Fly ash sulfur fixation melting harmless treatment method

A harmless treatment, fly ash technology, applied in the direction of chemical instruments and methods, combustion methods, incinerators, etc., can solve the problem of poor harmless treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The composition of fly ash is shown in Table 1 (%):

[0070]

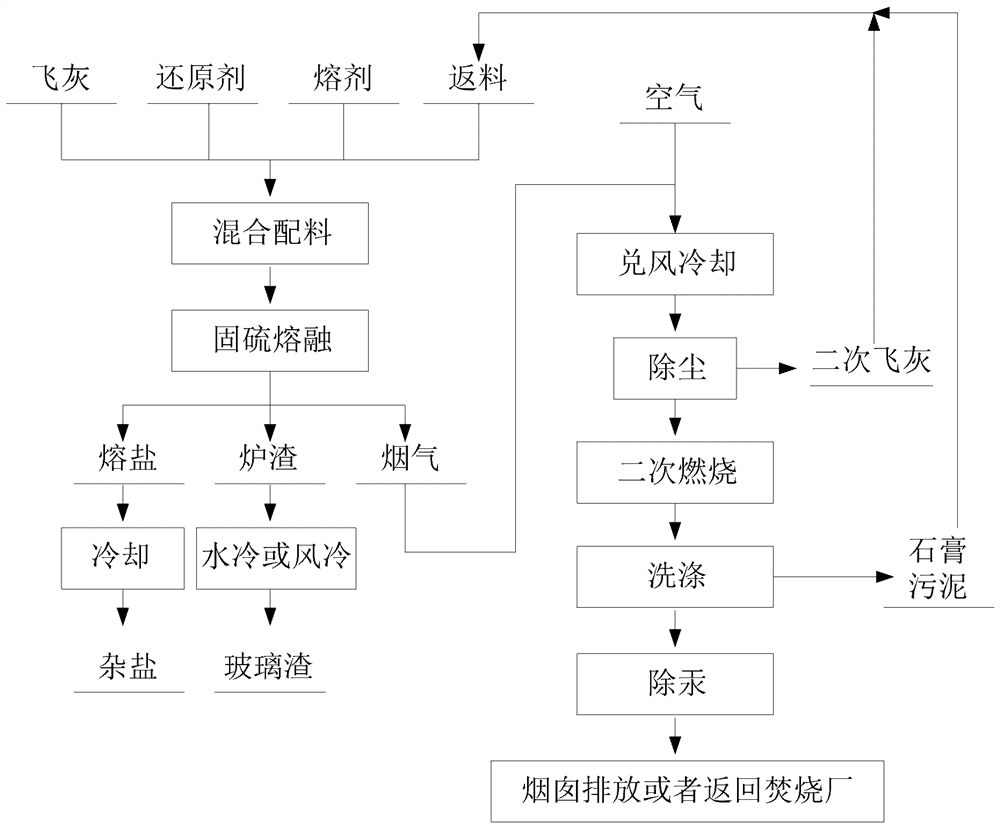

[0071] use figure 1 The process shown is to process the above-mentioned fly ash, and the processing capacity is 50t / d, the details are as follows:

[0072]Mix fly ash, reducing agent carbon powder (particle size2 =1.4) The mixing amount accounts for 15% of the fly ash amount, and the mixing amount of quartz sand accounts for 20% of the fly ash amount to obtain a mixed raw material. The molar ratio of C and S in the mixed raw material is 2.5, using SiO 2 -CaO-FeO slag type, SiO in mixed raw materials 2 and Al 2 o 3 The total weight of CaO and MgO is recorded as m, the total weight of CaO and MgO is recorded as n, FeO, MnO, Na 2 O and K 2 The total weight of O is recorded as l, m / n is 1.15, and l / m is 0.25.

[0073] The mixed raw materials are pressed into balls with a particle size of 2~4cm, and then sent to an electric furnace for sulfur fixation and melting. The electric furnace adopts a graphite ...

Embodiment 2

[0081] The difference from Example 1 is that the S / C of the mixed material is 3.5.

