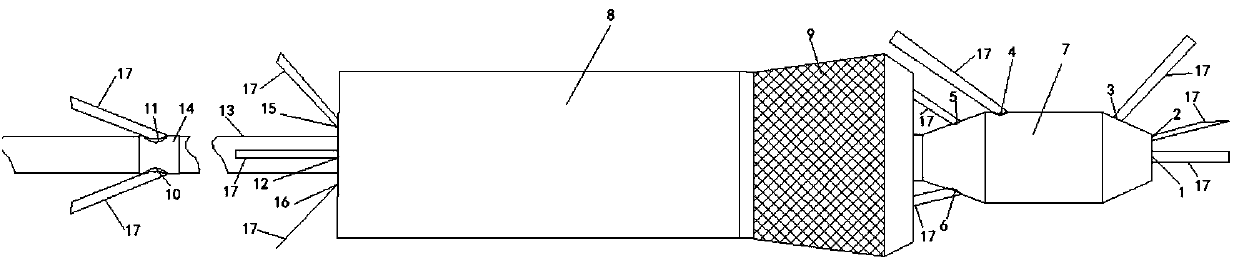

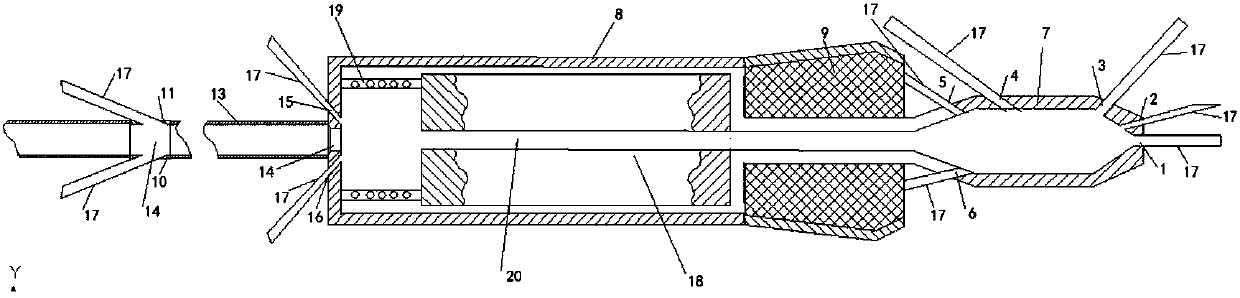

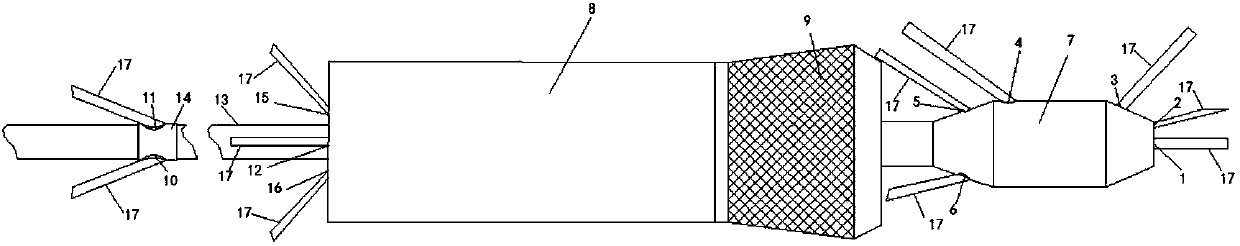

[0026] see Figure 1 to Figure 4 , shows the self-rotating high-pressure water jet adjustable drilling device of the present invention.

[0027] As shown in the figure, the self-rotating high-pressure water jet adjustable drilling device provided by the present invention may include a high-pressure pipe 13, a propeller 14, a fixed casing 8, a rotating body 18, a screen-like outer channel 9 and a rotating nozzle 7, wherein, The fixed casing 8 includes a cylindrical body, the high-pressure pipe 13 is arranged at the rear end of the cylindrical body, and a first thruster 14 is installed on the high-pressure pipe 13. Optionally, the high-pressure pipe 13 It can be connected with the first propeller 14 and the fixed casing 8 through threads, wherein the high-pressure pipe 13 can be fixed by the second propeller 21 installed at the rear end of the fixed casing 8, and the front end of the fixed casing 8 is connected with a screen Outer channel 9, the rotating body 18 is rotatably lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com