Plate type denitration catalyst and preparation method thereof

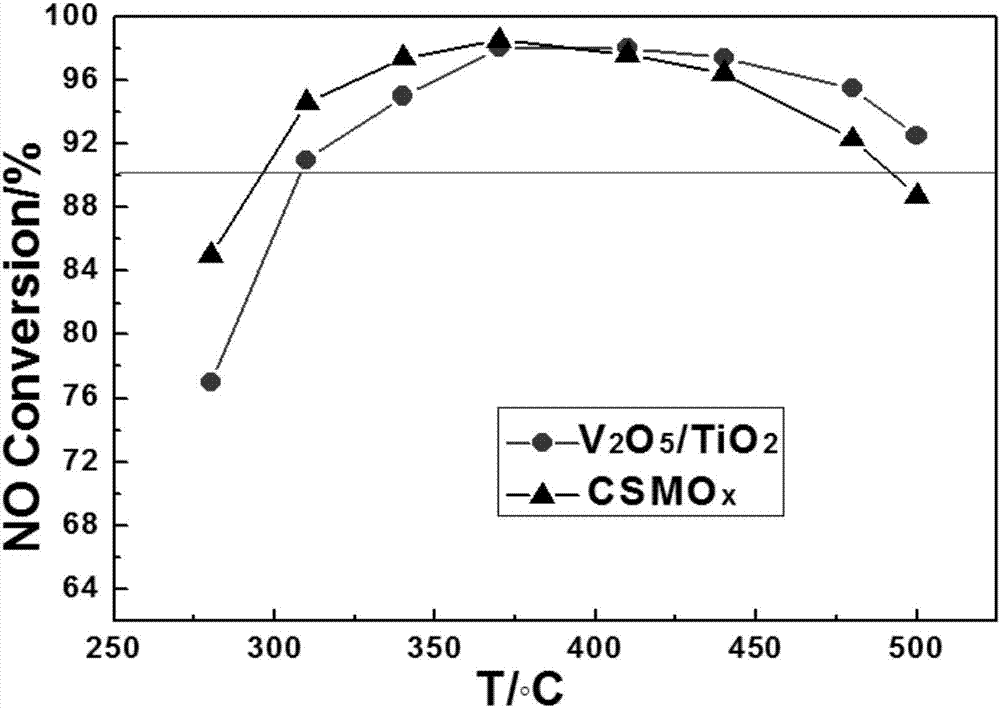

A denitrification catalyst and co-catalyst technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of poor anti-poisoning performance, achieve high mechanical strength, excellent anti-sulfur poisoning ability, and excellent anti-sulfur poisoning performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] (1) Preparation of cerium-antimony-molybdenum composite oxide precursor

[0037] Weigh 2.52g of cerium nitrate, add 2.27g of deionized water, dissolve and stir evenly at 80°C to obtain solution A;

[0038] Weigh 0.41g antimony nitrate, add 0.82g ethylene glycol solution, dissolve and stir evenly to obtain solution B;

[0039] Weigh 0.61g of ammonium heptamolybdate and 0.61g of citric acid monohydrate, add 3.05g of deionized water, dissolve and stir evenly to obtain solution C;

[0040] Drop solution C into solution A, add solution B dropwise to the mixed solution after mixing uniformly, and stir during the dropping process;

[0041] (2) Co-catalyst precursor ion solution configuration

[0042] Weigh 0.7g of cobalt nitrate and 0.07g of citric acid monohydrate, add 2.8g of deionized water; then stir evenly until the solution is clear to prepare the promoter of the promoter;

[0043] (3) Preparation of carrier

[0044] Weigh 19g of titanium dioxide and 1g of clay powder and mix them ev...

example 2

[0051] (1) Preparation of cerium-antimony-molybdenum composite oxide precursor

[0052] Weigh 3.78g of cerium nitrate, add 3.40g of deionized water, dissolve and stir evenly at 90°C to obtain solution A;

[0053] Weigh 0.82g of antimony nitrate, add 0.82g of ethylene glycol solution, dissolve and stir evenly to obtain solution B;

[0054] Weigh 0.92g of ammonium heptamolybdate and 1.00g of citric acid monohydrate, add 3.00g of deionized water, dissolve and stir evenly to obtain solution C;

[0055] Drop solution C into solution A, add solution B dropwise to the mixed solution after mixing uniformly, and stir during the dropping process;

[0056] (2) Co-catalyst precursor ion solution configuration

[0057] Weigh 0.82g of ammonium metatungstate and 0.82g of citric acid monohydrate, add 2g of deionized water; then stir evenly until the solution is clear, to prepare the promoter precursor;

[0058] (3) Preparation of carrier

[0059] Weigh 15g of titanium dioxide and 5g of clay powder and mix...

example 3

[0066] (1) Preparation of cerium-antimony-molybdenum composite oxide precursor

[0067] Weigh 2.68g of cerium oxalate, add 2.68g of deionized water, and dissolve and stir evenly at 80°C to obtain solution A;

[0068] Weigh 0.41g of antimony nitrate, add 0.45g of ethylene glycol solution, dissolve and stir evenly to obtain solution B;

[0069] Weigh 0.61g of ammonium heptamolybdate and 0.61g of citric acid monohydrate, add 3.01g of deionized water, dissolve and stir evenly to obtain solution C;

[0070] Drop solution C into solution A, add solution B dropwise to the mixed solution after mixing uniformly, and stir during the dropping process;

[0071] (2) Co-catalyst precursor ion solution configuration

[0072] Weigh 1.05g of lanthanum nitrate and 0.11g of citric acid monohydrate, add 2.8g of deionized water; then stir evenly until the solution is clear, to prepare the cocatalyst precursor;

[0073] (3) Preparation of carrier

[0074] Weigh 10g of titanium dioxide and 10g of clay powder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com