Patents

Literature

42results about How to "Avoid mass generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

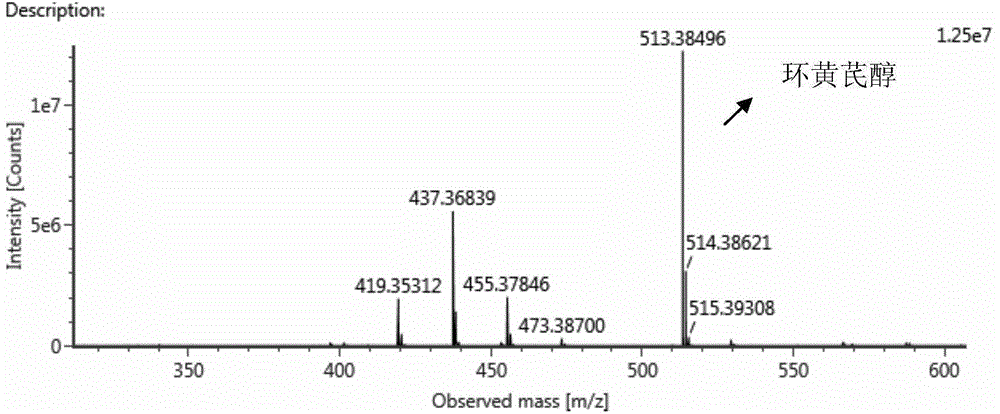

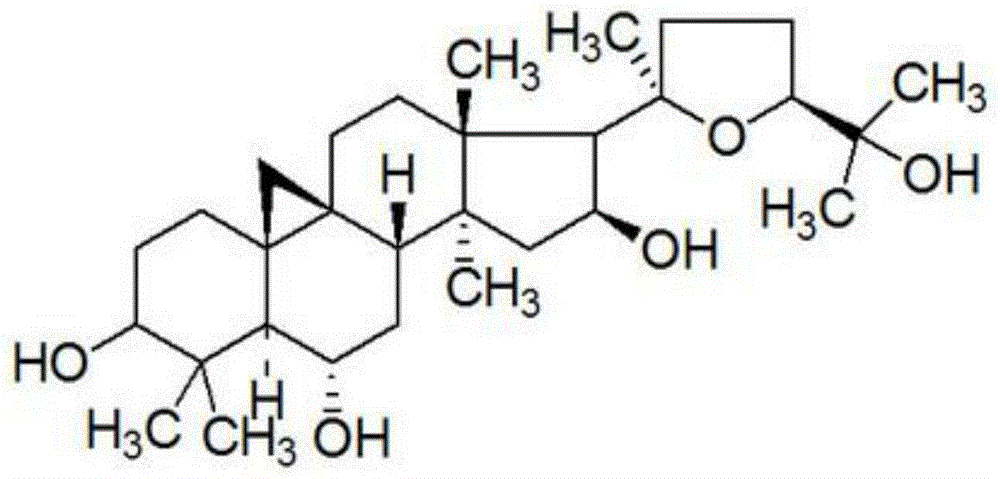

Method for preparation of Cycloastragenol by sulfuric acid hydrolysis

The invention relates to a method for preparation of Cycloastragenol by sulfuric acid hydrolysis. The method provided by the invention utilizes sulfuric acid to hydrolyze the Chinese medicine astragalus crude extract astragaloside, and realizes conversion of astragaloside to Cycloastragenol under certain hydrolysis condition, then performs impurity separation on the Cycloastragenol crude extract obtained by acid hydrolysis by chloroform and n-butanol extraction, and further makes use of silica gel column chromatography purification to finally obtain high purity Cycloastragenol. The invention aims to provide the method that can overcome the disadvantages of complex production process, low yield, high cost and the like of Cycloastragenol production and is suitable for large-scale production of different purity Cycloastragenol.

Owner:BEIJING UNIV OF CHEM TECH

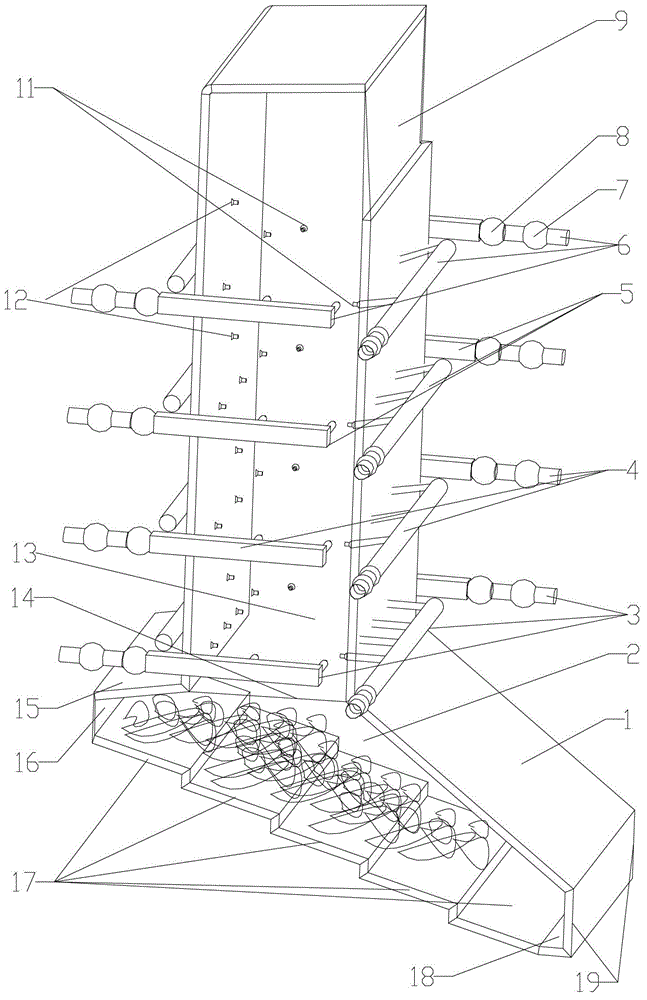

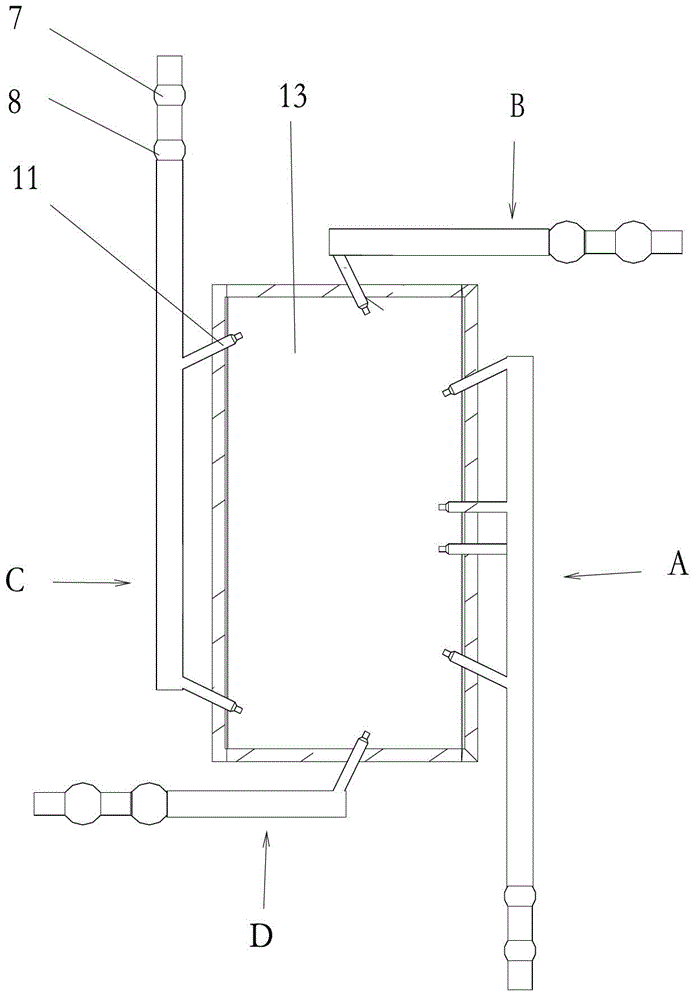

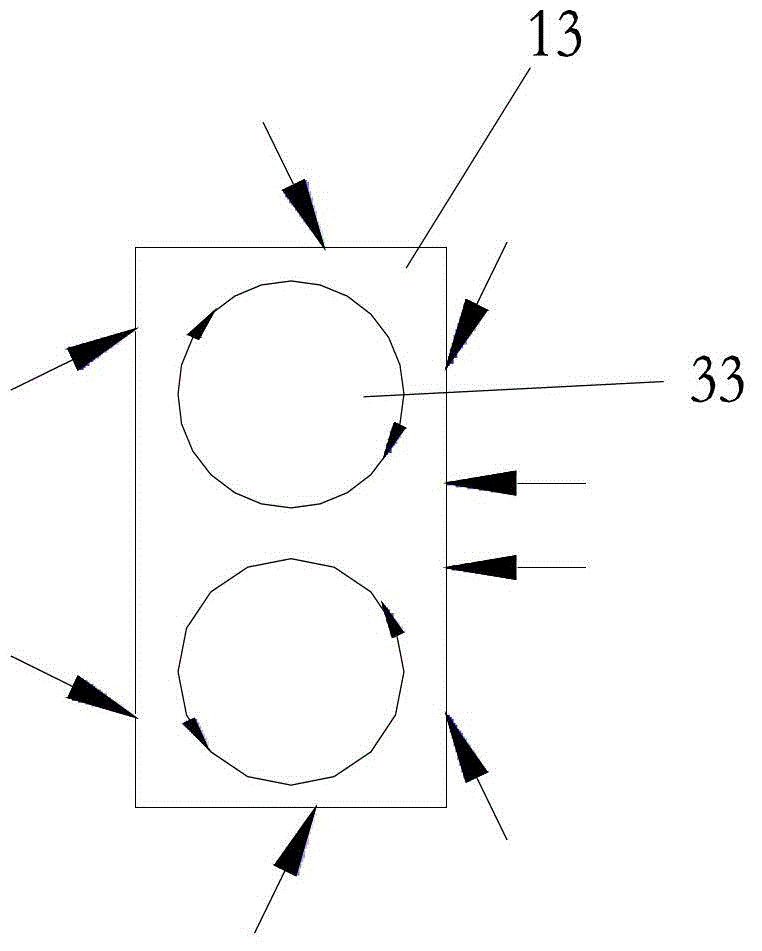

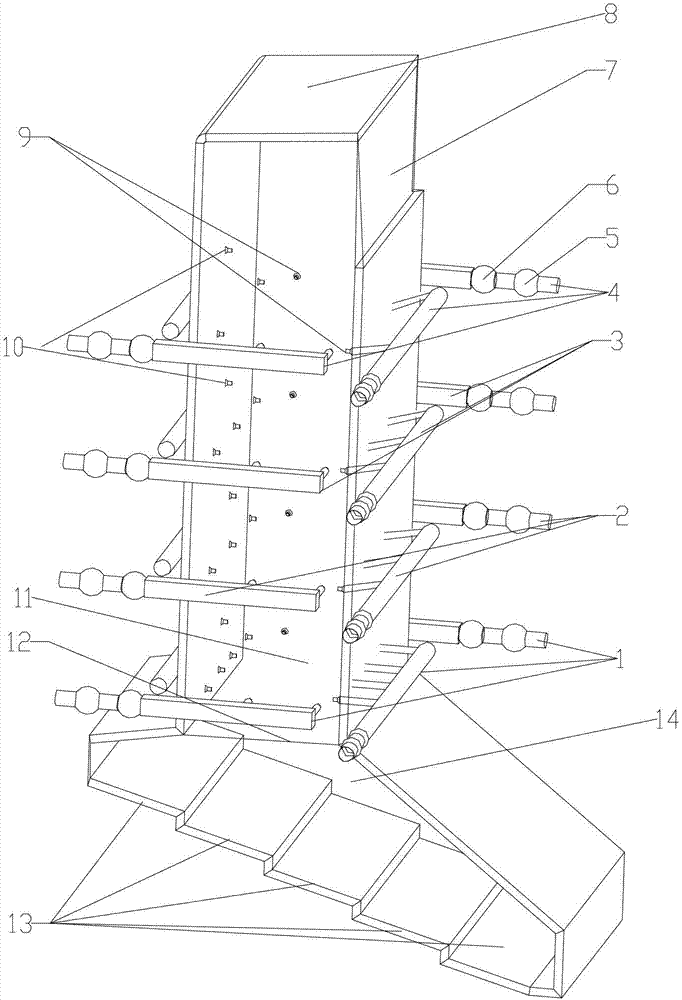

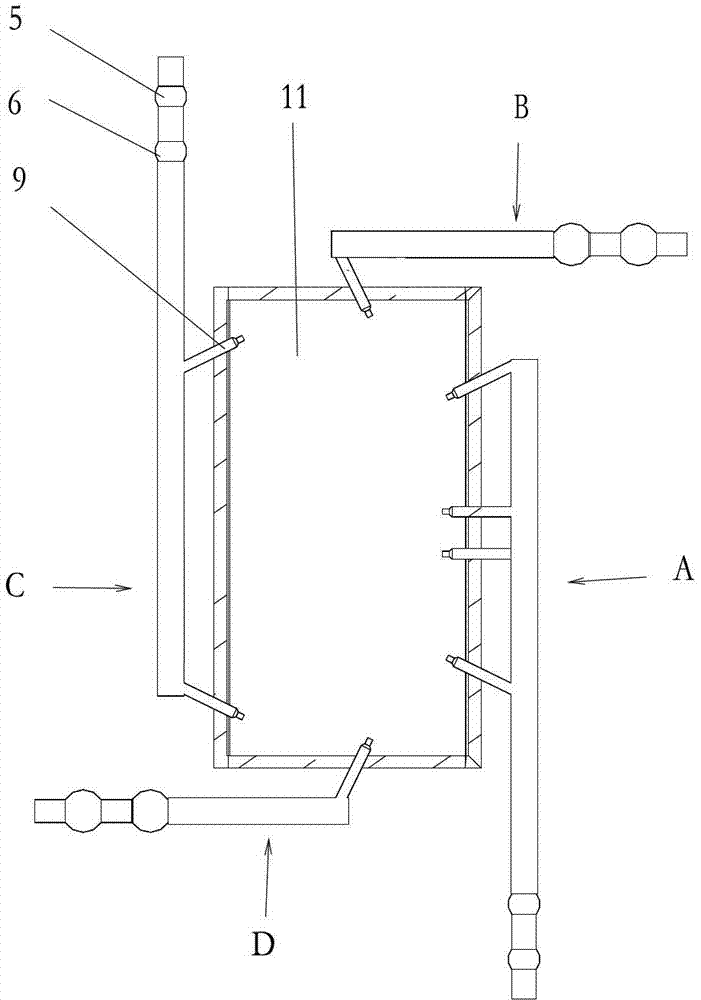

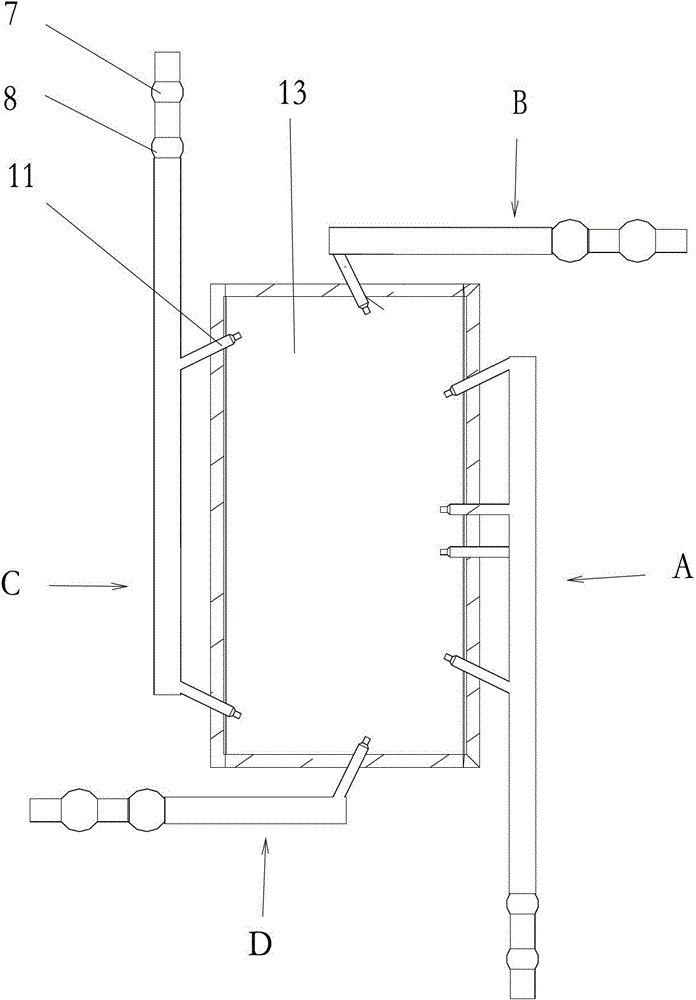

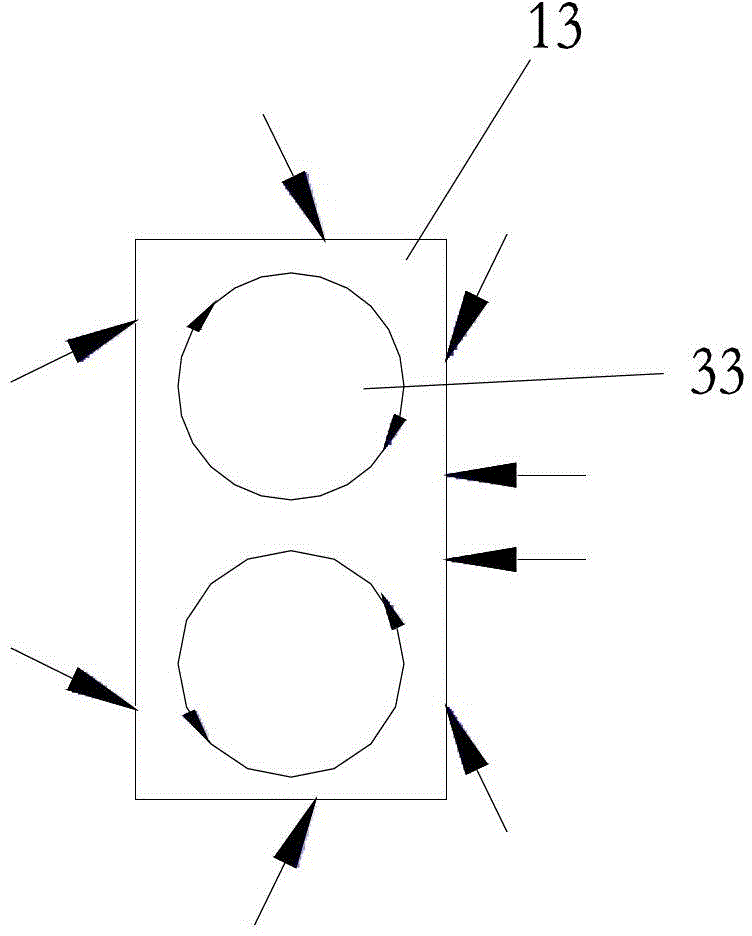

Method for garbage low-nitrogen and low-dioxin grate incineration and device of method for garbage low-nitrogen and low-dioxin grate incineration

ActiveCN102980194ALow running costEmission reductionIncinerator apparatusNon-combustible gases/liquids supplySlagLow nitrogen

The invention discloses a method for garbage low-nitrogen and low-dioxin grate incineration and a device of the method for garbage low-nitrogen and low-dioxin grate incineration. The device comprises a first channel and an incineration hearth which is arranged on the bottom of the first channel, wherein a blowing subassembly is arranged along the peripheral wall of the first channel and enables smoke in the first channel to form two groups of tangent circles and spirally ascend; and the smoke forms two groups of tangent circles and spirally ascends through the blowing subassembly in the first channel, the temperature of the first channel is controlled between 850 DEG C and 900 DEG C through regulating the air flow of a blowing nozzle of the blowing subassembly, the smoke residence time is above 2 seconds, the smoke flows to an outlet of the first channel finally, slag which is generated after garbage on the tail end of a grate is completely burnt is discharged through a slag discharge port, and accordingly, a garbage low-nitrogen and low-dioxin grate incineration process is completed. The method and the device have the advantages of high combustion efficiency, good environmental-friendly effect and low initial construction and operation cost, and are suitable for large, medium and small-scale treatment of industrial and urban garbage incineration.