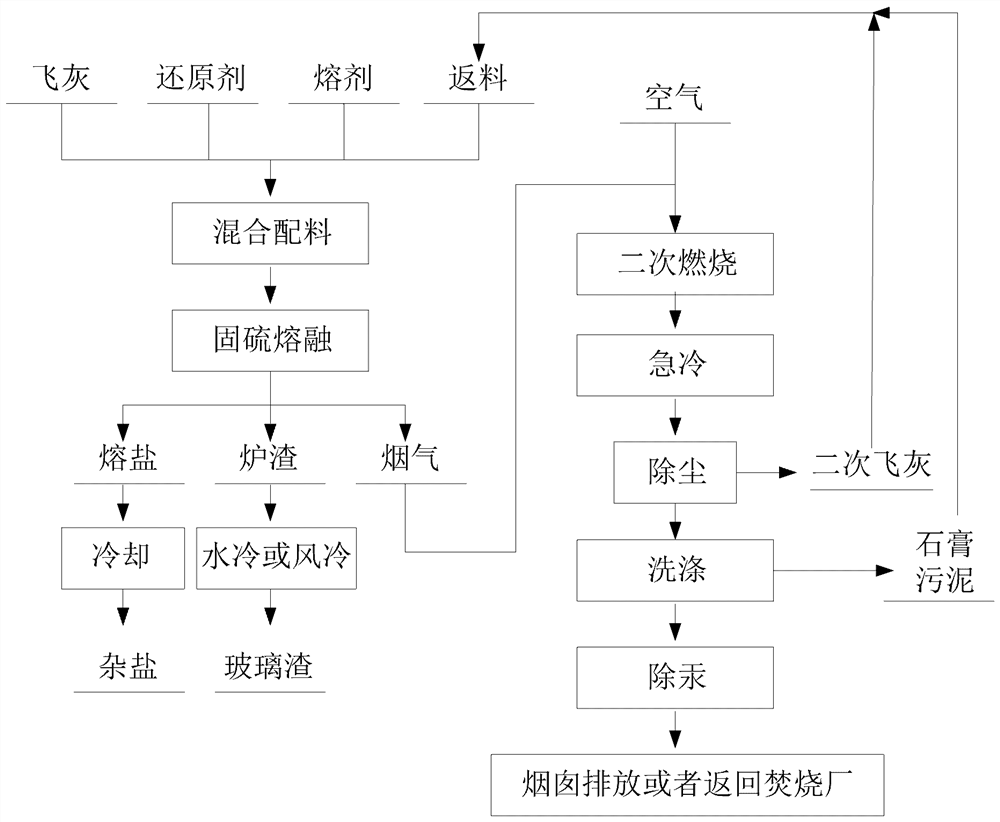

[0082] Other parameters are the same as in the embodiment. The flue gas outlet temperature is 1662°C, and the flue gas volume is 979Nm 3 / h (the air leakage is about 500Nm 3 / h). Outer exhaust gas volume 13848Nm 3 / h. The secondary combustion temperature is controlled at 900°C, and the fuel consumption is 79.46Nm 3 / h (natural gas). The composition of slag is shown in Table 5, the composition of molten salt is shown in Table 6, and the composition of secondary fly ash is shown in Table 7.

[0083]

[0084]

[0085]

[0086] Calculated: the direct sulfur fixation rate of this embodiment is 83.70% (relative to the original fly ash), and the remaining S is expressed as SO 2 into the flue gas in the form of deacidification into gypsum sludge. As the ingredients are C / S increased to 3.5 (compared to Example 1), the sulfur fixation effect becomes better, but the CO content in the fl...

Embodiment 3

[0088] Adopt electric furnace melting to handle fly ash, and embodiment 1 difference is as follows:

[0089] Fly ash, reducing agent carbon powder (particle size 2 -Al 2 o 3 -CaO slag type, SiO in mixed raw materials 2 and Al 2 o 3 The total weight of CaO and MgO is recorded as m, the total weight of CaO and MgO is recorded as n, and m / n is 1.20.

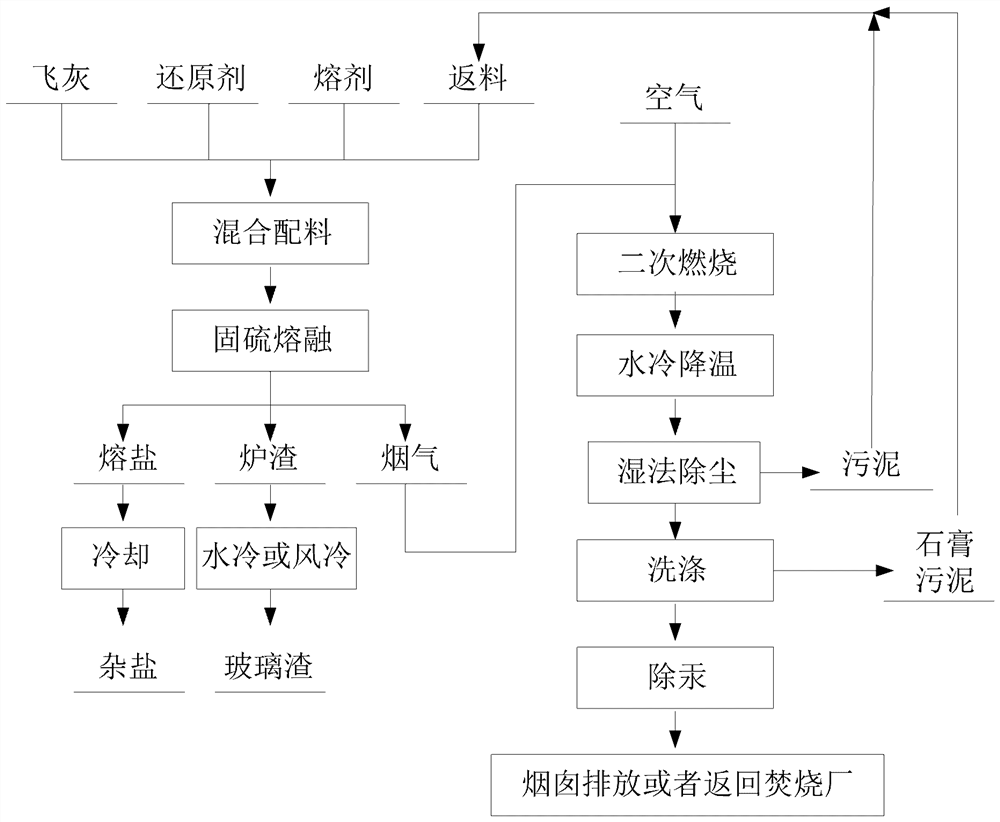

[0090] The electric furnace is used for melting and solidifying sulfur, the temperature of the slag is 1350°C, and the temperature of the molten salt layer is 1280°C. The depth of the slag is 500mm, the depth of the molten salt layer is 200mm, and the depth of the material layer is 100mm. The flue gas of the electric furnace is cooled by secondary combustion and sprayed with wind and water. The temperature of secondary combustion flue gas is 1200℃, and natural gas is blown into 00Nm 3 / h. The temperature is lowered to 200°C by wind cooling, the amount of water sprayed is 0.97t / h, and the compressed air is 2174Nm 3 / h, outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com