Patents

Literature

53results about How to "Wide active temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polynary metal oxide catalyst and preparing process thereof

ActiveCN101199933AHigh activityHigh low temperature activityCatalyst carriersCombined combustion mitigationCerium(IV) oxideManganese

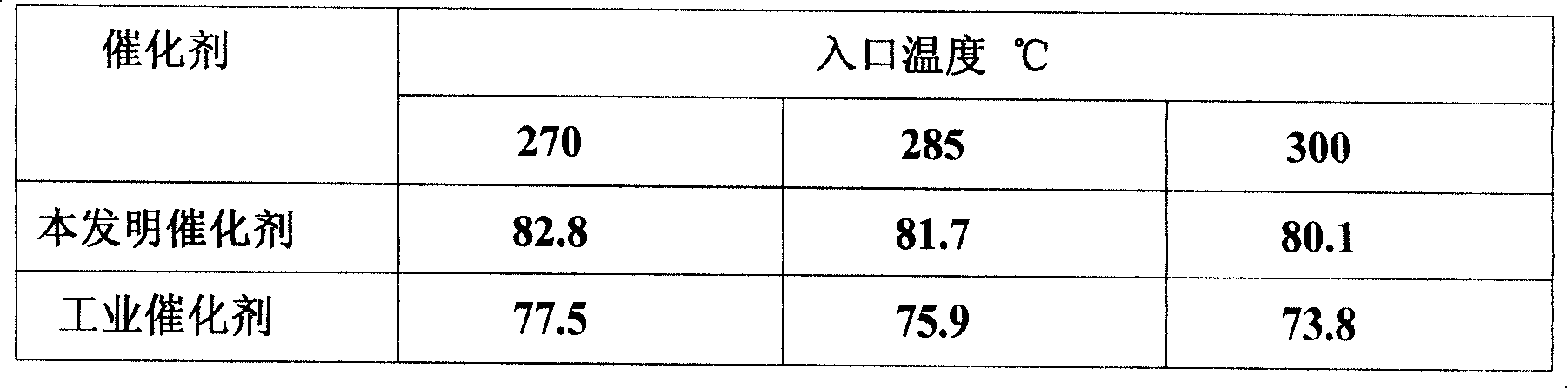

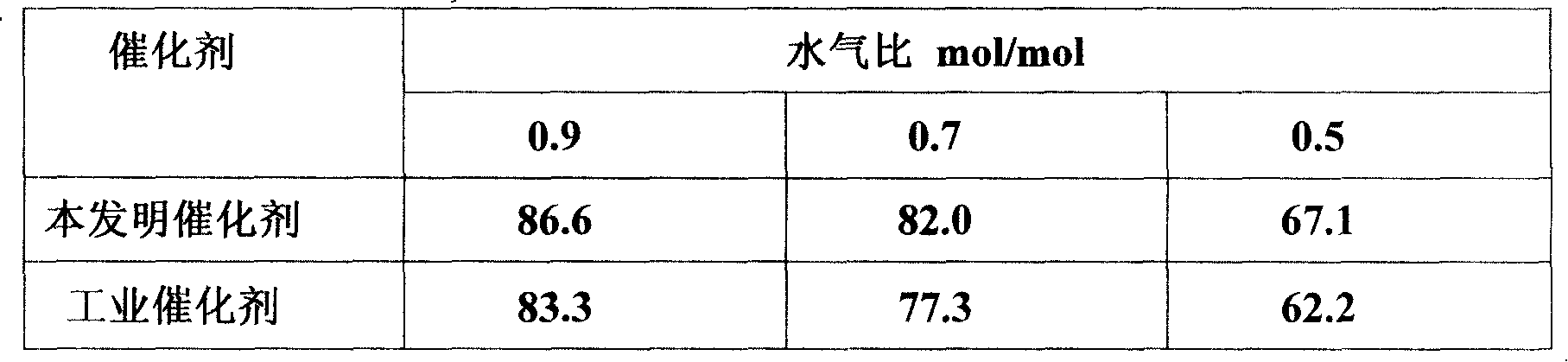

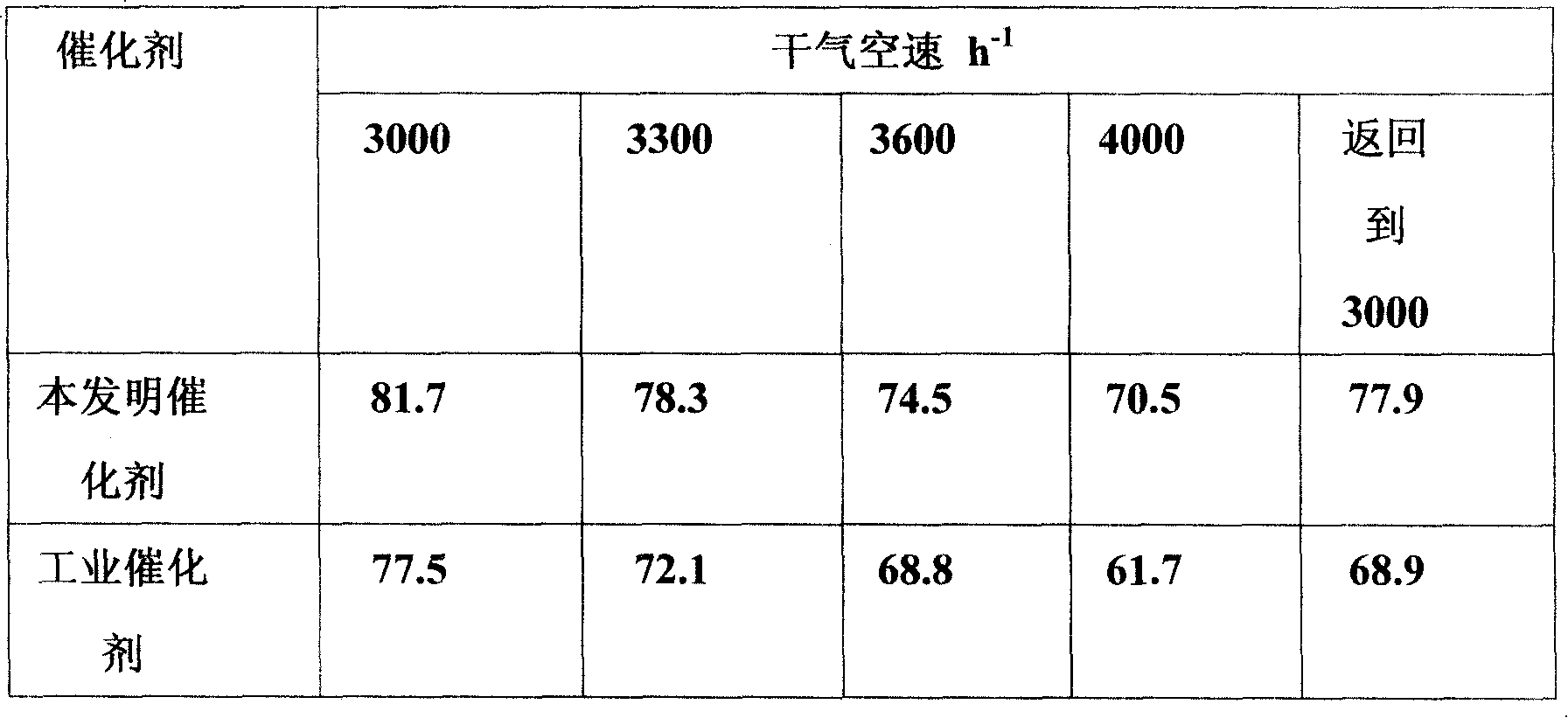

The invention discloses a multi-complex-metal-oxides catalyst and the preparation method. The catalyst carrier is multi-complex-metal-oxides solid alkali or surface solid alkali or the precursors of the solid alkali or surface solid alkali. The multi-complex-metal-oxides is complex oxides by combining two or more than two selections from alumina, titania, zirconium dioxide and ceria with one or more than one selections from magnesia, calcium oxide, baryta, potassium oxide and sodium oxide. Active ingredient is composed of cobalt oxides or / and nickel oxide and molybdenum trioxide or / and tungsten trioxide. The additive added to carriers or active components is the oxide of at least one of the following elements: cerium, lanthanum, zinc, zirconium, nickel or manganese. The invention has the advantages of high activity, high activity at low-temperature, high activity stability and wide temperature range of activity; high intensity, high intensity stability and high anti-hydration and anti-pulverization ability, wide water / gas ratio adaptability and wide range for impurity content. The catalyst of the invention is applied to the promotion of dirty water gas shift reaction.

Owner:汤海溶 +2

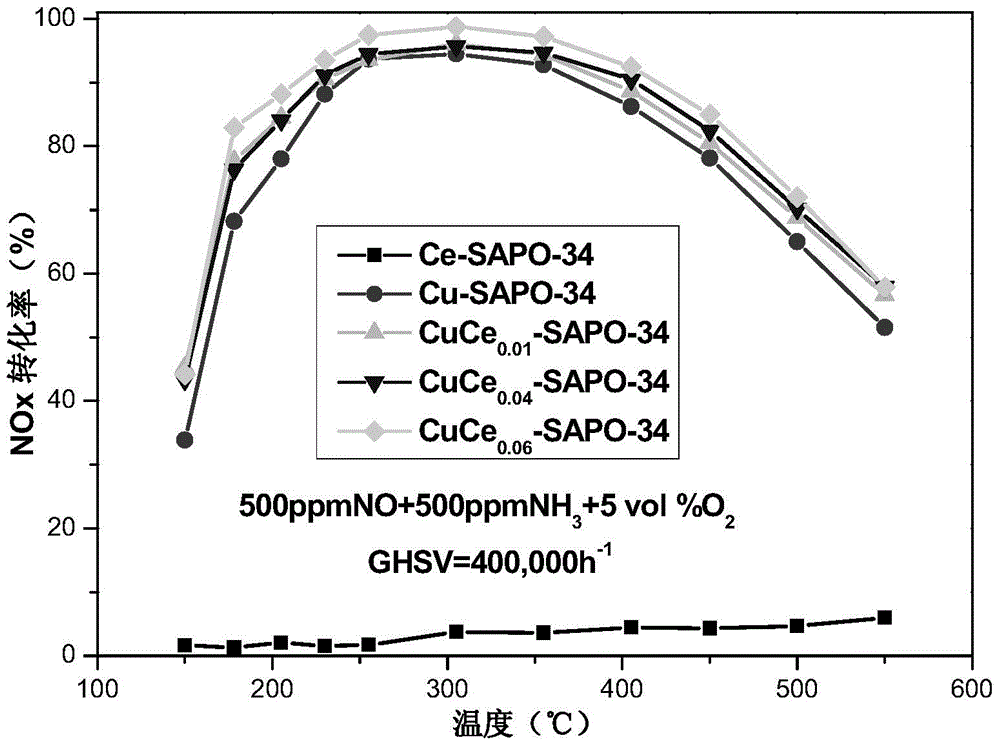

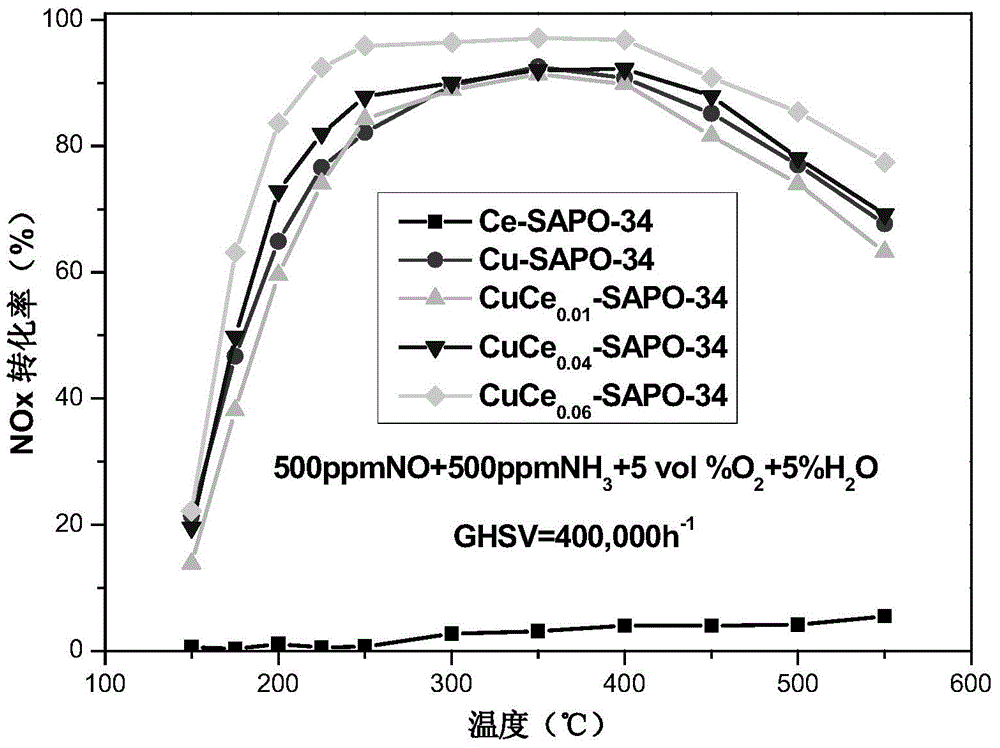

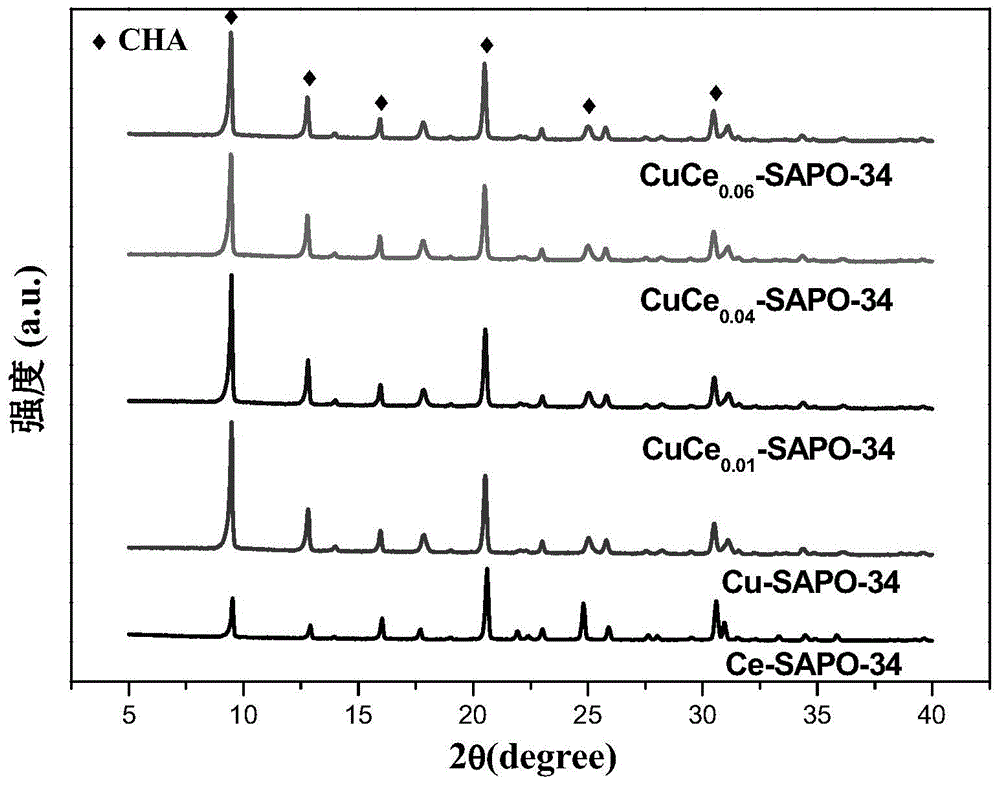

CuCe-SAPO-34 molecular sieve catalyst, as well as preparation method and use thereof

InactiveCN104888851ANo ion exchange step requiredReduce generationMolecular sieve catalystsDispersed particle separationGas phaseCerium

The invention provides a CuCe-SAPO-34 molecular sieve catalyst, as well as a preparation method and use thereof. The method comprises the following steps: adding pseudo-boehmite in deionized water, stirring, then adding ortho-phosphoric acid and fumed silica, uniformly mixing, then adding copper salt and tetraethylenepentamine, sufficiently mixing, adding cerate and n-propylamine, loading the completely mixed gel in a hydrothermal reaction kettle to crystallize, cooling at room temperature, separating the solid crystallized product from the mother liquor, washing to neutral, drying, and roasting in air to obtain the CuCe-SAPO-34 molecular sieve catalyst. The CuCe-SAPO-34 molecular sieve catalyst is prepared through the adoption of the hydrothermal synthesis method, and the molecular sieve catalyst with excellent NH3-SCR catalytic activity and water resistance is obtained by adjusting the loading amount of cerium through the control of the input of the cerate.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