Owner:SOUTH CHINA UNIV OF TECH

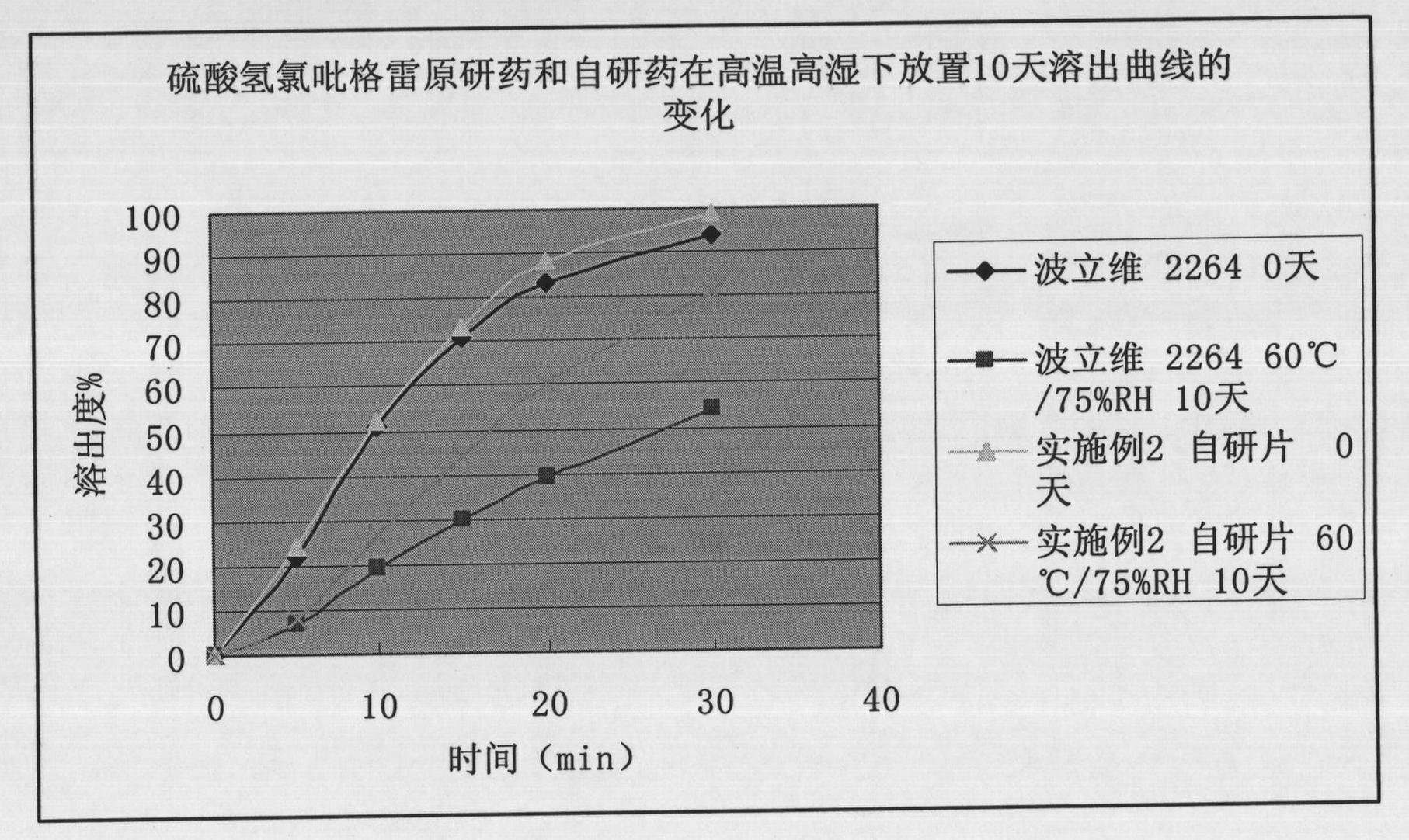

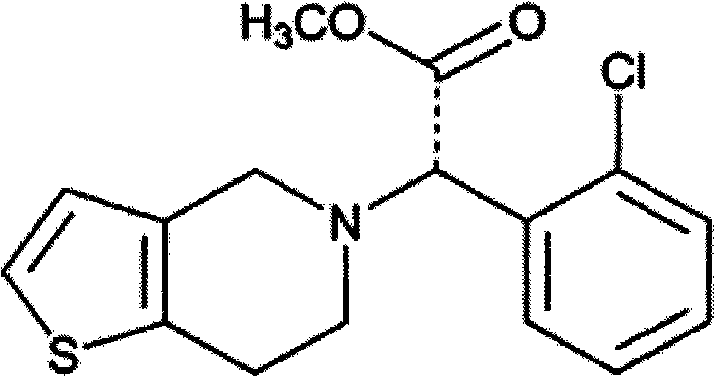

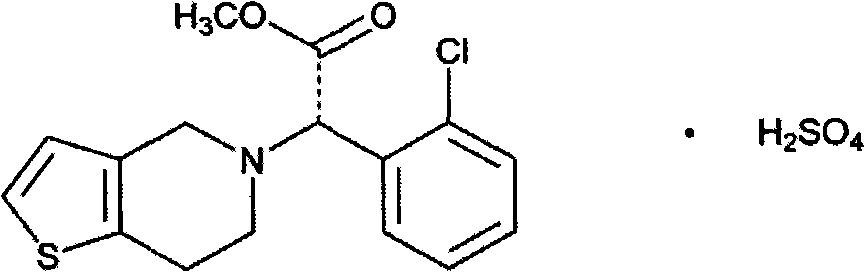

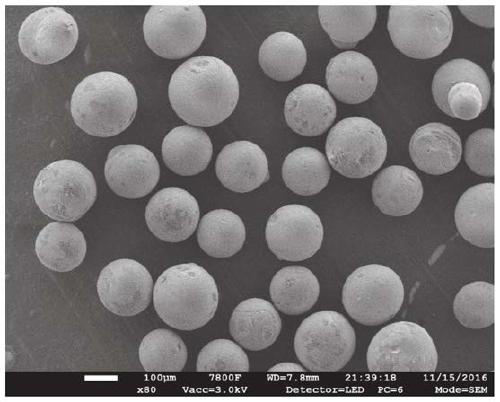

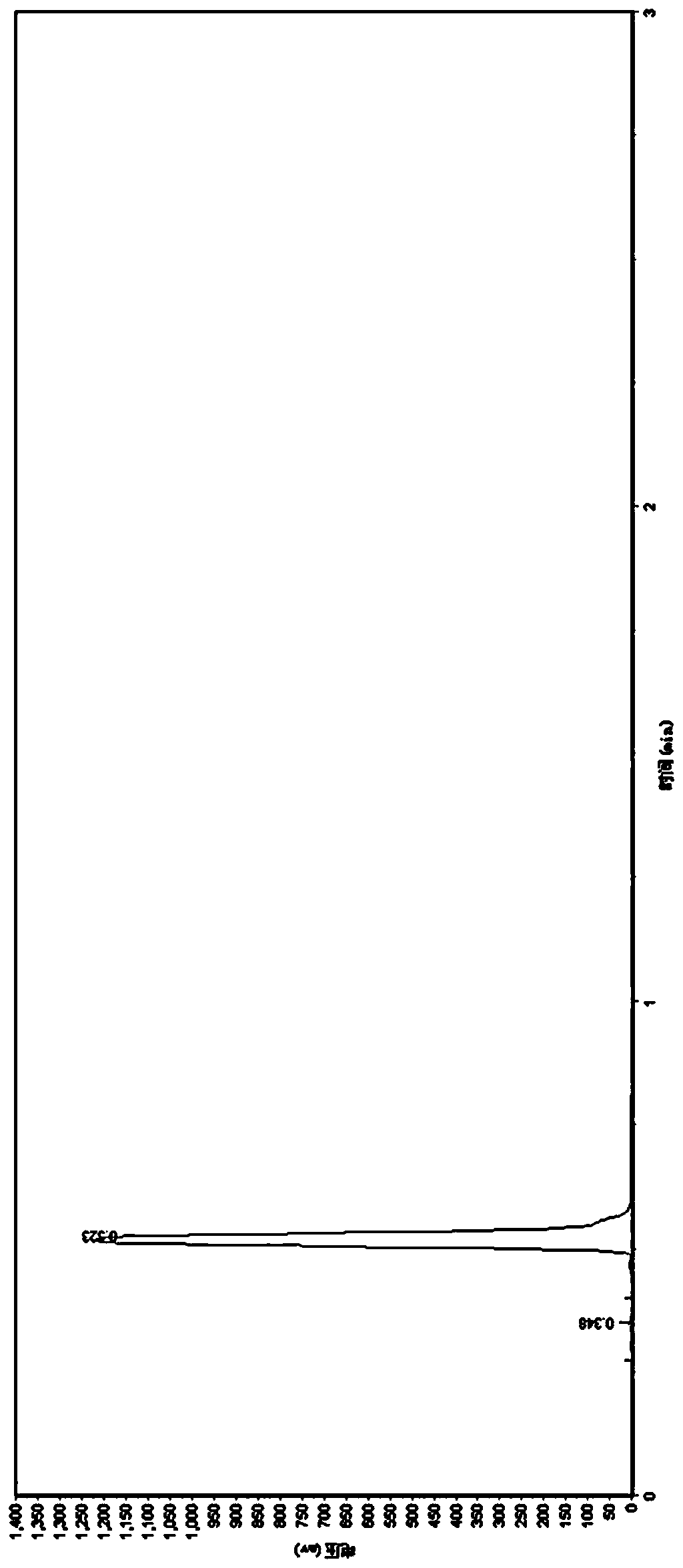

Composition containing clopidogrel bisulfate crystal particles

ActiveCN101851247ASolve the sticking problemAvoid mass generationOrganic active ingredientsOrganic chemistryCrystalline particleClopidogrel Bisulfate

The invention discloses clopidogrel bisulfate crystal particles with the median particle diameter of at least 120 microns. The invention also discloses a method for preparing the crystal particles, a pharmaceutical composition containing the crystal particles and a preparation method of the pharmaceutical composition.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

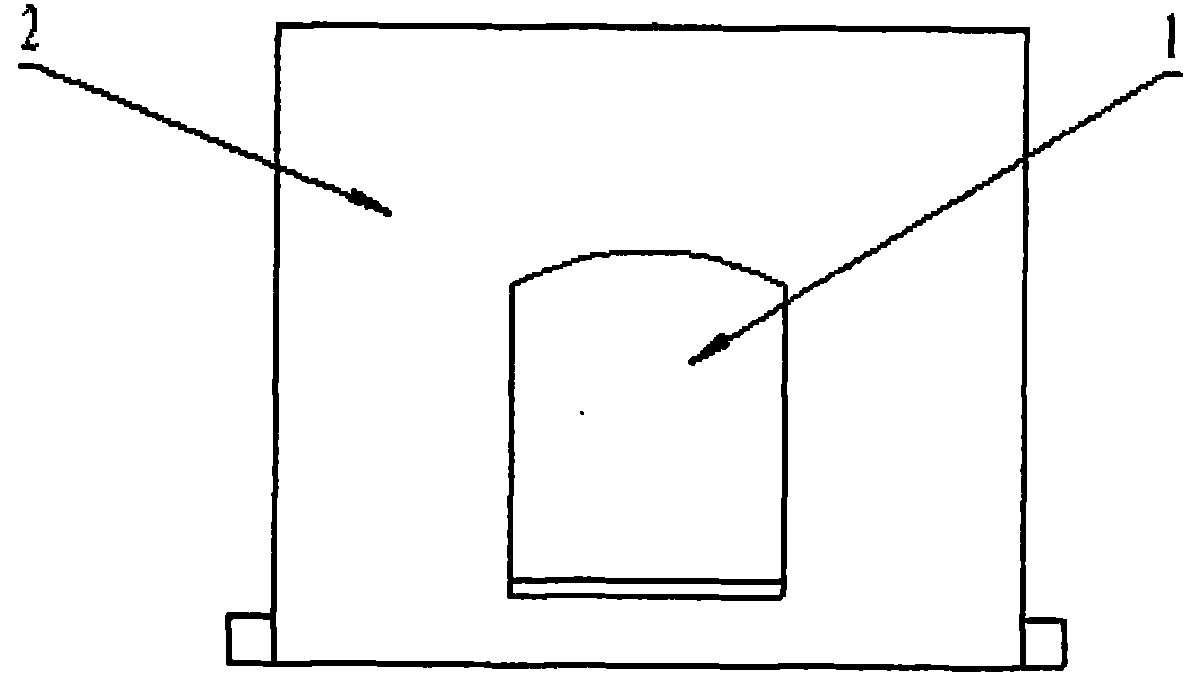

Down draft kiln

InactiveCN101846447ACalcination temperature is highUniform temperatureVertical furnacesWaste heat treatmentBrickEngineering

The invention relates to a down draft kiln, consisting of a furnace body (2), a furnace door (1), a fuel nozzle (3), a hearth (22) and smoke and air exit and entrance (5). The down draft kiln is characterized in that the furnace body (2) consists of a refractory brick layer (6), a thermal protective coating (7), an insulating layer (8) and a shell (9). The smoke and air exit and entrance (5) are arranged at the two sides of the bottom of the furnace body (1) and are internally provided with heat accumulators (10), and the fuel nozzle (3) is arranged above the smoke and air exit and entrance (5) and at the lower part of the furnace body (2). A fire absorbing hole (11) is positioned in the hearth (22) and between the smoke and air exist and entrance (5) and the fuel nozzle (3), a retaining wall (12) is arranged below the fire absorbing hole (11) to divide the smoke and air exist and entrance (5) at the two sides into two parts, and the top of the furnace body (2) is provided with a temperature measuring hole (4). The invention has the advantages of energy source saving, high heat utilization rate and environment protection.

Owner:TAIYUAN UNIV OF TECH +1

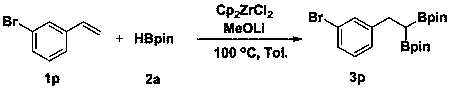

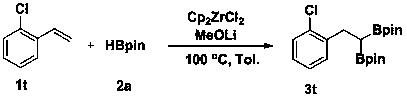

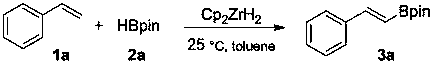

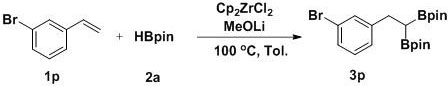

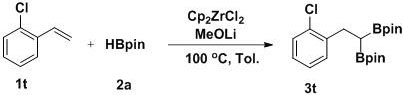

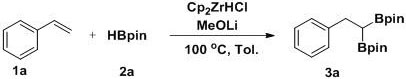

Method for preparation of gem-diboron compound by olefin selective 1, 1-diboronation

ActiveCN111217844AAtom economy is highMeet the requirements of green chemistryGroup 3/13 element organic compoundsCombinatorial chemistryAlkene

The invention relates to a method for preparation of a gem-diboron compound by olefin selective 1, 1-diboronation. The method includes: dissolving an olefin compound, a cyclopentadienyl early transition metal catalyst and an alkali compound in a solvent, then adding a borane compound, carrying out reaction at 60-150DEG C for 1-16h in a protective atmosphere, and then carrying out separation to obtain the gem-diboron compound. The method is simple and convenient to operate, low in cost, and high in reaction atom economy, and is suitable for industrial production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

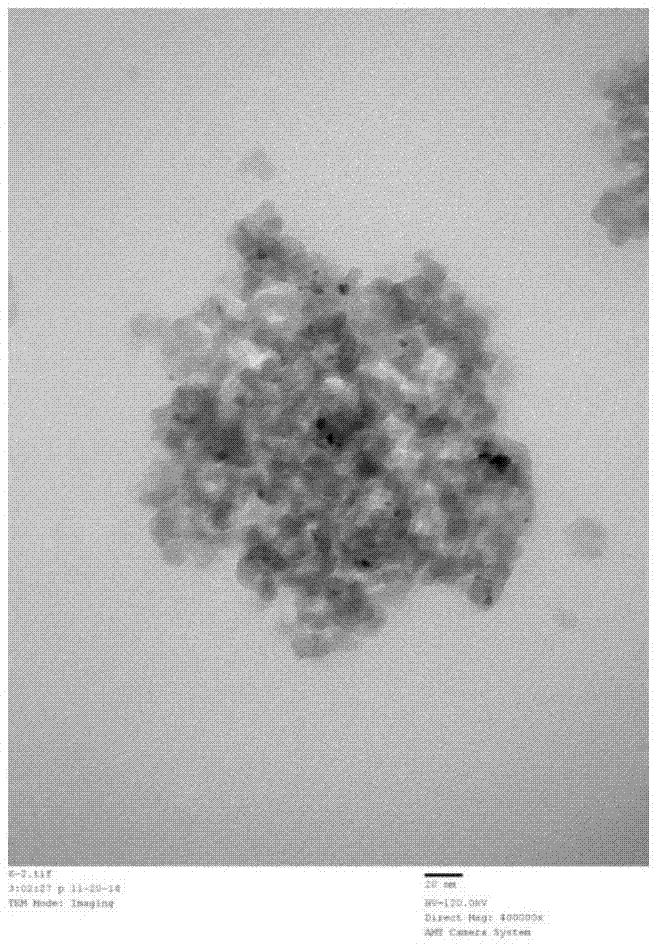

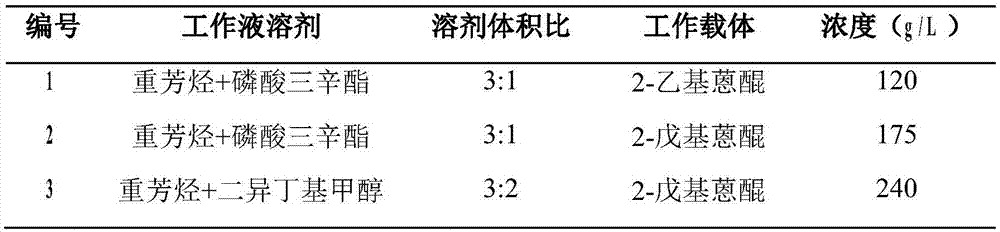

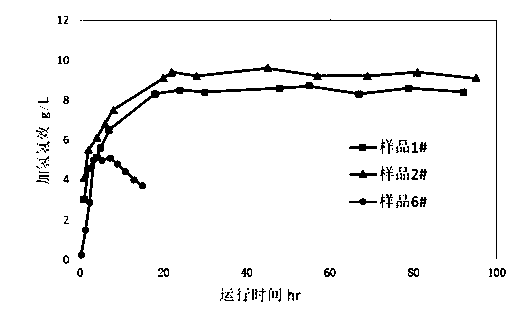

High-dispersion particle catalyst applied to synthesis of hydrogen peroxide as well as preparation method and application thereof

