A composite metal sulfate system flue-gas-denitration catalyst and a preparation method thereof

A denitrification catalyst and composite metal technology, applied in the field of environmental protection catalytic materials and air pollution control, can solve the problems of not having water resistance and sulfur resistance, achieve excellent resistance to sulfur poisoning, and maintain the effect of denitrification activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

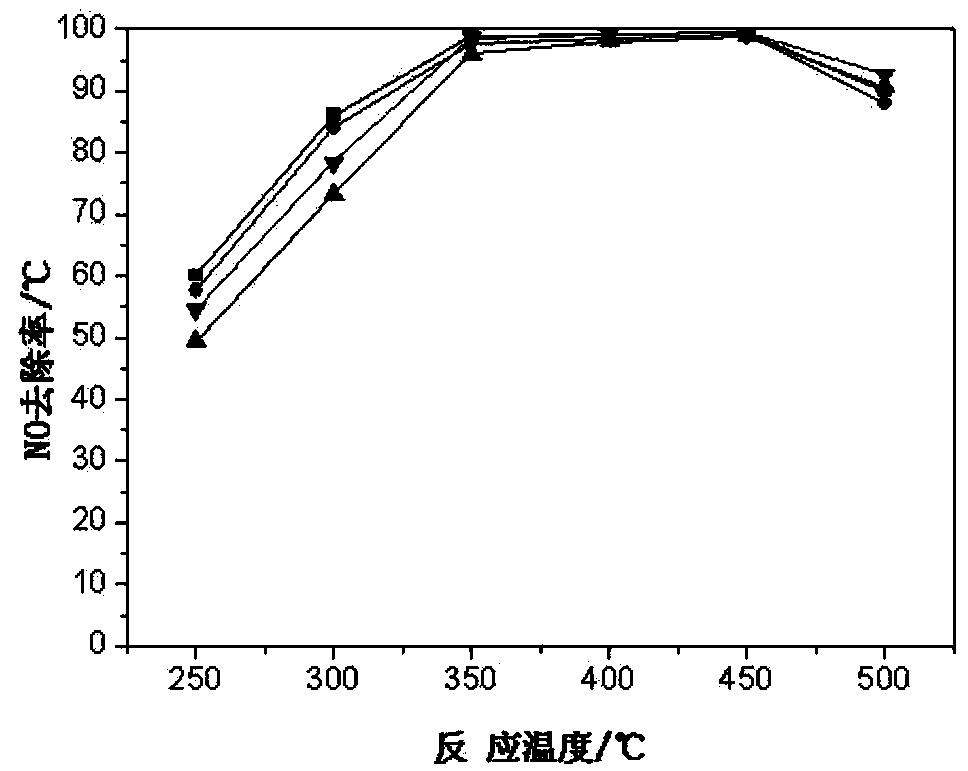

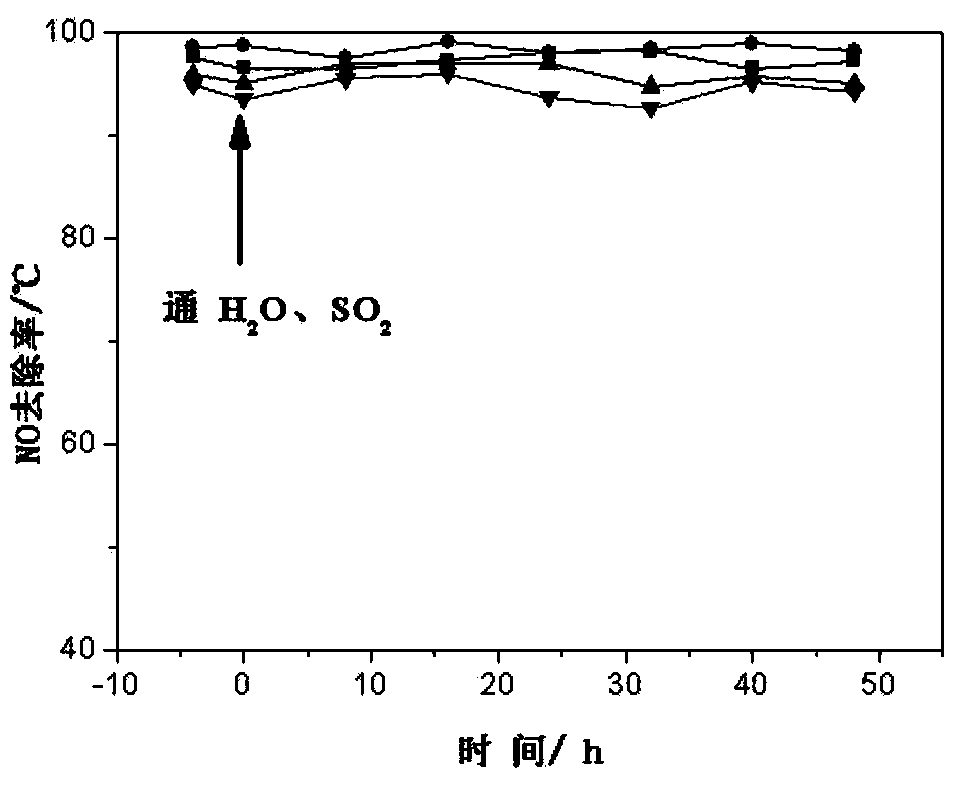

Examples

Embodiment 1

[0026] (1) Preparation of active component impregnation solution

[0027] 1.95g Ce(SO 4 ) 2 4H 2 O was dissolved in a certain amount of deionized water to obtain Ce(SO 4 ) 2 solution, to the Ce(SO 4 ) 2 The solution was mixed with 1.09g NiSO 4 ·6H 2 O was stirred and dissolved to obtain a stable solution with a sulfate mass fraction of 6.1%. In addition, the same Ce(SO 4 ) 2 The solution was mixed with 0.72g MnSO 4 ·H 2 O, 1gCuSO 4 ·5H 2 O, 0.64g SnSO 4 A stable solution was obtained.

[0028] (2) Loading of active components

[0029] Add 20 g of TiO to the above active solution 2 The carrier was stirred at 70°C for 2 hours with a magnetic stirrer, and viscous slurry was obtained after the water in the solution was evaporated;

[0030] (3) Catalyst molding and roasting

[0031] The above viscous slurry is stale for 24 hours, then extruded into a long strip with a diameter of 3mm through a vacuum extruder, dried at 80°C for 10h, and finally baked in a muffle f...

Embodiment 2

[0035] (1) Preparation of active component impregnation solution

[0036] 0.24g Ce(SO 4 ) 2 4H 2 O was dissolved in a certain amount of deionized water to obtain Ce(SO 4 ) 2 solution, and then doped with 0.31g NiSO 4 ·6H 2 O stirring and dissolving, obtaining sulfate massfraction is 5.5% stable solution;