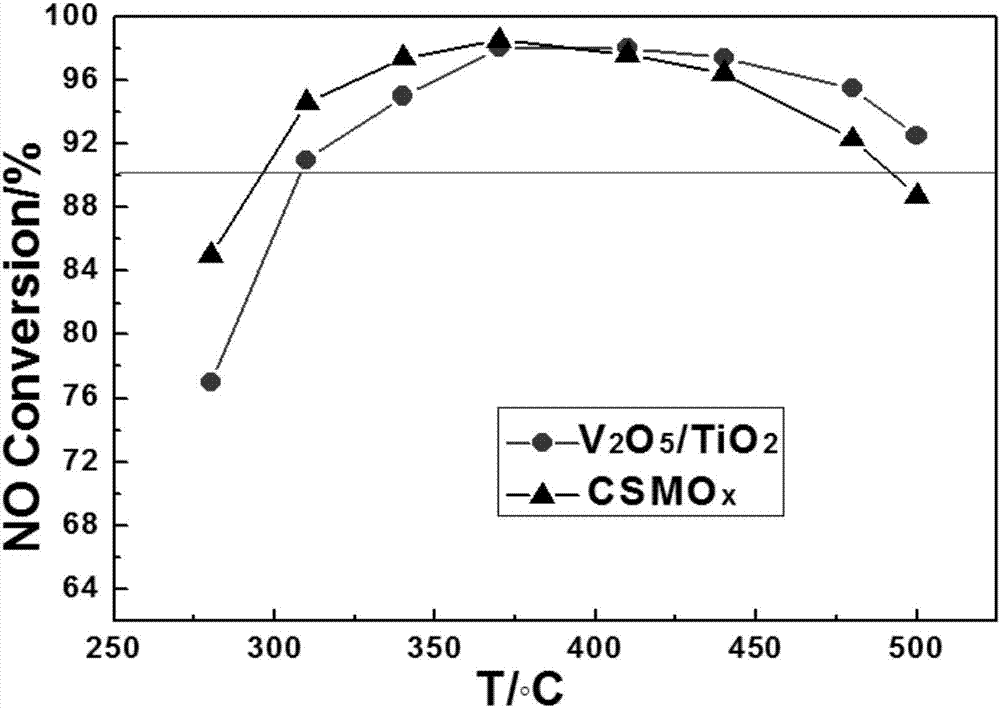

Catalyst for removing nitrogen oxide through selective catalytic reduction for Ce2O3 and V2O5 double active composition diesel truck

InactiveCN101559363ALow biological toxicityFacilitate catalytic reactionsInternal combustion piston enginesDispersed particle separationTraffic conditionsDiesel engine

The invention relates to a catalyst for removing nitrogen oxide through selective catalytic reduction for an automobile diesel engine adopting Ce2O3 and V2O5 double active compositions. The catalyst adopts scordierite honeycomb ceramics as a framework material, the Ce2O3 and the V2O5 as main active compositions, WO3 or MoO3 as an auxiliary catalyst composition, and TiO2 as a coating substrate, wherein the mass fraction of the main active compositions, namely the Ce2O3 and the V2O5, to the auxiliary catalyst composition WO3 or MoO3 to the coating substrate TiO2 is 1-3:6:12:85-93. The specific process comprises the following steps: preparing a TiO2 precursor solution; coating a TiO2 coating; coating an auxiliary catalyst; determining the loading of active compositions of oxides; and coating the main active compositions, namely the Ce2O3 and the V2O5. The catalyst replaces the V2O5 with high toxicity with the Ce2O3 with low toxicity, and reduces the environmental hazards of the catalyst, and the replaced catalyst has wider active temperature range, particularly greatly improves the low-temperature activity, and is particularly suitable for the traffic conditions of urban highways of China.

Owner:TIANJIN UNIV

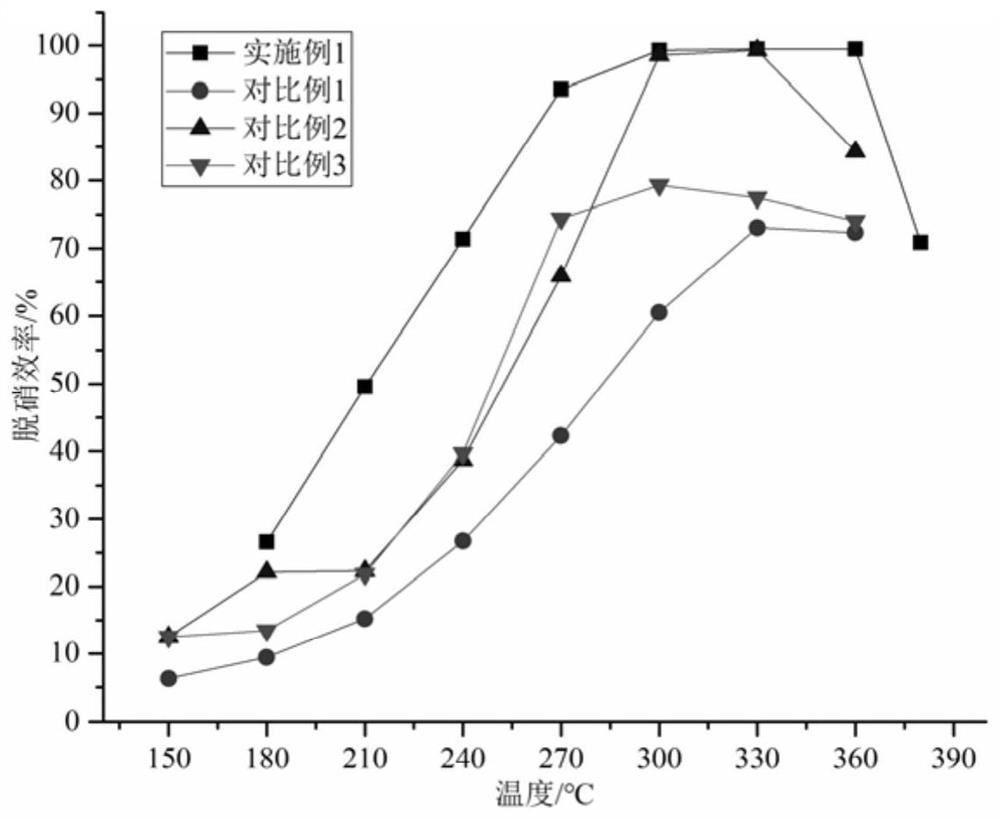

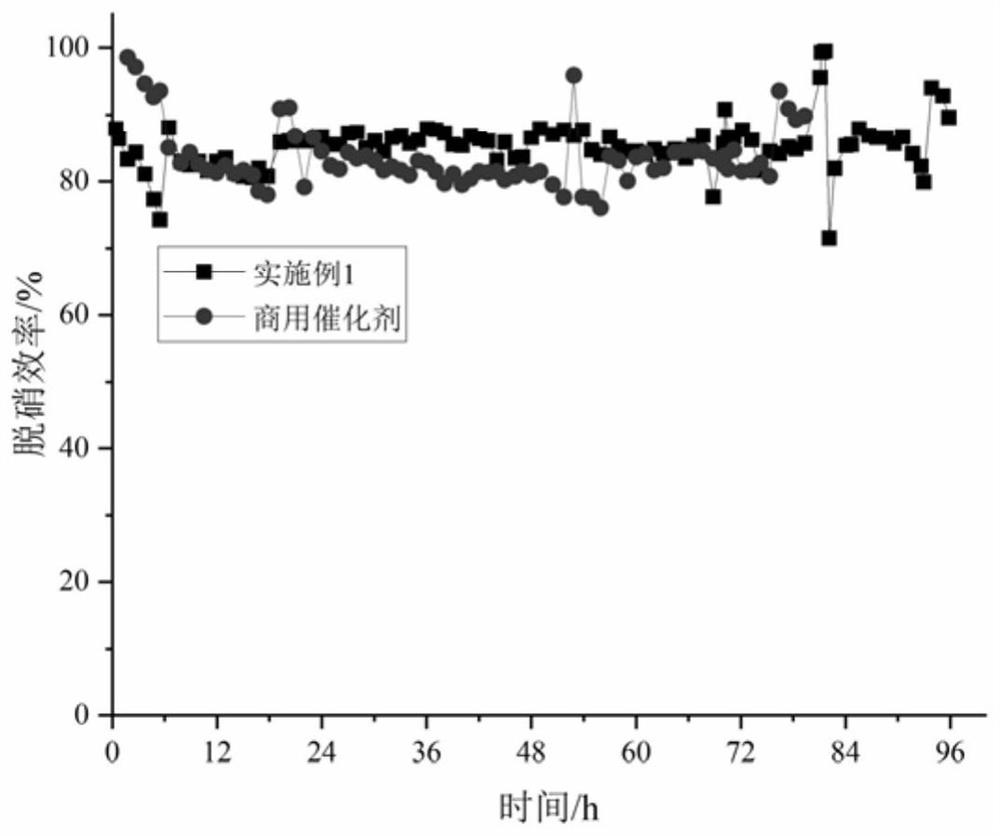

Flue gas denitrification catalyst with wide activity temperature interval as well as preparation method thereof

InactiveCN103894182AWide active temperature rangeGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentFlue gas

The invention discloses a flue gas denitrification catalyst with a wide activity temperature interval as well as a preparation method thereof. The flue gas denitrification catalyst comprises 65%-99.8% of carrier TiO2, 0.1%-10% of active component V2O5, 0.1%-10% of active component WO3 and 0.1%-15% of valence-variation metallic oxide. According to the invention, a ball mill is adopted for enabling the VWTiO2 catalyst and the valence-variation metal element oxide to be fully mixed mechanically, simplifies the technological process, reduces the energy consumption, and prevents the environment pollution; the prepared flue gas denitrification catalyst has a wide activity temperature interval and high capability of NOx removing activity and SO2 and H2O toxication resistance.

Owner:北京宏庚环保科技有限公司

Plate type denitration catalyst and preparation method thereof

InactiveCN107224979AWide active temperature rangeLow costGas treatmentDispersed particle separationSulfurActive component

The invention relates to a plate type denitration catalyst and a preparation method of the catalyst and belongs to the field of environment-friendly catalysis material and air pollution control. A cerium-antimony-molybdenum composite oxide serves as a catalytic active component; a tungsten, cobalt or lanthanum oxide serves as a promoter; a titanium dioxide and argil mixing component serves as a major carrier; mass percentages of the cerium-antimony-molybdenum composite oxide and the promoter oxide are 8-20% and 1-3% respectively by taking the mass of the titanium dioxide and argil mixing component carrier as a reference. The denitration activity of the catalyst reaches 98.5% or above, and the catalyst has excellent sulfur poisoning resistance.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

Supported copper-manganese-water-gas shift catalyst and preparation method thereof

ActiveCN102688765AHigh crystallinityConducive to loadHydrogenCatalyst activation/preparationLow loadHeat stability

The invention discloses a supported copper-manganese-water-gas shift catalyst and a preparation method thereof. The method comprises the following steps: enabling the copper-manganese mixed liquid and precipitator to flow in parallel for coprecipitation in a reactor in which the modified bauxite is pre-placed; ageing, filtering, drying and roasting after precipitation so as to obtain the supported copper-manganese-water-gas shift catalyst which adopts the modified bauxite as the carrier, wherein the component of the supported copper-manganese-water-gas shift catalyst is CuO and copper-manganese composite oxide. The general formula of the composite oxide is Cu(1+x)Mn(2-x)O4, wherein x is not greater than 0 and smaller than 0.6. According to the invention, the rich bauxite resource in our country is fully utilized to prepare the copper-manganese-water-gas shift catalyst which has high activity, high heat-resistant stability, low load and wide active temperature area and overcomes the shortcoming of bad heat stability and narrow active temperature area of the copper-based catalysts.

Owner:FUZHOU UNIV

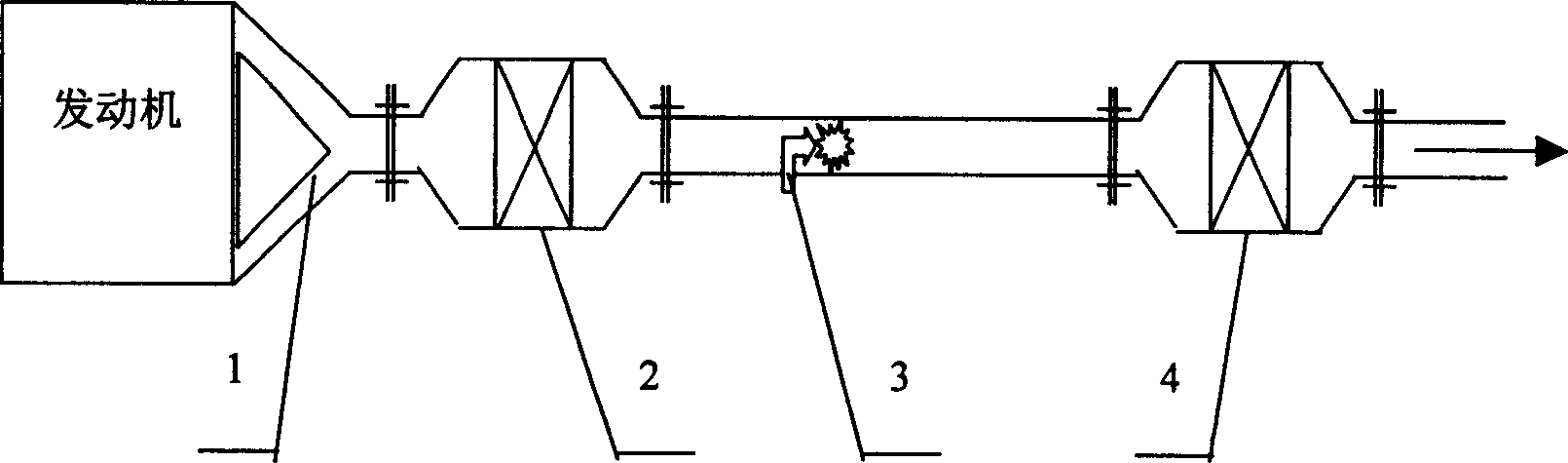

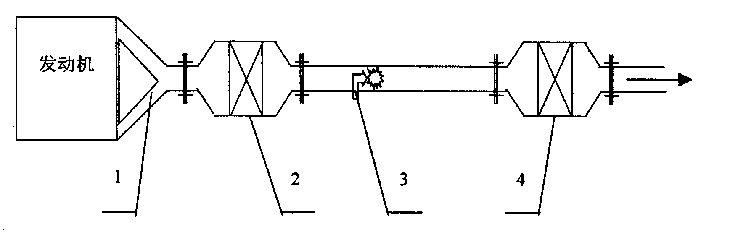

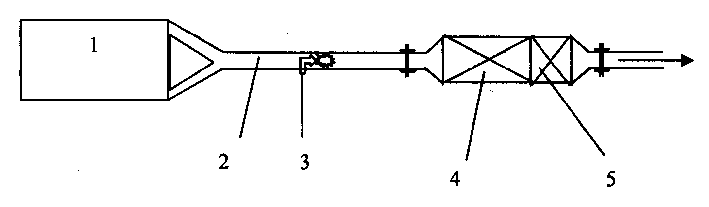

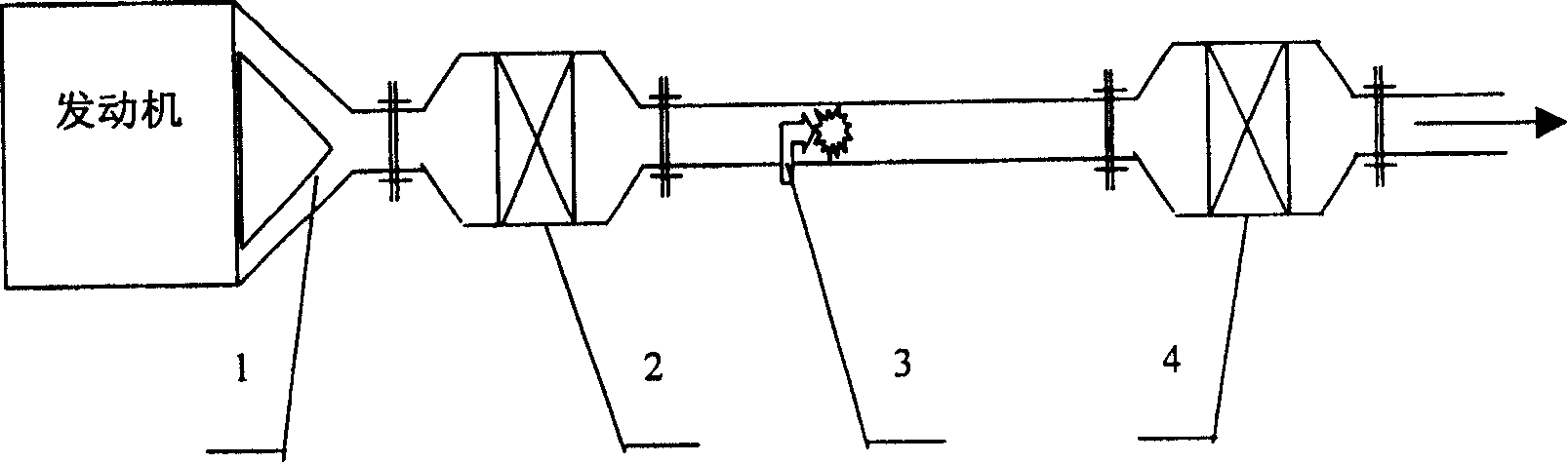

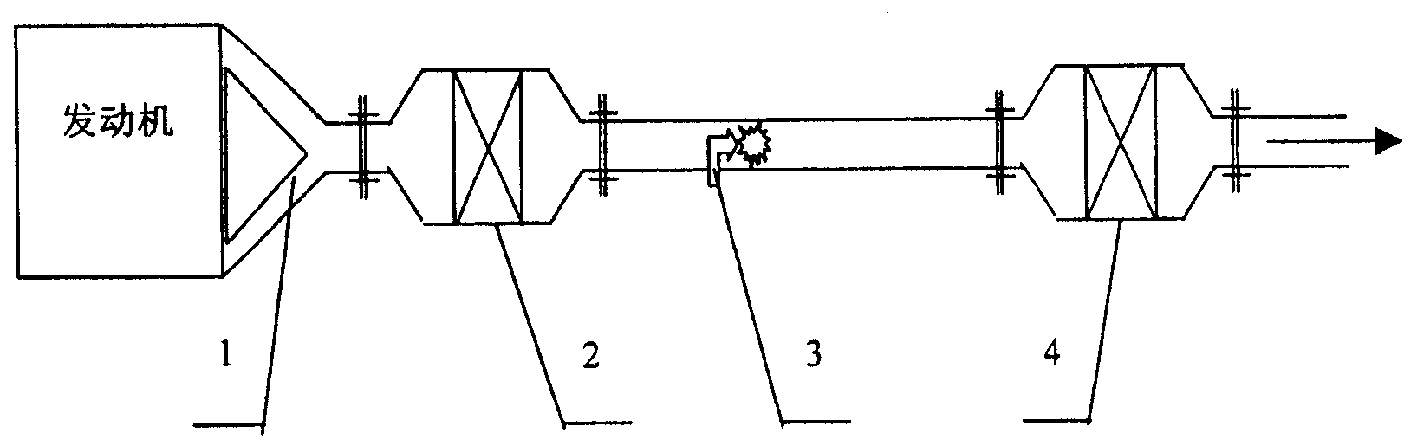

Rarefied-burning automobile exhaust gas catalyzing and purifying method and apparatus

InactiveCN1454701AEfficient purificationImprove purification efficiencyExhaust apparatusDispersed particle separationOxygen compoundCurrent technology

The invention is a kind of catalyst purifying method and device for tails of lean firing car. The invention sets two catalyzing reaction beds on the discharging pipe of the engine; there is an additional reducer nozzle in the middle of the two beds. The first bed uses hydrocarbon and carbon monoxide in tails to reduce nitrogen-oxygen compound, at the same time, the hydrocarbon and carbon monoxide are changed into carbon dioxide and water; the second bed uses the additional oxygen hydrocarbon reducer to reduce carbon-oxygen compound, at the same time, the additional reducer is changed into water and carbon dioxide. Compared with current technology scheme, it can spread the range of active temperature, enhances the purifying efficiency, takes advantage of hydrocarbon discharged by the engine and additional oxygen hydrocarbon.