InactiveCN107008492AHigh catalytic activityImprove stabilityMolecular sieve catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDispersityPhosphate

The invention provides a high-dispersion particle catalyst applied to synthesis of hydrogen peroxide as well as a preparation method and application thereof. The preparation method of the catalyst is characterized by taking one or combination of two of noble metals Pd and Pt as a main active component, loading the main active component on a composite carrier prepared from AlPO series, SAPO series, silicon zincate molecular sieves, phosphates and oxides to prepare the catalyst. The catalyst carrier has a micropore-mesopore compounded hierarchical porous structure; through micropores, the dispersity of active metals and the spillover of hydrogen atoms can be improved, so that the hydrogenation activity of the catalyst, and the consumption of the noble metals is reduced; through mesopores, diffusion channels are provided for reactants and products, so that the mass transfer in the pores is facilitated, the mass production of byproducts is effectively avoided, and then the selectivity of the catalyst is improved; in addition, the composite carrier is easy to modify; acidity and alkalinity can be regulated; the performance of the catalyst can be further improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

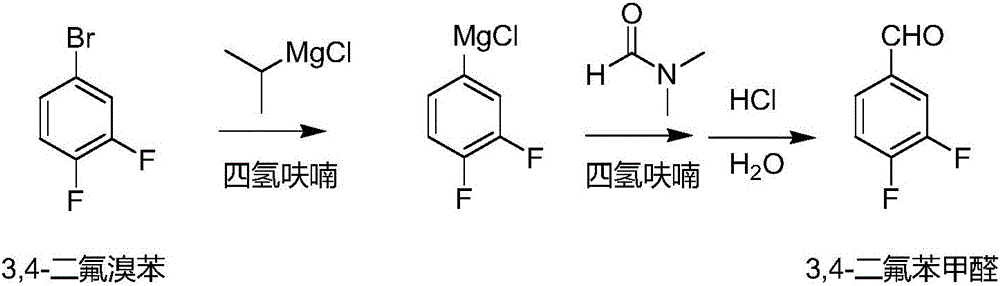

Method for preparing 3, 4-difluorobenzaldehyde

ActiveCN105859536AAvoid mass generationHigh reaction yieldOrganic compound preparationCarbonyl compound preparation by condensationOrganic synthesisMagnesium

The invention discloses a method for preparing 3, 4-difluorobenzaldehyde, and relates to the technical field of organic synthesis. The method includes carrying out Grignard exchange reaction on 3, 4-difluoro bromobenzene, tetrahydrofuran and a Grignard reagent to obtain first reaction products; carrying out reaction on the first reaction products and N, N-dimethylformamide to obtain second reaction products; treating the second reaction products to obtain the 3, 4-difluorobenzaldehyde. The 3, 4-difluoro bromobenzene is used as a raw material, and the tetrahydrofuran is used as a solvent. The method has the advantages that the Grignard exchange reaction is carried out on the 3, 4-difluoro bromobenzene and the freshly prepared Grignard reagent which is isopropylmagnesium chloride, and accordingly the problem of large quantities of generated byproducts due to excessively high reaction temperatures when 3, 4-difluoro bromobenzene and a Grignard reagent which is metal magnesium can be solved; the reaction is carried out on the N, N-dimethylformamide and the products already subjected to Grignard exchange, so that the 3, 4-difluorobenzaldehyde can be prepared, and the reaction yield can be increased.

Owner:BENGBU CHINA SYNCHEM TECH CO LTD

Novel process for preparing benzyl alcohol by alkali-free continuous hydrolysis of benzyl chloride

ActiveCN104926611ATransfer out in timeEasy to handleOrganic compound preparationHydroxy compound preparationAlkali freeDistillation

The invention relates to a novel process for preparing benzyl alcohol by alkali-free continuous hydrolysis of benzyl chloride. The process comprises the following steps of adding benzyl chloride, pure water and a specific mixed solvent of methylbenzene and cyclohexane into a primary normal-pressure reaction kettle according to a certain proportion, performing reaction for a certain time at certain temperature, continuing transferring a reaction product into a secondary pressure reaction kettle, adding an isopropylbenzene solvent, simultaneously adding methyl trioctyl ammonium chloride quaternary ammonium salt, continuing performing reaction for a certain time, cooling and settling obtained reaction liquid to separate an oil phase and an aqueous phase (containing benzyl alcohol and hydrochloric acid), and performing crude distillation and rectification on the oil phase to obtain a benzyl alcohol finished product. According to the process, a continuous feeding and discharging manner is adopted for reaction, and a corresponding solvent and a corresponding catalyst are combined, so that the yield rate of the product is increased, and the productivity is improved.

Owner:HUBEI GREENHOME MATERIALS TECH INC

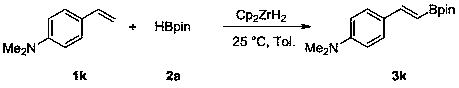

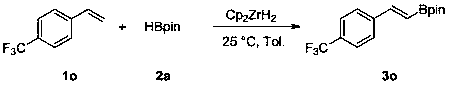

Synthetic method of alkenyl borate compound

ActiveCN110483561AAtom economy is highMeet the requirements of green chemistryGroup 3/13 element organic compoundsMetallocenesSynthesis methodsSolvent

The invention relates to a synthesis method of an alkenyl borate compound, which comprises the following steps: dissolving an olefin compound and a borane compound in a solvent, adding a zirconium catalyst, reacting at 0-150 DEG C for 5 minutes to 8 hours in a protective atmosphere, and separating to obtain the alkenyl borate compound. The method is simple and convenient to operate, low in cost, high in reaction atom economy and suitable for industrial production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

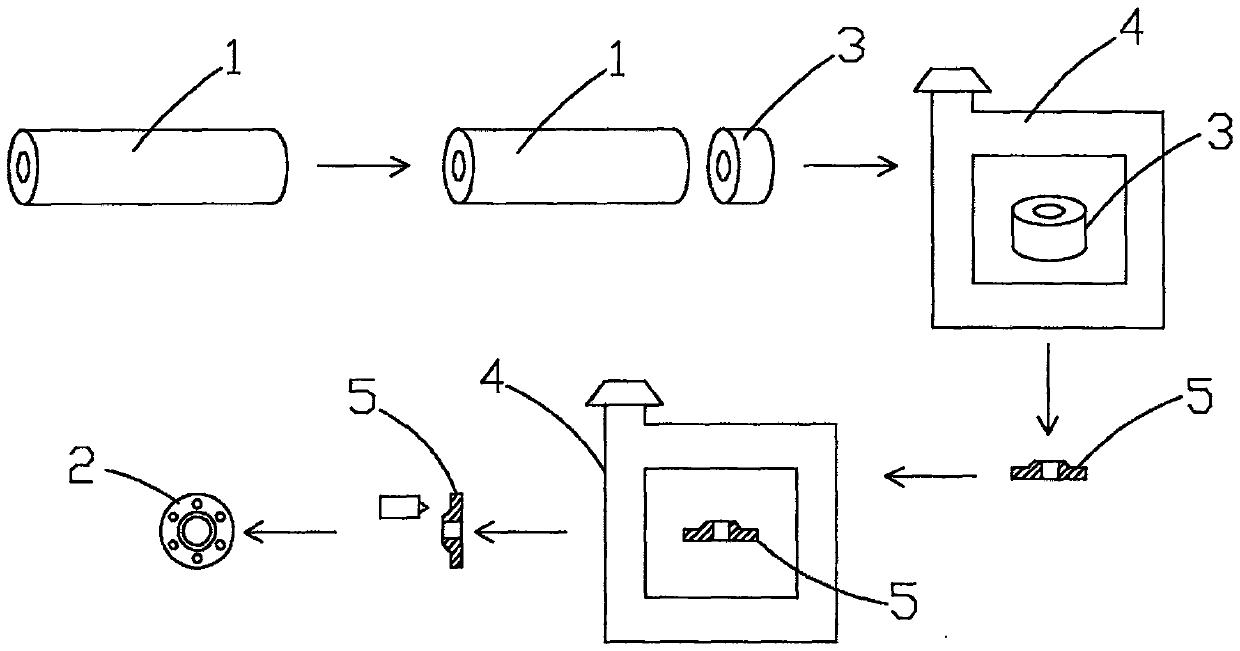

Flange manufacturing technology

The invention discloses a flange manufacturing technology. The technology comprises the steps of raw material thick-wall steel pipe re-inspection, forming of pipe blanks through cutting, heating, forging through a punch press, heat treatment, cutting and drilling, and marking and packaging. Thick-wall steel pipes serve as raw materials, and flange finished products are obtained after cutting, heating and forging, heat treatment, cutting and drilling. Compared with a traditional flange manufacturing technology, the technology remarkably improves the yield of the raw materials, greatly reduces generation of waste, effectively reduces the turning workload, prolongs the service life of a lathe cutter, and helps flange production enterprises to improve economic benefits.

Owner:宝成重工有限公司

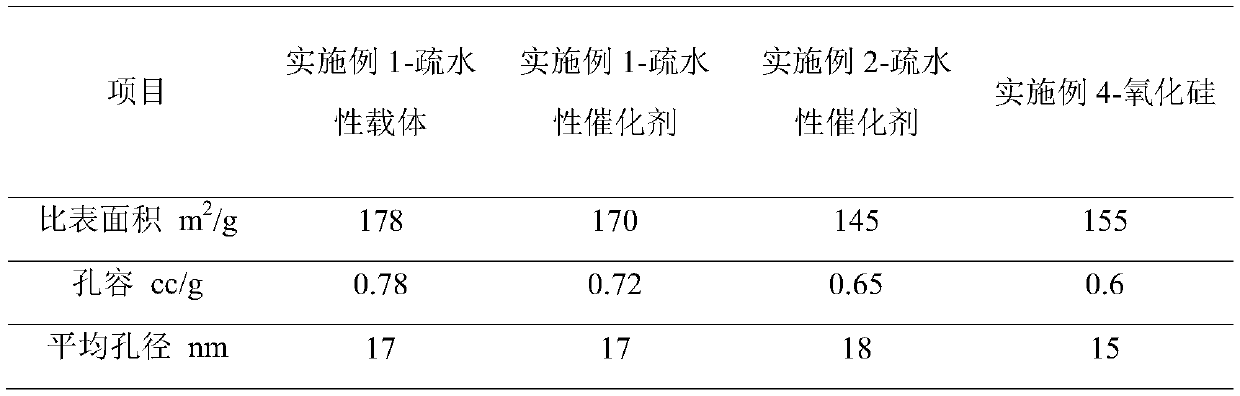

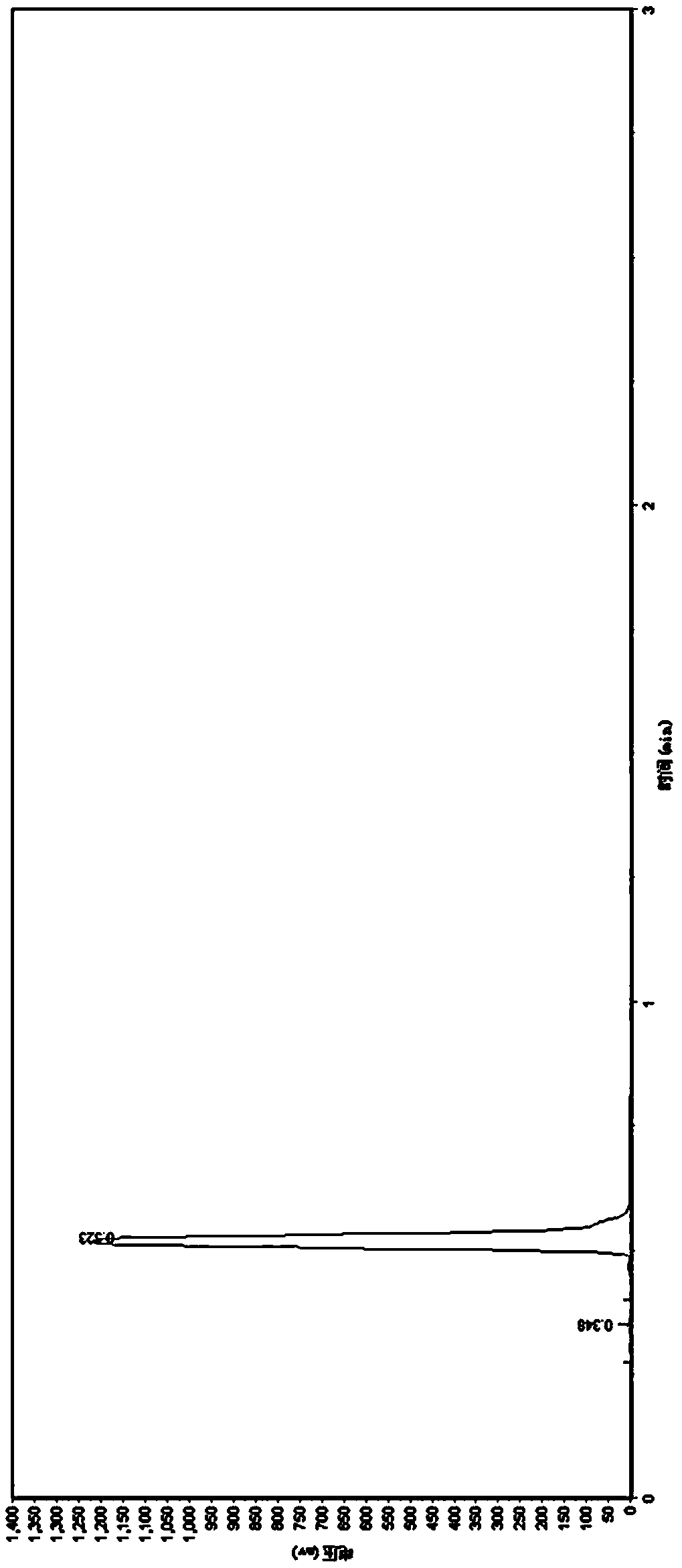

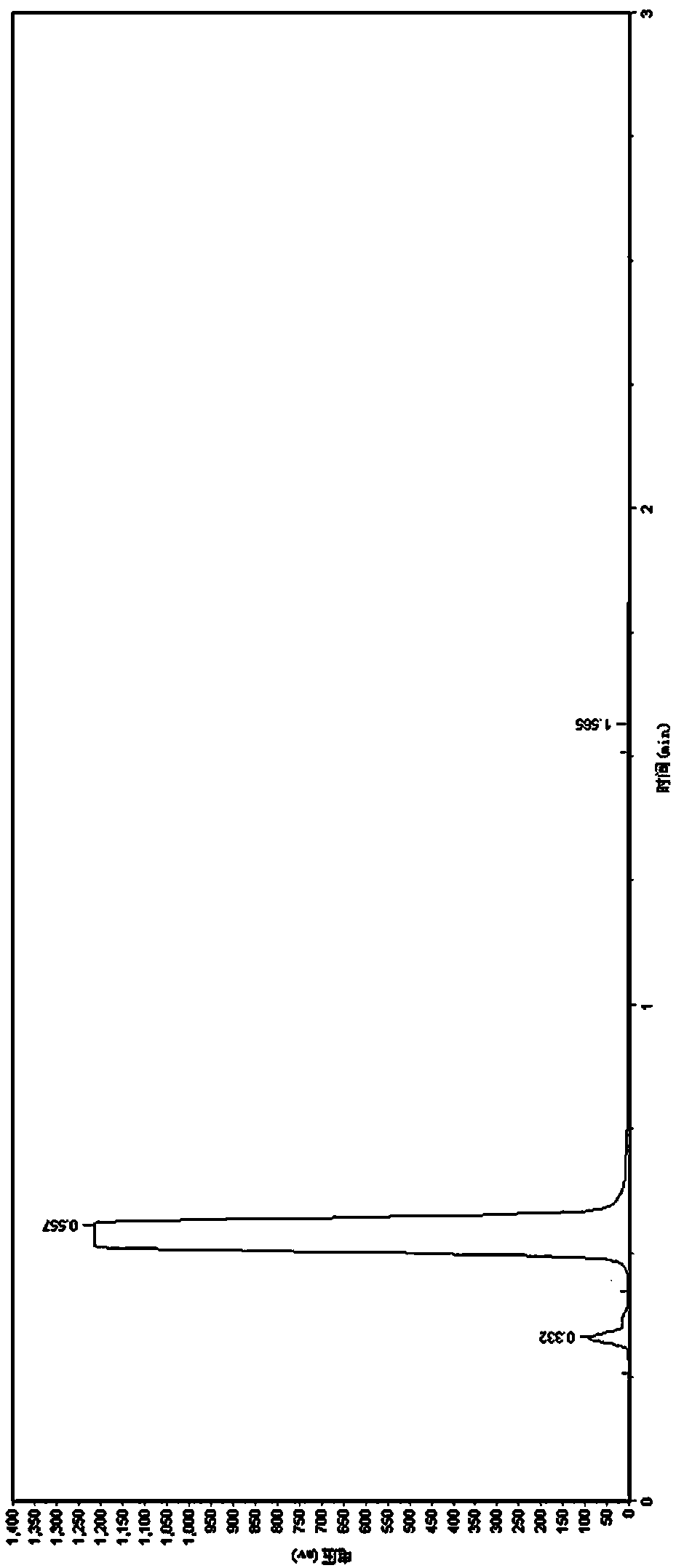

Precious metal catalyst as well as preparation method and application thereof

InactiveCN111437812AHigh selectivitySelectivePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsAnthraquinonesSlurry reactor

The invention discloses a noble metal catalyst as well as a preparation method and application thereof. The catalyst comprises a carrier and an active component, and the active component is loaded onthe carrier. The carrier comprises silicon oxide modified by organic groups. The active component comprises an active element, and the active element is selected from at least one of Pd and Pt. According to the hydrogenation catalyst, organic groups are introduced into the silicon oxide carrier to adjust the hydrophobicity and polarity of the carrier, the hydration effect of water in a hydrogenation working solution on the active component is avoided, the desorption effect of anthrahydroquinone serving as a species after anthraquinone hydrogenation is further improved, and the selectivity andstability of the hydrogenation catalyst are improved. The catalyst provided by the invention can be used in the process of producing hydrogen peroxide by slurry reactor anthraquinone catalytic hydrogenation, and the hydrogenation catalyst shows very high hydrogenation selectivity and stability.

