Patents

Literature

82results about "Hydrotreatment operations starting-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation catalysts precuring method and start working method of hydrogenation process

ActiveCN101492607AHigh vulcanization rateHigh sulfur retentionHydrotreatment operations starting-upCatalyst activation/preparationSulfurEconomic benefits

The invention discloses a method for precuring hydrogenation catalyst and a hydrogenation process operation method. During the presulfurization of the catalyst, intake of curing ingredient for partially precuring the catalyst is much more than theoretical sulfur demand of active hydrogenation metal in the catalyst. Precured hydrogenation catalyst and the hydrogenation catalyst which is not precured are mixed or layered in a reactor, and by operation and activation all catalyst is effectively cured. The method of the invention can precure the required catalyst, shorten the production period for precuring the catalyst, reduce the production cost and enhance economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for starting operation of catalyst for hydrocracking in oxidation state

InactiveCN101003749AStrong resistance to sulfur poisoningImprove hydrogenation performanceHydrotreatment operations starting-upOxidation stateNitrogen gas

This invention relates to a start-up method for oxidation-state hydrocracking catalyst used in oil refinery process. The method comprises: loading the oxidation-state hydrocracking catalyst into a reactor, introducing nitrogen to replace air in the reactor and pipelines, pressurizing to meet the pressure requirement of hydrocracking, switching to hydrogen after nitrogen flow is stable, raising the temperature of the catalyst bed to meet the temperature requirement of catalyst reduction after hydrogen flow is stable, keeping the temperature, adjusting the temperature of the catalyst bed to meet the temperature requirement of hydrocracking, adjusting hydrogen flux to meet the flux requirement of hydrocracking, and introducing hydrocarbon reactants. The method does not need pre-sulfurization of the catalyst with additional sulfurization agent, thus can avoid the problems caused by pre-sulfurization, and partially reduced catalyst has higher hydrocracking activity.

Owner:XIAMEN UNIV

Class II active center hydrogenation catalyst start-up vulcanization method

ActiveCN102311766AImprove catalytic performanceMoisturize thoroughlyHydrotreatment operations starting-upHydrocarbon oil crackingHydrogenVulcanization

The invention discloses a class II active center hydrogenation catalyst start-up vulcanization method, which comprises the following steps: (1) taking class II active center hydrogenation catalyst before vulcanization; (2) filling the class II active center hydrogenation catalyst before vulcanization into a reactor at normal temperature and pressure, introducing nitrogen to replace air in a reaction system, then replacing the nitrogen with hydrogen and carrying out gas seal; (3) continuing to adjust the temperature of a bed layer of the reactor, and introducing vulcanized oil to moisten the catalysts; (4) cycling the vulcanized oil in a closed mode in the reaction system, gradually injecting vulcanizers into the vulcanized oil, and raising the temperature continuously to complete vulcanization; and (5) adjusting the bed layer to the reaction temperature after vulcanization, and switching raw oil. The catalyst start-up vulcanization method disclosed by the invention is conductive to forming more class II hydrogenation active centers for the catalysts, and is conductive to improving the use performance of the catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Operating method for vulcanized hydrogenation catalyst

ActiveCN104593050ANo self-heatingNo flammability issuesMolecular sieve catalystsHydrotreatment operations starting-upHydrogenation reactionReaction temperature

The invention discloses an operating method for a vulcanized hydrogenation catalyst. The method comprises the following steps: impregnating the vulcanized hydrogenation catalyst with an organic complex solution of a group-VIII metal; carrying out heat treatment so as to allow a layer of a protective film to form on the surface of the vulcanized hydrogenation catalyst; carrying out treatment in the presence of inert gas so as to allow the group-VIII metal to be inlaid in the defect of molybdenum disulfide or tungsten disulfide, thereby forming a high-activity hydrogenation active phase; and then carrying out switching into hydrogen, adjusting pressure and temperature to reaction pressure and reaction temperature after air current is steady, feeding raw oil and beginning a hydrogenation reaction. The method provided by the invention can passivate the vulcanized catalyst, facilitates transportation, storage and filling of the catalyst and can improve hydrogenation performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalyst

ActiveCN103773436AChange processLess investmentHydrotreatment operations starting-upHydrocarbon oil crackingNaphthaEngineering

The invention discloses a start-up method for an ex-situ prevulcanization secondary activity center hydrogenation catalyst. After resistance to air loss of a device is qualified, circulating hydrogen compressor working load is adjusted to 0-20% of a maximum load, the catalyst reacts at a low temperature to release heat; when the bed layer temperature rise to 60-150 DEG C, start-up activation oil is introduced, the circulating hydrogen compressor working load is adjusted to 60-100% of the maximum load for wetting of the catalyst; the start-up activation oil is cycled in a reaction system closed path, the catalyst bed temperature is risen to 180 to 230 DEG C by heat exchange; a proper amount of olefin-enriched naphtha is added into the start-up activation oil, the catalyst bed temperature is risen to 300-380 DEG C to complete start-up activation. The start-up method, in the premise of no influence on the use properties of the secondary activity center hydrogenation catalyst, can better use the catalyst characteristics, reduce the device energy consumption, and reduce the device investment cost, and the start-up process can be simplified.

Owner:CHINA PETROLEUM & CHEM CORP +1

Start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalysts

ActiveCN102443412AImprove catalytic performanceIncrease the number ofHydrotreatment operations starting-upHydrocarbon oil crackingActivation methodHydrogen

The invention discloses a start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalysts, which comprises the following steps that: (1) the ex-situ prevulcanization secondary activity center hydrogenation catalysts are taken; (2) the ex-situ prevulcanization secondary activity center hydrogenation catalysts are filled into a reactor at normal temperature and normal pressure, nitrogen gas is introduced for replacing air in a reaction system, then, hydrogen gas is used for replacing the nitrogen gas, and the hydrogen tightness is carried out; (3) the temperature of a bed layer of the reactor is continuously regulated, start-up activation oil is introduced, and the catalysts are humidified; (4) the start-up activation oil carries out closed loop circulation in the reaction system, and the temperature is continuously raised for completing the start-up activation; and (5) after the activation completion, the bed layer is regulated to the reaction temperature, and raw material oil is switched. The catalyst start-up activation method is favorable for the catalysts to form more secondary hydrogenation active centers, and the use performance of the catalysts is favorably improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

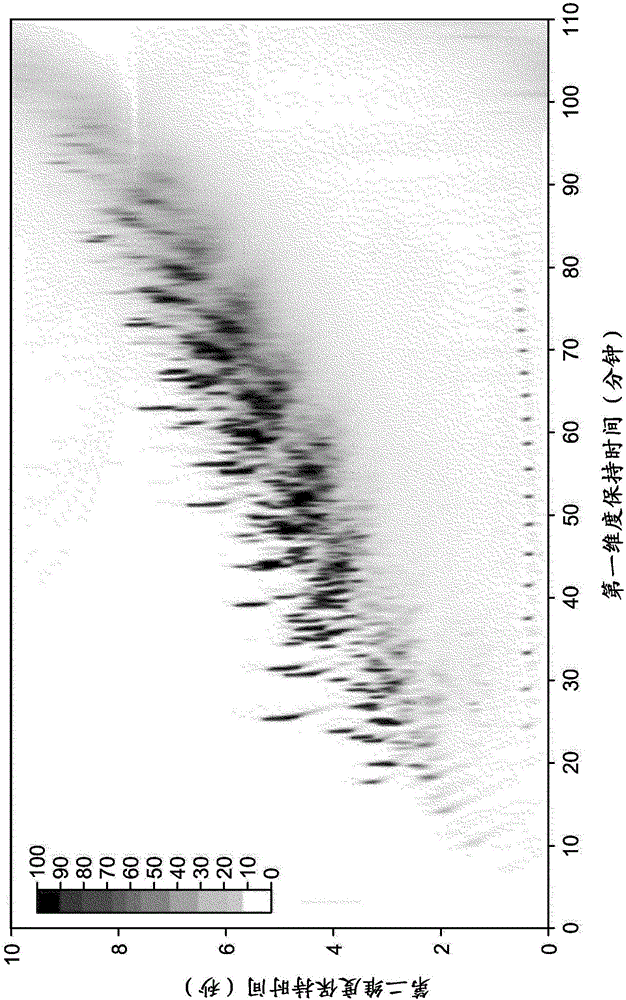

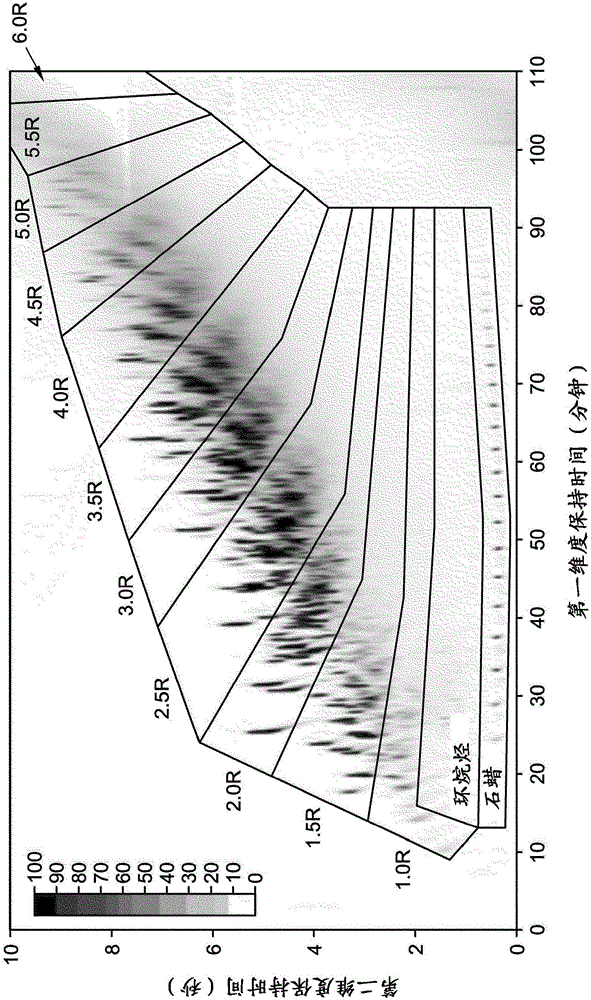

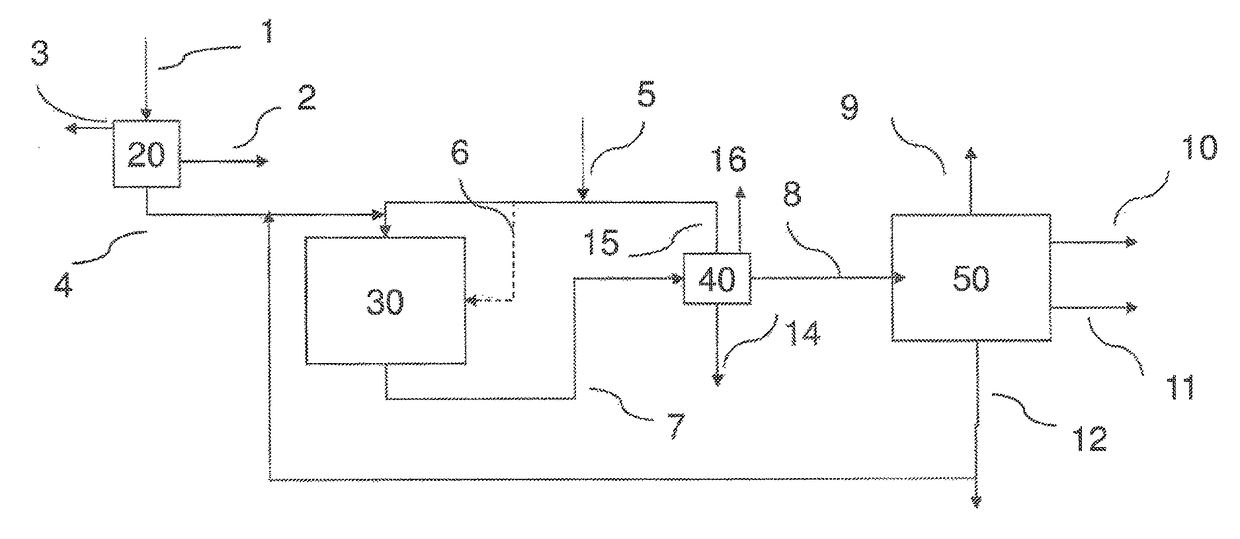

Pyrolysis tar upgrading using recycled product

ActiveUS9657239B2Pyrolysis tar hydroprocessing is improvedLesser rateHydrotreatment operations starting-upRefining to change hydrocarbon structural skeletonProcess engineeringFuel oil

The invention relates to a process for upgrading pyrolysis tar in the presence of a utility fluid. The utility fluid contains 1-ring and / or 2-ring aromatics and has a final boiling point ≦430° C. The invention also relates to the upgraded pyrolysis tar, and to the use of the upgraded pyrolysis tar, e.g., for fuel oil blending.

