Patents

Literature

111results about How to "Wide active temperature window" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas and preparation method thereof

InactiveCN102240557AHigh strength combinationSuitable for handlingMolecular sieve catalystsDispersed particle separationAlkaneRare earth

The invention relates to a catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas and a preparation method thereof and belongs to the fields of atmospheric pollution abatement technique and environment-friendly catalytic material. In the catalyst, the nickel-iron-manganese compound oxide is taken as a first active component; one or two of other transition metal, rare-earth metal or precious metal oxides are taken as a second active component; a self-made carrier or natural inorganic material carrier is taken as the carrier of the catalyst; and the contents (in percentage by weight) of the loads of the first and the second active components are respectively 5-20% and 0-10% on the basis of the weight of the carrier. The catalyst is a polymorphous catalyst, which can be spherical, columnar, starlike, bar-shaped, netty, flaky, ringlike, strip-shaped, block-shaped, honeycomb or powdery. The catalyst can be used for completely catalytically oxidizing CO(carbon monoxide), alkane, halogenated hydrocarbon, aromatic hydrocarbon and heterocyclic compounds at 200-350 DEG C. The catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas has the advantages of low initiation temperature, high conversion efficiency, low cost, wide application scope, and meets the industrial waste gas treatment requirements of various enterprises.

Owner:NANJING UNIV OF TECH

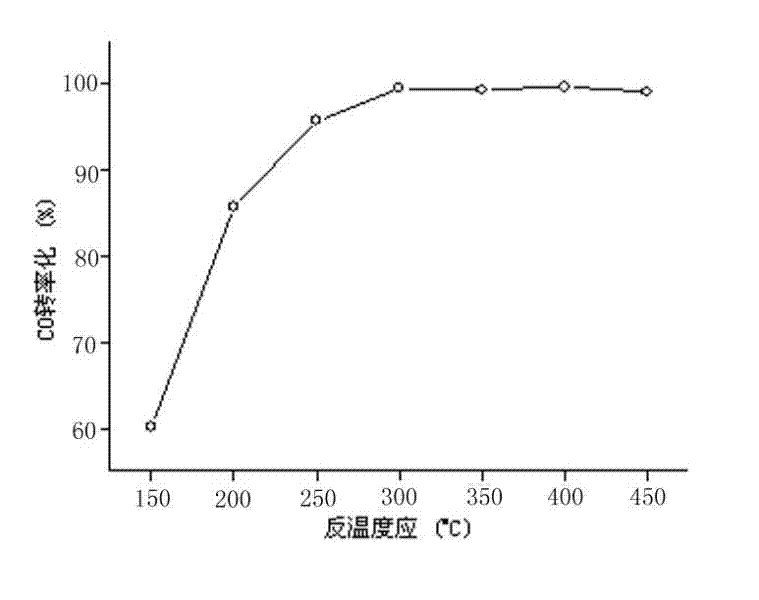

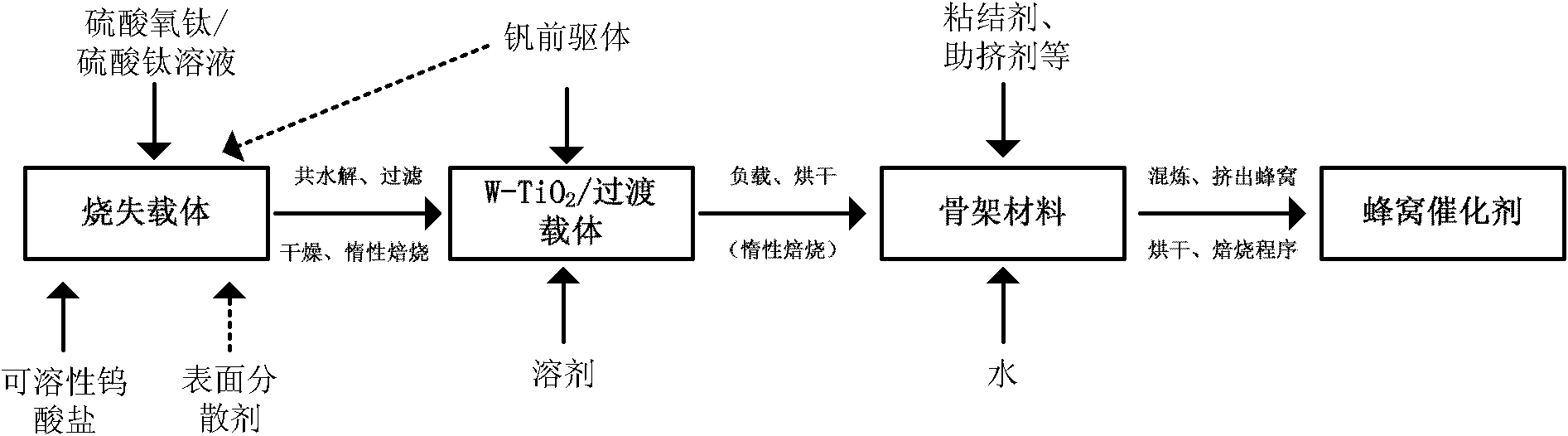

Surface deposition honeycomb flue gas denitration catalyst and preparation method thereof

ActiveCN102319559AWide active temperature windowAchieving Directional Selective LoadingDispersed particle separationCatalyst activation/preparationEnvironmental resistanceSlag

The invention relates to the environmental protection field of flue gas treatment of gas-fired boilers, in particular to a surface deposition honeycomb flue gas denitration catalyst and a preparation method thereof. The catalyst comprises a honeycomb framework which takes clay, soot dust or slag as a substrate; TiO2 is taken as an active carrier; WO3 and V2O5 serving as active ingredients are loaded on the TiO2 active carrier, and are uniformly distributed in the honeycomb framework; and the catalyst comprises the following components in percentage by weight: 60-80 percent of clay, soot dust or slag, 13-33 percent of TiO2, 1-5 percent of WO3 and 0.1-2 percent of V2O5. By transferring an ignition lost transition carrier, highly dispersion of catalyst nanoparticles on a molding catalyst pore cannel and an outer surface is realized, and the utilization ratio and catalytic activity of the active ingredients are increased greatly.

Owner:CHINA KINGSUN MATERIAL TECH

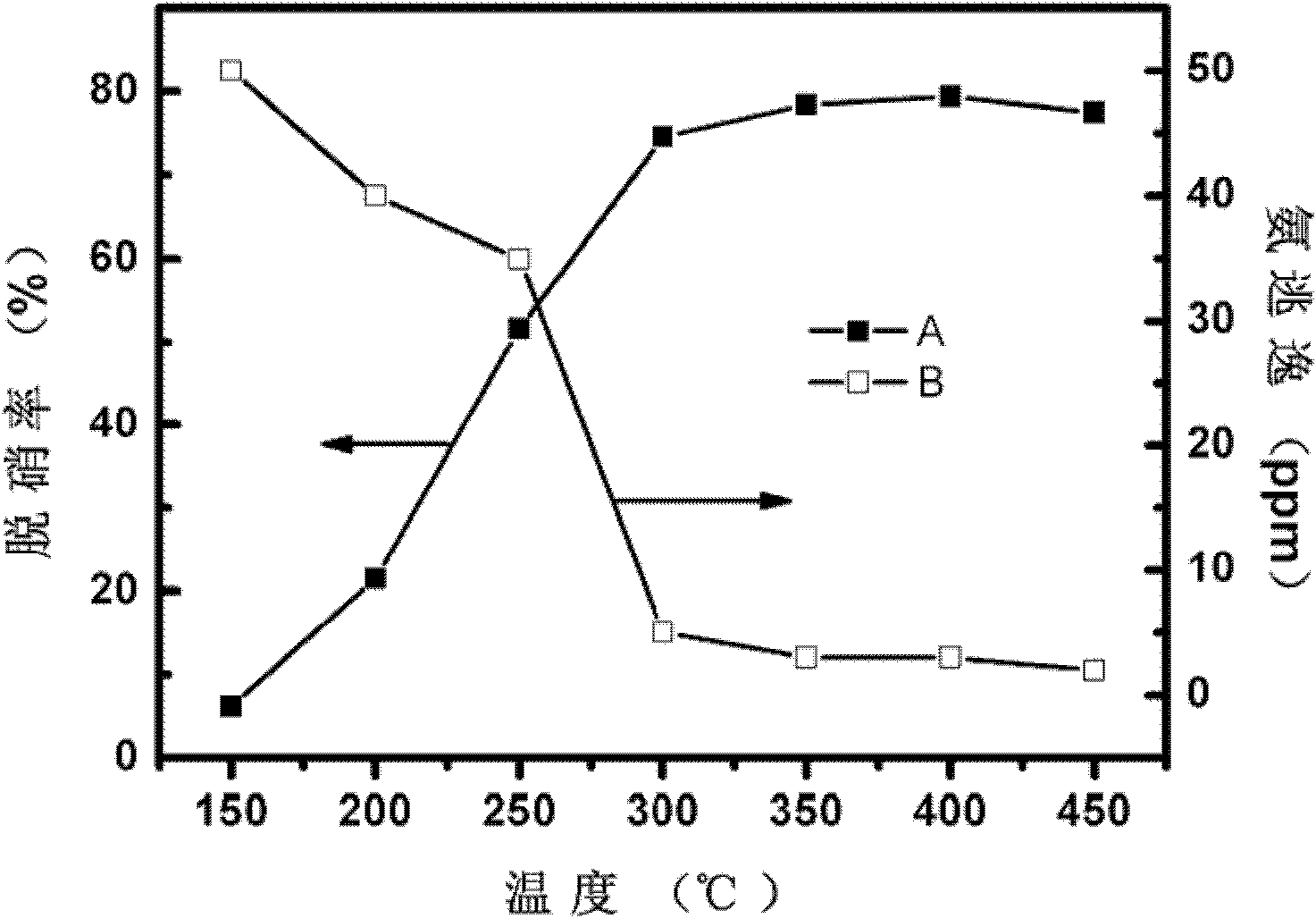

Plate-type catalyst capable of simultaneous denitration and demercuration and preparation method thereof

ActiveCN103657636ASimple preparation processWide active temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberActive component

The invention relates to a plate-type catalyst capable of simultaneous denitration and demercuration and a preparation method thereof and belongs to the field of air pollution control. According to the catalyst, fiberglass, active components, a bonder, an assistant and a carrier are used as catalyst paste, and a framework is coated with the catalyst paste, wherein the active components are V2O5 and MoO3, or V2O5 and WO3, and the carrier is TiO2; in the catalyst paste, the mass ratio of carrier, to fiberglass, to catalyst active component V2O5, to catalyst active component MoO3 or WO3 to bonder to assistant is 100:(1-8):(0.1-5):(2-10):(0.5-5):(0-15). The catalyst simultaneously complete selective catalytic reduction of NOx and catalytic oxidation of Hg<0> in an SCR reactor, the generated Hg<2+> is washed and solidified in desulphurization gypsum in a follow-up desulphurization device through the smoke wet process, and the simultaneous removal of NOx and HgO is realized on the condition that no smoke purification device is added.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

Flue gas denitration catalyst and preparation method and application thereof

ActiveCN102166522AEasy to prepareLow active onset temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFlue gas

The invention discloses a flue gas denitration catalyst. The catalyst comprises a carrier and a catalytic activity component, wherein the catalytic activity component is manganese, cobalt and cerium composite oxide, wherein the molar ratio of the manganese element to the cobalt element to the cerium element is 1:0.1-1:0.1-1. A preparation method of the flue gas denitration catalyst comprises the following steps of: (1) taking a soluble manganese salt, a soluble cobalt salt and a soluble cerium salt, wherein the molar ratio of the manganese element to the cobalt element to the cerium element is 1:0.1-1:0.1-1, dissolving the salts in deionized water, and adding ammonia water to adjust the pH value to between 5 and 7; (2) soaking a carrier in aqueous solution of citric acid, diluted hydrochloric acid or diluted nitric acid for 24 to 48 hours, drying the carrier, soaking the carrier in the solution of the step (1), standing the carrier for 24 hours and drying the carrier; and (3) roastingthe prepared sample in step (2) in air, and cooling the sample. The flue gas denitration catalyst has the advantages of simple preparation method, high poisoning resistance, no secondary pollution toenvironment, wide activity temperature window, low activity starting temperature and the like.

Owner:SHANDONG GEMSKY ENVIRONMENTAL PROTECTION TECH CO LTD

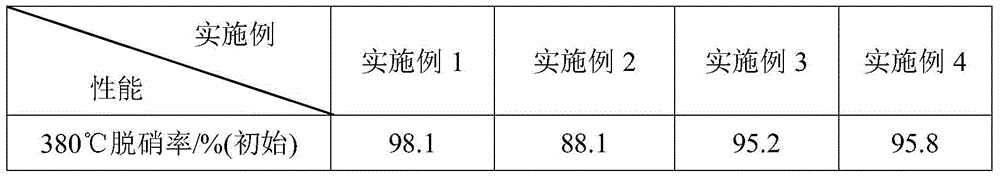

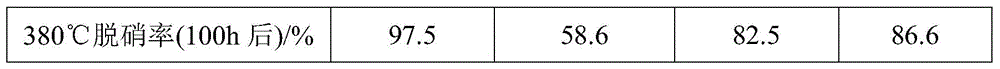

Denitration catalyst with SBA-15/TiO2 serving as carrier and preparing method thereof

ActiveCN105688974ALarge specific surface areaEnhanced mass transferMolecular sieve catalystsGlass fiberMolecular sieve

The invention discloses a denitration catalyst with SBA-15 / TiO2 as a carrier and a preparing method thereof.The denitration catalyst comprises 36wt%-85wt% of SBA-15 molecular sieves, 10wt%-40wt% of TiO2, 0.1wt%-1wt%V2O5, 1wt%-10wt% of active assistant, 1wt%-8wt% of glass fibers and 0.5wt%-5wt% of forming assistant.The preparing method includes the steps that after a titanium salt solution and an electrolyte solution are mixed, SBA-15 molecular sieves with skeletons containing rare-earth metal are added to be soaked, and a series of reactions are carried out to obtained the SBA-15 / TiO2 carrier; the carrier, an ammonium-metavanadate active assistant, glass fibers and a forming assistant are mixed to obtain the denitration catalyst.The denitration catalyst and the preparing method have the advantages that the prepared denitration catalyst is large in specific surface area, high in hydrothermal stability, wide in active temperature window and high in denitration efficiency; meanwhile, the preparing method is simple.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

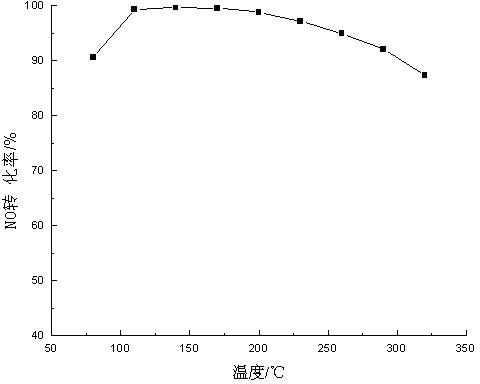

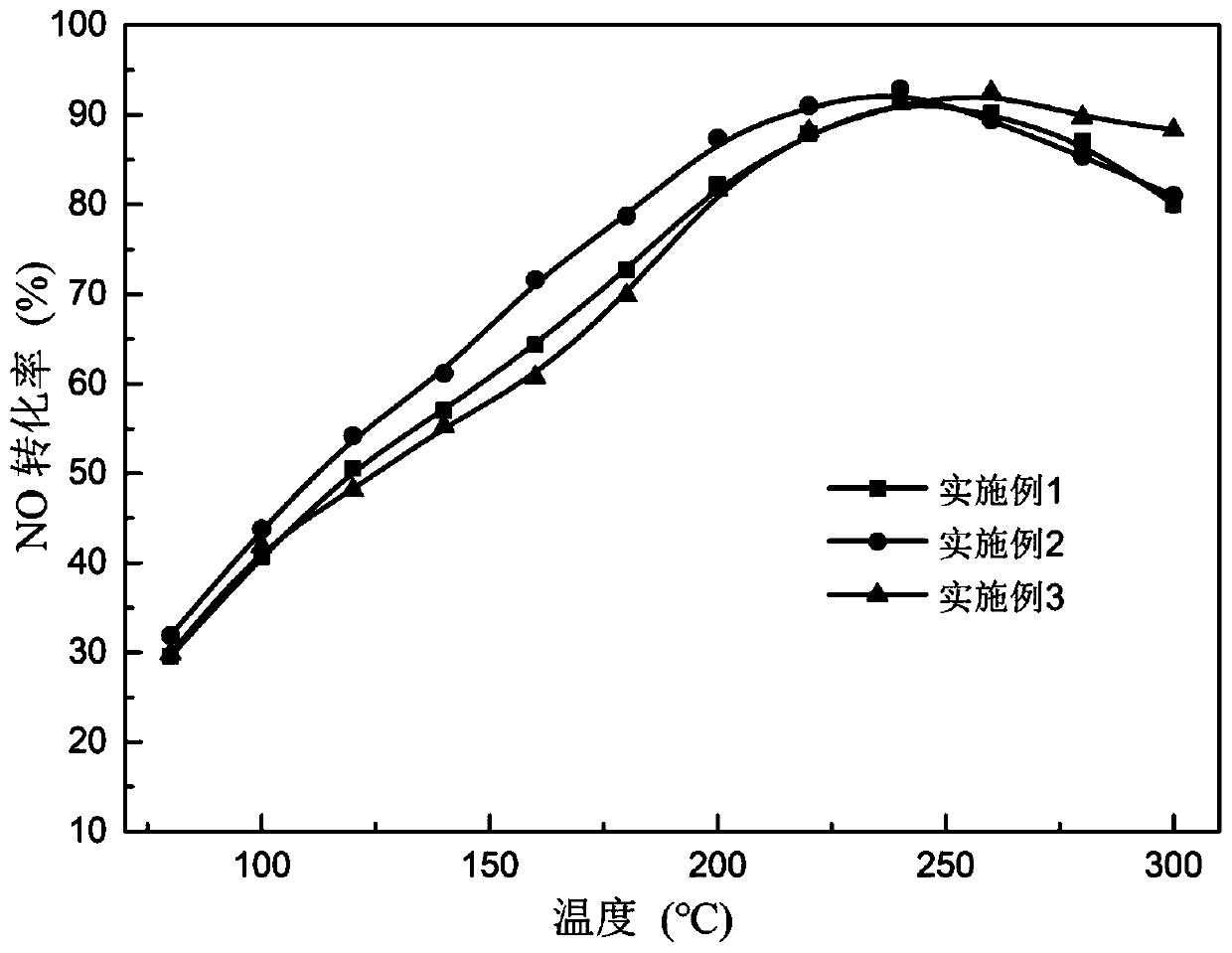

Composite smoke SCR (selective catalytic reduction) denitrification catalyst and preparation method thereof

