Patents

Literature

54results about How to "Strong resistance to sulfur poisoning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for starting operation of catalyst for hydrocracking in oxidation state

InactiveCN101003749AStrong resistance to sulfur poisoningImprove hydrogenation performanceHydrotreatment operations starting-upOxidation stateNitrogen gas

This invention relates to a start-up method for oxidation-state hydrocracking catalyst used in oil refinery process. The method comprises: loading the oxidation-state hydrocracking catalyst into a reactor, introducing nitrogen to replace air in the reactor and pipelines, pressurizing to meet the pressure requirement of hydrocracking, switching to hydrogen after nitrogen flow is stable, raising the temperature of the catalyst bed to meet the temperature requirement of catalyst reduction after hydrogen flow is stable, keeping the temperature, adjusting the temperature of the catalyst bed to meet the temperature requirement of hydrocracking, adjusting hydrogen flux to meet the flux requirement of hydrocracking, and introducing hydrocarbon reactants. The method does not need pre-sulfurization of the catalyst with additional sulfurization agent, thus can avoid the problems caused by pre-sulfurization, and partially reduced catalyst has higher hydrocracking activity.

Owner:XIAMEN UNIV

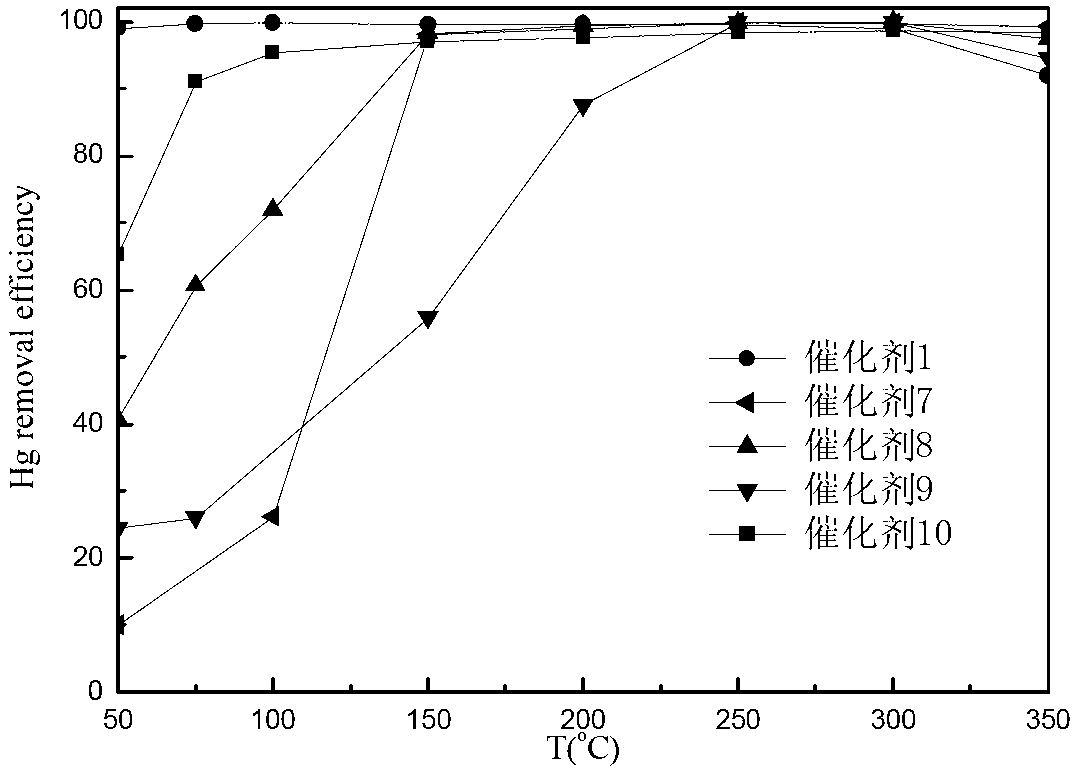

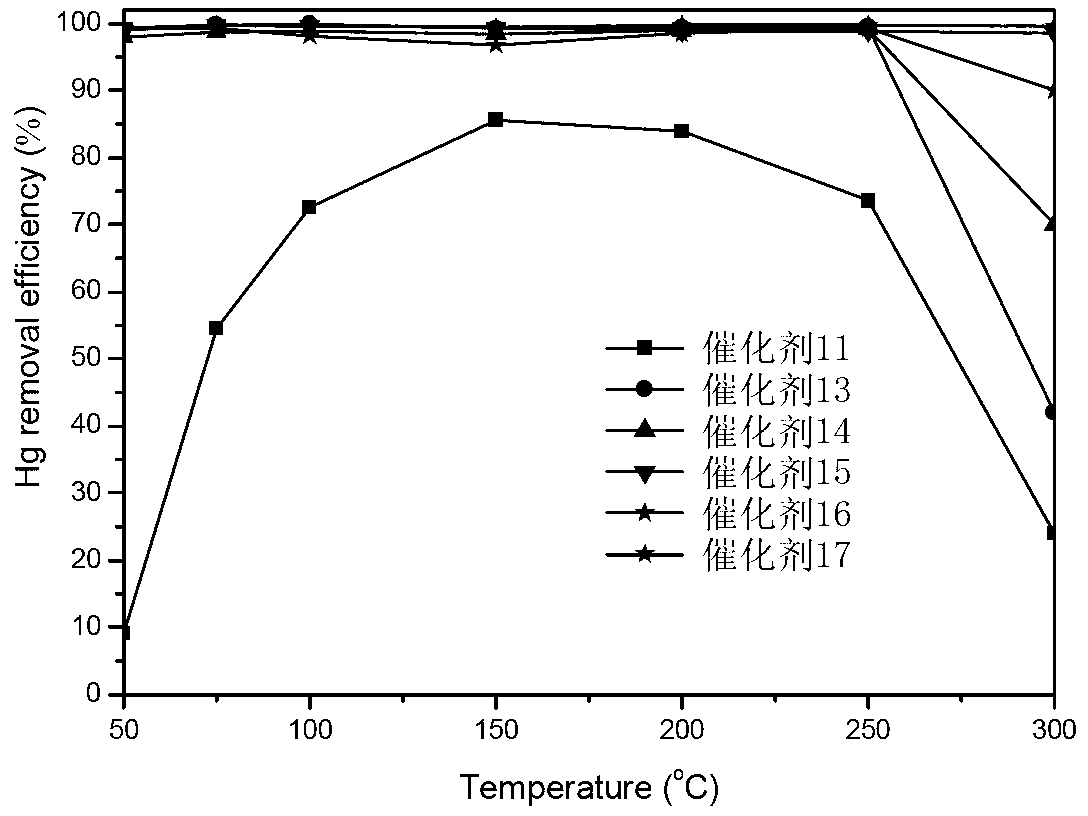

Catalyst for mercury oxidation and preparation method and purpose thereof

ActiveCN102698753AReduce dependenceImprove oxidation efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPower stationCatalytic oxidation

The invention discloses a copper-based composite catalyst for gas-state zero valent mercury oxidation in the field of smoke control and a preparation method and the purpose thereof. The copper-based catalyst is a copper-based composite oxide catalyst and / or a copper-based composite halide catalyst. The catalyst can utilize oxygen and trace HCI existing in smoke to achieve high efficiency conversion of zero valent mercury (HgO) and divalent mercury (Hg2+) under low temperature in a wider temperature range (500-300 DEG C) and can even achieve high efficiency oxidation of simple substance mercury in smoke free of HCI. The catalyst is suitable for catalytic oxidation of mercury in fire coal smoke, and the product Hg2+ of oxidation can be easily dissolved in water and can be removed by other pollutant control devices. The catalyst is simple in preparation method, wide in suitable temperature range, high in oxidation efficiency, weak in dependency on CI in the smoke, good in stability and high in SO2 poisoning resistance and has good application prospects and economical benefits in the fire coal smoke mercury discharge control fields including power station boilers, industrial boilers, industrial kilns and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

