High-activity and strong-sulfur-resistance catalyst for selectively catalytically reducing NOx (Nitrogen Oxide) at low temperature

A technology of catalyst and sulfur resistance, which is applied in the field of selective catalytic reduction to remove NOx at low temperature and catalyst with high sulfur resistance and its preparation. It can solve the problems of no reactivity and achieve strong resistance to sulfur poisoning and cost reduction. , cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of catalyst

[0024] (1) Preparation of chromium-manganese impregnation solution:

[0025] Add 8.08g of chromium nitrate and 7.42g of manganese acetate into 25mL of citric acid solution with a concentration of 1mol / L, and stir at room temperature for 3 hours to obtain a mixed solution;

[0026] (2) Impregnation of the carrier:

[0027] Using solution impregnation method, take 10g γ-Al 2 o 3 The carrier is immersed in the mixed solution obtained in step (1), and the temperature is raised to 60° C., while stirring continuously until all the water is evaporated to obtain a mixture;

[0028] (3) Activation of samples:

[0029]Dry the mixture obtained in step (2) at 100°C for 12 hours, and bake at 650°C for 5 hours;

[0030] (4) Forming of the catalyst:

[0031] The sample obtained in step (3) is pressed into tablets under a pressure of 10 kPa, and then ground and sieved to obtain 40-60 mesh particles to obtain the catalyst.

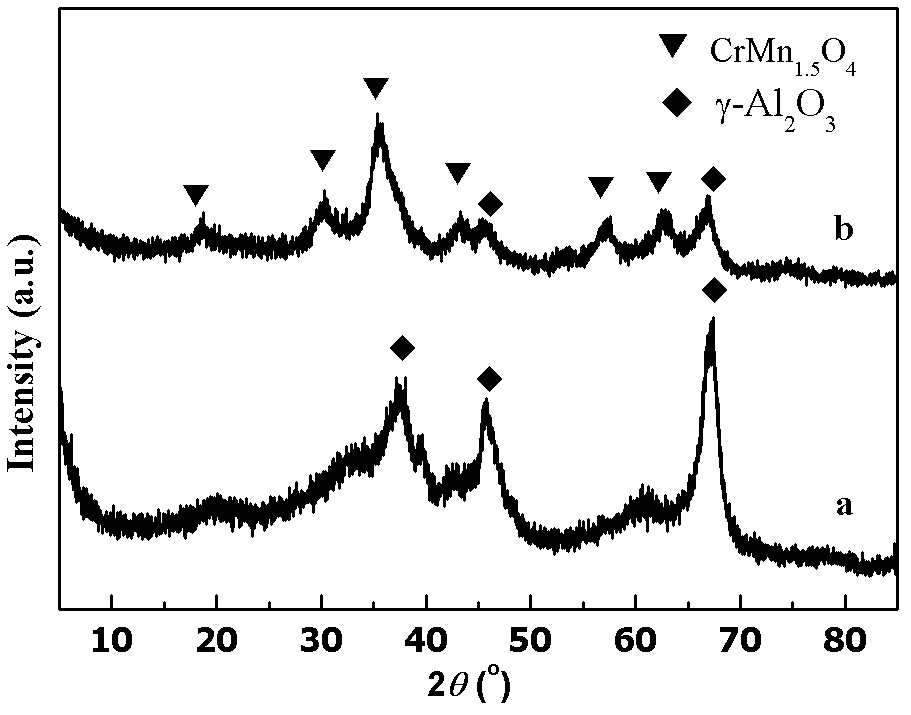

[0032] The X-ray diffracti...

Embodiment 2

[0036] The catalyst prepared in Example 1 was used for NO x Reaction, the reaction temperature is controlled at 120°C, and simulated flue gas is introduced: NO 1000ppm, NH 3 1000ppm, N 2 For balance. The total gas flow rate is 860mL·min -1 , Airspeed 10000h -1 , NO after stabilization x The conversion rate is 87.8%. Raise the reaction temperature to 360 °C, after stabilization, NO x The conversion rate is 92.7%.

Embodiment 3

[0038] Get the catalyst prepared in embodiment 1 and be used for NO x For removal reaction, the reaction temperature is controlled at 160°C, and simulated flue gas is introduced: NO 1000ppm, NH 3 1000ppm, N 2 For balance. The total gas flow rate is 860mL·min -1 , airspeed 30000h -1 . SO 2 Concentration increased to 200ppm to detect NO x removal efficiency, NO after 6 hours x The conversion rate was 83.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com