Owner:TSINGHUA UNIV

Catalyst for simultaneous denitration, demercuration and dioxin removal and preparation method thereof

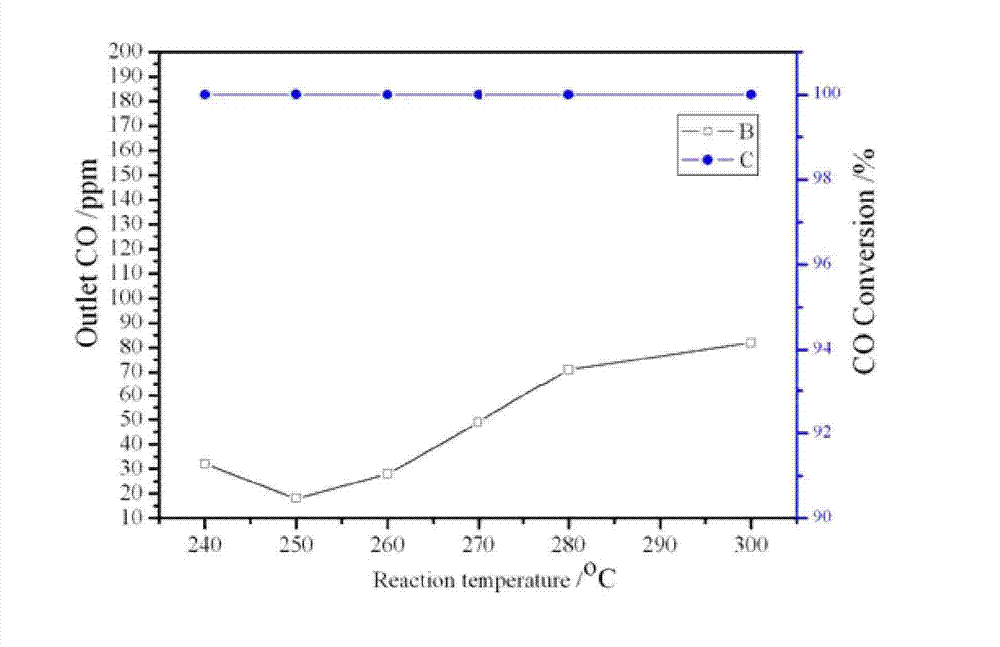

ActiveCN111167475AWide active temperature rangeStrong resistance to sulfur poisoningCatalyst carriersGas treatmentPtru catalystEngineering

The invention discloses a catalyst for simultaneous denitration, demercuration and dioxin removal and a preparation method thereof. According to the invention, cerium oxide and niobium pentoxide are used as catalytic active components, a mixture of nickel oxide and platinum nanoparticles is used as a cocatalyst, a titanium dioxide nanoneedle generated by modifying tetrabutyltitanate with hydrochloric acid is used as a main carrier, and the catalyst is used after hydrogen pretreatment. Based on the mass of the carrier, the mass percentage of the active components is 10%-30%, and the mass percentage of the cocatalyst is 0.1%-0.15%. The preparation method comprises the following steps: uniformly stirring the active components, a cocatalyst composite colloidal solution and the optimized and modified catalyst carrier, carrying out aging and extrusion molding, and then performing drying and roasting to obtain the catalyst. The catalyst is environment-friendly, can efficiently remove nitrate,mercury and dioxin at the same time, and has a wide active temperature interval and low SO2 oxidation efficiency. Within 240-500 DEG C, the denitration efficiency and the dioxin removal efficiency ofthe catalyst are both higher than 95%, and the mercury removal efficiency of the catalyst is higher than 99%. The catalyst can be widely applied to the fields of coal-fired power plants, chemical plants and the like.

Owner:南京环福新材料科技有限公司

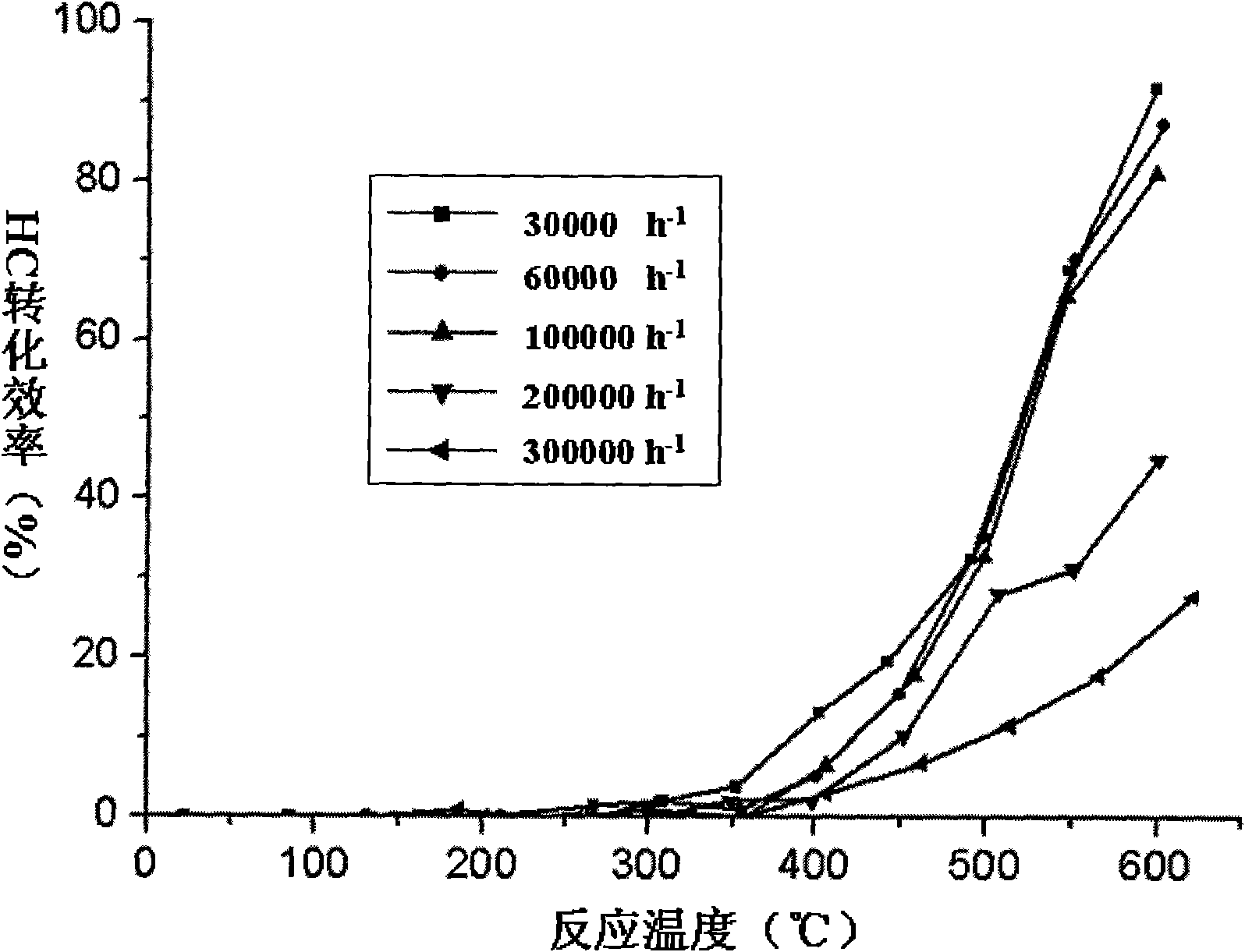

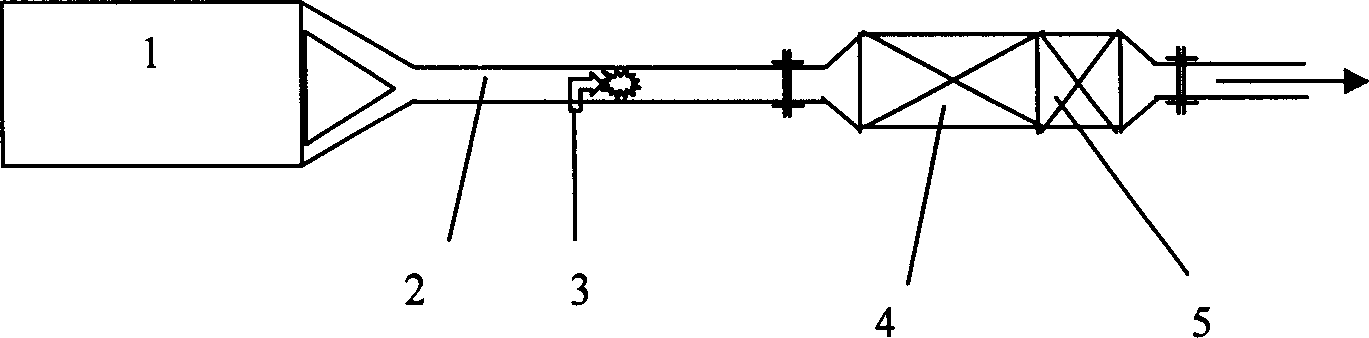

Fuel-lean vehicular engine exhaust gas catalyzing and purifying method

InactiveCN1454702AHigh NOx ConversionWide active temperature rangeInternal combustion piston enginesDispersed particle separationExhaust gasProduct gas

The invention is catalyst purifying method for tails discharged by fuel-lean car engine. The invention provides a method which applies to fuel-lean car engine, reduces NOx in tails efficiently in wide temperature range, and oxidizes HC and CO. The method includes following steps: sprays carbinol or alcohol into discharging pipe, and makes it blend with the engine tails; the mixed gas is transmitted to front grade catalyzing reaction bed which is loaded with transition metal oxide catalyst and the back grade catalyzing reaction bed which is loaded with laden noble metal catalyst, realizes the purification of NOx, HC and CO with high efficiency, and finally discharges normal gas. The invention can spread the range of NOx reduction active temperature.

Owner:TSINGHUA UNIV

Loaded nitrogen oxide purifying catalyst and its preparation

InactiveCN1470328AImprove thermal stabilityEasy to prepareMolecular sieve catalystsDispersed particle separationCopper oxideHigh activity

The invention is load nitrogen oxide clarifying catalyst and the manufacturing method. The character lies in that: it is special for clarifying nitrogen oxide of tail gas of diesel engine and rare combustion gasoline engine which load molybdenum and copper oxide on HZSM-5. the molecular expressing formula is: Cu-Mo / ZSM-5. the invention has following advantages: (1) initiative. (2) high activity. (3) the activity temperature region is wide. (4) high stability. (5) the method is simple and the cost is low.

Owner:TAIYUAN UNIV OF TECH

Preparation technology of catalyst used for high temperature catalytic decomposition of N2O

ActiveCN106391037AGood dispersionImprove heat resistanceNitrous oxide captureGas treatmentCooking & bakingCerium nitrate

The invention discloses a preparation technology of a catalyst used for high temperature catalytic decomposition of N2O. The preparation technology comprises the following steps: dissolving magnesium nitrate, cobalt nitrate, lanthanum nitrate, cerium nitrate, nickel nitrate and zirconium nitrate in water to form a mixed nitrate solution; adding ammonia water and aluminum hydroxide, and carrying out compacting, dehydrating, drying and baking to obtain a powder material; and uniformly rolling the powder material, desalinized water and a bonding agent, drying the rolled materials to obtain a granulation material, compacting the granulation material to form a porous cylinder, and calcining the porous cylinder to obtain the catalyst. The preparation technology has the following advantages: a co-precipitation method is selected, an active component reacts with a carrier substance precursor and a precipitating agent to realize co-precipitation, and the active component interacts with the carrier, so the active component is well and stably dispersed; and the active component and the carrier precipitate are commonly calcined at a high temperature of 1000-1300 DEG C, so the active component of the catalyst has good heat tolerance and difficulty loses, thereby the catalyst has the advantages of high efficiency, good stability and long service life.