Owner:EXXONMOBIL CHEM PAT INC

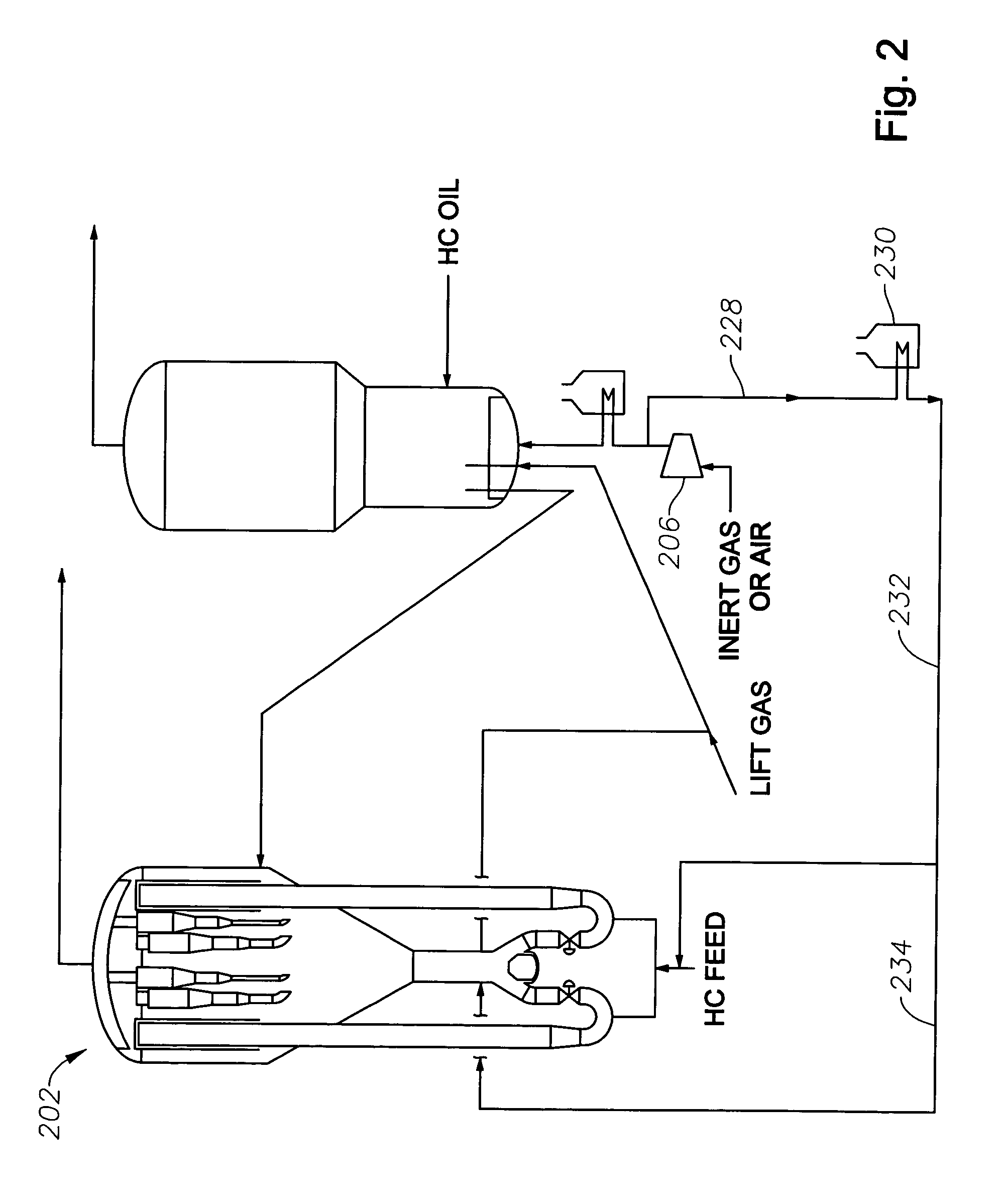

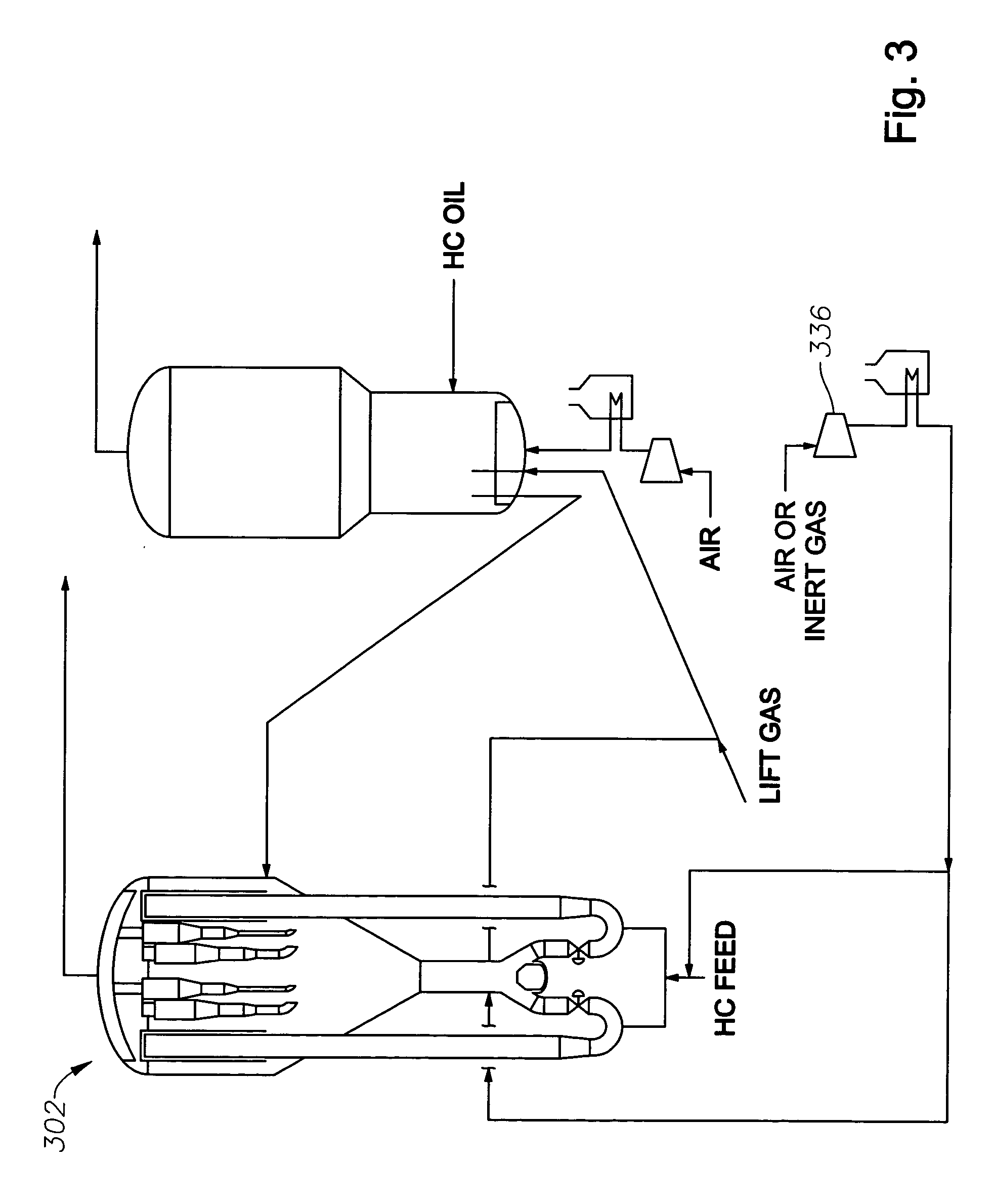

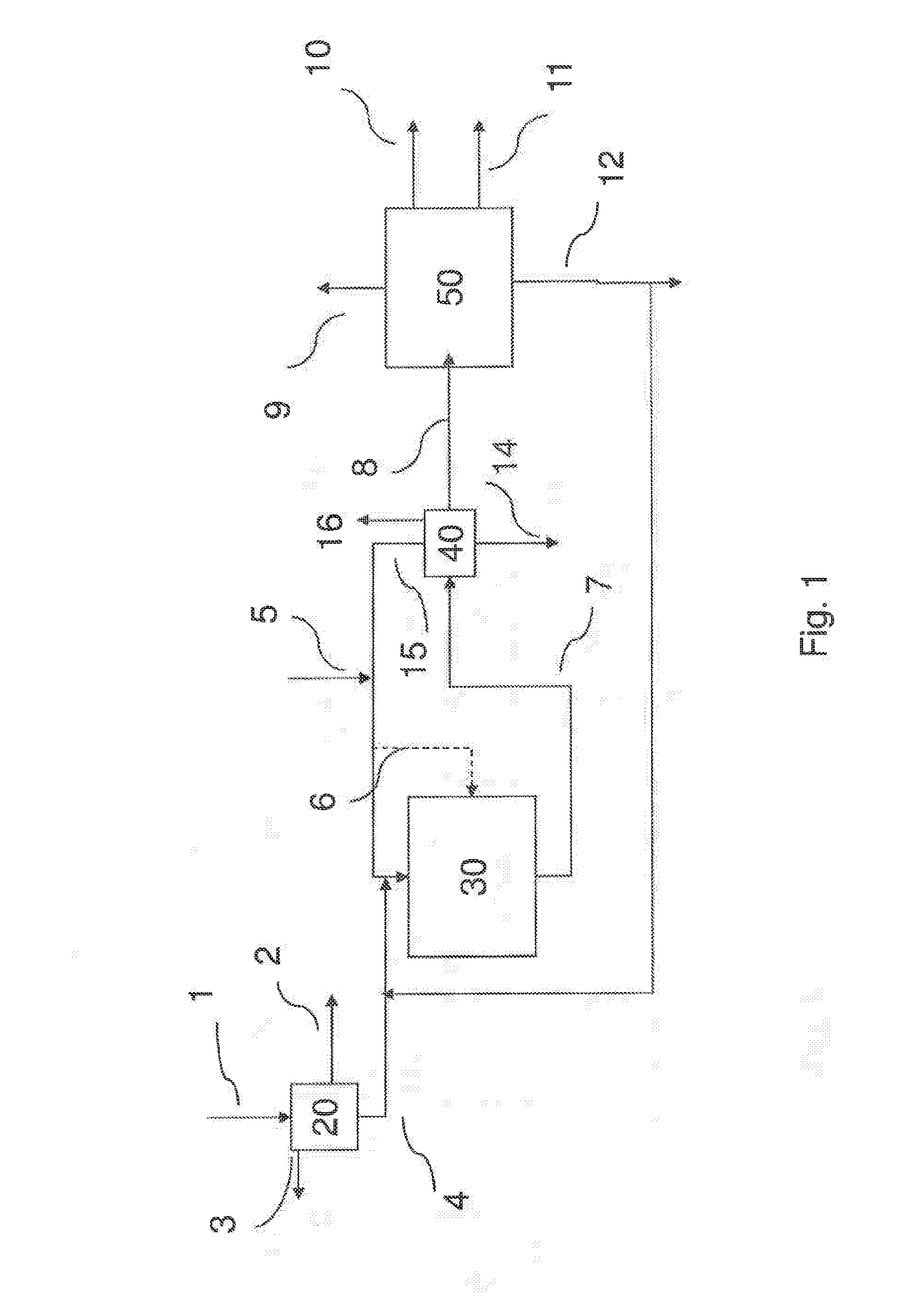

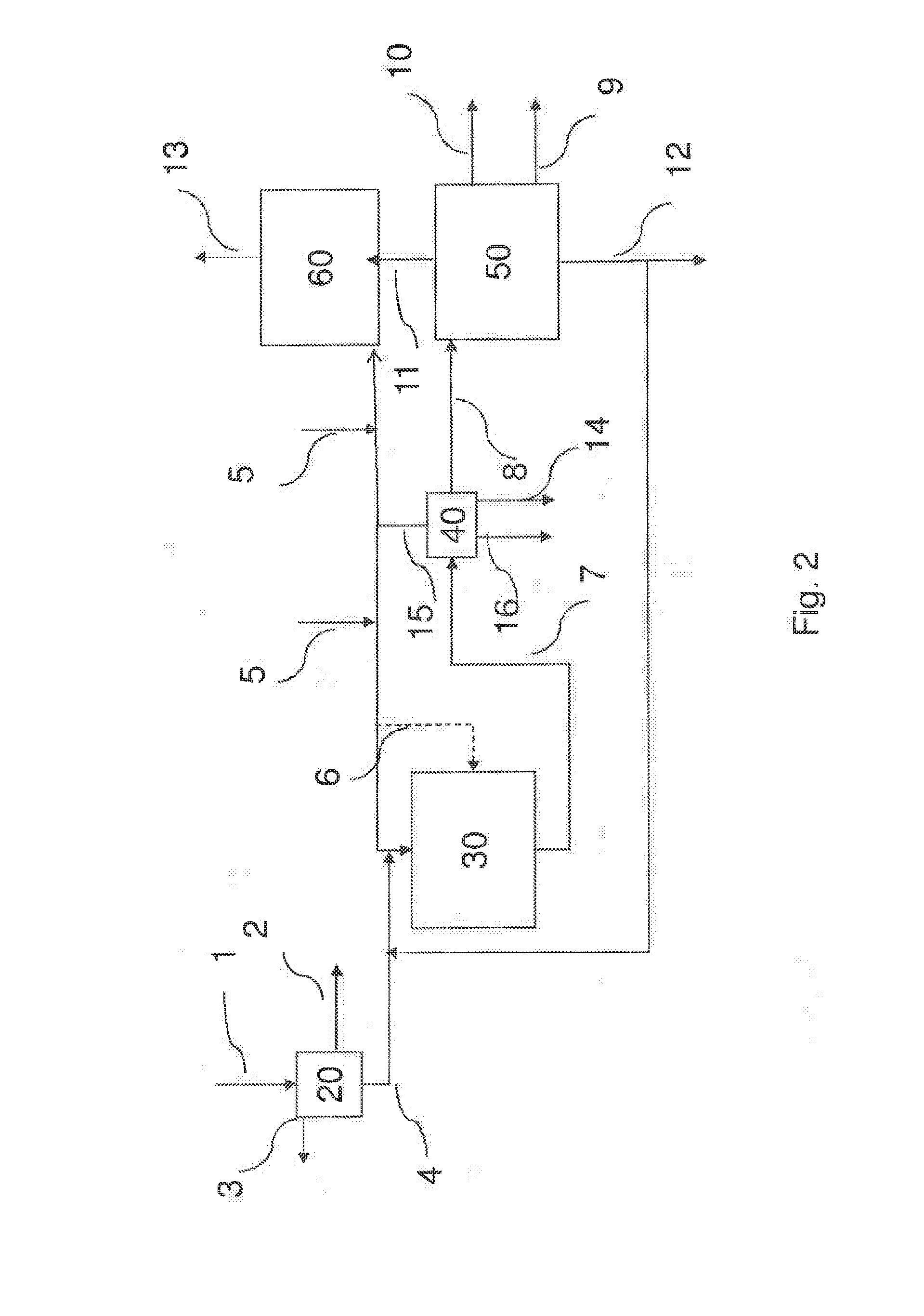

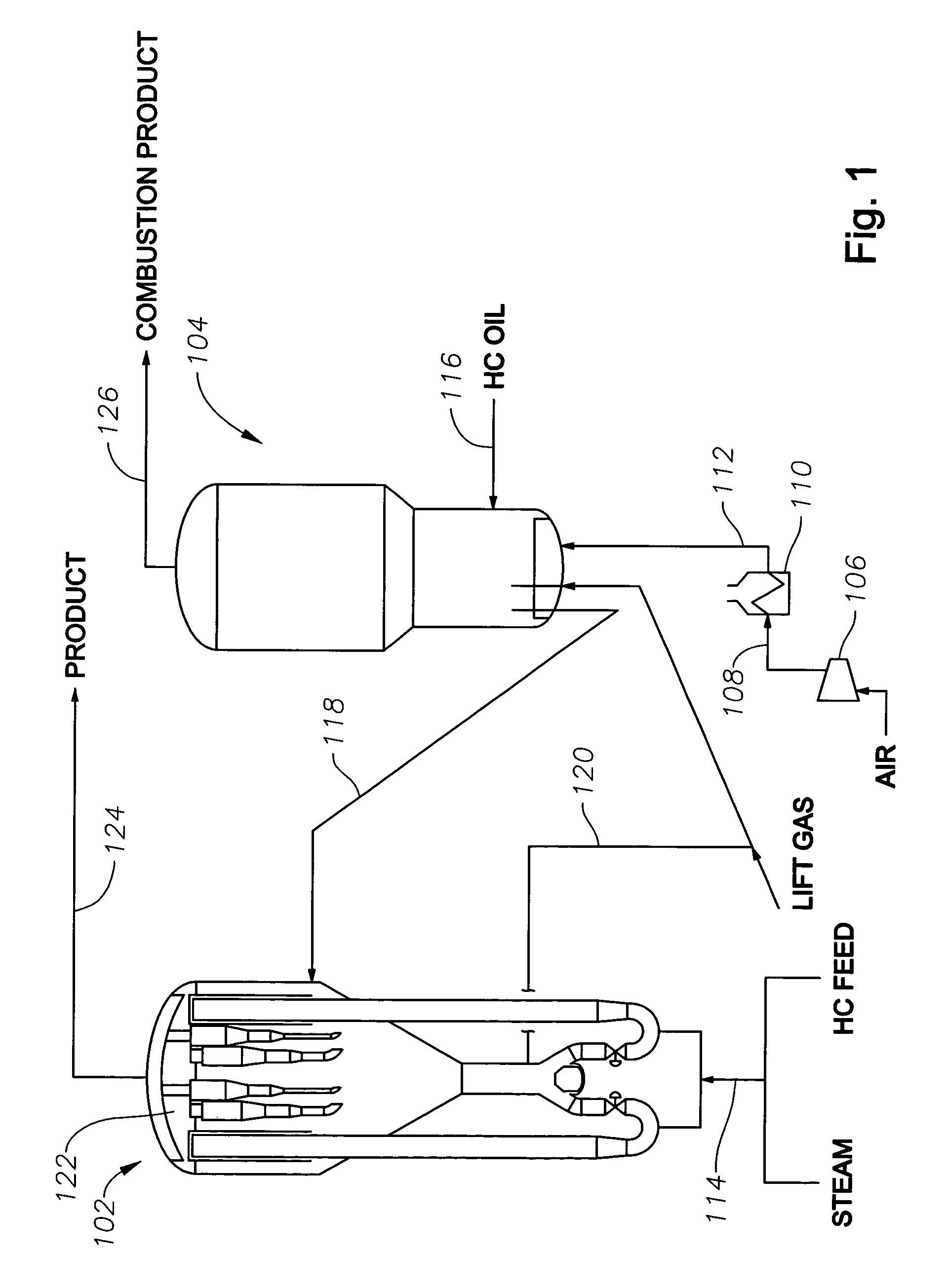

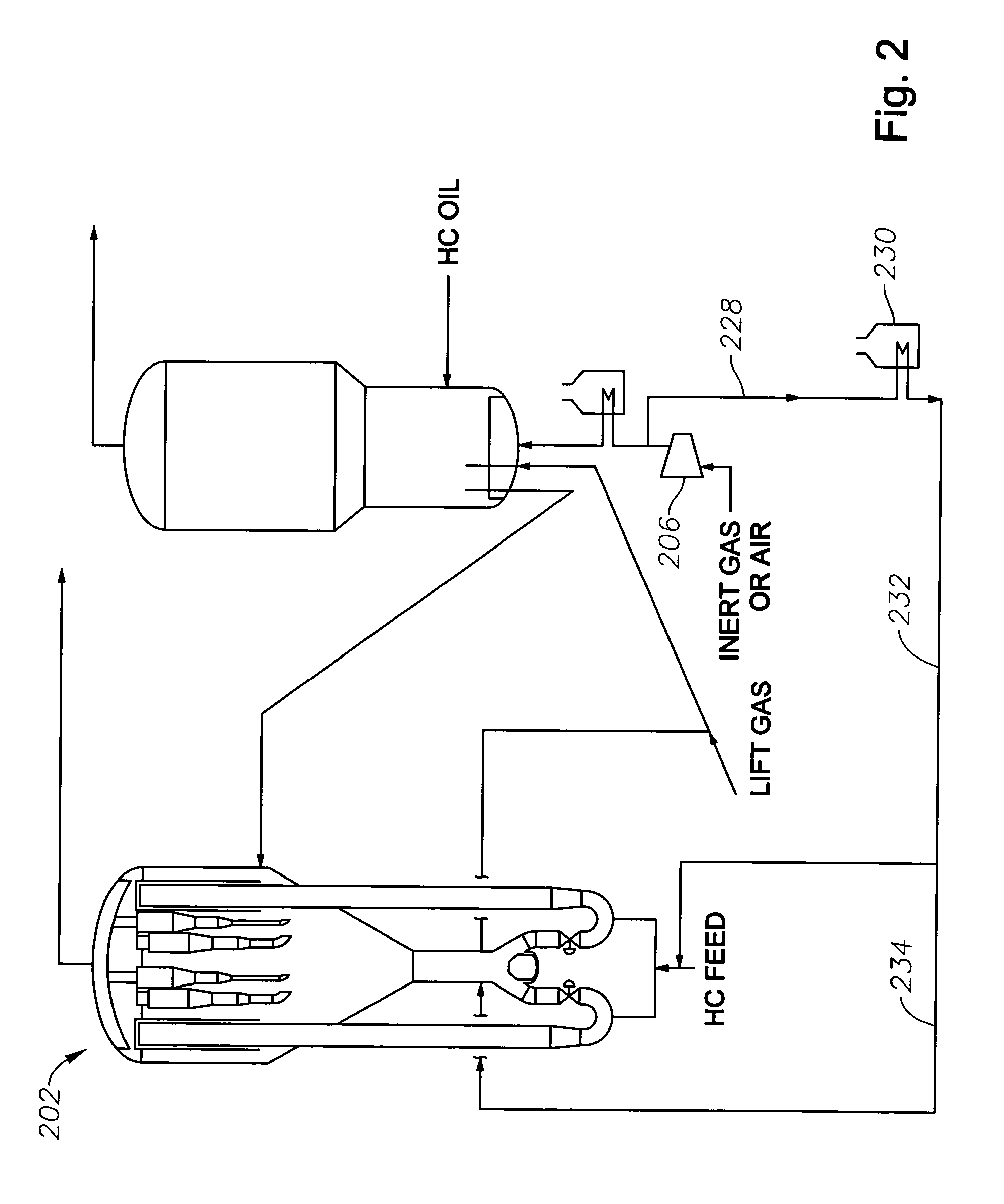

Method of starting up a reaction system

Owner:EXXONMOBIL CHEM PAT INC

Startup method of sulfuration type hydrogenation catalyst

ActiveCN104593051APrevent oxidationNo self-heatingMolecular sieve catalystsHydrotreatment operations starting-upHydrogenation reactionReaction temperature

The invention discloses a startup method of a sulfuration type hydrogenation catalyst. The method comprises the following steps: the sulfuration type hydrogenation catalyst is impregnated by using an organic complex solution of a VIII-group metal; a heat treatment is carried out, such that a protection film is formed on the surface of the sulfuration type hydrogenation catalyst; startup oil is introduced under the existence of an inert gas, and a treatment is carried out; the inert gas is switched into hydrogen, and the pressure and temperature are regulated to reaction pressure and reaction temperature when the gas flow is stable; raw oil is fed, and the hydrogenation reaction is started. With the method provided by the invention, the sulfuration type hydrogenation catalyst can be passivated, such that catalyst transportation, storage and loading are convenient. Also, the hydrogenation performance of the catalyst can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Starting method of hydrocracking unit

ActiveCN103789023AInitial activity inhibitionImprove adsorption capacityHydrotreatment operations starting-upTreatment with hydrotreatment processesLow nitrogenReaction zone

The invention relates to a starting method of a hydrocracking unit. A reaction zone of the hydrocracking unit is filled with an oxidation type hydrogenation catalyst. The starting method comprises steps of heating circulating gas to (150-225)+ / -15 DEG C, introducing a sulfurizing agent, performing sulfuration at a constant temperature of 230+ / -15 DEG C, heating continuously to raise the temperature to 370+ / -20 DEG C and performing sulfurization at the constant temperature, introducing low-nitrogen starting oil when the temperature decreases to 150+ / -15 DEG C after the catalyst sulfurization is finished, raising the temperature to 210+ / -20 DEG C and introducing nitrogen-containing light distillate oil, introducing nitrogen-containing heavy distillate oil instead when the temperature is 290+ / -15 DEG C or higher, introducing raw oil instead step by step when the temperature is 320+ / -15 DEG C and shifting to normal production. Compared with the prior art, the starting method replaces anhydrous liquid ammonia by the nitrogen-containing distillate oil and the starting process is smooth and steady.