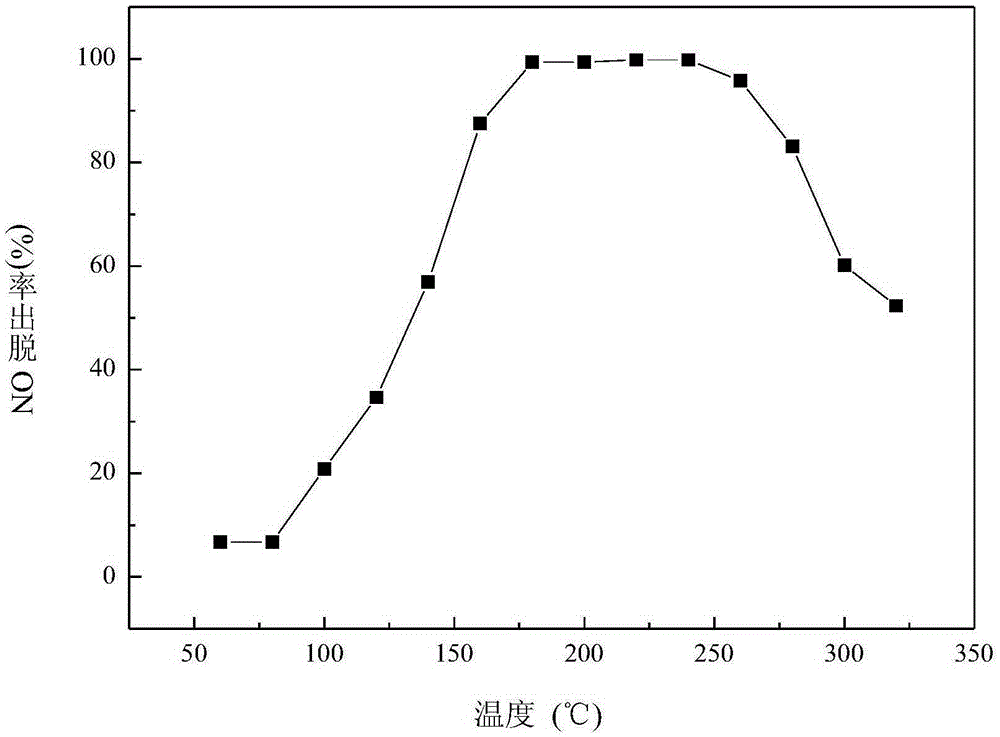

ActiveCN102950008AWide active temperature windowImprove SCR denitrification efficiencyMolecular sieve catalystsDispersed particle separationActivated carbonMolecular sieve

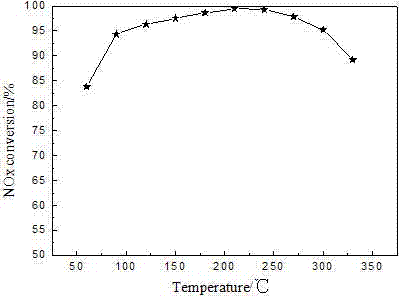

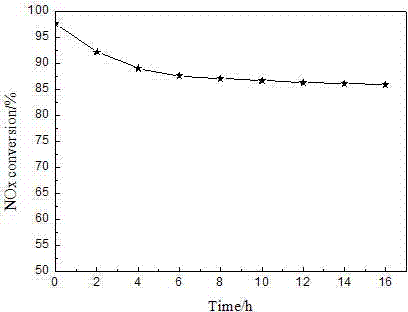

The invention relates to a composite smoke SCR (selective catalytic reduction) denitrification catalyst. The composite smoke SCR denitrification catalyst takes honeycomb ceramics, activated carbon or a molecular sieve as a carrier. A composite manganese-molybdenum-nickel-loaded metal oxide is an active component, one or more of copper, chromium, cerium, tin and lanthanum are used as cocatalysts, and the total mass of the active components of the catalyst and the cocatalysts accounts for 15-30% of the mass of the carrier, wherein the molar ratio of Mn to Mo to Ni is 1:(0.1-1):(0.1-1), and the molar ratio of manganese to a metallic element of the co-catalyst is 1: (0.1-1). The catalyst provided by the invention is prepared by adopting a dipping method. Compared with the existing denitrification catalyst suitable for the temperature lower than 300 DEG C, the catalyst provided by the invention has the advantages of high denitrification efficiency, low cost, simple production process, long service life, wide active temperature window, high SO2 and H2O poison resistance capability and the like. Within the temperature from 80 DEG C to 300 DEG C, the conversion rate of NO is more than 90%.

Owner:CHINA PETROLEUM & CHEM CORP +1

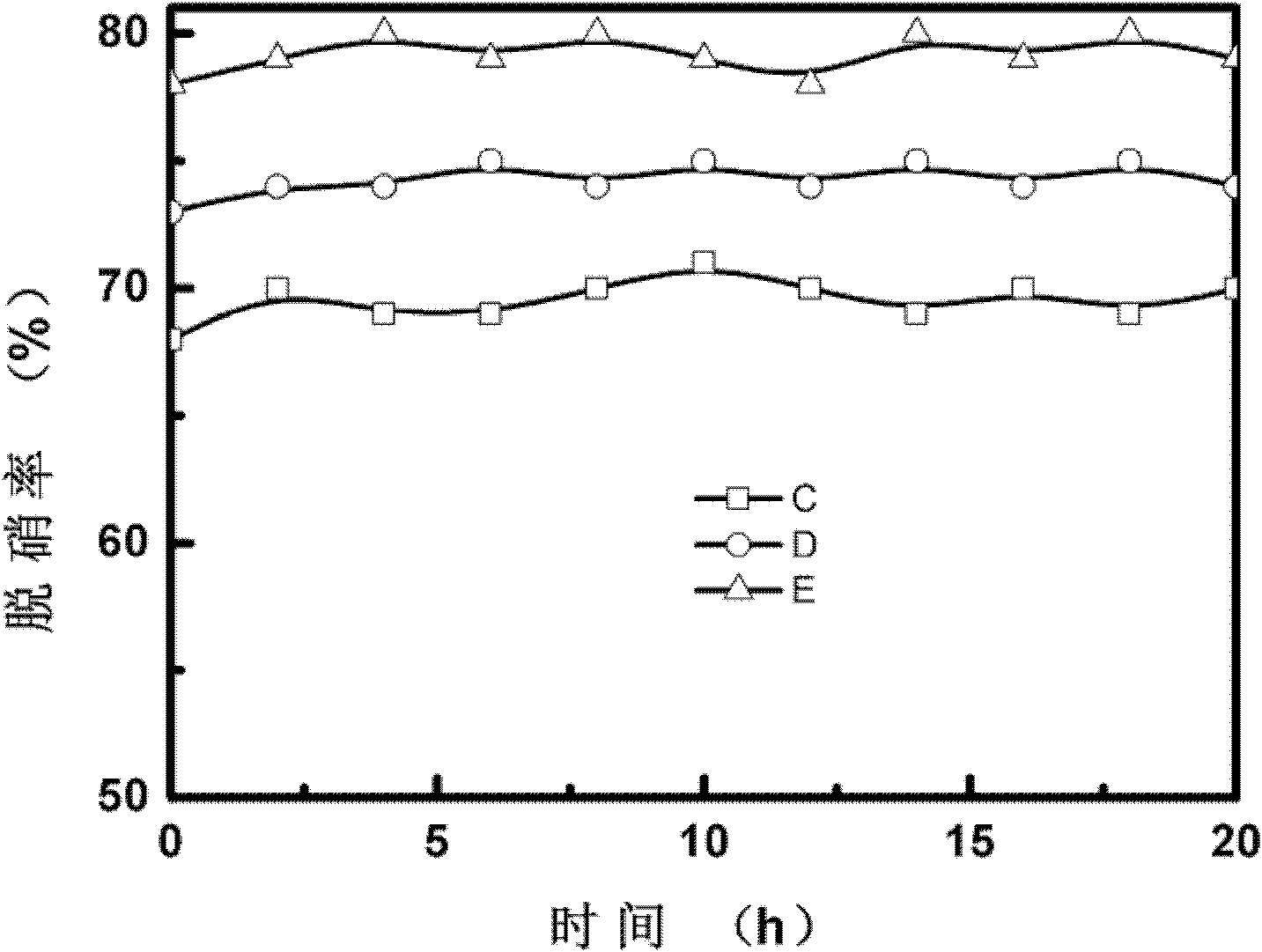

Composite catalyst capable of depriving nitre and mercury simultaneously and preparation method thereof

InactiveCN102716736AEasy to prepareWide active temperature windowMolecular sieve catalystsDispersed particle separationFiberPtru catalyst

The invention relates to a composite catalyst capable of depriving nitre and mercury simultaneously and a preparation method thereof, belongs to the technical field of air pollution control, and is used for depriving fire coal smoke nitric oxide and elementary substance mercury. The catalyst comprises an active component and a carrier, the active component is CeO2 and ZrO2, molar ratio of Ce and Zr is 1 / 0.1-1, the carrier is one or a plurality of kinds of honeycomb ceramics, a molecular sieve, a ceramic plate, activated carbon fibers, a silica gel carrier, kieselguhr, metal alloy and a filter bag. Quality of the carrier serves as a standard, and the content of the active component of the catalyst is 5%-30%. The composite catalyst further comprises an assistant which is one of or any combination of two of oxides of W, Cu, Fe, Ti and Ni. Quality of the carrier serves as a standard, and the content of the assistant is 0%-15%.

Owner:NANJING UNIV OF TECH

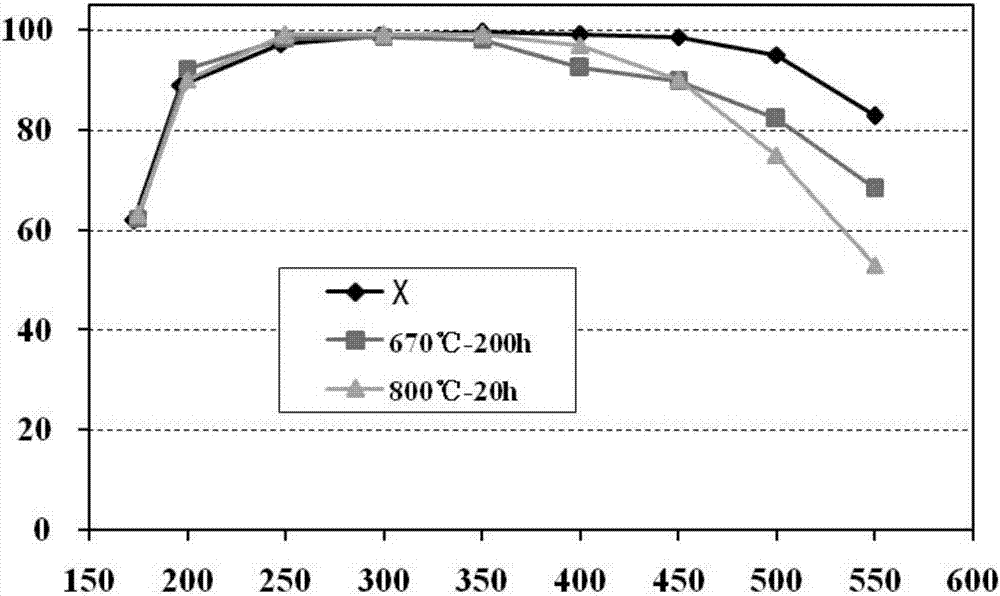

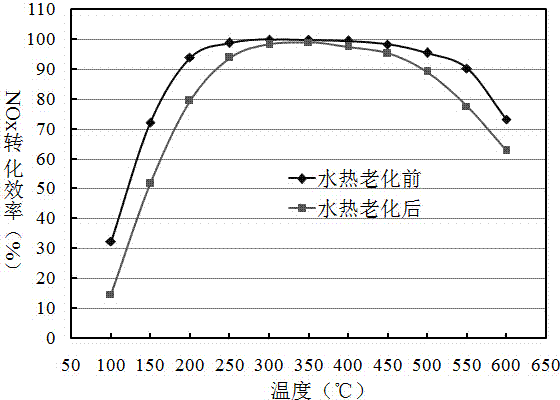

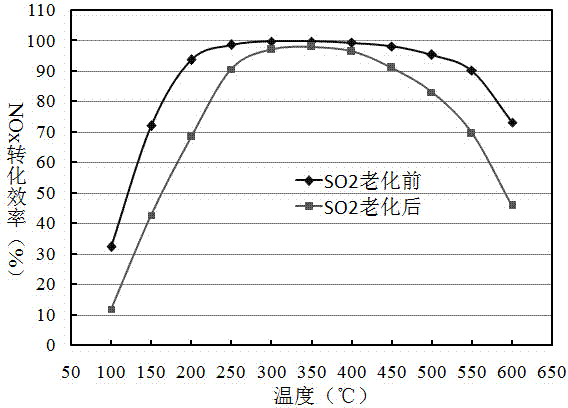

SCR catalyst for diesel exhaust purification and preparation method of SCR catalyst

ActiveCN106984357AGood resistance to hydrothermal agingWide active temperature windowGas treatmentMolecular sieve catalystsIon exchangeMolecular sieve

The invention discloses an SCR catalyst for diesel exhaust denitration and purification and a preparation method of the SCR catalyst. The catalyst is prepared from a transition or rare-earth metal element-modified zeolite molecular sieve as a carrier and metal elements such as Cu and Fe as active components. The preparation method comprises the steps of carrying out modified pretreatment of the zeolite molecular sieve; carrying out multiple liquid ion exchange; filtering and washing; drying and roasting; and finally pulping and coating a ceramic matrix to form a whole SCR catalyst. By adopting the modified zeolite molecular sieve as the carrier and nontoxic Cu and Fe as the active components, the SCR catalyst is harmless to a human body and friendly to the environment. Compared with an existing conventional method, the preparation method has the advantages that the ratios of species Cu and Fe at exchange sites in the prepared catalyst are obviously improved, the hydrothermal aging resistance is more excellent, the hydrothermal stability of the catalyst is improved, the high temperature resistance stability of the active components such as Cu and Fe is better, dispersion is more uniform, the active temperature window is effectively widened and the SCR catalyst has higher medium-high temperature activity and hydrothermal stability.

Owner:SINOCAT ENVIRONMENTAL TECH

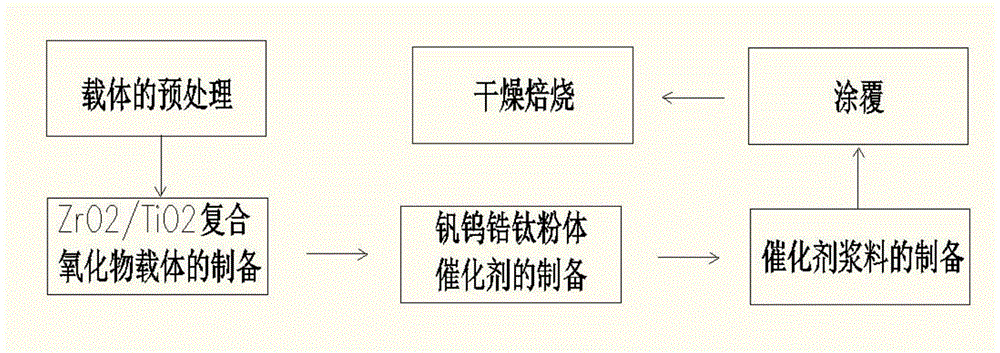

Monolithic SCR (Selective Catalytic Reduction) honeycomb catalyst for processing diesel exhaust and preparation method of catalyst

ActiveCN103908970AEvenly dispersedLarge specific surface areaCatalyst carriersDispersed particle separationRare earthSlurry

