Rare earth heteropoly acid salt doped iron-based catalyst and its application in flue gas denitrification

An iron-based catalyst and heteropoly acid salt technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve high cost and operating temperature, environmental and human poisoning, active component vanadium Toxic and other problems, to achieve the effect of strong anti-sulfur poisoning ability, less investment, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of Rare Earth Heteropolyacid Salt Doped Iron-Based Catalyst

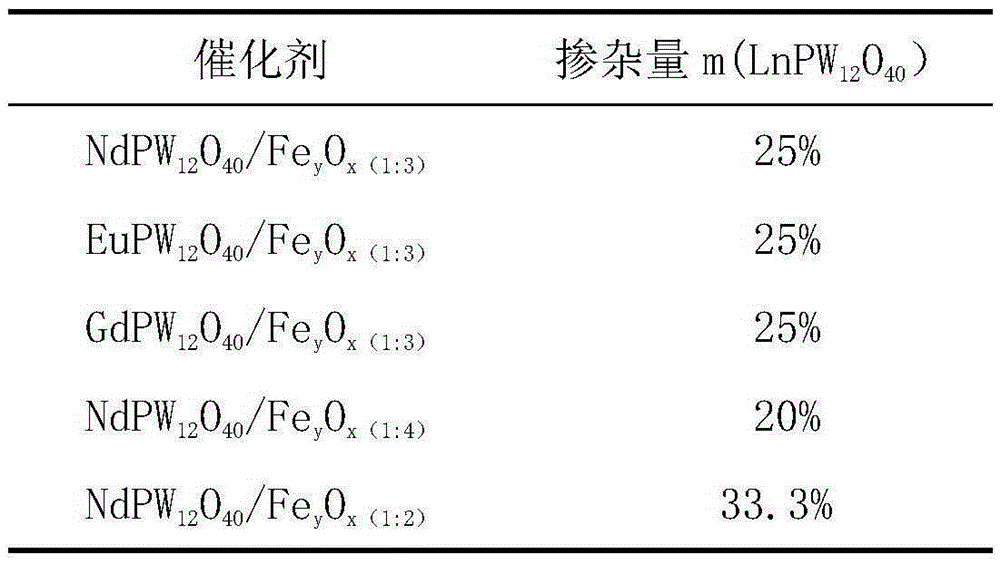

[0023] Rare earth heteropolyacid salt-doped iron-based catalyst, composed of rare earth heteropolyacid salt and iron oxide mechanically mixed, the mass ratio of rare earth heteropolyacid salt to iron oxide is 1:2, 1:3 or 1:4, including 5 kinds described in table 1. Its preparation method is as follows:

[0024] (1) Keggin structure rare earth phosphotungstate (LnPW 12 o 40 , Ln=Nd, Nd, Eu):

[0025] (1) Accurately weigh 8.964g (3.0mmol) of phosphotungstic acid, add 30ml 1+1 ethanol to dissolve it;

[0026] (2) Add excessive 10% rare earth nitrates under vigorous stirring at 75° C., and continue to react for 45 minutes; Salt);

[0027] (3) After the above reaction is completed, distill at normal pressure (remove ethanol and water, distill to 1 / 4 of the original volume), cool and crystallize naturally, filter, dry the filter cake at 120°C for 2h, and then roast at 300°C for 3h, namely...

Embodiment 2

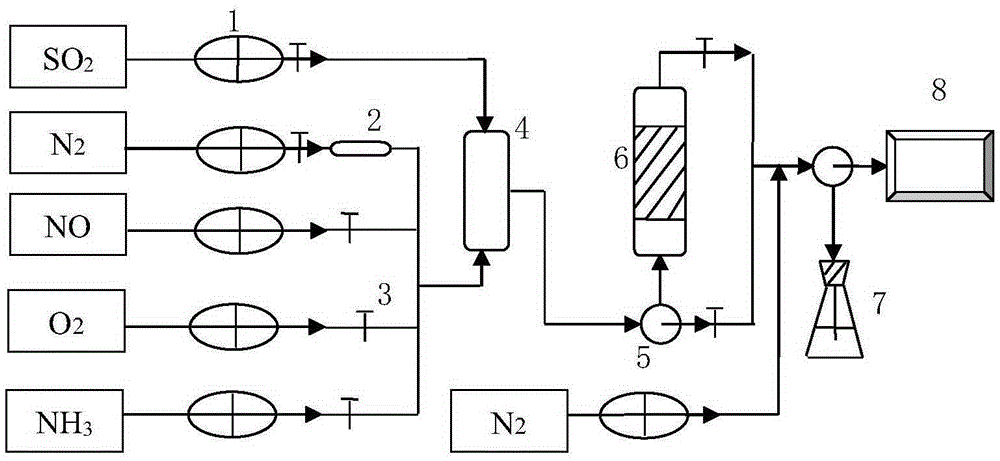

[0030] Embodiment 2 Phosphotungstic acid rare earth gadolinium salt doped iron-based catalyst (NdPW 12 o 40 / Fe y o x(1:3) ) denitrification activity test

[0031] Catalytic activity was evaluated by figure 1 The device shown is complete. A fixed-bed reactor was used, and the catalyst was loaded into a quartz reaction tube with an inner diameter of 8mm, and both ends were fixed with quartz wool, and placed in a tubular electric furnace to control the reaction temperature. The flue gas composition is simulated with cylinder gas, where NO x (NO+NO 2 ) concentration is 1050ppm, NH 3 The concentration is 1150ppm, O 2 The volume fraction is divided into 6%, and nitrogen is used as the balance gas. The total flow rate is 100ml / min, and the space velocity is 15000h -1 , each gas flow is controlled and regulated by a mass flow meter. NO and NO in the outlet gas 2 Content by TH-9905 type NO / NO 2 Analyzer determination. The reaction test temperature is within the range of ...

Embodiment 3

[0033] Embodiment 3 Phosphotungstic acid rare earth europium salt doped iron-based catalyst (EuPW 12 o 40 / Fe y o x(1:3) ) denitrification activity test

[0034] Catalytic activity was evaluated by figure 1 The device shown is complete. NO in simulated flue gas x (NO+NO 2 ) concentration is 1050ppm, NH 3 The concentration is 1150ppm, O 2 The volume fraction is divided into 6%, and nitrogen is used as the balance gas. The total flow rate is 100ml / min, and the space velocity is 15000h -1 , The reaction test temperature is 150 ~ 400 ℃. The conversion rate of nitrogen oxides was 44.7%, 69.9%, 99.6%, 100%, 100% and 85.6% respectively when the bed temperature was 150°C, 200°C, 250°C, 300°C, 350°C and 400°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com