Owner:CHINA PETROLEUM & CHEM CORP +1

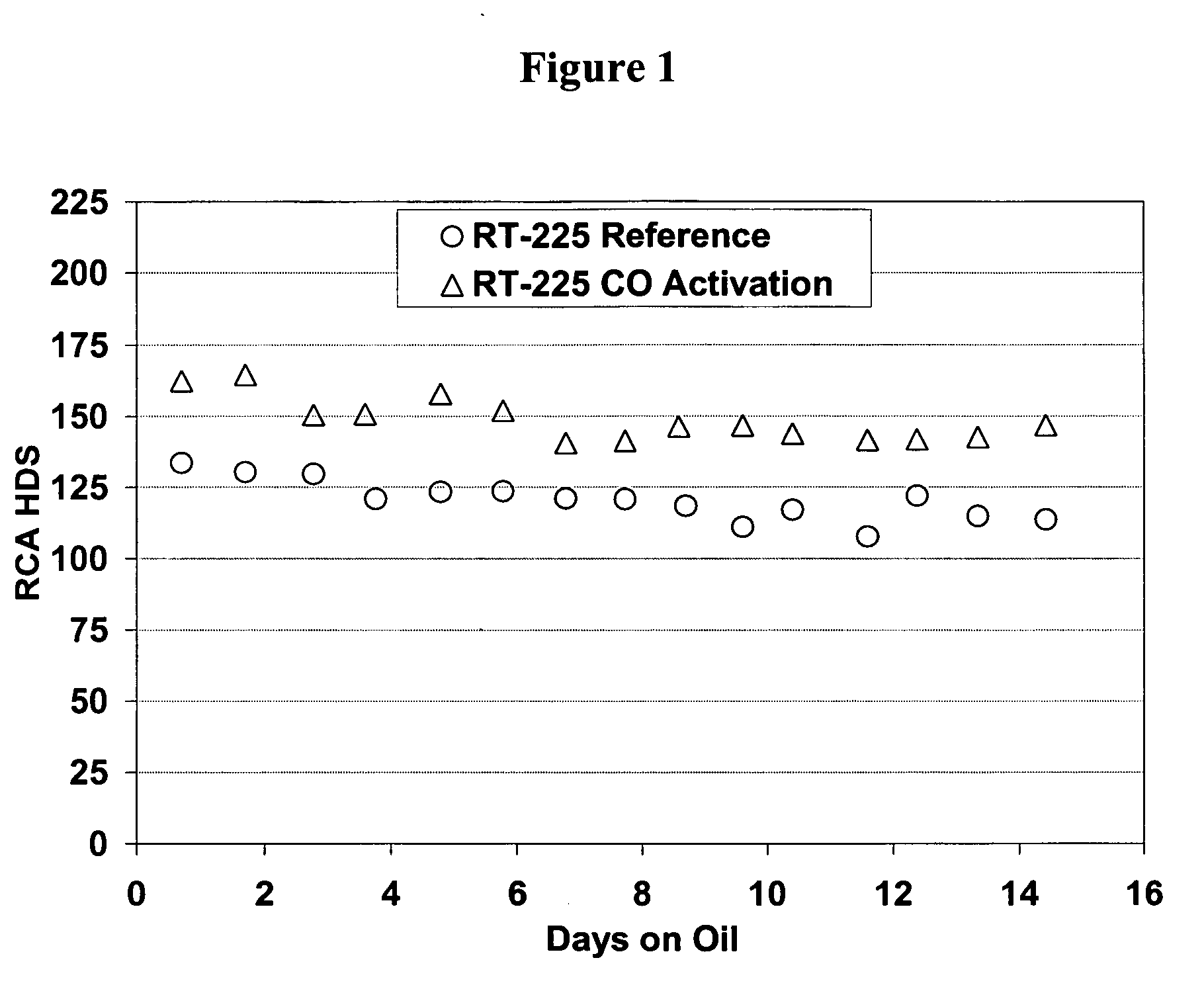

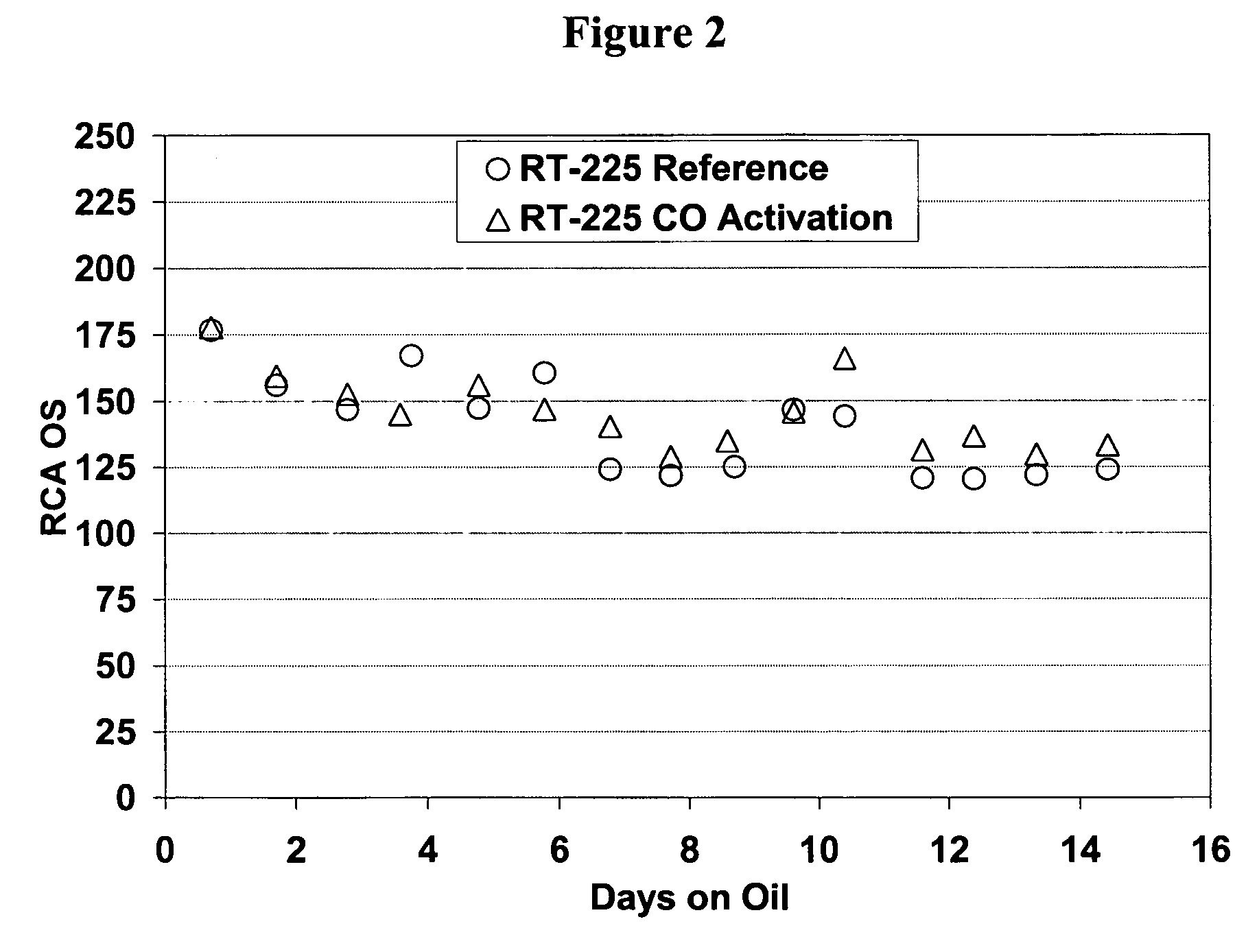

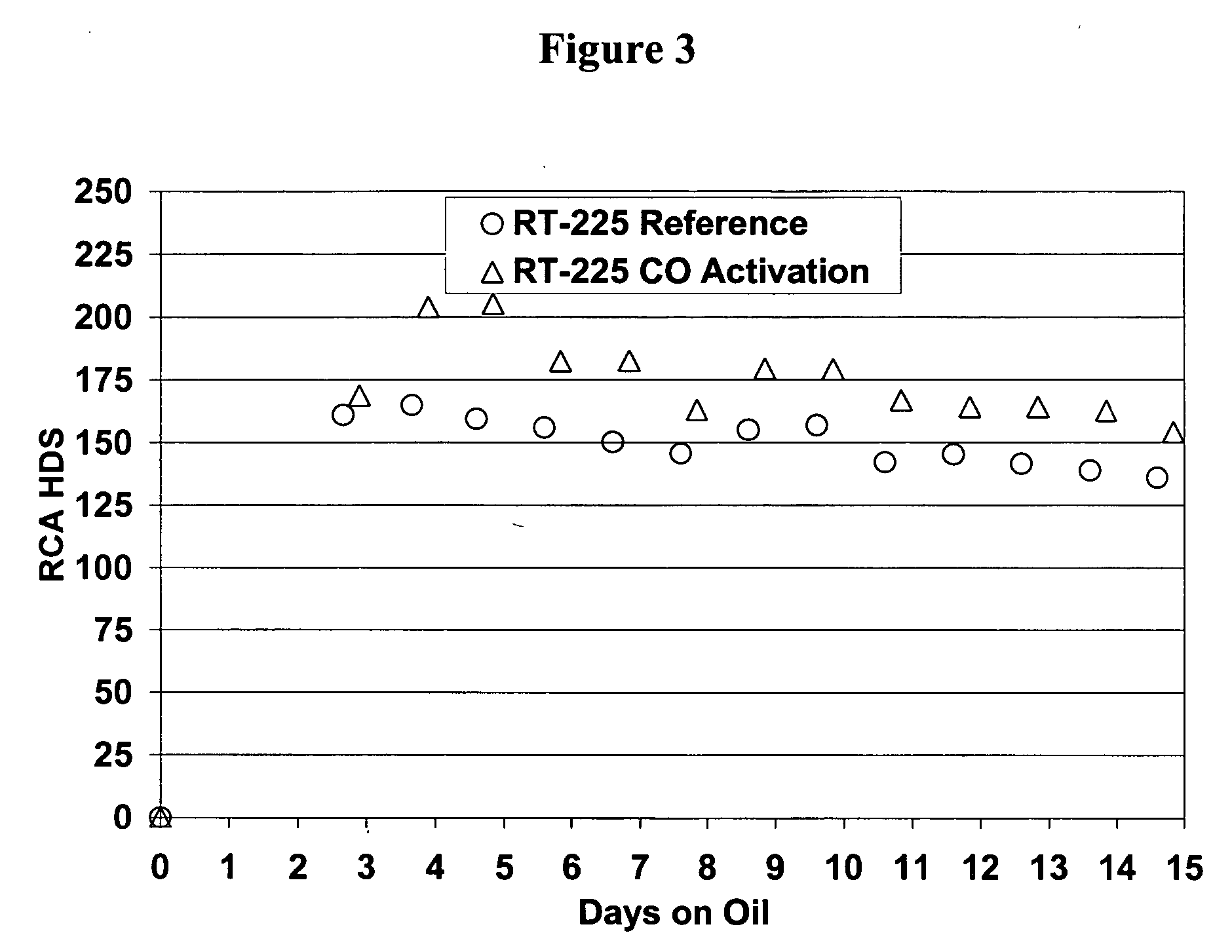

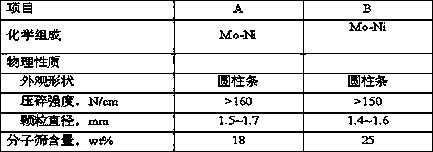

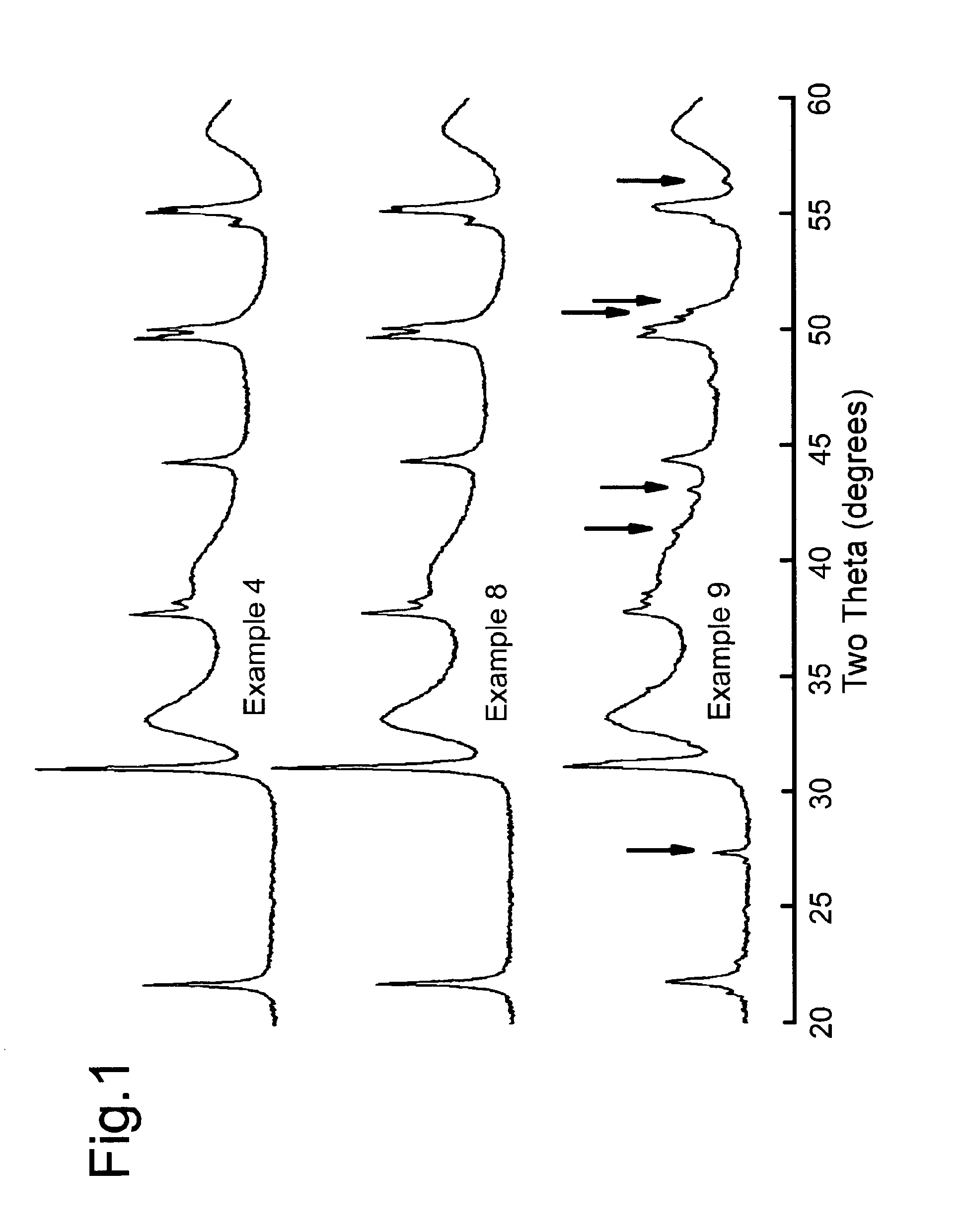

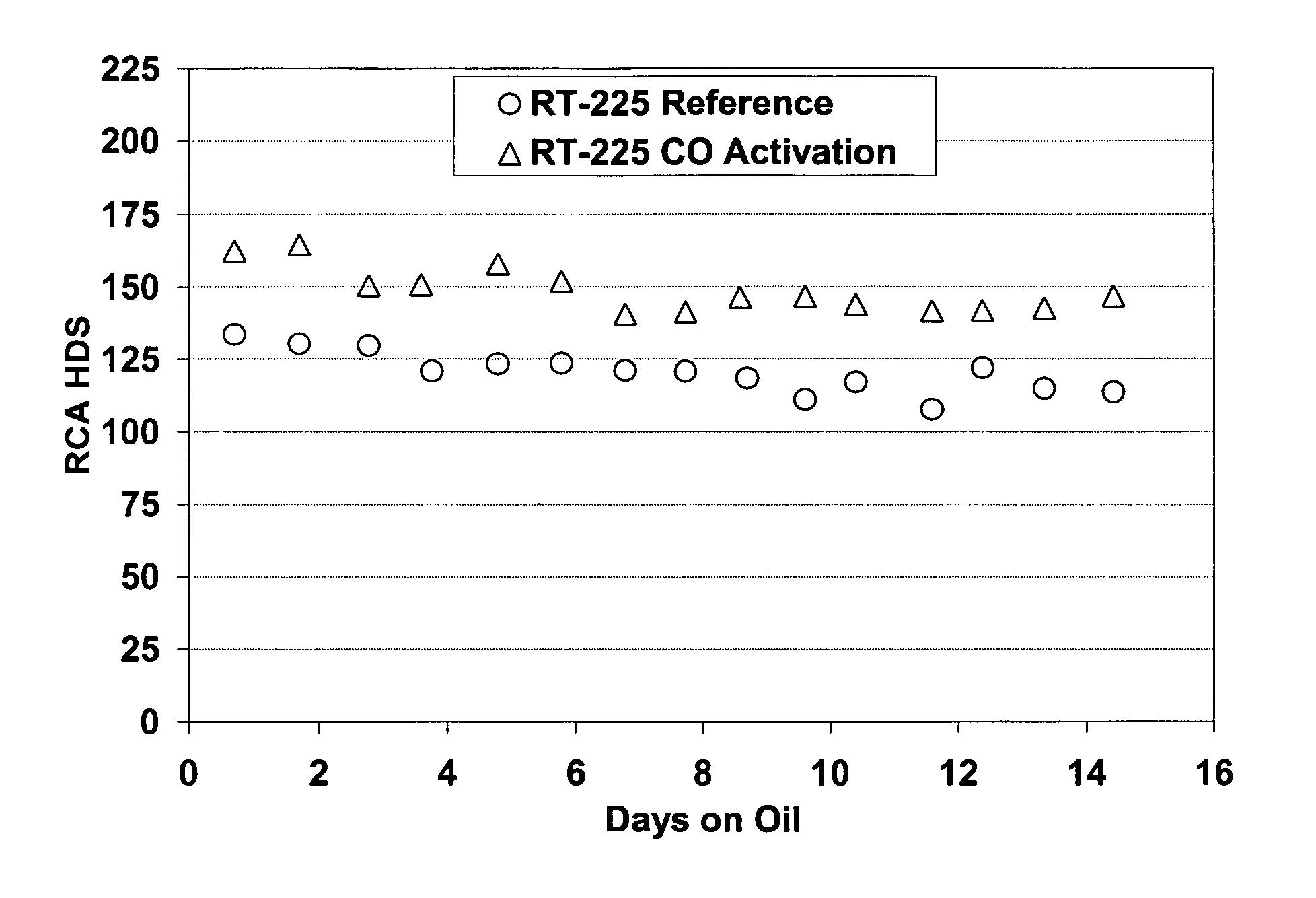

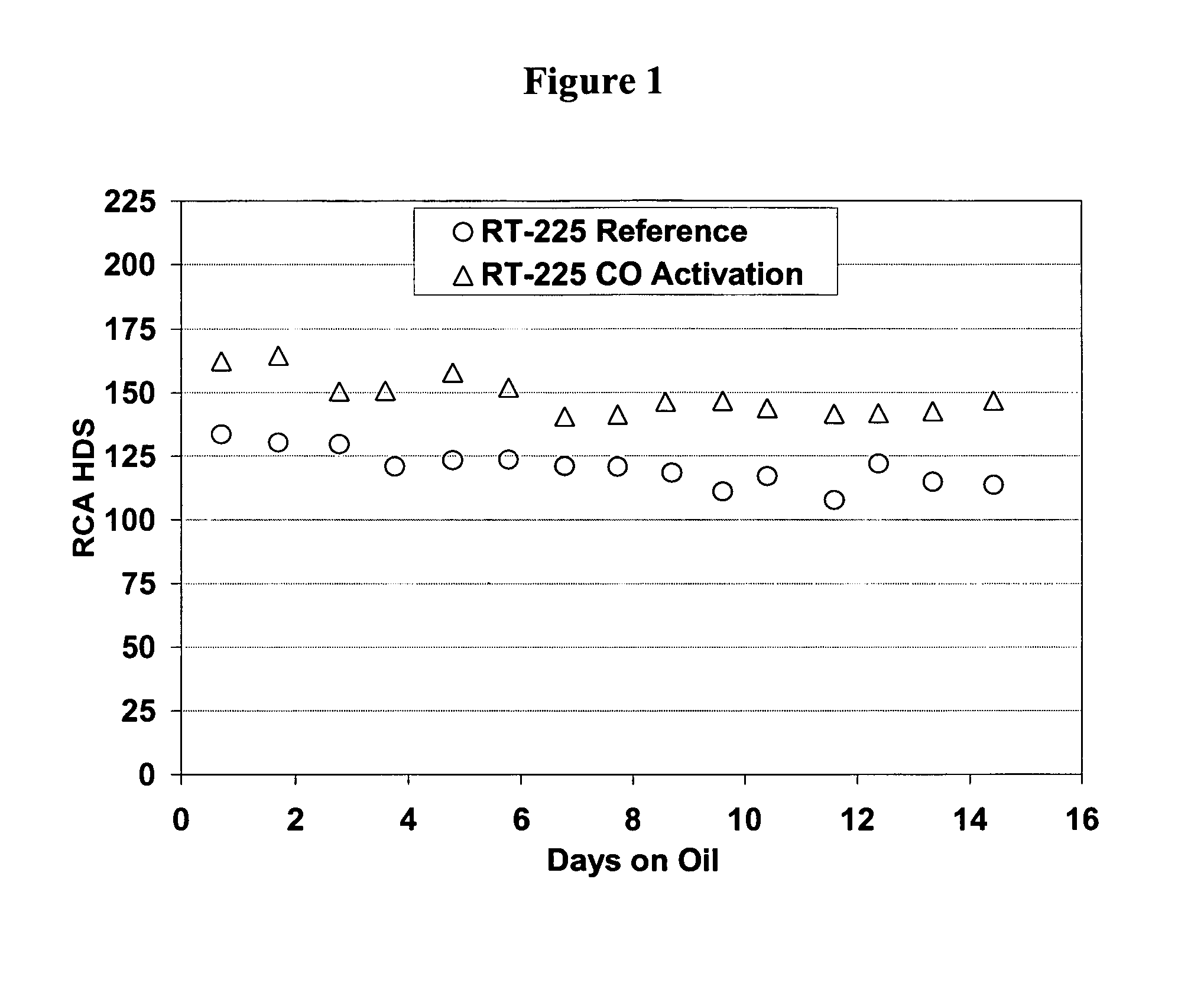

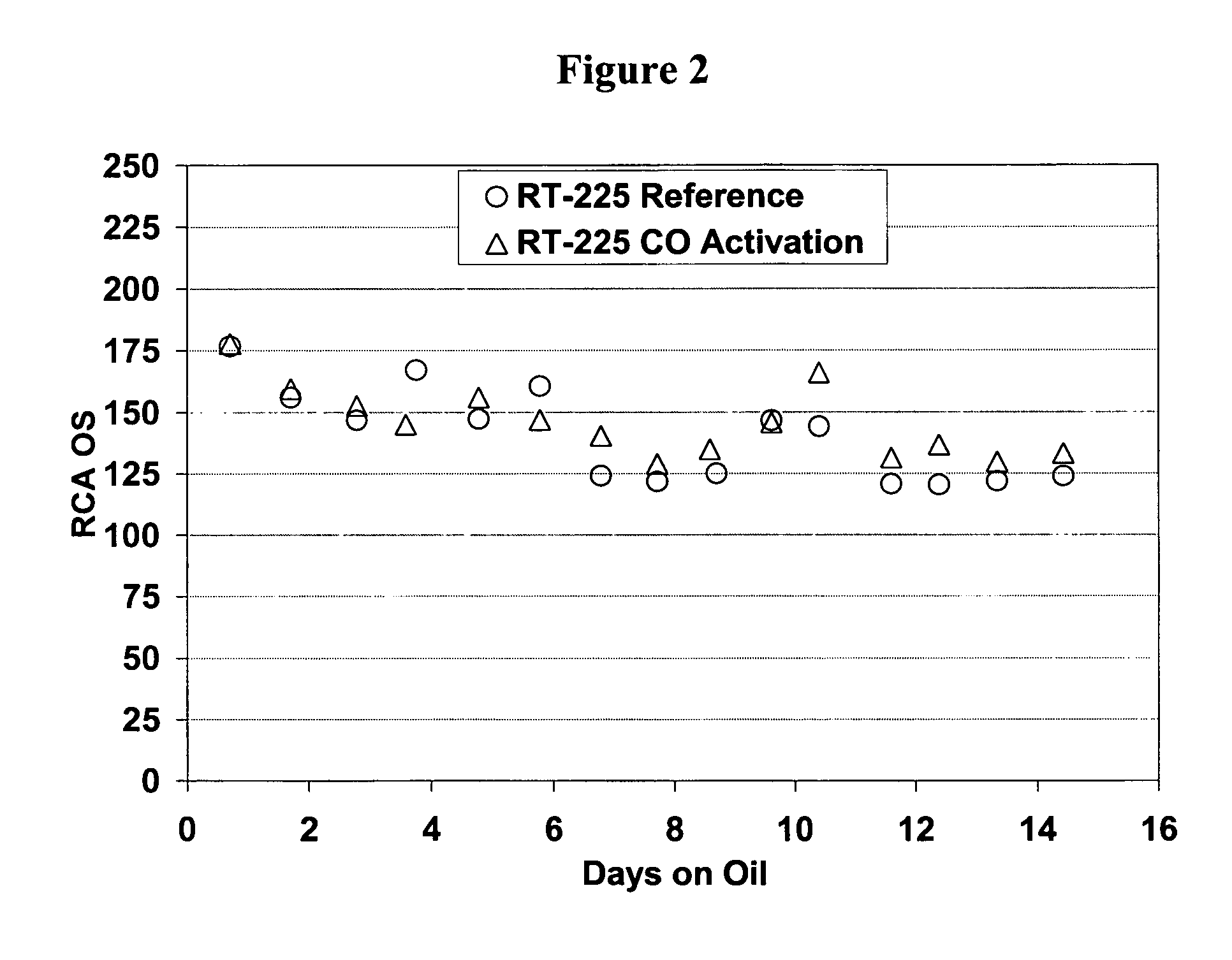

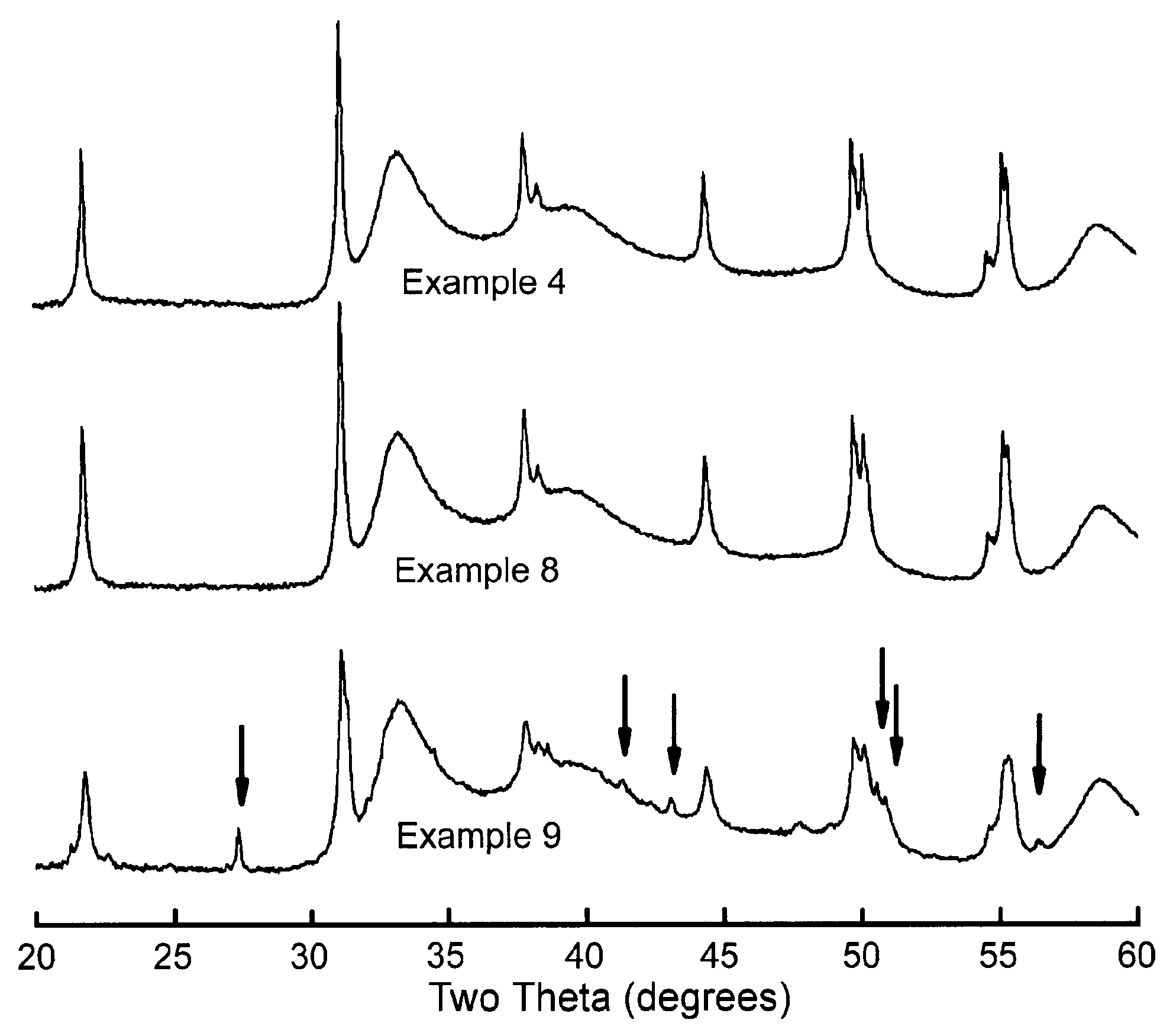

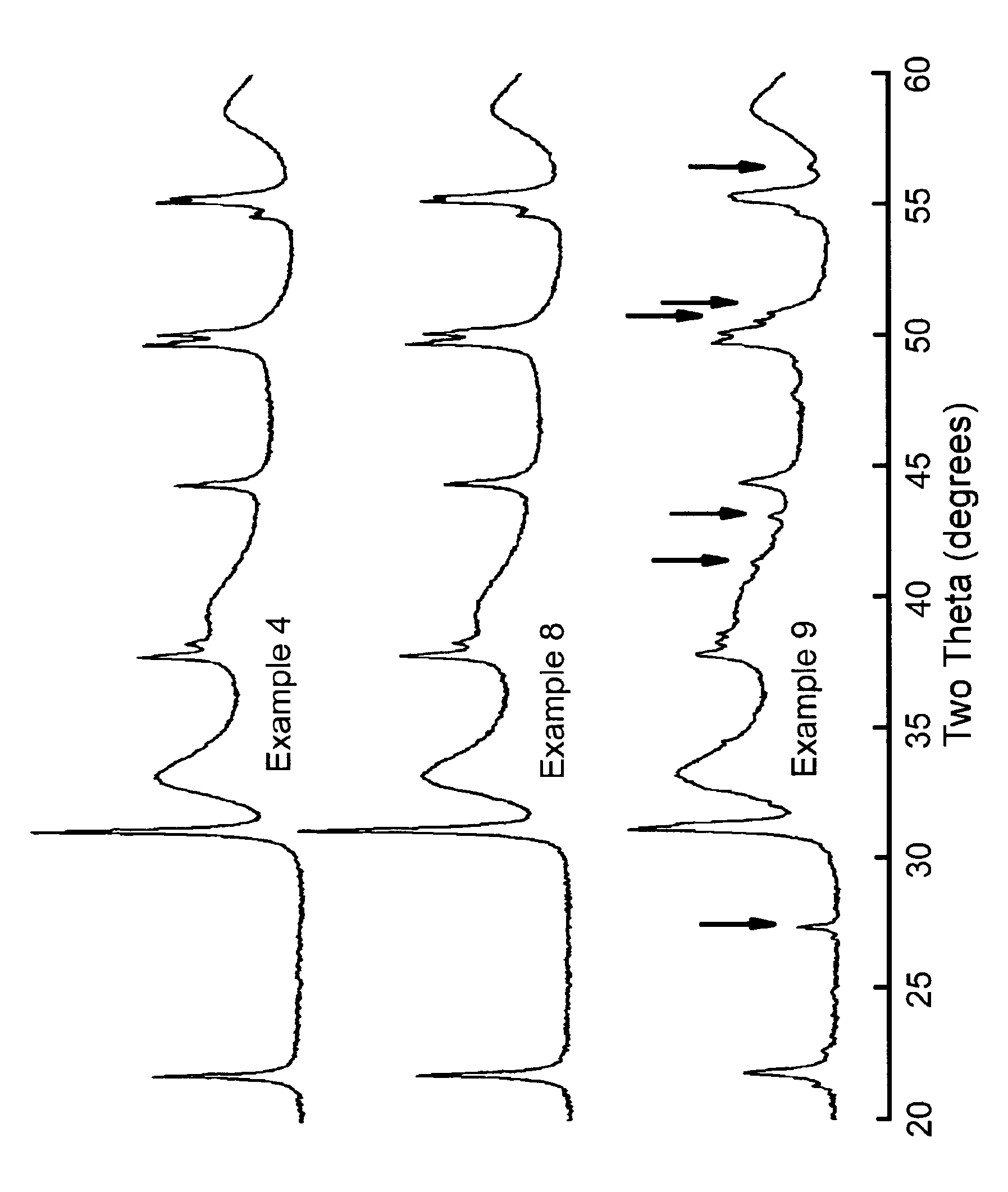

Activating hydroprocessing catalysts using carbon monoxide and use of catalysts for hydroprocessing

ActiveUS20060231464A1Hydrotreatment operations starting-upHydrocarbon oils treatment control/regulationOrganic chemistryCo treatments

This invention relates to a process for activating a hydroprocessing catalyst and the use of activated catalyst for hydroprocessing. More particularly, hydroprocessing catalysts are activated in the presence of carbon monoxide. The catalysts that have been activated by CO treatment have improved activity.

Owner:EXXON RES & ENG CO

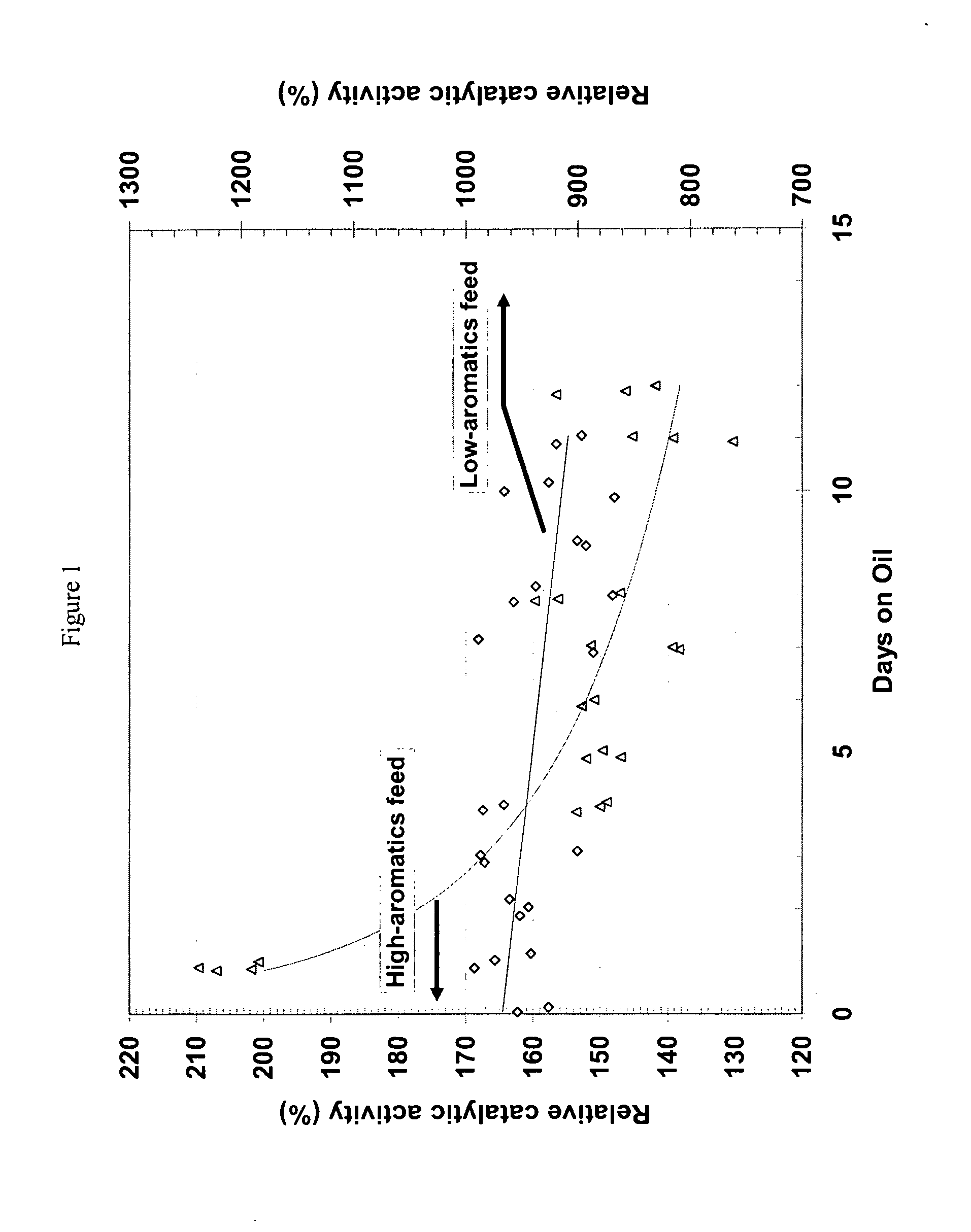

Hydrotreating process

InactiveUS20110203971A1Reduce decreaseHydrotreatment operations starting-upCatalytic naphtha reformingSulfur containingHydrocarbon

A process for hydrotreating a first aromatics- and sulfur-containing hydrocarbon feed using a fresh supported CoMo catalyst, includes treating the fresh catalyst under first hydrotreating conditions with a second hydrocarbon feed having a lower aromatics content than the first feed.

Owner:EXXON RES & ENG CO

Shut-down method of coal tar hydrotreating process