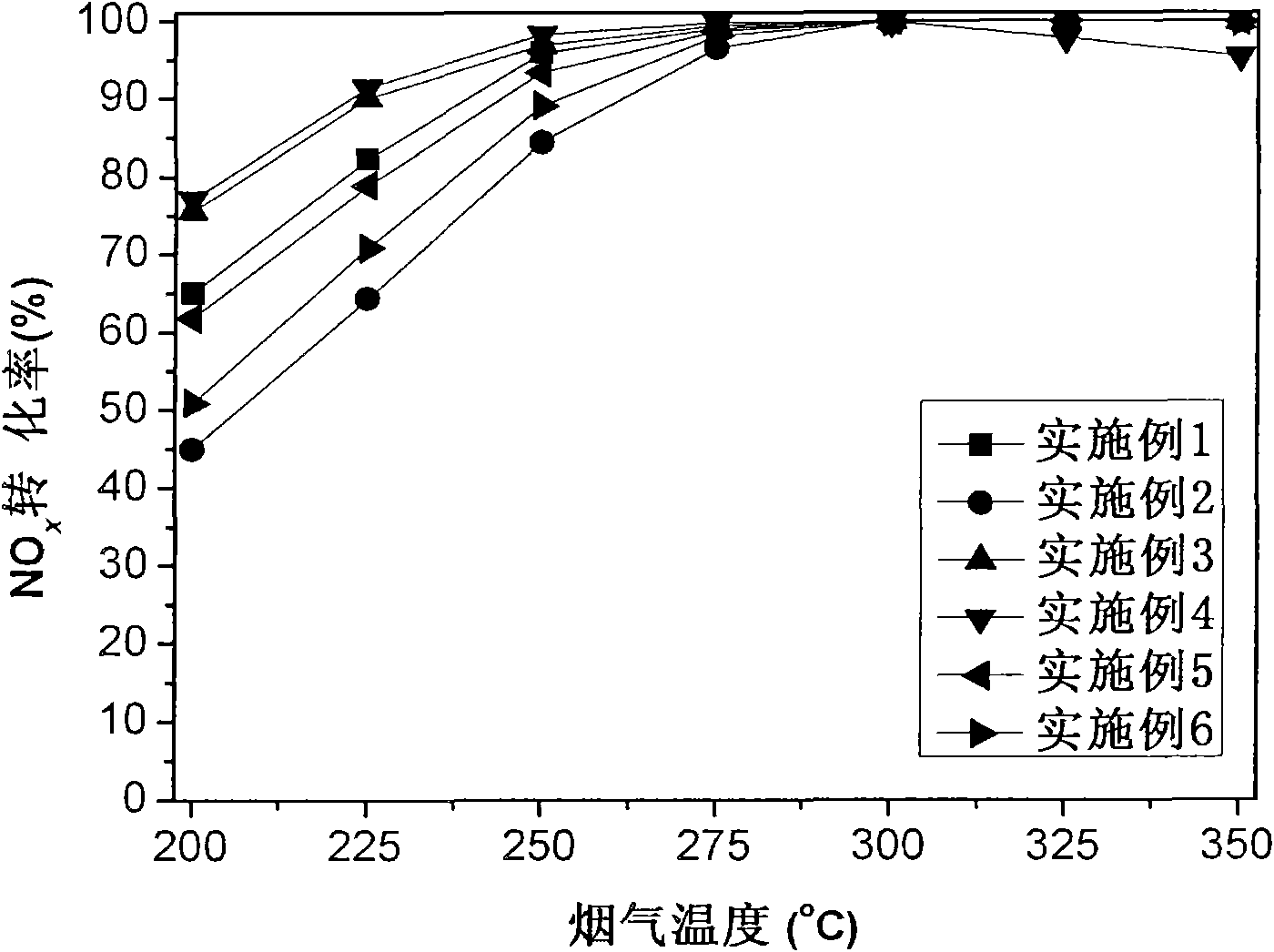

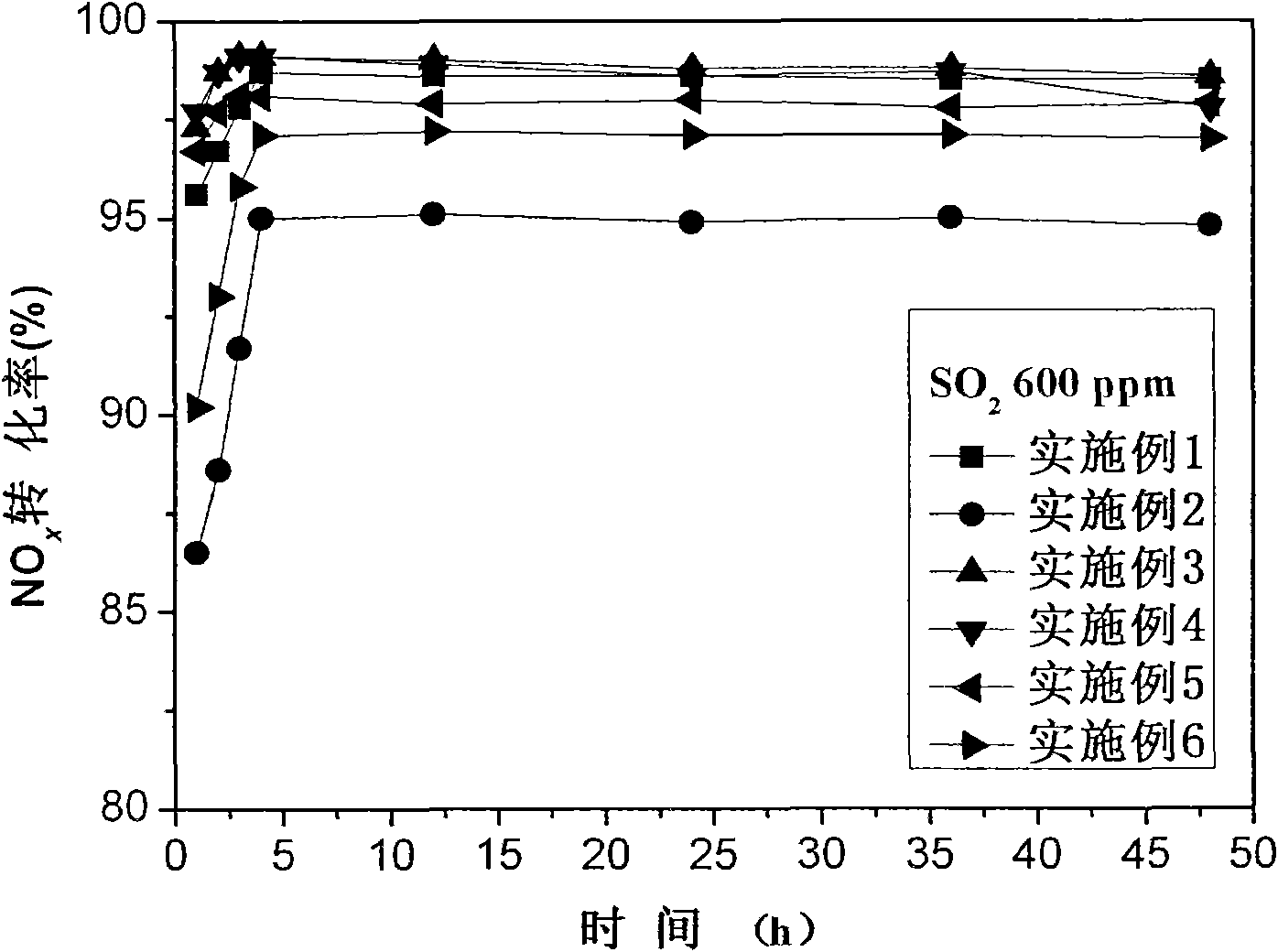

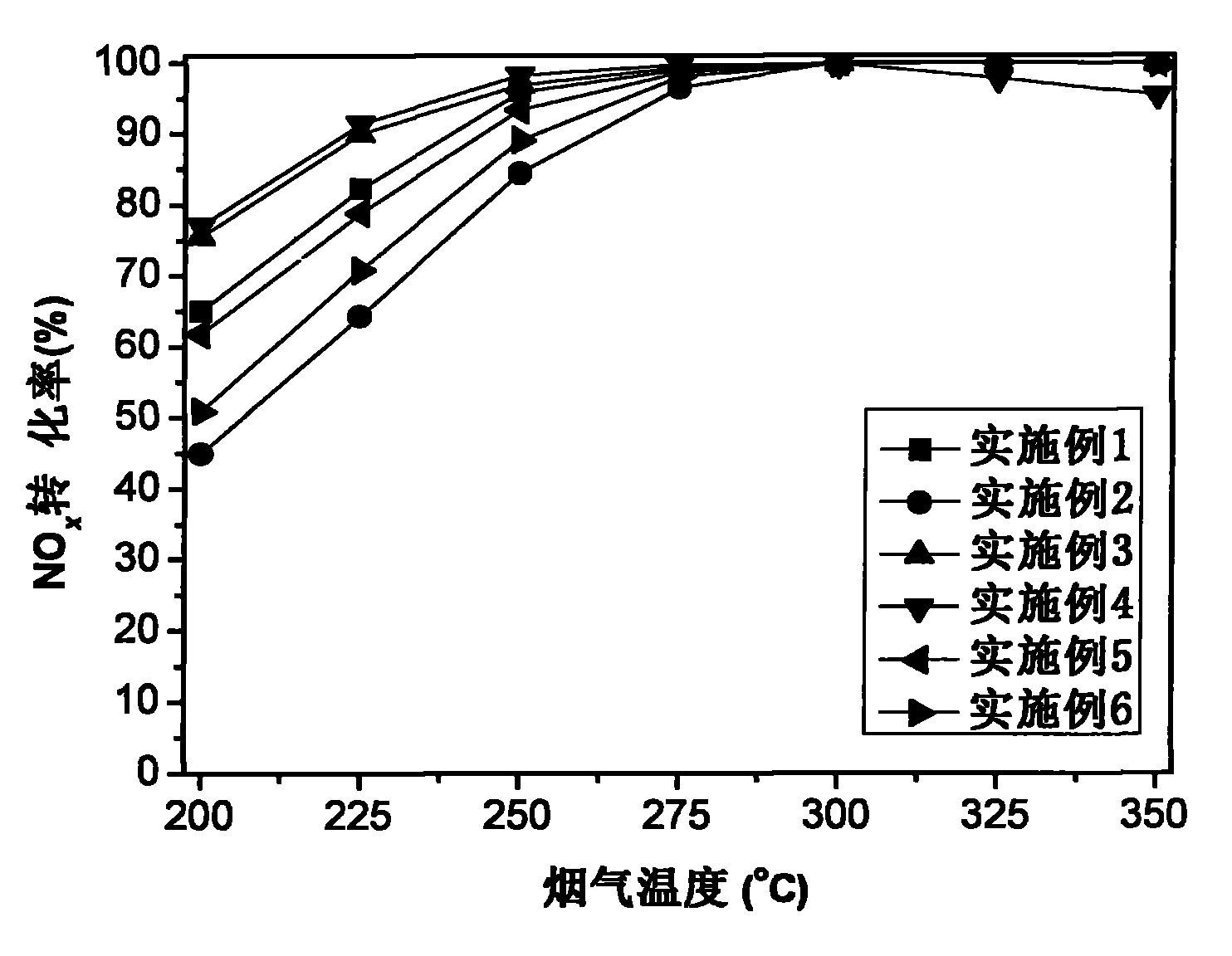

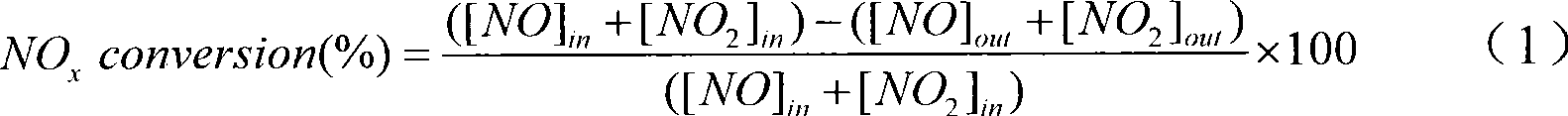

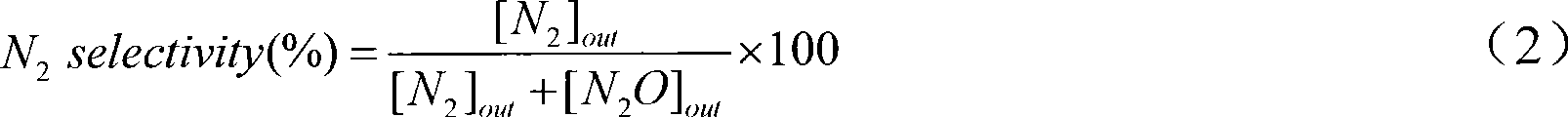

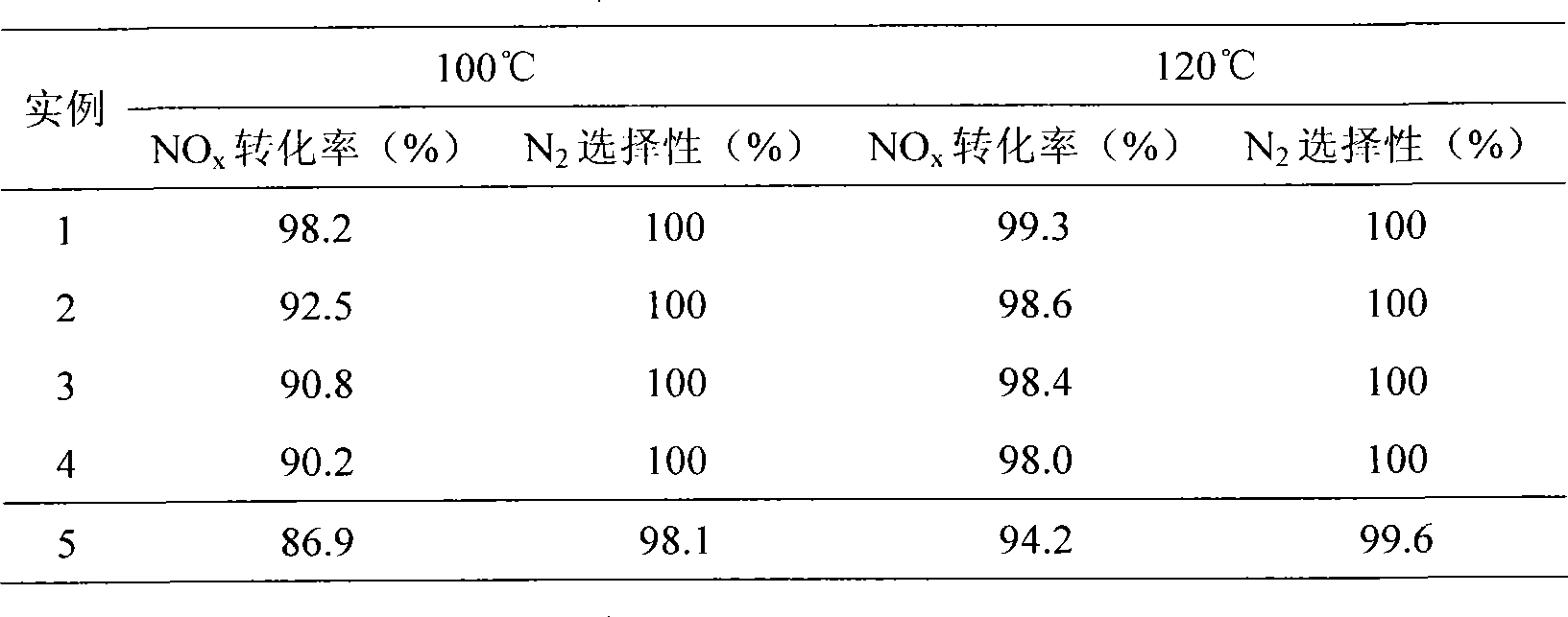

Supported SCR denitration catalyst of medium and low temperature flue gas and preparation method and application thereof

InactiveCN101773837AEasy to prepareStrong resistance to sulfur poisoningDispersed particle separationCatalyst activation/preparationFlue gasOxide

The invention discloses a supported SCR denitration catalyst of medium and low temperature flue gas and a preparation method and application thereof. The catalyst comprises the following components: vanadium element, transition metal M and carrier. The addition of the vanadium element is 0.5-4wt% of the total mass of the catalyst by weight percent via calculating the amount of V2O5; the addition of the transition metal M is 1-14wt% of the total mass of the catalyst by weight percent via calculating the total amount of oxide; and the addition of the carrier is 80-98.5wt% of the total mass of the catalyst by weight percent. Compared with the widely used commercial catalyst, the catalyst of the invention reduces the cost by more than 30%, broadens the medium and low temperature ranges of SCR catalyst activity, and has the characteristics of simple preparation, low cost, high activity, strong sulfur poisoning resistance and the like.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