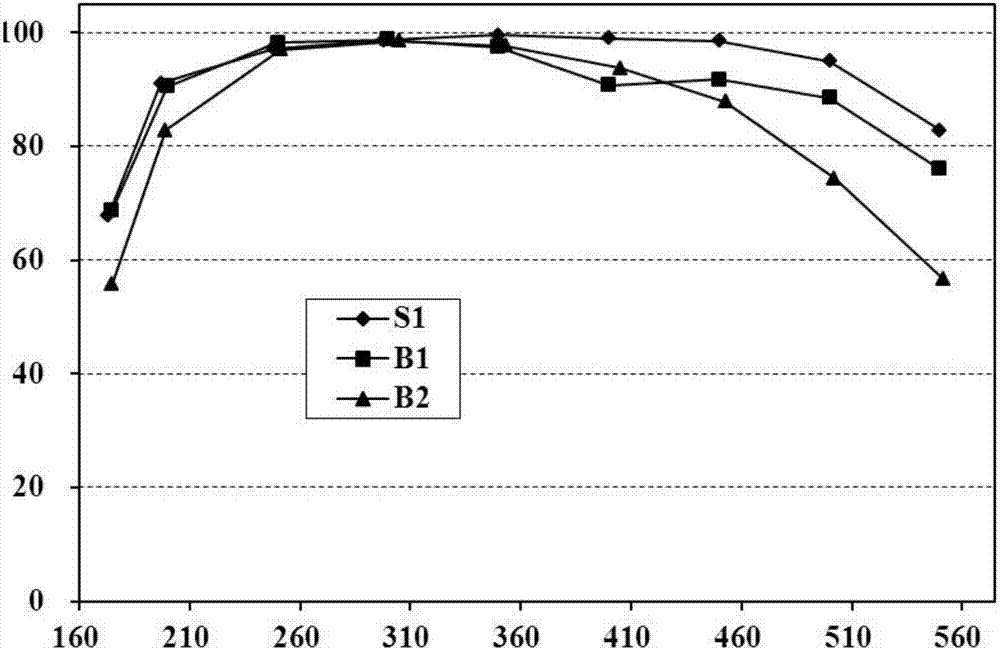

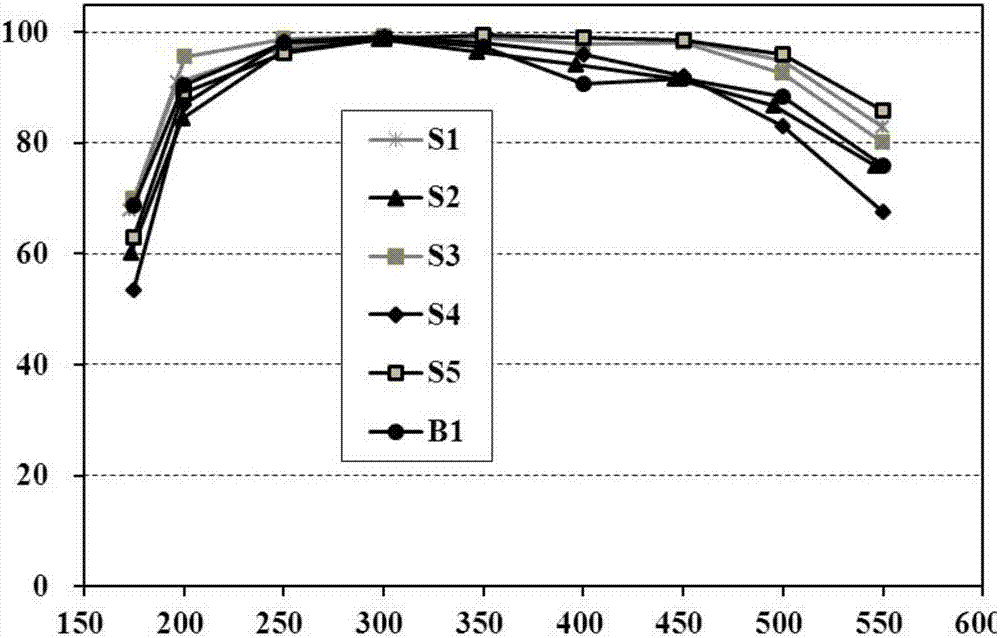

The invention discloses a monolithic SCR (Selective Catalytic Reduction) honeycomb catalyst for processing diesel exhaust and a preparation method of the catalyst. The catalyst comprises a honeycomb ceramic carrier and a coating; the coating coats a honeycomb hole, and the coating consists of a ZrO2 / TiO2 composite oxide carrier and catalyst active components. The ZrO2 / TiO2 composite oxide carrier comprises the following components in percentage by weight: 5wt%-20wt% of ZrO2 and 50wt%-85wt% of TiO2. The catalyst active components comprise the following components in percentage by weight: 1wt%-5wt% of V2O5, 1wt%-10wt% of WO, 1wt%-5wt% of Fe2O3, 1wt%-5wt% of CuO, 1wt%-10wt% of rare earth metal oxide and the balance of an adhesion agent. The preparation method of the catalyst comprises the following steps: firstly preparing the ZrO2 / TiO2 composite oxide carrier, subsequently preparing a vanadium-tungsten-zirconium-titanium powder catalyst, then dispersing the vanadium-tungsten-zirconium-titanium powder catalyst in other components to prepare a catalyst slurry; and then coating the honeycomb ceramic carrier with the catalyst slurry, drying and roasting, and then preparing the monolithic SCR honeycomb catalyst. The monolithic SCR honeycomb catalyst is suitable for purifying diesel exhaust NOx and has the characteristics of wide active temperature window at 160-550 DEG C, high NOx removal rate, strong antitoxic performance, long service life and simplicity in preparation.

Owner:浙江欧信环保科技有限公司

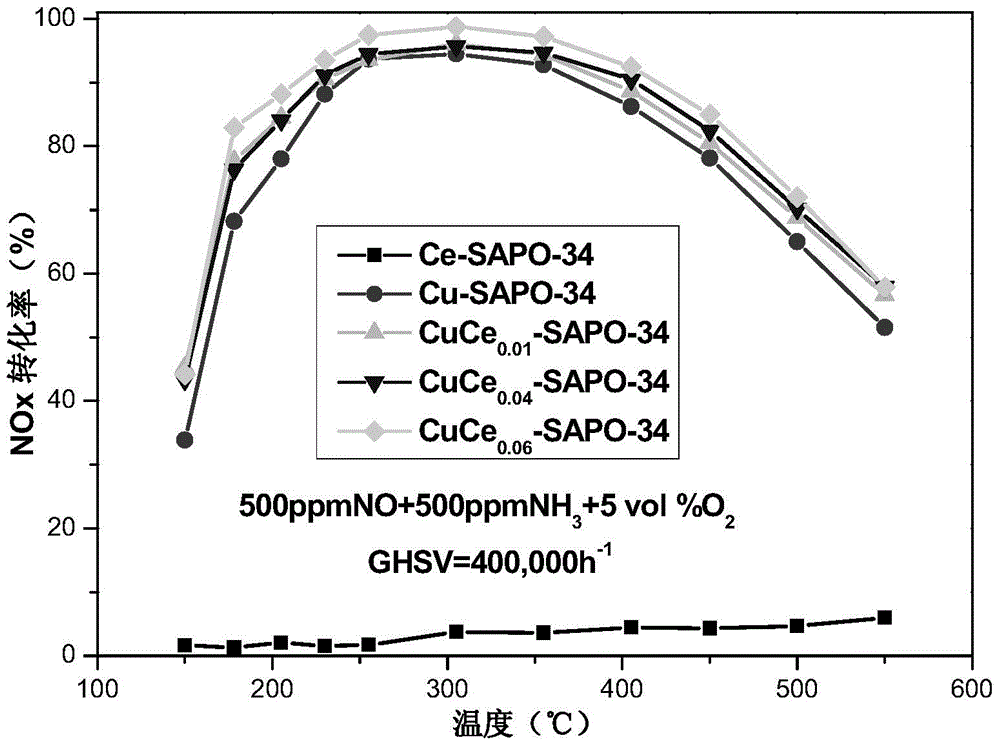

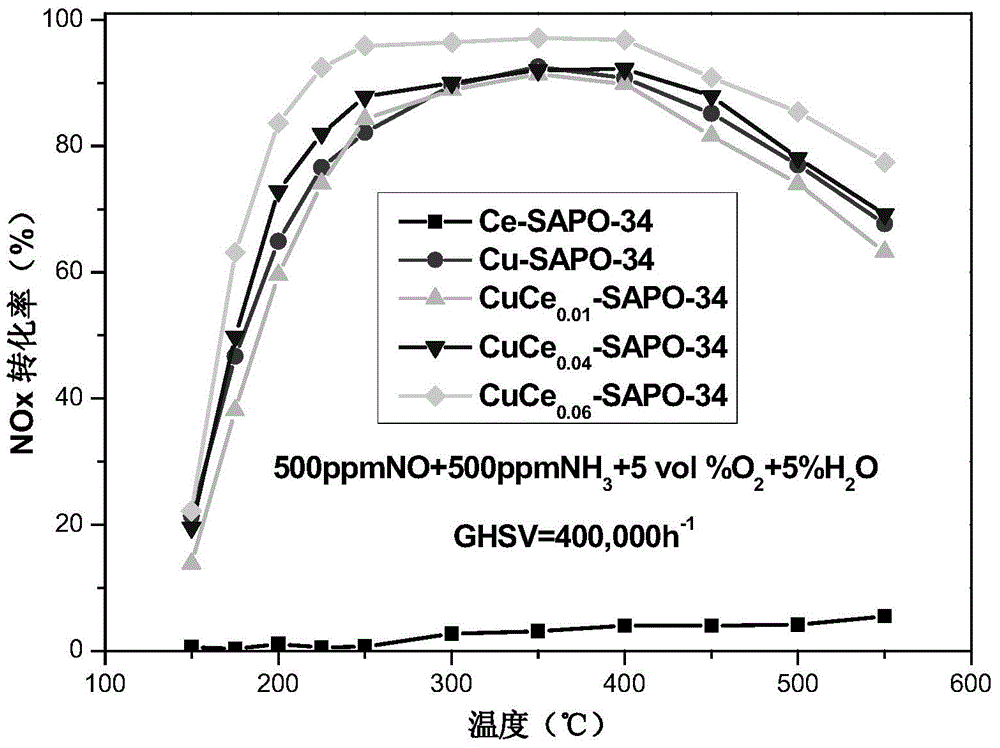

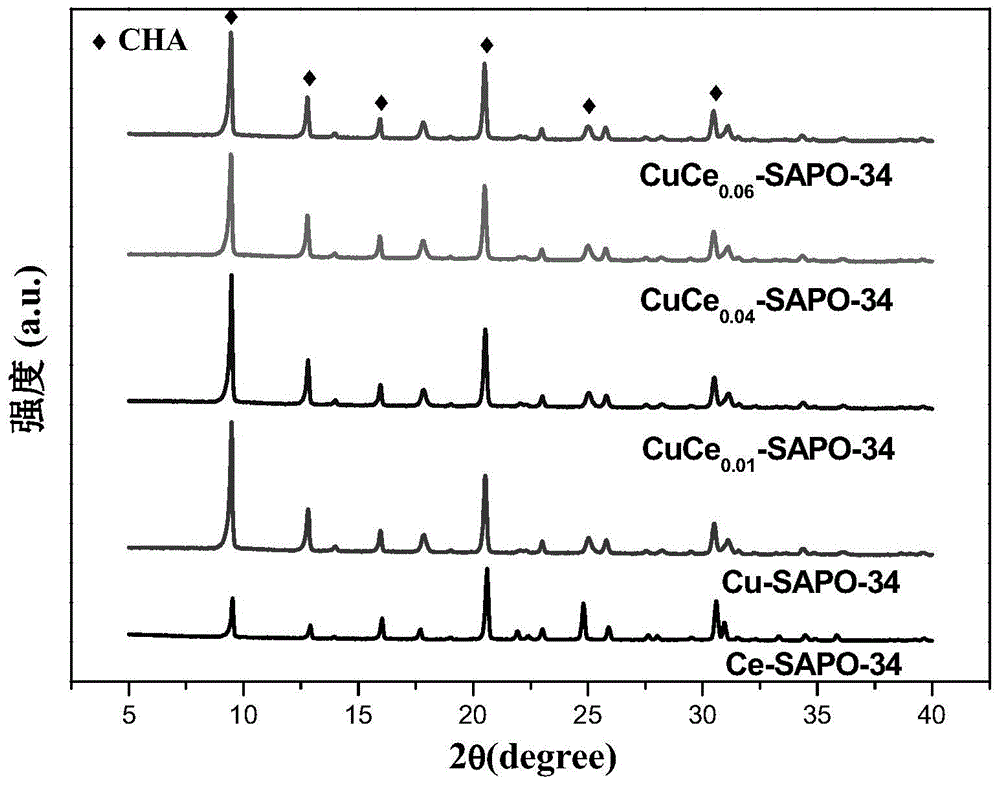

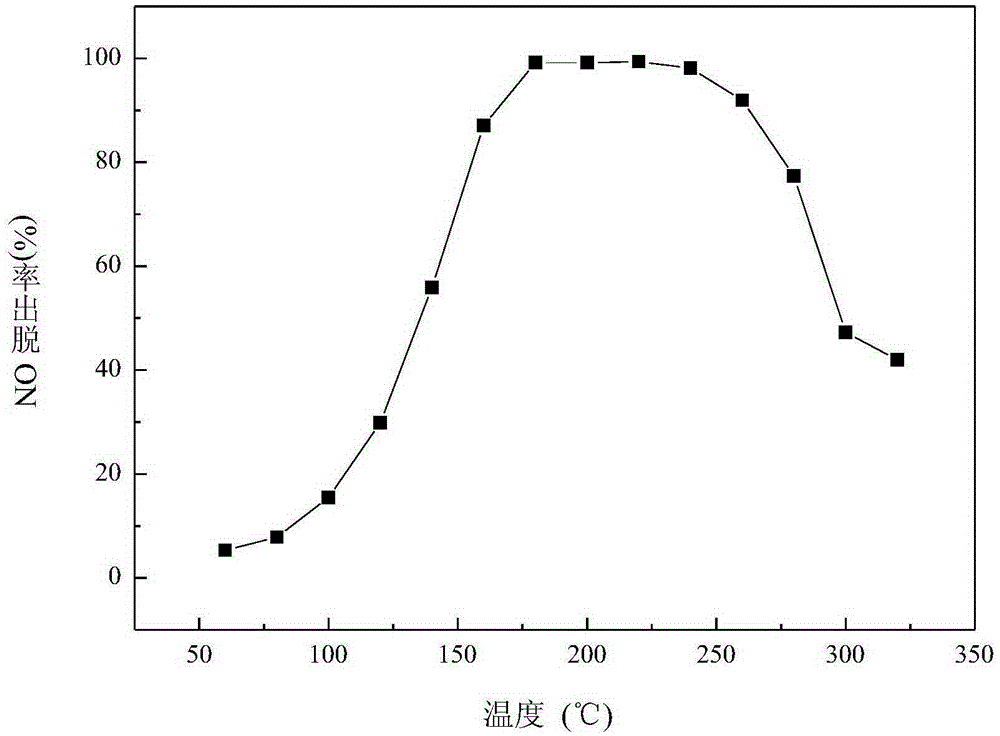

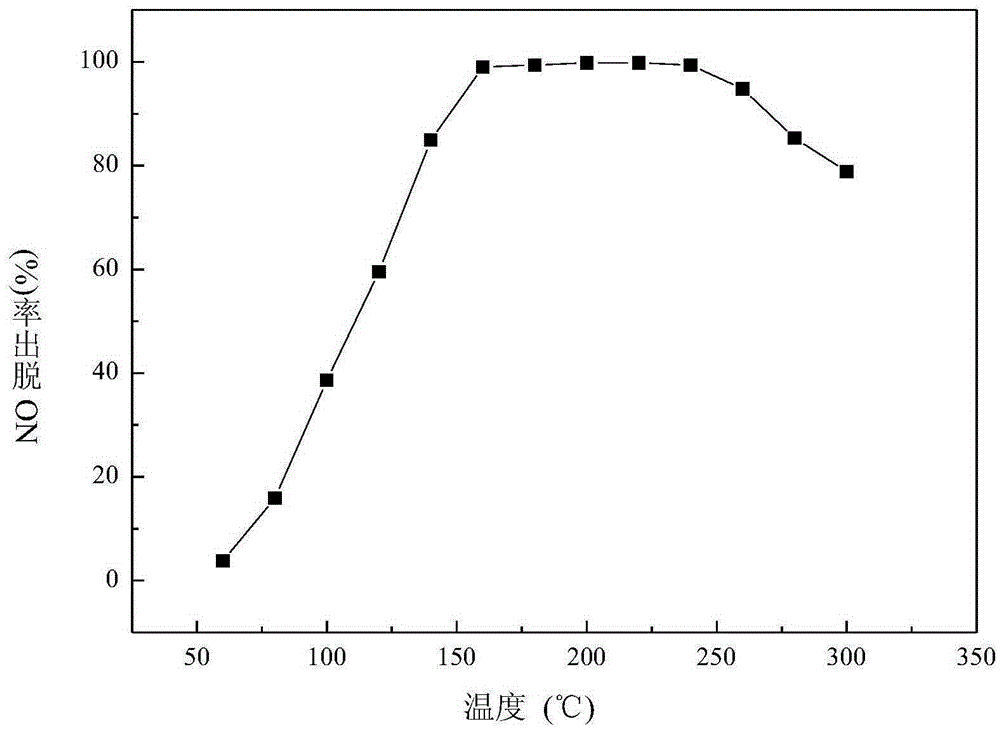

CuCe-SAPO-34 molecular sieve catalyst, as well as preparation method and use thereof

InactiveCN104888851ANo ion exchange step requiredReduce generationMolecular sieve catalystsDispersed particle separationGas phaseCerium

The invention provides a CuCe-SAPO-34 molecular sieve catalyst, as well as a preparation method and use thereof. The method comprises the following steps: adding pseudo-boehmite in deionized water, stirring, then adding ortho-phosphoric acid and fumed silica, uniformly mixing, then adding copper salt and tetraethylenepentamine, sufficiently mixing, adding cerate and n-propylamine, loading the completely mixed gel in a hydrothermal reaction kettle to crystallize, cooling at room temperature, separating the solid crystallized product from the mother liquor, washing to neutral, drying, and roasting in air to obtain the CuCe-SAPO-34 molecular sieve catalyst. The CuCe-SAPO-34 molecular sieve catalyst is prepared through the adoption of the hydrothermal synthesis method, and the molecular sieve catalyst with excellent NH3-SCR catalytic activity and water resistance is obtained by adjusting the loading amount of cerium through the control of the input of the cerate.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method of novel SCR smoke denitrification catalyst adopting titanium-containing blast furnace slag as carrier

ActiveCN105327698AThe pre-processing process is simpleWon't happenMetal/metal-oxides/metal-hydroxide catalystsSlagTitanium

The invention belongs to the field of the utilization of blast furnace slag, and particularly relates to a preparation method of a novel SCR smoke denitrification catalyst adopting titanium-containing blast furnace slag as a carrier. The preparation method comprises the following steps: a, pretreating the titanium-containing blast furnace slag; and b, preparing the catalyst. The preparation method of the catalyst is simple and easy in operation, high in blast furnace slag utilization rate, capable of effectively solving the resource waste and environmental pollution problem caused by the extensive application of the titanium-containing blast furnace slag and capable of enlarging the application field of the blast furnace slag; the catalyst prepared in the method is high in activity, wide in active temperature window and capable of maintaining relatively high denitrification activity at the temperature of 160 to 260 DEG C.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Diesel vehicle exhaust purification SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

ActiveCN103769080AImprove performanceWide active temperature windowMetal/metal-oxides/metal-hydroxide catalystsTungstateAmmonium metavanadate

The invention discloses a diesel vehicle exhaust purification SCR (Selective Catalytic Reduction) catalyst. The catalyst comprises a cordierite honeycomb ceramic carrier and a coating which is loaded on the cordierite honeycomb ceramic carrier; the coating comprises the following raw materials: titanium dioxide / silicon dioxide composite oxide powder, ammonium tungstate and ammonium metavanadate according to a mass ratio of 100:(12-18):(3-6). A preparation method of the catalyst comprises the steps of mixing the ammonium tungstate with the titanium dioxide / silicon dioxide composite oxide powder firstly to prepare TiO2-SiO2 / WO3 pccowder, then mixing the ammonium metavanadate with TiO2-SiO2 / WO3 to prepare slurry to be coated, and then coating the cordierite honeycomb ceramic carrier with the slurry to be coated by using an impregnation method. The catalyst is wide in activity temperature window, high in high-temperature activity and water / heat resistant stability, and good in reproducibility.

