Preparation method of CO selective methanation catalyst

A methanation catalyst and selective technology, which is applied in the field of preparation of CO selective methanation catalyst, can solve the problems of reaction temperature being deeply influenced by gas space velocity, low catalyst reaction temperature, increased production cost, etc., to achieve catalytic activity and Effects of improved stability, increased catalyst activity, and easy conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

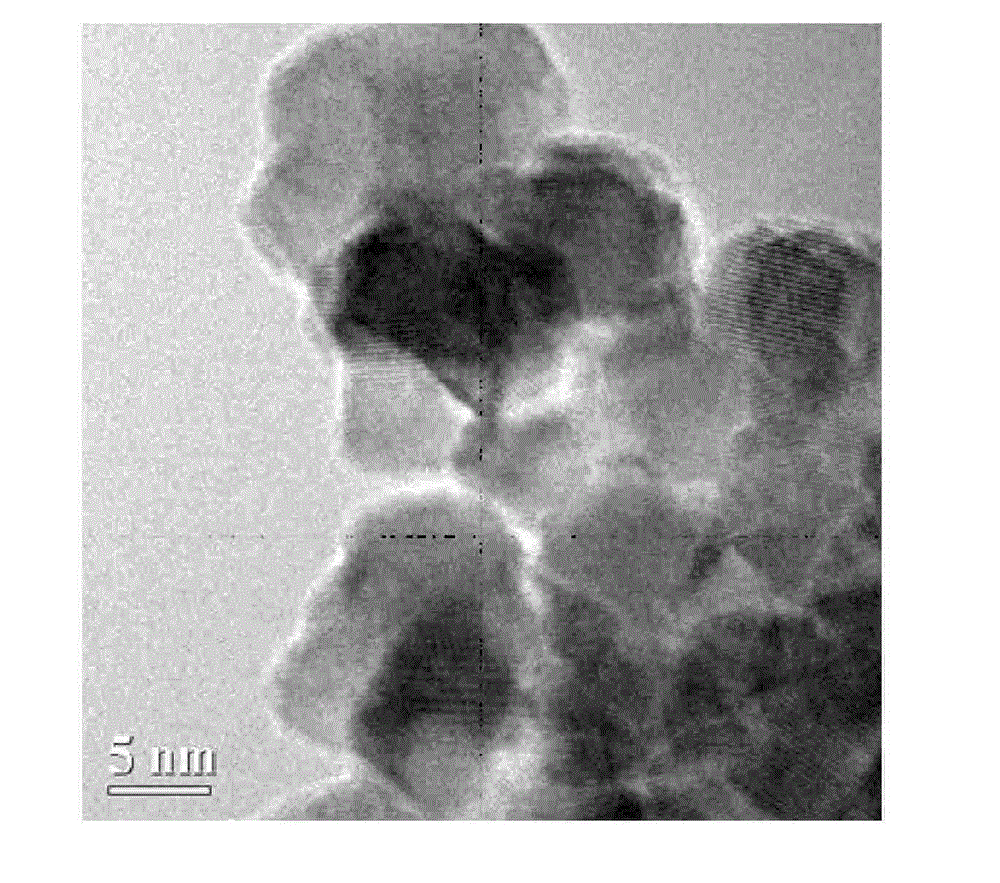

[0031] A CO selective methanation catalyst, including active component Ru, also includes nano-cerium-zirconium composite oxide support, wherein the molar ratio of Ce, Zr is 3:1; the content of Ru accounts for 0.5wt% of the catalyst; characterized by TEM ,like figure 1 As shown, the particle diameter of the nano-cerium-zirconium composite oxide carrier is 5-20nm, mostly 5-10nm. The preparation method is as follows:

[0032] (1) the nitrate that the mol ratio is 3: 1 Ce: Zr is dissolved in deionized water, is configured into the solution of concentration 0.2mol / L; Concentration is that the industrial ammonia water of 25% is diluted 1.5 times as precipitating agent, in continuous Under stirring, add the above-mentioned salt solution dropwise to the above-mentioned precipitant at a rate of 5ml / min, and control the pH to 9. After the precipitation is complete, age at room temperature for 6 hours, wash with deionized water for 6 times, and replace the obtained precipitate with abso...

Embodiment 2

[0036] A CO selective methanation catalyst, including active component Ru, also includes nano-cerium-zirconium composite oxide support, wherein the molar ratio of Ce, Zr is 1:3; the content of Ru accounts for 0.2wt% of the catalyst; characterized by TEM ,like figure 1 As shown, the particle diameter of the nano-cerium-zirconium composite oxide carrier is 5-20nm, mostly 5-10nm. The preparation method is as follows:

[0037] (1) be that the nitrate of Ce: Zr that molar ratio is 1: 3 is dissolved in deionized water, is configured into the solution of concentration 0.2mol / L; Concentration is that the industrial ammonia water of 25% is diluted 1.5 times as precipitation agent, in continuous Under stirring, add the above-mentioned salt solution dropwise to the above-mentioned precipitant at a rate of 5ml / min, and control the pH to 13. After the precipitation is complete, age at room temperature for 6 hours, wash with deionized water for 6 times, and replace the obtained precipitate...

Embodiment 3

[0041] A CO selective methanation catalyst, including active component Ru, also includes nano-cerium-zirconium composite oxide support, wherein the molar ratio of Ce, Zr is 1:6; the content of Ru accounts for 2wt% of the catalyst; characterized by TEM, like figure 1 As shown, the particle diameter of the nano-cerium-zirconium composite oxide carrier is 5-20nm, mostly 5-10nm. The preparation method is as follows:

[0042] (1) be that the nitrate of Ce: Zr that molar ratio is 1: 6 is dissolved in deionized water, is configured into the solution of concentration 0.2mol / L; Concentration is that the industrial ammonia water of 25% is diluted 1.5 times as precipitation agent, in continuous Under stirring, add the above-mentioned salt solution dropwise to the above-mentioned precipitant at a rate of 5ml / min, and control the pH to 11. After the precipitation is complete, age at room temperature for 6 hours, wash with deionized water for 6 times, and replace the obtained precipitate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com