VOCs (voltaic organic chemical) catalytic combustion catalyst with anti-sulfur poisoning function and preparation method thereof

A catalytic combustion and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of high cost and complicated catalyst preparation process, and achieve cost Low, excellent anti-sulfur poisoning ability, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

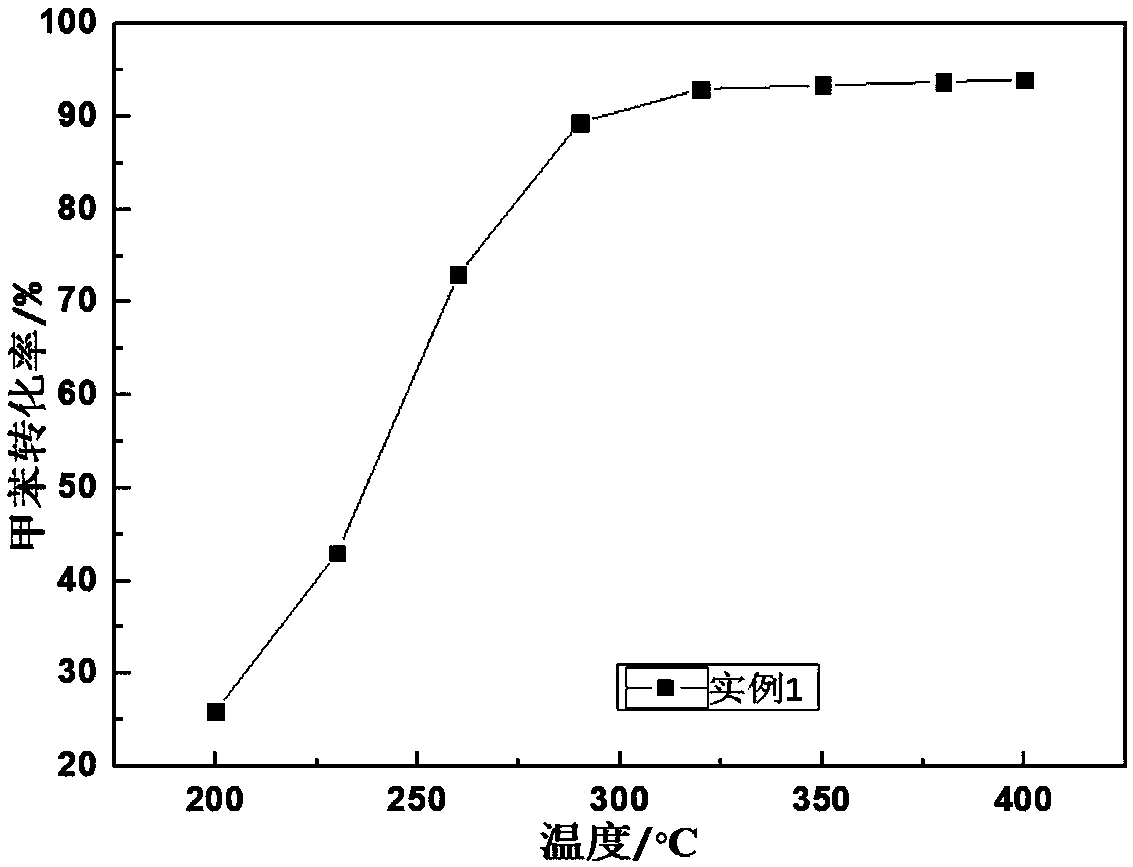

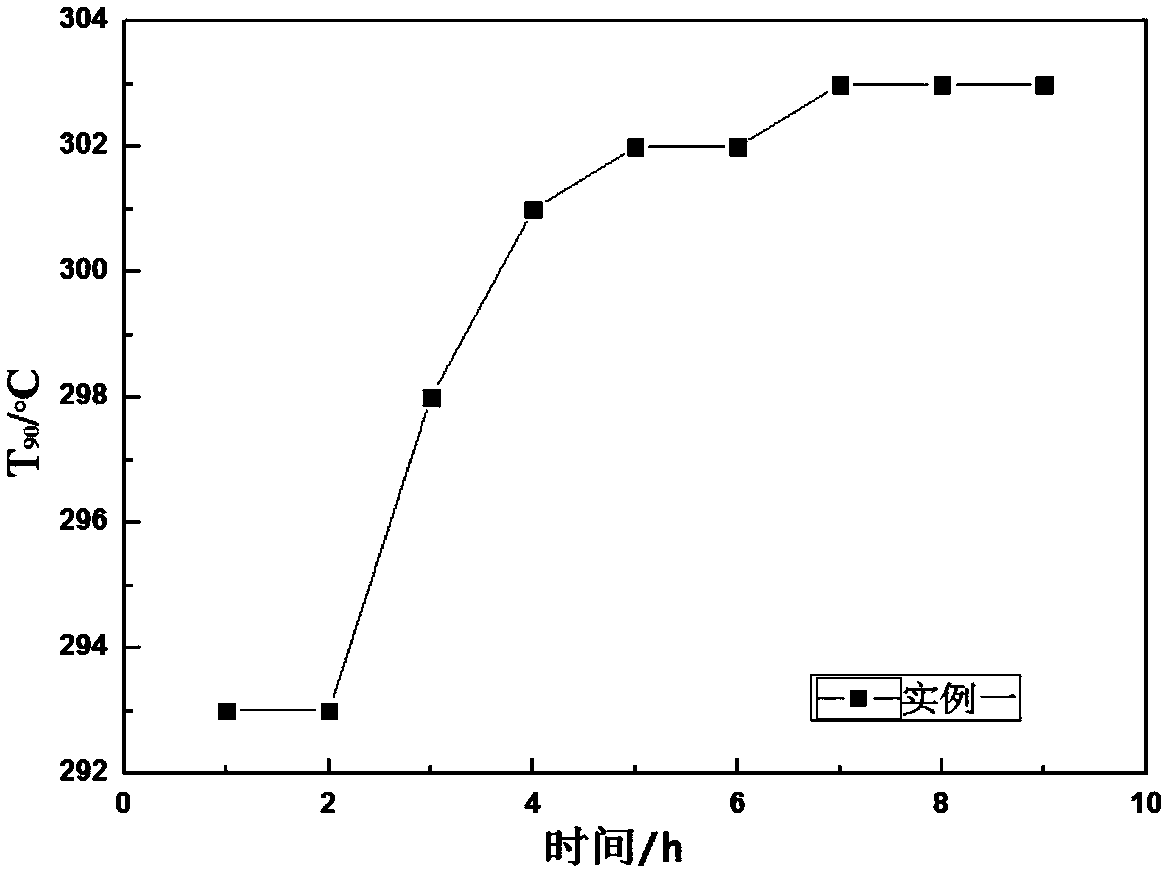

Examples

Embodiment 1

[0024] Preparation:

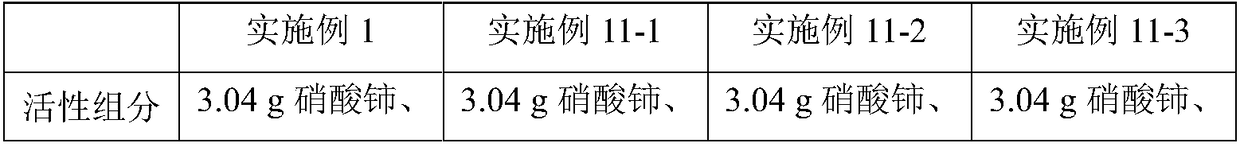

[0025] (1) Preparation of active components

[0026] Weigh 3.04g of cerium nitrate, 0.89g of antimony acetate, 0.75g of copper nitrate and 1.75g of cobalt nitrate according to the molar ratio of 0.7:0.3:0.4:0.6 and dissolve them in 25.8g of absolute ethanol, stir well to obtain mixed active component solution Ⅰ ;

[0027] (2) Co-catalyst precursor ion solution configuration

[0028] Weigh 1.28g of tetrabutyl titanate and 0.79g of zirconium oxychloride, dissolve in 9.15g of absolute ethanol, and stir evenly to obtain co-catalyst precursor solution II;

[0029] (3) Mix the active component solution prepared in step (1) with the co-catalyst precursor solution prepared in step (2), and stir evenly to obtain solution III;

[0030] (4) Weigh 40.5g TiO 2 , blended with solution Ⅲ, according to: the mass ratio of active component oxides: promoter oxides: carrier oxides is 0.08:0.015:1, prepare catalyst samples, dry in an oven at 80°C for 5h, and place in a ...

Embodiment 2

[0033] Preparation:

[0034] (1) Preparation of active components

[0035] Weigh and dissolve 2.83g of cerium sulfate, 1.27g of ethylene glycol antimony, and 1.88g of copper nitrate in 18.0g of absolute ethanol according to the molar ratio of 0.7:0.3:1, and stir evenly to obtain mixed active component solution I;