Owner:DONGFENG COMML VEHICLE CO LTD

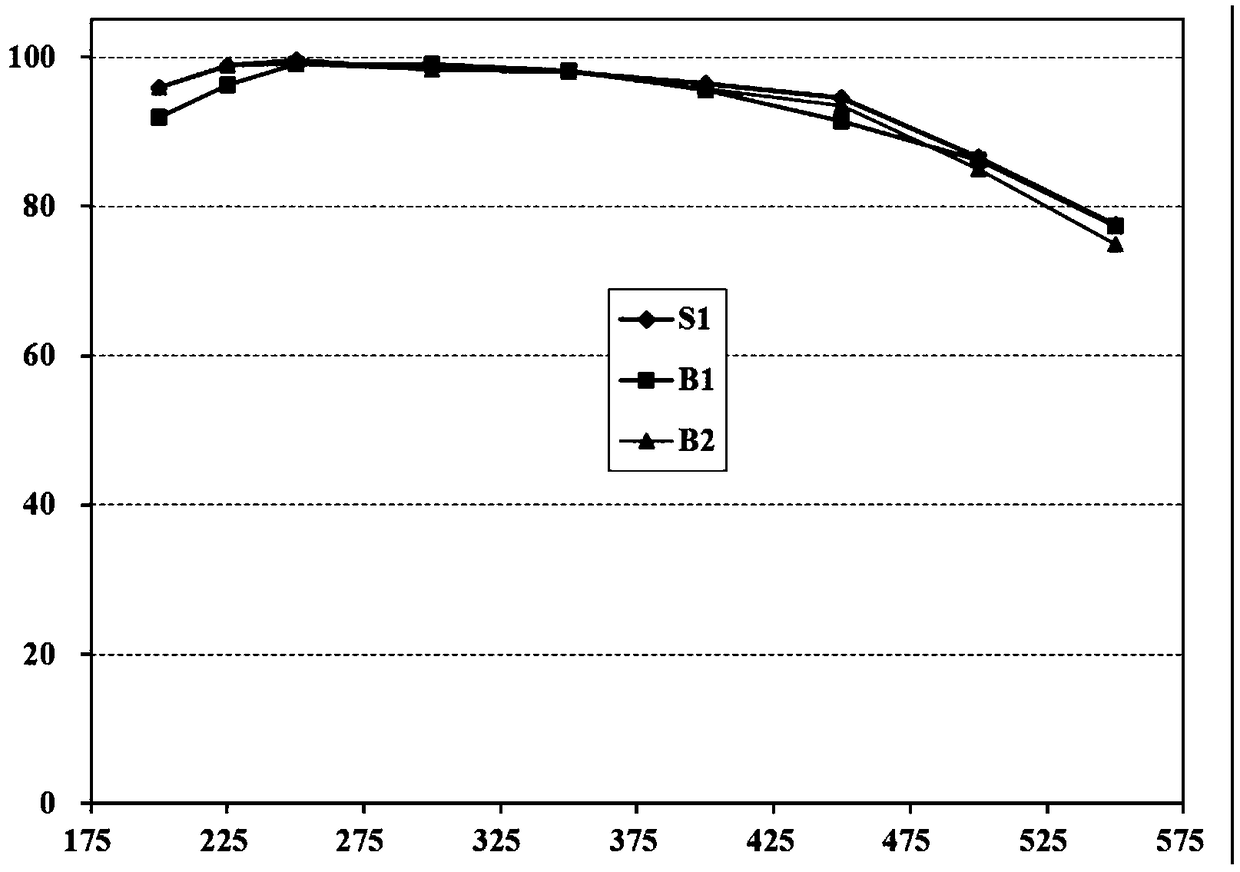

Combined catalyst for improving denitration performance and application thereof

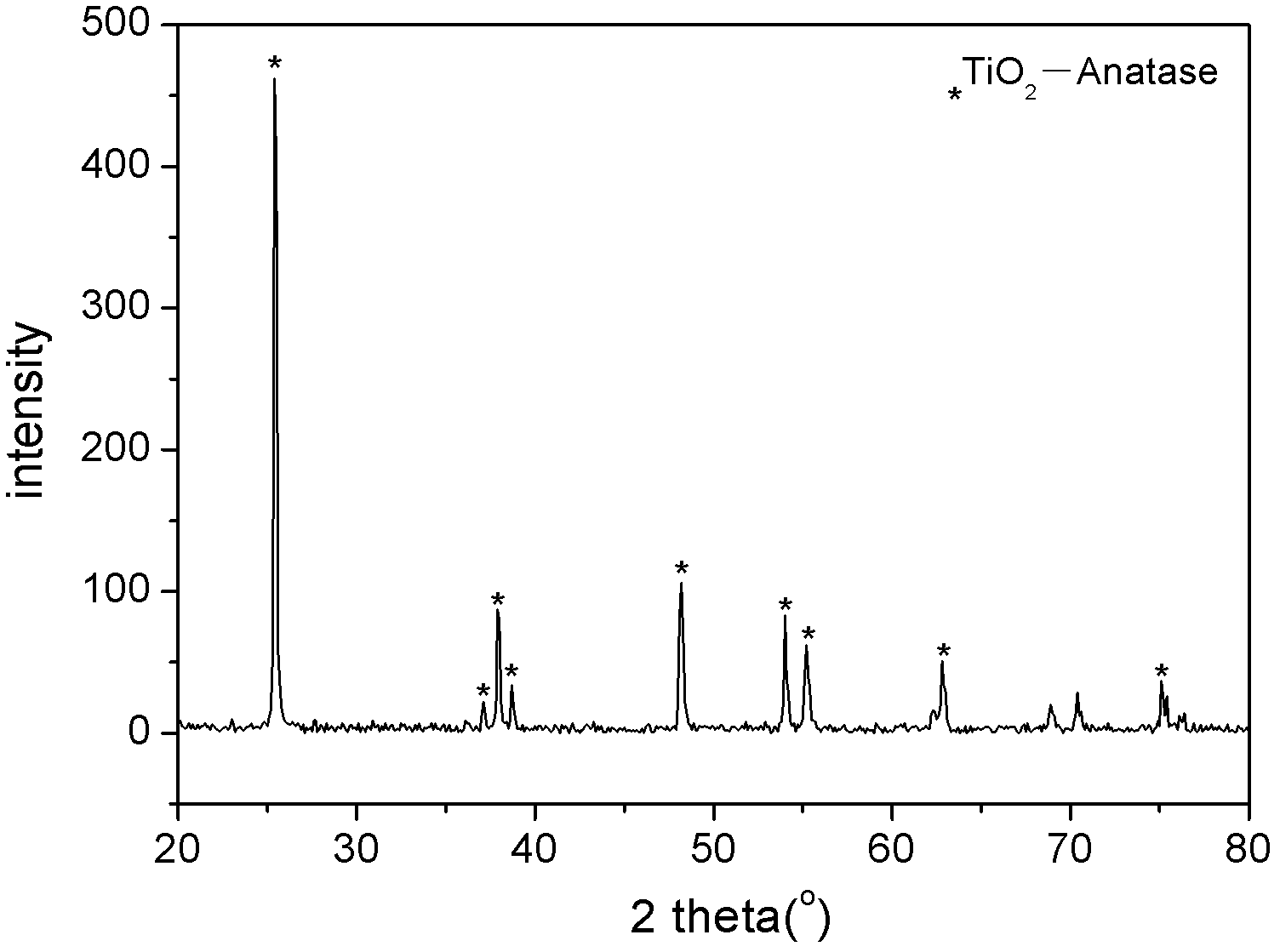

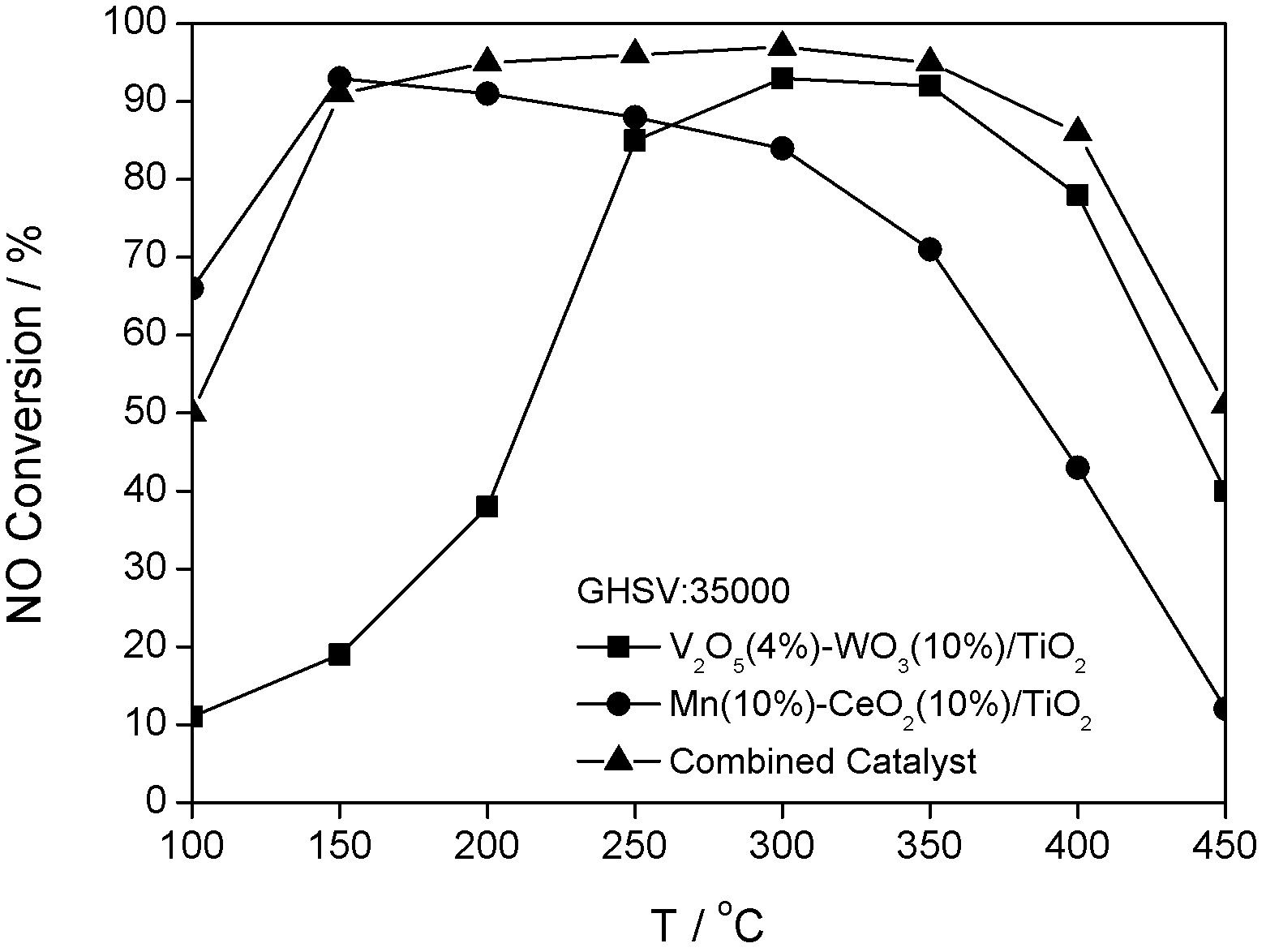

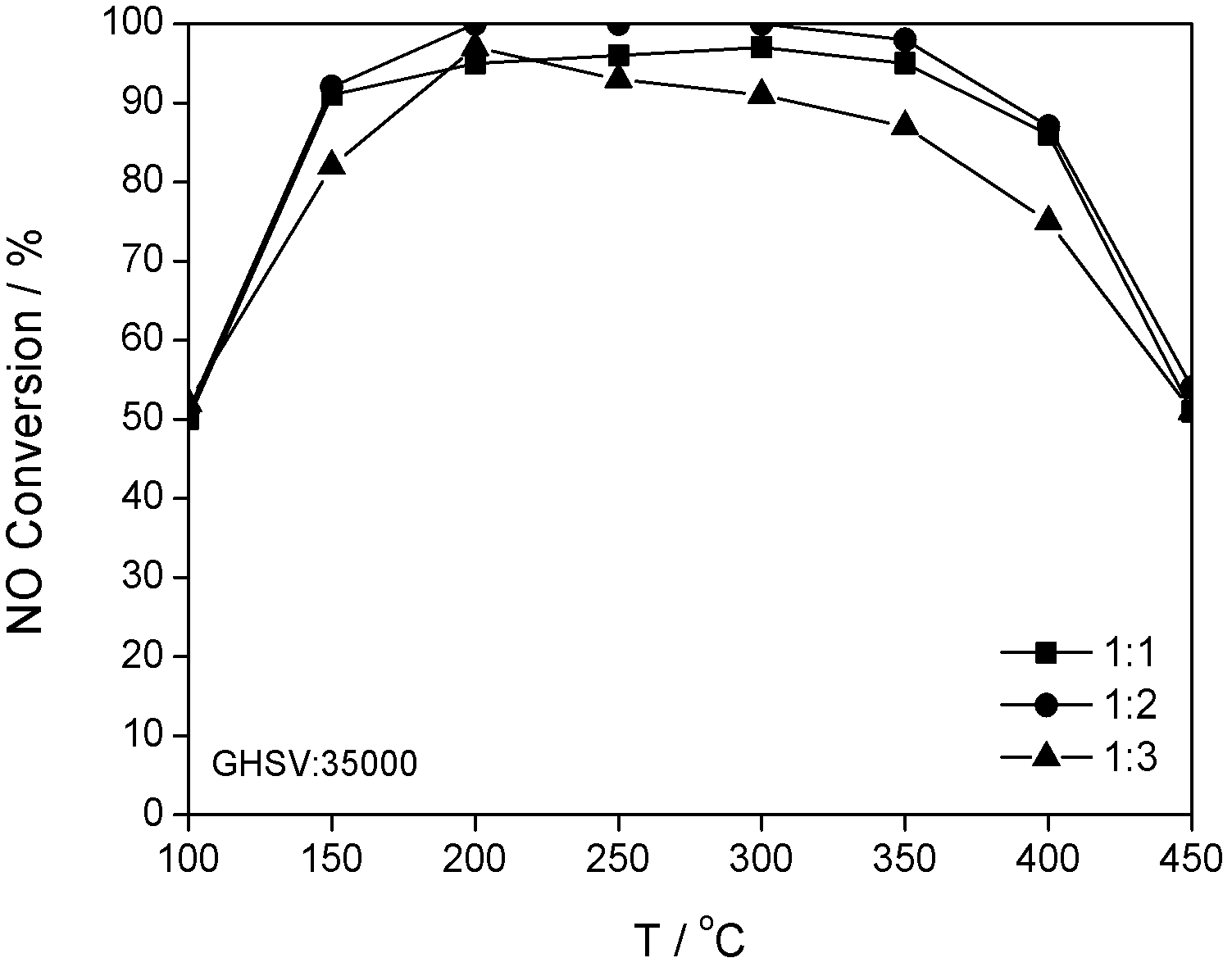

InactiveCN102600832AEfficient removalHigh and low temperature - high temperature catalytic activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioEngineering

The invention discloses a combined catalyst for improving denitration performance and an application thereof, which belongs to the field of catalysts. In the catalyst, industrial anatase crystal form TiO2 is taken as a carrier; V2O5-WO3 / TiO2 is put at the front section of MnOx-CeO2 / TiO2, and is called front section; MnOx-CeO2 / TiO2 is called back section; the front section refers to a section where an air current main body is contacted firstly; the back section refers to a section where the air current main body is contacted secondly; the mass ratio of the front section to the back section is 1:1-1:3; V2O5 accounts for 2-4 percent of the mass of the carrier TiO2; WO3 accounts for 8-10 percent of the mass of the carrier TiO2; Mn accounts for 10-20 percent of the mass of the carrier TiO2; CeO2 accounts for 8-10 percent of the mass of the carrier TiO2; and MnOx is taken as the general name of MnO2 and Mn2O3. The combined catalyst can be applied to an integral catalyst for industrial application. The combined catalyst has a wider active temperature window; particularly, the removing efficiency of NOx by NH3-SCR is greatly increased under the exhaust low-temperature wording condition of a diesel engine; and moreover, the same NOx removing efficiency as the conventional catalyst can be obtained at a medium-high temperature section.

