Method of starting up a reaction system

一种反应系统、反应器的技术,应用在化学仪器和方法、液态烃混合物的制备、加氢处理操作的开车等方向,能够解决无催化活性、分子筛没有工业价值、小催化活性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0119] If no binder is used in the preparation of the molecular sieve catalyst, the catalyst is considered to be a binderless catalyst. If a binder is used, the amount of binder used to prepare the molecular sieve catalyst is from about 2 to about 30 weight percent, based on the total weight of binder, molecular sieve, and optionally included matrix material (excluding liquid, i.e. after drying). Preferably, the amount of binder used to prepare the molecular sieve catalyst is from about 5 to about 20 wt%, more preferably from about 7 to about 15 wt%, based on the total weight of binder, molecular sieve, and optionally included matrix material (excluding liquid, ie after drying).

[0120] If the catalyst composition contains binder and matrix material, the weight ratio of binder to matrix material is generally 1:15 to 1:5, for example 1:10 to 1:4, especially 1:6 to 1:5. The amount of binder is generally about 2 to about 30 wt%, such as about 5 to about 20 wt%, especially abou...

Embodiment 1

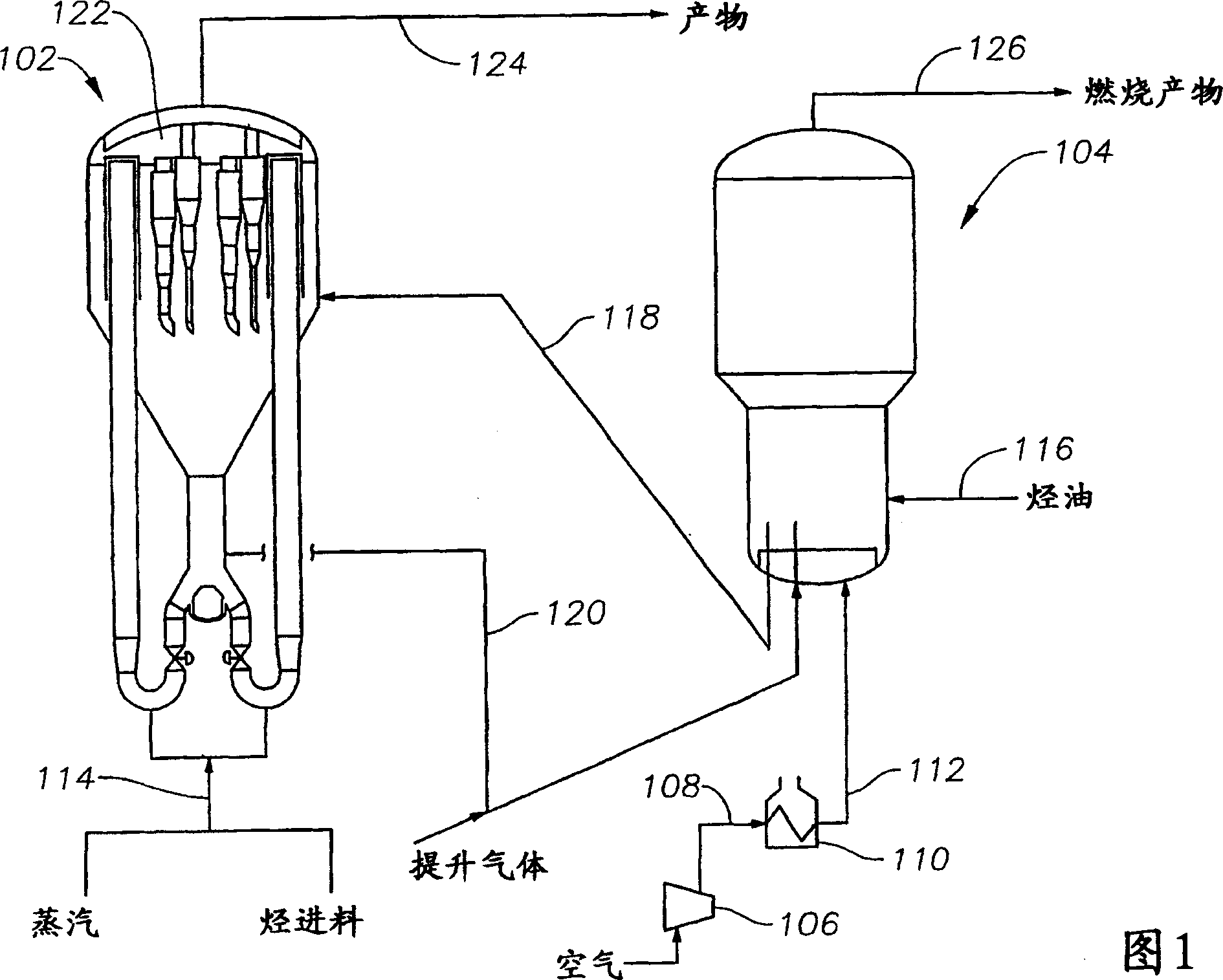

[0183] One example of starting up a system containing a molecular sieve catalyst that is susceptible to deactivation by contact with water molecules is illustrated with respect to FIG. 1 , which is a flow diagram of a reaction system comprising a reactor 102 and a regenerator 104 . The flow diagram of Figure 1 relates specifically to a system for converting oxygenates to olefins, although it is specifically relevant to any system incorporating a reactor and regenerator. According to the embodiment shown in Figure 1, the regenerator 104 is heated by injecting hot air. Air is input to the regenerator 104 by sending air from the compressor 106 , through conduit 108 , to the heater and burner 110 , and into the regenerator 104 via conduit 112 . The regenerator 104 is heated at 400°F (204°C) for 8 hours, at which point the refractory material in the regenerator 104 will be substantially dry.