[0037] (2) Loading of active components

[0038] Add 20 g of TiO to the above active solution 2 The carrier was stirred at 80°C for 1 hour with a magnetic stirrer, and viscous slurry was obtained after the water in the solution was evaporated;

[0039] (3) Catalyst molding and roasting

[0040] The above viscous slurry is stale for 30 hours, then extruded into a strip shape with a diameter of 3mm through a vacuum extruder, dried at 70°C for 8 hours, and finally baked in a muffle furnace at 400°C for 5 hours to obtain the flue gas SCR DeNOx catalyst with TiO 2 Carrier quality as the benchmark, in which the active component Ce(SO 4 ) 2 The mass percentage is 1%, a...

Embodiment 3

[0044] (1) Preparation of active component impregnation solution

[0045] 0.61g Ce(SO 4 ) 2 4H 2 O was dissolved in a certain amount of deionized water to obtain Ce(SO 4 ) 2 solution, then add 0.25g SnSO 4 , stirring and dissolving to obtain a sulfate mass fraction of 7.8% stable solution;

[0046] (2) Loading of active components

[0047] Add 20 g of TiO to the above active solution 2 The carrier was stirred at 90°C for 3 hours with a magnetic stirrer, and a viscous slurry was obtained after the water in the solution was evaporated;

[0048] (3) Catalyst molding and roasting

[0049] The above viscous slurry is stale for 40 hours, then extruded into a strip shape with a diameter of 3mm through a vacuum extruder, dried at 100°C for 10h, and finally baked in a muffle furnace at 550°C for 4 hours to obtain the flue gas SCR DeNOx catalyst with TiO 2 Carrier quality as the benchmark, in which the active component Ce(SO 4 ) 2 The mass percentage is 2.5%, and the mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com