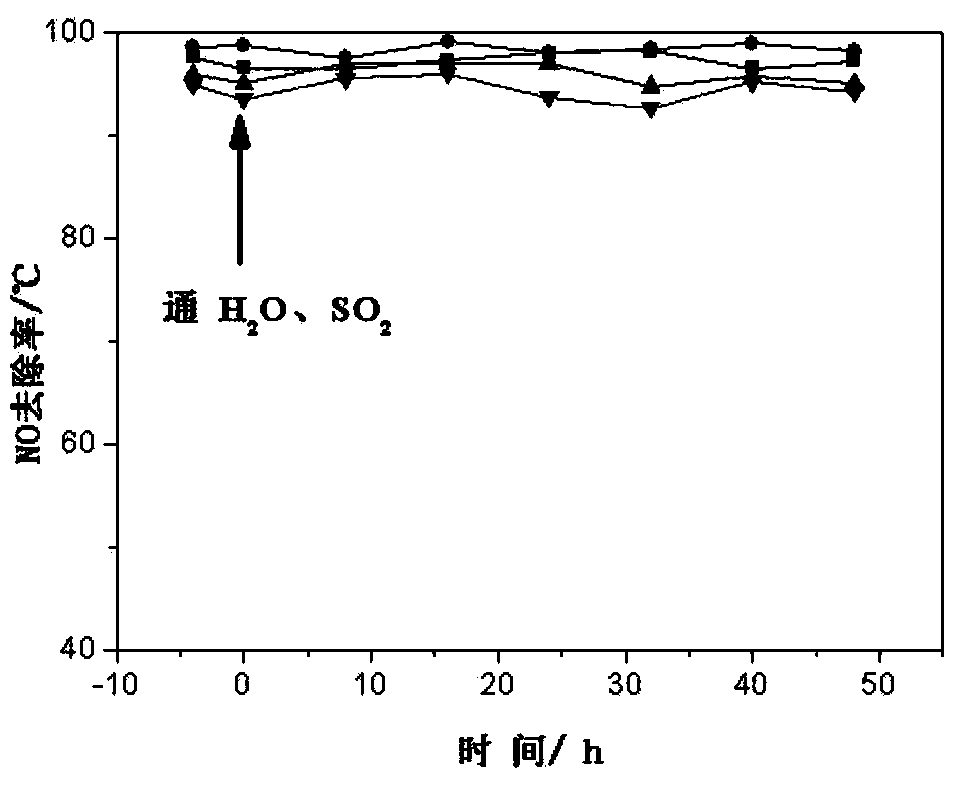

Ferro manganese composite oxides catalyst and preparation method and use thereof

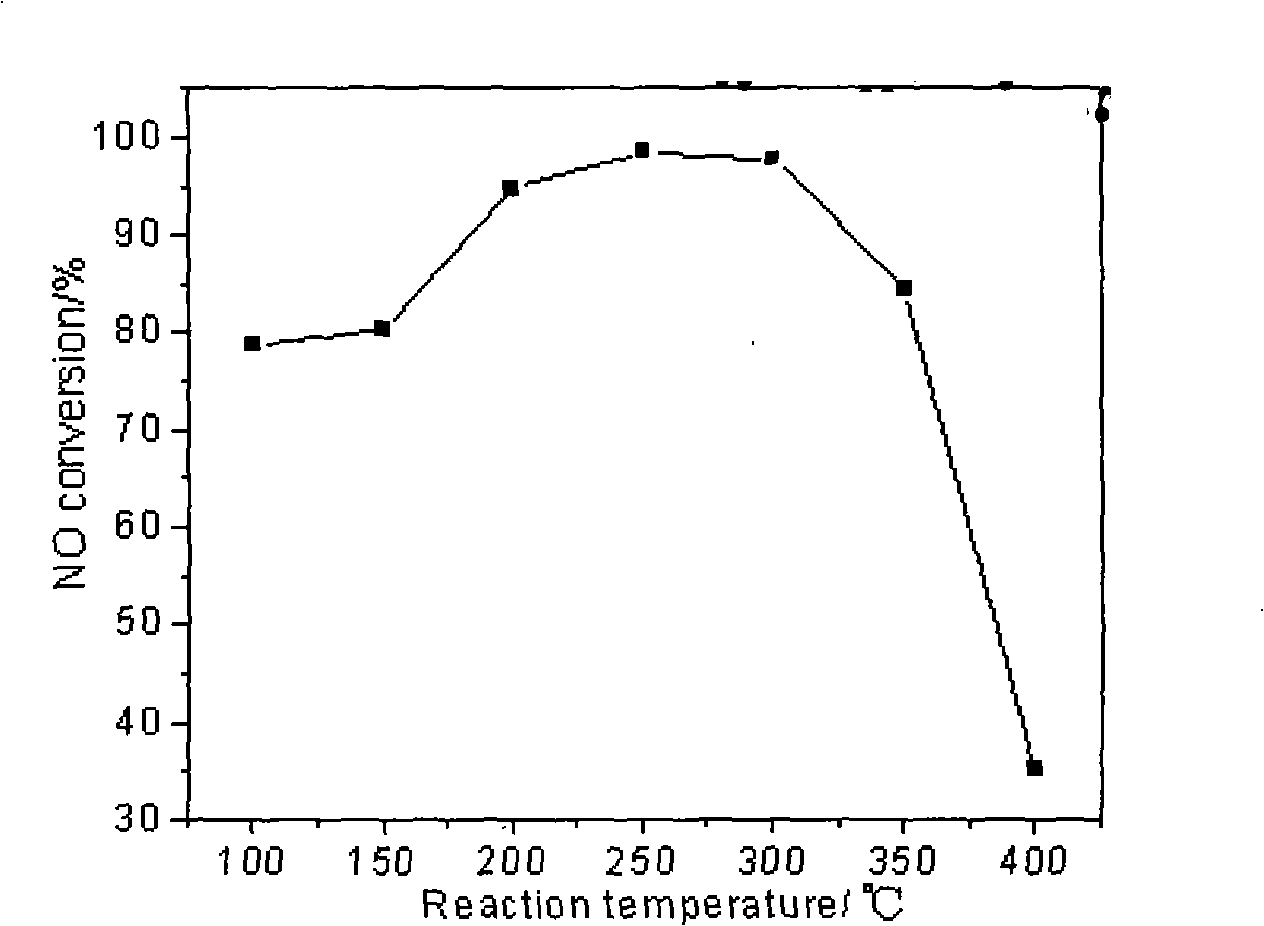

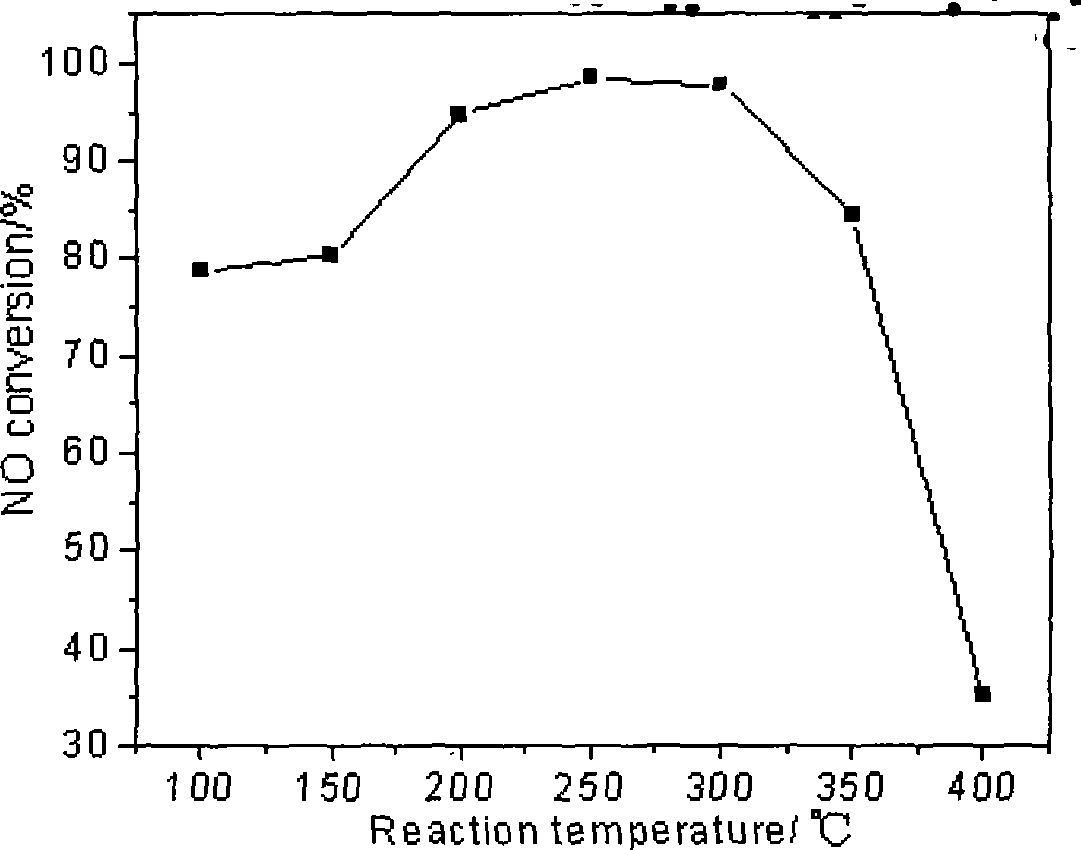

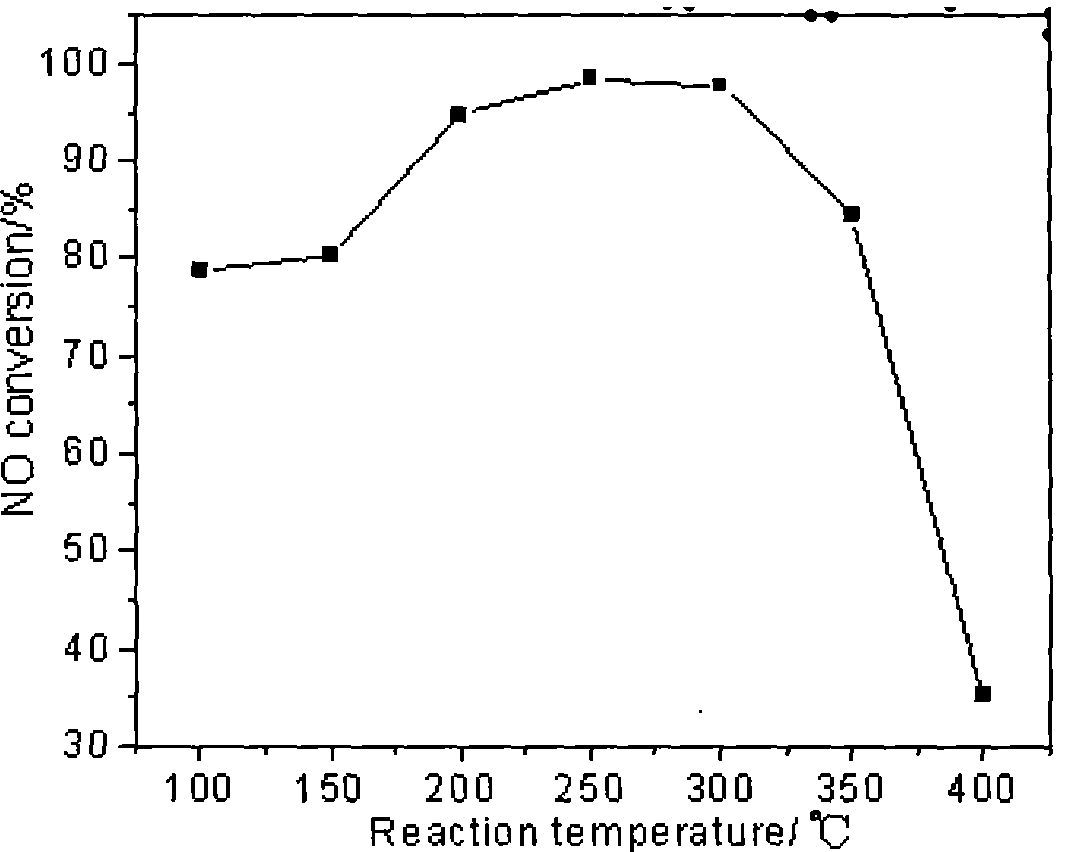

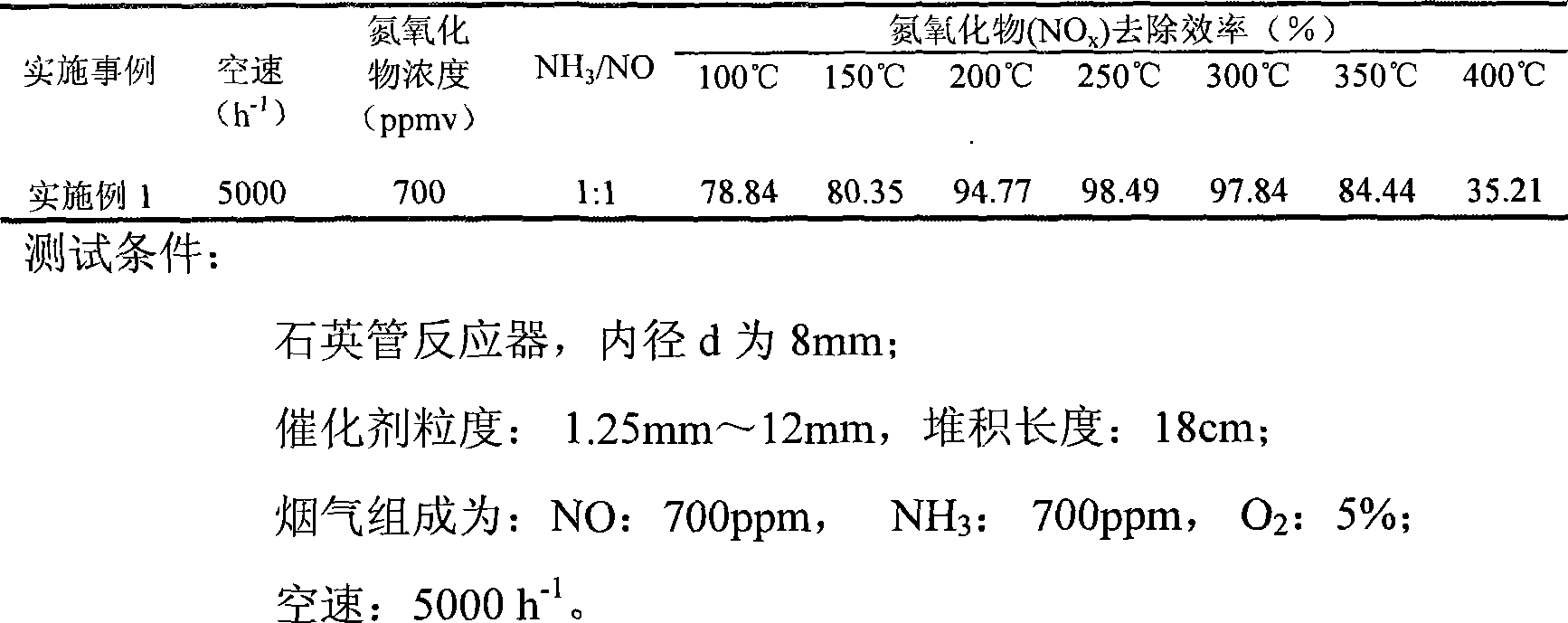

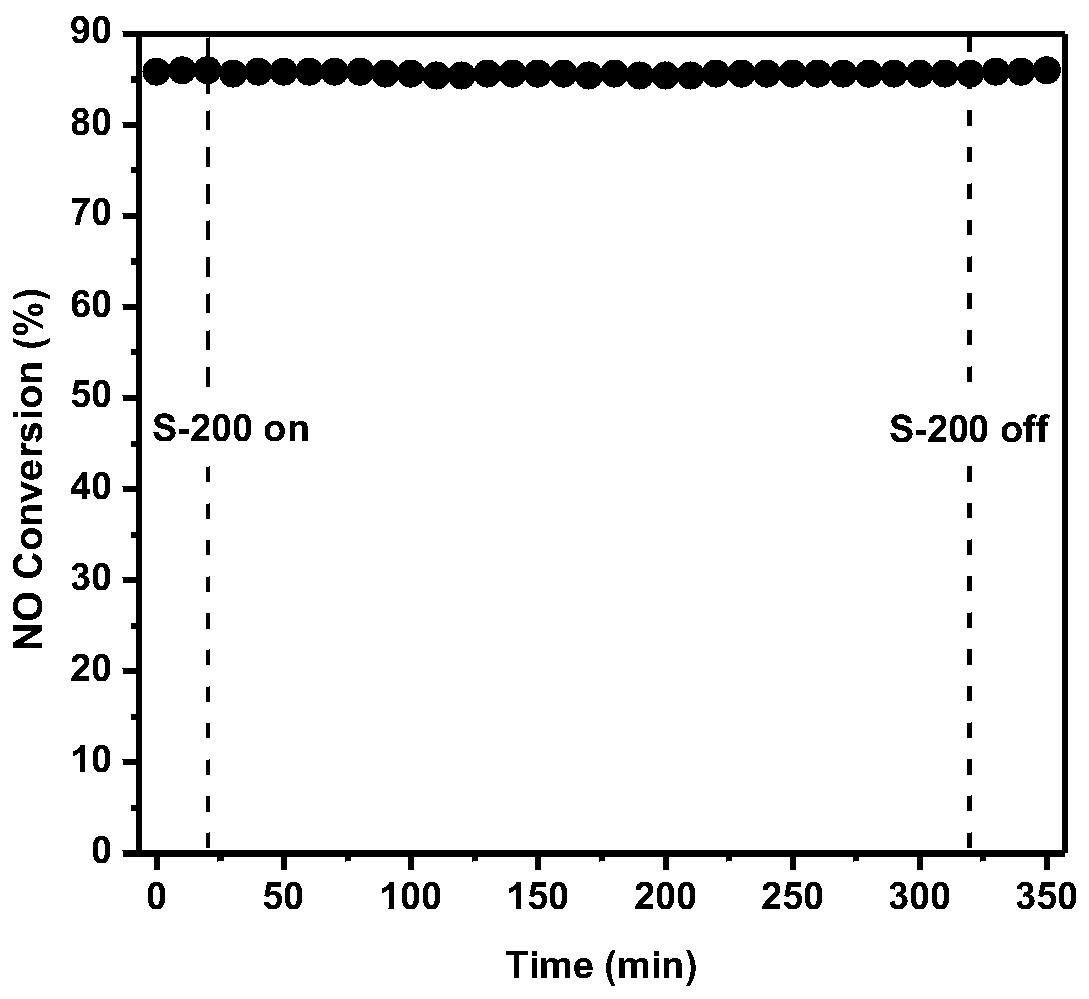

InactiveCN101507928AReduced denitrification efficiencyHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsIron saltsManganese

The invention discloses an iron-manganese compound oxide catalyst for selectively catalyzing and reducing nitric oxides in flue gas at a low temperature and a preparation method thereof and application thereof. The catalyst comprises active components such as iron element, manganese element, auxiliary agent element and the like. The method for preparing the catalyst comprises the following steps: 1, the iron salt and the manganese salt are mixed, and added with nitrate or acetate of the auxiliary agent element to obtain a mixed metal salt; 2, a solution of citric acid is added in the mixed metal salt and evenly mixed by stirring; 3, at the constant temperature of between 40 and 160 DEG C, the mixed solution is dried to give a solid; 4, the solid is calcined in the air for 1 to 8 hours, the calcination temperature is between 200 and 900 DEG C, and a mixed oxide is obtained; and 5, the mixed oxide is ground, tabletted and screened to obtain the finished product of the catalyst. The catalyst can selectively catalyze and reduce nitric oxides in the flue gas at a low temperature under the aerobic condition, so that the catalyst has the characteristics of high activity, high selectivity and high stability.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of catalyst of sulfur containing transition metal atomic cluster compound for hydrodesulfurizing

InactiveCN1785517ARaw materials are easy to obtainLow priceCatalyst activation/preparationRefining to eliminate hetero atomsChemical reactionElectrolysis

A process for preparing the catalyst containing the S and the atom cluster compound of transition metal (Mo or W) and used for hydrodesulfurizing is disclosed. Said atom cluster compound of Mo or W is prepared from its oxide through electrolyzing in acid solution, sulfurizing, oxidizing, concentrating, separation and chemical reaction. Its advantage is high hydrodesulfurizing performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

SCR flue gas denitration composite catalyst and preparation method thereof

ActiveCN101352678AGood chemical stabilityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTitanium zirconiumCerium

The invention relates to a compound catalyst for SCR flue gas denitration and a preparation method thereof, pertaining to the technical fields of environmental protection catalytic materials and atmosphere pollution controlling. The compound catalyst takes aluminum-based, titanium-based or zirconium-based ceramics as a carrier and titanium-zirconium-aluminum-cerium complex metal oxide as an active ingredient of the compound catalyst. The preparation method adopted includes: the aluminum-based, titanium-based or zirconium-based ceramics is impregnated in a titanium-zirconium-aluminum-cerium complex colloidal sol, and then dried and roasted to prepare compound catalyst active coatings. Compared with the prior art, the compound catalyst not only promotes the activity and the chemical stability of the catalyst and extends the temperature window of the catalytic activity, but also enhances the mechanical and thermal stability of a catalyst carrier, is environment protective and cheap without secondary pollution, prolongs the service life of the catalyst and lowers the load of the active ingredient.

Owner:NANJING UNIV OF TECH

A composite metal sulfate system flue-gas-denitration catalyst and a preparation method thereof

ActiveCN103638939AStrong resistance to sulfur poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeric sulfateWater vapor

The invention relates to a composite metal sulfate system flue-gas-denitration catalyst and a preparation method thereof, and belongs to the technical fields of environmental-friendly catalytic materials and atmospheric pollution control. The catalyst and the preparation method thereof are characterized in that titanium dioxide is used as a carrier, ceric sulfate is used as an active component, and a transition-metal sulfate is used as a cocatalyst; the weight percent of the active component of the catalyst is 1-25% based on the weight of the carrier; and the weight ratio of the active component to the auxiliary is 1: (0.1-0.9). The catalyst is prepared by utilization of a direct sulfate-dipping method. Compared with technical performances of selective catalytic reduction (SCR) denitration catalysts at present, the catalyst provided by the invention broadens the middle / high-temperature denitration active temperature window, and enhances vapor-poison tolerance and sulfur dioxide poison tolerance of the catalyst significantly. The preparation technology of the catalyst is simple, environmental friendly, cheap, and free of secondary pollution.

Owner:NANJING UNIV OF TECH

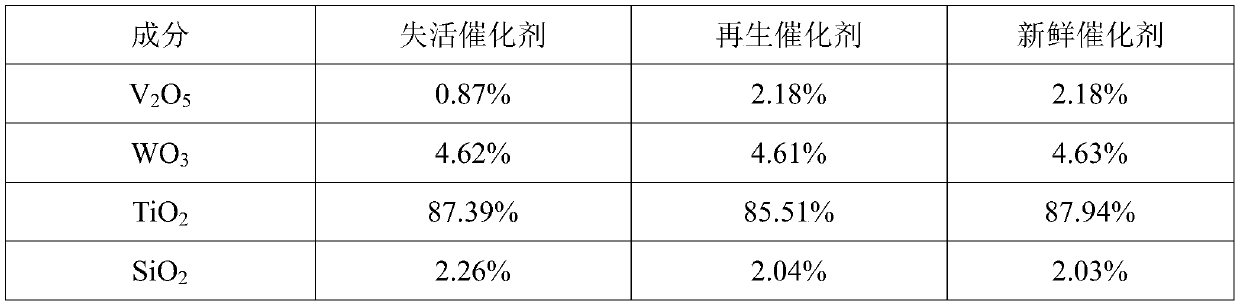

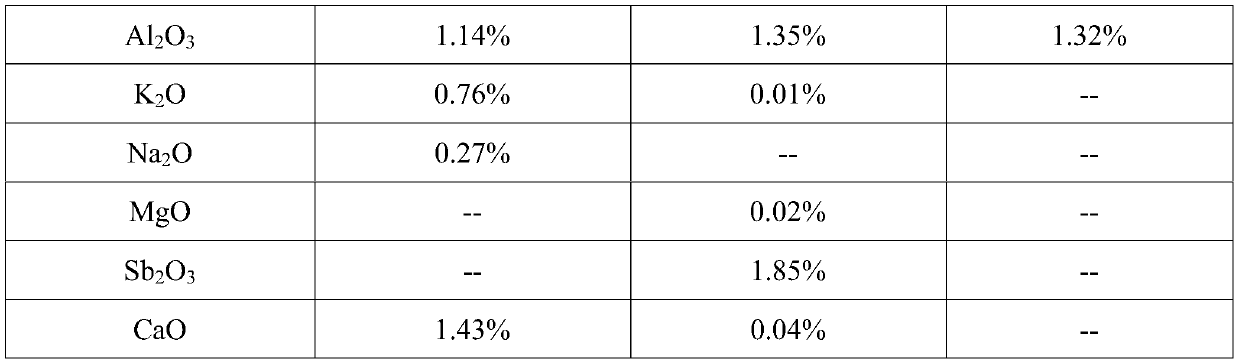

Reutilization method of inactivated SCR denitration catalyst

ActiveCN110354914ARealize resource utilizationReduce crushGas treatmentHeterogenous catalyst chemical elementsSulfurActive component

The invention belongs to the field of environmental protection technology and denitration catalysis, and particularly relates to a reutilization method of an inactivated SCR denitration catalyst. Thereutilization method specifically comprises the following steps: soot blowing, cleaning by a cleanout fluid, reductive acid leaching, auxiliary agent loading, active component loading and the like. Bytaking the integral inactivated SCR denitration catalyst as a raw material, the low-temperature SCR denitration catalyst is obtained by carrying out in situ regeneration. The regeneration catalyst has very high catalytic activity and sulfur poisoning resistance in a temperature range of 150-300 DEG C.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

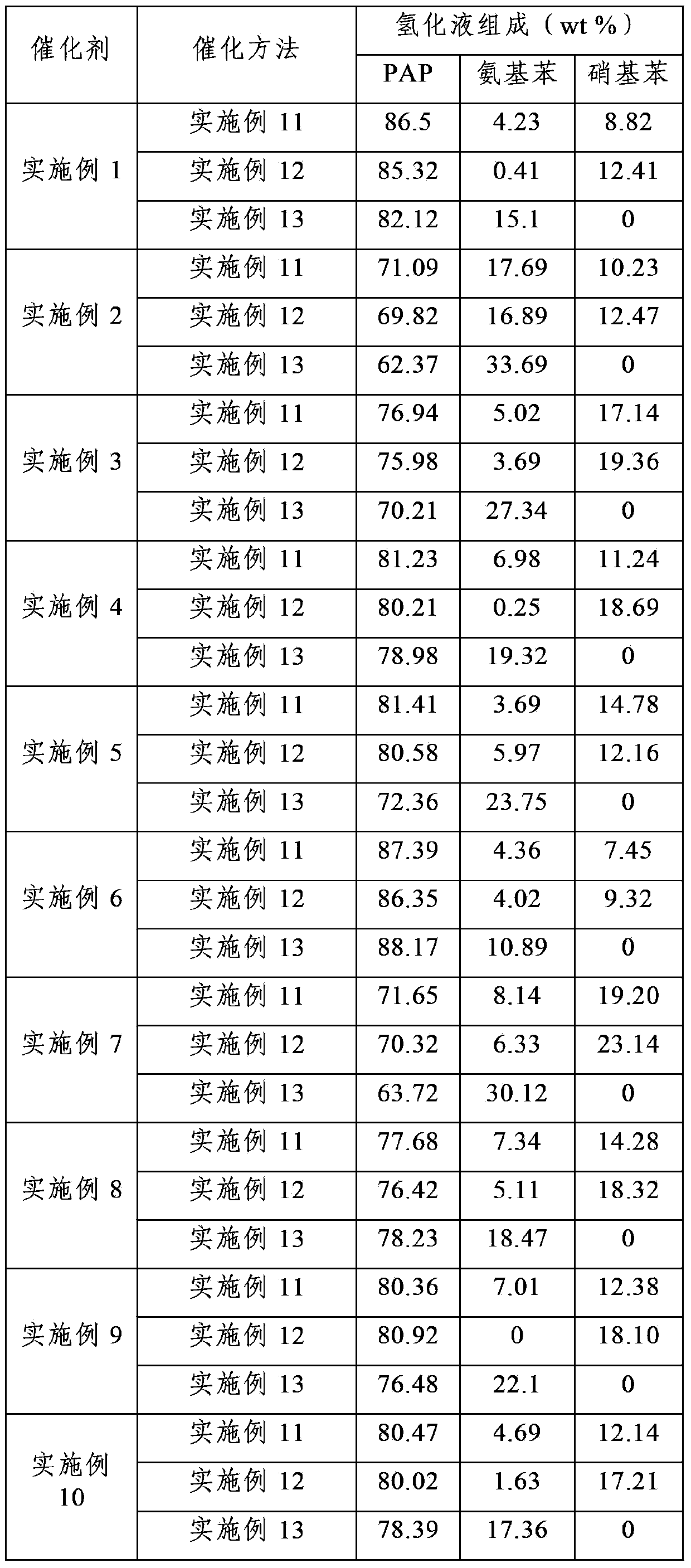

Preparation method and application of catalyst for one-step preparation of p-aminophenol from nitrobenzene

InactiveCN103357407AExtended service lifeHigh catalytic activityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsPlatinum saltsP-Aminophenol

The invention discloses a preparation method of a catalyst for the one-step preparation of p-aminophenol from nitrobenzene. The method comprises the following steps: preprocessing active carbon; loading a platinum salt; loading a vanadate; and reducing a catalyst, wherein the mass percentage contents of platinum and vanadium in the catalyst are 0.5-5% and 0.05-0.2% respectively. The invention also discloses a method for the one-step preparation of p-aminophenol from nitrobenzene through utilizing the catalyst. The addition of a certain amount of metallic vanadium to the Pt / C catalyst reduces the poisoning effect of sulfides in the nitrobenzene raw material to platinum, prolongs the service life of the catalyst and also improves the catalysis activity and selectivity of the catalyst; and the prepared catalyst has stable performances and very good repeatability, can be used for catalyzing the one-step preparation of p-aminophenol from nitrobenzene, reduces the purity requirement of the raw material nitrobenzene and reduces the catalysis cost.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Catalyzer for purifying CO under certain environmental condition

InactiveCN1498680AHigh activityGood resistance to water vapor poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentReaction temperature

A catalyst for convering CO to CO2 isn environmental condition in order to clean air is composed of gold as its active component and MOx / Al2O3 as carrier, where MOx may be CoOx or FeOx, MiOx, MnOx, CuOx and ZnOx. With it the CO can be converted to CO2 at -30-50 deg.C, in ordinary ambient condition.