Owner:四川蜀泰化工科技有限公司

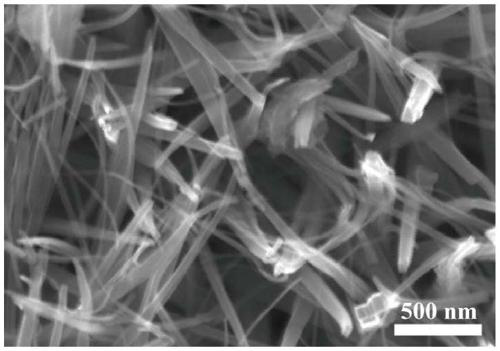

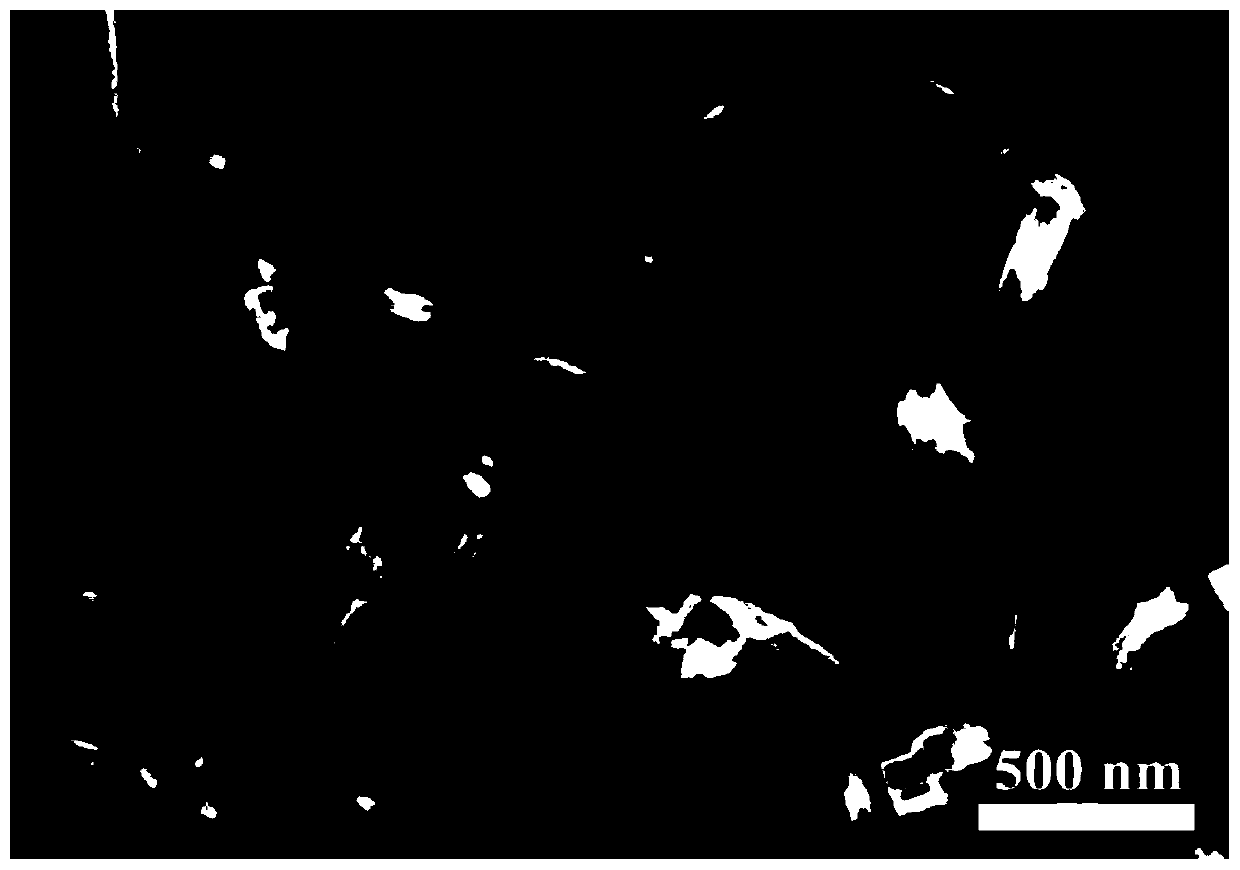

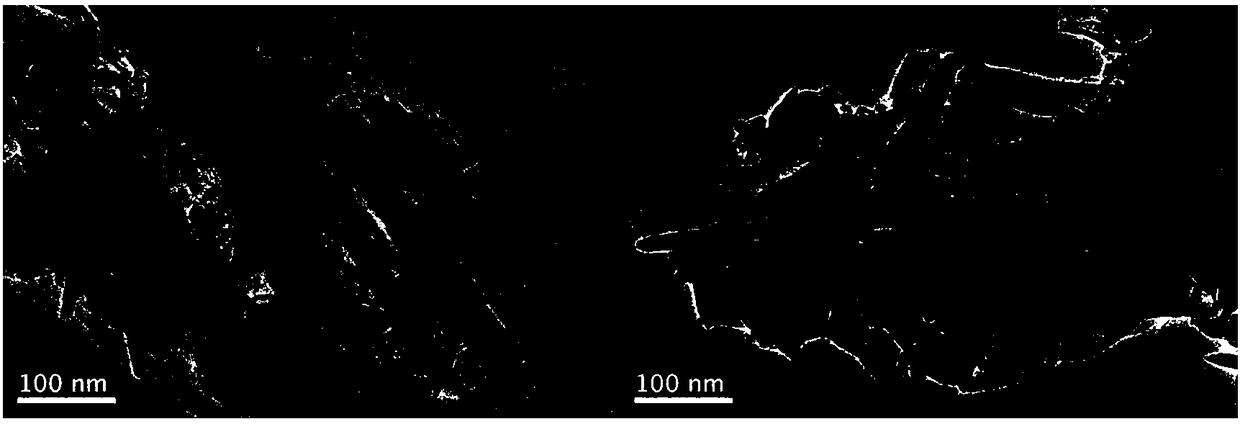

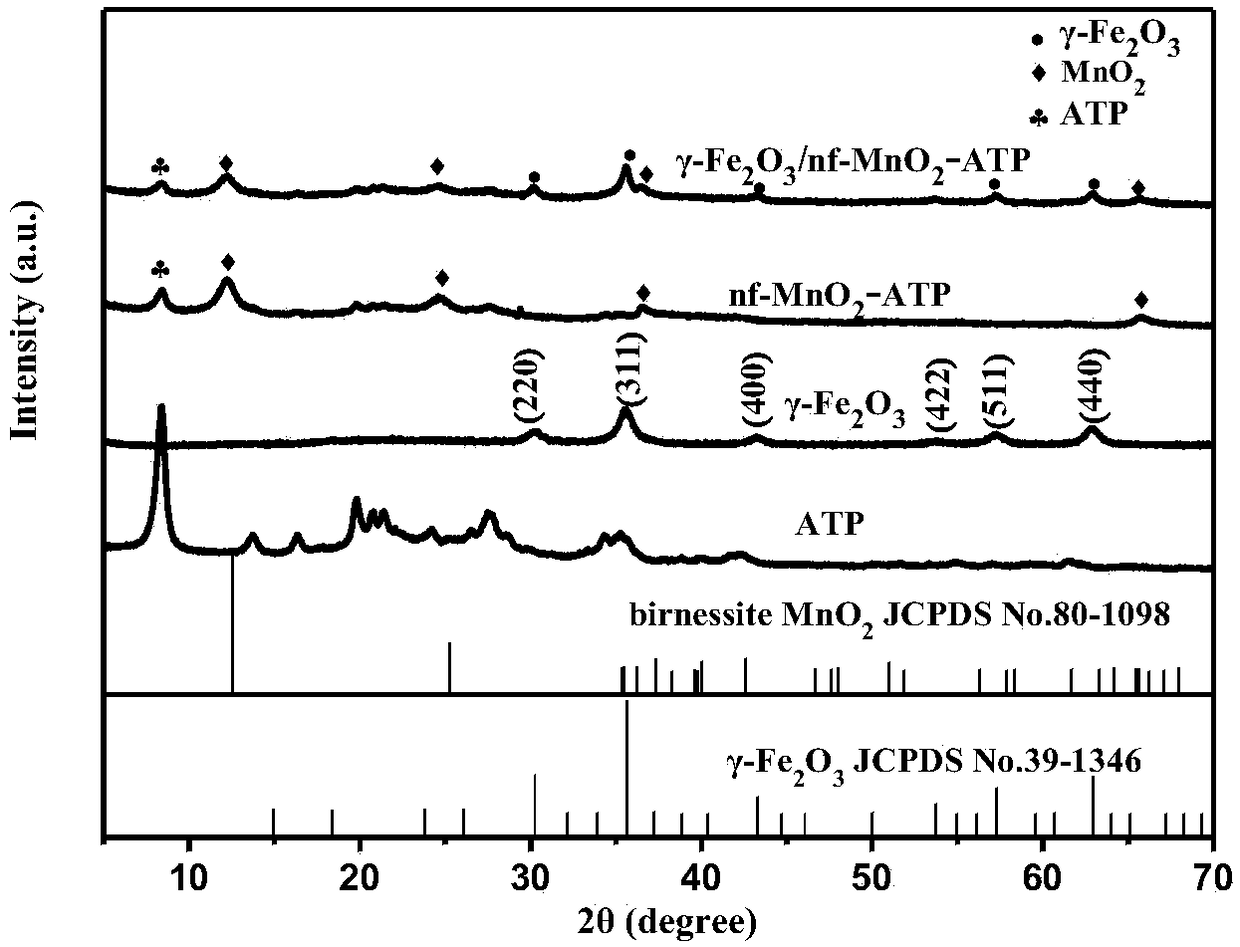

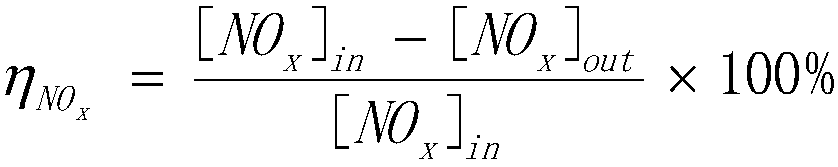

Gamma-Fe2O3 nanoparticle modified nf-MnO2/ATP low-temperature denitration catalyst

ActiveCN108465470AWide active temperatureImprove performanceGas treatmentDispersed particle separationFlue gasCatalyst support

The invention belongs to the field of flue gas denitration, and specifically provides a gamma-Fe2O3 nanoparticle modified nf-MnO2 / ATP low-temperature denitration catalyst. Directed at the disadvantages of low carrier strength, poor SO2 resistance and complicated preparation method for a conventional flue gas denitration catalyst, the invention provides the gamma-Fe2O3 nanoparticle modified nf-MnO2 / ATP low-temperature denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: with attapulgite clay with large specific surface area and high adsorption performance as a carrier and a reducing agent, allowing the attapulgite clay to react with KMnO4 under a hydrothermal condition so as to prepare a nanoflower-like MnO2-coated attapulgite clay (nf-MnO2-ATP) catalyst, preparing high-performance gamma-Fe2O3 nanoparticles under a low-temperature hydrothermal condition at the same time, and subjecting nf-MnO2 / ATP to surface modification with the high-performance gamma-Fe2O3 nanoparticles so as to prepare the gamma-Fe2O3 / nf-MnO2-ATP denitration catalyst. Thus, N2 selectivity and SO2 resistance of nf-MnO2-ATP are improved. Meanwhile, the preparation method provided by the invention has mild preparation conditions and simple preparation process, and is a safe and highly-efficient preparation method for a low-temperature denitration catalyst.

Owner:CHANGZHOU UNIV

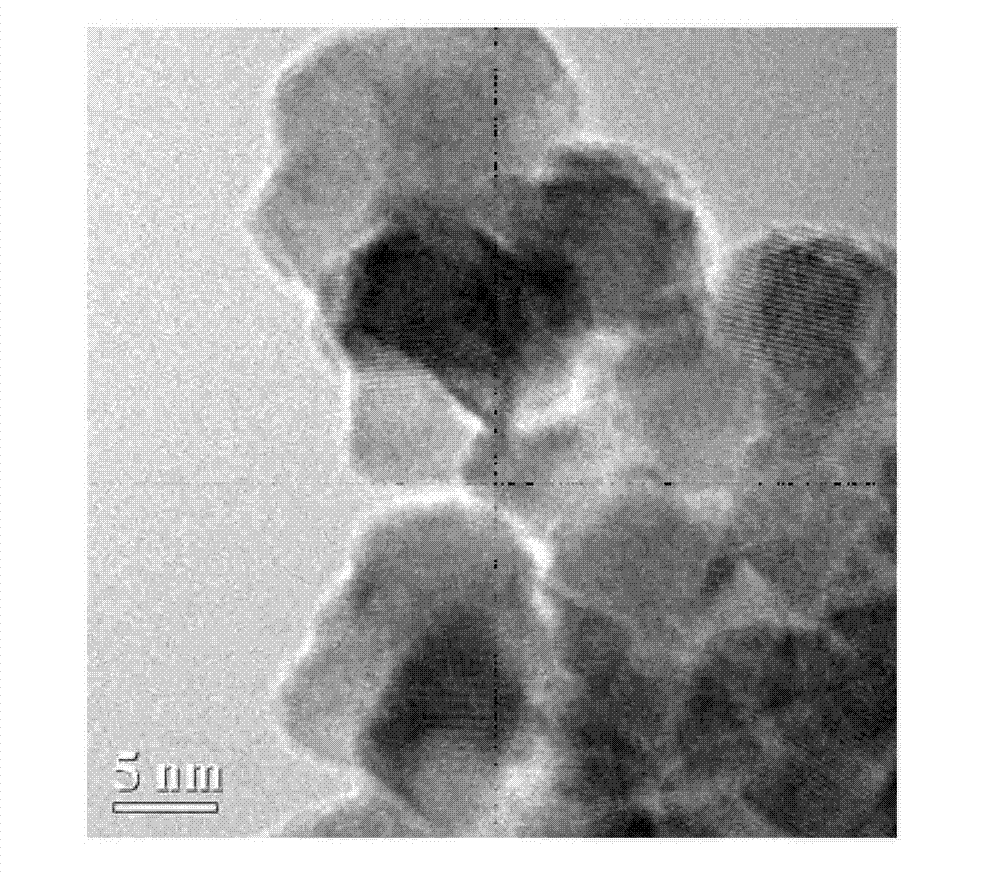

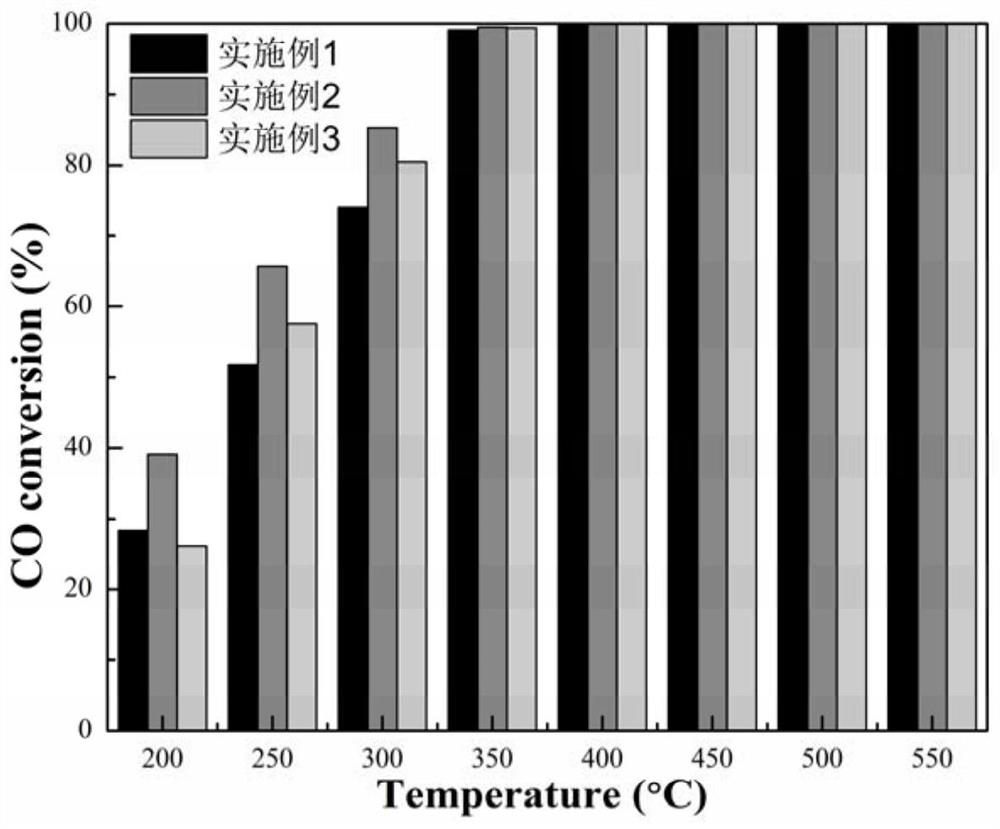

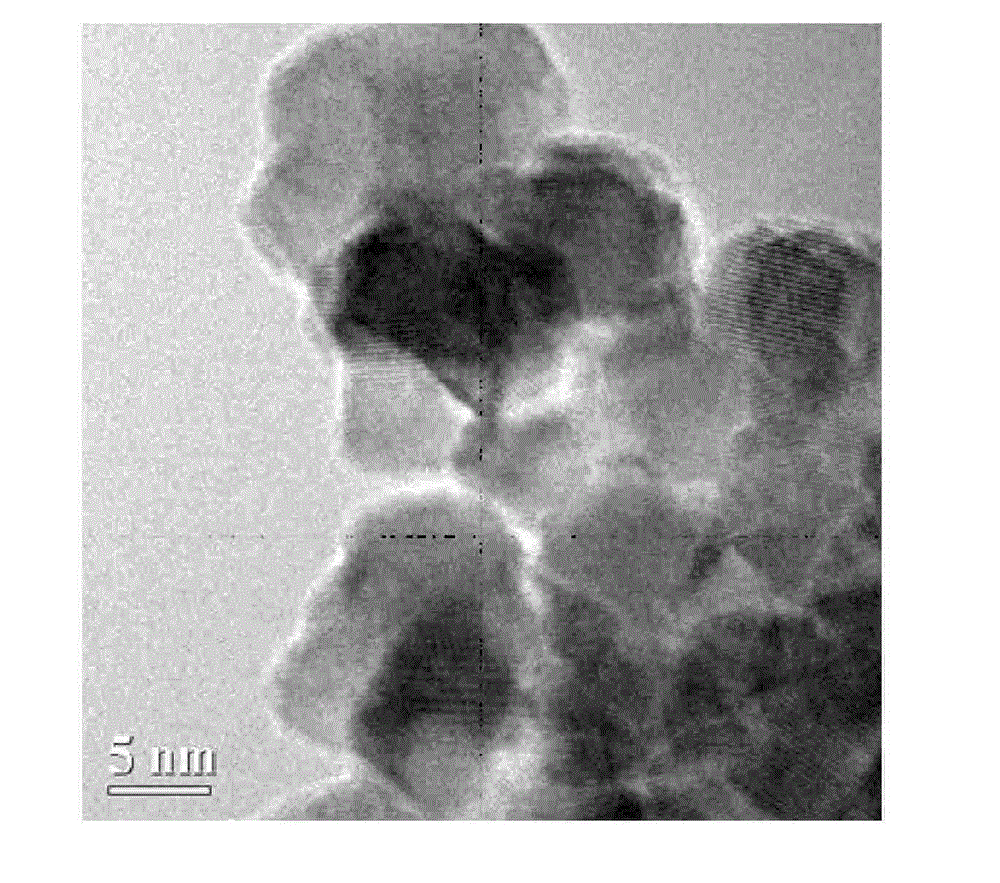

CO selective methanation monolithic catalyst and preparation method thereof

ActiveCN101607199AHigh selectivityHigh activityHydrocarbon from carbon oxidesFuel cellsMethanationCerium

The invention discloses a CO selective methanation monolithic catalyst and a preparation method thereof, in particular relates to a CO selective methanation monolithic catalyst using nanometer cerium-zirconium composite oxide as a carrier and a preparation method thereof. The catalyst comprises an active ingredient Ru, a porous material matrix and the nanometer cerium-zirconium composite oxide carrier, wherein the mol ratio of Ce to Zr is 1-36:6; the coating quantity of the nanometer cerium-zirconium composite oxide is 6-30 wt % of that of the porous material matrix; the content of Ru is 0.2-2 wt % of that of the catalyst; and the particle diameter of the nanometer cerium-zirconium composite oxide carrier is 5-20nm. The CO selective methanation monolithic catalyst has good activity and high strength, has high selectivity in the whole reaction temperature area, greatly prevents the unnecessary consumption of hydrogen in reformed gas, and has simple preparation technology and relativelylow cost.