[0036] (2) Co-catalyst precursor ion solution configuration

[0037] Weigh 0.73g of tetrabutyl titanate, dissolve it in 3.65g of absolute ethanol, and stir evenly to obtain co-catalyst precursor solution II;

[0038] (3) Mix the active component solution prepared in step (1) with the co-catalyst precursor solution prepared in step (2), and stir evenly to obtain solution III;

[0039] (4) Weigh 17.2g TiO 2, blended with solution Ⅲ, according to: the mass ratio of active component oxide: promoter oxide: carrier oxide is 0.1:0.01:1, prepare the catalyst sample, dry it in an oven at 100°C for 10h, and then place it in a muffle furnace for calcination at 550°C 3h, th...

Embodiment 3

[0042] Preparation:

[0043] (1) Preparation of active components

[0044] Weigh 2.22g of cerium acetate, 0.92g of antimony acetate, 0.32g of copper sulfate and 2.33g of cobalt nitrate according to the molar ratio of 0.7:0.3:0.2:0.8 and dissolve them in 23.16g of absolute ethanol, stir well to obtain mixed active component solution Ⅰ ;

[0045] (2) Co-catalyst precursor ion solution configuration

[0046] Weigh 1.09g of zirconium oxychloride, dissolve it in 6.06g of absolute ethanol, and stir evenly to obtain co-catalyst precursor solution II;

[0047] (3) Mix the active component solution prepared in step (1) with the co-catalyst precursor solution prepared in step (2), and stir evenly to obtain solution III;

[0048] (4) Weigh 20.9g TiO 2 , blended with solution Ⅲ, according to: the mass ratio of active component oxides: promoter oxides: carrier oxides is 0.15:0.02:1, prepare catalyst samples, dry in an oven at 90°C for 8 hours, and place them in a muffle furnace for cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com