Owner:NO 63971 TROOPS PLA +1

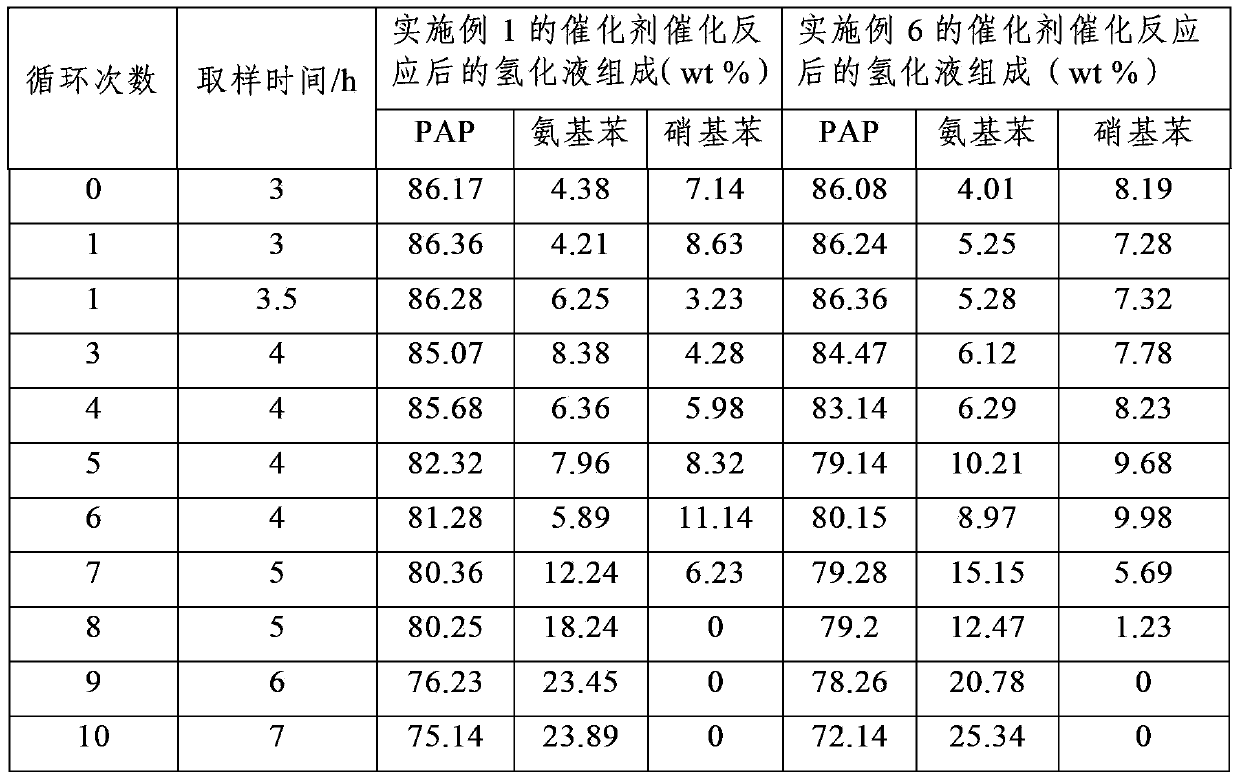

Plate type denitration catalyst and preparation method thereof

InactiveCN107224979AWide active temperature rangeLow costGas treatmentDispersed particle separationSulfurActive component

The invention relates to a plate type denitration catalyst and a preparation method of the catalyst and belongs to the field of environment-friendly catalysis material and air pollution control. A cerium-antimony-molybdenum composite oxide serves as a catalytic active component; a tungsten, cobalt or lanthanum oxide serves as a promoter; a titanium dioxide and argil mixing component serves as a major carrier; mass percentages of the cerium-antimony-molybdenum composite oxide and the promoter oxide are 8-20% and 1-3% respectively by taking the mass of the titanium dioxide and argil mixing component carrier as a reference. The denitration activity of the catalyst reaches 98.5% or above, and the catalyst has excellent sulfur poisoning resistance.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

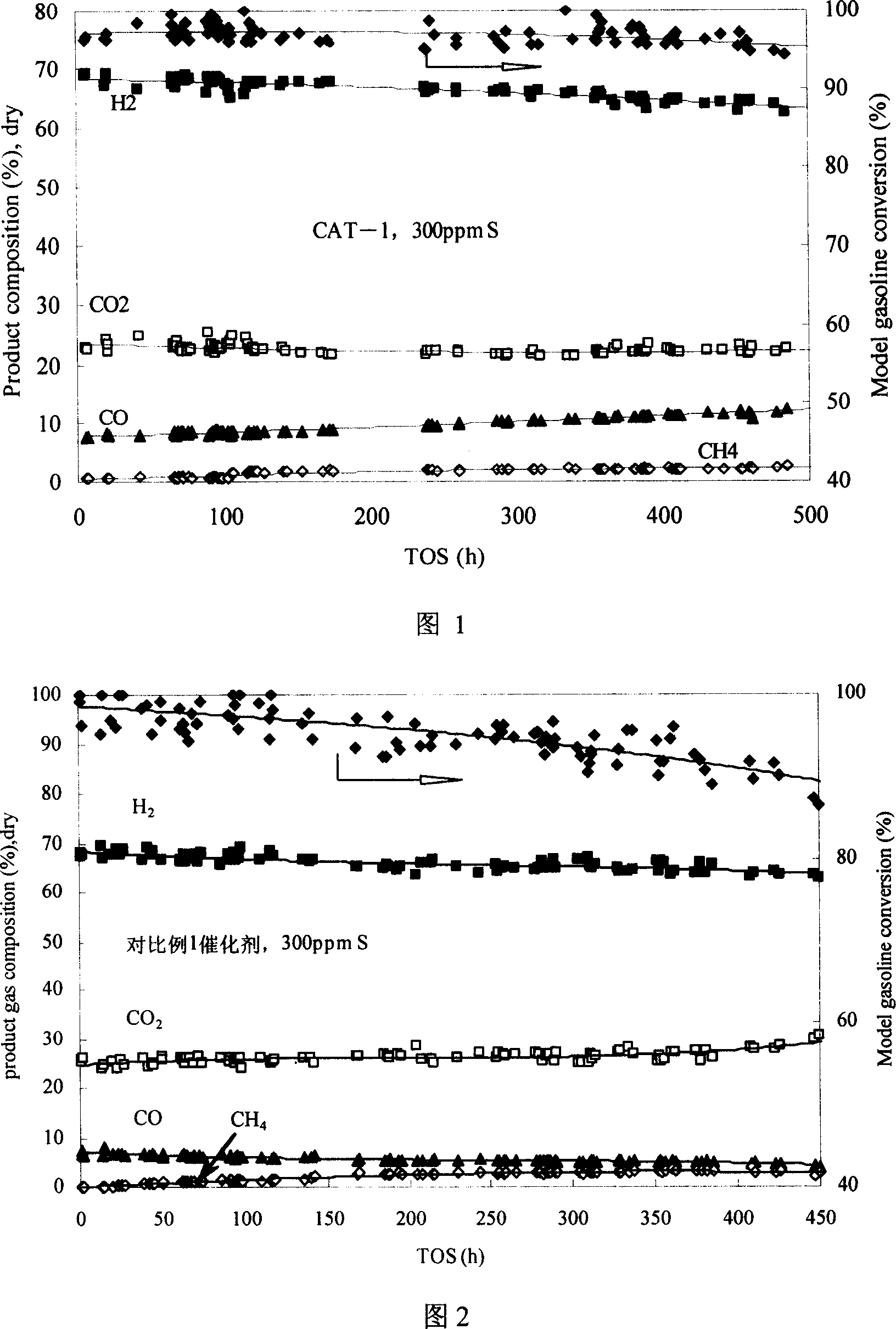

Gasoline oxidation reformation and hydrogenation catalyst

InactiveCN1428292AHigh catalytic activityGood anti-carbon performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlkaline earth metal

The gasoline oxidation reformation hydrogen manufacturing catalyst is a loaded catalyst using one of Al2O3, ZrO2, TiO2, MgO and iolite as carrier, and is characterized by that RuO2 is used as main catalytic component, its content is 0.1-0.8 wt% of total weight of said catalyst, and one or several kinds of oxides of rare earth elements, oxides of alkaline earth metals and oxides of alkali metals are used as auxiliary catalytic component, and its content is 1-10 wt% of total weight of said catalyst.

Owner:KAILING CHEM ZHANGJIAGANG CO LTD

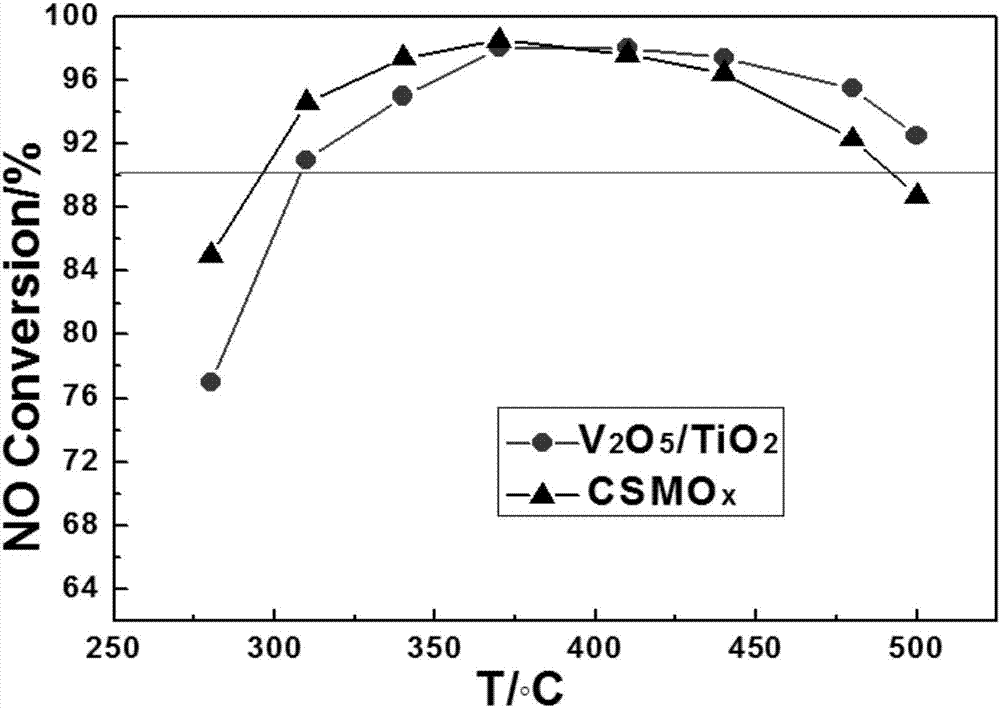

Catalyst for simultaneous denitration, demercuration and dioxin removal and preparation method thereof

ActiveCN111167475AWide active temperature rangeStrong resistance to sulfur poisoningCatalyst carriersGas treatmentPtru catalystEngineering

The invention discloses a catalyst for simultaneous denitration, demercuration and dioxin removal and a preparation method thereof. According to the invention, cerium oxide and niobium pentoxide are used as catalytic active components, a mixture of nickel oxide and platinum nanoparticles is used as a cocatalyst, a titanium dioxide nanoneedle generated by modifying tetrabutyltitanate with hydrochloric acid is used as a main carrier, and the catalyst is used after hydrogen pretreatment. Based on the mass of the carrier, the mass percentage of the active components is 10%-30%, and the mass percentage of the cocatalyst is 0.1%-0.15%. The preparation method comprises the following steps: uniformly stirring the active components, a cocatalyst composite colloidal solution and the optimized and modified catalyst carrier, carrying out aging and extrusion molding, and then performing drying and roasting to obtain the catalyst. The catalyst is environment-friendly, can efficiently remove nitrate,mercury and dioxin at the same time, and has a wide active temperature interval and low SO2 oxidation efficiency. Within 240-500 DEG C, the denitration efficiency and the dioxin removal efficiency ofthe catalyst are both higher than 95%, and the mercury removal efficiency of the catalyst is higher than 99%. The catalyst can be widely applied to the fields of coal-fired power plants, chemical plants and the like.