Owner:HANERGY TECH

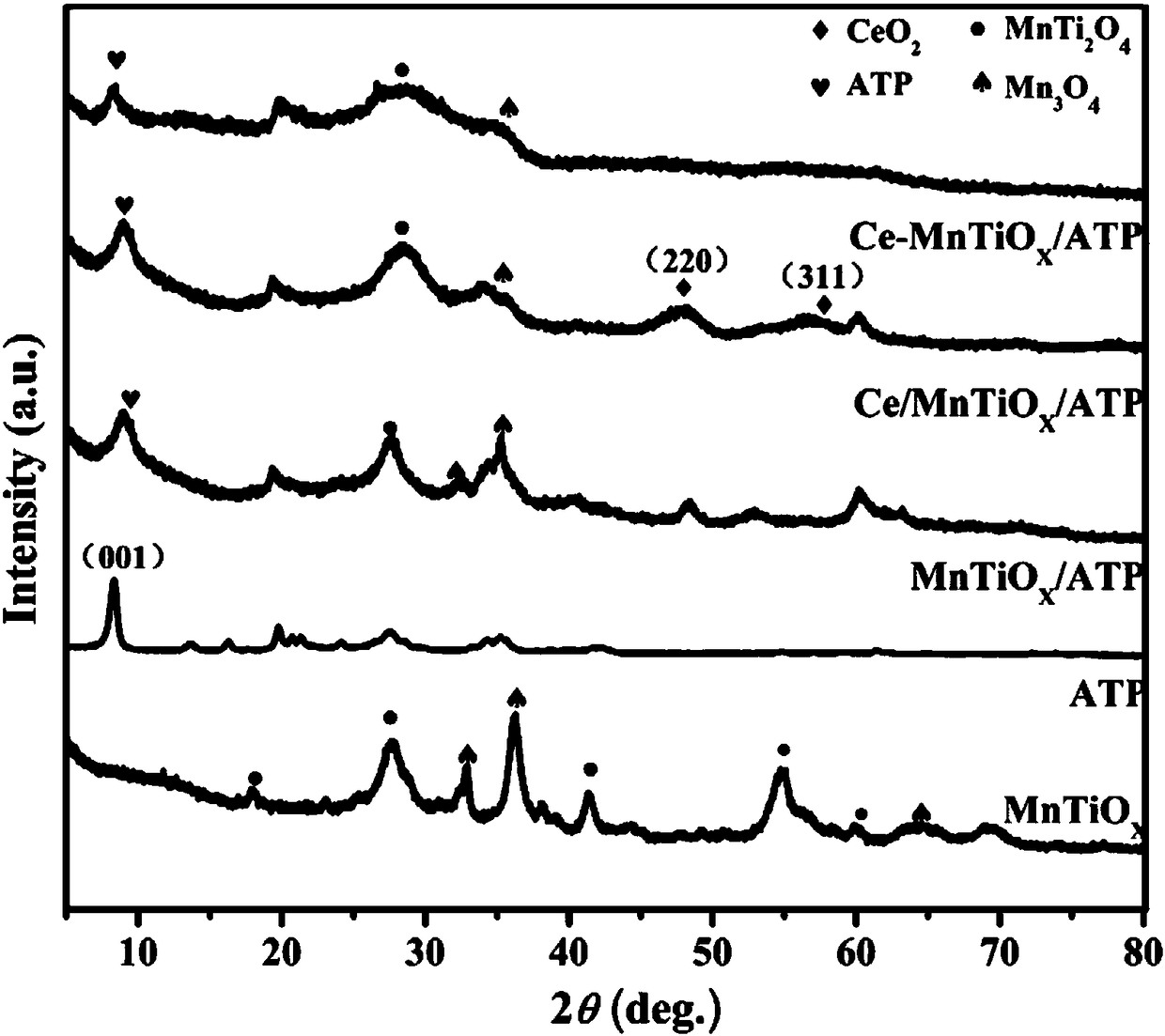

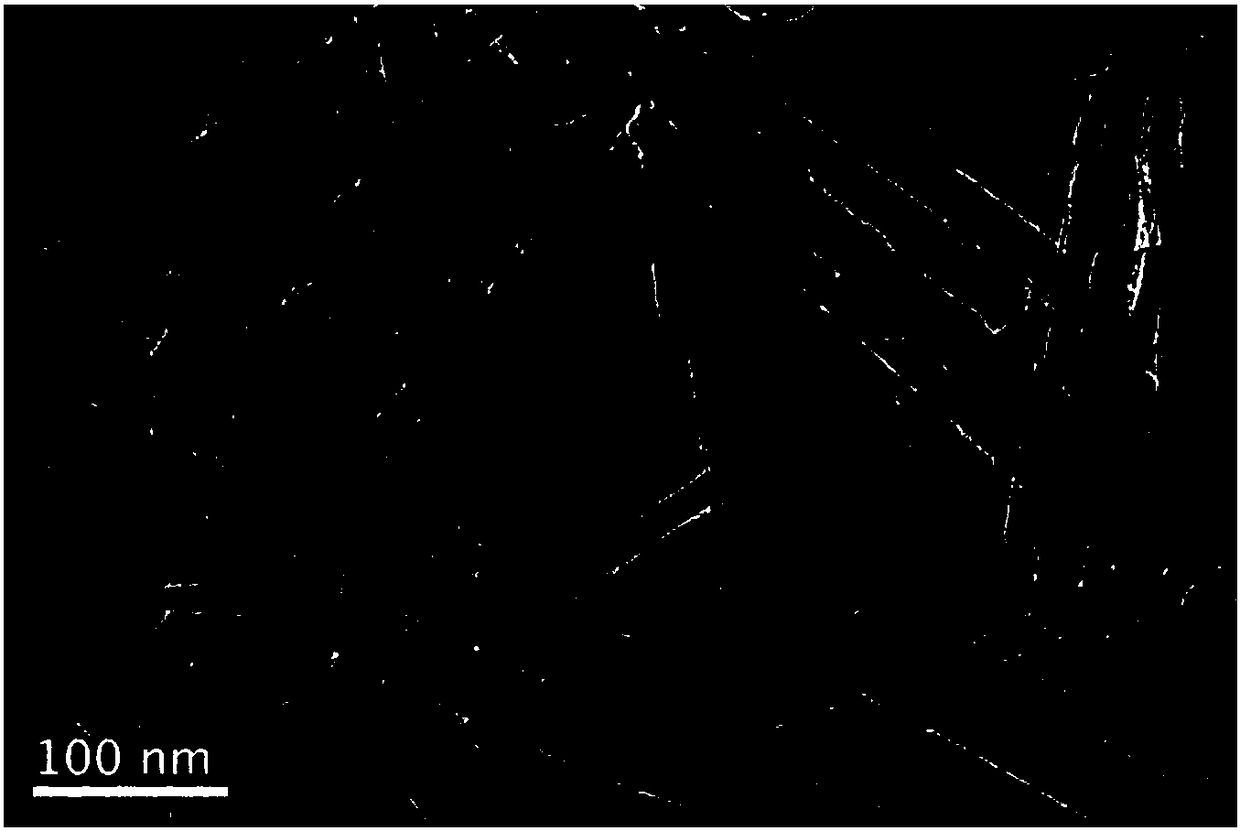

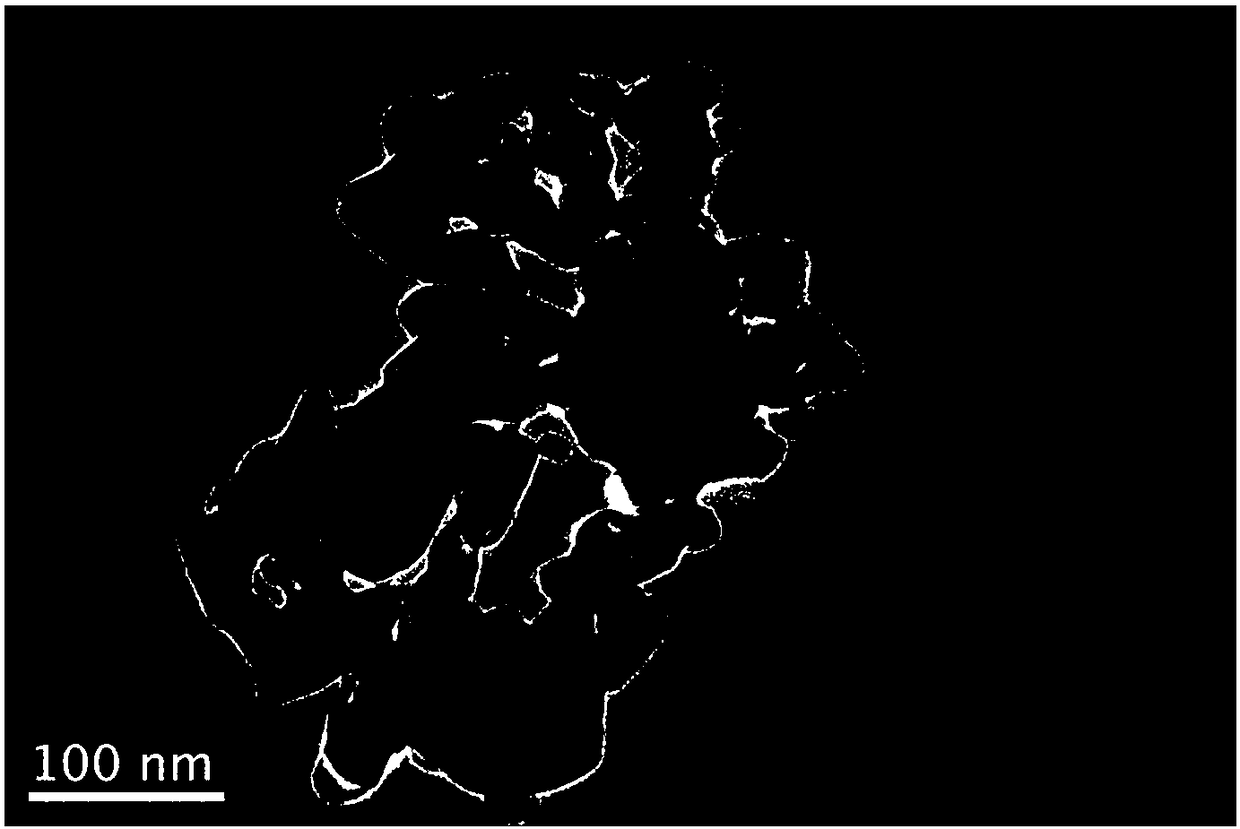

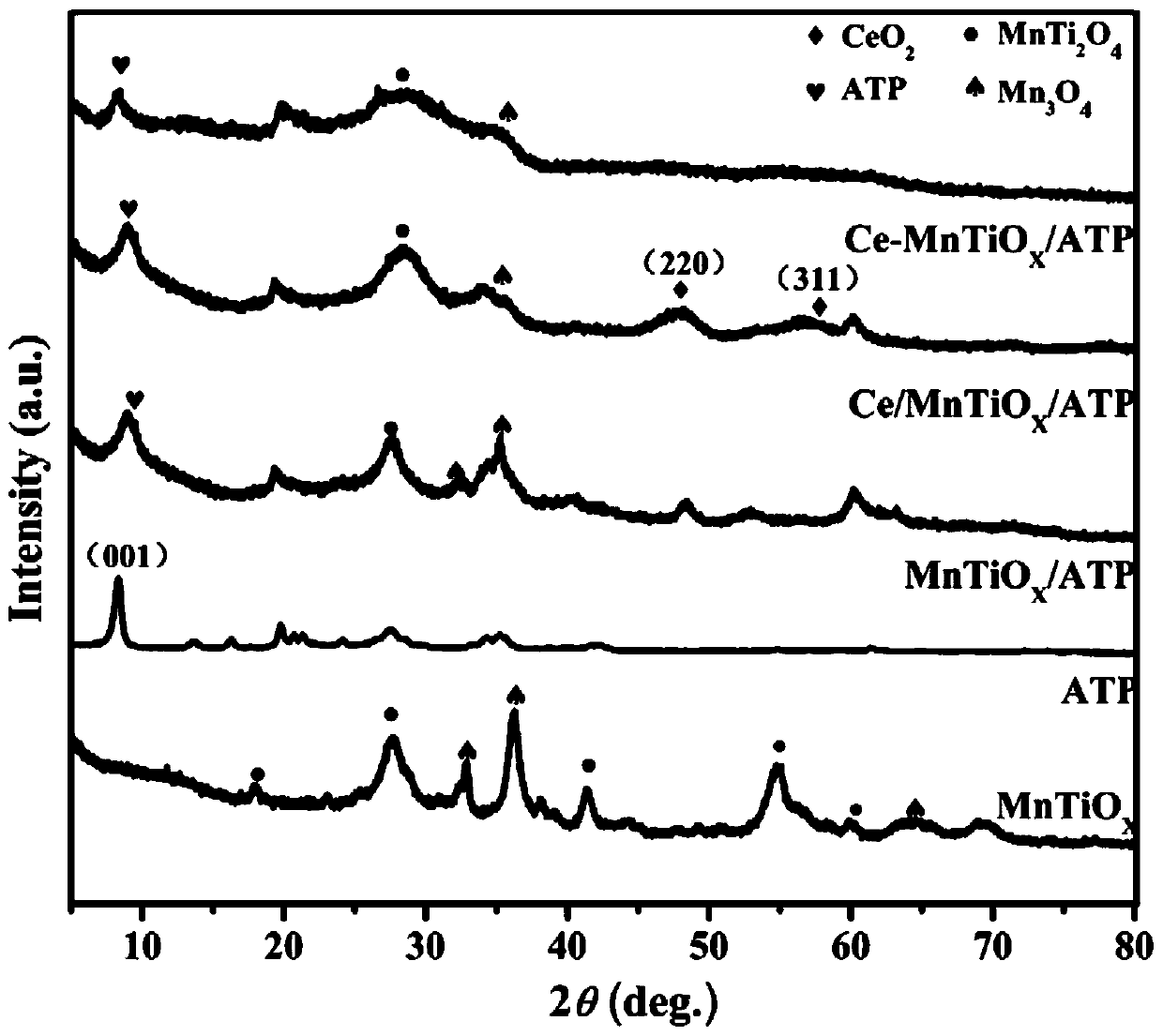

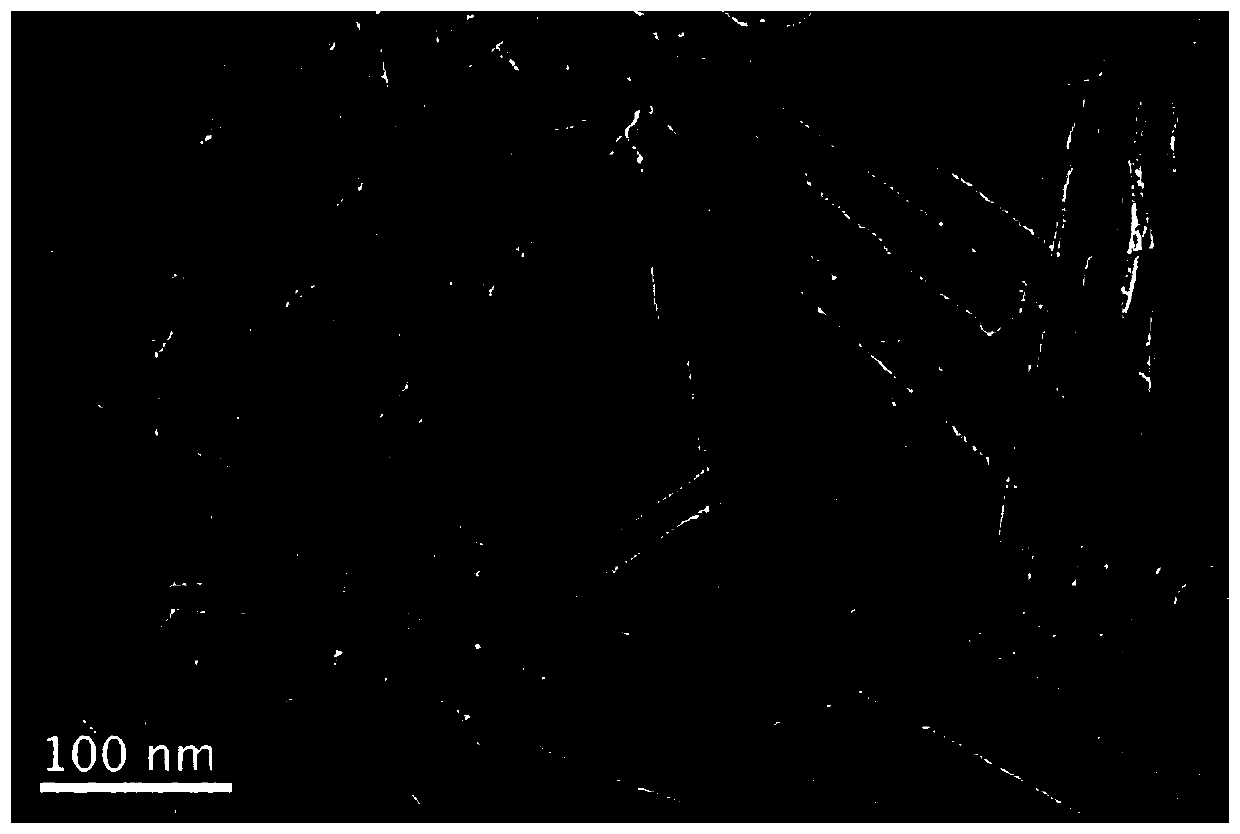

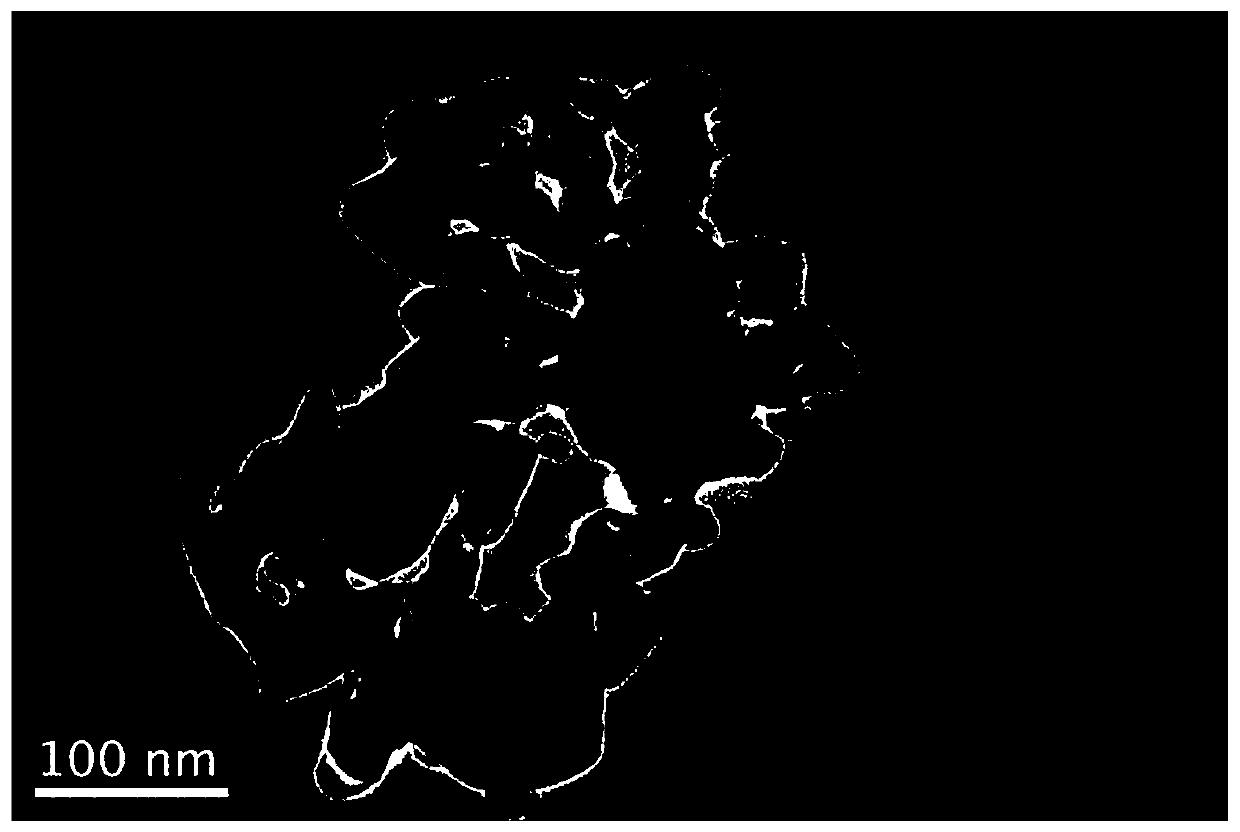

Attapulgite-loaded cerium-doped MnTiOX three-membered component low-temperature denitration catalyst and preparation method

ActiveCN108393085AImprove mechanical stabilityImprove thermal stabilityGas treatmentHeterogenous catalyst chemical elementsReaction temperatureCerium

The invention belongs to the field of flue gas denitrification, and particularly relates to an attapulgite-loaded cerium-doped MnTiOX three-membered component low-temperature denitration catalyst anda preparation method. Elliptoidal MnTiOX is prepared by the method, and elliptoidal MnTiOX is a spinel-type MnTi2O4 and Mn3O4 composite oxide, and cerium element is doped therein to form a three-membered metal oxide loaded on a non-metal clay attapulgite surface. Clay-type attapulgite with low cost is taken as a carrier of the catalyst, and loads a Ce-Mn-Ti three-membered composite oxide by a one-step precipitation method. The preparation process is simple, economical and practical, any template is not needed, the catalyst is easy to form, the capabilities of transmitting electrons and ions and storing oxygen by the catalyst are enhanced, the active reaction temperature is effectively lowered, the thermal stability and the service life of the catalyst are greatly improved and prolonged, the denitrification activity and sulfur resistance are improved, and an activity window is wide.

Owner:CHANGZHOU UNIV

CO selective methanation catalyst and preparation method thereof

ActiveCN101607198BHigh activityHigh selectivityHydrocarbon from carbon oxidesCell electrodesMethanationReaction temperature

The invention discloses a CO selective methanation catalyst and a preparation method thereof, in particular relates to a CO selective methanation catalyst which uses nanometer cerium-zirconium composite oxide as a carrier and a preparation method thereof. The CO selective methanation catalyst comprises an active ingredient Ru and the