[0184] While heating regenerator 104 , reactor 102 is also heated by injecting superheat...

Embodiment 2

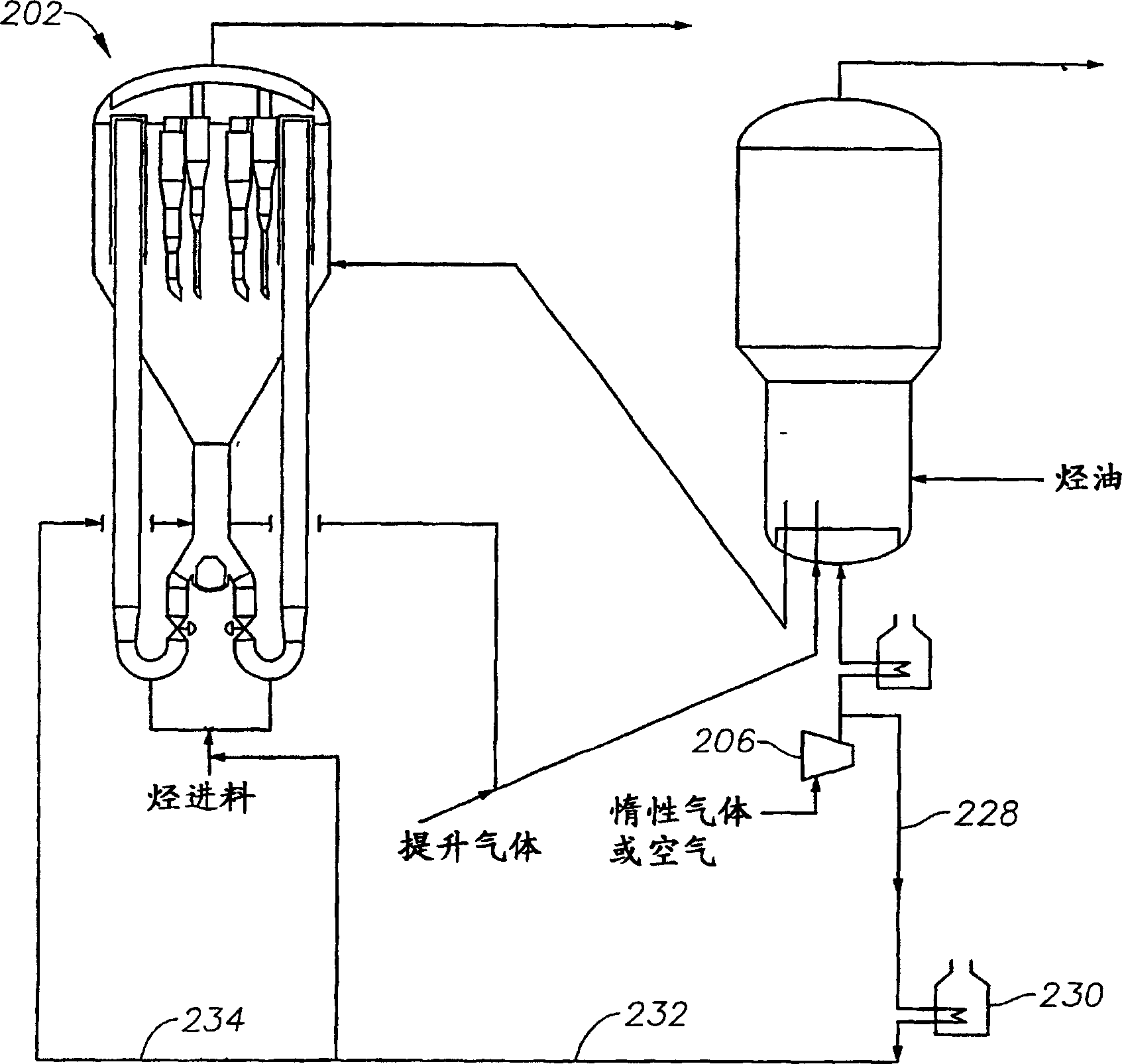

[0189] according to figure 2 Another example illustrating the start-up of a reaction system containing a molecular sieve catalyst that is easily deactivated by contact with water molecules is a flow chart of the reaction system shown in FIG. 1 . according to figure 2, the heating process is the same as in Example 1, except that relatively dry gas is used to heat the reactor 202 instead of steam. according to figure 2 , part of the air delivered by the air compressor 206 is delivered to the drying heater 230 via the conduit 228 to heat the air to an appropriate temperature as described in Embodiment 1. As a result of increasing the temperature of the air, the air is at low relative hydraulic pressure and is considered substantially dry. The dry air is delivered to reactor 202 via conduits 232 and 234, and the start-up procedure of Example 1 is continued.

PUM

| Property | Measurement | Unit |

|---|---|---|

| humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com