Owner:SHANXI LUAN MINING GRP +1

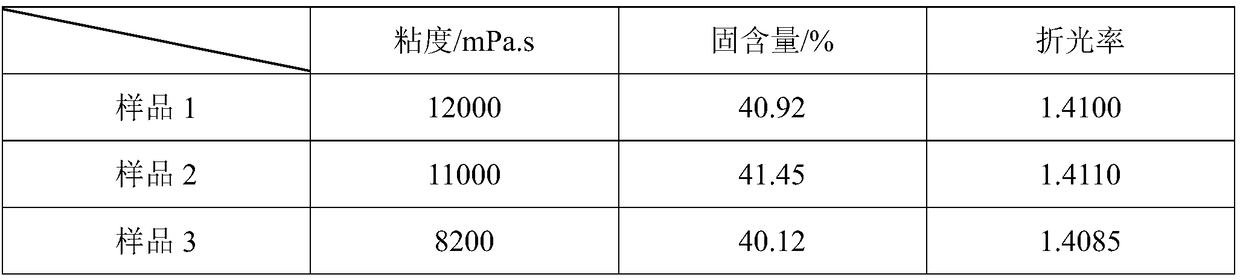

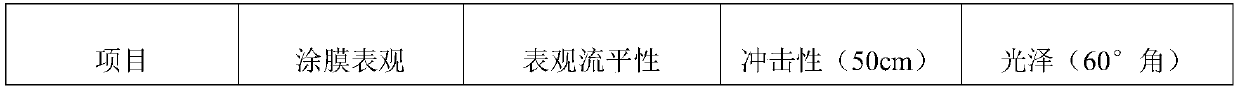

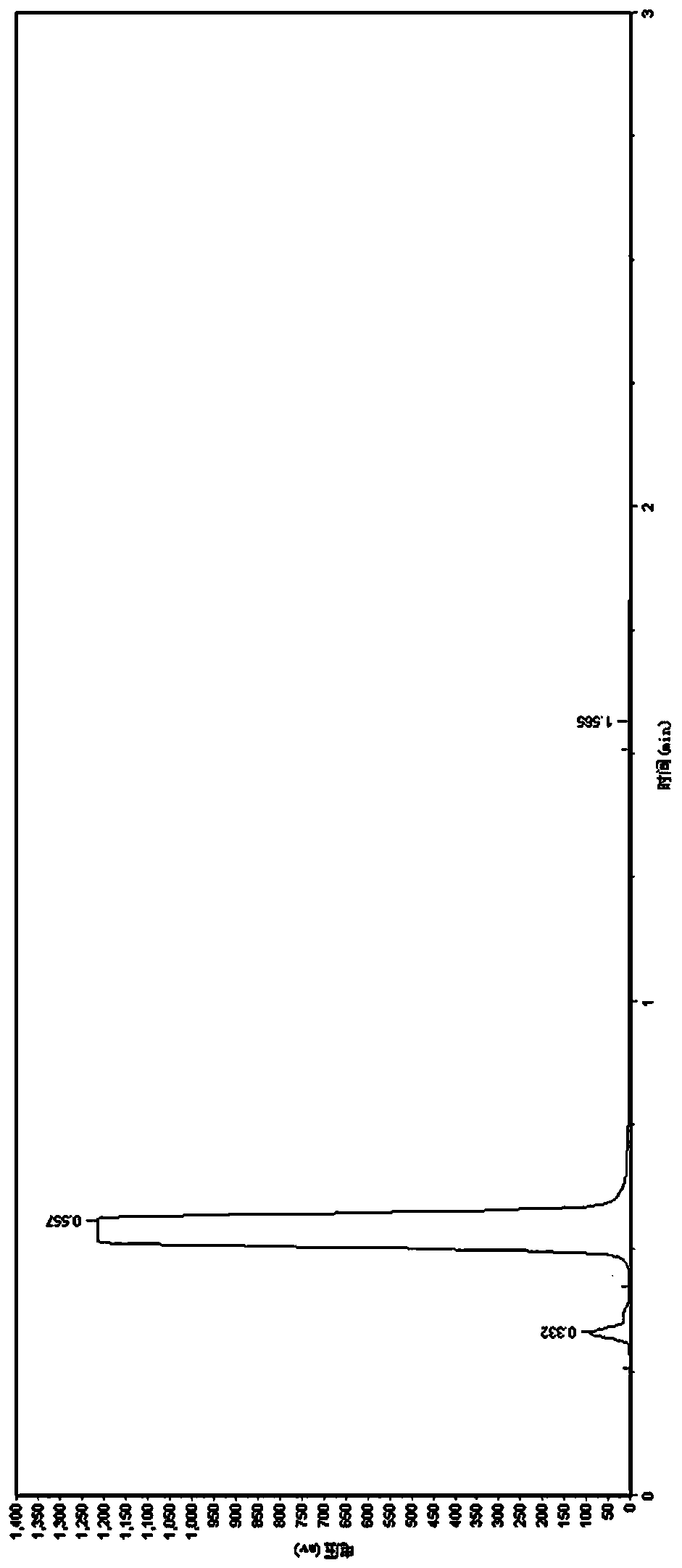

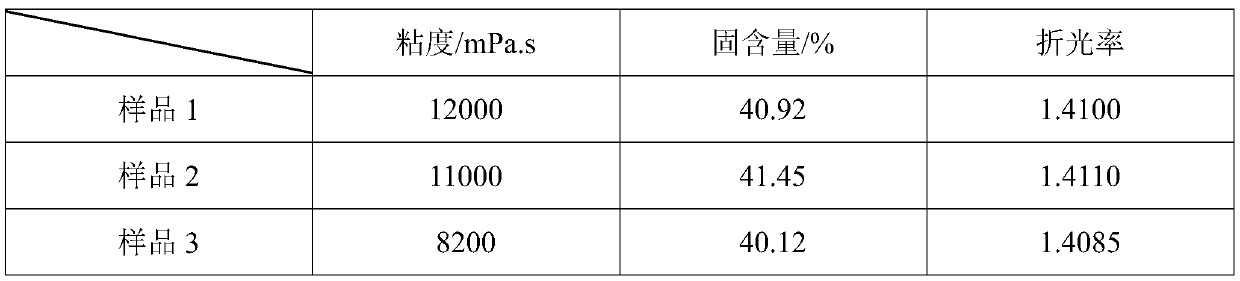

High-yield preparation method of high-purity dimethyl diallyl ammonium chloride monomer

ActiveCN109438250ALess impuritiesHigh purityAmino compound purification/separationOrganic compound preparationIonChemistry

The invention belongs to the technical field of organic synthesis, and specifically relates to a high-yield preparation method of a high-purity dimethyl diallyl ammonium chloride monomer. According tothe preparation method provided by the invention, a segmented type chloropropene and sodium hydroxide solution alternative and dropwise adding method is adopted, the most suitable alternative and dropwise adding amount and the most suitable reaction time of the chloropropene and the sodium hydroxide solution can be found through a large amount of small-scale tests and by adopting an acid-base indicator, the chloropropene can be prevented from being located in strong base environment, a large amount of byproducts such as allyl alcohol can be effectively prevented from being generated, the utilization rate of the chloropropene can be effectively increased, and by adopting a pressure-proof closed reaction kettle, dimethylamine is enabled not to leak and can completely take part in reaction.A dimethyl diallyl ammonium chloride monomer solution obtained through the preparation method is light in color and less in impurities, activated carbon is not used for decoloring and removing the impurities, the purity is high, the contents of amine salt and chlorine ions are extremely low, the yield is approximate to ideal value, a product is used for homopolymerization experiments, a colorless,transparent and clear polymer solution is obtained, and the viscosity and the molecular weight of the colorless, transparent and clear polymer solution are far higher than those of like products.

Owner:SHANDONG TIANCHENG CHEM CO LTD

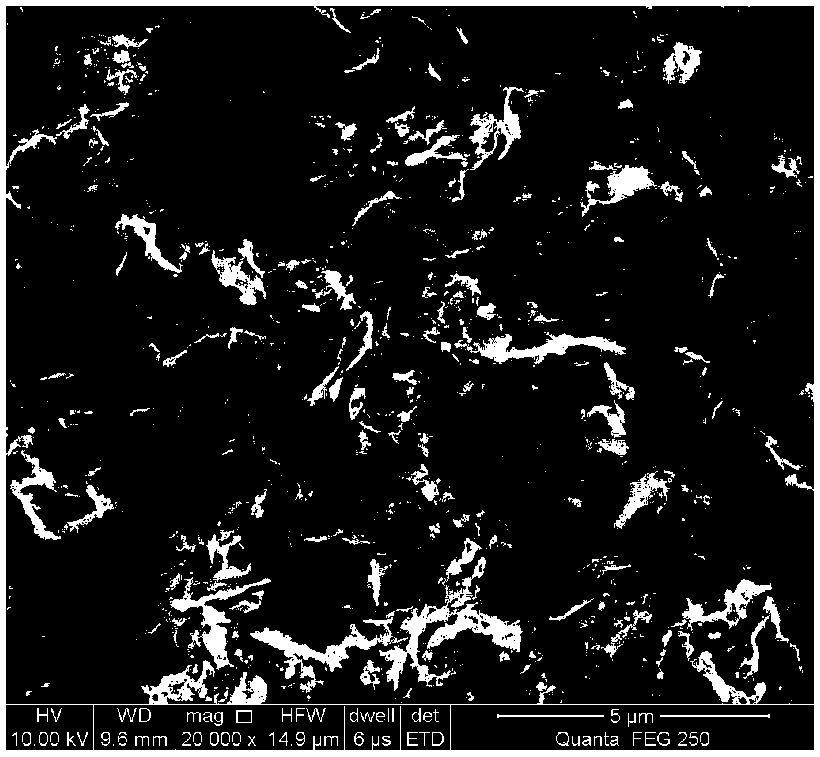

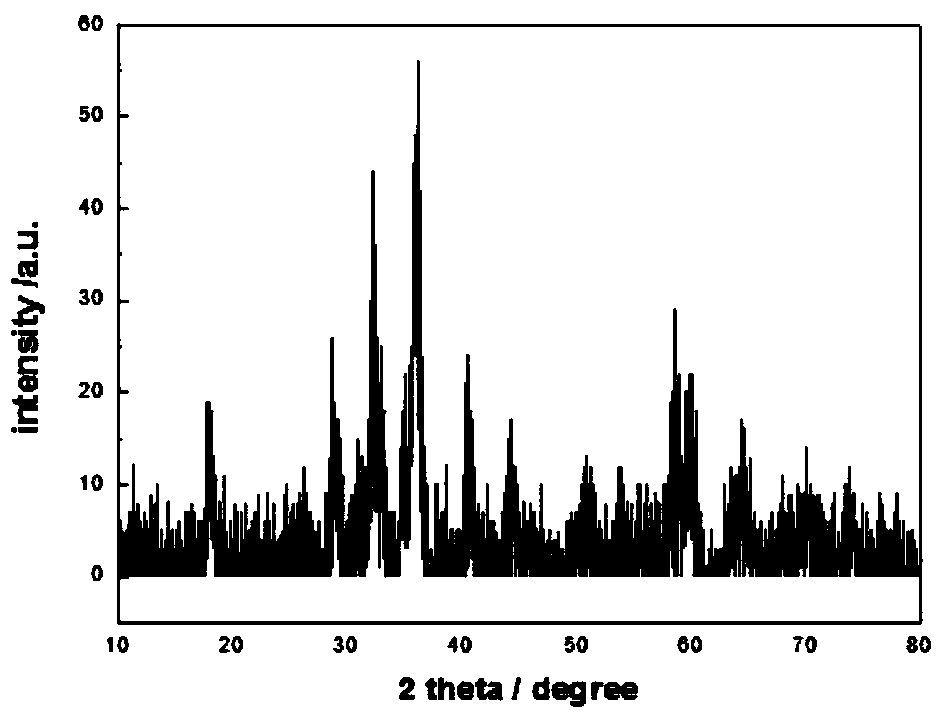

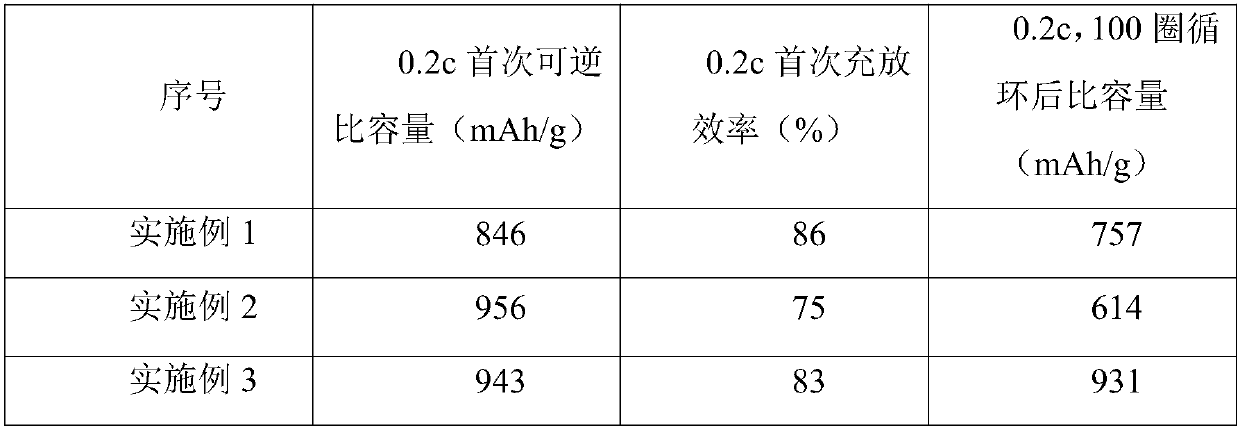

Metal-carbon composite negative electrode material as well as preparation method and application thereof

ActiveCN110061199AEvenly dispersedTightly boundElectrode thermal treatmentSecondary cellsCarbon compositesThree stage

The invention belongs to the field of battery materials, and particularly relates to a preparation method of a metal-carbon composite negative electrode material; the preparation method comprises thesteps of mixing bituminous coal with a metal source to obtain a mixture; and sequentially performing first-stage sintering, second-stage sintering and third-stage sintering on the mixture to obtain the composite negative electrodes material, wherein the sintering temperature is 300 DEG C or below in the first-stage sintering; the sintering temperature is 400-600 DEG C in the second-stage sintering; and the sintering temperature is 700-1,200 DEG C in the third-stage sintering. The invention also discloses the negative electrode material prepared by adopting the preparation method and an application of the negative electrode material in preparation of a negative electrode of a lithium ion battery. According to the method, bituminous coal is creatively adopted as a raw material; and the raw material is matched with the metal source, and the battery negative electrode material with excellent electrical property can be prepared under the special three-stage sintering mechanism.

Owner:HUNAN JINYE HIGH TECH CO LTD

Sugar cane juice and starch fermenting process for producing yeast

The sugar cane juice and starch fermenting process for producing yeast includes: squeezing sugar cane and clarifying to obtain sugar cane juice containing sugar in 11-17 %, setting the sugar cane juice into fermenter, introducing sterilized nitrogen source and phosphorus source, inoculating yeast seed liquid in 5-20 vol%, ventilating and stirring, and culturing. The process utilizes both sugar cane juice and starch as carbon source and energy source separately, and thus has high cell density, high yeast yield and high yeast quality. In addition, the process has the circulation of partial waste water and less pollutant draining.