nanometer cerium-zirconium composite oxide carrier, wherein themol ratio of Ce to Zr is 1-36:6; the content of Ru is 0.2-2 wt% of the catalyst; and the particle diameter of the nanometer cerium-zirconium composite oxide carrier is 5-20nm. The CO selective methanation catalyst has good activity, has high selectivity in the whole reaction temperature area, greatly prevents the unnecessary consumption of hydrogen in reformed gas, and has simple preparation technology and relatively low cost.

Owner:HANERGY TECH

Multifunctional environment catalytic material for tail gas purification and preparation method and application thereof

ActiveCN111744501AWide active temperature rangeComponent friendlyGas treatmentHeterogenous catalyst chemical elementsPtru catalystManganese

The invention discloses a multifunctional environment catalytic material for tail gas purification and a preparation method thereof, and belongs to the field of environment-friendly catalytic materials and air pollution treatment. The material is prepared by taking cerium-manganese-copper composite oxide as a catalytic active component, molybdenum-zirconium composite oxide as a cocatalyst and titanium dioxide as a carrier and adopting a step-by-step in-situ growth method. The catalyst is environment-friendly, not only can efficiently catalyze and remove nitric oxide, mercury, dioxin and carbonmonoxide at the same time, but also is wide in active temperature interval and low in SO2 oxidation efficiency. The denitration efficiency and the dioxin removal efficiency within the temperature of350-500 DEG C are both greater than 95%, and the mercury removal efficiency and the carbon monoxide removal efficiency are both greater than 99%. The product can be widely applied to the fields of industrial tail gas purification of gas power plants, gas power generation plants, waste incineration, high-speed diesel engines and the like.

Owner:NANJING UNIV OF TECH +1

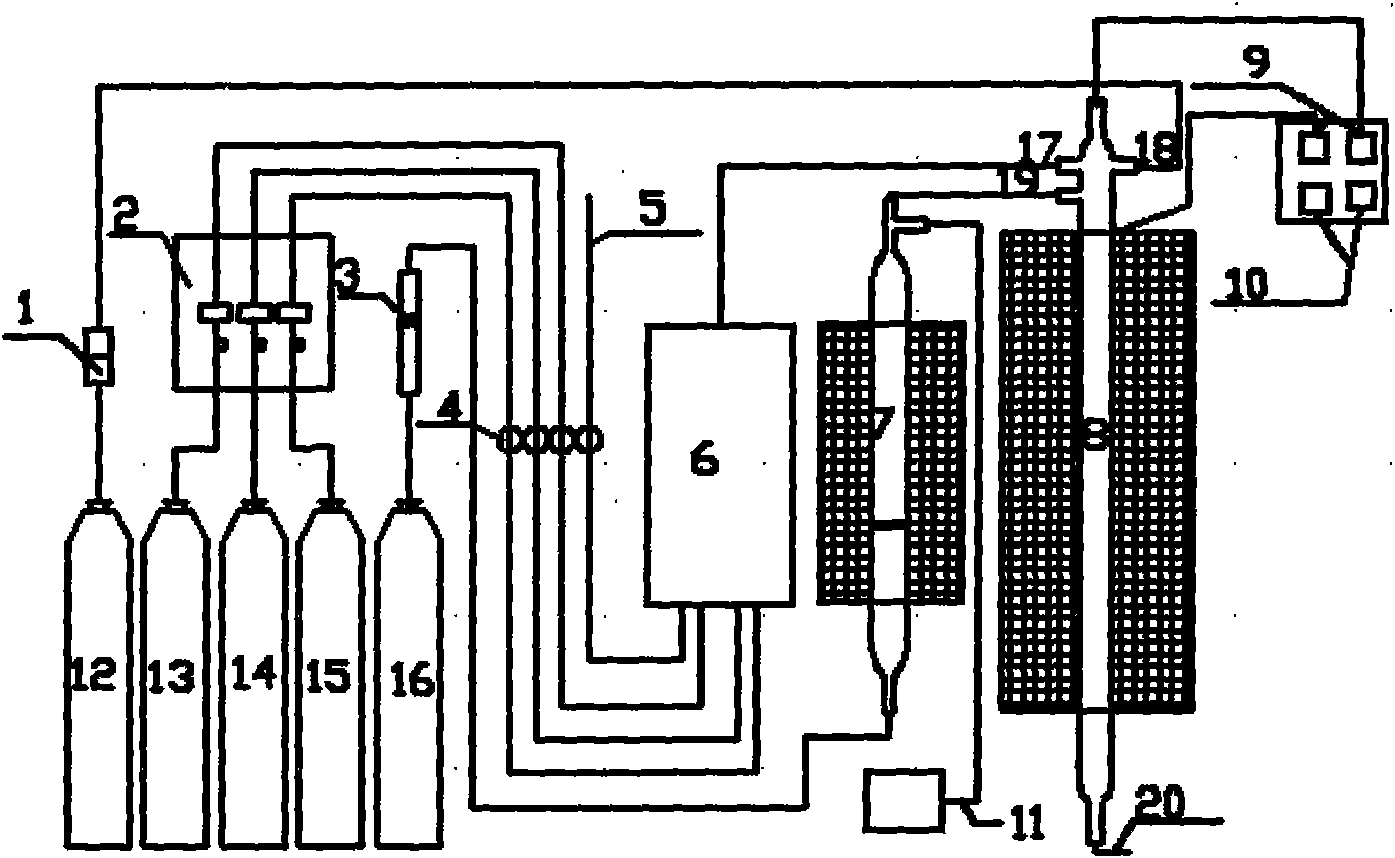

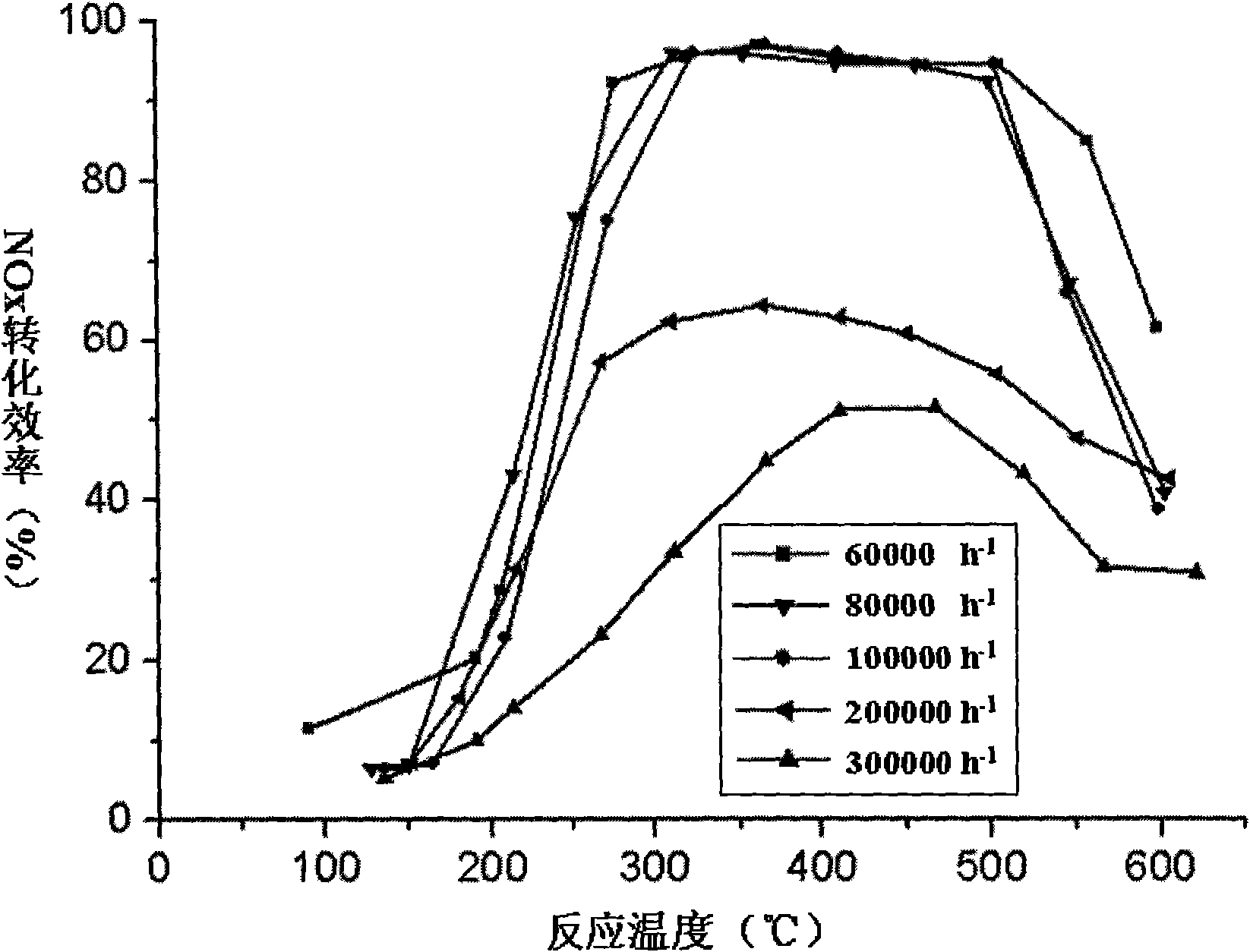

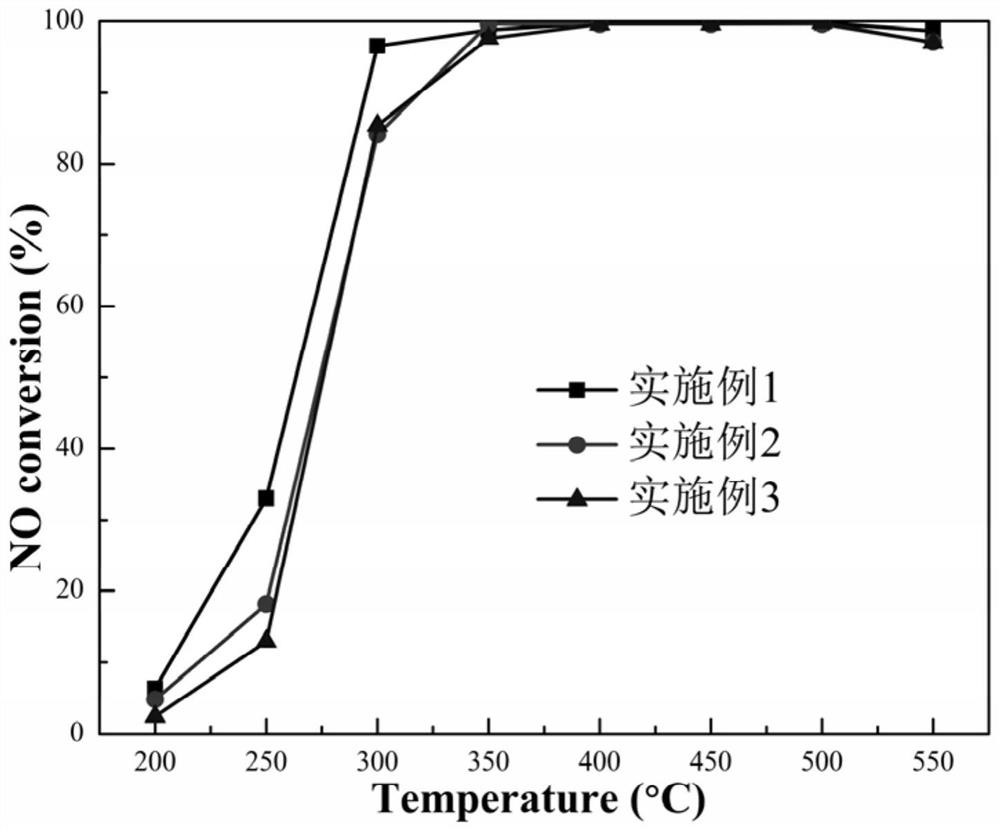

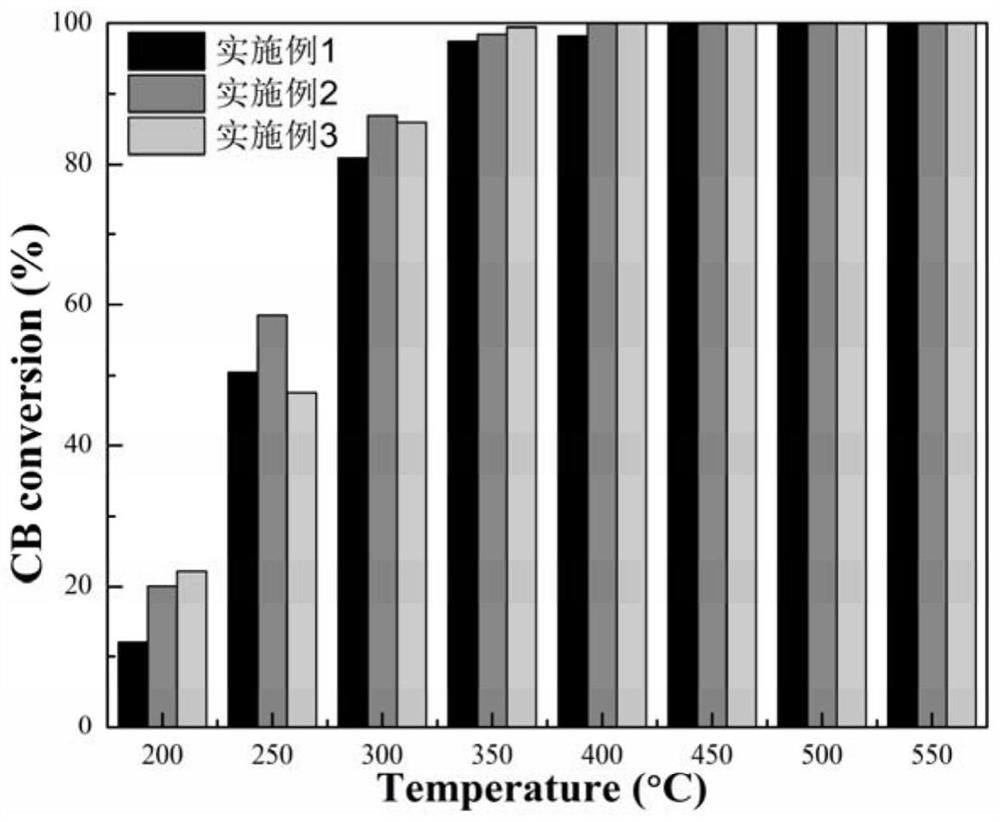

Process for preparing honeycomb-shaped SCR catalyst for purifying diesel car tail gas