Owner:南京环福新材料科技有限公司

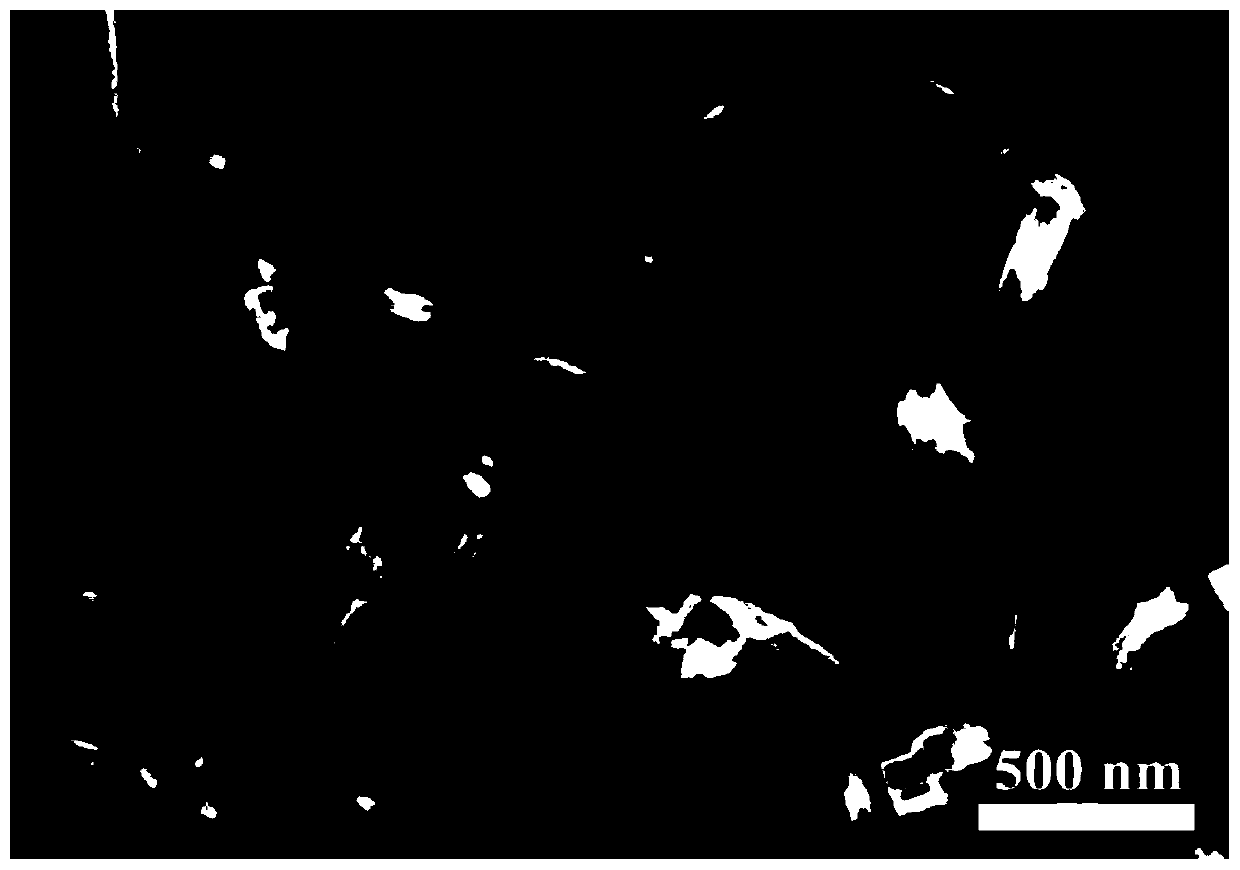

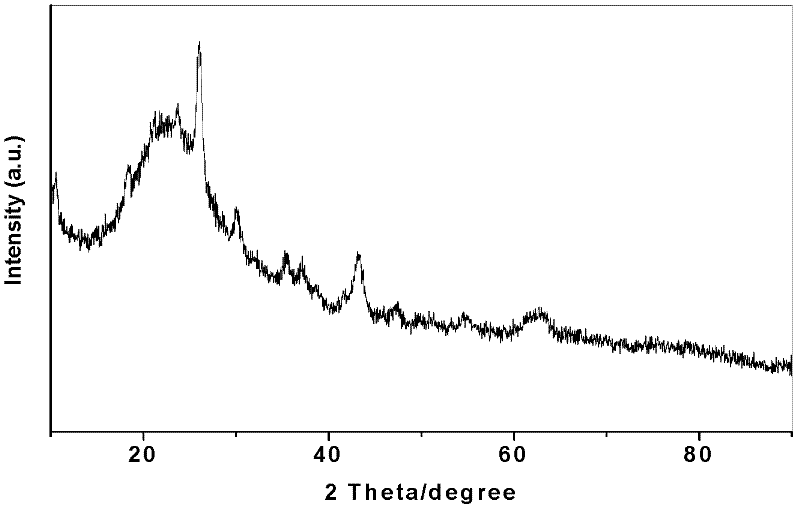

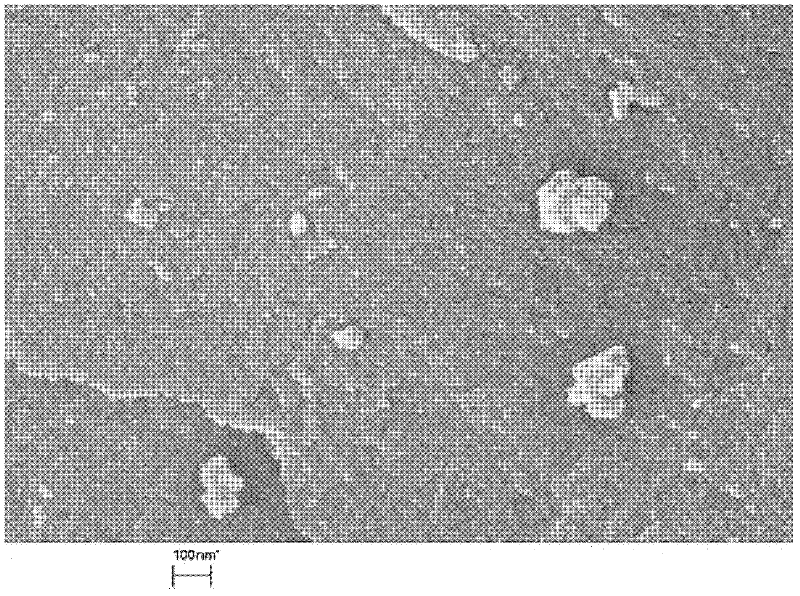

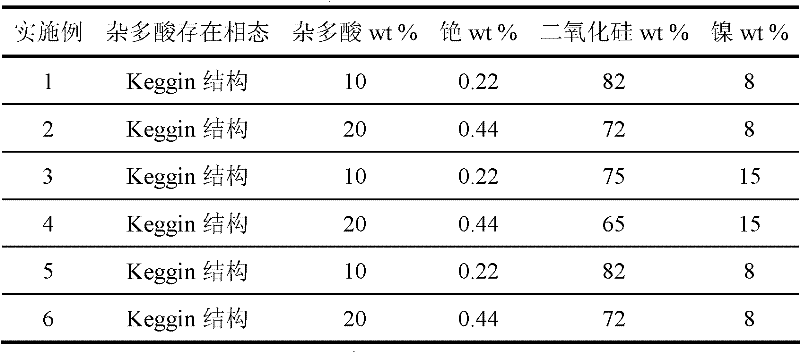

Heteropolyacid-containing aromatics hydrogenation catalyst and preparation method thereof

InactiveCN102335621ASimple compositionGood dispersionHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltWater soluble

The invention discloses a heteropolyacid-containing aromatics hydrogenation catalyst and a preparation method thereof, relating to a catalyst. The invention provides the heteropolyacid-containing aromatics hydrogenation with high sulphur resistance and high activity and the preparation method thereof. The catalyst comprises caesium heteropolyacid salts, hydrogenated components and a carrier, wherein the heteropolyacid caesium salts are caesium phosphotungstate or caesium silicotungstate, and the like; the hydrogenated components comprise Ni transition metal element, and the like; the carrier is a porous heat-resisting inorganic material; and the contents of all the components of the catalyst in percentage by mass are that: 5-40 percent of heteropolyacid, 0.2-0.5 percent of caesium, 5-20 percent of hydrogenated component and the balance of carrier. The preparation method comprises the following steps of: adding an water-soluble nickel salt solution and water-soluble heteropolyacid caesium salts into the carrier and impregnating; drying solid matters obtained through liquid-solid separation, and then roasting; preparing an aqueous caesium heteropolyacid salt solution, adding the aqueous caesium heteropolyacid salt solution to the obtained solid matters; impregnating and drying; and tabletting and forming to obtain the heteropolyacid-containing aromatics hydrogenation catalyst.

Owner:XIAMEN UNIV

Thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst and preparation method thereof

ActiveCN110354843ALarge specific surface areaImprove denitrification activityGas treatmentHeterogenous catalyst chemical elementsChromium trioxideSilicon dioxide

The embodiment provides a thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst. A catalyst carrier is a titanium dioxide-coated silicon dioxide composite nanotube, an active component is vanadium pentoxide, and a catalytic assistant is molybdenum trioxide and chromium trioxide. The thin-wall honeycomb SCR denitration catalyst with low-temperature sulfur resistance performance is prepared by adopting an extrusion molding process. The catalyst has good low-temperature activity and sulfur poisoning resistance, can solve the problems of low activity and sulfur poisoning of the catalyst in low-temperature flue gas, and is suitable for low-temperature sulfur-containing flue gas; by adding various inorganic and organic forming additives and optimizing the drying androasting processes, the wall thickness of the catalyst is reduced on the basis of maintaining the mechanical strength of the catalyst, the sulfur poisoning resistance of the catalyst is improved, theproduction cost is reduced, and the thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst has good economic benefits. The embodiment also provides a preparation method ofthe thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Storage reduction catalyst used for removing nitrogen oxide in lean burn engine tail gas and preparation method

ActiveCN102172526AEasy to prepareEasy to operateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryReduction Activity

The invention relates to a storage reduction catalyst used for removing nitrogen oxide in lean burn engine tail gas and a preparation method. The preparation method comprises the following steps of: with soluble cerium salt and zirconium salt as raw materials, alkali as coprecipitator and polyethylene glycol as thickening agent, preparing a cerium zirconium powder carrier according to the atom ratio of Ce to Zr of (6-8):(4-2); with soluble barium salt as a raw material, loading the barium salt onto the cerium zirconium powder carrier by adopting an isovolumetric method, wherein BaO accounts for 20-40% of the mass of the catalyst; then loading one or two precious metals of Pt and Pd accounting for 1.0-3.0% of the mass of the catalyst by adopting the isovolumetric method, thus a sample I isobtained; with Al2O3 as a carrier, loading one or two precious metals of Rh and Pd accounting for 0.5-2.0% of the mass of the catalyst by adopting the isovolumetric method, thus a sample II is obtained; and mechanically mixing the sample I and the sample II according to the mass ratio of (1-3):1, thus the nitrogen oxide storage reduction catalyst comprising 50-75% of ((Pt,Pd) / BaO / CexZr(1-x)O2) and 50-25% of ((Rh,Pd) / Al2O3) is obtained, wherein NOx conversion rate of the catalyst can reach more than 80%. After treatment in presence of high-temperature water vapour or SO2 is carried out, the nitrogen oxide storage reduction activity is maintained to be more than 80%.

Owner:CATARC AUTOMOTIVE TEST CENT TIANJIN CO LTD +1

CrXCo3-XO4 spinel type catalyst and preparation method thereof

InactiveCN101722004AImprove thermal stabilitySimple structureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHeat stabilitySpinel

The invention relates to a CrXCo3-XO4 spinel type catalyst for purifying tail gas of gas-fueled vehicles. An A site of a spinel AB2O4 structure comprises positive divalent cobalt elements, and a B site comprises chromium elements or chromium elements and positive divalent cobalt elements, wherein the molar ratio of the positive divalent cobalt elements to the sum of positive trivalent cobalt elements and the chromium elements to oxygen elements is 1:2:4. The preparation method of the CrXCo3-XO4 spinel type catalyst comprises the steps of: (1) respectively preparing a chromic nitrate solution and a cobalt nitrate solution with deionized water; (2) according to the proportion of the cobalt elements and the chromium elements, weighing the chromic nitrate solution and the cobalt nitrate solution which are prepared in the step (1), and uniformly mixing the two solutions by magnetic stirring; (3) adding an ammonia solution to regulate the pH value to obtain a suspension; and (4) carrying out vacuum filtration on the suspension obtained in the step (3), putting filter cakes in a drying box for drying, and then, transferring the filter cakes into a muffle furnace for roasting. The CrXCo3-XO4 spinel type catalyst has the characteristics of good heat stability, simple structure, low cost and wide application prospects.

