CrXCo3-XO4 spinel type catalyst and preparation method thereof

A spinel-type catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as poor methane oxidation effect and unsatisfactory tail gas purification effect, and achieve outstanding methane oxidation ability , Abundant raw materials, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

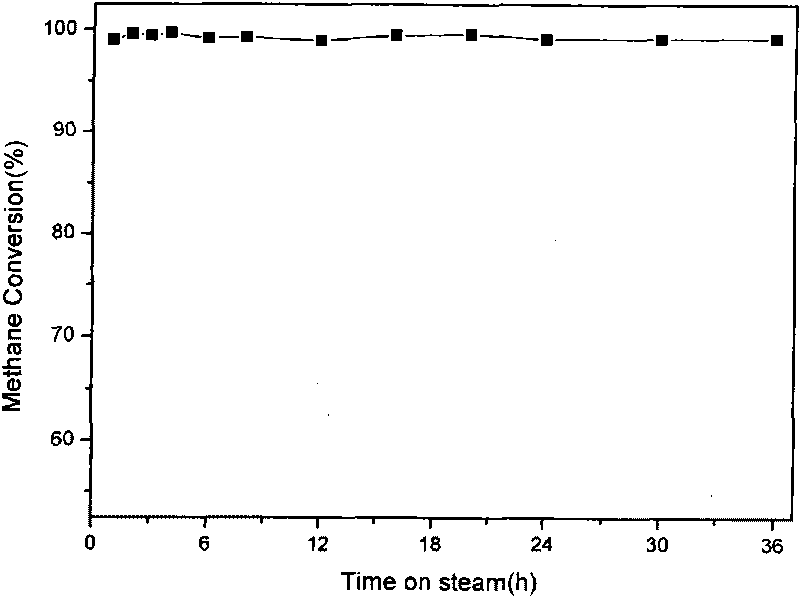

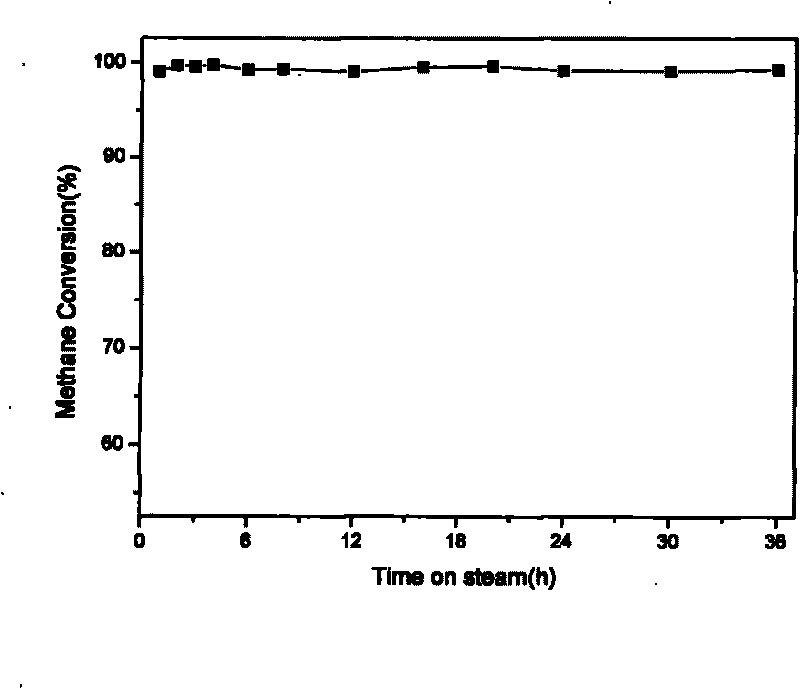

Image

Examples

Embodiment 1

[0014] Example 1: Cr 0.5 co 2.5 o 4 (X=0.5) Preparation of Catalyst

[0015] A kind of Cr used for purification of exhaust gas of natural gas vehicles X co 3-X o 4 Spinel type catalyst, characterized in that: spinel AB is composed of cobalt element in positive divalent 2 o 4 In the A position of the structure, the chromium element or the chromium element and the positive trivalent cobalt element together constitute the B position; wherein: X=0.5; the positive divalent cobalt element, the positive trivalent cobalt element and chromium in the series of catalysts The molar ratio of elements to oxygen is 1:2:4. Through crystal phase analysis, the spinel structure in the catalyst accounts for 95%.

[0016] A kind of Cr used for purification of exhaust gas of natural gas vehicles X co 3-X o 4 The preparation method of spinel type catalyst, concrete steps are as follows:

[0017] 1. Prepare respectively 0.75mol / L chromium nitrate solution and 0.75mol / L cobalt nitrate solu...

Embodiment 2

[0021] Example 2: CrCo 2 o 4 (X=1.0) Preparation of Catalyst

[0022] A kind of Cr used for purification of exhaust gas of natural gas vehicles X co 3-X o 4 Spinel-type catalyst, composed of cobalt element with positive divalent value, spinel AB 2 o 4 In the A position of the structure, the chromium element or the chromium element and the positive trivalent cobalt element together constitute the B position; wherein: X=1.0; the positive divalent cobalt element, the positive trivalent cobalt element and chromium in the series of catalysts The molar ratio of elements to oxygen is 1:2:4. Through crystal phase analysis, the spinel structure in the catalyst accounts for 98%.

[0023] A kind of Cr used for purification of exhaust gas of natural gas vehicles X co 3-X o 4 The preparation method of spinel type catalyst, concrete steps are as follows:

[0024] 1. Prepare respectively 0.5mol / L chromium nitrate solution and 1.0mol / L cobalt nitrate solution with deionized water; ...

Embodiment 3

[0028] Example 3: Cr 2 CoO 4 (X=2.0) Preparation of Catalyst

[0029] A kind of Cr used for purification of exhaust gas of natural gas vehicles X co 3-X o 4 Spinel-type catalyst, composed of cobalt element with positive divalent value, spinel AB 2 o 4 In the A position of the structure, the chromium element or the chromium element and the positive trivalent cobalt element together constitute the B position; where: X=2.0; the positive divalent cobalt element, the positive trivalent cobalt element and chromium in the series of catalysts The molar ratio of elements to oxygen is 1:2:4. Through crystal phase analysis, the spinel structure in the catalyst accounts for 99%.

[0030] A kind of Cr used for purification of exhaust gas of natural gas vehicles X co 3-X o 4 The preparation method of spinel type catalyst, concrete steps are as follows:

[0031] 1. Prepare respectively 1.0mol / L chromium nitrate solution and 0.5mol / L cobalt nitrate solution with deionized water;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com