Owner:BEIJING UNIV OF CHEM TECH

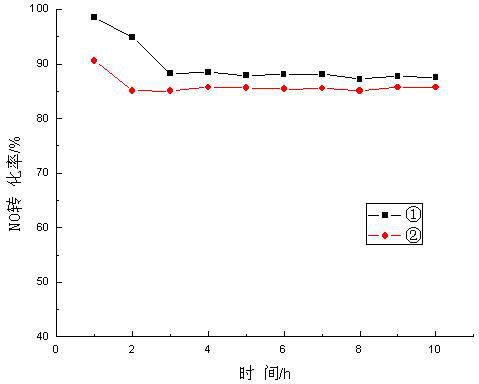

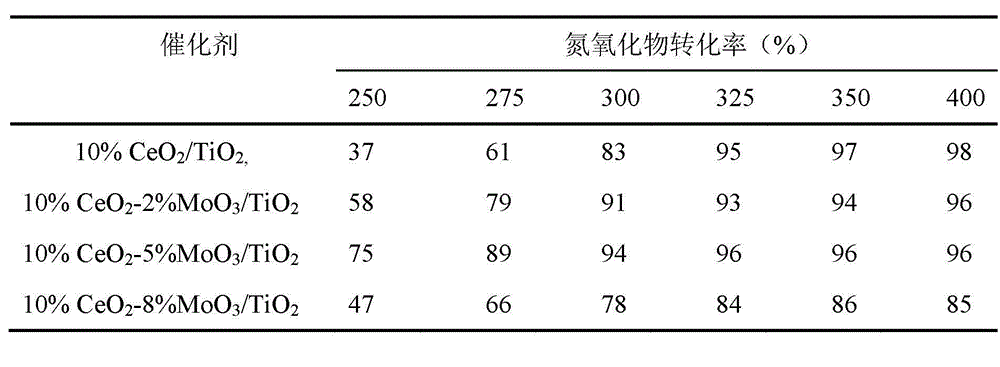

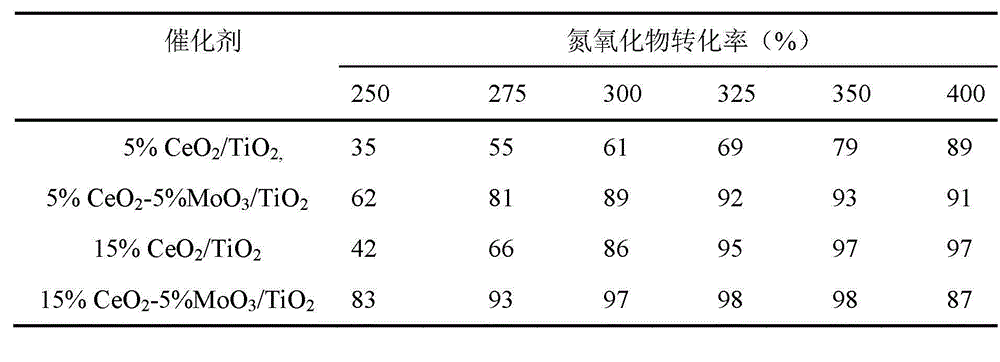

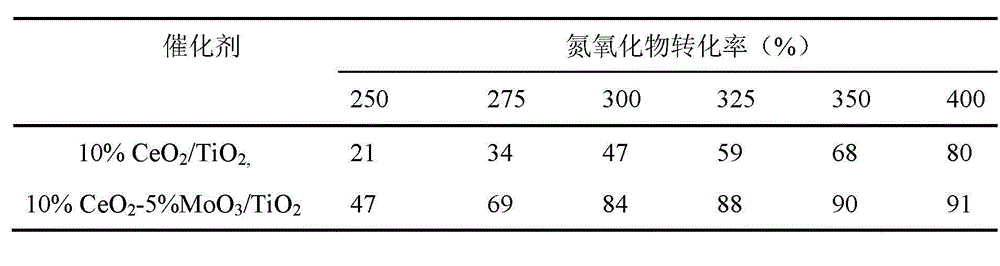

Compounded denitration catalyst, as well as preparation method and application thereof

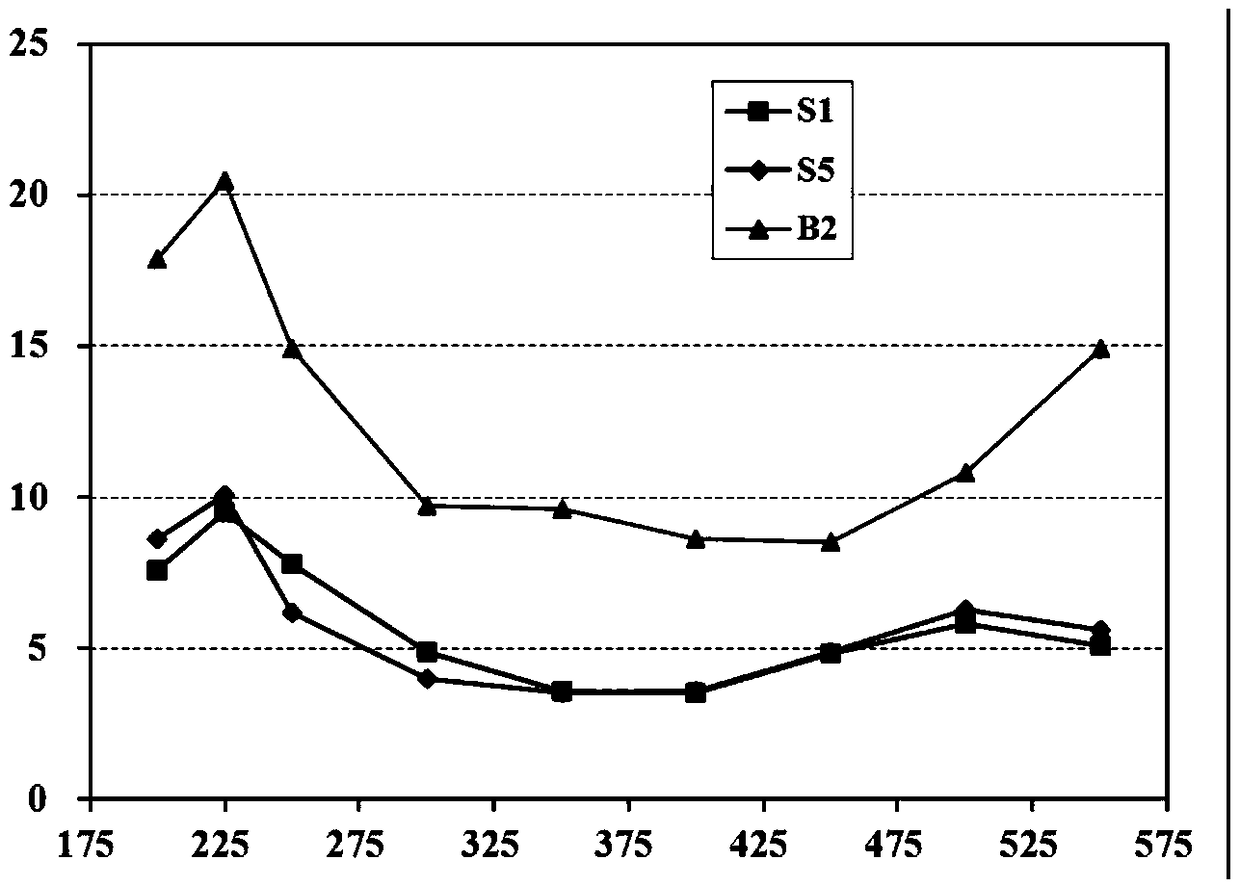

ActiveCN102909004AImprove low temperature denitrification performanceWide active temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureFixed bed

The invention provides a compounded denitration catalyst and a preparation method thereof, and belongs to the technical field of environment catalysis and atmospheric pollution controlling. The catalyst adopts titanium dioxide as a carrier, cerium dioxide as a main active component, and molybdenum trioxide as secondary active component performing a synergistic effect, and is prepared according to a stepped impregnation method. The compounded denitration catalyst is characterized in that due to the adding of molybdenum trioxide, the denitration performance of cerium-titanium catalyst is improved obviously, the active temperature window is widened, and the water resistance of the catalyst is also improved obviously. The method for reducing nitrogen oxides comprises the following steps: filling the catalyst into a fixed bed reactor; controlling the reaction temperature range to be 250 to 400 DEG C; and taking ammonia as a reducing agent. The cerium-molybdenum-titanium compounded catalyst prepared according to the invention is 12,8000 per hour in space velocity, and can purify nitrogen oxides with the efficiency ranging from 83 to 98 percent at the temperature ranging from 250 to 400 DEG C.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing molecular sieve SCR catalyst, and catalyst prepared therethrough

ActiveCN109174173AMaintain a wide active temperature windowImprove anti-aging propertiesNitrous oxide captureGas treatmentMolecular sieveThermal ageing

The invention discloses a method for preparing a molecular sieve SCR catalyst, and the catalyst prepared therethrough. Several molecular sieves are mixed, and then undergo ion exchange modification treatment by a transition metal or a rare earth metal, Fe is loaded through isopyknic impregnation, and Cu is loaded through one-stage or multistage liquid ion exchange. A technology for modifying the stable molecular sieve mixture with the transition and rare earth metals, a technology for loading Fe by the isopyknic impregnation process and a technology for loading Cu by the one-stage or multistage liquid ion exchange are combined, and a catalysis material obtained through stable and effective modification and loading control is applied to a carrier matrix after being blended to form a slurryin order to prepare the monolithic catalyst; results of fresh sample activity test and hydrothermal aging test show that the catalyst has a wide active temperature window and excellent hydrothermal aging resistance, and the N2O generation amount of the catalyst prepared in the invention is significantly lower than that of previous catalysts of the same type.

Owner:SINOCAT ENVIRONMENTAL TECH

Copper-based molecular sieve catalyst used for diesel engine NOx removing using low-temperature NH3-SCR and preparation method of copper-based molecular sieve catalyst

InactiveCN108525701AWide active temperature windowImprove removal efficiencyInternal combustion piston enginesMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a copper-based molecular sieve catalyst used for diesel engine NOx removing using low-temperature NH3-SCR and a preparation method of the copper-based molecular sieve catalystand belongs to the technical field of diesel engine tail gas pollutant control. The catalyst uses silicon-aluminum-phosphorus-oxygen tetrahedron (SAPO-34) as the carrier, Cu as the main active component and Ce as the promoter component. Chemical element proportion used during the preparation is 1Al:1P:0.25Si:0.06Cu-TEPA:(0.01 / 0.04 / 0.06 / 0.08)Ce:1.6PA:40H2O. The preparation method specifically includes: synthesizing Cu-TEPA; loading the copper serving as the main active component, determining the loading capacity of the Ce serving as the promoter, loading the Ce serving as the promoter, and performing one-pot synthesizing of the CuCe-SAPO-34 integral structure. The copper-based molecular sieve catalyst and the preparation method thereof have the advantages that the copper and cerium molecular sieve catalyst is used to replace a traditional vanadium-based catalyst, the environmental harm of the catalyst is lowered, low-temperature activity and high-temperature and low-temperature selectivity are increased greatly, the catalyst can effectively reduce NOx in the wide temperature window of 150-550 DEG C, and the catalyst is high in sulfur resistance and hydrothermal aging resistance andapplicable to high-sulfur diesel oil and city road traffic conditions of China.

Owner:上海倍绿环保科技有限公司

Titanium-based nano-composite metal oxide catalyst and preparation method thereof

InactiveCN102125834ASimple preparation processShort cycleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSelf-propagating high-temperature synthesisDiesel engine

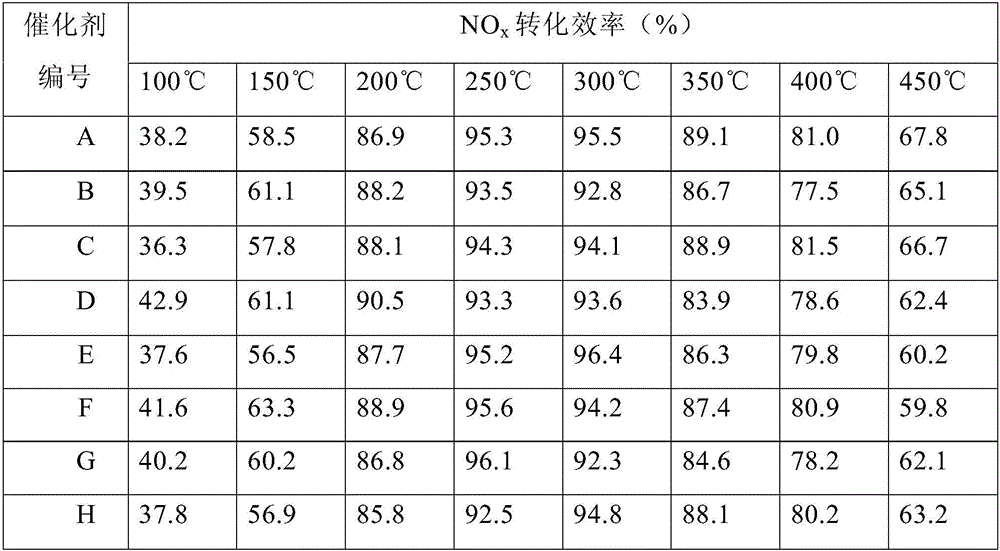

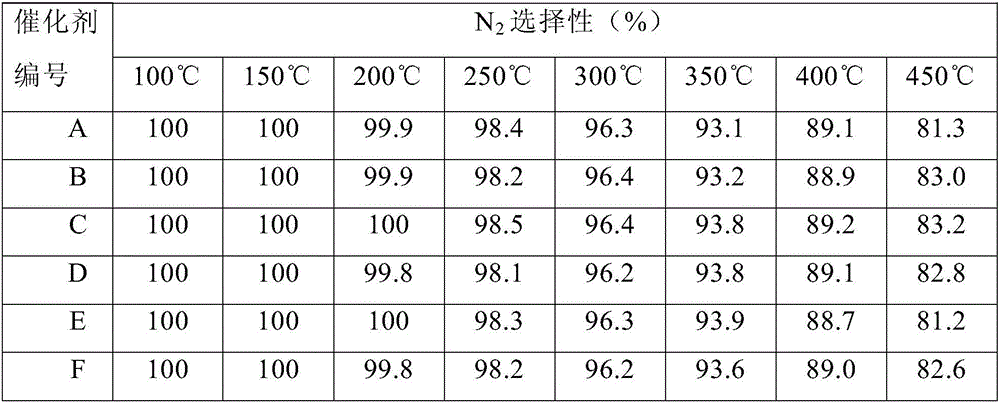

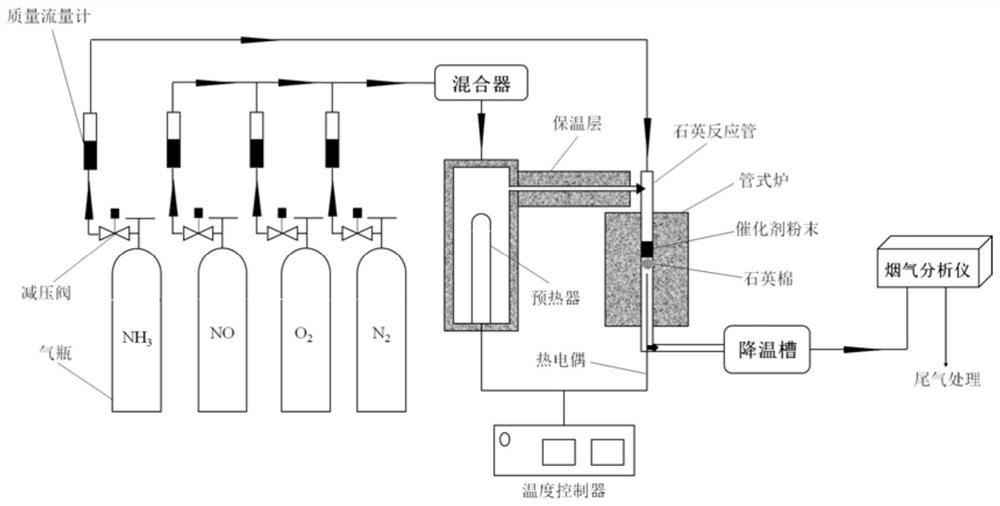

The invention discloses a titanium-based nano-composite metal oxide catalyst and a preparation method thereof, belonging to the technical field of control on exhaust contaminants in diesel engine tail gas. In the invention, the titanium-based nano-composite metal oxide catalyst is prepared by taking TiO2 as a carrier and taking metal oxides (VOx, MnOx and CeOx) as active components by adopting a self-propagating high-temperature synthesis (SHS) method, wherein the molar percentage of the TiO2 is 80-95%, the molar percentage of the VOx is 2-20%, the molar percentage of the MnOx is 2-10%, and the molar percentage of the CeOx is 2-10%. The preparation method of the titanium-based nano-composite metal oxide catalyst comprises the following steps of: preparing a TiO(NO3)2 precursor solution; determining the loads of the active components of the metal oxides; preparing a precursor solution of the active components of the metal oxides; and preparing the catalyst by SHS. The catalyst prepared by the method disclosed by the invention has the advantages of large specific surface area, large pore volume, proper pore size distribution and low degree of crystallization, all active species are highly dispersed and are interactive, the catalyst has higher NOx removing rate and N2 selectivity in a wide temperature window at 100-450 DEG C, and the catalyst has strong anti-sulfur and anti-water poisoning performance and is suitable for treating NOx in diesel engine tail gas of automobiles and ships.