Owner:SOUTH CHINA UNIV OF TECH

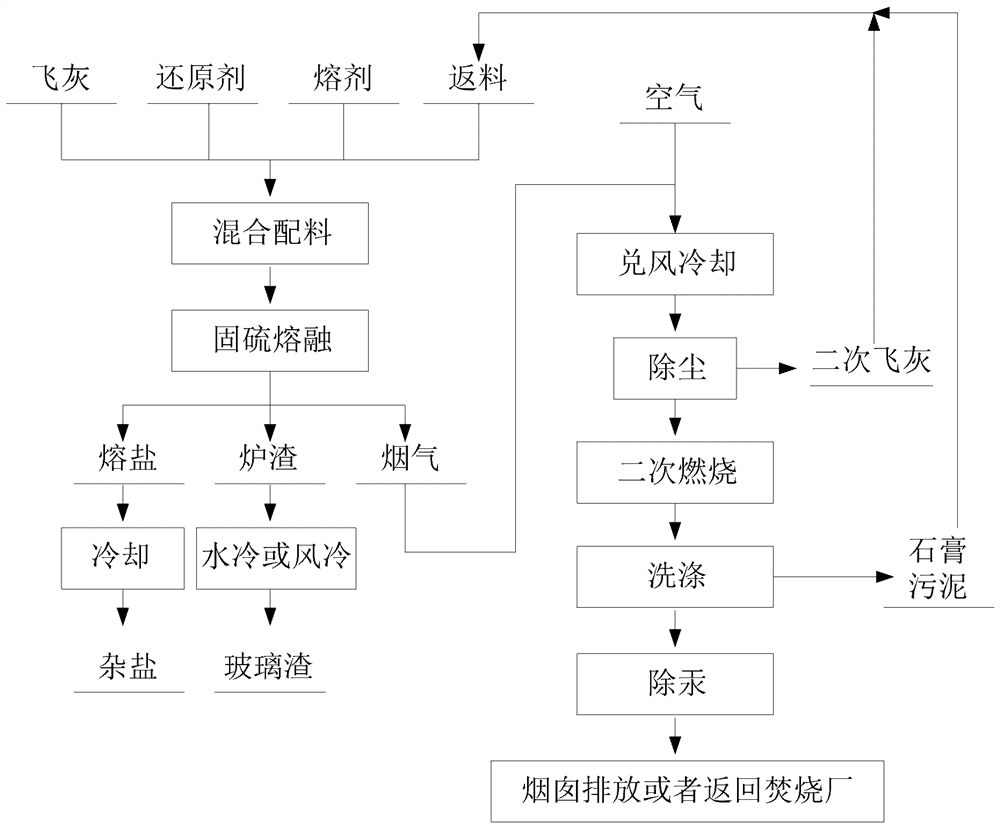

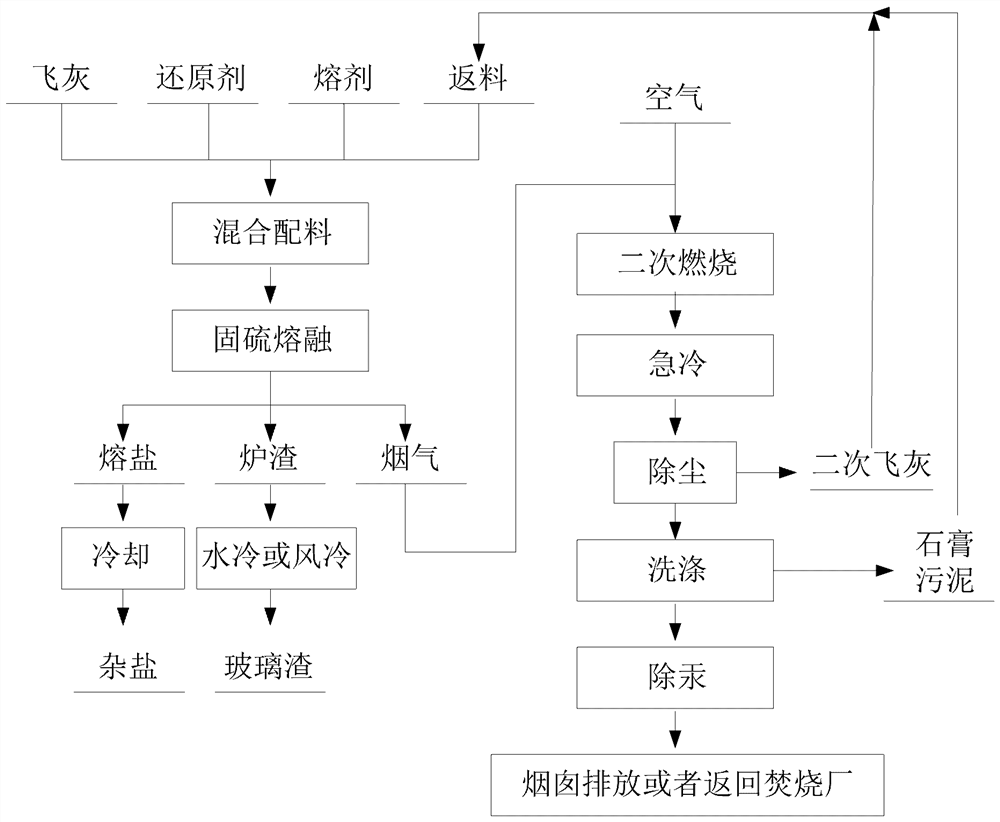

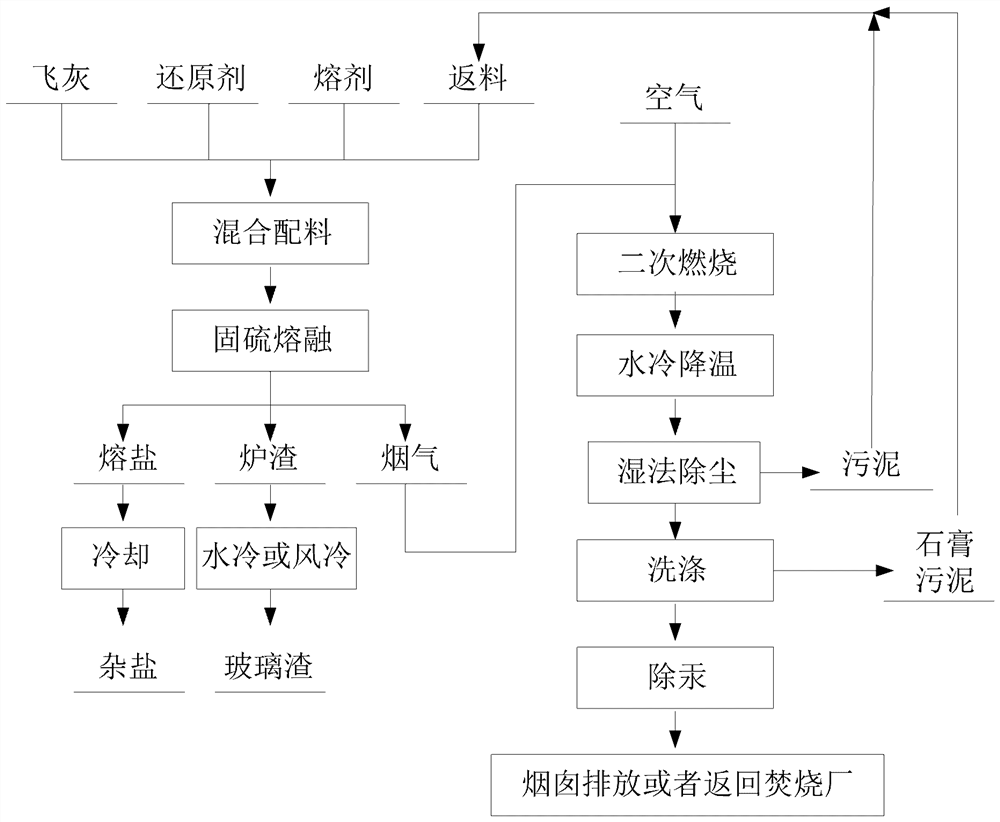

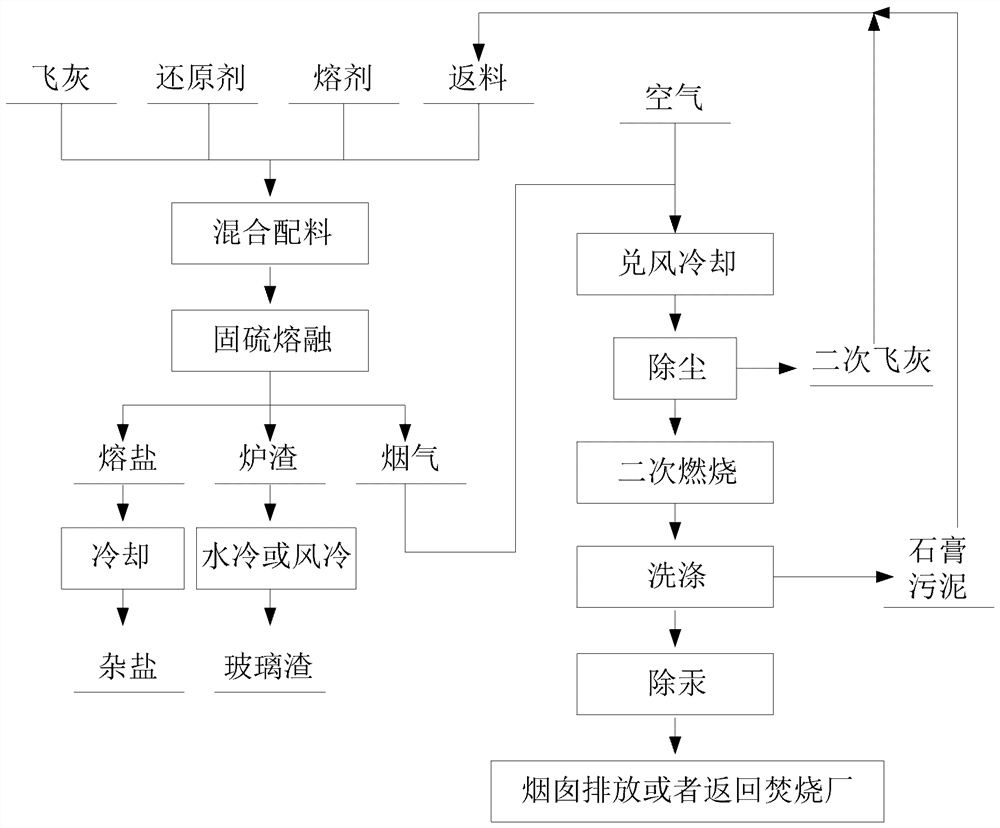

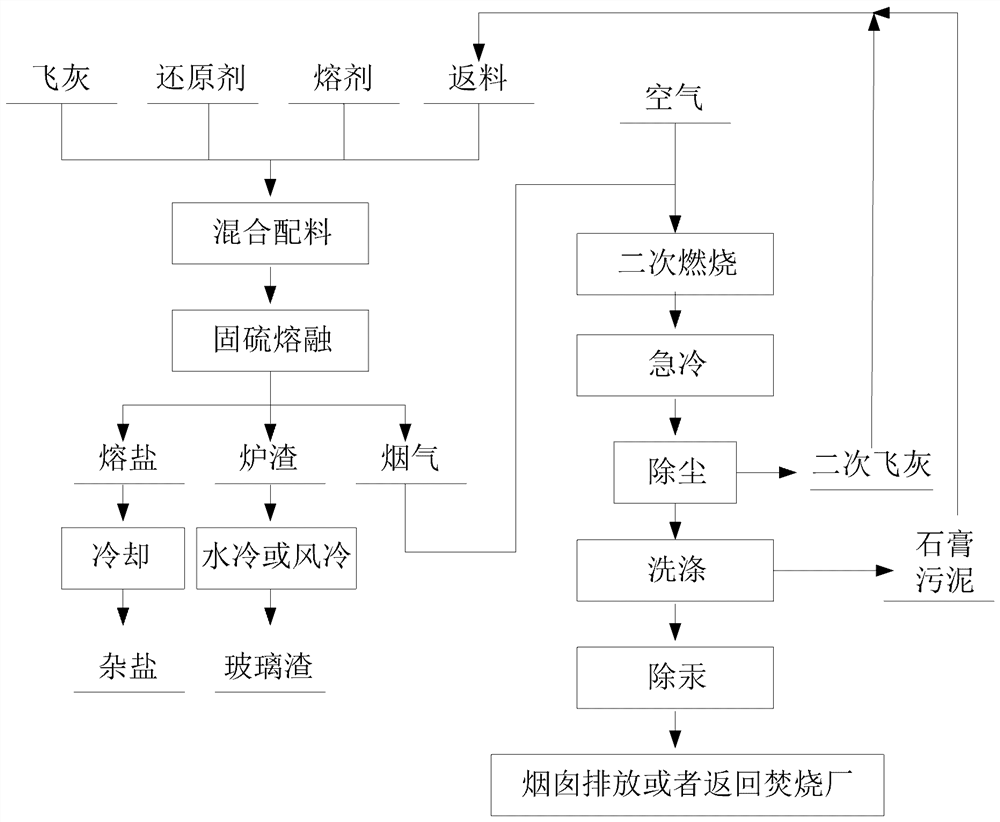

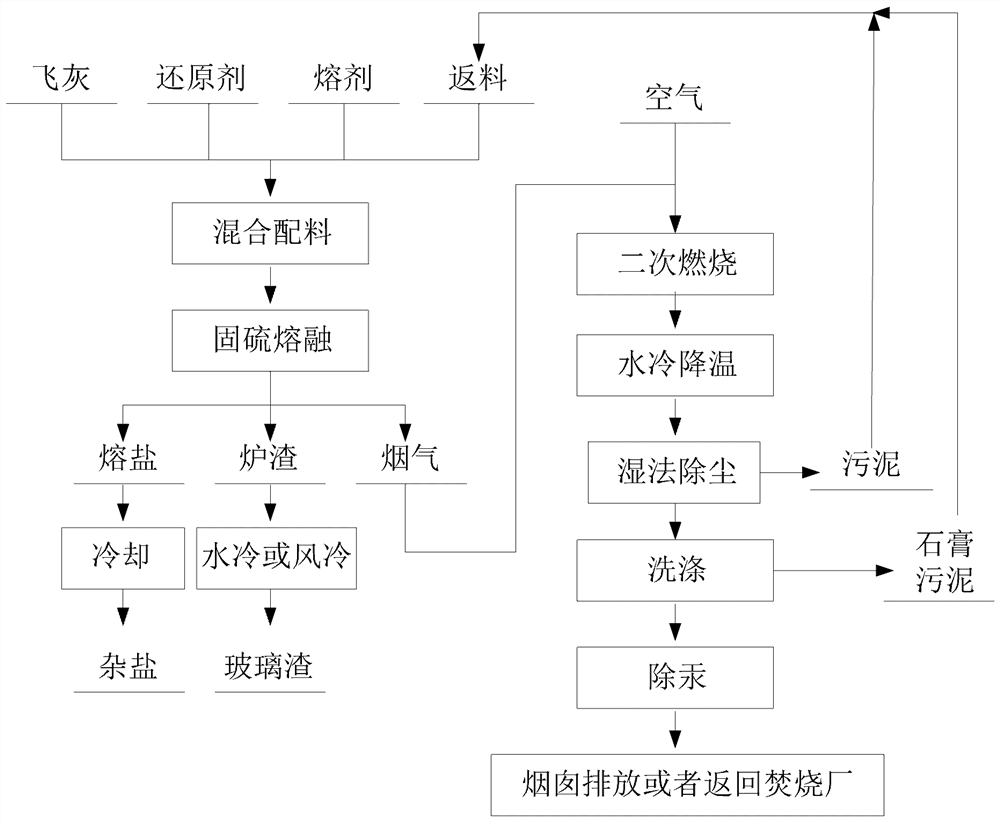

Fly ash sulfur fixation melting harmless treatment method

ActiveCN113020229ASolve the problem of poor harmless treatment effectEasy to handleTransportation and packagingSolid waste disposalExhaust gasSlag

The invention provides a fly ash sulfur fixation melting harmless treatment method. The method comprises the following steps that fly ash, a reducing agent and flux are mixed to obtain a mixed raw material, wherein the molar ratio of C to S in the mixed raw material is 2.5 to 3.5; the slag type is controlled to be an SiO2-Al2O3-CaO slag type, and m / n is 0.8 to 1.5; or the slag type is controlled to be an SiO2-CaO-FeO slag type, m / n is 1.0 to 1.6, and l / m is 0.15 to 0.30; the mixed raw material is fed into an electric furnace in a blowing mode or a pressed material ball mode to be subjected to sulfur fixation melting, the temperature of a slag layer is controlled to range from 1250 DEG C to 1350 DEG C in the period, the temperature of a molten salt layer on the top of the slag layer is controlled to be smaller than 1200 DEG C, and molten salt, slag and exhaust gas are obtained; the molten salt is cooled, and the slag is subjected to water cooling or air cooling; and the exhaust gas is treated through one of three modes. According to the method, a systematic solution is provided for fly ash treatment in the aspects of material blending, sulfur fixation melting, exhaust gas treatment and the like, and the maximum harmless treatment is achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

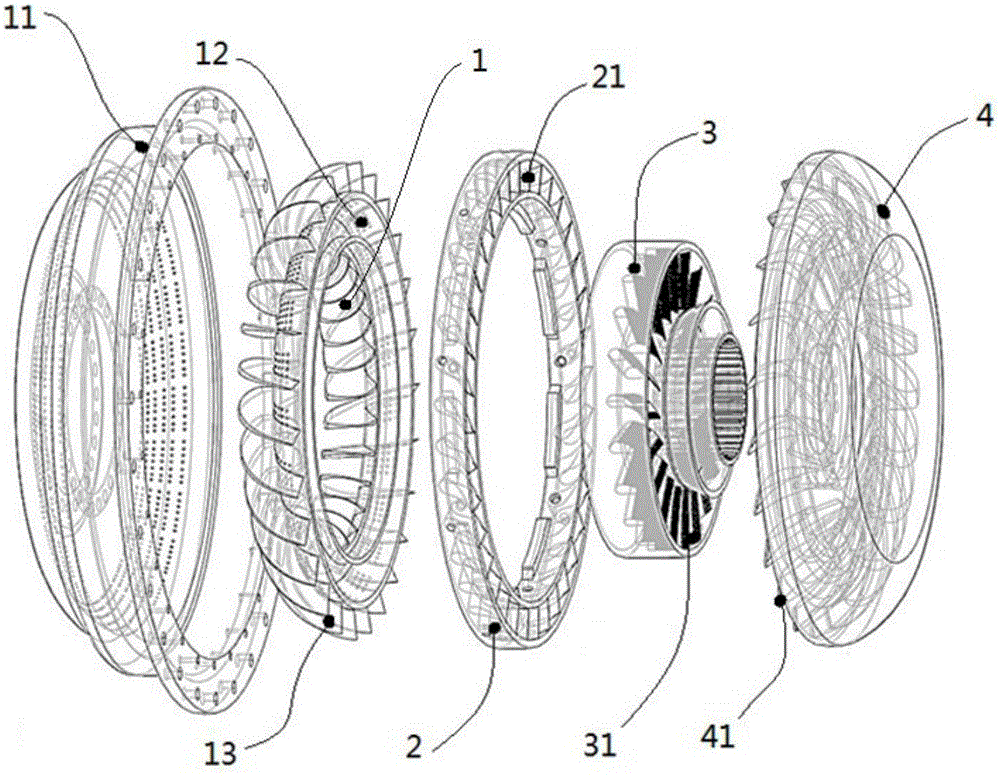

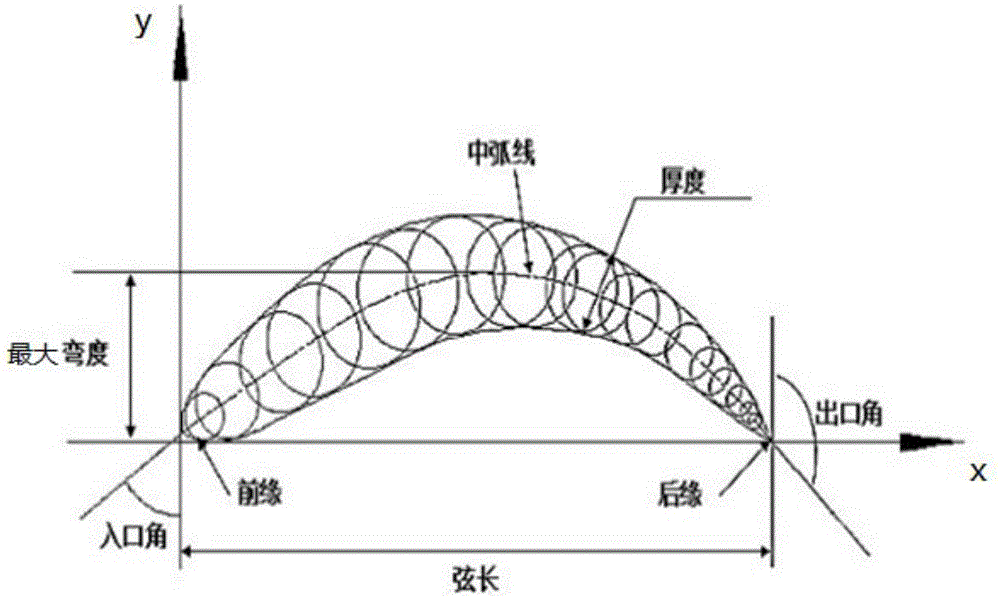

Coupling bionic double-turbine hydraulic torque converter

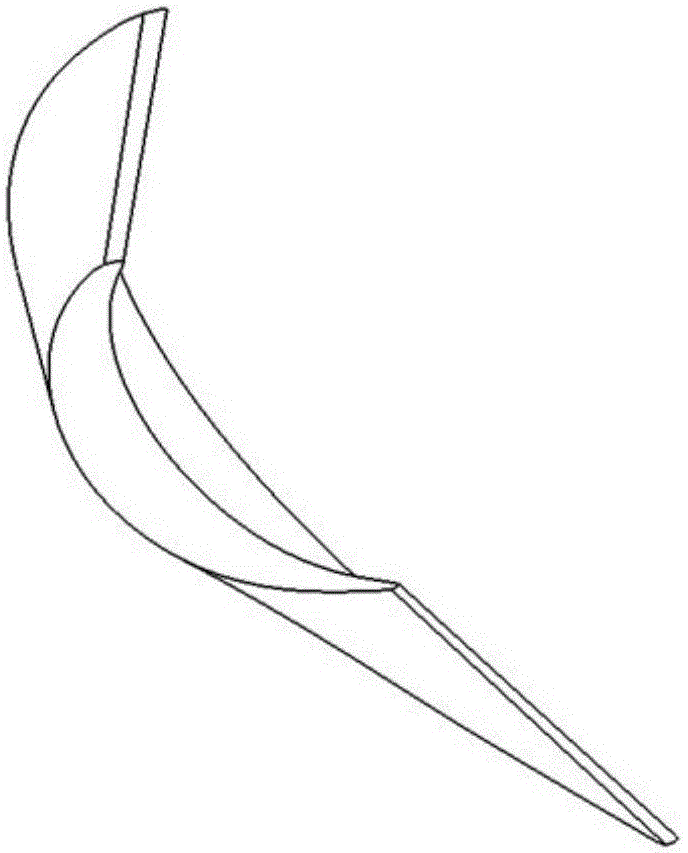

InactiveCN105156628AIncrease starting torque ratioImprove efficiencyFluid gearingsTurbine bladeCoupling

The invention relates to a coupling bionic double-turbine hydraulic torque converter. The coupling bionic double-turbine hydraulic torque converter comprises a pump wheel, a pump wheel outer ring, a pump wheel inner ring, a first turbine, a guide wheel and a second turbine. Vanes of the pump wheel are bionic wheels. The polynomial of the circular rector distribution function of the pump wheel is y=ax4+bx3+cx2+dx+e, wherein x is the transverse coordinate of each equal diversion point on an arc line, y is the corresponding circular rector distribution value, 3.0619<=a<=6.0894, -6.0787<=b<=-3.8151, -0.406<=c<=0.0147, -0.1814<=d<=0.4725, and 0.5972<=e<=1.5149. The vanes of the pump wheel are bionic wheels. Compared with a traditional common double-turbine hydraulic torque converter, the starting torque ratio and efficiency are increased, and the capacity factor of the pump wheel is larger than that of a hydraulic torque converter with common vanes.