ActiveCN101089139APrevent precipitationEasy to cleanHydrotreatment operations starting-upCoal tarReaction system

The present invention discloses shut-down method of coal tar hydrotreating process. After the coal tar hydrotreating reaction is finished, the shut-down oil containing polar matter is first pumped into the reaction system for cleaning the pipeline and the reactor, and conventional shut-down oil is then added into the apparatus. Compared with available technology, the present invention has the advantages of complete cleaning of the reaction apparatus and capacity of ensuring the fluent shut-down.

Owner:CHINA PETROLEUM & CHEM CORP +1

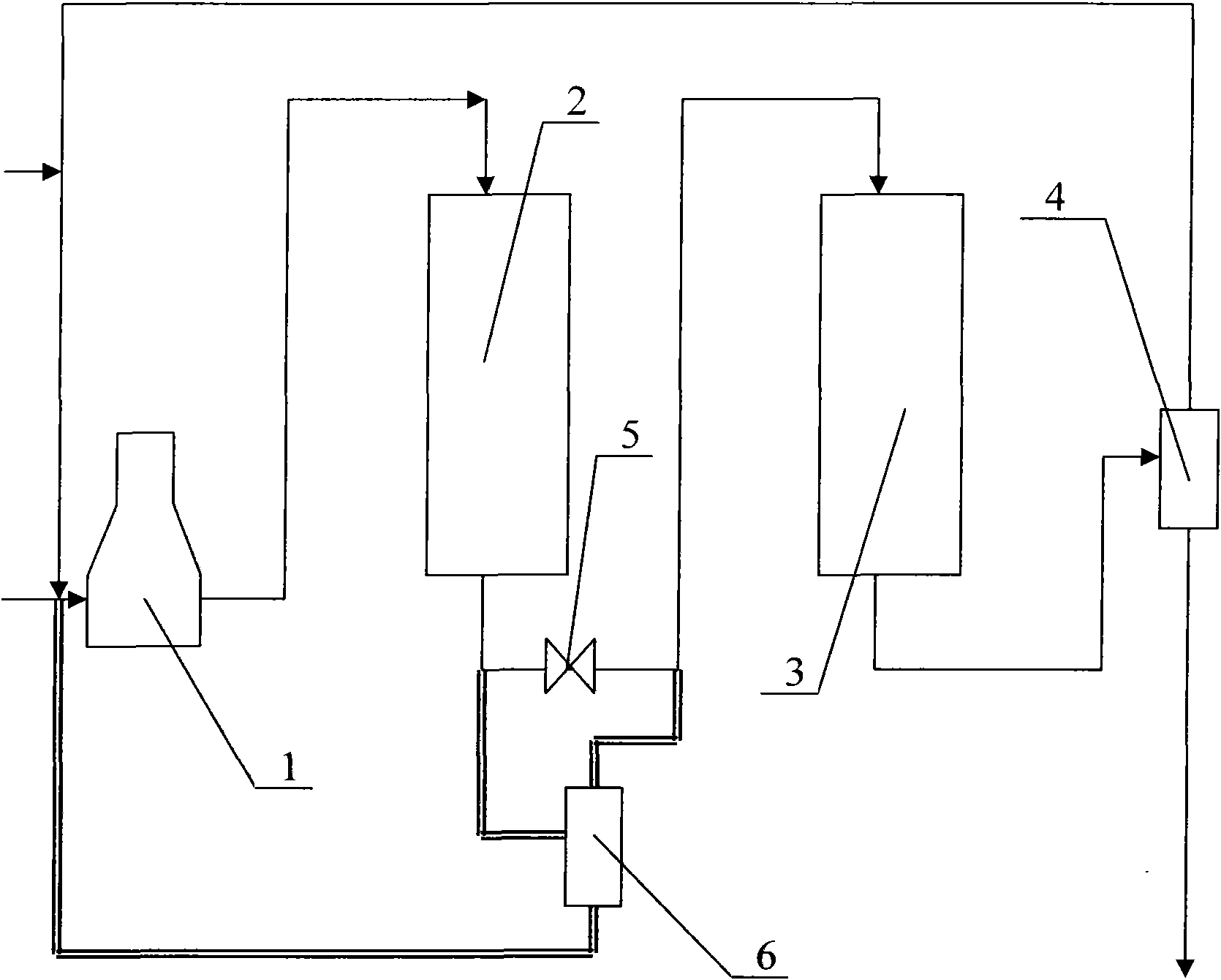

Startup sulfurization method for trickle bed class-II active center hydrogenation catalyst

ActiveCN102311765AForm a large numberImprove catalytic performanceHydrotreatment operations starting-upHydrocarbon oil crackingHydrogenClosed loop

The invention discloses a startup sulfurization method for a trickle bed class-II active center hydrogenation catalyst, which comprises the following steps: (1) preparing a class-II active center hydrogenation catalyst; (2) filling the class-II active center hydrogenation catalyst into a trickle bed reactor at normal temperature and normal pressure, introducing nitrogen to replace the air in a reaction system, sealing the nitrogen tightly, replacing the nitrogen with hydrogen, and sealing the hydrogen tightly; (3) regulating the temperature of a catalyst bed layer, introducing sulfurized oil from the bottom of the reactor, and wetting the class-II active center hydrogenation catalyst; (4) after the reactor is fully filled with sulfurized oil, introducing the sulfurized oil and hydrogen from the top of the reactor, forming closed-loop circulation in the reaction system, adding a sulfurizing agent into sulfurized oil gradually, and continuing to rise the temperature to complete sulfurization; and (5) after sulfurization is accomplished, introducing raw material oil from the top of the reactor. In the sulfurization method disclosed by the invention, the process is simple, the operation is convenient and quick, and the sulfurization effect is more ideal than the conventional method. Therefore, the method is more favorable for improving the number of class-II active center and consequently improving the activity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing hydrocarbons

ActiveUS20160130509A1Reduce the amount requiredMaintained at low levelHydrotreatment operations starting-upRefining to change hydrocarbon structural skeletonHydrodeoxygenationHydrocarbon

The present invention relates to a process for converting feedstock comprising materials of biological origin into hydrocarbons, said process comprising the steps where a) feedstock comprising at least one material of biological origin is subjected to purification treatment to obtain purified feedstock, and b) the purified feedstock is subjected to hydroprocessing in the presence of at least one hydrodeoxygenation catalyst, at least one hydrodewaxing catalyst and at least one hydrodearomatization catalyst to obtain a hydroprocessing product.

