Method for preparing polythiourea by means of polymerizing multiple components of isocyanide, sulfur and amine and application of polythiourea

A polythiourea, multi-component technology, used in the analysis of materials, material excitation analysis, material analysis by optical means, etc., to achieve high yield, high atom economy, and good film formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

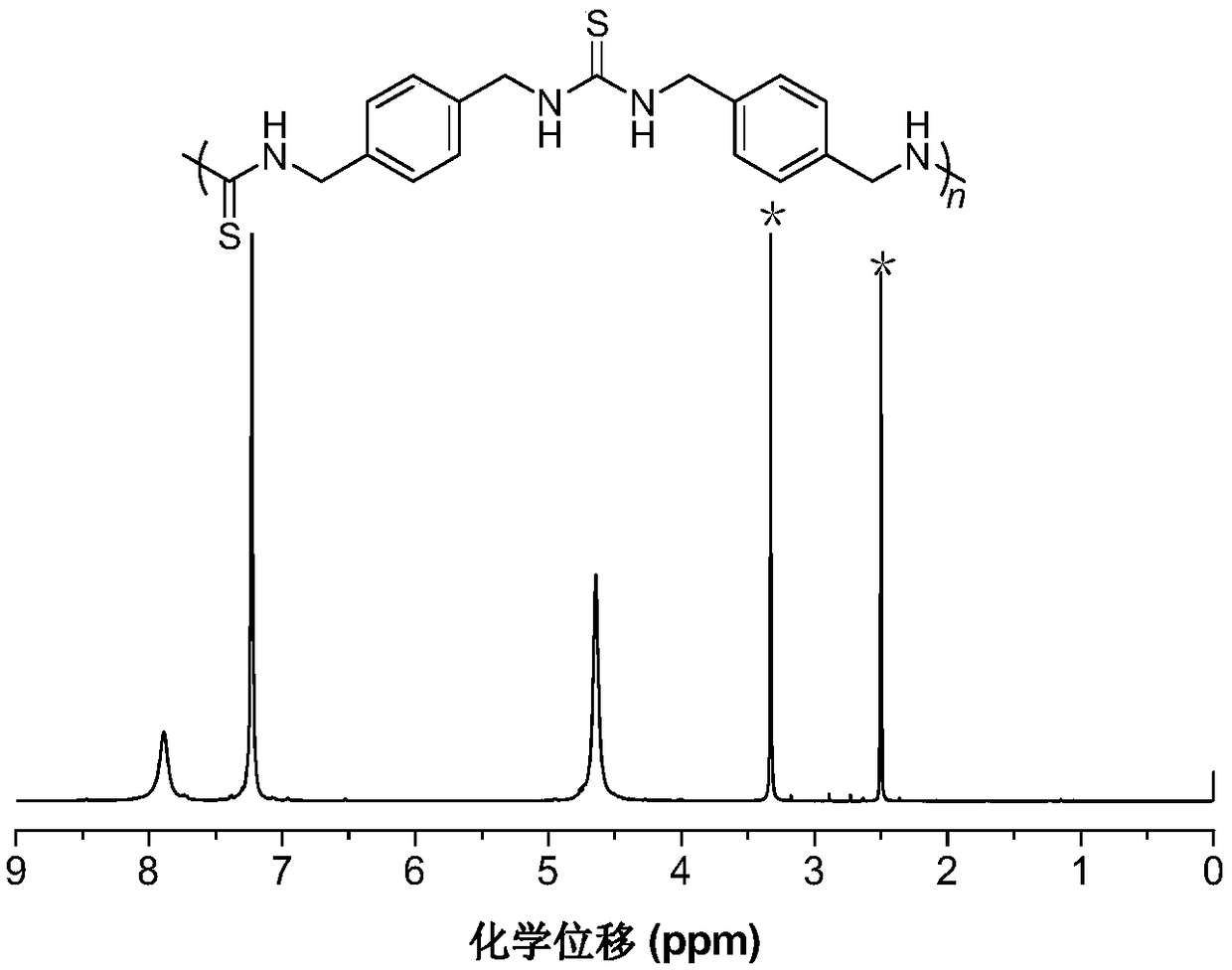

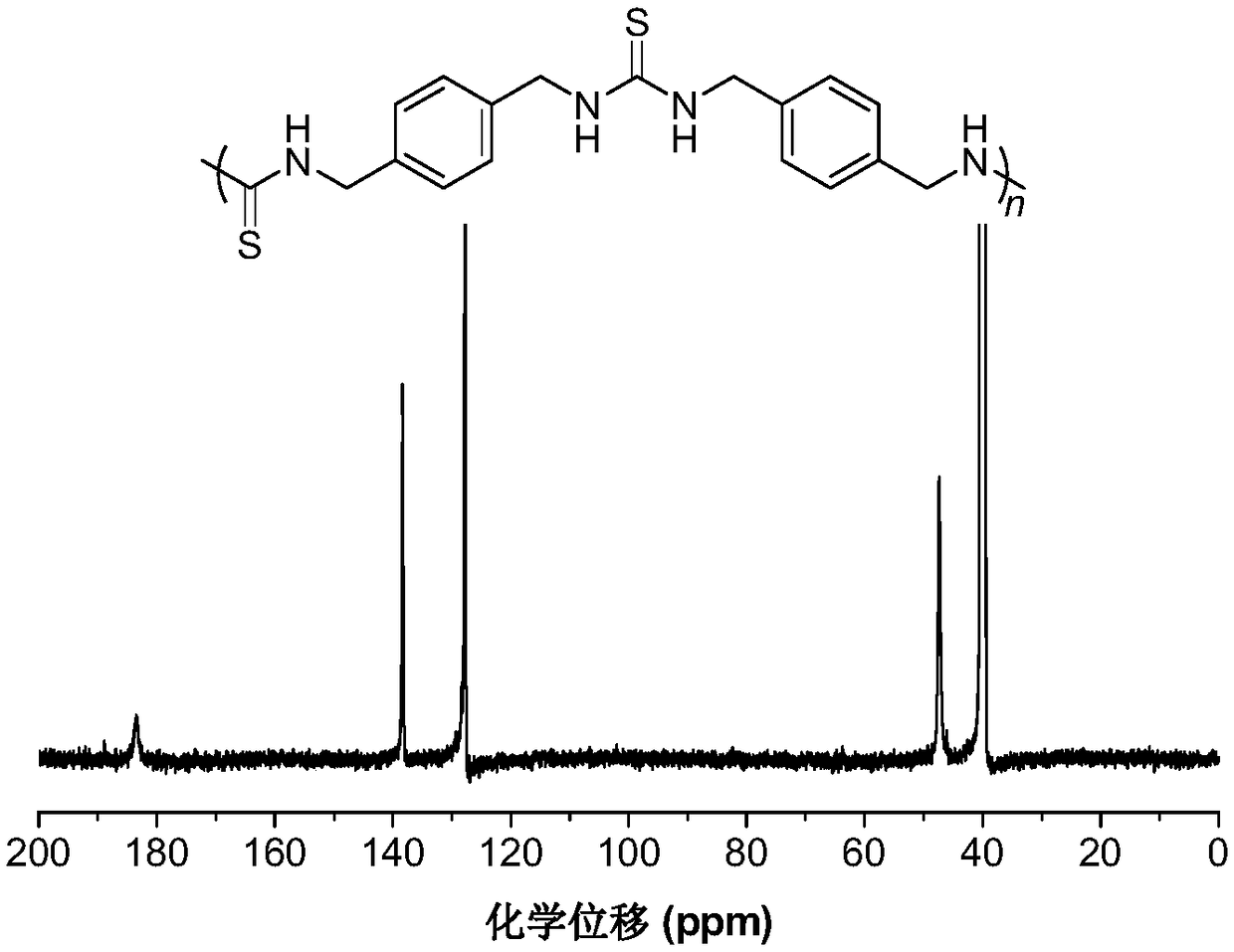

[0047] A method for preparing polythiourea by multicomponent polymerization of isonitrile, sulfur and amine, the steps are as follows:

[0048] (1) Under the protection of inert gas, 81.7 mg of p-xylylenediamine, 93.7 mg of p-xylylenediacetonitrile and 76.9 mg of sublimed sulfur were added to 0.4 mL of N,N-dimethylformamide and 0.2 mL of toluene and mixed Dissolve in the solvent, heat up to 100 °C, and stir for 1 h;

[0049] (2) Cool to room temperature after the reaction, dilute the reaction mother liquor with 5 mL of N,N-dimethylformamide solution, and add it dropwise (the rate of dropwise addition is 2 drops / sec) into 100 mL of methanol solution for precipitation , the precipitate was collected, dried (the drying temperature was 60° C.) to constant weight, and the polythiourea was obtained. The product yield of this example was 88%, the weight-average molecular weight was 30,000 g / mol, and the PDI was 1.42.

[0050] The terephthalic acid nitrile of this embodiment is disc...

