Start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalysts

A technology of external presulfurization and hydrogenation catalyst, which is applied in the fields of start-up of hydroprocessing operation, petroleum industry, hydrocarbon oil cracking, etc., to achieve the effect of simple process, avoiding poisoning, and sufficient and thorough wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

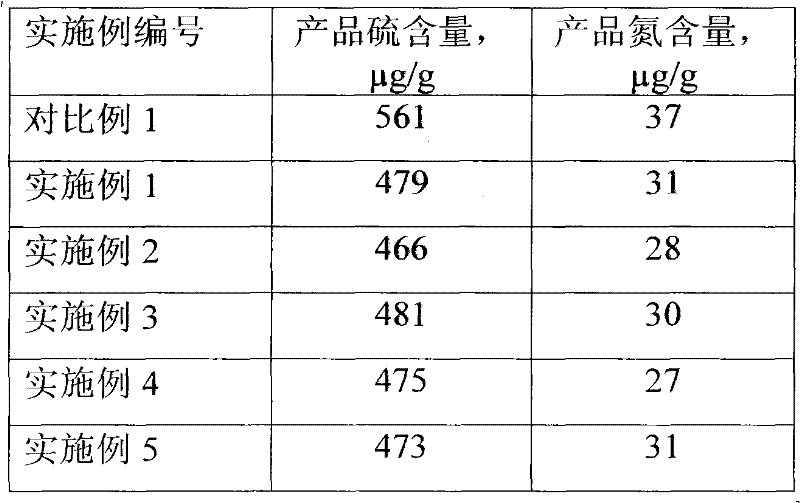

Embodiment 1

[0036] 100g of pre-sulfurized hydrofining catalyst outside the reactor was loaded into a small reactor, and the airtightness was qualified. The hydrogen partial pressure was adjusted to 6.0MPa, and the temperature was raised at 20°C / h. When the temperature rose to 90°C, the start-up oil was introduced, and the closed-circuit circulation of the device was carried out. The starting oil is straight-run kerosene, the conditions are hydrogen oil volume ratio 350:1, volume space velocity 2.0h -1 . Raise the temperature to 180°C at 20°C / h, keep the temperature constant for 8 hours, continue to raise the temperature to 320°C after finishing the constant temperature, and keep the temperature constant for 2 hours. After the constant temperature is over, switch the raw material oil according to the operation. After switching the feedstock, it was raised to 348°C and operated for 48 hours to analyze the oil samples of the finished product. The catalyst activity results are shown in Table ...

Embodiment 2

[0038] Put 100g of pre-sulfurized hydrofining catalyst outside the reactor into a small reactor, the airtightness is qualified, the hydrogen partial pressure is adjusted to 6.0MPa, and the temperature is raised at 20°C / h, and when it rises to 90°C, start-up oil and hydrogen are introduced, and the device is closed. Circulation, the starting oil is straight-run kerosene, the condition is that the volume ratio of hydrogen to oil is 350:1, and the volume space velocity is 1.5h -1 . Raise the temperature to 180°C at 20°C / h, keep the temperature constant for 8 hours, continue to raise the temperature to 320°C after finishing the constant temperature, and keep the temperature constant for 2 hours. After the constant temperature is over, switch the raw material oil according to the operation. After switching the feedstock, it was raised to 348°C and operated for 48 hours to analyze the oil samples of the finished product. The catalyst activity results are shown in Table 2.

Embodiment 3

[0040] Put 100g of pre-sulfurized hydrofining catalyst outside the reactor into a small reactor, the airtightness is qualified, the hydrogen partial pressure is adjusted to 6.0MPa, and the temperature is raised at 20°C / h, and when it rises to 95°C, start-up oil and hydrogen are introduced, and the device is closed. Circulation, the starting oil is straight-run kerosene, the condition is that the volume ratio of hydrogen to oil is 350:1, and the volume space velocity is 2.0h -1 . Raise the temperature to 180°C at 20°C / h, keep the temperature constant for 8 hours, continue to raise the temperature to 320°C after finishing the constant temperature, keep the temperature constant for 3 hours, and switch the raw material oil according to the operation. After switching the feedstock, it was raised to 348°C and operated for 48 hours to analyze the oil samples of the finished product. The catalyst activity results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com