Multi-component polymerization method based on alkyne and sulfonyl azide as well as sulfonyl-containing polymer and application

A binary sulfonyl azide and sulfonyl azide technology, applied in analytical materials, material excitation analysis, instruments, etc., can solve problems such as complex monomer design, lack, and limited development of functional materials, and achieve atom economy High, easy to separate, unique application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

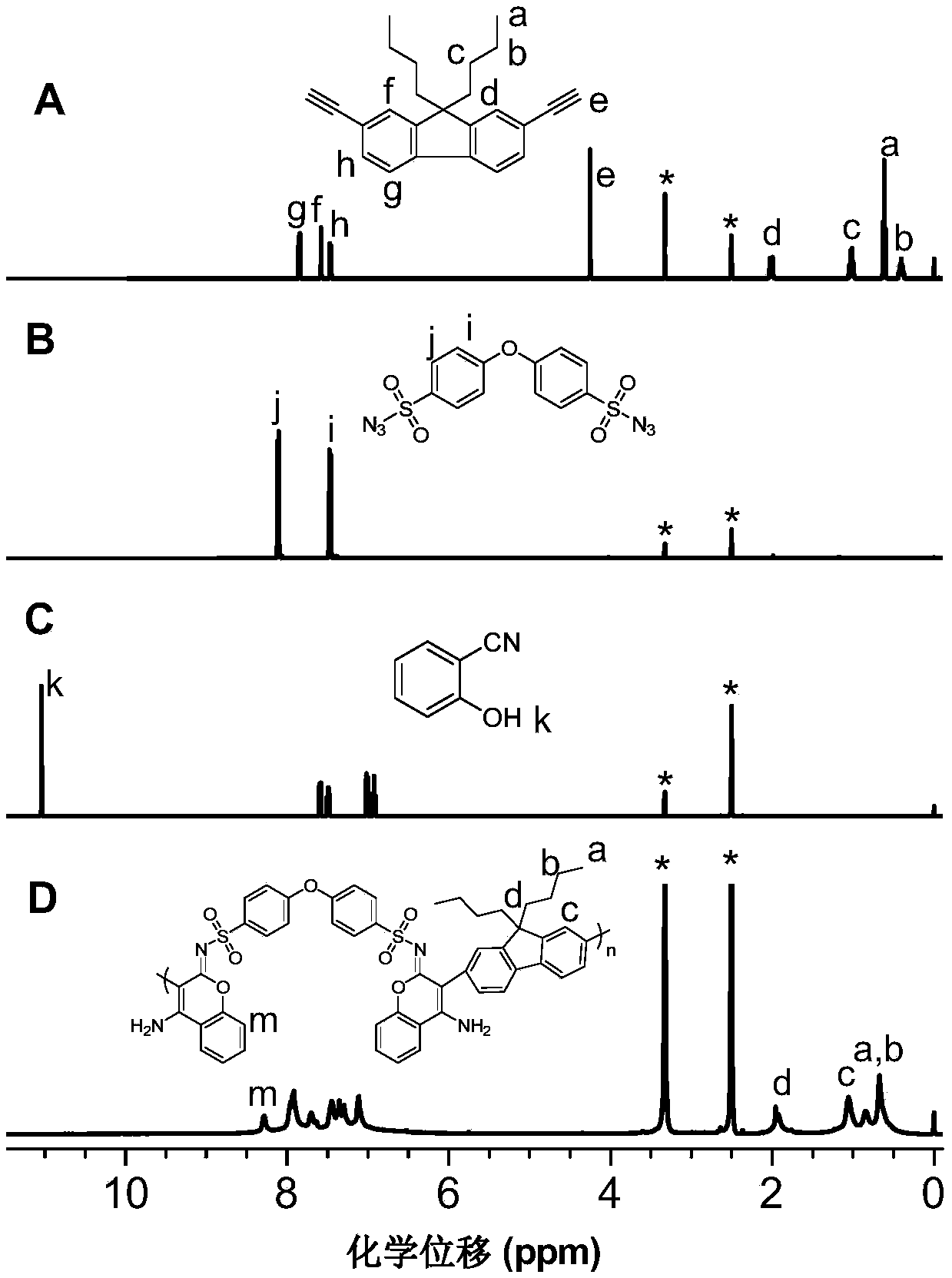

[0058] Polymer P1 was prepared by the multicomponent polymerization of the binary alkyne compound 1a, the binary sulfonyl azido compound 2a and the third component compound 3:

[0059]

[0060] Among them, monomer 1a is synthesized according to the synthesis method in the published literature (Macromolecules, 2014, 47, 1325), and monomer 2a is synthesized according to the synthesis method in the published literature (J. Energ. Mater., 2007, 25, 79) Synthesized by method, the monomer 3 can be purchased directly.

[0061] Take a 25mL Schlenk polymerization tube with a branch, and add magnetons, monomer 1a (0.10mmol, 33mg), monomer 2a (0.10mmol, 38mg), monomer 3 (0.25mmol, 30mg) and CuCl (0.02mmol, 2mg), vacuumize and change nitrogen for 3 times, add 2mL of anhydrous DCM to it with a syringe, and stir the solution evenly; add Et 3 N (0.30mmol, 42μL), stirred at 40°C for 1.5h, stopped the reaction, cooled to room temperature; added 1mL DMF to dilute the reaction solution, pass...

Embodiment 2

[0064] When monomer 1b is used to replace monomer 1a in Example 1, it is prepared by multi-component polymerization of binary alkyne compound monomer 1b, binary sulfonyl azide compound monomer 2a and third component compound monomer 3 Polymer P2:

[0065]

[0066] Wherein, monomer 1b is synthesized according to the synthesis method in the published literature (Polym.Chem.2012, 3, 1481). The process for preparing polymer P2 was similar to the process for preparing polymer P1 described above.

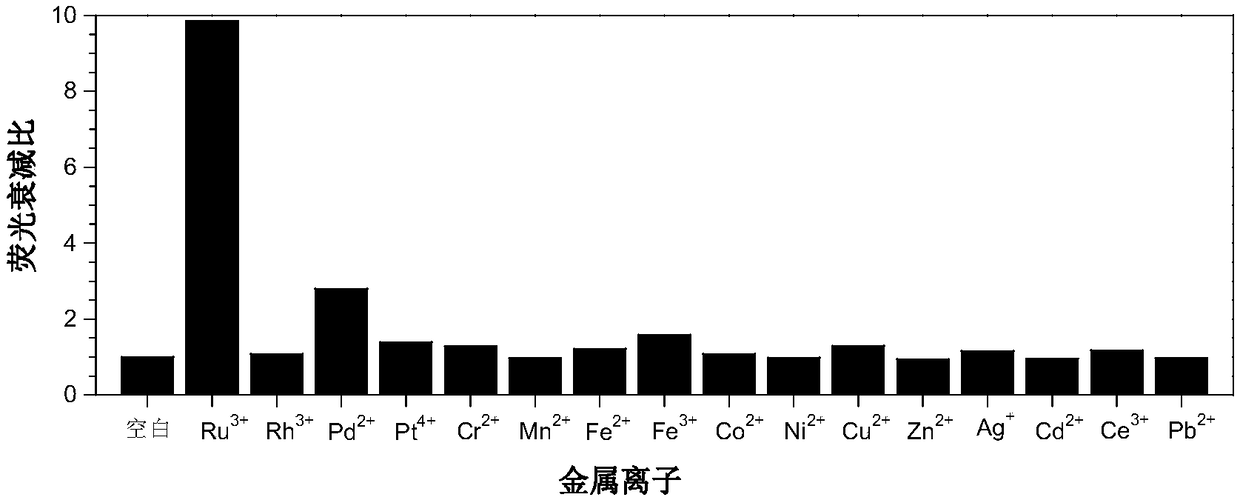

[0067] Polymer P2 has a yield of 96%, a weight average molecular weight of 37700 g / mol, and a PDI of 2.85. The detection results of the polymer for different metal ions are as follows: figure 2 shown. figure 2 It shows that different metal ions have different degrees of fluorescence quenching of polymer P2 solution. The polymer has the performance of selectively responding to ruthenium ions and can be used to detect ruthenium ions.