Owner:JILIN UNIV

Control system and method for flue dynamic air distribution cooperating with SNCR denitration

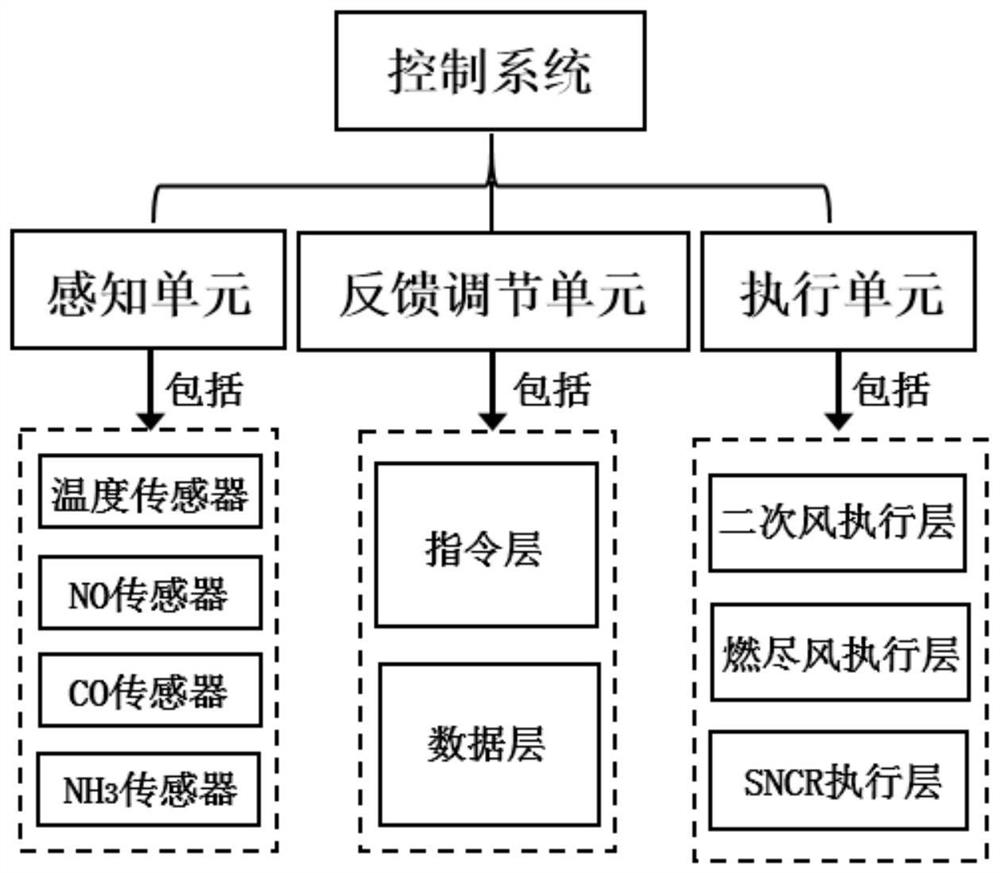

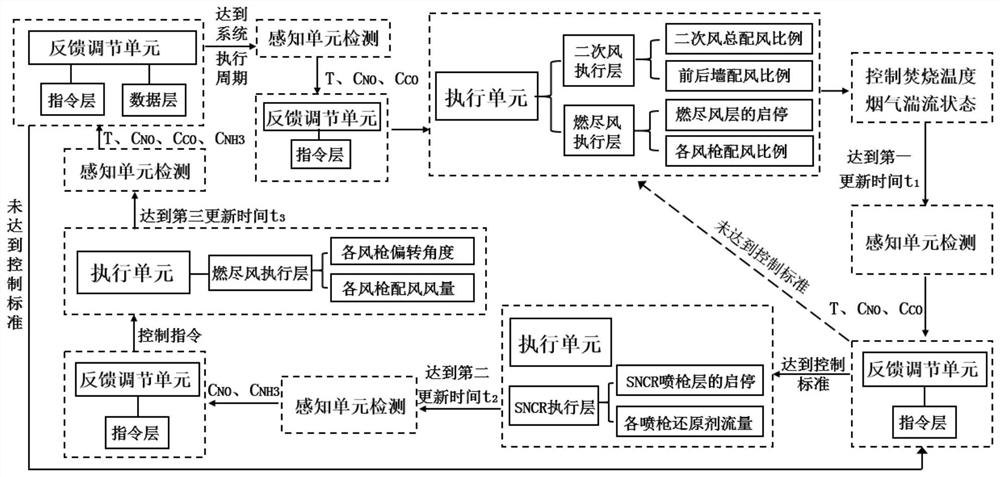

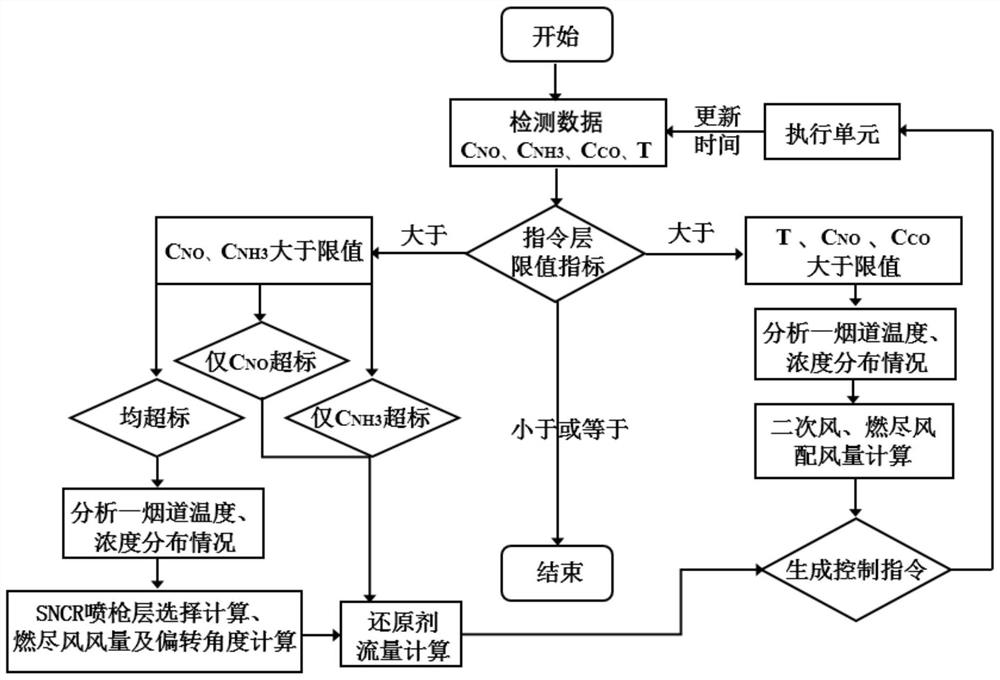

PendingCN112728544AReduce generationImprove denitrification efficiencyGas treatmentDispersed particle separationThermodynamicsControl system

The invention provides a control system and method for flue dynamic air distribution cooperating with SNCR denitration. The control system is composed of a sensing unit, an executing unit and a feedback adjusting unit, wherein the sensing unit comprises a temperature, NO concentration, CO concentration and NH3 concentration detection module, the execution unit comprises a secondary air execution layer, an over fire air execution layer and an SNCR execution layer, and the feedback adjustment unit comprises an instruction layer and a data layer. The control method comprises: detecting the parameters by the sensing unit; analyzing the data and generating a control instruction through the feedback adjustment unit, and storing detection parameters and the control instruction; and dynamically regulating and controlling the air distribution state and the reducing agent injection state through the execution unit. The control system and the control method have a feedback regulation function to realize dynamic regulation and control of combustion and denitration and self-correction of the system, and can be widely applied to the technical field of low-nitrogen combustion and SNCR denitration.

Owner:SOUTH CHINA UNIV OF TECH

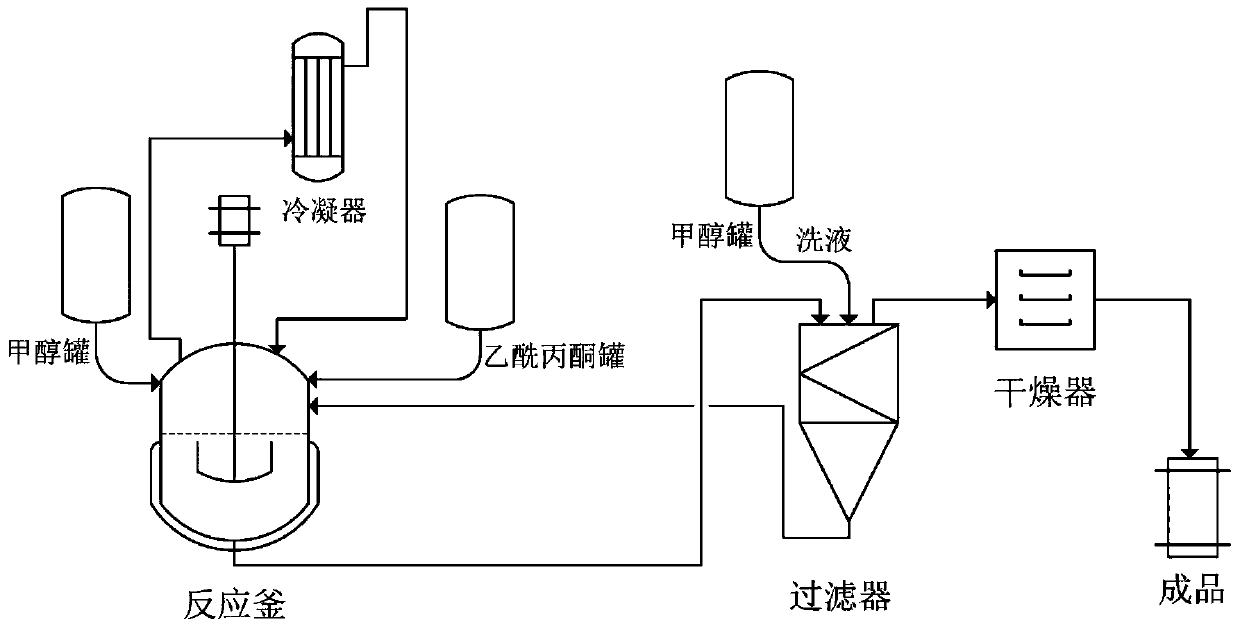

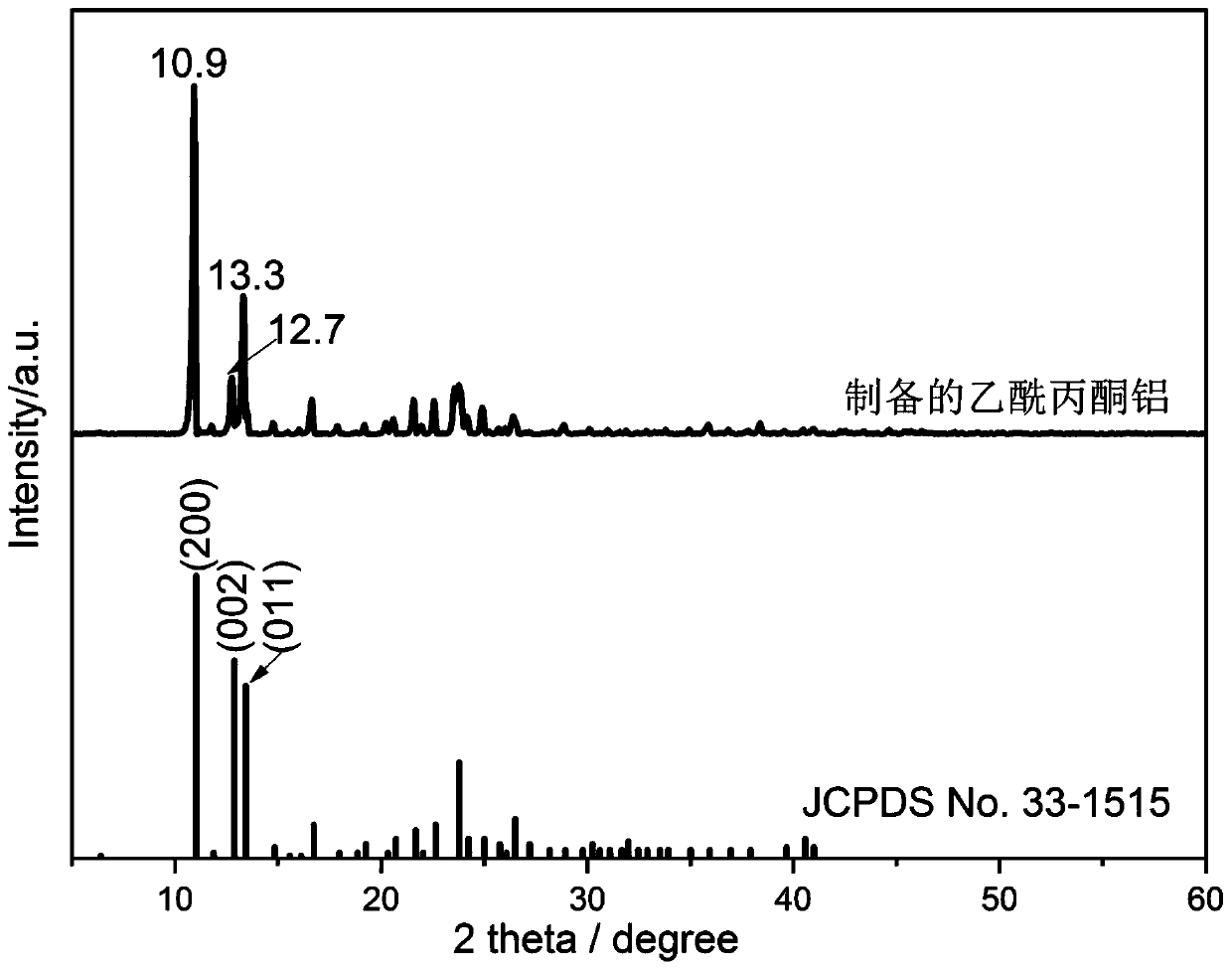

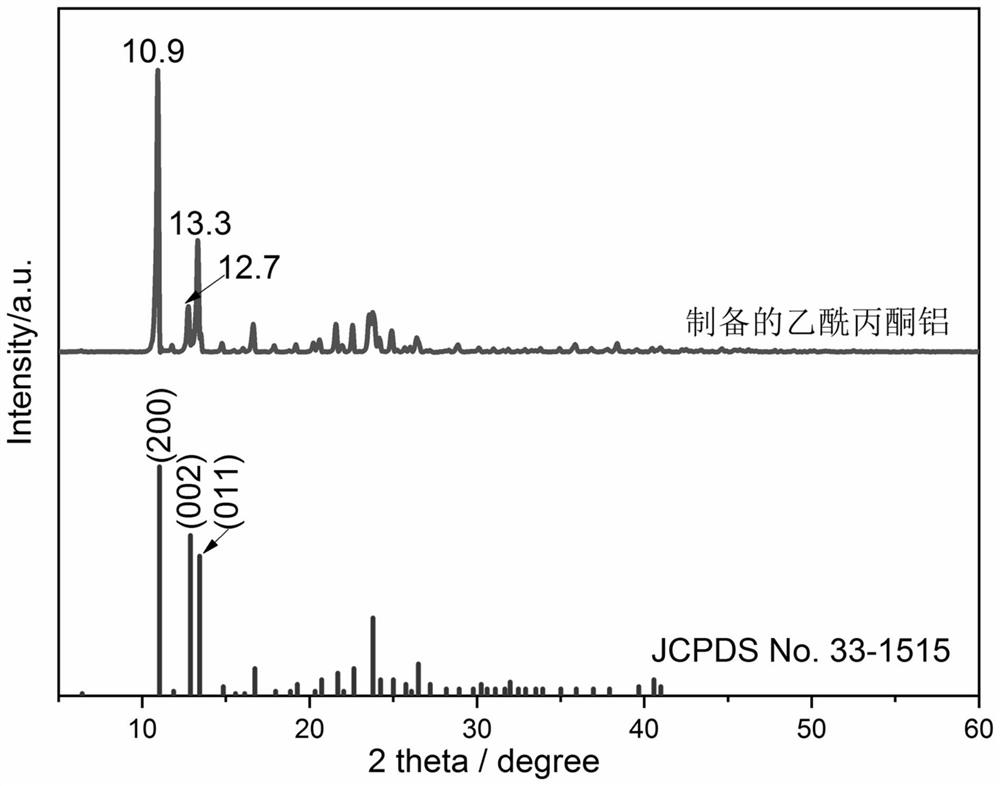

Preparation method of aluminum acetylacetonate

ActiveCN110437051AReduce generationIncrease profitPreparation of aldehyde/ketone chelatesOrganic acidLower grade

The invention discloses a preparation method of aluminum acetylacetonate, which comprises the following steps: 1) in a reactor, mixing aluminum powder with C1-C3 low-grade fatty alcohol, and adding organic acid to adjust the pH value to 2-4.5; 2) adding acetylacetone for reaction, and then adding alkali liquor to adjust the pH value to 6-7; and 3) filtering the product obtained in the step 2), andwashing and drying the filter residue to obtain the aluminum acetylacetonate. The method is free of water as a solvent, reduces the generation of wastewater, promotes the reaction by a small amount of organic acid as a pH value regulator, improves the utilization rate of the raw material acetylacetone, achieves the cyclic utilization of the solvent, and saves the cost.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

A method for preparing gem-diboron compounds by selective 1,1-diboration of alkenes

ActiveCN111217844BAtom economy is highMeet the requirements of green chemistryGroup 3/13 element organic compoundsCombinatorial chemistryAlkene

