Catalyst for removing NOx of diesel engine and preparation method thereof

A catalyst and diesel engine technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unfavorable human health and environmental friendliness, so as to improve the reaction rate and NOx removal efficiency, improve and The effect of stabilizing catalyst performance, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

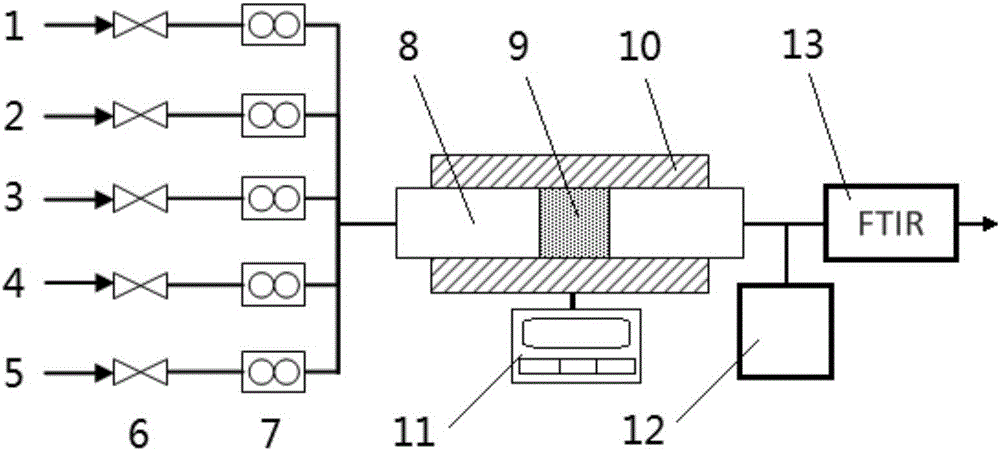

Image

Examples

Embodiment 1

[0040] (1) Carry out alcoholysis, hydrolysis and concentrated nitric acid dissolution of tetra-n-butyl titanate to generate TiO(NO 3 ) 2 Solution, weigh 5.105g of tetra-n-butyl titanate, carry out alcoholysis and hydrolysis successively. First measure 10ml of absolute ethanol for titration and stirring, then measure 12ml of deionized water for titration and stirring to obtain a white flocculent precipitate. Finally, 9ml of concentrated nitric acid was added to dissolve the precipitate to obtain TiO(NO 3 ) 2 Clear solution.

[0041] (2)TiO 2 Determination of carrier, metal oxide main active component and co-catalyst loading

[0042] According to TiO 2 : CeO 2 :CuO:WO 3 = 1: 0.431: 0.0664: 0.1935 mass ratio to calculate the dosage of each component of the catalyst are: tetra-n-butyl titanate 5.105g, cerium nitrate hexahydrate 1.303g, copper nitrate trihydrate 0.242g, ammonium tungstate 3.043g .

[0043] (3) TiO 2 Carrier components, CeO 2 with CuO main active compone...

Embodiment 2

[0046] (1) Carry out alcoholysis, hydrolysis and concentrated nitric acid dissolution of tetra-n-butyl titanate to generate TiO(NO 3 ) 2 the solution

[0047] Weigh 2.552 g of tetra-n-butyl titanate, and carry out alcoholysis and hydrolysis successively. First measure 8ml of absolute ethanol for titration and stirring, then measure 8ml of deionized water for titration and stirring to obtain a white flocculent precipitate. Finally, 6ml of concentrated nitric acid was added to dissolve the precipitate to obtain TiO(NO 3 ) 2 Clear solution.

[0048] (2)TiO 2 Determination of carrier, metal oxide main active component and co-catalyst loading

[0049] According to TiO 2 : CeO 2 :CuO:WO 3 = 1: 0.431: 0.0664: 0.1935 mass ratio to calculate the dosage of each component of the catalyst are: tetra-n-butyl titanate 2.552g, cerium nitrate hexahydrate 0.651g, copper nitrate trihydrate 0.121g, ammonium tungstate 1.521g .

[0050] (3) TiO 2 Carrier components, CeO 2 with CuO mai...

Embodiment 3

[0053] (1) Carry out alcoholysis, hydrolysis and concentrated nitric acid dissolution of tetra-n-butyl titanate to generate TiO(NO 3 ) 2 the solution

[0054]Weigh 17.866g of tetra-n-butyl titanate, and carry out alcoholysis and hydrolysis successively. First measure 38ml of absolute ethanol for titration and stirring, then measure 40ml of deionized water for titration and stirring to obtain a white flocculent precipitate. Finally, 35ml of concentrated nitric acid was added to dissolve the precipitate to obtain TiO(NO 3 ) 2 Clear solution.

[0055] (2)TiO 2 Determination of carrier, metal oxide main active component and co-catalyst loading

[0056] According to TiO 2 : CeO 2 :CuO:WO 3 = 1: 0.431: 0.0664: 0.1935 mass ratio to calculate the dosage of each component of the catalyst are: tetra-n-butyl titanate 17.866g, cerium nitrate hexahydrate 4.559g, copper nitrate trihydrate 0.846g, ammonium tungstate 10.649g .

[0057] (3) TiO 2 Carrier components, CeO 2 with CuO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com