Owner:SHANGHAI JIAO TONG UNIV

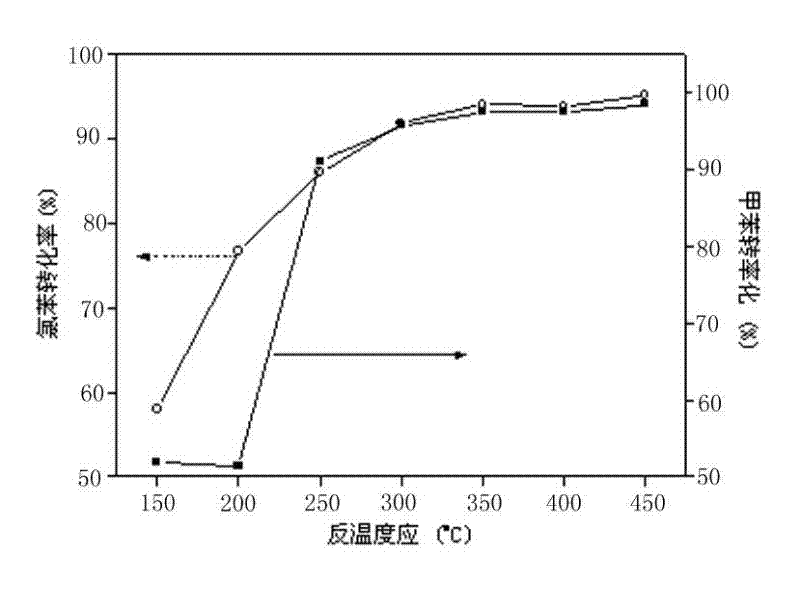

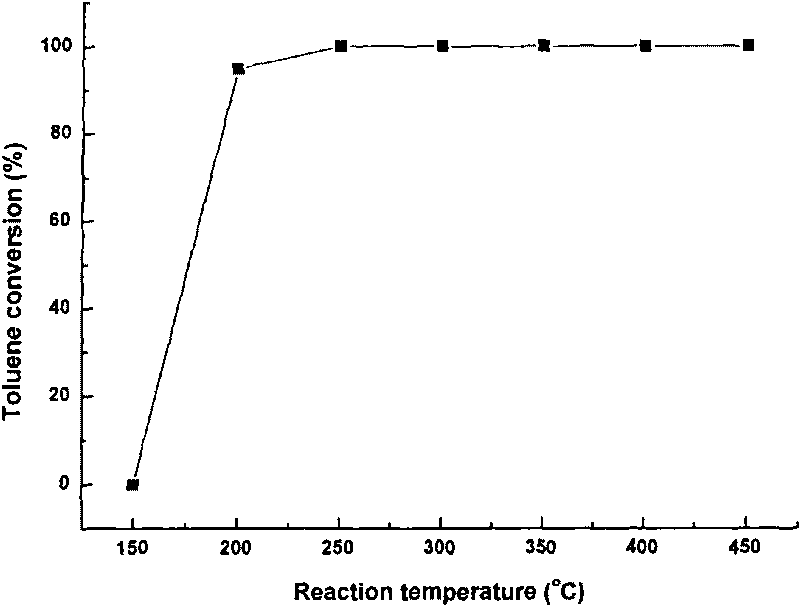

Catalyst for treating organic waste gas and preparation method thereof

InactiveCN101733127ASuitable for handlingFully catalyzedDispersed particle separationCatalyst activation/preparationPtru catalystExhaust fumes

The invention relates to a catalyst for treating organic waste gas and a preparation method thereof, belonging to the control technology of atmospheric pollution and the field of environment protection materials. In the catalyst, copper oxide, manganese oxide and titanium oxide are used as active ingredients, and a catalyst carrier is self-made; based on the mass of the carrier, the active ingredients are mixed in the molar ratio of copper oxide, manganese oxide to titanium oxide being 1-4: 1-4: 0.5-1; and the mass percentage of the capacity of the active ingredient is 1-20%. The self-made carrier is prepared by using silicon oxide, aluminum oxide, magnesium oxide and ferric oxide as components which are baked at high temperature, wherein the mass percentage of the material is 28-55% of silicon oxide, 20-40% of aluminum oxide, 10-30% of magnesium oxide and 0.5-2% of ferric oxide; and the carrier is modified or modified through an aluminum oxide coating by using 5-20% acid in mass percentage. The catalyst can completely catalyze toluene at 250 DEG C, and the complete catalysis temperature is reduced by about 20 DEG C compared with the same kind of catalysts.

Owner:NANJING UNIV OF TECH

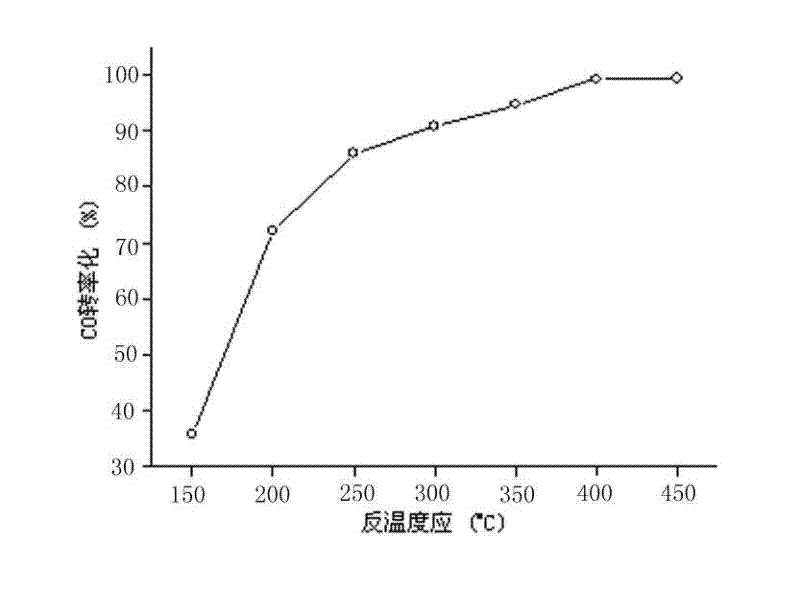

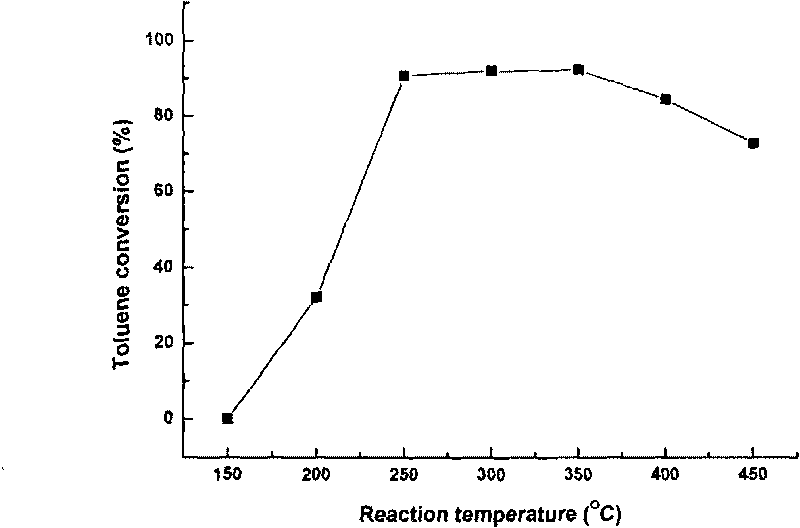

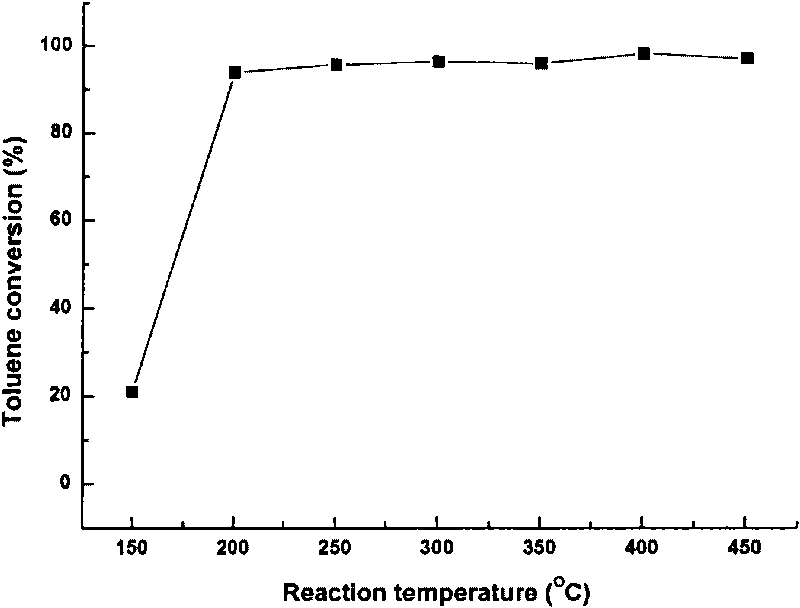

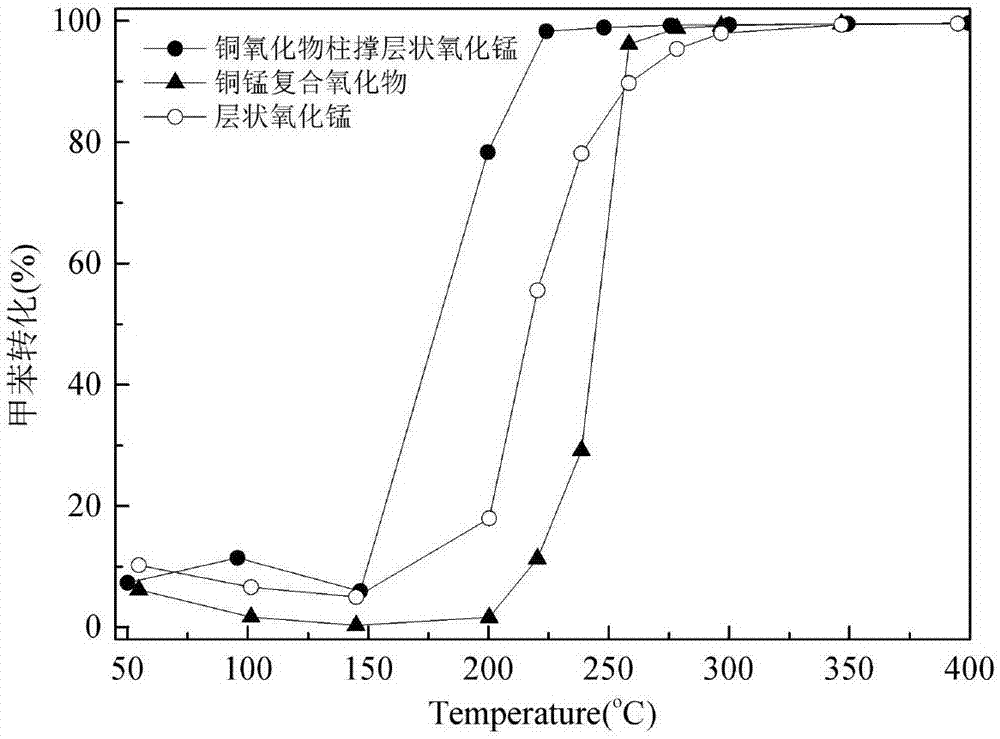

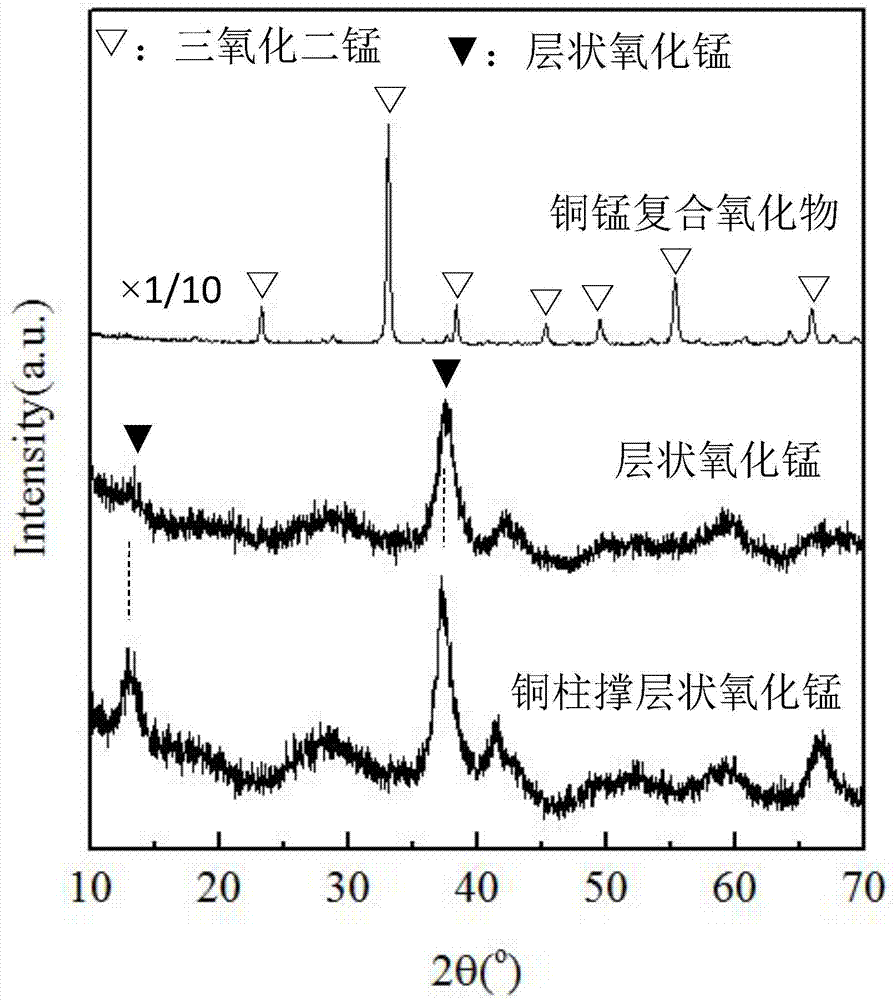

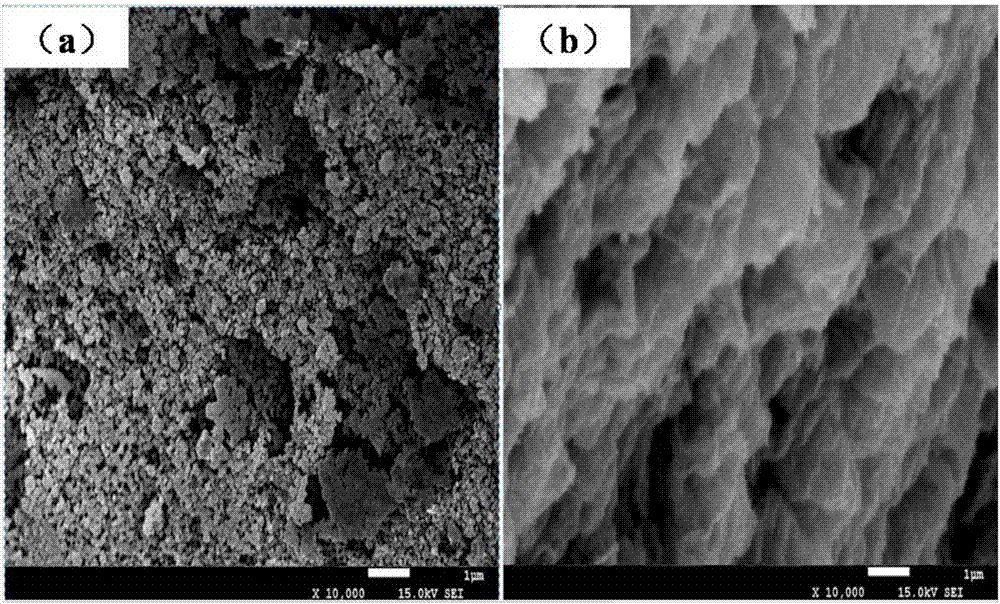

Copper oxide pillared layered manganese oxide catalyst as well as preparation method and application thereof

ActiveCN107282068ANovel structureHigh catalytic activityCatalyst activation/preparationIncinerator apparatusAir atmosphereCatalytic oxidation

The invention provides a copper oxide pillared layered manganese oxide catalyst as well as a preparation method and an application thereof. The method comprises the steps as follows: (1) a manganese salt and copper salt mixed solution is mixed with an alkaline solution with stirring; (2) a coprecipitate obtained in step (1) is oxidized with stirring; (3) a substance obtained in step (3) is subjected to solid-liquid separation and washing; (4) a layered manganese oxide material of a copper ion interlayer obtained in step (3) is placed in a calcinator to be heated to 100-500 DEG C in an air atmosphere for 2-5 h, and the copper oxide pillared layered manganese oxide catalyst is obtained after cooling. The prepared catalyst can be applied to catalytic oxidation of VOCs (volatile organic chemicals) and has the advantages of low initiation temperature, wide active temperature window and the like, the initiation temperature of methylbenzene burning under catalysis of the catalyst can be reduced to 180 DEG C, and the catalytic oxidation efficiency of VOCs can be kept at 100% at the temperature of 220-400 DEG C.

Owner:SICHUAN UNIV +1

Catalyst for removing NOx of diesel engine and preparation method thereof

InactiveCN106000414AReduce NOxImprove activity and stabilityMetal/metal-oxides/metal-hydroxide catalystsChemistryOxide

The invention discloses a catalyst for removing NOx of a diesel engine. The catalyst for removing the NOx of the diesel engine is characterized in that the catalyst is a multi-element metal oxide, and comprises TiO2 which serves as a carrier component, CeO2 and CuO which serve as main active ingredients, and WO3 which serves as a catalyst promoter component; the mass percentage of various components are respectively as follows: 55 to 65 percent of TiO2, 23 to 28 percent of CeO2, 3 to 5 percent of CuO, and 10 to 13 percent of WO3, and the sum of the mass percentage is 100 percent; the catalyst can be used in a catalysis process of NH3-SCR in a wide temperature window; the multi-element metal oxide catalyst provided by the invention has a relatively wide active temperature window, and particularly the removal efficiency of the NH3-SCR to NOx is improved under the working conditions of low exhaust temperature (100 to 250 DEG C) of the diesel engine, so that the purpose of greatly reducing the NOx in a wide exhaust temperature window of the diesel engine at 100 to 450 DEG C is achieved; therefore, the catalyst is particularly suitable for the traffic conditions of urban roads of China.