Owner:TSINGHUA UNIV

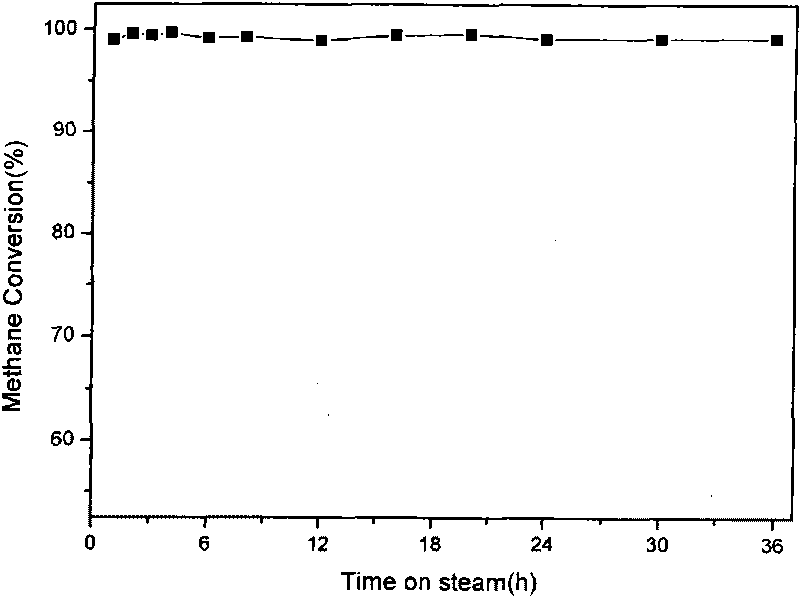

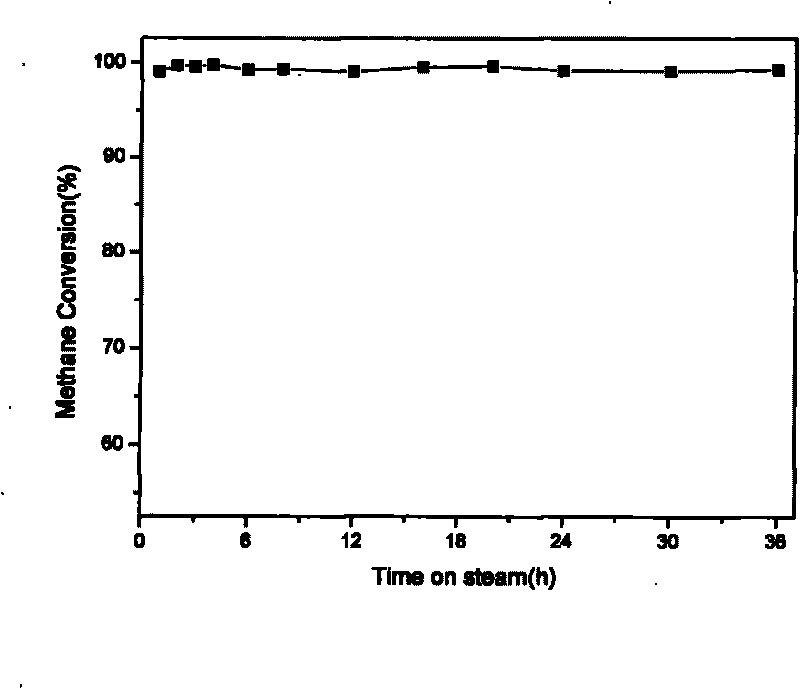

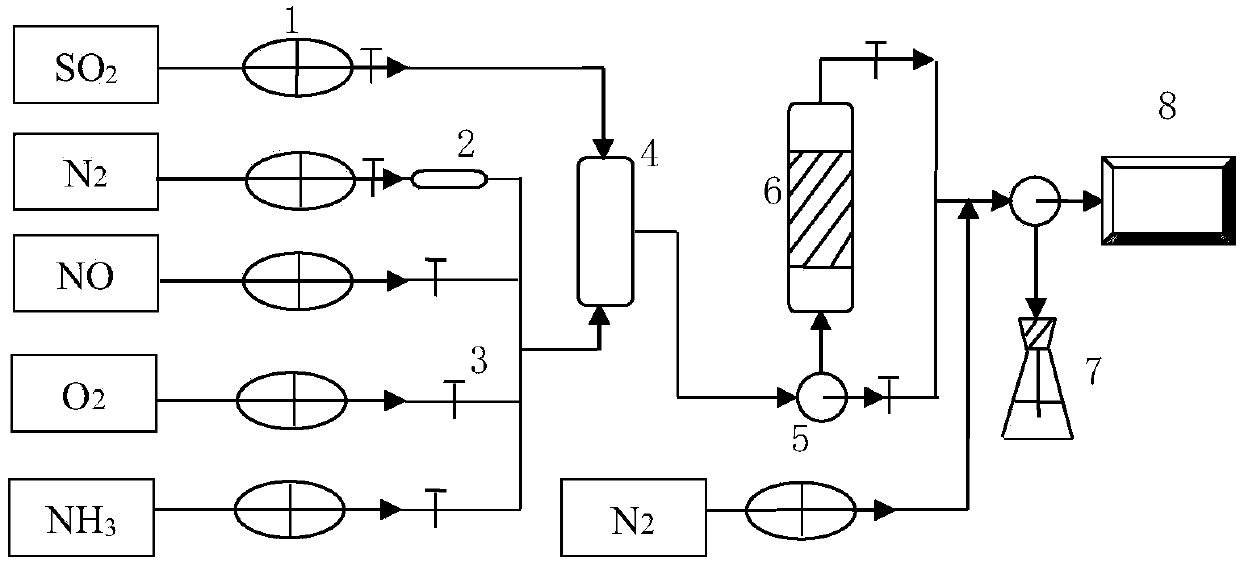

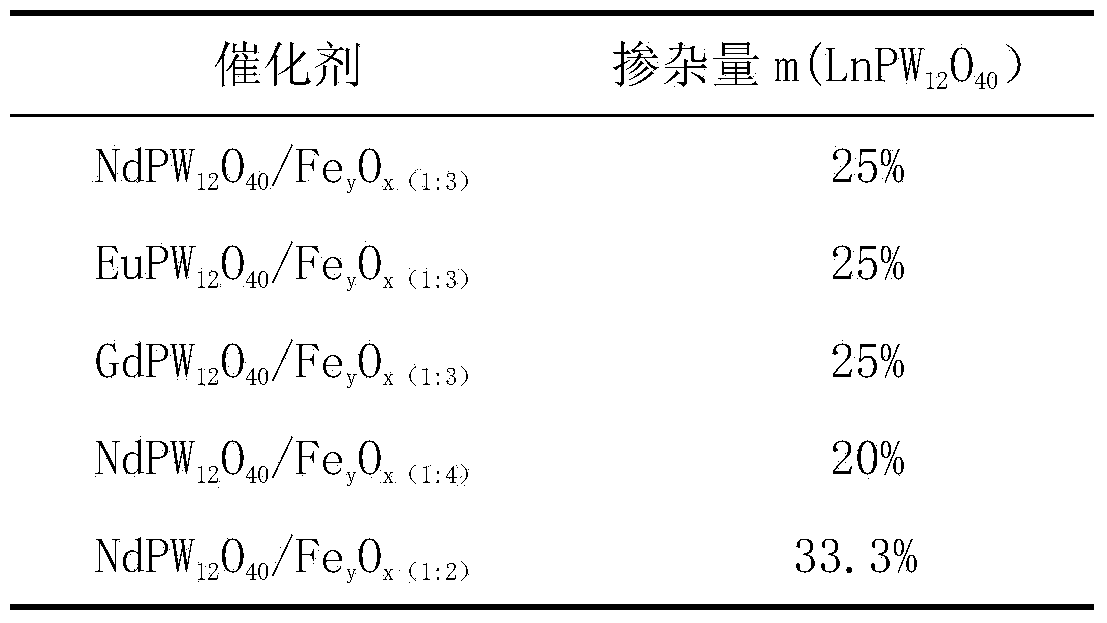

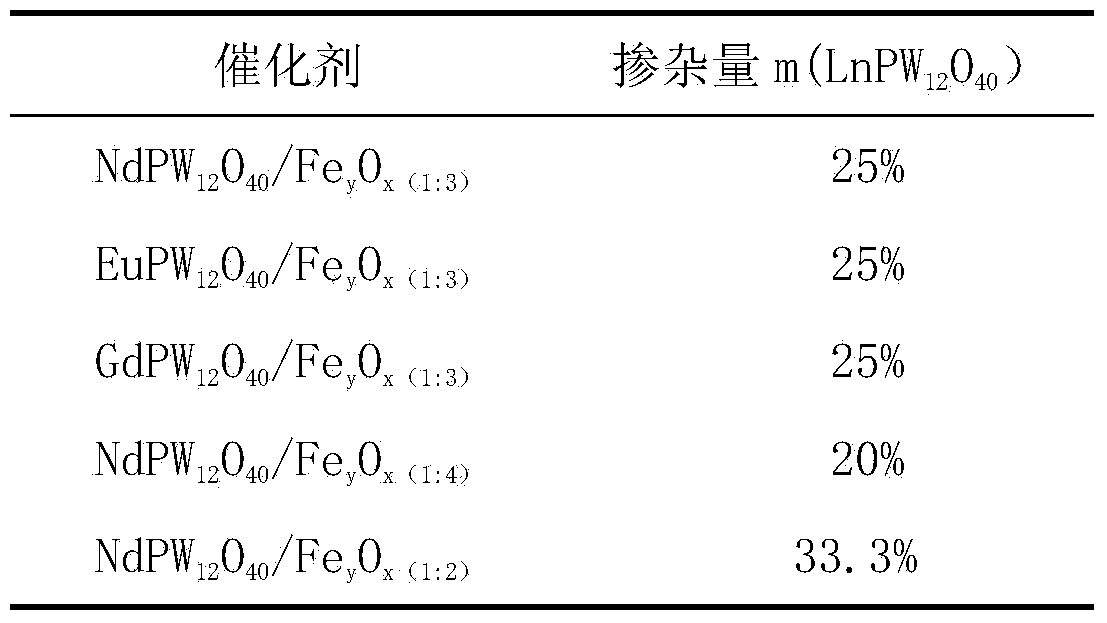

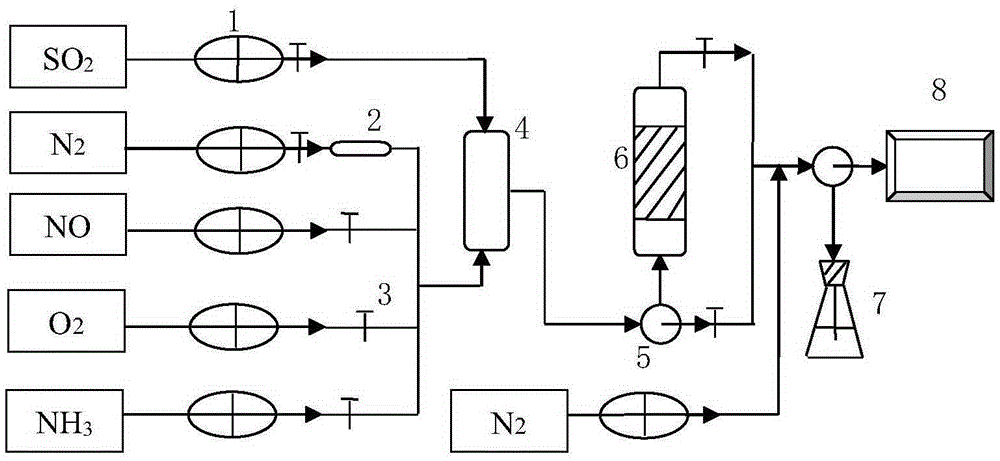

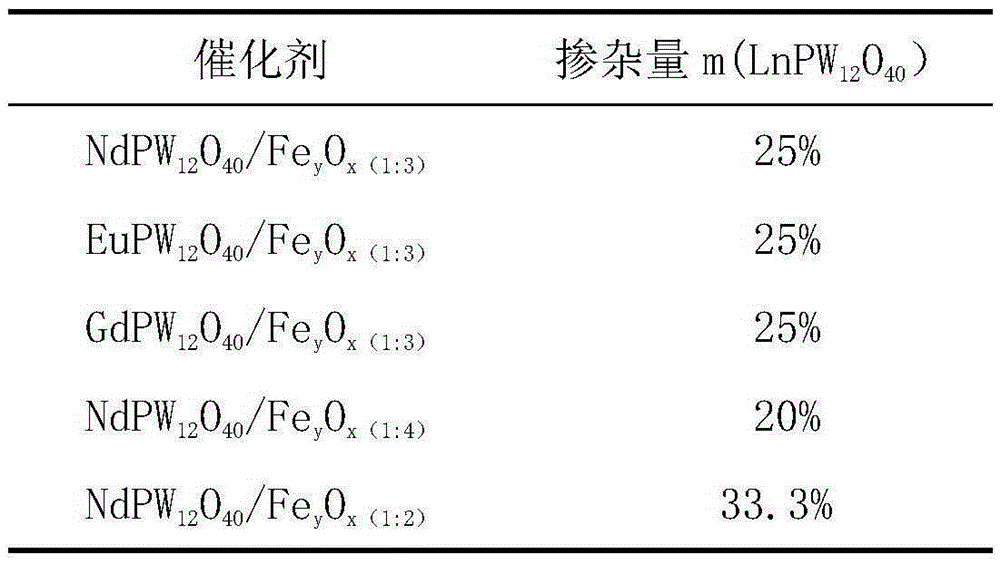

Rare-earth heteropolyacid salt-doped iron-based catalyst and application of catalyst in flue gas denitration

InactiveCN103990480AEasy to prepareNo pollution in the processPhysical/chemical process catalystsDispersed particle separationMass ratioRare earth

The invention discloses a rare-earth heteropolyacid salt-doped iron-based catalyst which is formed by mechanical mixing of rare-earth heteropolyacid salt and iron oxide, wherein mass ratio of rare-earth heteropolyacid salt to iron oxide is 1:2, 1:3 or 1:4; and rare-earth heteropolyacid salt is selected from Keggin structured rare-earth phosphotungstate. The rare-earth heteropolyacid salt-doped iron-based catalyst can be used in selective catalytic reduction of NOx and flue gas denitration. In specific application, ammonia gas is used as a reducing agent and mixed proportionally; and under conditions of a certain space velocity, nitrogen oxide concentration, reaction temperature and normal pressure and in the presence of oxygen, nitrogen oxide in flue gas is removed, and nitrogen oxide is converted to nitrogen. The catalyst provided by the invention has advantages of simple preparation method, no toxicity, no harm, no pollution, high catalytic activity, high stability, high denitration efficiency, high sulfur-resistance performance, simple processing equipment and little investment, and is suitable for industrial popularization.

Owner:SHANDONG UNIV

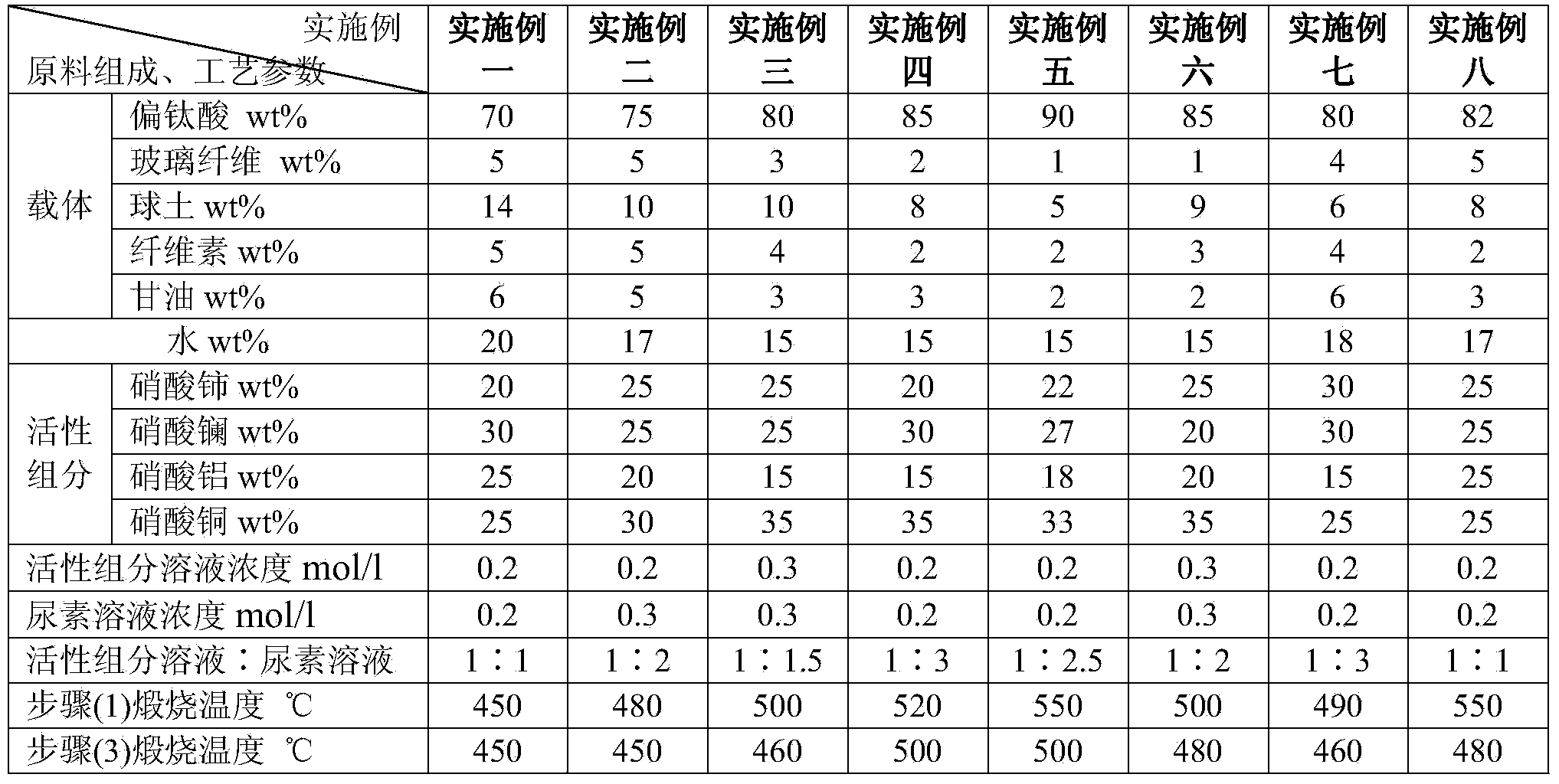

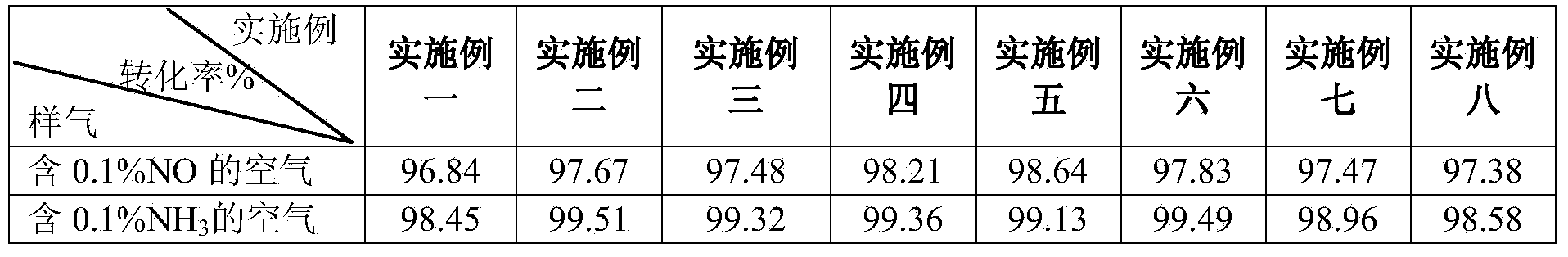

Ceramic honeycomb catalyst for high-temperature waste gas denitrification and preparation method thereof

InactiveCN104056667ALow cost productionImprove denitrification abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCelluloseCopper nitrate

The invention discloses a ceramic honeycomb catalyst for high-temperature waste gas denitrification. The ceramic honeycomb catalyst for high-temperature waste gas denitrification comprises carriers and active components, wherein the carriers comprise 70wt%-90wt% of metatitanic acid, 1wt%-5wt% of glass fibers, 5wt%-25% of ball clay, 2wt%-5w% of cellulose and 2wt%-6wt% of glycerinum; the active components comprise 20wt%-30wt% of cerous nitrate, 20wt%-30wt% of lanthanum nitrate, 15wt%-25wt% of aluminum nitrate and 25wt%-35wt% of copper nitrate. Additionally, the invention also discloses a preparation method of the ceramic honeycomb catalyst for high-temperature waste gas denitrification. According to the invention, the denitrification catalyst is produced at low cost; the obtained catalyst is high in denitrification and sulfur poisoning resistance, and has high catalytic activity even at low temperature, and the service life of the catalyst is prolonged.

Owner:PINGXIANG HEXIN ENVIRONMENTAL PROTECTION STUFFINGEQUIP CO LTD

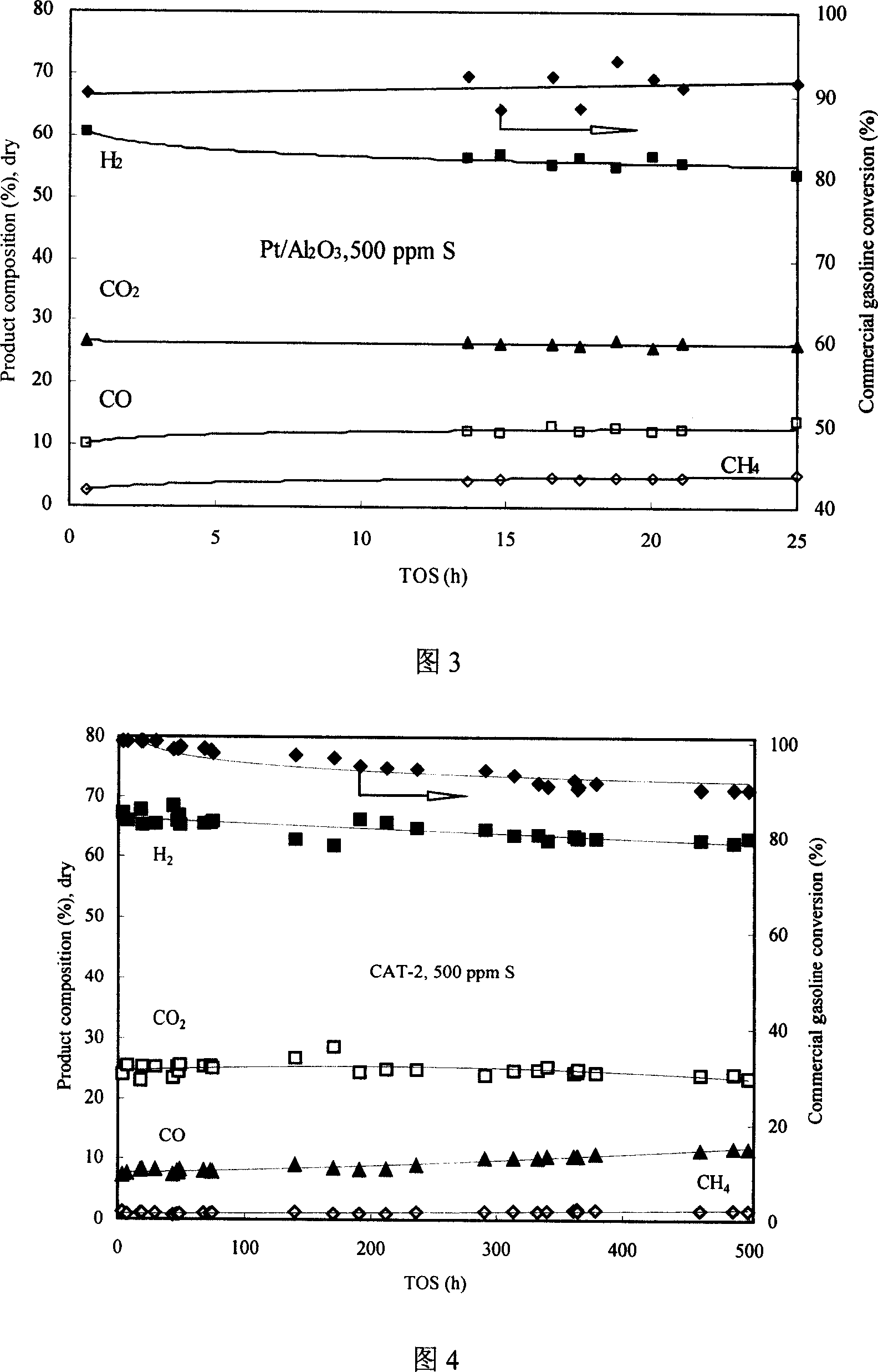

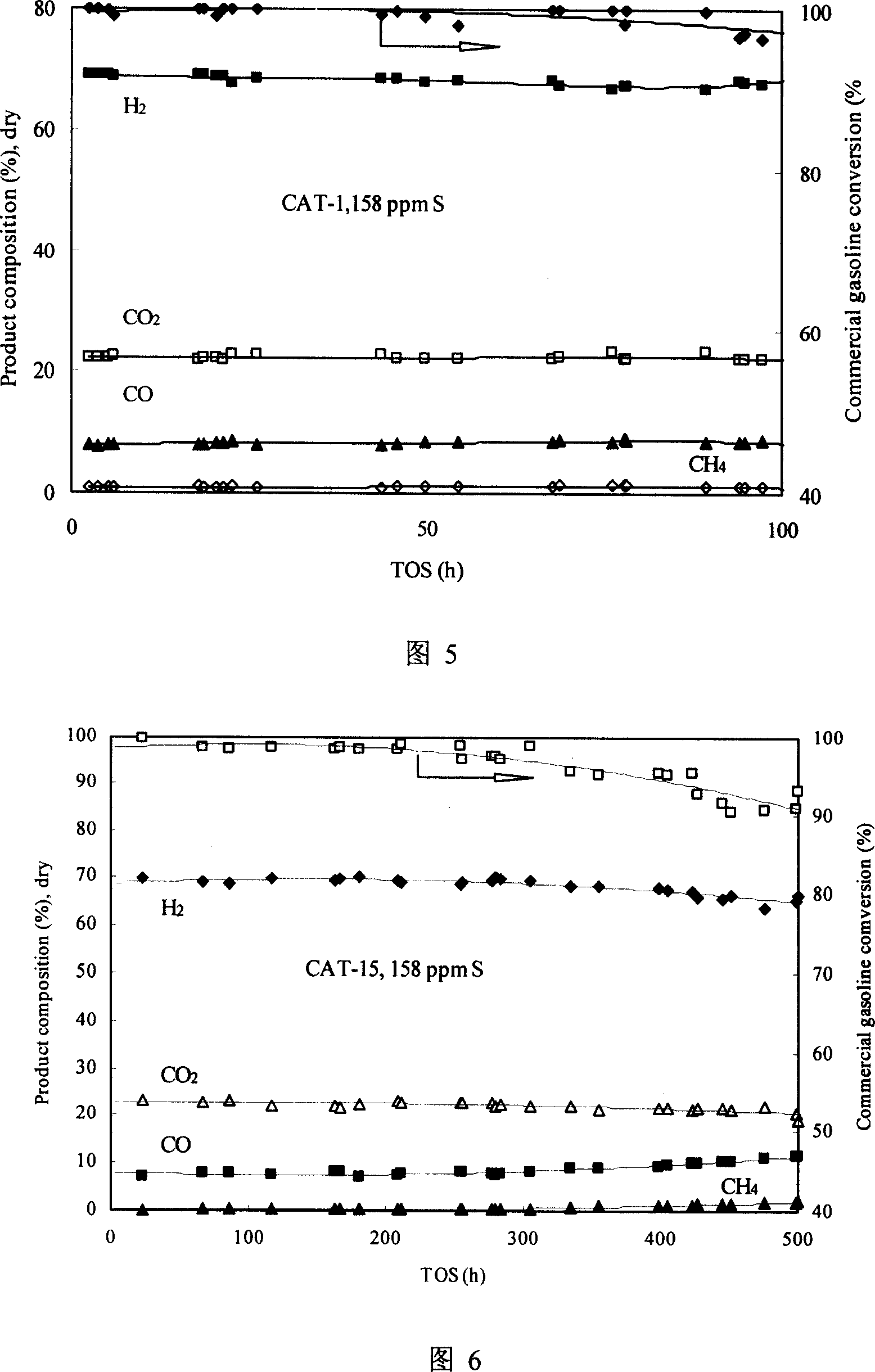

Catalyst for autothermal reformation of gasoline or diesel oil, preparation and application

InactiveCN101007278AHigh activity/selectivityImprove stabilityHydrogenCatalyst activation/preparationChemical industryRare earth

The invention involves an accelerant with high activity / selectivity, good stability and strong resistance to sulfur poisoning which is used for gasoline self-heating reforming hydrogen production process and its preparation and usage, and it belongs to energy resource and oil chemical industry catalysis material and its production technology field. The load-type metal catalyst provided by the invention is a rare earth oxides modified loading metal catalyst, the content of the rare earth oxides in the catalyst is 0.4%-20%, the content of active metal component is 0.3%-5%, the content of the carrier is 75%-99.3%. Compared with the prior technology, the hydrogenation catalyst need not add additional manufacturing equipment and has performance of high activity / selectivity, good stability and strong resistance-sulfur poisoning. The catalyst is easy to manufacture, cost of manufacturing is small and cost is very low, the prepared catalysts can meet the strength requirement of actual process to the catalyst, etc.

