Preparation method of novel SCR smoke denitrification catalyst adopting titanium-containing blast furnace slag as carrier

A technology for denitration catalyst and blast furnace slag, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of large amount of acid and difficult industrialized implementation, etc. Achieve the effect of high activity, low preparation cost and high denitration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a denitration catalyst with titanium-containing blast furnace slag as a carrier, which is characterized in that it comprises the following steps:

[0029] a. Pretreatment of titanium-containing blast furnace slag:

[0030] The titanium-containing blast furnace slag is crushed, ball-milled, and sieved to obtain titanium-containing blast furnace slag powder;

[0031] B, the preparation of catalyst:

[0032] Take the active components and additives and add water to prepare a mixed solution, add the titanium-containing blast furnace slag powder obtained in step a into the mixed solution, and after ultrasonication, stirring, impregnation, drying and calcination, cooling can obtain the denitrification of titanium-containing blast furnace slag as a carrier Catalyst; the active component is manganese oxide, and the auxiliary agent is cerium oxide.

[0033] Wherein, the particle size of the titanium-containing blast furnace slag po...

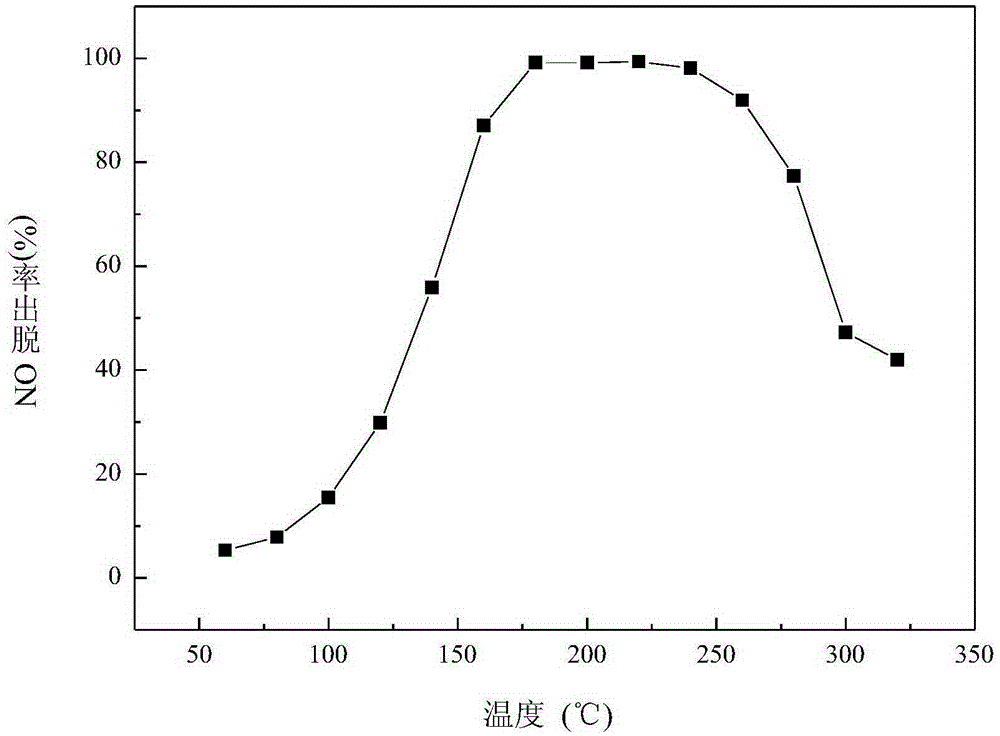

Embodiment 1

[0045] a. Pretreatment of titanium-containing blast furnace slag. The titanium-containing blast furnace slag is crushed, ball-milled, sieved, and the powder with a particle size of 180-200 mesh is taken for use.

[0046] b. Catalyst prepared by excess impregnation method. Get the titanium-containing blast furnace slag powder 10g that obtains in a, 50% manganese nitrate solution (Chinese medicine, AR) 5.72mL, Ce(NO 3 ) 3 ·6H 2 O (Chinese medicine, AR) 5.34g, dissolved in 100mL deionized water, after ultrasonic treatment for 30min, impregnated under rapid stirring conditions for 6h, dried at 120°C for 48h, heated at 10°C / min to 500°C in an air atmosphere for heat preservation and calcination After 6 hours, the catalyst sample 1 was obtained after natural cooling.

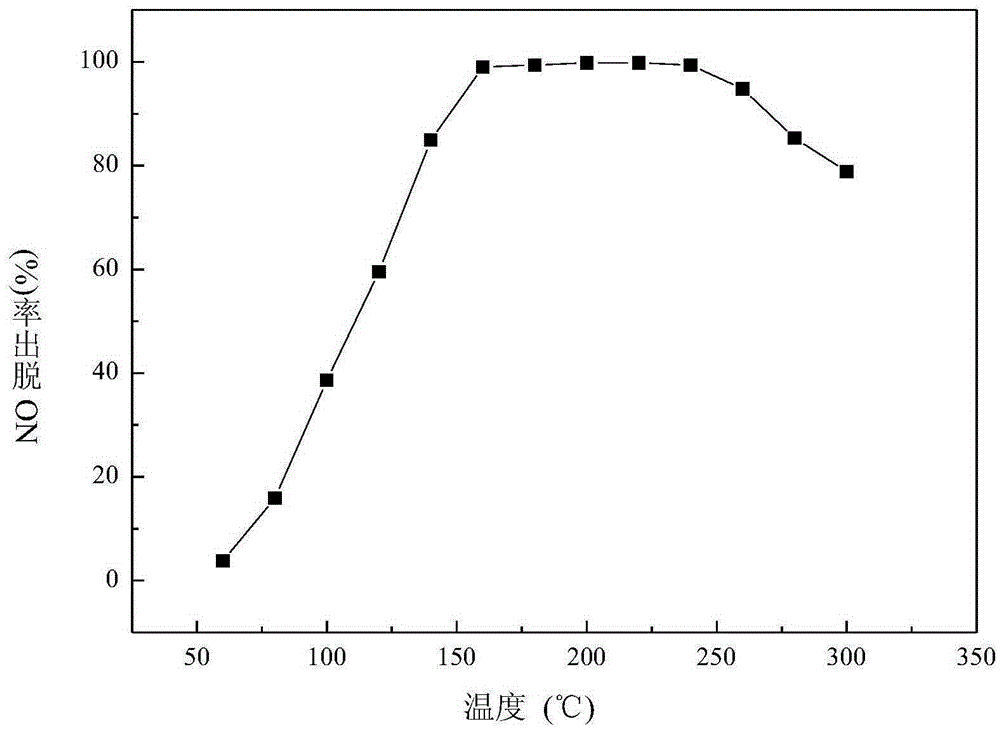

Embodiment 2

[0048] a. Pretreatment of titanium-containing blast furnace slag. The titanium-containing blast furnace slag is crushed, ball-milled, sieved, and the powder with a particle size of 100-120 mesh is taken for use.

[0049] b. Catalyst prepared by excess impregnation method. Get 10g of titanium-containing blast furnace slag powder obtained in a, 50% manganese nitrate solution (Sinopharm, AR) 5.07mL, Ce(NO 3 ) 3 ·6H 2 O (Sinopharm, AR) 1.89g, dissolved in 100mL deionized water, ultrasonically treated for 30min, impregnated for 6h under rapid stirring conditions, dried at 120°C for 48h, heated at 10°C / min to 500°C in an air atmosphere for calcination After 6 hours, the catalyst sample 2 was obtained after natural cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com