Coupling bionic double-turbine hydraulic torque converter

A hydraulic torque converter, bionic double technology, applied in the direction of belt/chain/gear, transmission device, fluid transmission device, etc., can solve the problems of low efficiency, environmental degradation, waste of resources and energy, etc., to improve performance and improve Starting torque ratio and efficiency, effects of sticking and drag reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

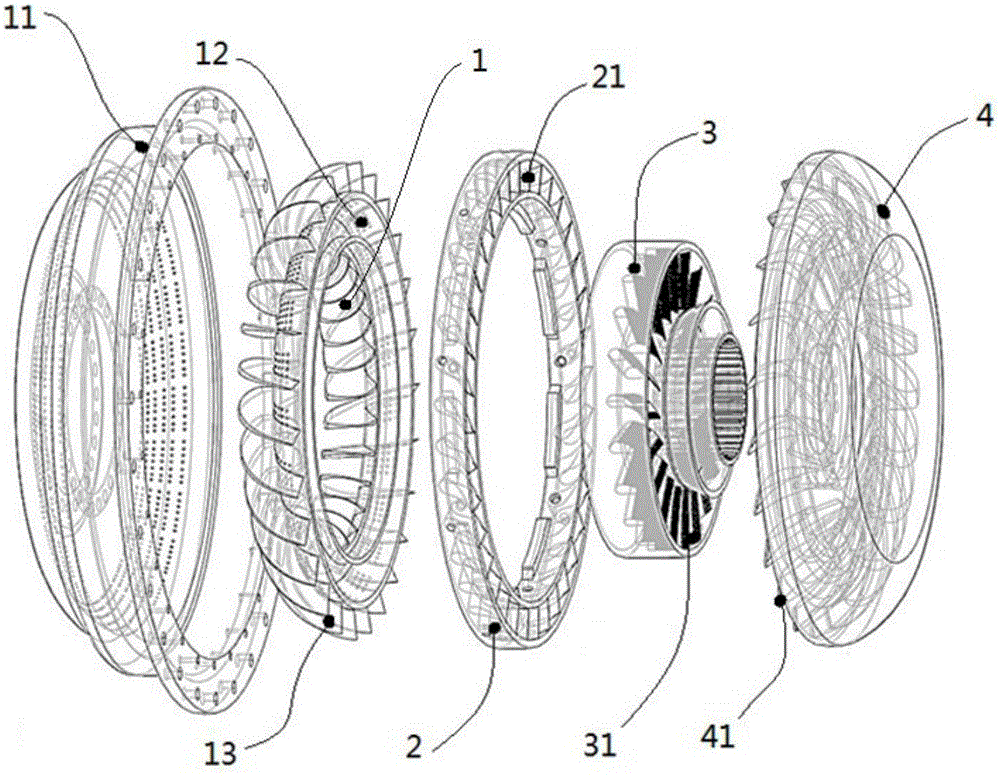

[0051] Such as figure 1 As shown, the YJSW335 twin-turbine hydraulic torque converter includes a pump wheel 1 , a pump wheel outer ring 11 , a pump wheel inner ring 12 , a first turbine 2 , a guide wheel 3 , and a second turbine 4 .