InactiveCN101433803AEasy to prepareHigh activityMolecular sieve catalystsInternal combustion piston enginesHigh rateEngineering

The invention provides a diesel truck tail gas cleaning catalyst and a method for preparing the same. The cleaning catalyst is used for controlling pollutions caused by the tail gas of the diesel truck and a lean-burn gasoline locomotive. Under the condition that the temperature is between 260 and 550 DEG C and the idle speed is between 60, 000 and 80, 000 per hour, the cleaning catalyst is used for performing a catalytic activity test on a sample for a plurality of times, all the NO conversion rates reach more than 95 percent, and the highest rate is 100 percent; and after a 500-hour life test, the catalytic activity of the cleaning catalyst is not affected at all, and the cleaning catalyst has the characteristics of water resistance, low cost and simple preparation method; besides, the cleaning catalyst is particularly suitable for the purifying treatments of the tail gas of various diesel trucks.

Owner:TAIYUAN UNIV OF TECH

Kelp-shaped Mn-Fe double-metal oxide loaded CeO2 catalyst, preparation method thereof and application of catalyst

ActiveCN108579756AWide active temperature rangeLow costGas treatmentDispersed particle separationCalcinationBimetal

The invention belongs to the field of flue gas denitrification, in particular to a kelp-shaped Mn-Fe double-metal oxide loaded CeO2 low-temperature flue gas denitrification catalyst, provides a preparation method of the kelp-shaped Mn-Fe double-metal oxide loaded CeO2 low-temperature flue gas denitrification catalyst, and aims to solve the problems that an existing loaded denitrification catalystis low in selectivity and efficiency, poor in specificity, nonuniform and bad in stability, active components are not easily fixed on catalyst carriers, active windows of the catalyst are narrow in actual use of flue gas pipelines and easily poisoned by SO2 and the like. A wrinkled kelp-shaped Mn-Fe double-metal oxide is prepared by a hot water-calcination method and serves as a carrier, the Mn-Fedouble-metal oxide can also serve as a low-temperature active component, CeO2 particles are loaded on the oxide to improve sulfur resistance, and the catalyst is an environmental-friendly NH3-SCR denitrification catalyst with a great application prospect.

Owner:CHANGZHOU UNIV

A kind of preparation technology for the catalyst of high temperature catalytic decomposition of N2O

ActiveCN106391037BGood dispersionImprove heat resistanceNitrous oxide captureDispersed particle separationCerium nitrateAluminium hydroxide

Owner:四川蜀泰化工科技有限公司

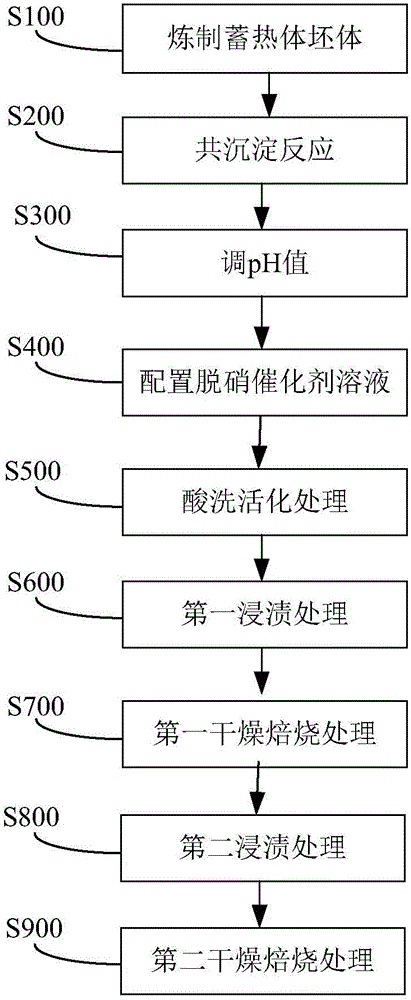

Denitrifying honeycomb heat accumulator and preparation method thereof

PendingCN106731815AIncrease heat storageIncrease heat releaseGas treatmentHeterogenous catalyst chemical elementsSlagCarbide

The invention discloses a denitrifying honeycomb heat accumulator and a preparation method thereof. The denitrifying honeycomb heat accumulator comprises a honeycomb heat accumulator and a loaded mixture, wherein the honeycomb heat accumulator comprises inorganic powder; and the loaded mixture, which is loaded to the honeycomb heat accumulator, comprises a denitrifying catalyst and an additive; the additive comprises carbide slag. The denitrifying honeycomb heat accumulator has the functions of denitrification and heat accumulation without independently arranging the heat accumulator and the denitration catalyst, so that the arranging space can be lowered and the cost is lowered. By means of the heat-accumulating effect of the heat accumulator, the heat accumulator is arranged as required, so that the catalyst in the heat accumulator is stabilized in the optimum temperature range for denitration reaction, and therefore, the denitration efficiency is high and the emission-reducing effect is obvious.

Owner:SHENWU TECH GRP CO LTD

Production process of urea solution for vehicles

InactiveCN111111407AReduce contentShort stayUrea derivatives preparationGas treatmentProcess engineeringChemistry

The invention discloses a production process urea solution for vehicles. The production process comprises the following steps: S1, cooling raw urine in a raw urine tank to a temperature of 85-90 DEG C, and carrying out centrifugal impurity removal on the cooled raw urine to obtain pure raw urine; S2, introducing pure raw urine into a urine cooling crystallizer, keeping a temperature in the urinecooling crystallizer at 20-60 DEG C, and allowing urea crystal suspension liquid to be formed under the action of a stirrer in the urine cooling crystallizer; and S3, carrying out centrifugal separation on the urea crystal suspension liquid prepared in the step S2 to obtain urea crystals and a urea solution containing a small amount of urea. According to the invention, urine is used as a raw material; and compared with granular urea, the retention time of urea in the urine in a production system is shortened, and the contents of biuret, metal ions and the like are reduced, so product quality can be improved.

Owner:安徽德利来环保科技有限公司

Rarefied-burning automobile exhaust gas catalyzing and purifying method and apparatus

InactiveCN1246070CEfficient purificationImprove purification efficiencyExhaust apparatusDispersed particle separationHydrocotyle bowlesioidesOxygen compound

The invention is a kind of catalyst purifying method and device for tails of lean firing car. The invention sets two catalyzing reaction beds on the discharging pipe of the engine; there is an additional reducer nozzle in the middle of the two beds. The first bed uses hydrocarbon and carbon monoxide in tails to reduce nitrogen-oxygen compound, at the same time, the hydrocarbon and carbon monoxide are changed into carbon dioxide and water; the second bed uses the additional oxygen hydrocarbon reducer to reduce carbon-oxygen compound, at the same time, the additional reducer is changed into water and carbon dioxide. Compared with current technology scheme, it can spread the range of active temperature, enhances the purifying efficiency, takes advantage of hydrocarbon discharged by the engine and additional oxygen hydrocarbon.

Owner:TSINGHUA UNIV

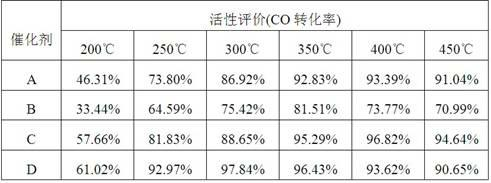

Multifunctional catalyst, and preparation method and application thereof

ActiveCN111167487AImprove denitrification efficiencyWide active temperature rangeGas treatmentInternal combustion piston enginesComposite oxideTitanium oxide

The invention discloses a multifunctional catalyst, and a preparation method and application thereof. A mixture of zirconium hydrogen phosphate and titanium trioxide is taken as a carrier, a cerium-manganese-iron composite oxide is taken as a catalytic active component, and strontium oxide is taken as a cocatalyst. Based on the mass of the carrier, the mass percentage of the active component is 2-4%, and the mass percentage of the cocatalyst is 0.5-1%. The preparation method comprises the following steps: uniformly stirring the active component, a cocatalyst precursor solution and the catalystcarrier, performing aging, and then carrying out extrusion molding, drying, and roasting. The catalyst is environmentally friendly, can remove NOx in diesel engine tail gas and synergistically catalyze and remove CO and HC at a low temperature, and has a wide active temperature interval and low SO2 oxidation efficiency. The denitration efficiency of the catalyst is higher than 95% and reaches upto 100% in a temperature range of 150-350 DEG C, and the oxidation efficiency of CO and HC is higher than 90% and reaches up to 98.7% and 97.6%, respectively. The catalyst is high in cost performanceand particularly applicable to the field of low-speed diesel engine tail gas purification.

Owner:南京环福新材料科技有限公司

Preparation method of CO selective methanation catalyst

ActiveCN101607200BEasy to prepareGood repeatabilityHydrocarbon from carbon oxidesFinal product manufactureWater bathsNitrate

The invention discloses a preparation method of a CO selective methanation catalyst, in particular to a preparation method of a CO selective methanation catalyst using nanometer cerium-zirconium composite oxide as a carrier, which comprises the following steps: dissolving the nitrates of Ce and Zr into water; keeping the pH value within the range from 9 to 13; and then stirring, precipitating, aging and washing; using a drying medium to replace water in the obtained precipitate, and baking the precipitate under the temperature of 300-900 DEG C for 5-8h after being dried; mixing the product and water together, and then being pulverized by ultrasound to obtain suspension liquid; heating and stirring the suspension liquid in the water bath, and then mixing with the precursor of Ru, wherein the pH value is controlled between 9 and 11; fully depositing and precipitating Ru on the product; aging the product at water bath temperature, and then, washing, drying and baking the product under the temperature of 300-900 DEG C for 2-5h; and finally, obtaining the CO selective methanation catalyst. The preparation method has the advantages of simple technology, relatively low cost, good catalyst activity, high strength and high selectivity in the whole reaction temperature area.

Owner:HANERGY TECH

Catalyst for low-temperature SCR denitrification in cement industry and preparation method thereof

ActiveCN106076358BImprove denitrification efficiencyWide active temperature rangeGas treatmentHeterogenous catalyst chemical elementsManganese oxideYttrium