Owner:EAST CHINA NORMAL UNIV

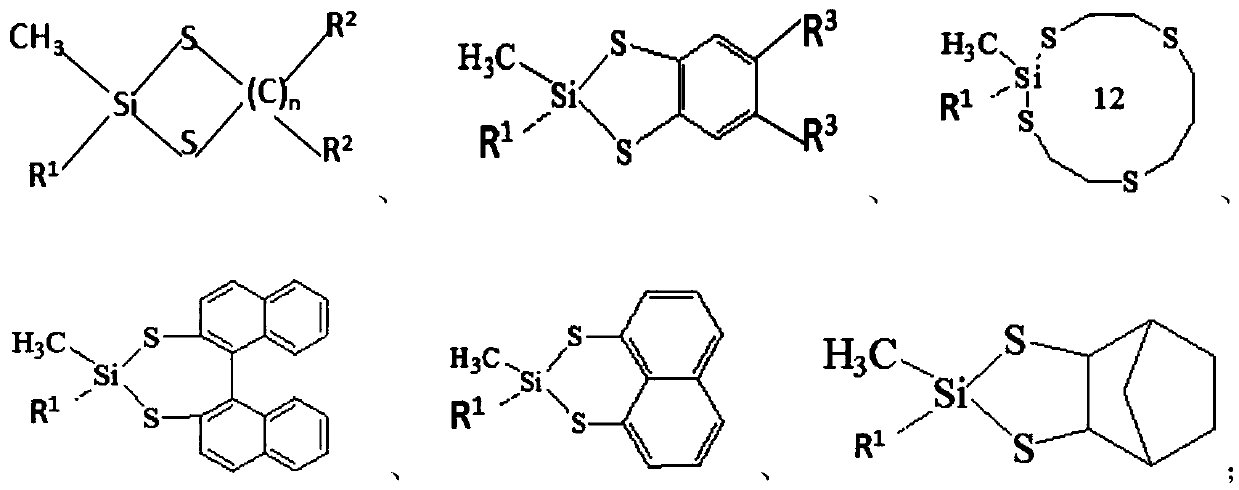

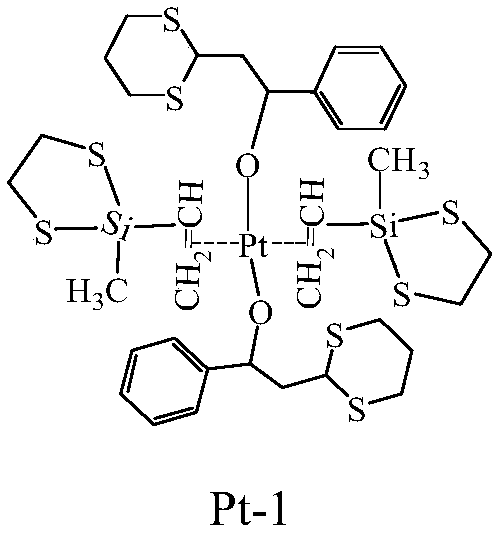

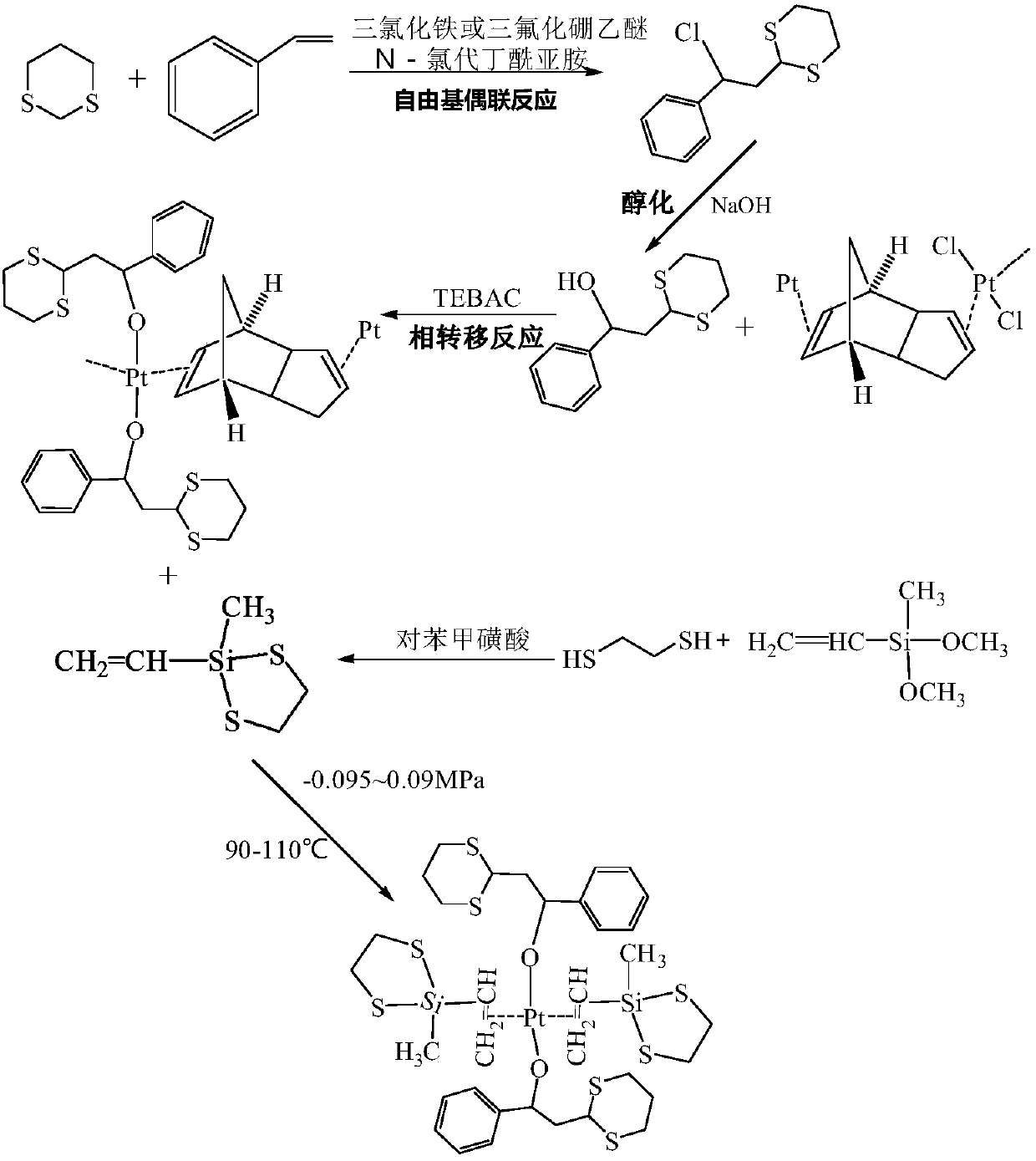

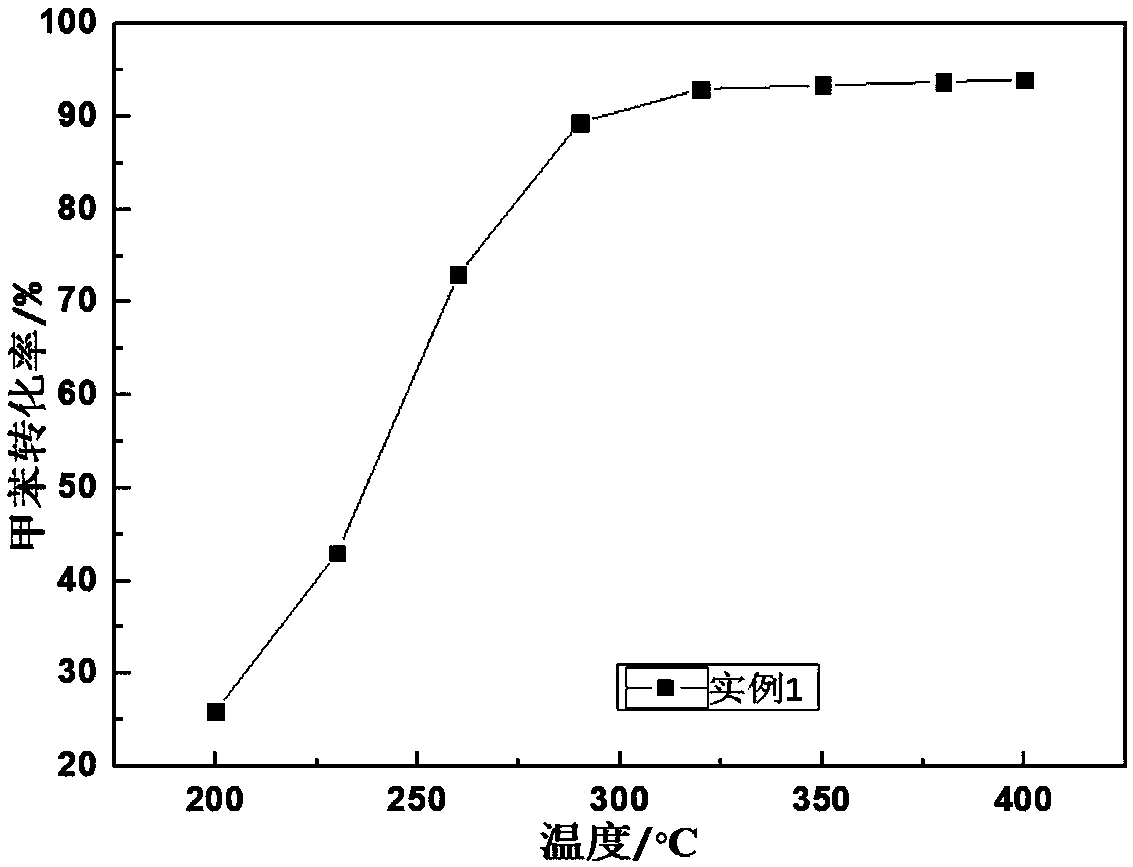

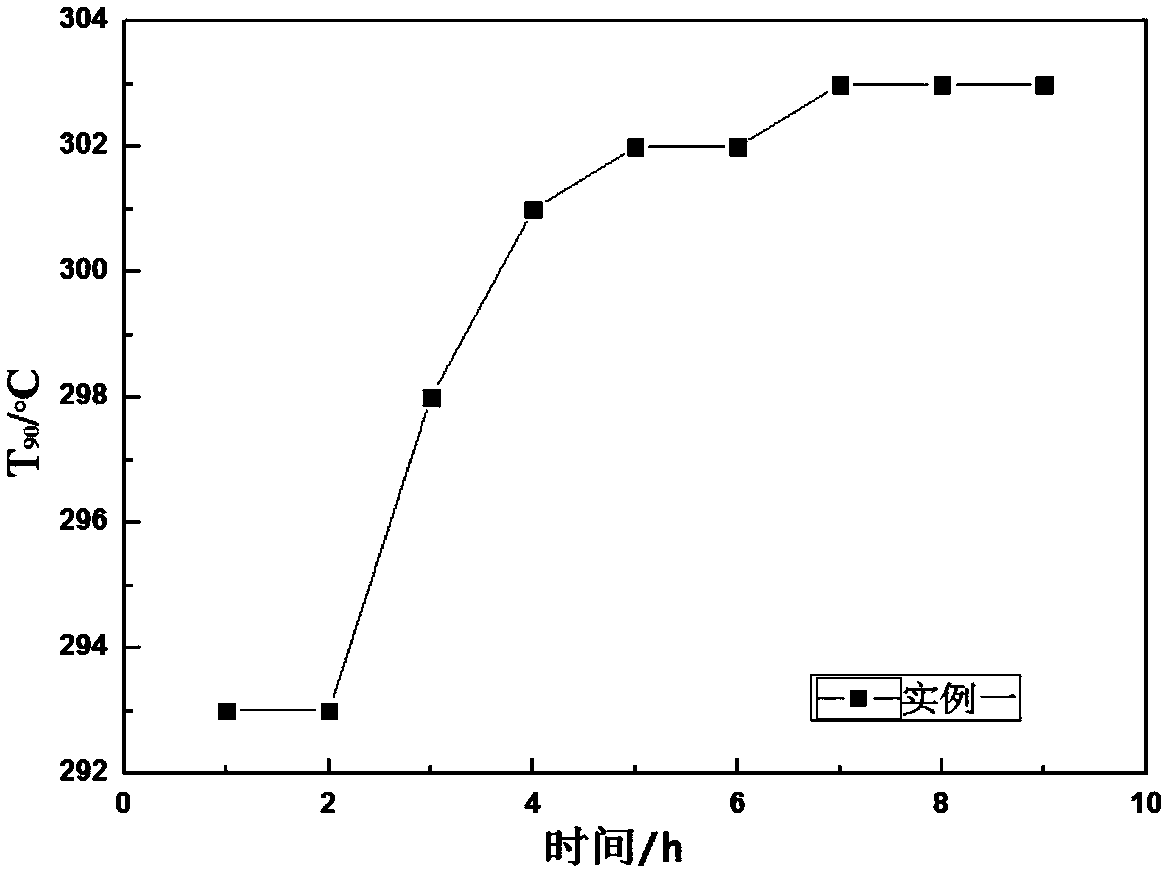

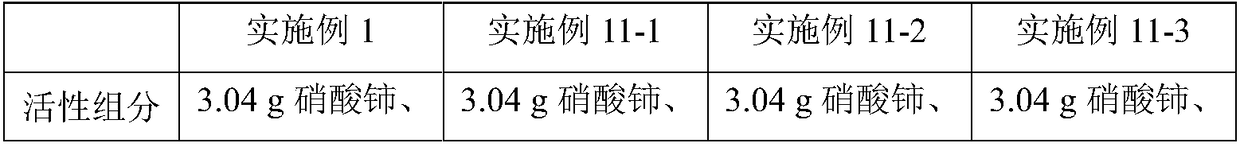

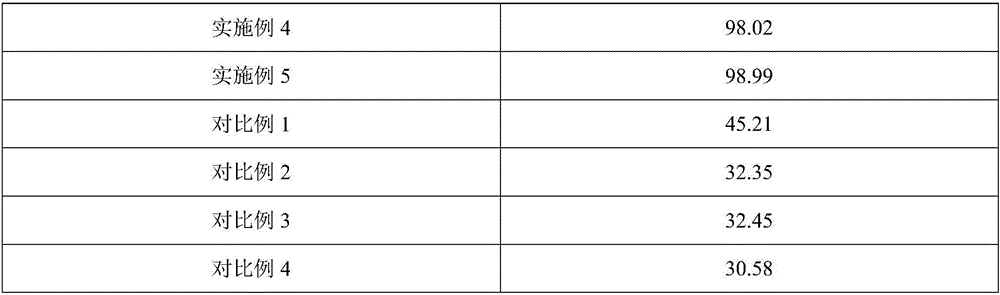

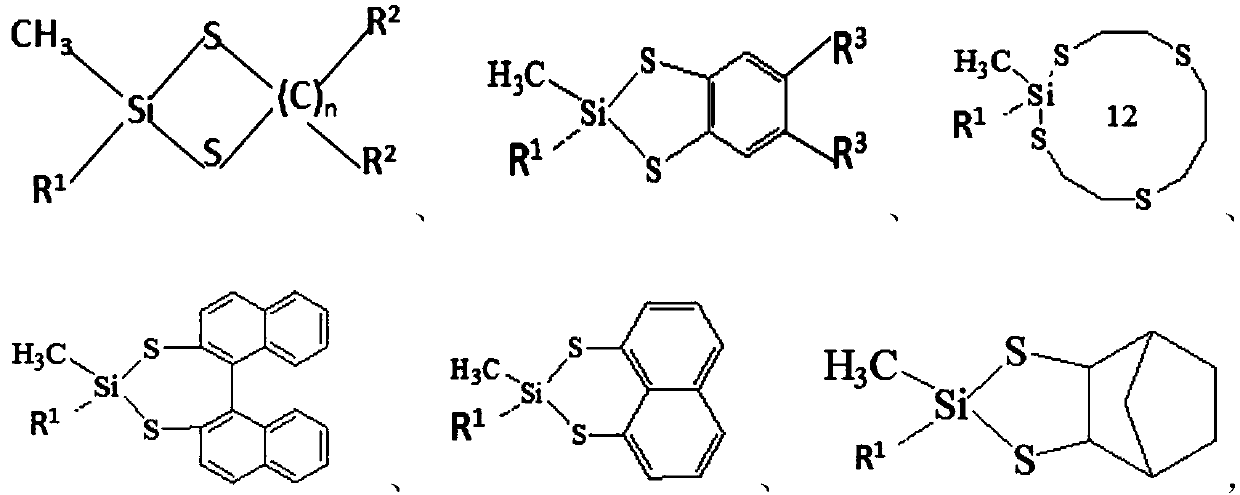

Preparation method of anti-sulfur poisoning platinum complex

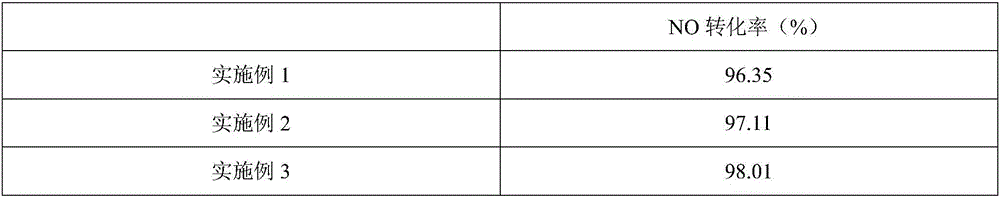

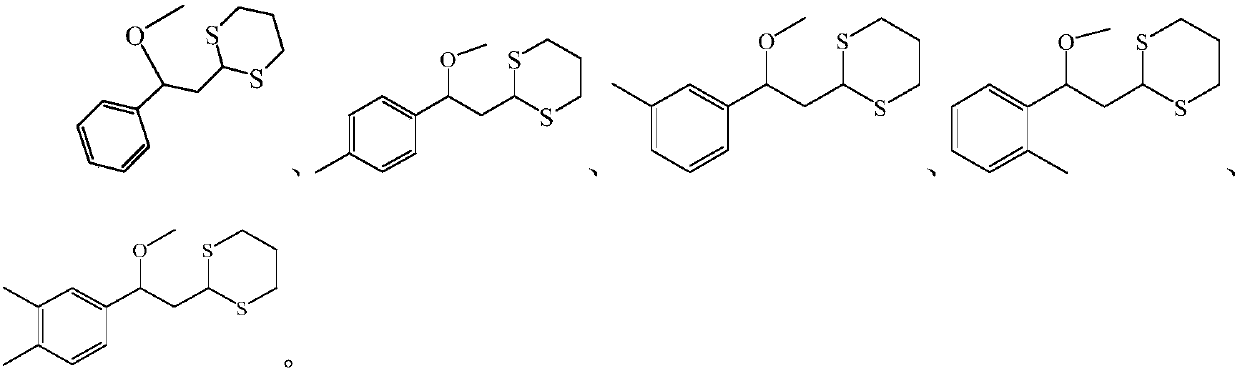

InactiveCN108794537AHigh activityLong storage periodOrganic-compounds/hydrides/coordination-complexes catalystsPlatinum organic compoundsDithianeBenzene

The invention provides a preparation method of an anti-sulfur poisoning platinum complex. The preparation method comprises the following steps: preparing a 1,3-dithiane benzene containing derivative intermediate A, preparing an unsaturated symmetrical epithio-silane intermediate B, connecting the 1,3-dithiane benzene containing derivative intermediate A to Pt through a phase transfer substitutionbond, then firstly substituting and then chelating the unsaturated symmetrical epithio-silane intermediate B to Pt, and obtaining the anti-sulfur poisoning platinum complex. The preparation method issimple and convenient, the reaction condition is mild, the production efficiency is high, the cost is low, and the industrial production is realized. A prepared catalyst has a highly symmetric complexstructure, the anti-sulfur poisoning platinum complex is stable at the room temperature, can be stored for long and has an excellent anti-sulfur poisoning catalytic effect, the catalytic activity ismore than 92%, the curing degrees of a sulfur-containing system and a non-sulfur system are basically the same and both reach more than 90%, and the anti-sulfur poisoning platinum complex has an excellent anti-sulfur poisoning capability, and is widely applied to the hydrosilylation.

Owner:GUANGDONG UNIV OF TECH

VOCs (voltaic organic chemical) catalytic combustion catalyst with anti-sulfur poisoning function and preparation method thereof

InactiveCN108176397AStrong resistance to sulfur poisoningLow costHeterogenous catalyst chemical elementsCatalyst activation/preparationTitanium dioxideToluene

The invention discloses a VOCs (voltaic organic chemical) catalytic combustion catalyst with anti-sulfur poisoning function and a preparation method thereof. The catalyst is prepared from an active component and a TiO2 (titanium dioxide) carrier, wherein the active component is CexSbyAzO2; A is selected from at least one of Cu (copper), Co (cobalt) and Mn (manganese); x is greater than or equal to0.6, and is smaller than or equal to 1.0; y is greater than or equal to 0.2, and is smaller than or equal to 0.4; z is greater than 0, and is smaller than or equal to 1. The preparation method comprises the following steps of firstly, preparing the active component; then, preparing a catalyst additive precursor solution; mixing the active component and the catalyst additive precursor solution, drying, and calcining, so as to obtain the catalyst. The prepared VOCs catalytic combustion catalyst has the characteristics that the anti-sulfur poisoning ability is excellent, and the conversion rateof toluene can reach 94%; the cost is low, the technology is simple, the catalyst is suitable for industrialized production, and the like.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

SCR flue gas denitration composite catalyst and preparation method thereof

ActiveCN101352678BGood chemical stabilityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTitanium zirconiumCerium

The invention relates to a compound catalyst for SCR flue gas denitration and a preparation method thereof, pertaining to the technical fields of environmental protection catalytic materials and atmosphere pollution controlling. The compound catalyst takes aluminum-based, titanium-based or zirconium-based ceramics as a carrier and titanium-zirconium-aluminum-cerium complex metal oxide as an active ingredient of the compound catalyst. The preparation method adopted includes: the aluminum-based, titanium-based or zirconium-based ceramics is impregnated in a titanium-zirconium-aluminum-cerium complex colloidal sol, and then dried and roasted to prepare compound catalyst active coatings. Compared with the prior art, the compound catalyst not only promotes the activity and the chemical stability of the catalyst and extends the temperature window of the catalytic activity, but also enhances the mechanical and thermal stability of a catalyst carrier, is environment protective and cheap without secondary pollution, prolongs the service life of the catalyst and lowers the load of the active ingredient.

Owner:NANJING TECH UNIV

Non-metal doped metal oxide denitration catalyst with strong sulfur tolerance and preparation method thereof

ActiveCN111530448AStrong resistance to sulfur poisoningExcellent medium and high temperature activityDispersed particle separationCatalyst activation/preparationPtru catalystCalcination

The invention discloses a non-metal doped metal oxide denitration catalyst with strong sulfur tolerance and a preparation method thereof. The denitration catalyst is mainly prepared by the following steps: using a sol-gel method to prepare a metal oxide, adding a non-metal element precursor in the gelling process, and then obtaining the non-metal doped metal oxide through high temperature calcination, and finally loading 10wt% of an active metal component on the non-metal doped metal oxide to obtain the catalyst. The catalyst provided by the invention has the advantages of excellent medium-high temperature activity, excellent cycling stability, simple preparation method, extremely strong sulfur poisoning resistance and the like, and can be used for catalytic treatment of nitrogen oxides intail gas generated by various stationary pollution sources of coal-fired power plants, waste incineration boilers, steel mills, cement plants and the like. The preparation method is simple and low-cost.