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

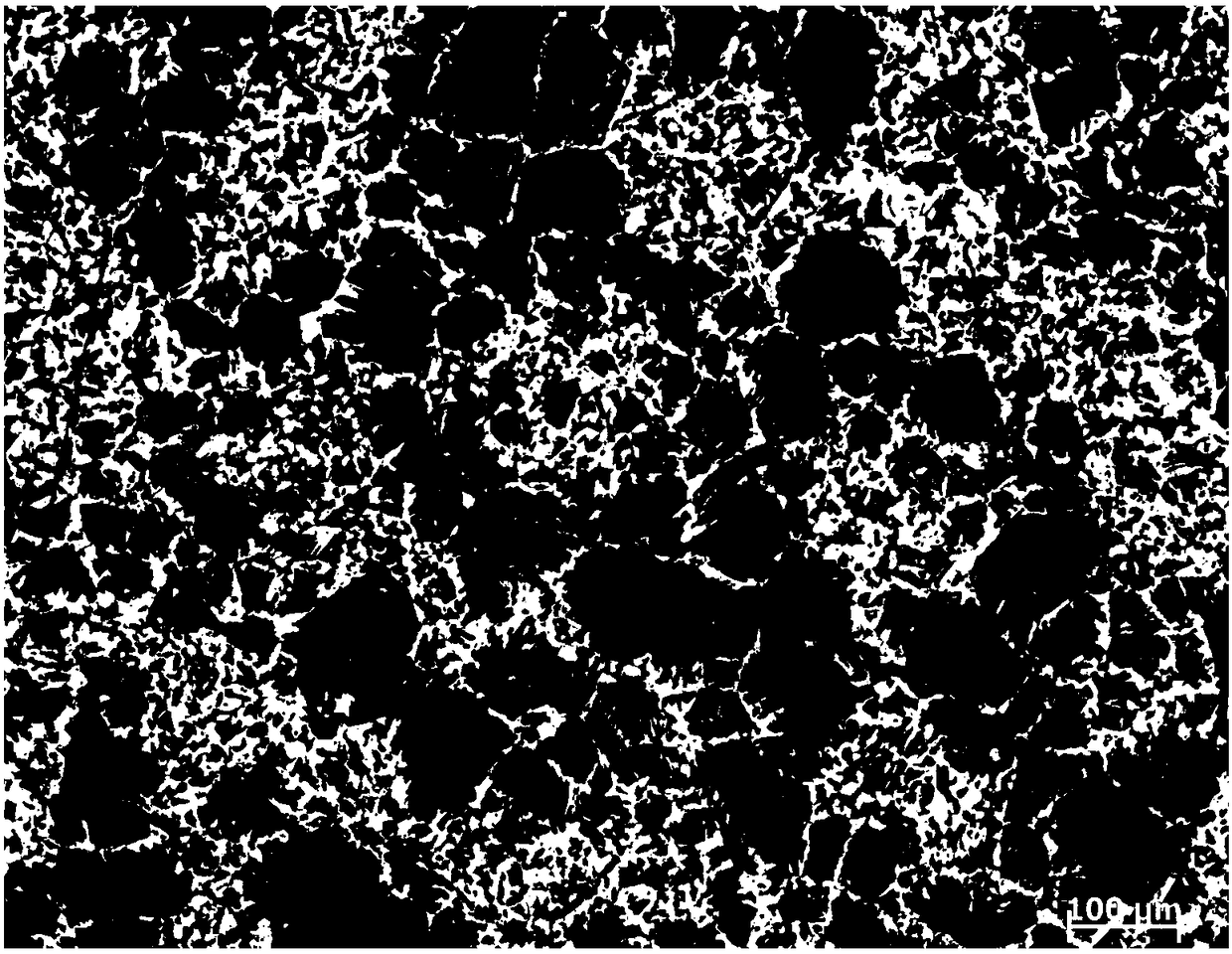

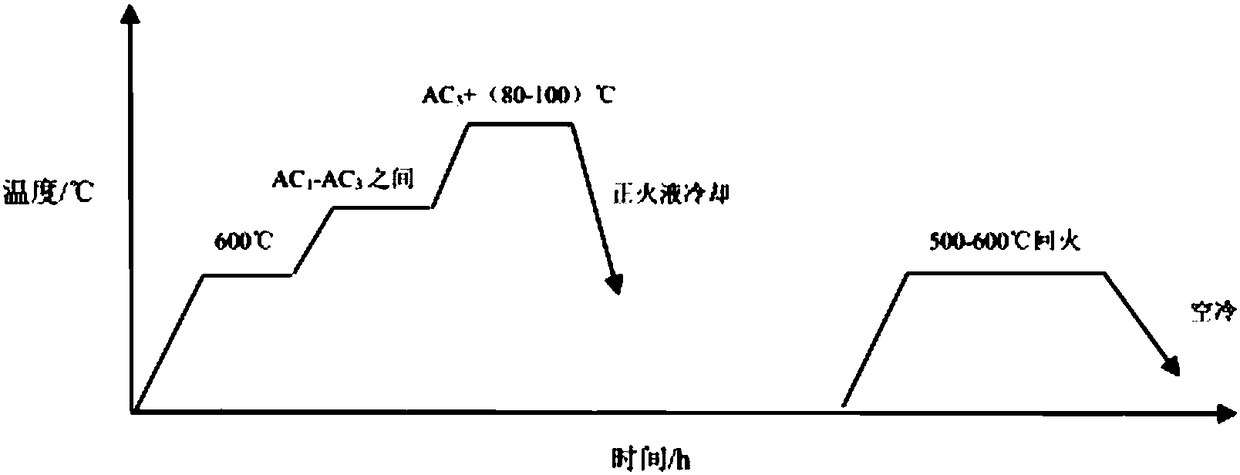

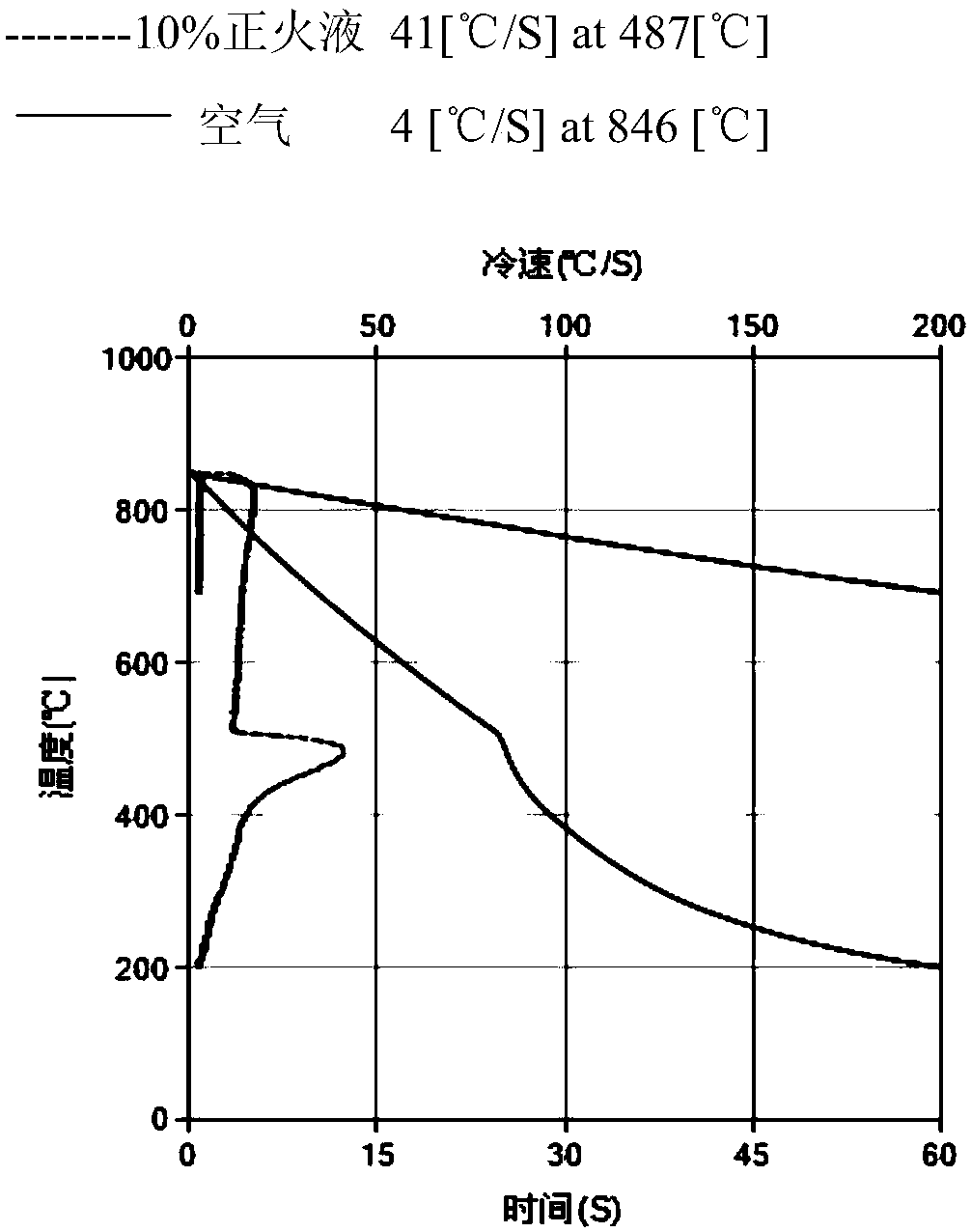

A kind of normalizing liquid for steel castings and normalizing cooling process for steel castings

ActiveCN106011403BControl precipitationGrain refinementQuenching agentsCarboxymethyl cellulosePolyvinyl alcohol

The invention relates to a steel casting normalizing solution and a steel casting normalizing cooling technique, belonging to the technical field of heat treatment of steel castings. The normalizing solution is a high-molecular polymer water solution. The high-molecular polymer water solution is composed of the following components in percentage by weight: 5-15% of polyvinyl alcohol, 10-25% of sodium polyacrylate, 0.5-1.0% of sodium carboxymethyl cellulose, 3-6% of additive and the balance of water. The steel casting normalizing solution and steel casting normalizing cooling technique improve the cooling uniformity, inhibit the pro-eutectoid phase, and solve the technical problems of poor mechanical anisotropy, poor impact toughness and low yield-tensile ratio.

Owner:NANJING KERUN LUBRICANTS

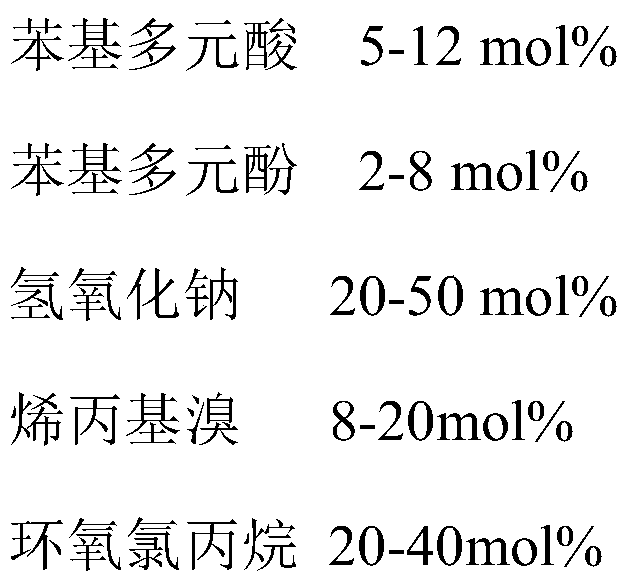

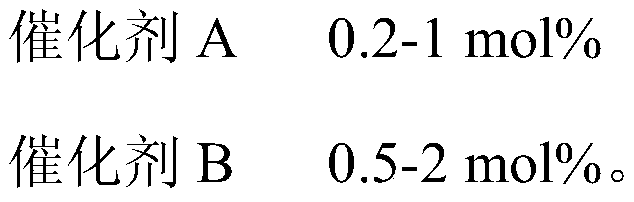

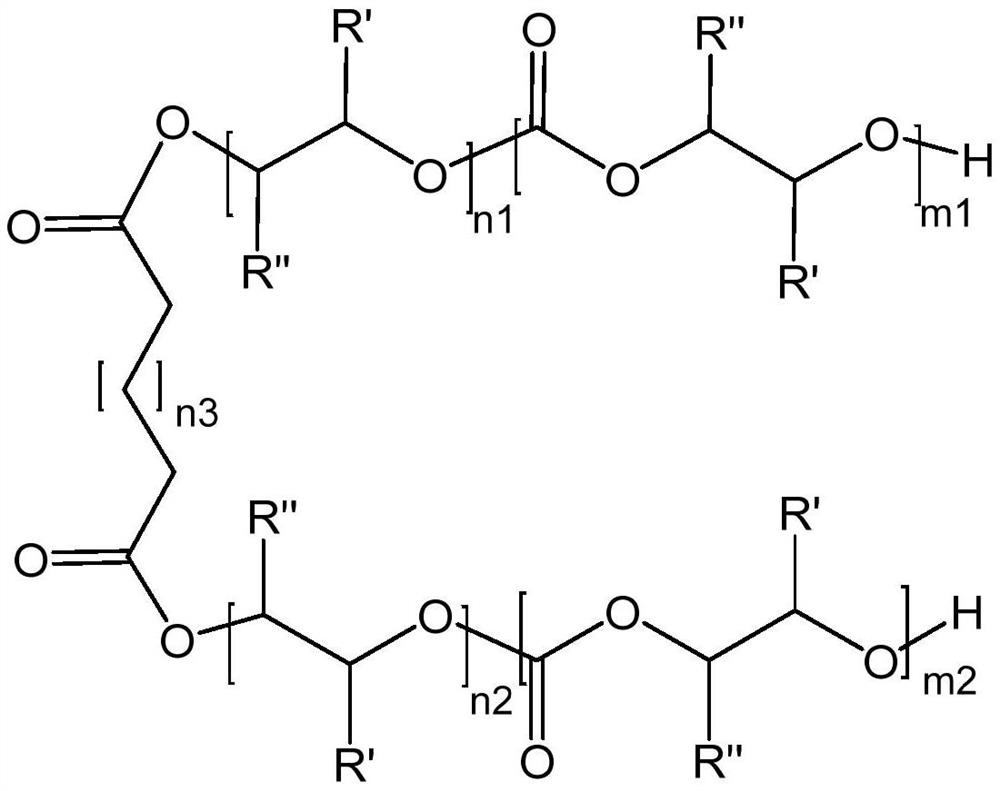

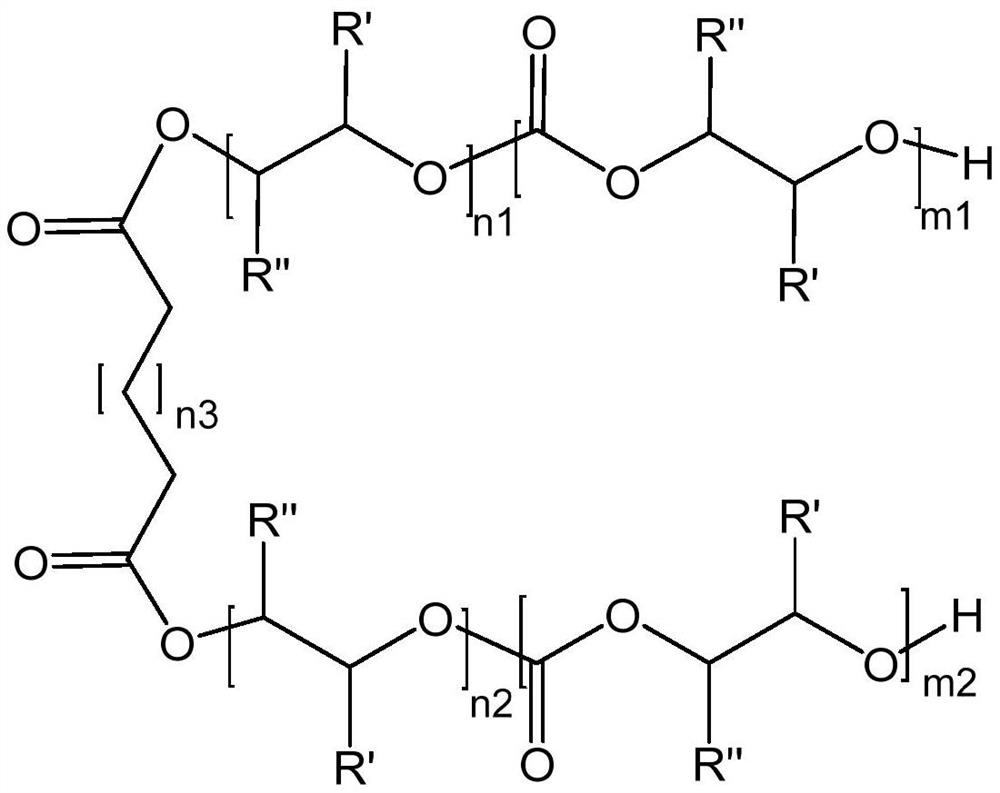

A kind of curing agent for carboxyl resin, preparation method and application composition

ActiveCN108503813BIncrease crosslink densityAvoid mass generationInksPowdery paintsPolymer sciencePtru catalyst

The invention provides a curing agent for carboxyl resin as well as a preparation method and an application of the curing agent. The curing agent is prepared from main raw materials including phenyl polyacid, phenyl polyphenol, sodium hydroxide, allyl bromide, epichlorohydrin and a catalyst through joint reaction. The curing agent contains both epoxy groups and double-bond groups, so that the curing agent can be subjected to a reaction with carboxyl groups in branch chains of carboxyl acrylic resin and can also be subjected to a reaction with double bonds remaining in main chains, and a densefilm with higher crosslinking density is formed.