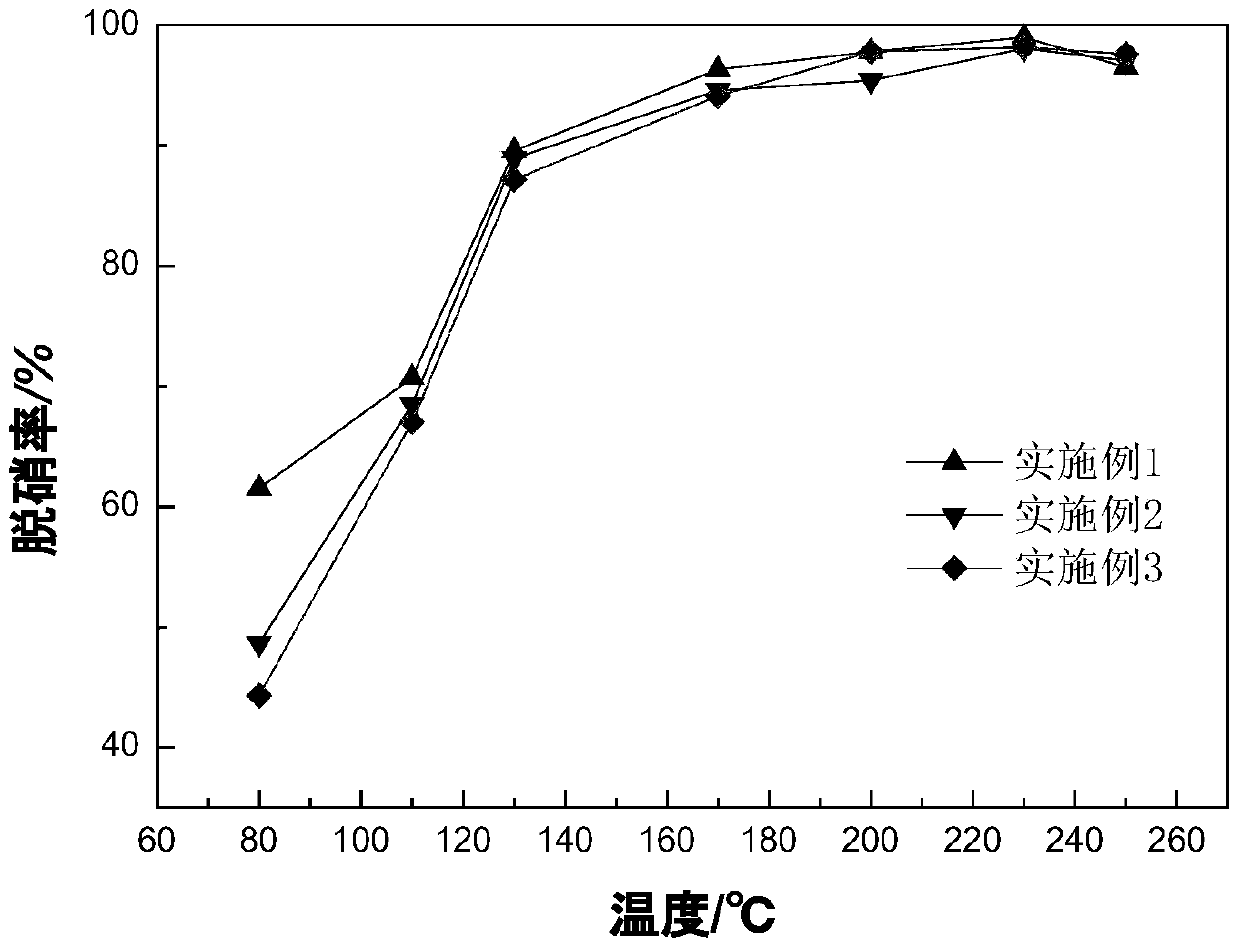

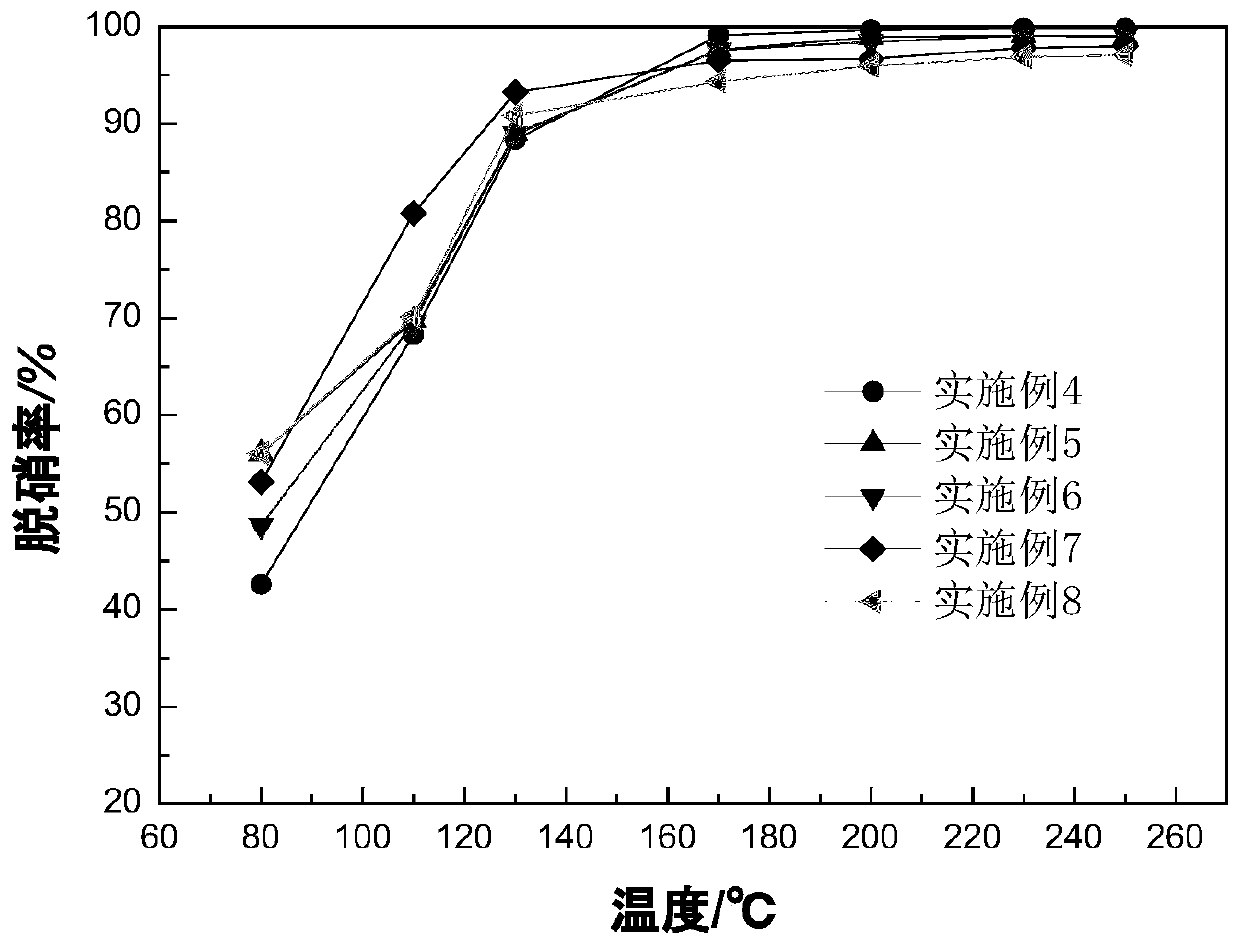

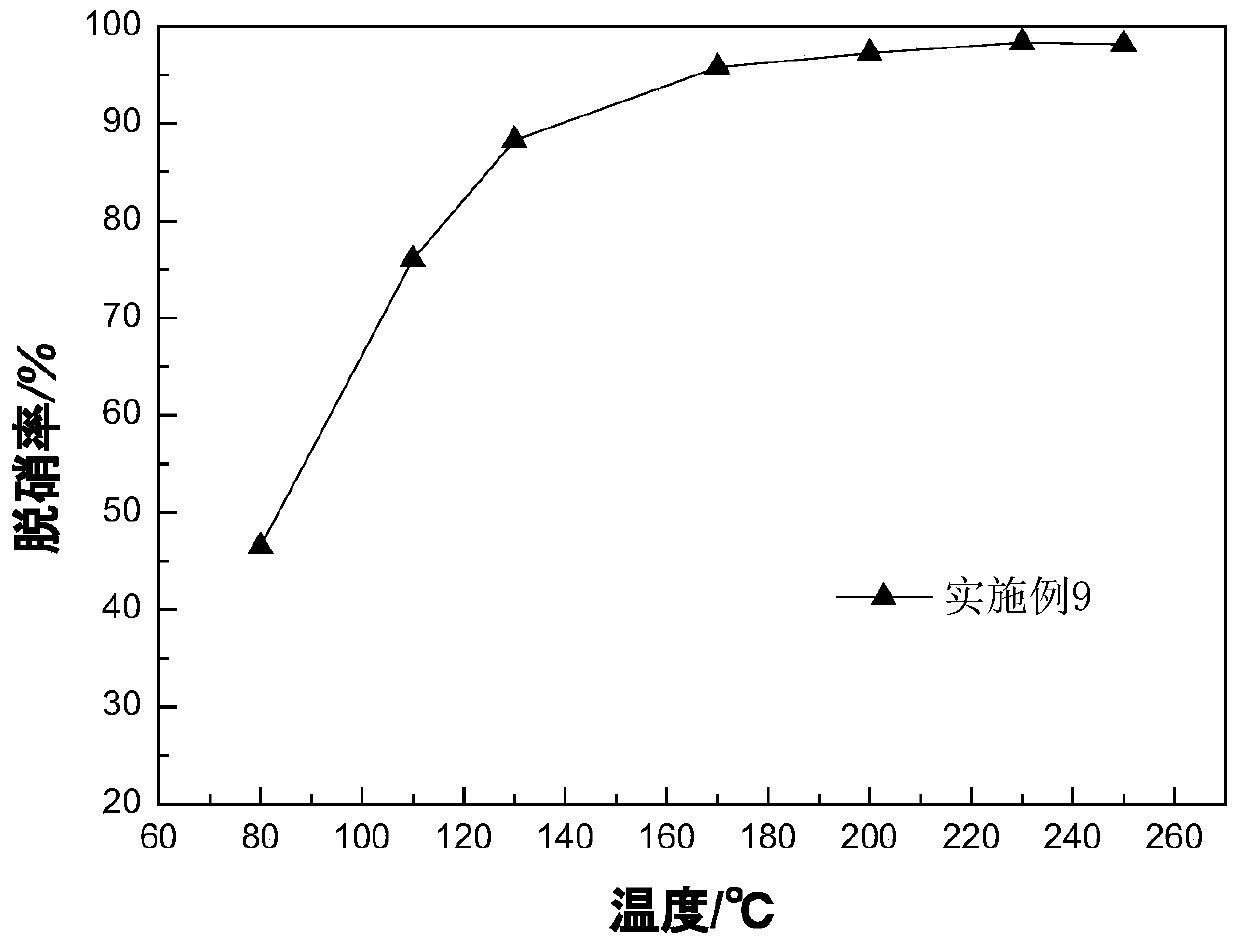

The invention relates to a catalyst for low temperature SCR denitration in cement industry and a preparation method thereof. The catalyst adopts lanthanum oxide and / or iron oxide as the catalytic active components, adopts manganese oxide or a mixture of yttrium oxide and / or praseodymium oxide and manganese oxide as the cocatalyst, and employs titanium dioxide and / or alumina as the carrier. On the basis of the carrier mass, the mass percentage content of the active components is 0.5%-15%, and the mass percentage content of the cocatalyst is 5%-35%. The preparation method consists of: stirring the active components, a cocatalyst ion precursor composite solution, the carrier and an organic forming agent evenly, carrying out mulling, ageing and extrusion molding, and then conducting drying and roasting, thus obtaining the catalyst. The catalyst has the advantages of environment-friendly components, high NOx removal efficiency at low temperature, wide active temperature window, high mechanical strength, simple preparation process, and low cost. At 130DEG C, the SCR denitration efficiency is greater than 85%, in the temperature range of 170-250DEG C, the denitration efficiency is greater than 94%, and can reach a maximum of 99.8%. The catalyst provided by the invention has high cost performance, and is especially suitable for low temperature flue gas denitration in cement plants.

Owner:NANJING TECH UNIV

Loaded nitrogen oxide purifying catalyst and its preparation

InactiveCN1293940CImprove thermal stabilityEasy to prepareMolecular sieve catalystsDispersed particle separationCopper oxideHigh activity

The invention is load nitrogen oxide clarifying catalyst and the manufacturing method. The character lies in that: it is special for clarifying nitrogen oxide of tail gas of diesel engine and rare combustion gasoline engine which load molybdenum and copper oxide on HZSM-5. the molecular expressing formula is: Cu-Mo / ZSM-5. the invention has following advantages: (1) initiative. (2) high activity. (3) the activity temperature region is wide. (4) high stability. (5) the method is simple and the cost is low.

Owner:TAIYUAN UNIV OF TECH

Wide-temperature vanadium-free denitration catalyst as well as preparation method and application thereof

PendingCN114247465AIncrease dispersionWide active temperature rangeMolecular sieve catalystsDispersed particle separationMolecular sieveUltrasonic oscillation

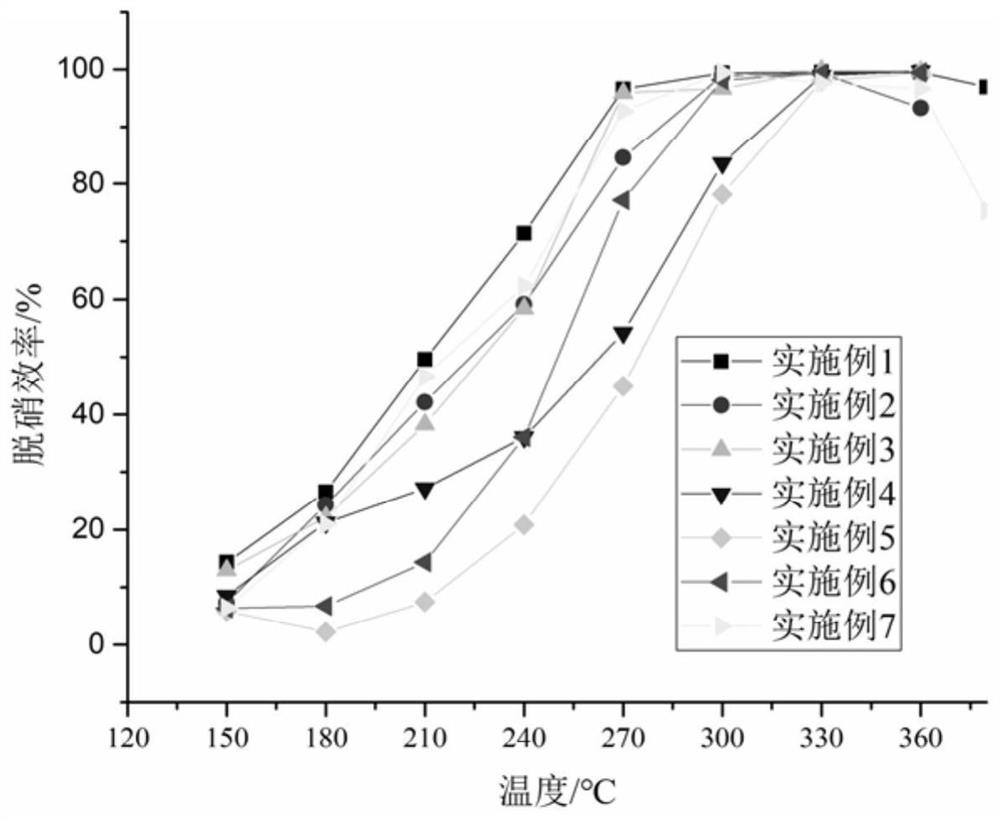

The invention discloses a wide-temperature vanadium-free denitration catalyst preparation method, which comprises: 1, dissolving a chromium-containing precursor, an iron-containing precursor and a copper-containing precursor in deionized water, and stirring in a water bath at a temperature of 20-30 DEG C for 30-60 min to obtain a mixed solution; step 2, adding a pretreated HY molecular sieve into the mixed solution obtained in the step 1, and heating in a water bath to 70-80 DEG C under a stirring condition to obtain a viscous mixture; and step 3, sequentially carrying out ultrasonic oscillation, room-temperature aging, drying, roasting and cooling treatment on the obtained viscous mixture to obtain the catalyst, the mass ratio of the HY molecular sieve to the Fe precursor is (1.33-2.67): 1. The prepared wide-temperature vanadium-free denitration catalyst is wide in active temperature range, low in activation temperature and high in denitration efficiency, the composite desulfurization catalyst can be arranged in equipment behind a dust remover and a desulfurization tower, the service mechanical life of the catalyst is prolonged, and the denitration efficiency can reach 95% or above within the range of 200-360 DEG C under the sulfur-free working condition.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

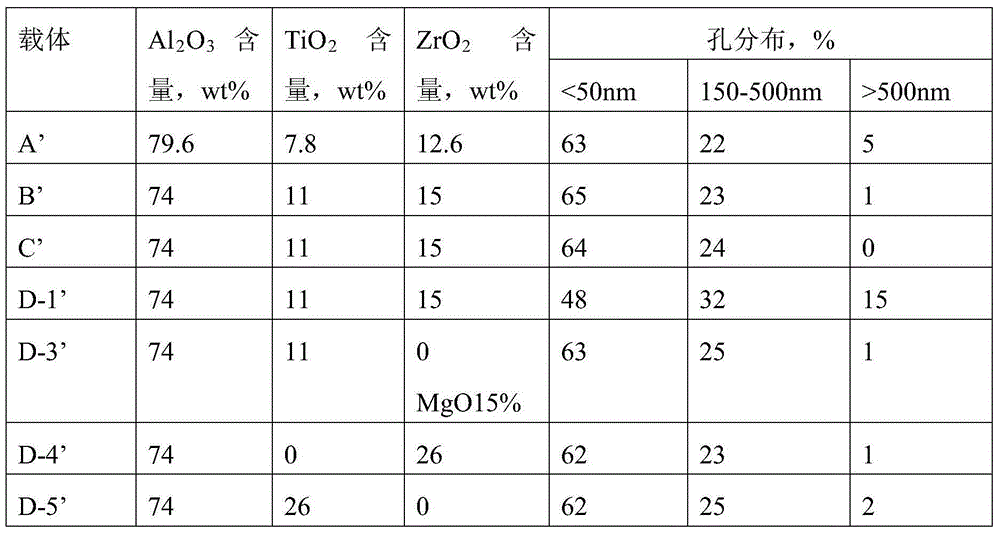

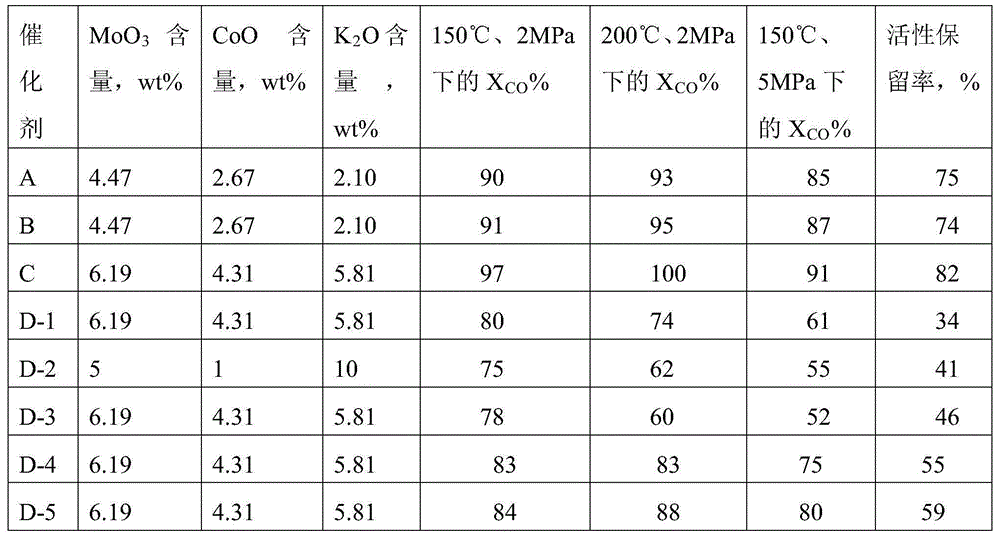

A low-temperature sulfur-tolerant shift catalyst and its preparation method

ActiveCN104607199BGood hydration resistanceExtended service lifeHydrogenMetal/metal-oxides/metal-hydroxide catalystsPore distributionAlkaline earth metal

Owner:山东京博众诚清洁能源有限公司

A kind of preparation method of anti-sulfur denitration catalyst

InactiveCN106807360BSmall particle sizeIncrease the areaGas treatmentHeterogenous catalyst chemical elementsWater vaporSulfur

The invention discloses a preparation method of a sulfur-resistant and denitration catalyst. The preparation method of the sulfur-resistant and denitration catalyst comprises the following steps: preparing TiO2 hydrosol, preparing a TiO2-SiO2 composite carrier, modifying the TiO2-SiO2 composite carrier and preparing a V2O5-WO3 / TiO2-SiO2 catalyst. The sulfur-resistant and denitration catalyst prepared by the method takes the modified TiO2 as a catalyst carrier raw material, and the prepared TiO2-SiO2 composite carriers are modified again, so the use of titanium dioxide is avoided and the production cost is reduced; furthermore, the raw material and the composite carrier are modified, so that the grain size of the composite carrier is reduced, the specific surface area and the uniformity degree of the composite carrier are increased, the prepared sulfur-resistant and denitration catalyst is long in service life, wide in active temperature interval, particularly high in low-temperature activity and high high-temperautre stability, and the preparation process is simple, low in toxicity, high in water vapor resistance and strong in SO2 resistance.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

A kind of attapulgite supported cerium doped mntio x Ternary component low-temperature denitrification catalyst and preparation method thereof

ActiveCN108393085BImprove mechanical stabilityImprove thermal stabilityGas treatmentHeterogenous catalyst chemical elementsCeriumReaction temperature

The invention belongs to the field of flue gas denitration, and in particular relates to attapulgite-loaded cerium-doped MnTiO X Ternary component low-temperature denitration catalyst and preparation method. The method of the present invention prepares an elliptical MnTiO X , which is the spinel type MnTi 2 O 4 and Mn 3 O 4 The composite oxide is doped with cerium element to form a ternary metal oxide, which is loaded on the surface of the non-metallic clay attapulgite. The catalyst uses inexpensive clay-based attapulgite as a carrier and supports Ce‑Mn‑Ti ternary composite oxide through a one-step precipitation method. The preparation process of the present invention is simple, economical, does not require any template, the catalyst is easy to shape, enhances the catalyst's ability to transfer electrons and ions to store oxygen, effectively reduces the active reaction temperature, greatly improves the thermal stability and service life of the catalyst, and increases Denitrification activity and sulfur resistance, and wide activity window.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com