Owner:UPM-KYMMENE OYJ

Heavy aromatic solvents for catalyst reactivation

ActiveUS20210155858A1Hydrotreatment operations starting-upCatalyst regeneration/reactivationAromatic solventPtru catalyst

Compositions and methods for restoring catalytic activity by dissolving soft coke with a solvent, one method including detecting soft coke deposition on a catalyst composition; preparing an aromatic bottoms composition with a Hildebrand solubility parameter of at least about 20 SI to remove the soft coke from the catalyst composition; and washing the catalyst composition with the aromatic bottoms composition until at least a portion of the soft coke deposition is removed.

Owner:SAUDI ARABIAN OIL CO

Upgrading hydrocarbon pyrolysis products

ActiveCN106414673ALow variabilitySlow down the rate of increaseHydrotreatment operations starting-upLiquid carbonaceous fuelsTarDiluent

The invention relates to a utility fluid, such as a fluid containing aromatic and non- aromatic ringed molecules, useful as a diluent when hydroprocessing pyrolysis tar, such as steam cracker tar. The specified utility fluid comprises >= 10.0 wt% aromatic and non- aromatic ring compounds and each of the following: (a) >= 1.0 wt% of 1.0 ring class compounds; (b) >= 5.0 wt% of 1.5 ring class compounds; (c) >= 5.0 wt% of 2.0 ring class compounds; and (d) <= 0.1 wt% of 5.0 ring class compounds. The invention also relates to methods for producing such a utility fluid and to processes for hydroprocessing pyrolysis tar.

Owner:EXXONMOBIL CHEM PAT INC

Method of starting up a reaction system

Owner:EXXONMOBIL CHEM PAT INC

Suspension bed heavy oil hydrogenation process start-up method

ActiveCN102311762AEasy to operateLow costHydrotreatment operations starting-upHydrocarbon oil crackingReaction temperatureHydrogenation process

The invention discloses a suspension bed heavy oil hydrogenation process start-up method, which comprises the following steps: a reactor is firstly pre-heated by hot gas after a device is qualified in gas seal, after the reactor is pre-heated to 200-360 DEG C, raw oil containing a dispersive type catalyst and pre-heated to the same temperature and hydrogen are mixed and sent into a suspension bed reactor, the temperature of the reactor is further raised, and the material flow after reaction is fully cycled; and after the temperature of the reactor is raised to the reaction temperature, cycling operation is stopped, and device start-up is ended. In the method disclosed by the invention, light distillate and frequent switching operation used in the conventional heavy oil hydrogenation device are omitted, the start-up process is simplified, and the operation cost is reduced; and because the suspension bed hydrogenation start-up method is closely combined with the characteristics of suspension bed hydrogenation technology, the advantages of the technology are fully exerted, and the start-up method disclosed by the invention has wide adaptability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application method of second-kind active site hydrogenation catalyst

InactiveCN102465005AImprove catalytic performanceEasy to wetHydrotreatment operations starting-upHydrocarbon oil crackingReactive siteHydrogenation reaction

The invention discloses an application method of a second-kind active site hydrogenation catalyst, comprising the following steps: (1) taking the second-kind active site hydrogenation catalyst and putting in a reaction at a normal temperature under a normal pressure, letting in the air in a nitrogen displacement reaction system; (2) when the temperature of the reactor being within normal temperature to 135 DEG C, introducing catalyst moistening oil; (3) after introducing the moistening oil, carrying out airtight inspection by heating and boosting according to a routine method; and (4) after qualifying the airtight inspection, carrying out catalyst activation, after the activation, adjusting to hydrogenation conditions, then introducing hydrogenation raw materials for hydrogenation reaction. The catalyst application method is beneficial for the catalyst to form more second-kind active sites and is beneficial for increasing the performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

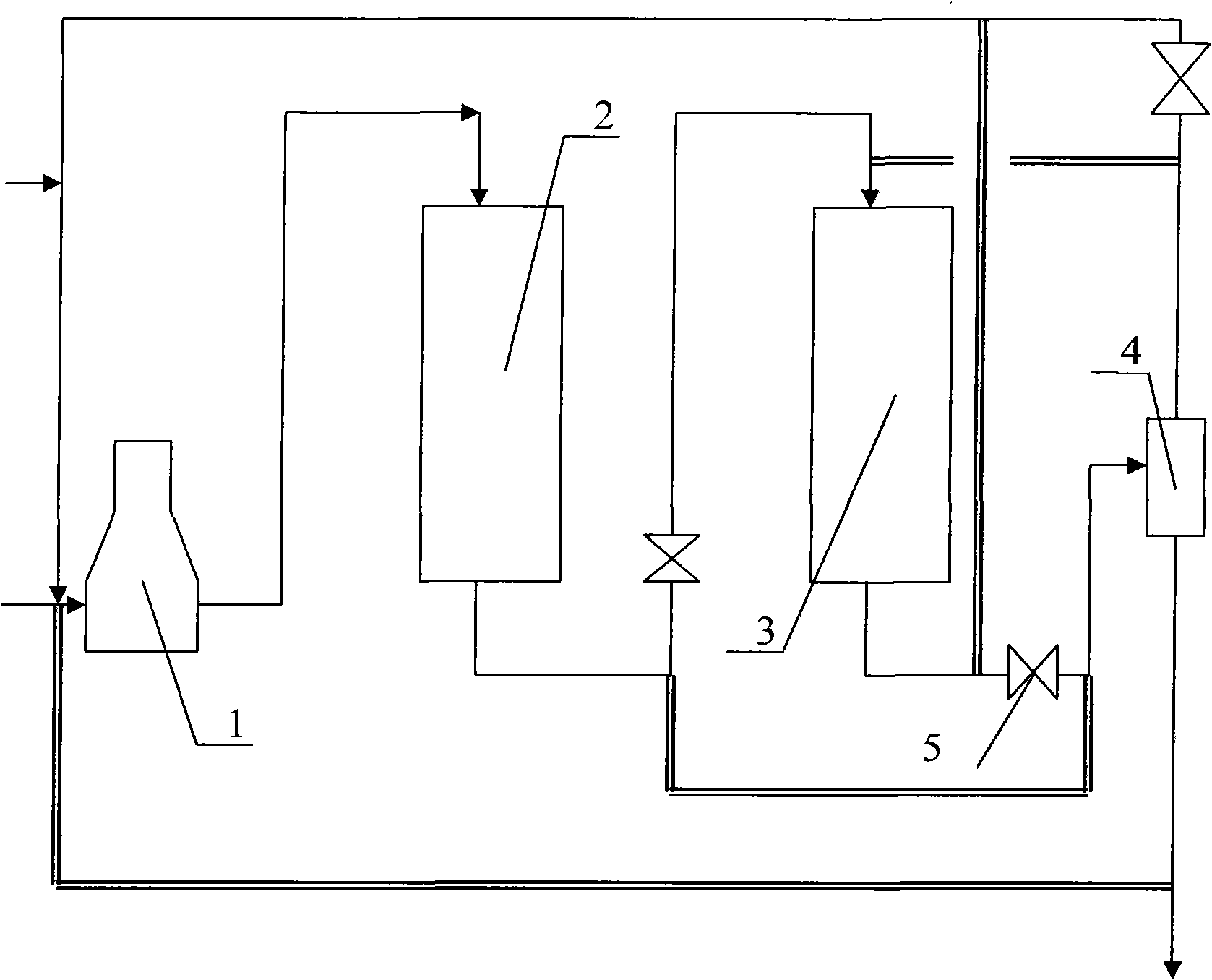

Hydrocracking process start-up vulcanization method

ActiveCN102311792AAvoid the problem of insufficient hydrogenation performanceImprove vulcanization effectHydrotreatment operations starting-upTreatment with hydrotreatment processesVapor–liquid separatorVulcanization

The invention discloses a hydrocracking process start-up vulcanization method. A hydrocracking process comprises a hydrocracking pre-refining reactor and a hydrocracking reactor, and oxidation state catalysts are used for each reactor; and the reactors are used for carrying out operations of gas replacement, catalyst drying, gas seal and the like. Under the condition of catalyst vulcanization, vulcanized oil and hydrogen enter a gas-liquid separator after entering the hydrocracking pre-refining reactor, liquid separated by the gas-liquid separator is cycled back to the hydrocracking pre-refining reactor and is cycled in a closed type in the hydrocracking pre-refining reactor, gas separated by the gas-liquid separator enters the hydrocracking reactor, and gas discharged from the hydrocracking reactor is cycled back to the hydrocracking pre-refining reactor. Compared with the prior art, the vulcanization method disclosed by the invention has a good catalyst vulcanization effect and a more prominent reaction effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing hydrocarbons

ActiveUS9663720B2Effectively and economically converting feedstockReduce the amount requiredHydrotreatment operations starting-upRefining to change hydrocarbon structural skeletonHydrodeoxygenationHydrocarbon

The present invention relates to a process for converting feedstock comprising materials of biological origin into hydrocarbons, said process comprising the steps where a) feedstock comprising at least one material of biological origin is subjected to purification treatment to obtain purified feedstock, and b) the purified feedstock is subjected to hydroprocessing in the presence of at least one hydrodeoxygenation catalyst, at least one hydrodewaxing catalyst and at least one hydrodearomatization catalyst to obtain a hydroprocessing product.

