Reutilization method of inactivated SCR denitration catalyst

A denitration catalyst and catalyst technology, which are applied in the field of environmental protection technology and denitration catalysis, can solve the problems of a regenerated catalyst that cannot obtain low-temperature flue gas according to demand, an unsatisfactory removal effect of catalyst surface deposits, and a low catalyst activity, so as to reduce SO2 oxidation. efficiency, realize resource utilization, and improve the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

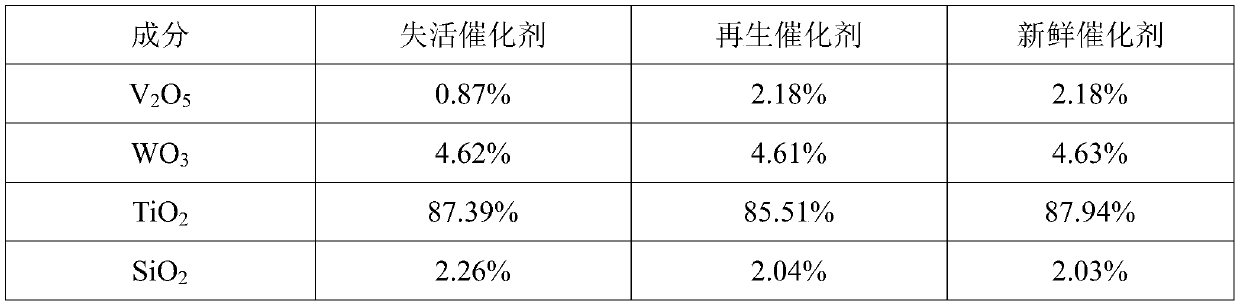

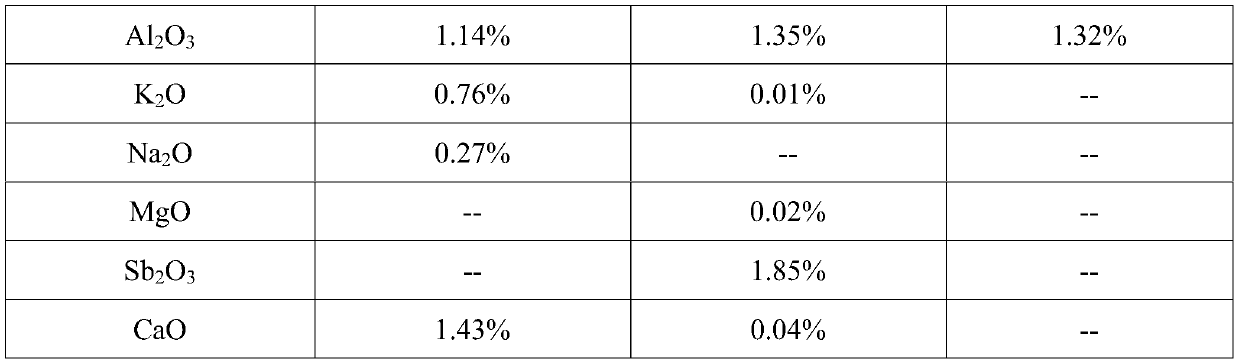

[0025] The deactivated denitrification catalyst was selected from a coal-fired power plant in Southwest China after 24000 hours of V 2 o 5 -WO 3 / TiO 2 Honeycomb SCR denitrification catalyst.

[0026] 1) Deashing: Blow the catalyst with dry and clean compressed air to remove the ash on the surface of the catalyst and in the pores;

[0027] 2) cleaning: at first the catalyst after purging is put into containing 0.1wt% Pingpinga, 2wt% hydroxypropyl methylcellulose, 1wt% diammonium hydrogen phosphate, 1wt% sodium lignosulfonate, 1wt% polyacrylic acid ( Molecular weight: 3000) in the cleaning solution, bubbling and cleaning 2 times, the cleaning time is 6h / time; then the catalyst after cleaning is put into the aqueous solution containing 0.2mol / L ethylene glycol and 5mol / L sulfuric acid for heat treatment, at 60 ℃ for 24 hours; after the reaction, put the catalyst into deionized water and wash it 3 times by bubbling, and the cleaning time is 4 hours each time; the washed catal...

Embodiment 2

[0037] The deactivated denitrification catalyst is selected from a coal-fired power plant in Southwest China after 20000 hours of V 2 o 5 -WO 3 / TiO 2 Flat-plate SCR denitration catalyst.

[0038] 1) Deashing: Blow the catalyst with dry and clean compressed air to remove the ash on the surface of the catalyst and in the pores;

[0039] 2) Cleaning: first put the purged catalyst into a mixture containing 0.5wt% Pingpinga, 0.2wt% hydroxypropyl methylcellulose, 4wt% diammonium hydrogen phosphate, 4wt% sodium lignosulfonate, 0.2wt% poly In the cleaning solution of acrylic acid (molecular weight: 6000), bubbling and cleaning 2 times, the cleaning time is 5h / time; then the catalyst after cleaning is put into an aqueous solution containing 2mol / L ethylene glycol and 1mol / L sulfuric acid for heat treatment, and then React at 80°C for 6 hours; after the reaction, put the catalyst into deionized water and wash it 3 times by bubbling, and the cleaning time is 4 hours each time; the w...

Embodiment 3

[0048] The deactivated denitrification catalyst was selected from a coal-fired power plant in Southwest China after 22000 hours of V 2 o 5 -MoO 3 / TiO 2 Flat-plate SCR denitration catalyst.

[0049] 1) Deashing: Blow the catalyst with dry and clean compressed air to remove the ash on the surface of the catalyst and in the pores;

[0050] 2) Cleaning: first put the purged catalyst into a mixture containing 0.3wt% Pingpinga, 1wt% hydroxypropyl methylcellulose, 2wt% diammonium hydrogen phosphate, 3wt% sodium lignosulfonate, 0.5wt% polyacrylic acid (Molecular weight: 6000) in the cleaning solution, bubble cleaning 2 times, cleaning time 4h / time; Then the catalyst after cleaning is put into the aqueous solution that contains 1mol / L ethylene glycol and 3mol / L sulfuric acid and heat treatment, at 60 ℃ for 12 hours; after the reaction, put the catalyst into deionized water and wash it 3 times by bubbling, and the cleaning time is 3 hours each time; the washed catalyst can be dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com