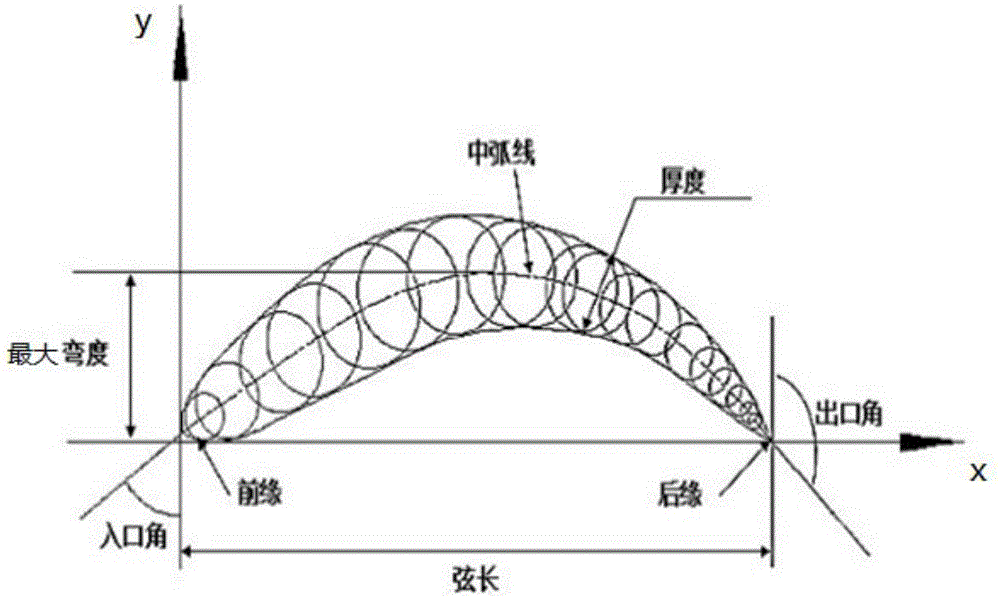

[0052] The vane measurement parameters of each component in the twin-turbine hydraulic torque converter are as follows: figure 2 As shown, including the chord length, thickness, maximum camber, entrance angle, exit angle, etc. of the section.

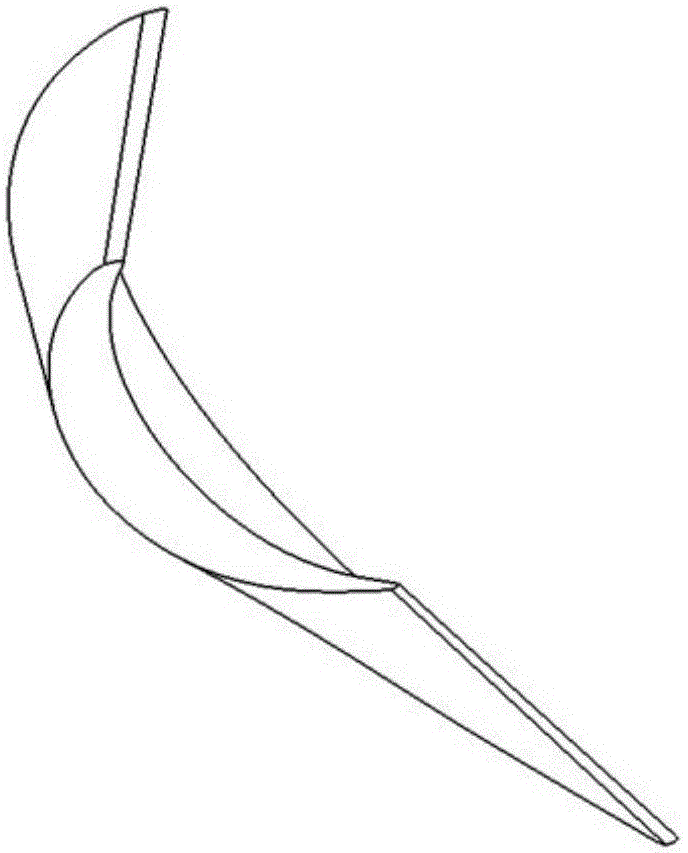

[0053] 1. Bionic blade

[0054] 1.1 Second turbine bionic blade,

[0055] The present invention uses bionic technology to change its circulation distribution function on the basis of not changing other structural parameters of the second turbine blade, and the circulation distribution function polynomial is: y=ax 2 +bx+c. Among them, x is the abscissa of each equal point on the middle arc, and y is the corresponding distribution value of circulation. The value ranges of parameters a, b, c are as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com