Synthetic method of alkenyl borate compound

A kind of technology of alkenyl borate and synthesis method, which is applied in the field of organic synthesis and transition metal catalysis, can solve the problems of poor compatibility of functional groups, low atom economy, poor regioselectivity, etc., and achieve mild conditions, high atom economy, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

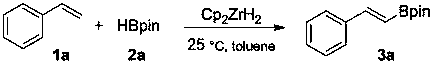

[0022] Embodiment 1 A kind of synthetic method of alkenyl borate compound:

[0023]

[0024] Add styrene 1a (0.2 mmol, 23 μL), pinacol borane 2a (0.2 mmol, 29 μL), toluene (1 mL), Cp 2 ZrH 2 (0.01 mmol, 2.3 mg), stirred at 25°C for 10 minutes under nitrogen (1 atm) atmosphere. GC detected that the reaction was complete. Diatomaceous earth filtration, the solvent was spin-dried under reduced pressure, and the residue was purified by silica gel column chromatography, using petroleum ether: ethyl acetate (40 mL: 1 mL) as the eluent to obtain a colorless oily substance, styrene boric acid pina Alcohol ester 3a (42 mg, 92%).

[0025] The characterization data of this compound are as follows: 1 H NMR (400 MHz, Chloroform- d ) δ 7.49 (d, J =7.7 Hz, 2H), 7.40 (d, J = 18.4 Hz, 1H), 7.32 (m, 3H), 6.17 (d, J = 18.4 Hz,1H), 1.32 (s, 12H). 13 C NMR (101 MHz, Chloroform- d ) δ 149.5, 137.5, 128.9, 128.6, 127.1, 83.3, 24.8. 11 B NMR (128 MHz, Chloroform- d ) δ 30.38.

Embodiment 2

[0026] Embodiment 2 A kind of synthesis method of alkenyl borate compound:

[0027]

[0028] Add styrene 1a (0.2 mmol, 23 μL), pinacol borane 2a (0.2 mmol, 29 μL), toluene (1 mL), Cp 2 ZrH 2 (0.01 mmol, 2.3 mg), the reaction was stirred at 25°C for 10 minutes under an argon (1 atm) atmosphere. GC detected that the reaction was complete. Diatomaceous earth filtration, the solvent was spin-dried under reduced pressure, and the residue was purified by silica gel column chromatography, using petroleum ether: ethyl acetate (40 mL: 1 mL) as the eluent to obtain a colorless oily substance, styrene boric acid pina Alcohol ester 3a (41 mg, 90%).

[0029] The characterization data of this compound are as follows: 1 H NMR (400 MHz, Chloroform- d ) δ 7.49 (d, J =7.7 Hz, 2H), 7.40 (d, J = 18.4 Hz, 1H), 7.32 (m, 3H), 6.17 (d, J = 18.4 Hz,1H), 1.32 (s, 12H). 13 C NMR (101 MHz, Chloroform- d ) δ 149.5, 137.5, 128.9, 128.6, 127.1, 83.3, 24.8. 11 B NMR (128 MHz, Chloroform- d ...

Embodiment 3

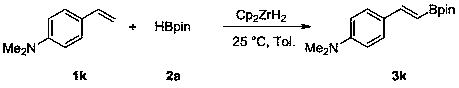

[0030] Embodiment 3 A kind of synthesis method of alkenyl borate compound:

[0031]

[0032] Add styrene 1a (0.2 mmol, 23 μL), pinacol borane 2a (0.2 mmol, 29 μL), toluene (1 mL), Cp 2 ZrH 2 (0.01 mmol, 2.3 mg), stirred and reacted at 0°C for 8 hours under nitrogen (1 atm) atmosphere. Diatomaceous earth filtration, the solvent was spin-dried under reduced pressure, and the residue was purified by silica gel column chromatography, using petroleum ether: ethyl acetate (40 mL: 1 mL) as the eluent to obtain a colorless oily product, styrene boric acid pinacol Ester 3a (8.2 mg, 18%).

[0033] The characterization data of this compound are as follows: 1 H NMR (400 MHz, Chloroform- d ) δ 7.49 (d, J =7.7 Hz, 2H), 7.40 (d, J = 18.4 Hz, 1H), 7.32 (m, 3H), 6.17 (d, J = 18.4 Hz,1H), 1.32 (s, 12H). 13 C NMR (101 MHz, Chloroform- d ) δ 149.5, 137.5, 128.9, 128.6, 127.1, 83.3, 24.8. 11 B NMR (128 MHz, Chloroform- d ) δ 30.38.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com