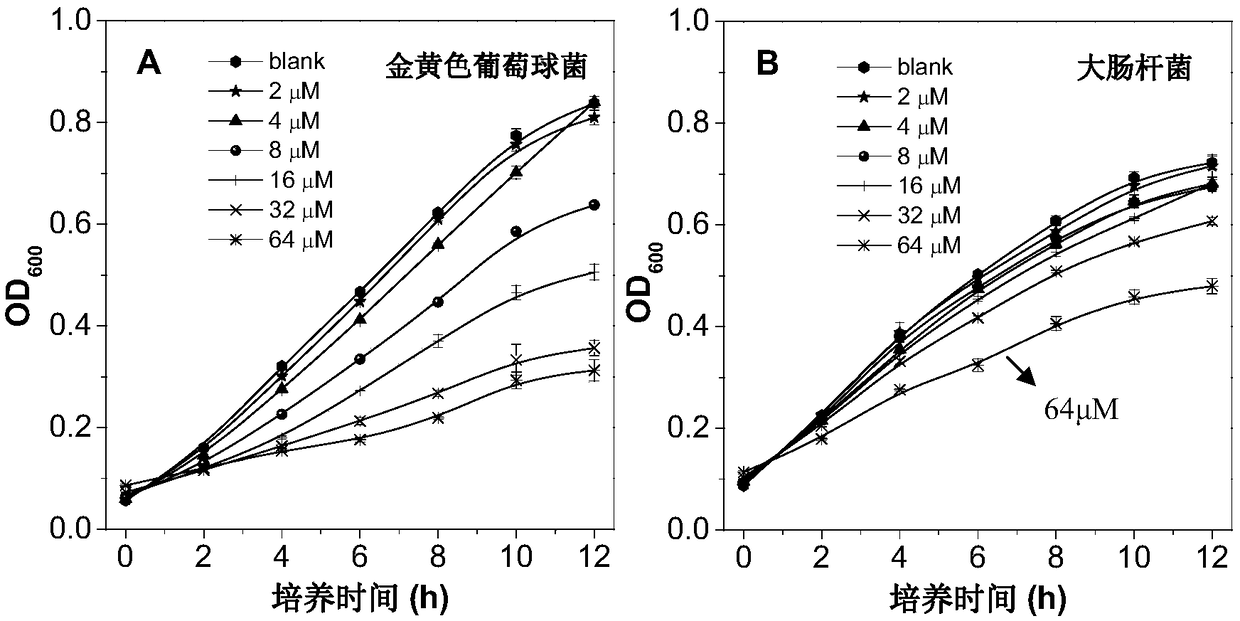

[0068] The different concentrations of P2 in ...

Embodiment 3

[0070] Polymer P3 was prepared from the multicomponent polymerization of the binary alkyne compound 1b, the binary sulfonyl azido compound 2a and the third component compound 4:

[0071]

[0072] Among them, the monomer 4 can be purchased directly.

[0073] Take a 25mL Schlenk polymerization tube with a branch, add magneton, monomer 1b (0.10mmol, 38mg), monomer 2a (0.10mmol, 38mg), monomer 4 (0.25mmol, 30mg) and CuCl (0.02mmol, 2mg), vacuumize and change nitrogen for 3 times, add 2mL DCM to it with a syringe, and stir the solution evenly; add Et 3 N (0.30mmol, 42μL), stirred at 40°C for 0.5h, stopped the reaction, cooled to room temperature; added 1mL DMF to dilute the reaction solution, passed the diluted reaction solution through a glass dropper filter device with cotton, and gradually Add dropwise to 150mL of high-speed stirring methanol to precipitate, after standing still, filter with filter paper, rinse the product on the filter paper with a large amount of methanol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com