Owner:SHANGHAI JIAO TONG UNIV

Low-temperature SCR denitration catalyst and preparation method thereof

InactiveCN113083320AImprove denitrification effectHigh low temperature activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFlue gas

The invention discloses a low-temperature SCR denitration catalyst and a preparation method thereof, and belongs to the technical field of low-temperature SCR denitration. According to the method, an FCC waste catalyst and modified biochar are used as supporting carriers, transition metal oxides are used as active components, the loading amount of transition metal elements in the components is 5-20% of the weight of the carriers, the active components are loaded on the carriers by adopting an impregnation method, then drying treatment is performed, and finally roasting is performed in a nitrogen atmosphere, and the low-temperature SCR denitration catalyst disclosed by the invention is obtained. The problems of low low-temperature denitration activity and high cost of a vanadium-titanium catalyst are solved, resource comprehensive utilization of the FCC waste catalyst is achieved, damage of industrial solid waste to the environment is reduced, and the prepared SCR catalyst has excellent denitration performance under the low-temperature condition and has good application prospects and market prospects for low-temperature denitration of industrial flue gas.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

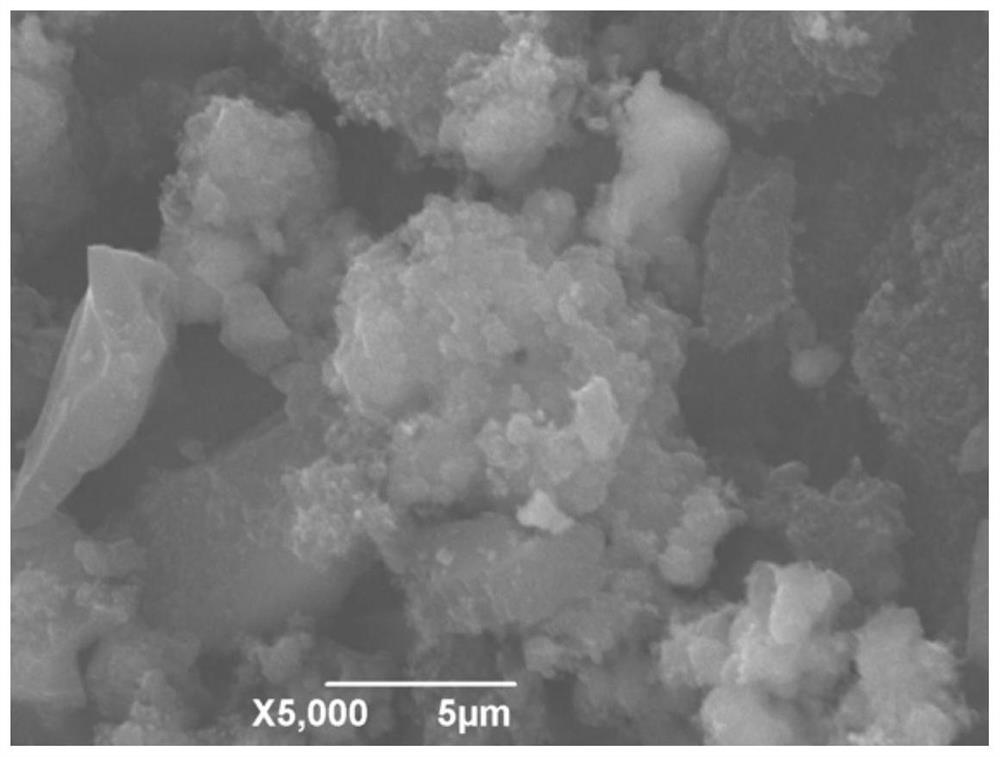

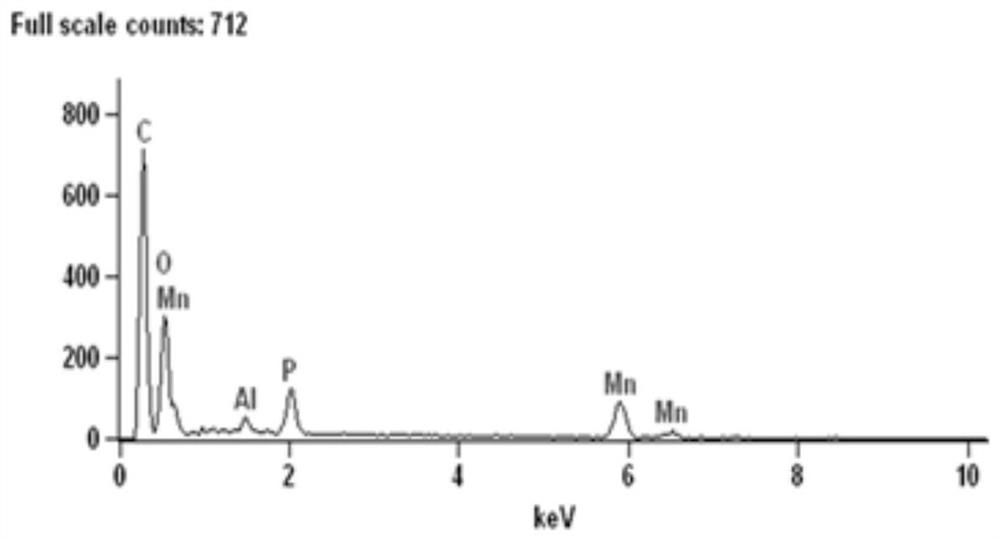

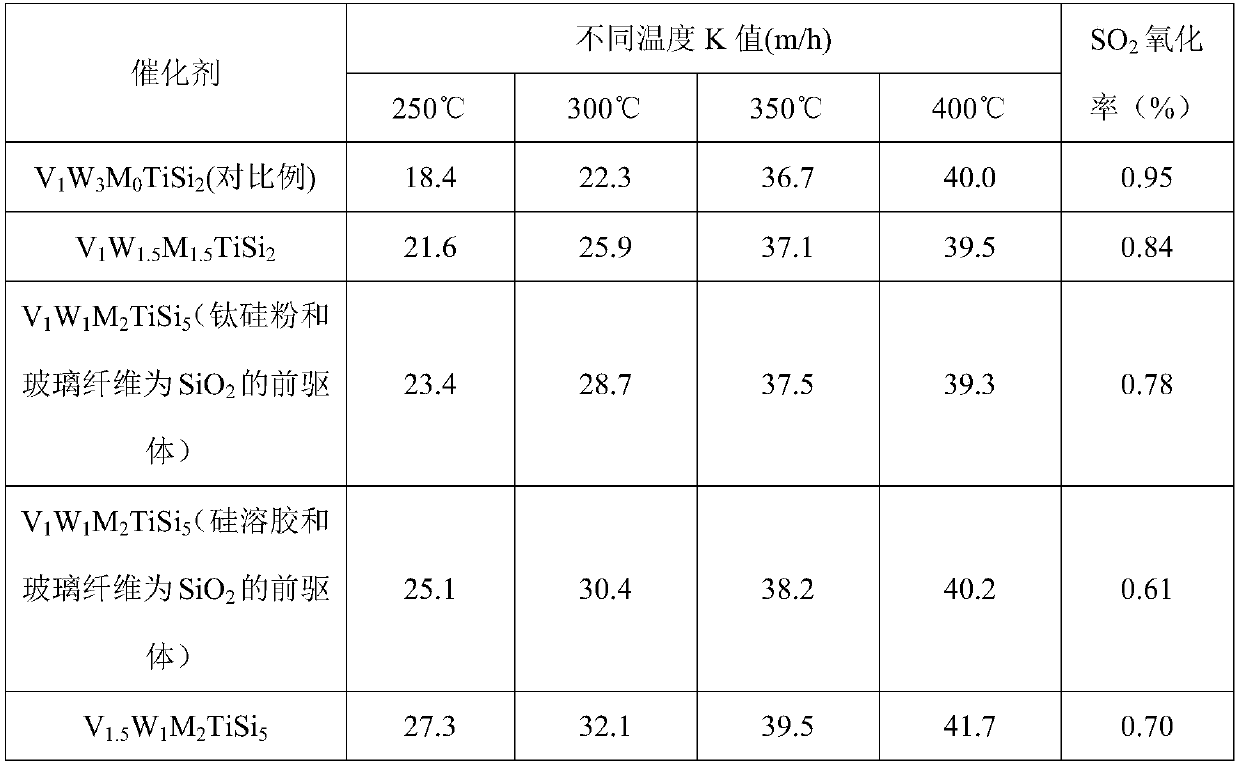

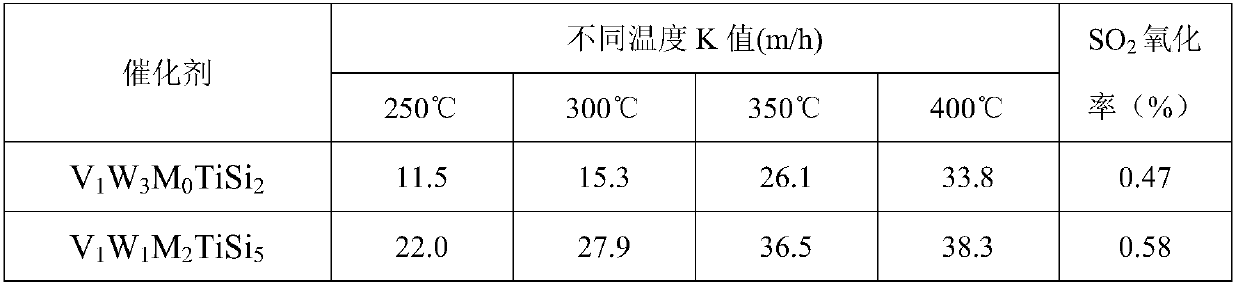

Arsenic poisoning resistance and wide active temperature window integrated low-SO2-oxidation-ratio SCR (selective catalytic reduction) denitration catalyst and preparation method thereof

PendingCN108031466AImprove performanceSolve the strength problemGas treatmentHeterogenous catalyst chemical elementsActive componentArsenic poisoning

The invention discloses an arsenic poisoning resistance and wide active temperature window integrated low-SO2-oxidation-ratio SCR (selective catalytic reduction) denitration catalyst and a preparationmethod thereof. The catalyst is characterized by comprising, by weight, 0.5%-5% of V2O5, 0.5%-5% of WO3, 0.5%-15% of MoO3, 2%-20% of SiO2 and the balance TiO2, wherein V2O5, WO3, MoO3, TiO2 and SiO2are key components, and oxides with main components of TiO2 and SiO2 form a composite carrier of the catalyst. By adoption of a special modifying agent and a preparation method, the composite carrierenhances mutual action between active components and the carrier, a large specific surface area is provided, uniform dispersion level of the active component is improved, and a significant effect on catalyst performance improvement is achieved. Under the joint action of multiple factors, the catalyst has advantages of wide active temperature window, arsenic poisoning resistance and low SO2 oxidation ratio.

Owner:ZHEJIANG ZHENENG CATALYST TECH CO LTD +1

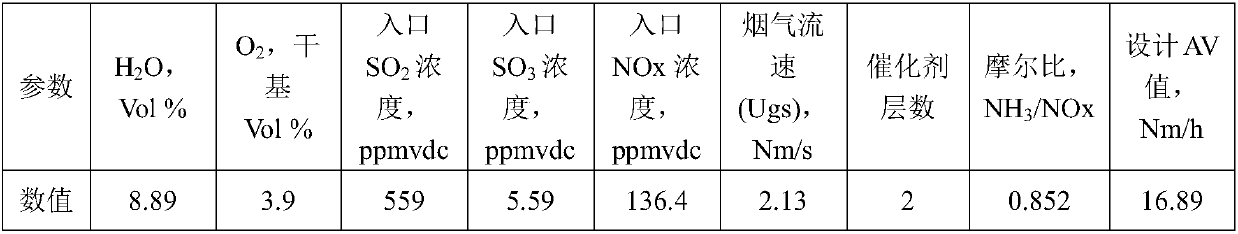

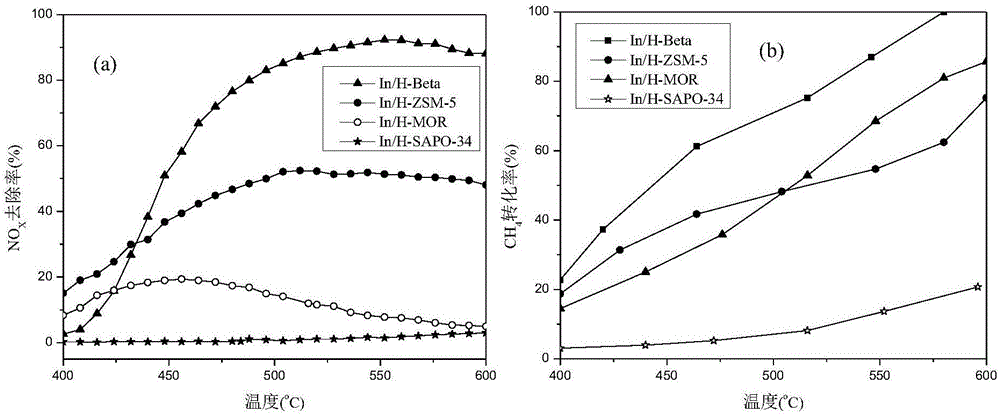

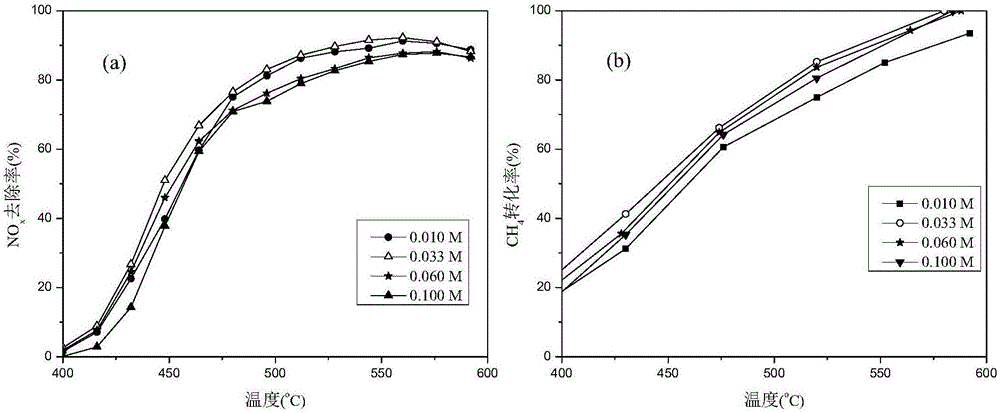

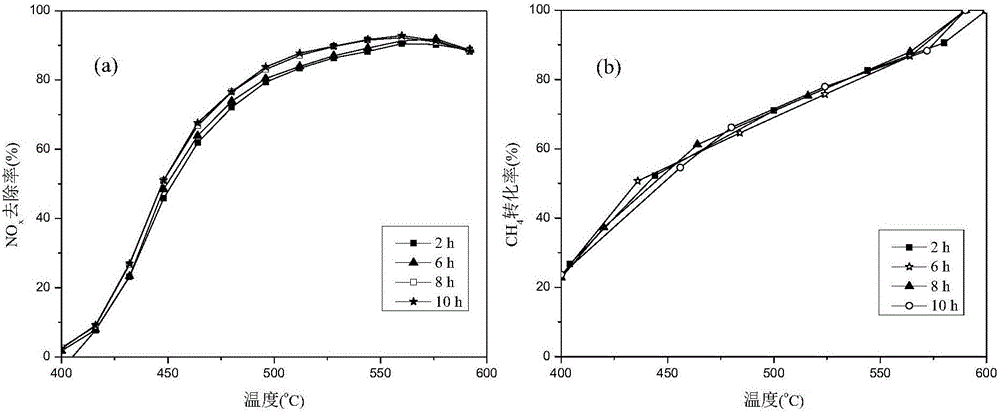

Efficient CH4-SCR denitration catalyst under oxygen-enriched condition and preparation method and application thereof

InactiveCN106807440AGood catalytic activityAnti-SO

<sub>2</sub>

good performanceGas treatmentMolecular sieve catalystsMolecular sieveIndium

The invention provides an efficient CH4-SCR denitration catalyst under an oxygen-enriched condition and a preparation method and application thereof. The efficient CH4-SCR denitration catalyst is characterized in that the active component of the efficient CH4-SCR denitration catalyst is indium, the indium is supported on an H-Beta molecular sieve, and the weight content of the indium is 5.52-8.20wt% of that of the H-Beta molecular sieve. Compared with the prior art, the efficient CH4-SCR denitration catalyst has the advantages that the catalyst has good selective catalytic activity under high O2 concentration and high air speed, NOx removing rate is close to 100%, CH4 utilization rate can exceed 100%, and the catalyst is wide in activity temperature window and good in SO2 resistance.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Preparation method for high-temperature flue gas denitrification catalyst and product of high-temperature flue gas denitrification catalyst

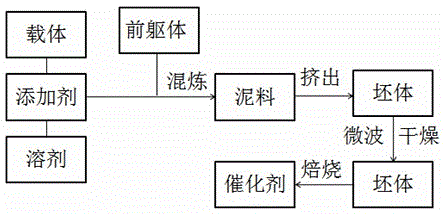

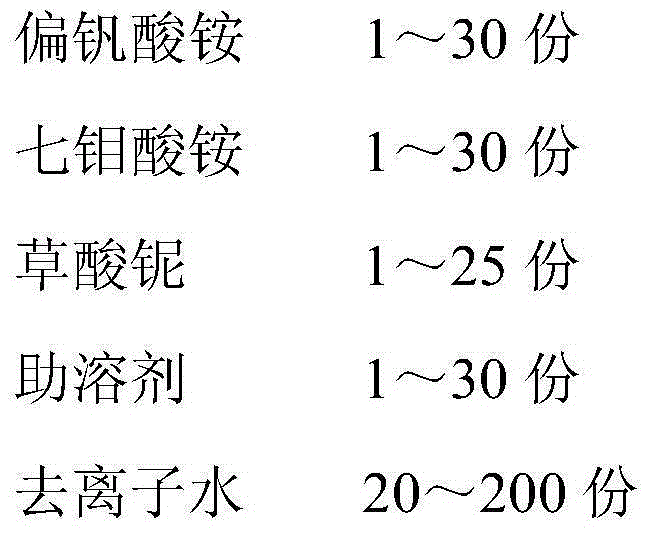

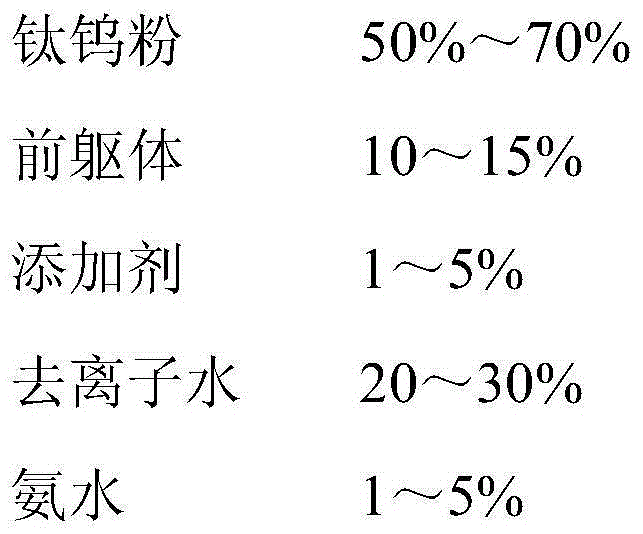

InactiveCN105080605ASolve the problem of low denitrification efficiencyOvercome crackingOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationTwo stepDrying time