Owner:HUANGSHAN HUAHUI TECH

A kind of preparation method of aluminum acetylacetonate

ActiveCN110437051BReduce generationIncrease profitPreparation of aldehyde/ketone chelatesOrganic acidPhysical chemistry

The invention discloses a preparation method of aluminum acetylacetonate. The preparation method of aluminum acetylacetonate comprises the following steps: 1) in a reactor, mix aluminum powder with C1-C3 lower aliphatic alcohol, add organic acid to adjust the pH to 2-4.5; 2) add acetylacetone for reaction , and then adding lye to adjust the pH to 6-7; 3) filtering the product of step 2), washing the filter residue, and drying to obtain aluminum acetylacetonate. The method for preparing aluminum acetylacetonate of the present invention does not use water as a solvent, which reduces the generation of waste water, and adds a small amount of organic acid as a pH value regulator, which promotes the reaction, improves the utilization rate of raw material acetylacetone, and the solvent can be recycled, saving energy. costs.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

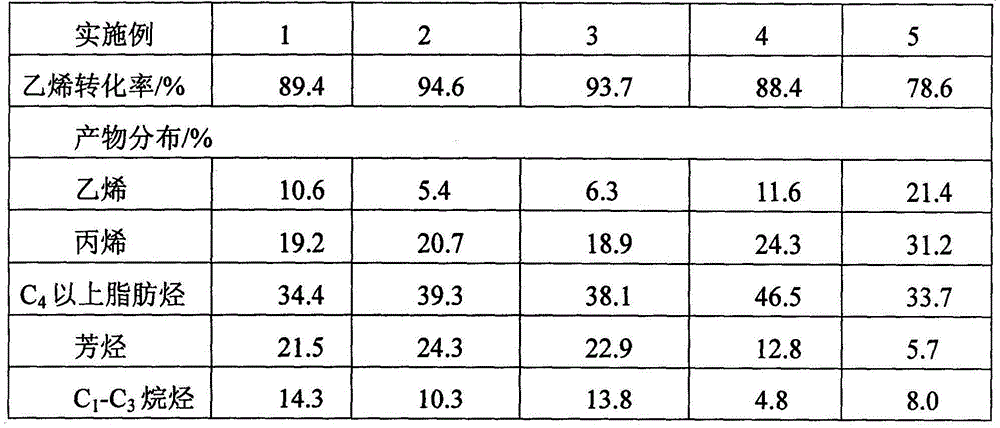

Air blowing-in device of garbage low-nitrogen and low-dioxin grate incinerator

InactiveCN102954473ALow running costEmission reductionIncinerator apparatusNon-combustible gases/liquids supplyLow nitrogenGarbage disposal

The invention discloses an air blowing-in device of a garbage low-nitrogen and low-dioxin grate incinerator. The air blowing-in device comprises a first passage and an incinerator hearth, wherein the incinerator hearth is arranged at the bottom of the first passage; a first passage ceiling is arranged at the top end of the first passage; four air blowing assemblies are arranged along peripheral walls of the first passage; the distance between each two adjacent air blowing assemblies is 1 / 5 of the height of the first passage; the fourair blowing assemblies are a secondary air assembly, a tertiary air assembly, a quartic air assembly and a quintic air assembly in sequence from bottom to top; air blowing nozzles of the four air blowing assemblies spray air currents obliquely and downwards to compel smoke to rise in a curvilinear way in the first passage; and the rise time of the smoke rising in the curvilinear way in the first passage is long relative to the time consumption of the smoke rising without resistance. Through the smoke staying for a longer time, a condition is created for pollutants such as dioxin, furan and the like to stay for above two seconds at a temperature above 850 DEG C; the most of the dioxin can be burned; the emission of the pollutants can be reduced; the combustion efficiency is improved; and the running cost for garbage disposal is decreased.

Owner:SOUTH CHINA UNIV OF TECH

A kind of high-yield preparation method of high-purity dimethyl diallyl ammonium chloride monomer

ActiveCN109438250BAvoid mass generationHigh purityAmino compound purification/separationOrganic compound preparationActivated carbonOrganic synthesis

The present invention belongs to the technical field of organic synthesis, and particularly relates to a method for preparing a high purity dimethyl diallyl ammonium chloride monomer in high yield. The preparation method provided by the present invention involves stagewise and alternating addition of allyl chloride and sodium hydroxide solution dropwise, the optimum alternate addition amounts and reaction times of allyl chloride and sodium hydroxide being determined using an acid-base indicator through extensive tests. The preparation method prevents allyl chloride from being present in a highly alkaline environment, which avoids generation of byproducts such as allyl alcohol in large amounts, and increases the utilization rate of allyl chloride. Further, the preparation method employs a pressure-resistant closed reaction vessel to ensure that dimethylamine does not leak and can participate completely in the reaction. The dimethyl diallyl ammonium chloride monomer solution obtained by the preparation method has a light color and few impurities, does not require decoloration and impurity removal with activated carbon, and has a high purity, has very low contents of amine salts and chlorine ions, and a yield approximate to an ideal value. Use of the product in a homopolymerization experiment affords a colorless, transparent and clear polymer solution, with the viscosity and molecular weight thereof being far superior to those of like products.

Owner:SHANDONG TIANCHENG CHEM CO LTD

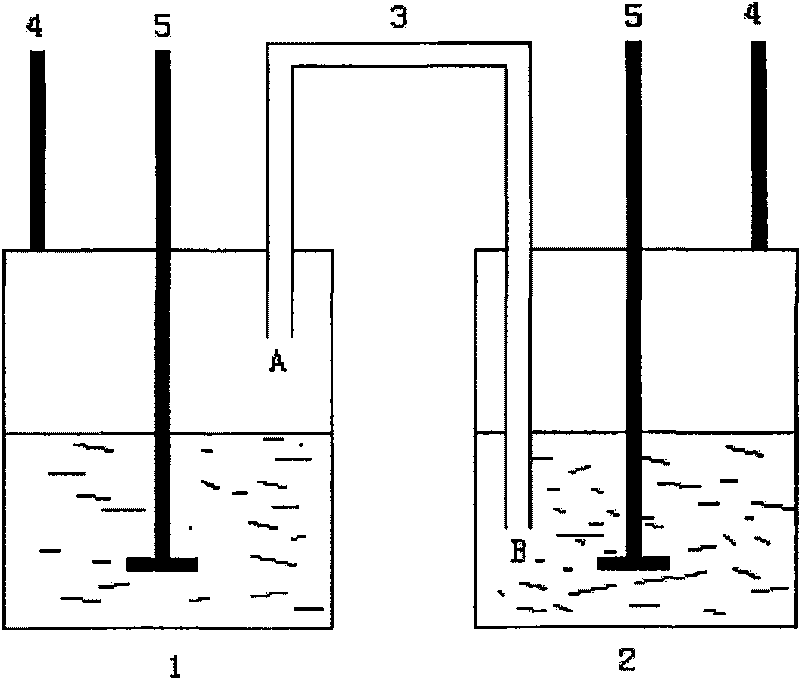

Hydrogenation method of acryionitrile-butadiene-rubber latex

A hydrogenation method of nitrile latex belongs to the hydrogenation field of nitrile rubber latex. The disadvantages of the existing hydrogenation method of nitrile latex are that the cost is high and hydrogenated products generate cross bonding. The hydrogenation method of nitrile latex realizes hydrogenation through following technical scheme, respectively adding organic solvent and nitrile latex in two communicated reaction vessels and heating, when the temperature of the organic solvent reaching 130 to 145 DEG C and the temperature of the nitrile latex reaching 50 to 70 DEG C, keeping thetemperature constant for 4 to 48h, adding the derivative of hydrazine in the organic solvent in batches during the temperature constant period. The total amount of the added derivative of hydrazine is 1 to 3 times of the mole number of the carbon-carbon double bond in the hydrogenated nitrile latex. The method of the invention has the advantages of low cost and little pollution. The prepared hydrogenated nitrile latex has the advantages of low degree of cross linking and good processing property.

Owner:BEIJING UNIV OF CHEM TECH

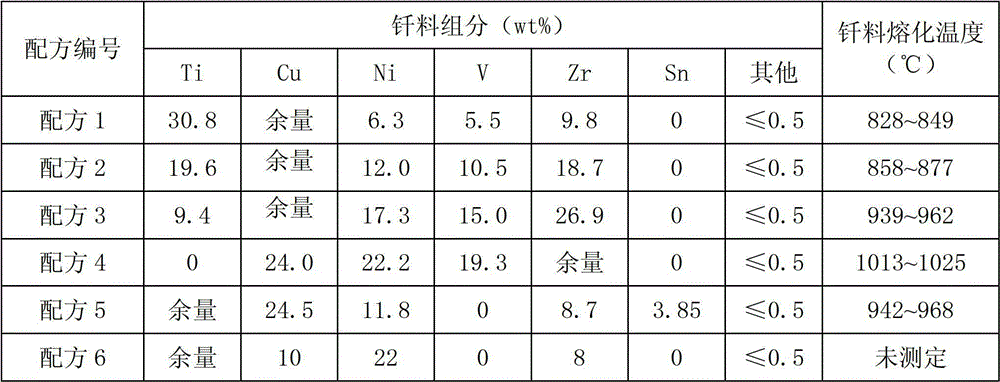

Brazing filler metal for brazing titanium alloy and steel or titanium aluminum alloy as well as steel

InactiveCN102794578BImprove wettabilityAvoid mass generationWelding/cutting media/materialsSoldering mediaTitanium alloyFiller metal

The invention provides brazing filler metal for brazing titanium alloy and steel or titanium aluminum alloy as well as steel. The brazing filler metal is characterized by comprising the following components in parts by weight: 0-40 parts of Ti, 24-50 parts of Cu, 6-23 parts of Ni, 5-20 parts of V and 9-35 parts of Zr. The brazing filler metal has a good wetting effect for both titanium alloy or titanium aluminum alloy base metal and steel base metal; large quantities of inter-brittle metal compounds can be prevented from being generated to a certain degree; and a high-strength brazing connector can be obtained by using the brazing filler metal.

Owner:DALIAN UNIV OF TECH

Harmless treatment method of fly ash solid sulfur melting

ActiveCN113020229BSolve the problem of poor harmless treatment effectEasy to handleSolid waste disposalTransportation and packagingFlue gasSlag

The invention provides a harmless treatment method for solid sulfur melting of fly ash. The method includes: mixing fly ash, reducing agent, and flux to obtain mixed raw materials; wherein the molar ratio of C and S in the mixed raw materials is 2.5 to 3.5; the control slag type is SiO 2 ‑Al 2 o 3 ‑CaO slag type, and m / n is 0.8~1.5; or, the control slag type is SiO 2 ‑CaO‑FeO slag type, and m / n is 1.0~1.6, l / m=0.15~0.30; the mixed raw materials are sent into the electric furnace in the form of injection or pressed balls for sulfur solidification and melting, during which the temperature of the slag layer is controlled at 1250~1350°C, and control the temperature of the molten salt layer above the slag layer below 1200°C to obtain molten salt, slag and flue gas; cool the molten salt, and water-cool or air-cool the slag; use one of three methods Dispose of fumes. The invention provides a systematic solution for fly ash treatment from the aspects of batching, solid sulfur melting, flue gas treatment, etc., and realizes the maximum degree of harmless treatment.

Owner:CHINA ENFI ENGINEERING CORPORATION

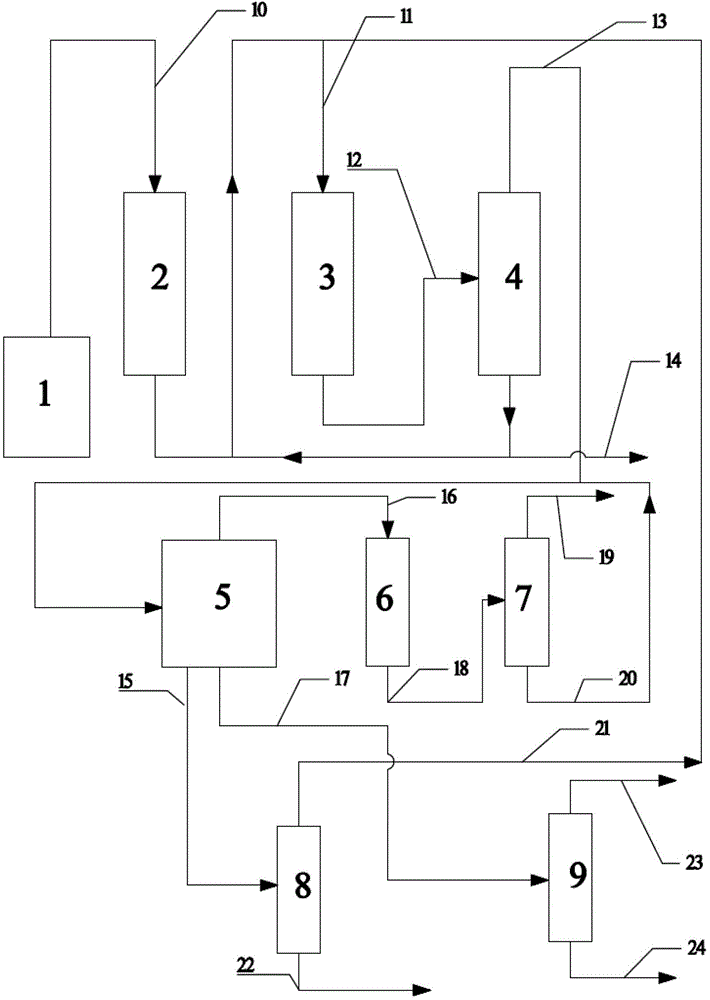

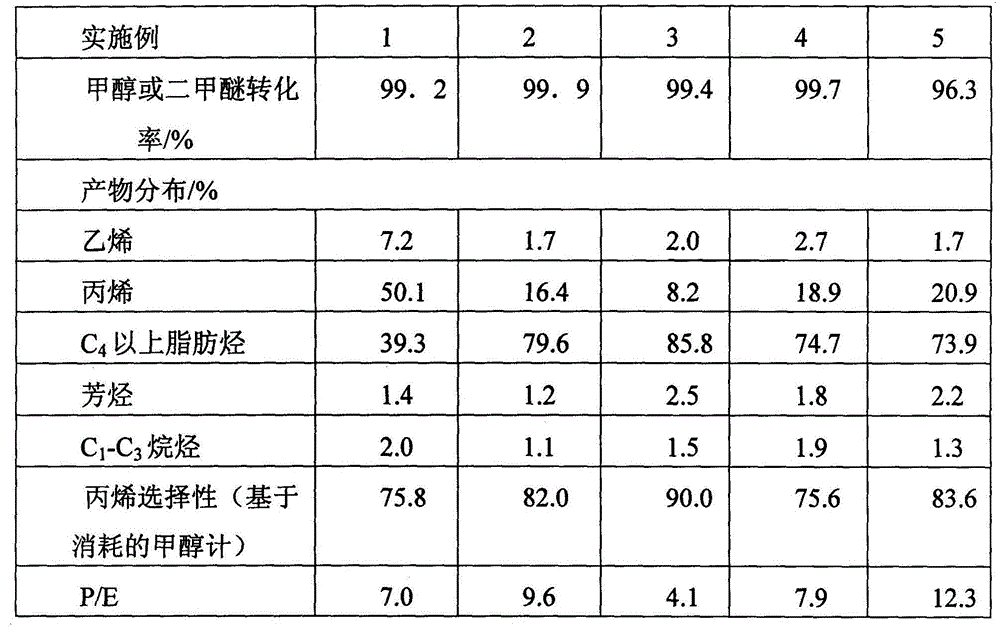

Preparation process for propylene from methanol or dimethyl ether

ActiveCN103382145BAvoid mass generationHigh yieldHydrocarbon from oxygen organic compoundsEthylene productionHigh carbonFractionation

The invention relates to a preparation process for propylene from methanol or dimethyl ether. The process comprises the following steps: allowing the raw materials consisting of methanol or dimethyl ether, water and above-C4 components returned from a separation system to undergo a reaction in a first reactor so as to produce propylene-rich C1-C10 components which enter into the separation system; separating propylene from the separation system as a product and allowing above-C4 components to return to the reactor; and subjecting C1-C2 components in the separation system to a reaction in a second reactor to produce above-C3 high-carbon substances and returning the above-C3 high-carbon substances to the separation system to promote yield of propylene; wherein selectivity of propylene in the first reactor is greater than 70%, and the yield of propylene after propylene-yield promotion by the second reactor is greater than 75%. Compared with the prior art, the process provided by the invention has the advantages of high selectivity of the product propylene, no need for an ethylene cryogenic fractionation system, low content of C2 and below-C2 components, simplification of the separation system and substantial reduction of energy consumption of the separation system.

Owner:PUJING CHEM IND SHA

A low-nitrogen and low-dioxin fire grate incineration method and device for garbage

ActiveCN102980194BLow running costEmission reductionIncinerator apparatusNon-combustible gases/liquids supplyEnvironmental resistanceLow nitrogen

The invention discloses a method for garbage low-nitrogen and low-dioxin grate incineration and a device of the method for garbage low-nitrogen and low-dioxin grate incineration. The device comprises a first channel and an incineration hearth which is arranged on the bottom of the first channel, wherein a blowing subassembly is arranged along the peripheral wall of the first channel and enables smoke in the first channel to form two groups of tangent circles and spirally ascend; and the smoke forms two groups of tangent circles and spirally ascends through the blowing subassembly in the first channel, the temperature of the first channel is controlled between 850 DEG C and 900 DEG C through regulating the air flow of a blowing nozzle of the blowing subassembly, the smoke residence time is above 2 seconds, the smoke flows to an outlet of the first channel finally, slag which is generated after garbage on the tail end of a grate is completely burnt is discharged through a slag discharge port, and accordingly, a garbage low-nitrogen and low-dioxin grate incineration process is completed. The method and the device have the advantages of high combustion efficiency, good environmental-friendly effect and low initial construction and operation cost, and are suitable for large, medium and small-scale treatment of industrial and urban garbage incineration.

Owner:SOUTH CHINA UNIV OF TECH

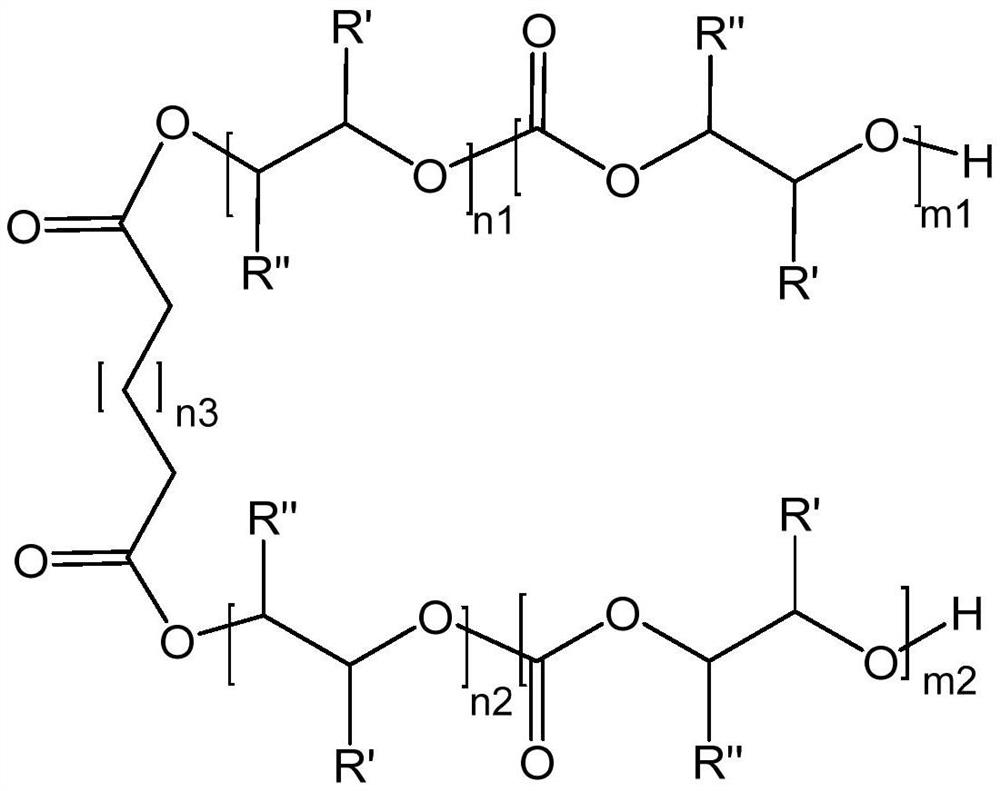

A kind of preparation method of polycarbonate-polyether diol

Owner:合肥普力先进材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com