Embodiment 2

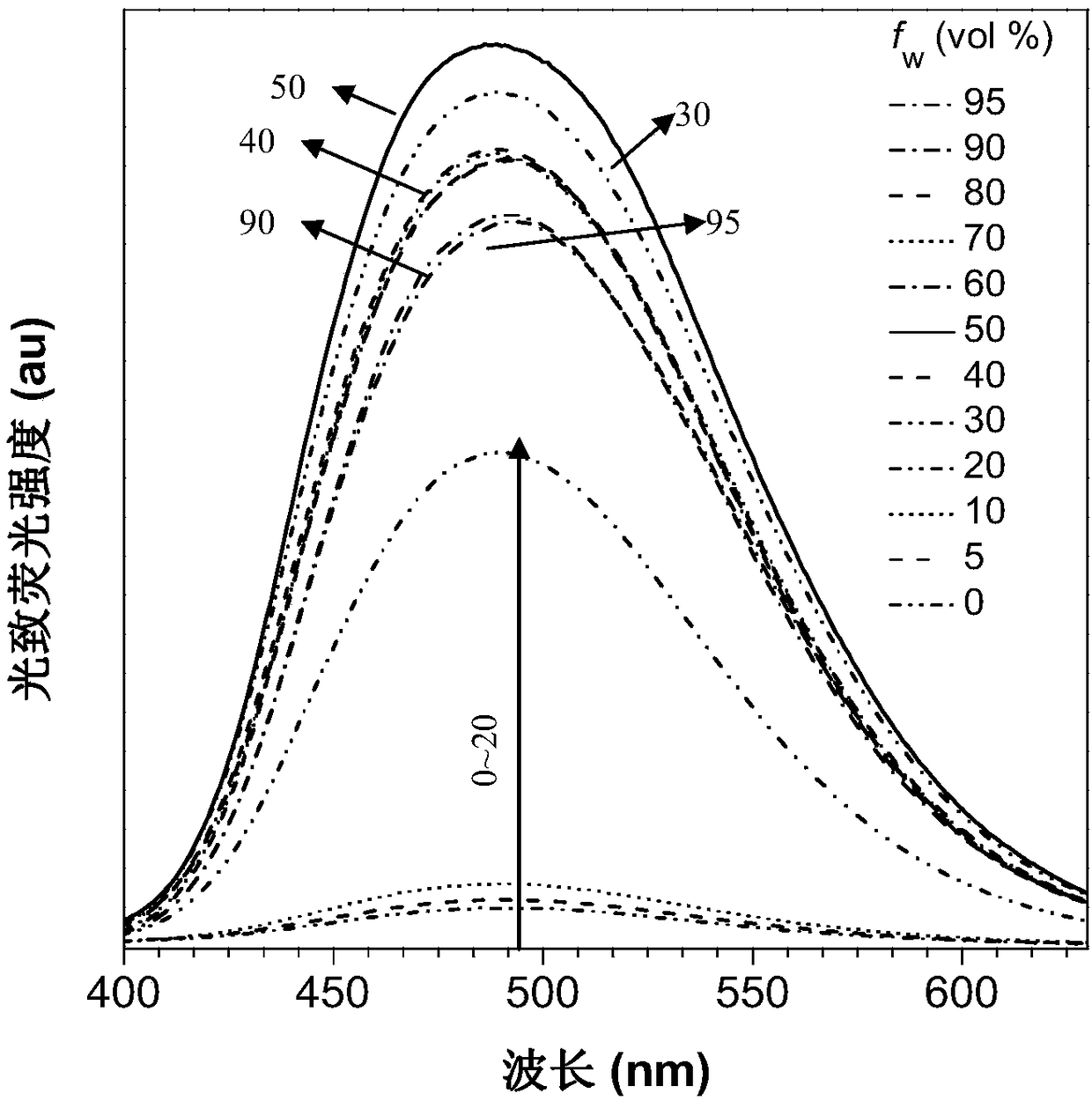

[0063] A method for preparing polythiourea by multicomponent polymerization of isonitrile, sulfur and amine, the steps are as follows:

[0064] (1) Under the protection of inert gas or air, mix 72 μL of dimethylpropanediamine (0.6 mmol), 229.5 mg of 1,2-bis-p-isocyanophenyl-1,2-diphenylethylene and 76.9 mg of Sublimation sulfur was added to 0.4 mL of N,N-dimethylformamide and 0.2 mL of toluene mixed solvent to dissolve, heated to 100°C, and reacted under stirring for 1 h;

[0065] (2) Cool to room temperature after the reaction, dilute the reaction mother liquor with 5 mL of N,N-dimethylformamide solution, and then add it dropwise (the rate of dropwise addition is 2 drops / sec) into 100 mL of methanol solution for precipitation , collect the precipitate, and dry (the drying temperature is 60° C.) to constant weight to obtain polythiourea P2. The product yield of this example was 89%, the weight average molecular weight was 24300 g / mol, and the PDI was 1.39.

[0066] The p-xyl...

Embodiment 3

[0077] A method for preparing polythiourea by multicomponent polymerization of isonitrile, sulfur and amine, the steps are as follows:

[0078] (1) Under the protection of inert gas or air, add 72 μL of dimethylpropanediamine, 81.6 mg of 1,6-adiponitrile and 76.9 mg of sublimed sulfur to 0.4 mL of N,N-dimethylmethane The amide was dissolved in a mixed solvent of 0.2 mL of toluene, heated to 100 °C, and reacted under stirring for 1 h;

[0079] (2) Cool to room temperature after the reaction, dilute the reaction mother liquor with 5 mL of N,N-dimethylformamide solution, and then add it dropwise (the rate of dropwise addition is 2 drops / sec) into 100 mL of methanol solution for precipitation , the precipitate was collected, dried (the drying temperature was 60° C.) to constant weight, and the polythiourea P3 was obtained. The yield of the reaction was >99%, the weight average molecular weight was 122500 g / mol, and the PDI was 2.35.

[0080] The reaction equation involved in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com