Owner:UPM-KYMMENE OYJ

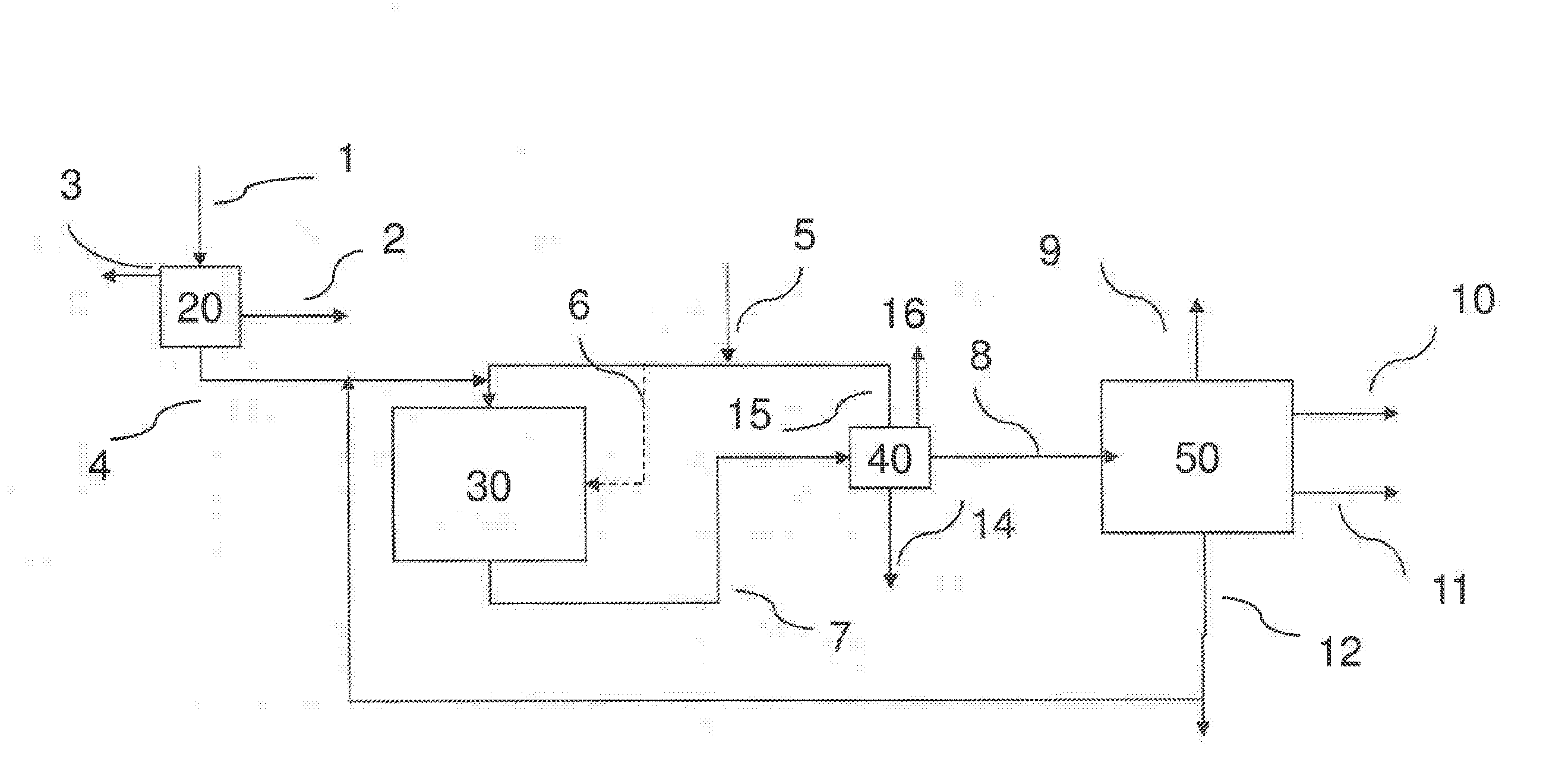

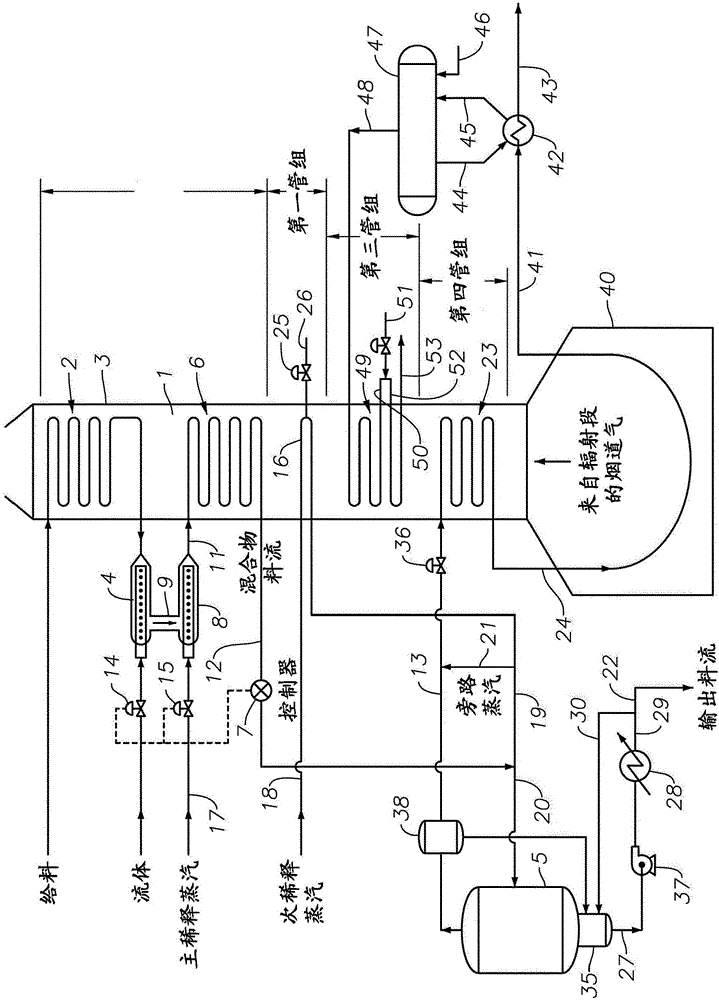

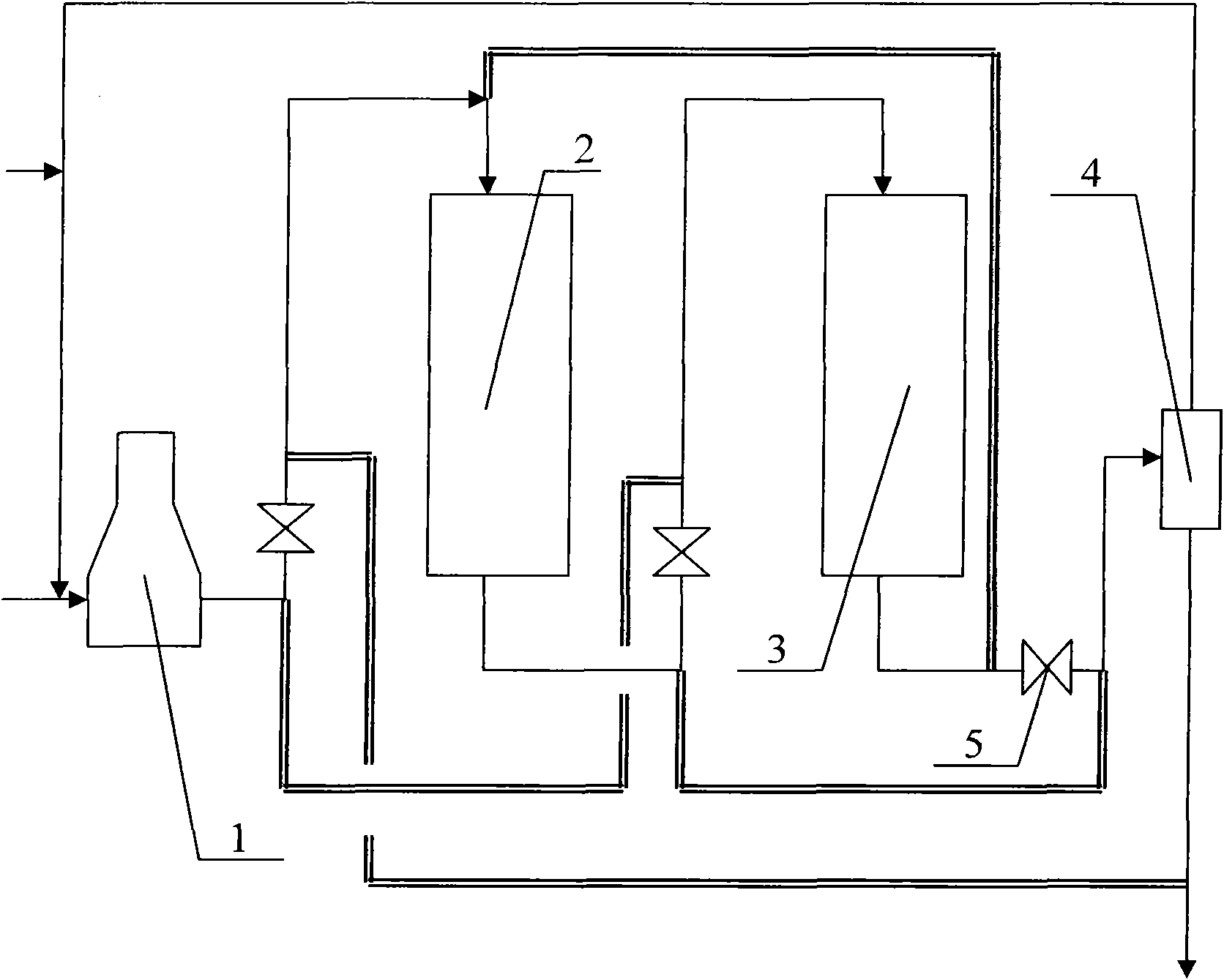

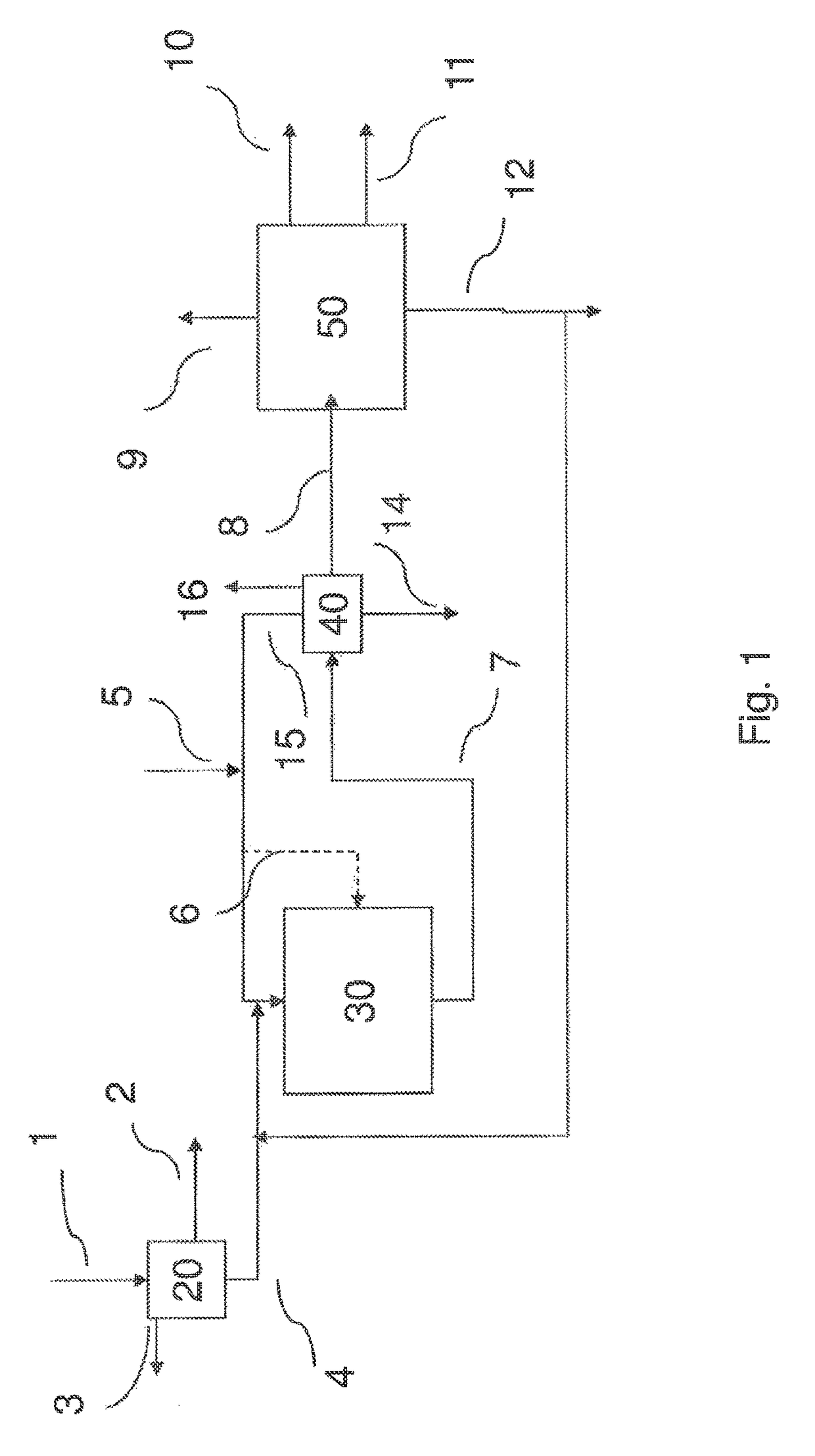

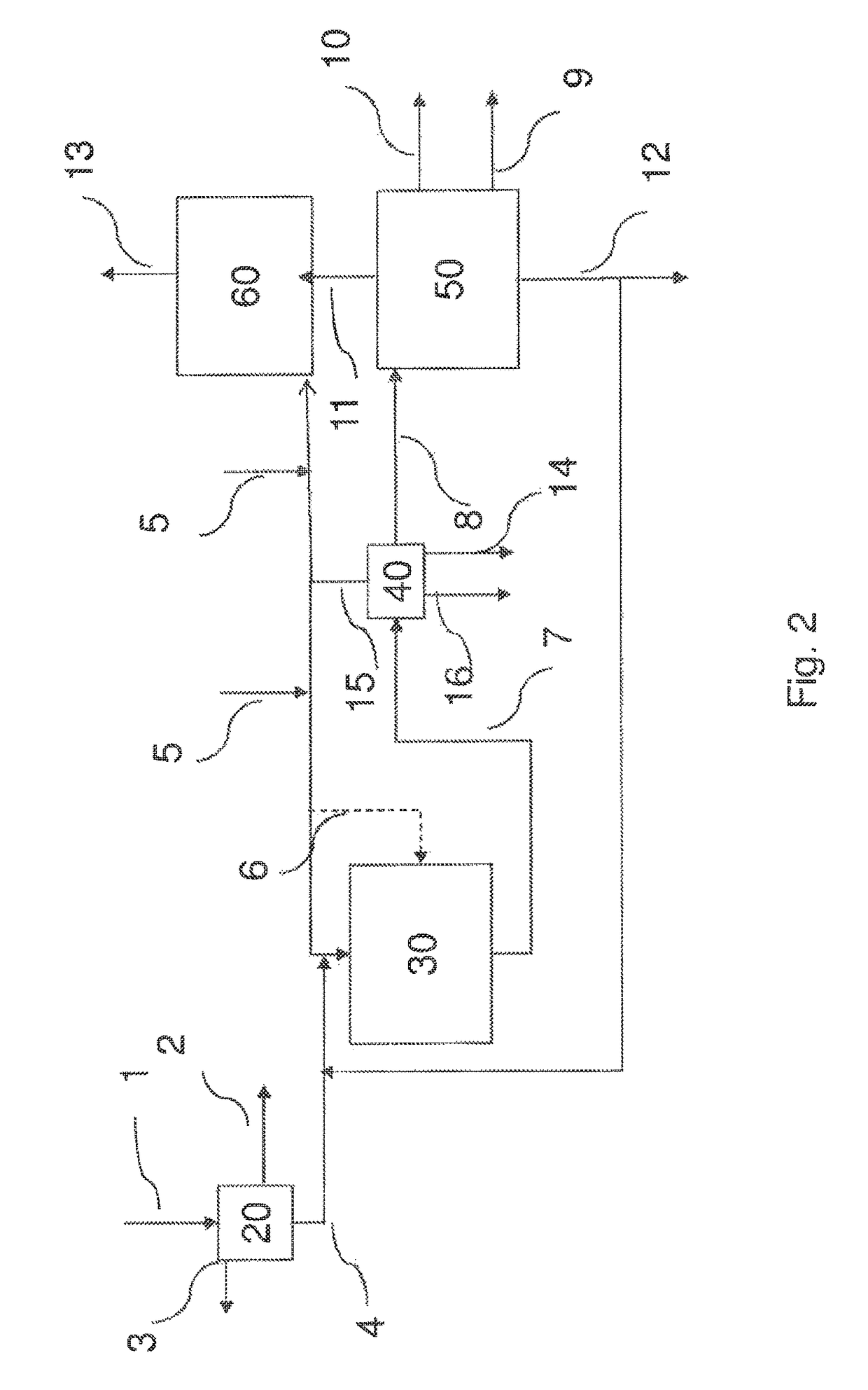

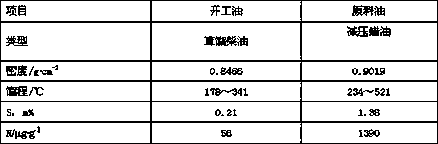

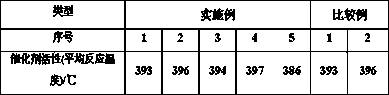

Wet Start-up Method for Hydrogenation Unit, Energy-Saving Hydrogenation Process and Hydrogenation Apparatus

ActiveUS20140124408A1Smooth and steady start-up processGuaranteed uptimeHydrotreatment operations starting-upTreatment with hydrotreatment processesChemistryStart up

The present invention relates to a wet start-up method for hydrogenation unit, an energy-saving hydrogenation process, and a hydrogenation apparatus. The method involves heating a start-up activating oil to a specific temperature and flowing the heated oil through a bed of hydrogenation catalyst bed, so that the temperature at the catalyst bed layer is increased to 180±10° C. or above by means of heat exchange and the reaction heat generated from activation in the start-up method.

Owner:CHINA PETROCHEMICAL CORP +1

Efficient start-up method of hydrocracking catalyst

ActiveCN109777480AAvoid investmentHigh activityHydrotreatment operations starting-upTreatment with hydrotreatment processesMolecular sieveVulcanization

The invention discloses an efficient start-up method of a hydrocracking catalyst. The start-up method comprises the following steps: introducing raw material oil in the vulcanization process, after vulcanization is completed, adjusting a reaction temperature, and when the mass yield of light oil less than 360 DEG C is stabilized at 45-50%, adjusting to a hydrocracking reaction condition to carry out a hydrocracking reaction, wherein the hydrocracking catalyst comprises 10-30% of a molecular sieve by weight, and the molecular sieve comprises, but not limited, a Y type or a USY (Ultra-Stable Y Zeolite) type molecular sieve. The method is simple in start-up and raw material switching process, stable in operation and capable of avoiding consumption of a passivant in the start-up process and potential danger in the ammonia injection process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for the start-up of a catalytic process

InactiveUS20110000822A1Hydrotreatment operations starting-upCatalyst activation/preparationHydrogenMetal catalyst

The present invention relates to a process for starting up a hydrotreating process using a bulk metal catalyst, said process comprising the steps of: i) providing a hydrocarbon feed stream containing less than 100 ppmw nitrogen-containing species; ii) adding a nitrogen-containing compound to said hydrocarbon feed stream; and iii) contacting the resultant feed stream with the bulk metal catalyst in the presence of hydrogen and a sulfur-containing species. The present invention also relates to a process for hydrotreating a hydrocarbon feedstock, said process comprising the steps of: i) providing a hydrocarbon feed stream containing less than 100 ppmw nitrogen-containing species; ii) adding a nitrogen-containing compound to said hydrocarbon feed stream; iii) contacting the resultant feed stream with a bulk metal catalyst in the presence of hydrogen and a sulfur-containing species; and iv) subsequently contacting the resultant bulk metal catalyst with the hydrocarbon feedstock in the presence of hydrogen.

Owner:SHELL OIL CO

Activating hydroprocessing catalysts using carbon monoxide and use of catalysts for hydroprocessing

InactiveUS7988848B2Hydrotreatment operations starting-upHydrocarbon oils treatment control/regulationOrganic chemistryChemistry

This invention relates to a process for activating a hydroprocessing catalyst and the use of activated catalyst for hydroprocessing. More particularly, hydroprocessing catalysts are activated in the presence of carbon monoxide. The catalysts that have been activated by CO treatment have improved activity.

Owner:EXXON RES & ENG CO

Starting method of hydrogenation catalyst

ActiveCN112742427AShorten start timeHigh activityHydrotreatment operations starting-upCatalyst activation/preparationNickel saltPtru catalyst

The invention discloses a starting method of a hydrogenation catalyst, which comprises the following steps: (1) respectively mixing a hydrogenation catalyst carrier with a thiomolybdate and / or thiotungstate solution and a nickel salt and / or cobalt salt solution, and drying to obtain an intermediate-state hydrogenation catalyst; (2) uniformly mixing a vulcanizing agent with the intermediate-state hydrogenation catalyst obtained in the step (1), then carrying out heat treatment, cooling, and adding a phosphorus-containing substance; (3) drying the material obtained in the step (2) to obtain a presulfurized catalyst; and (4) loading the presulfurized catalyst in the step (3) into a reactor, and carrying out wet activation start-up. According to the method, the safety problem of hydrogen embrittlement of the reactor caused by too high initial activity temperature of the catalyst is solved, the ex-situ presulfurization process of the catalyst and a presulfurization catalyst start-up activation method are also improved, and the activity of the catalyst is improved while the initial activation temperature of the catalyst is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for the start-up of a catalytic process

A process for starting up a hydrotreating process using a bulk metal catalyst. The process comprises the steps of providing a hydrocarbon feed stream containing less than 100 ppmw nitrogen containing species; and adding a nitrogen-containing compound to the hydrocarbon feed stream followed by contacting the resulting feed stream with the bulk metal catalyst in the presence of hydrogen and a sulfur-containing species.