The invention relates to a preparation method for a high-temperature flue gas denitrification catalyst and belongs to the technical field of flue gas denitrification. The preparation method comprises the following two steps: preparing a precursor; and preparing a catalyst. According to the technical scheme, the preparation method comprises the steps: by taking V2O5 as a main active component and Nb2O5 and MoO3 as an auxiliary active component, preparing the precursor of V2O5, Nb2O5 and MoO3; and then mixing the precursor by titanium tungsten powder taking TiO2 and WO3 as main components through extrusion molding, drying and water removal and roasting processes to prepare the catalyst. The problem that the SCR denitration efficiency is relatively low when the flue gas temperature of a coal-fired power plant is 280-300 DEG C is solved. Moreover, in the catalyst preparation process, a microwave drying technology is adopted to overcome the defect of cracking and uneven size distribution caused by temperature gradient in a conventional drying technology, so that the drying time is shortened and the production efficiency is improved. The invention further relates to a denitrification catalyst prepared by the method, so that the low-temperature activity of the catalyst is improved and the active temperature window is expanded, and the preparation method has beneficial technical effects.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

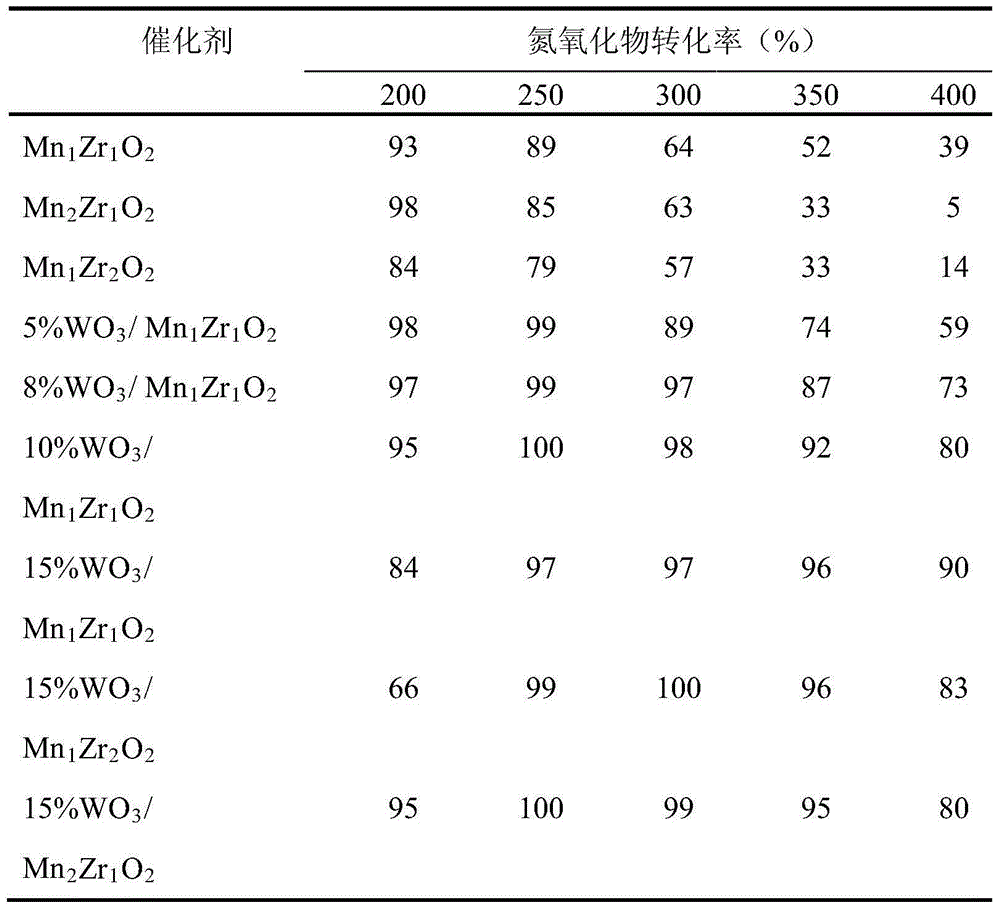

Non-vanadium denitration catalyst, preparation method and applications thereof

ActiveCN104475083AImprove denitrification effectWide active temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentManganese

The present invention relates to a non-vanadium denitration catalyst, a preparation method and applications thereof, and belongs to the technical field of environment catalysis and air pollution control. According to the present invention, the catalyst adopts a manganese zirconium composite oxide as a carrier, tungsten trioxide is adopted as an active component, the manganese zirconium composite oxide is prepared by adopting a hydrothermal method, and the tungsten trioxide addition adopts an impregnation method; the catalyst is characterized in that high toxicity vanadium is not adopted as the active component while the purification efficiency on nitrogen oxides achieves 80-100% at a temperature of 200-400 DEG C at an airspeed of 128000 h<-1>; and the non-vanadium denitration catalyst of the present invention is suitable for elimination of NOx in waste gases discharged from thermal power plants, smelters, industrial boilers, diesel vehicles and the like.

Owner:BEIJING UNIV OF CHEM TECH

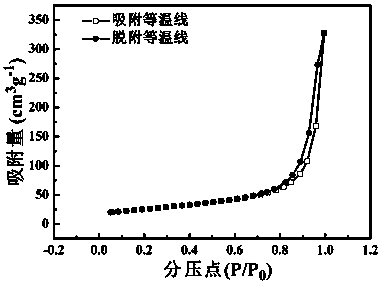

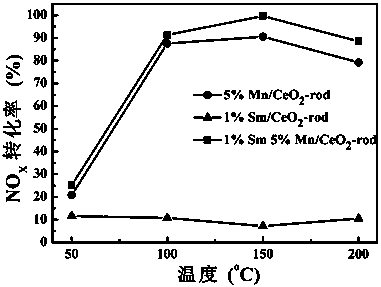

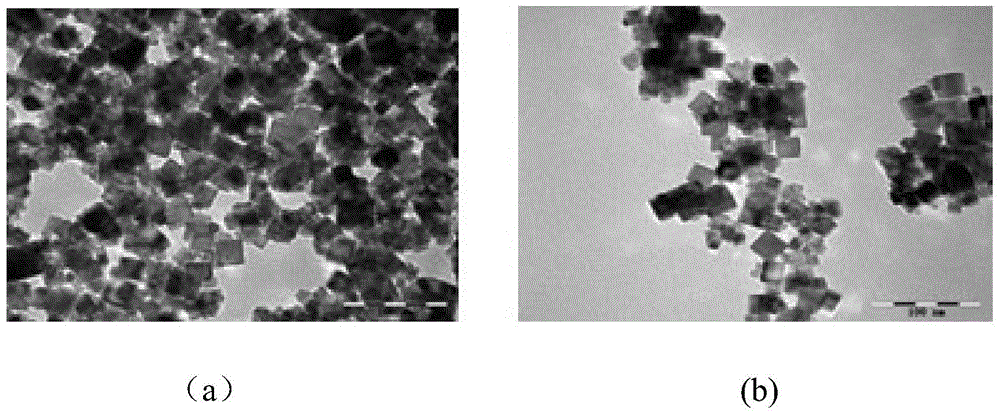

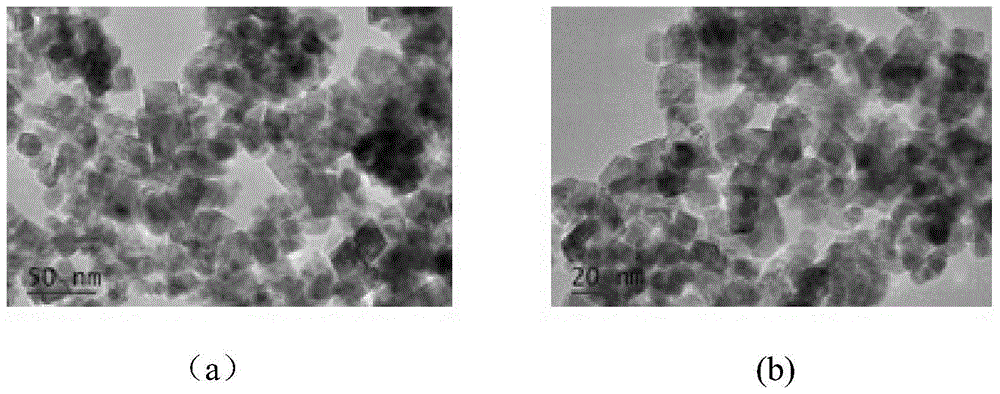

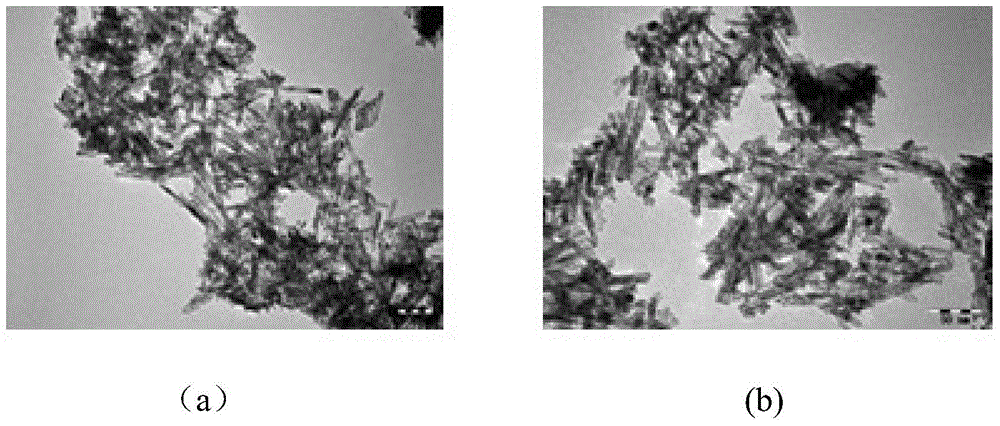

Rod-shaped cerium oxide-supported samarium-manganese composite oxide catalyst and preparation method thereof

InactiveCN108993481AIncrease contentEnhanced oxidation-reductionHeterogenous catalyst chemical elementsDispersed particle separationNitrogen oxidesOxidation state

The invention relates to a preparation method of a rod-shaped cerium oxide-supported samarium-manganese composite oxide catalyst. The method comprises: S01, carrier preparation: a, mixing a cerium nitrate hexahydrate solution and a sodium hydroxide solution through stirring to obtain a first mixed solution, b, transferring the first mixed solution into a reactor and carrying out high temperature treatment and c, carrying out high temperature roasting on a sample subjected to high temperature treatment to obtain a rod-shaped cerium oxide carrier, and S02, catalyst preparation: d, preparing a second mixed solution of samarium nitrate and manganese nitrate, e, dipping the rod-shaped cerium oxide carrier in the second mixed solution and f, carrying out high temperature roasting on the soaked sample to obtain an oxidation state catalyst. The catalyst is in a wide temperature range of 100-200 DEG C and the purification efficiency of nitrogen oxide is 90% or more.

Owner:YANCHENG ENVIRONMENTAL ENG TECH RES & DEV CENT TSINGHUA UNIV

Denitration catalyst employing shape effect for enhancing low temperature activity, preparation method and application thereof

InactiveCN105664924AReduce and avoid poisoningExtended service lifeGas treatmentDispersed particle separationPtru catalystGlass furnace

The invention discloses a preparation method of a denitration catalyst employing shape effect for enhancing low temperature activity, which belongs to the technical field of control of atmosphere pollution. The method comprises the following steps: 1) weighing a CeO2 carrier and dissolving the CeO2 carrier in deionized water, weighing a manganous nitrate solution according to a mol ratio of Mn to Ce being 1.5:5-2:5, dumping the weighed CeO2 carrier in the manganous nitrate solution to obtain reaction liquid; 2) evaporating the reaction liquid under oil bath to dryness, then placing the material in a roasting oven for drying the material at the temperature of 105-115 DEG C to obtain a dried material; and 3) calcinating the dried material in a muffle furnace at the temperature of 395-405 DEG C for 3-4 hours to obtain the denitration catalyst employing shape effect for enhancing low temperature activity which takes CeO2 as the carrier. The invention also discloses the catalyst prepared by the method and an application thereof. The denitration catalyst has the advantages of good low temperature activity, high selectivity and wide activity temperature window. The preparation method has the advantages of simple and controllable process, and convenient operation process, and can be used in tail ends of the flue gas purifying apparatus in fire coal power plants, cement plants, and glass kilns and furnaces. The preparation method has the characteristics of energy saving and environmental protection.

Owner:NANJING UNIV

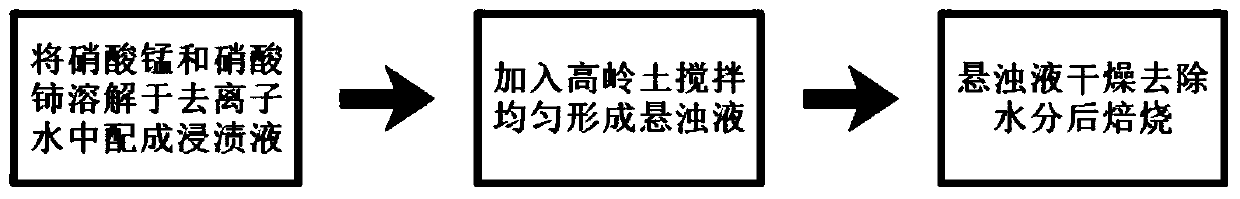

Low-temperature SCR denitration catalyst based on kaoline and preparation method of catalyst

InactiveCN110314681AReduce manufacturing costLarge specific surface areaGas treatmentDispersed particle separationActive componentCerium oxide

The invention belongs to the field of denitration catalysts, and discloses a low-temperature SCR denitration catalyst based on kaoline and a preparation method of the catalyst. The SCR denitration catalyst comprises a carrier and active components attached to the carrier, the carrier is the kaoline, and the active components are manganite and cerium oxide. The invention further discloses the preparation method of the above SCR denitration catalyst. The preparation method comprises the following steps that (a) manganous nitrate and cerous nitrate are selected as raw materials, mixed and dissolved in deionized water to form steeping liquid; (b) the kaoline is added into the steeping liquid, stirring is conducted at the indoor temperature, and suspension liquid is obtained; (c) the suspensionliquid is subjected to magnetic stirring to be in a sticky state, a mixture in the sticky state is obtained, dried and roasted, and the required catalyst is obtained. According to the catalyst and the preparation method, the cost of the catalyst is reduced, the catalysis efficiency is high, and a guidance effect is achieved on research for a low-temperature denitration catalyst.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of molecular sieve-based low-temperature environment-friendly SCR denitration catalyst

ActiveCN112657541AReduce the use temperatureWide active temperature windowMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention discloses a preparation method of a molecular sieve-based low-temperature environment-friendly SCR denitration catalyst, which comprises the following steps: by using a ZSM-5 molecular sieve as a carrier and Fe2O3 modified or supported Fe2O3 and CuO as active components, mixing with ceramic powder, a binder and an additive under acidic conditions, stirring, kneading or coating to obtain the molecular sieve-based low-temperature environment-friendly SCR denitration catalyst. The catalyst prepared by the invention can efficiently remove nitrogen oxide under a low-temperature condition, and has the advantages of reducing the denitration reaction temperature, widening the active temperature window of the denitration process and improving the design flexibility of the denitration and desulfurization process flow. The advantages of water vapor aging resistance, good stability and the like are realized. In the preparation process of the catalyst, the raw materials are cheap and easy to obtain, the preparation cost is low, harmful substances with secondary pollution cannot be generated in the use, replacement and regeneration processes of the catalyst, and compared with a traditional SCR denitration catalyst, the SCR denitration catalyst has the obvious advantage of environmental friendliness.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST

SCR catalyst for ship diesel engine post-treatment, and preparation method thereof

InactiveCN104841476AImprove catalytic performanceImprove denitrification rateMolecular sieve catalystsInternal combustion piston enginesCeriumManganese

The invention relates to a catalyst, and especially relates to an SCR catalyst for ship diesel engine post-treatment, and a preparation method thereof. The catalyst adopts a ZSM-5 molecular sieve with a high specific surface area as a supporter, and adopts vanadium, tungsten, copper, manganese and cerium metal elements as active components. The specific surface area of the ZSM-5 molecular sieve with a high specific surface area is above 500m<2> / g, and the specific pore volume of the ZSM-5 molecular sieve with a high specific surface area is above 0.6mL / g. The preparation method comprises the following steps: preprocessing ZSM-5 molecular sieve powder with a high specific surface area to remove superfluous water in the molecular sieve powder; mixing the active components with water to obtain an active component solution, wherein the volume of water is the product of the mass of the ZSM-5 molecular sieve and the specific pore volume of the ZSM-5 molecular sieve; adding the active component solution to the preprocessed ZSM-5 molecular sieve with a high specific surface area in a dropwise manner, and continuously stirring to obtain a viscous material; and heating the viscous material for drying, and calcining; and cooling. The catalyst has the advantages of high catalysis activity, high hydrothermal stability, high sulfur resistance, and wide active temperature window, and can guarantee that denitration of tail gas of ship diesel engines meets requirements of Tier III standards.

Owner:碗海鹰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com