Owner:SHANGHAI UNIV

Flue gas denitration catalyst and preparation method thereof

InactiveCN106268959AImprove denitrification rateExtended service lifeGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsMANGANESE ACETATEGlass fiber

The invention discloses a flue gas denitration catalyst and a preparation method thereof. The catalyst takes fiberglass powder as a carrier, manganese acetate and potassium perchlorate loaded by the fiberglass powder are taken as active ingredients, and ferroferric oxide and cerium oxide are taken as promoters; the mass ratio of the active ingredients, the promoters and the carrier is 1:(5-12):(58-75). According to the flue gas denitration catalyst, the denitration rate is high, the service life is long, the active temperature window is wide, and the sulfur poisoning resistance is high. Specifically, the NO conversion rate of the flue gas denitration catalyst can reach 95% or above in the temperature range of 90-300 DGE C, the high NO conversion rate can be maintained after the catalyst is used by 16 hours, the catalytic activity is only weakened slightly, and the catalyst has high sulfur poisoning resistance.

Owner:张进

Load type gold catalyst with stabilized catalyzing performance and its preparation process

InactiveCN100389873CStable and stableMeet practical requirementsCatalyst carriersDispersed particle separationActive componentSpinel

A carried Au catalyst with high catalytic stability is composed proportionally of the active component (Au) and the carrier chosen from MIOx, MILOx modified Al2O3 and TiO2 / Al2O3. It features the strong mutual action between Au nano-particles and transition metal oxide with spinel structure and the alloy structure formed by part of Au particles and transition metal, resulting in high catalytic activity and stability.

Owner:SHANXI RUISHI PROTECTION TECH

Gasoline oxidation reformation and hydrogenation catalyst

InactiveCN1186121CHigh catalytic activityImprove anti-carbon performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlkaline earth metal

The gasoline oxidation reformation hydrogen manufacturing catalyst is a loaded catalyst using one of Al2O3, ZrO2, TiO2, MgO and iolite as carrier, and is characterized by that RuO2 is used as main catalytic component, its content is 0.1-0.8 wt% of total weight of said catalyst, and one or several kinds of oxides of rare earth elements, oxides of alkaline earth metals and oxides of alkali metals are used as auxiliary catalytic component, and its content is 1-10 wt% of total weight of said catalyst.

Owner:KAILING CHEM ZHANGJIAGANG CO LTD

Platinum complex resistant to sulfur poisoning and applications thereof

ActiveCN108516993AGood catalytic activityStable at room temperatureGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneAddition reaction

The invention discloses a platinum complex resistant to sulfur poisoning and applications thereof. The platinum complex has a complexing symmetric structure, which comprises a 1,3-dithiane benzene containing derivative group and symmetric unsaturated epithio-silane; wherein the 1,3-dithiane benzene containing derivative group comprises a benzene ring and a symmetric epithio- six-membered ring. ThePt catalyst has a highly symmetrical complexing structure and a very good effect on resisting sulfur poisoning. The catalytic activity is 92% or more. The catalytic effect in a sulfur system is basically the same as that in a non-sulfur system. The Pt catalyst has a good performing on resisting sulfur poisoning, is very stable at a room temperature, and can be stored for a long term. Solved are the problems that in the prior art, the storage time of a conventional Pt catalyst is short, the conventional Pt catalyst should be strictly sealed, and the catalytic activity of the Pt catalyst is lost after the Pt catalyst is poisoned by sulfur containing compounds. The Pt catalyst can be widely used in silicon-hydrogen addition reactions.

Owner:GUANGDONG UNIV OF TECH

Rare earth heteropoly acid salt doped iron-based catalyst and its application in flue gas denitrification

InactiveCN103990480BEasy to prepareNo pollution in the processPhysical/chemical process catalystsDispersed particle separationMass ratioRare earth

Owner:SHANDONG UNIV

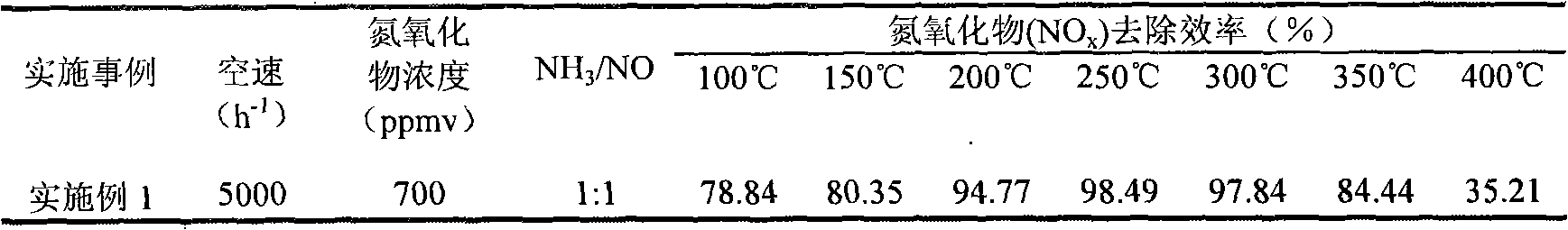

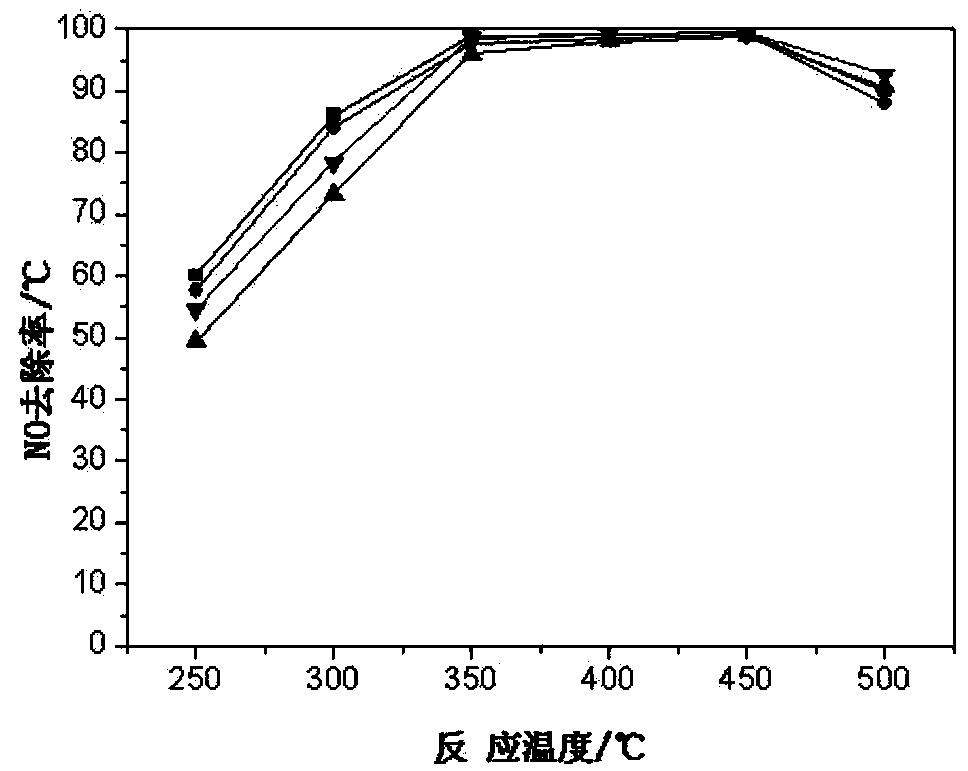

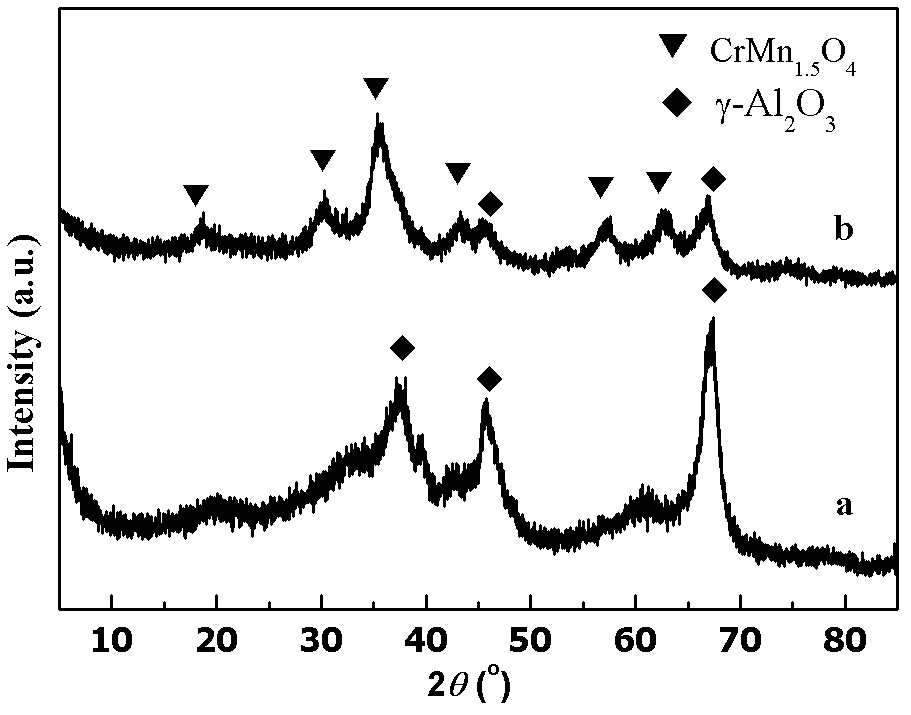

High-activity and strong-sulfur-resistance catalyst for selectively catalytically reducing NOx (Nitrogen Oxide) at low temperature

InactiveCN102350342BHigh activityHigh activity under high sulfur conditionsMolecular sieve catalystsDispersed particle separationPtru catalystNitrogen oxides

The invention discloses a high-activity and strong-sulfur-resistance catalyst for selectively catalytically reducing NOx (Nitrogen Oxide) at a low temperature as well as a preparation method and application thereof. The catalyst is a supported catalyst which is provided with a CrMn1.5O4 active crystal phase and comprises the following components in percentage by weight: 10-30% of chromium manganese oxide and 70-90% of porous carrier. The preparation method of the catalyst comprises the following steps of: dissolving chromium and manganese metal salts into a citric acid solution; immersing theporous carrier into the mixed solution; raising temperature and agitating until water is evaporated to obtain a mixture; drying the mixture at a temperature of 100-150 DEG C and then roasting the mixture at a temperature of 500-650 DEG C for 2-5 hours; milling the roasted mixture and sieving to obtain the catalyst. In the invention, the low-temperature activity of the catalyst prepared by using the method is better, the efficient removal of the NOx can be realized at a temperature of 180 DEG C and an air speed of 30000 h<-1>, and the removal rate is more than 90%. In the presence of SO2 with high concentration, the sulfur resistance of the catalyst is better.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com