Owner:SHELL OIL CO

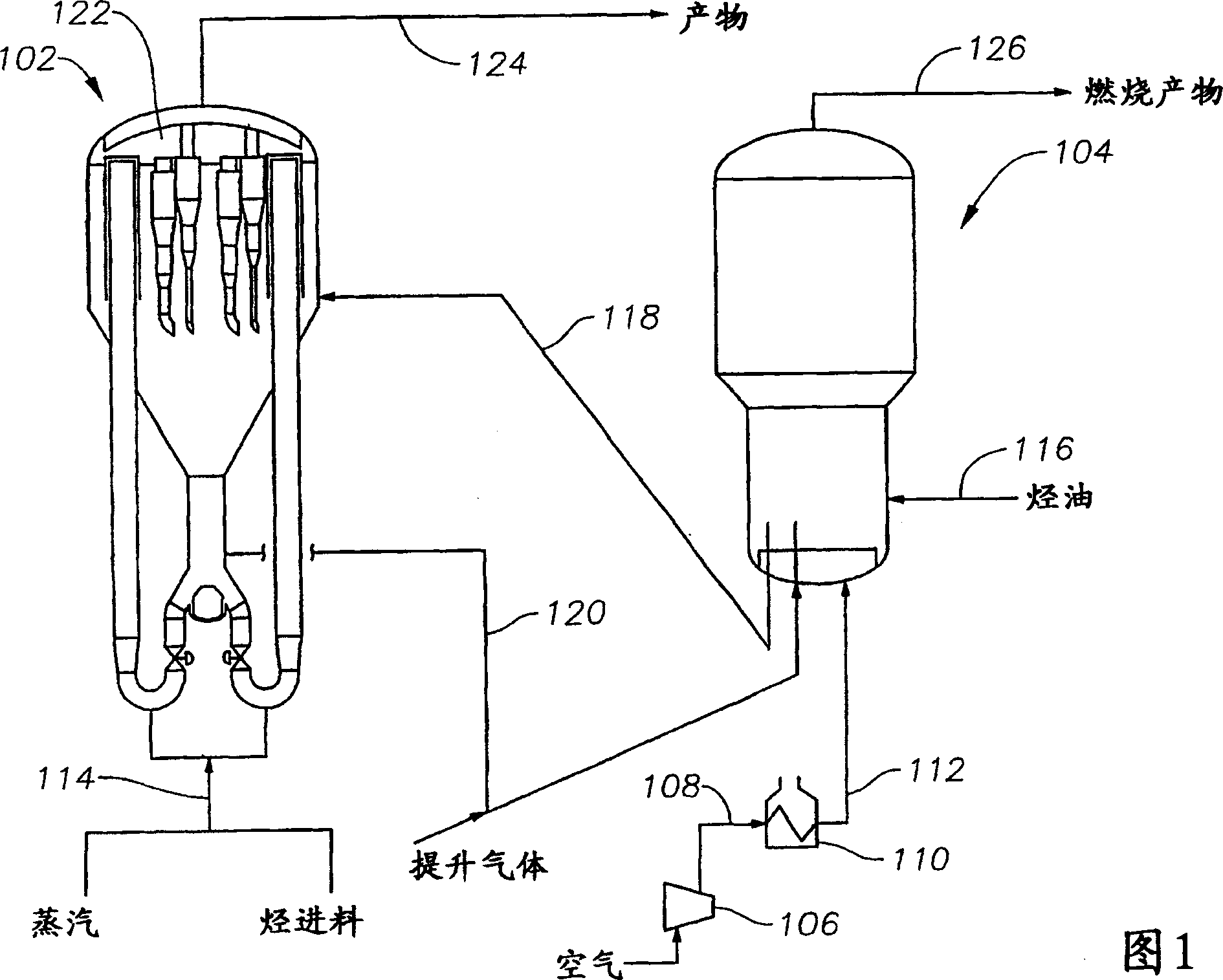

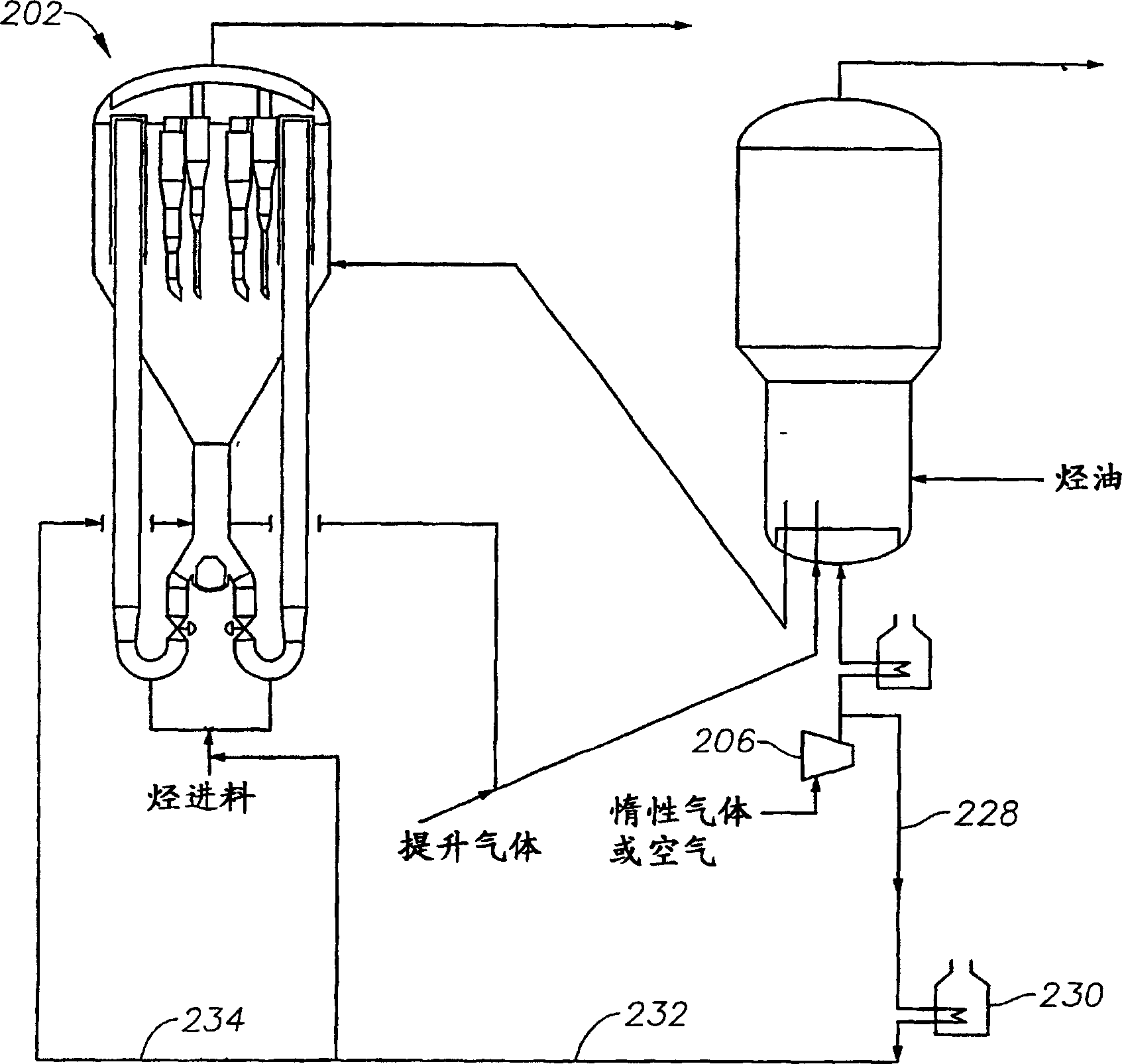

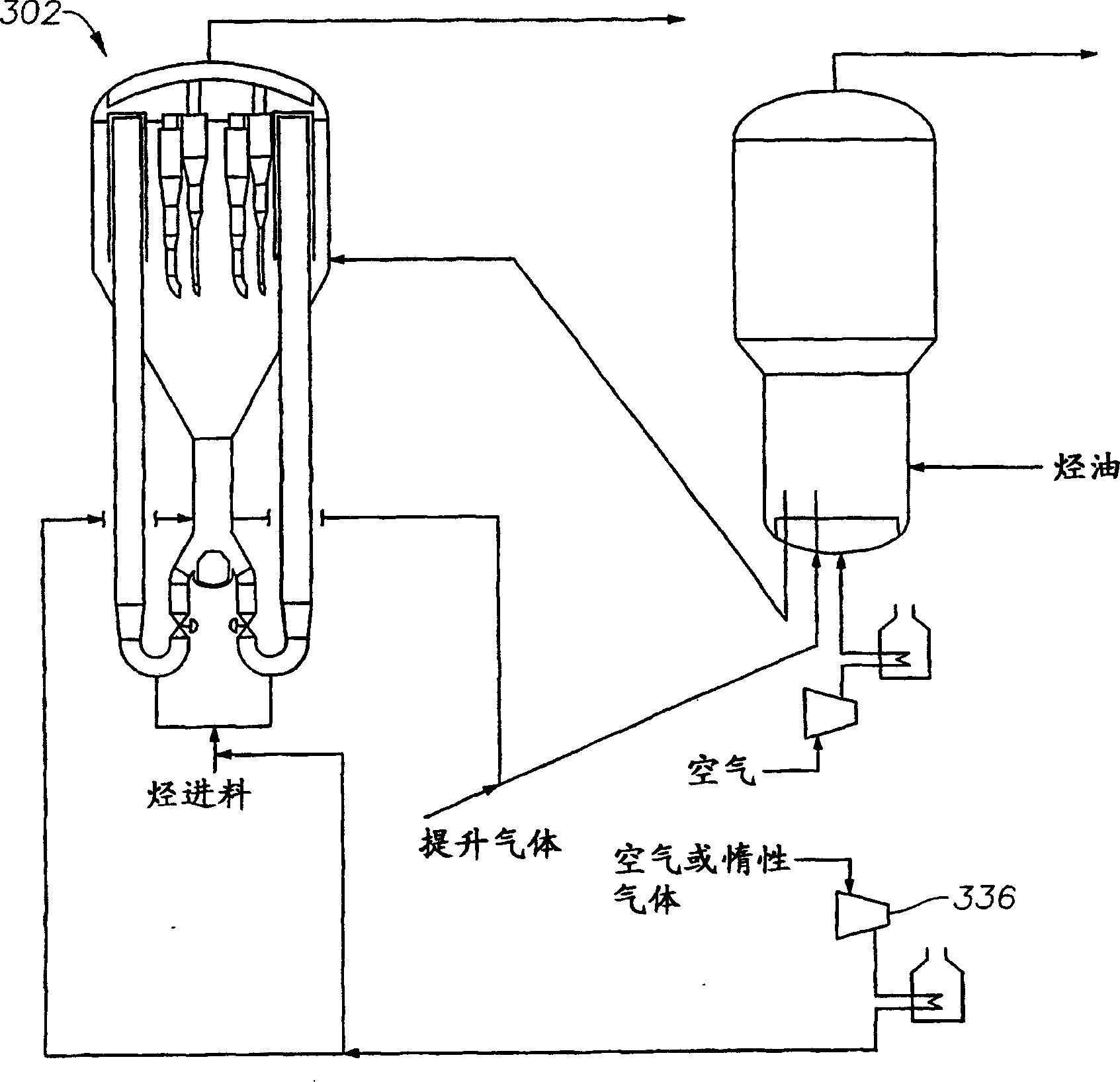

Method of starting up a reaction system

ActiveUS7259287B2Hydrocarbon by isomerisationCatalytic crackingMolecular sieveComputational chemistry

Owner:EXXONMOBIL CHEM PAT INC

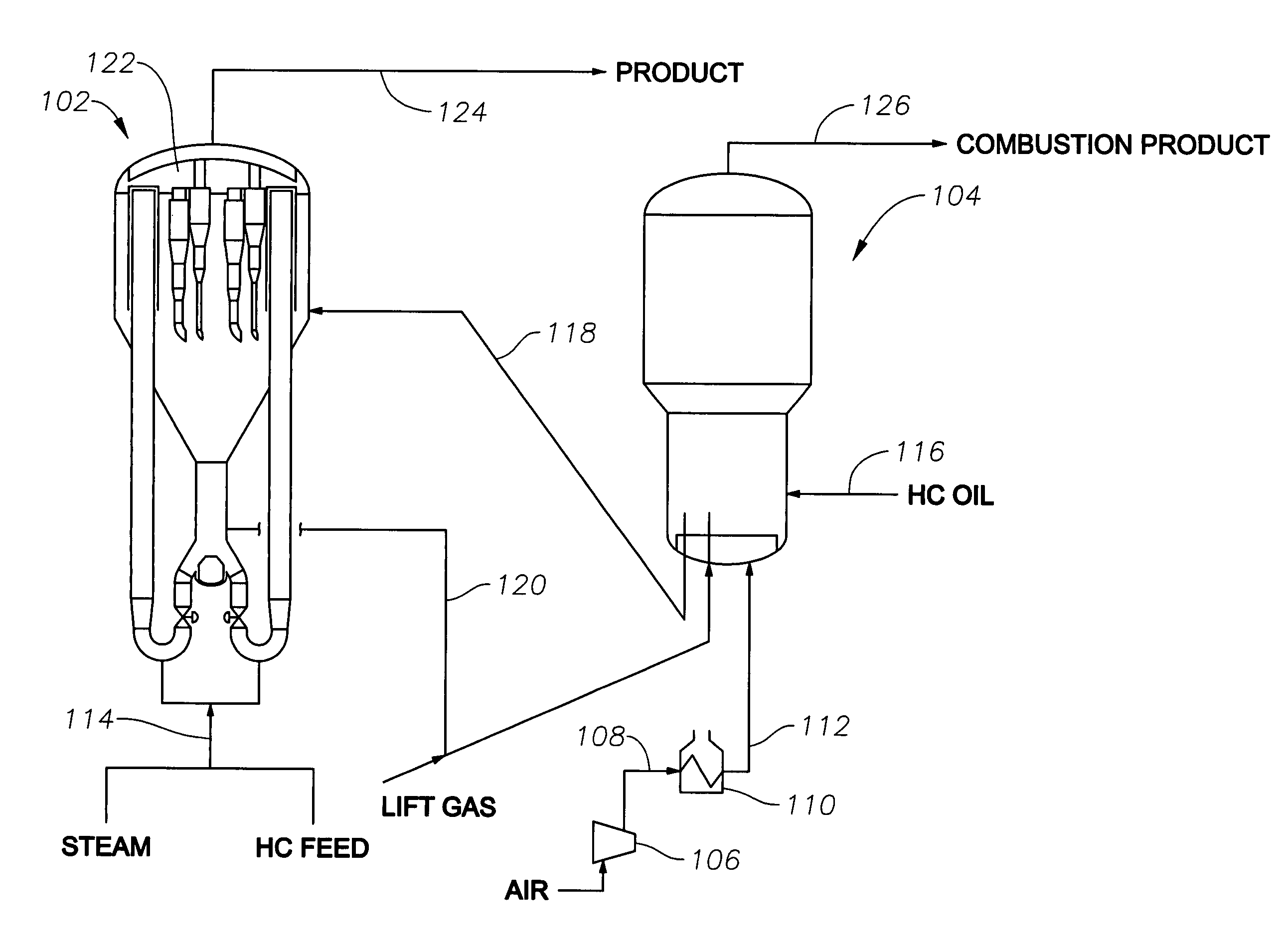

Start-up method for fluidized bed

ActiveCN102212386AAvoid cloggingAvoid breakingHydrotreatment operations starting-upHydrocarbon oil crackingWaxFluidized bed

The invention discloses a start-up method for a fluidized bed. The start-up method for the fluidized bed comprises the following steps of: bonding a micro-spherical fluidized bed catalyst into globular, hemispheric, columnar, flake or irregular catalyst particles by using a wax material, wherein the diameter of the catalyst particle is 2 to 20mm according to the equivalent volume sphericity; packing the catalyst particles in a reactor of the fluidized bed for carrying out the air tight operation; introducing starting-up oil below a melting point of the wax material in the catalyst particles and carrying out the cyclic operation; raising the temperature of the reactor of the fluidized bed to be higher than that the temperature of the melting point of the wax material in the catalyst particles by 5 to 100 DEG C; dissolving the wax material in the catalyst particles in the start-up oil; and activating the micro-spherical fluidized bed catalyst. According to the start-up method for the fluidized bed, the problem that the micro-spherical catalyst is broken due to the extrusion and collision and is polluted by dust in the process of placing the micro-spherical catalyst into the reactor is solved; the catalyst particles are prevented from being taken out from the reactor or causing stoppage in the start-up process of the device; and the start-up method has the advantages of short start-up time, high efficiency and good effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Refining to eliminate hetero atoms Hydrocarbon oils refining Effluent separation Refining by aromatic hydrocarbon hydrogenation Hydrocarbon by hydrogenation Hydrocarbon by saturated bond conversion Liquid hydrocarbon mixture production Bio-feedstock Hydrocarbon from saturated and unsaturated hydrocarbon addition Hydrocarbon oils treatment products

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com