Precious metal catalyst as well as preparation method and application thereof

A precious metal catalyst, silicon oxide technology, used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Active components are easy to lose, and catalysts are difficult to use in practice, so as to avoid hydration, improve selectivity and stability, and improve activity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

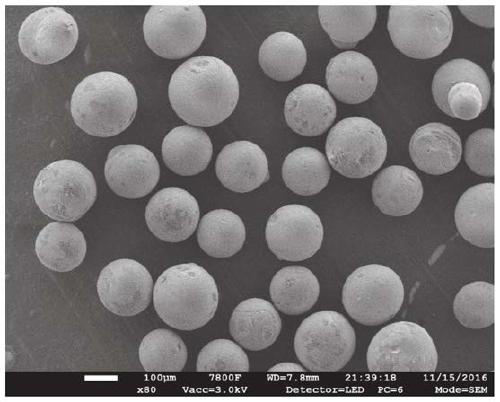

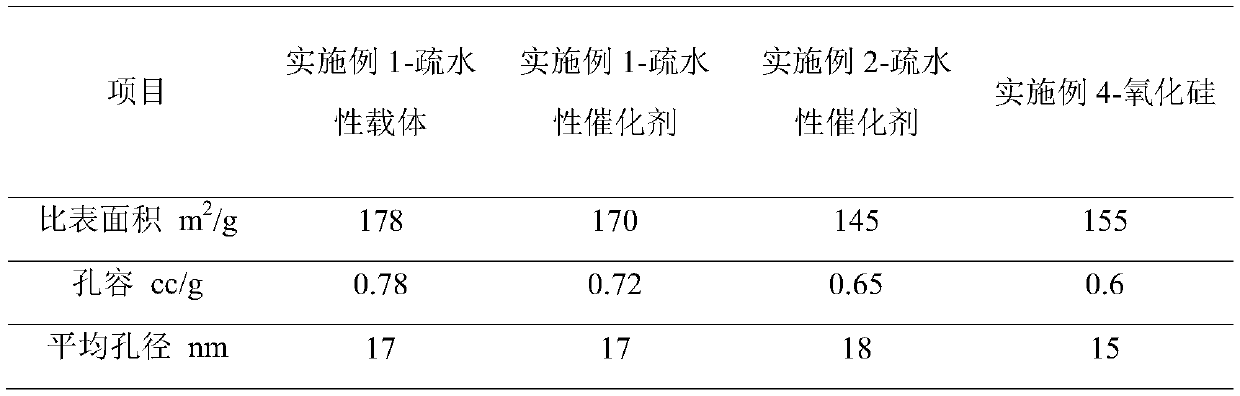

[0056] 1) Preparation method of hydrophobic silica carrier

[0057] The organosilicon sol with a solid content of 20% was prepared into spherical silica powder by means of centrifugal spray drying. Wherein, the average particle size of the nano-silicon oxide in the organosilicon sol is 30nm, the surface of the nano-silicon oxide particles is mainly methyl groups, and the selected solvent is methyl ethyl ketone. The control parameters of concrete centrifugal spray drying are as follows:

[0058] a, the drying gas of spray drying is selected as nitrogen;

[0059] b. Control the rotation speed of spray drying to be 10000r / min;

[0060] c. The inlet temperature of spray drying is 160°C, and the outlet temperature is maintained between 90-100°C.

[0061] 2) Preparation of hydrophobic catalyst

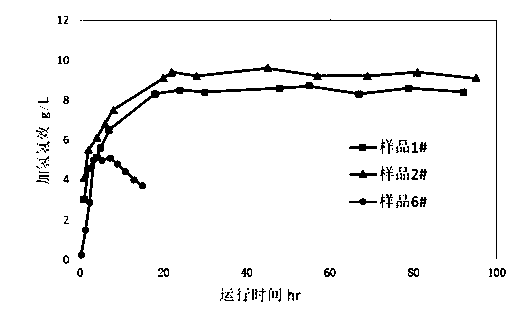

[0062] Take 5 g of the above-mentioned spherical silica powder with a particle size of 120-400 mesh, and then add 6.5 g of palladium acetate organic solution with a concentration of 3 mg...

Embodiment 2

[0067] 1) Preparation method of hydrophobic catalyst

[0068] Weigh 50 g of organosilicon sol with a solid content of 20%. Among them, the average particle size of the nano-silica in the organosilicon sol is 30nm, the surface of the nano-silica particles is mainly methyl groups, and the selected solvent is methyl ethyl ketone. Add 13.0 g of palladium acetate organic solution with a concentration of 3 mg / ml to the above organosilicon sol, wherein the solvent of palladium acetate is methanol solution, and then stir at room temperature for 30 min.

[0069] The above organosilicon sol mixed with active components was prepared into spherical catalyst particles by centrifugal spray drying, and the control parameters of centrifugal spray drying were as described in Example 1.

[0070] The sample after centrifugal spray drying was roasted at 300°C for 2 hours to obtain the oxidized complex II;

[0071] 2) Reduction treatment

[0072] Put the above oxidized complex II into a tube fu...

Embodiment 3

[0075] Preparation of samples 3#~5#

[0076] The difference between the preparation method of sample 3# and the preparation method of sample 1# is that the solid content of the organosilicon sol is 15wt%, the average particle size of the nano-silica in the organosilicon sol is 65nm, and the surface of the nano-silicon oxide particles is mainly phenyl 2-methylpropionate palladium(II) with a concentration of 15mg / ml is dissolved in methanol, the organic solution of 2-methylpropionate palladium(II) is 6.5g, and the temperature of sintering I is 200°C, which is denoted as Sample 3#. In sample 3#, the mass content of palladium in the noble metal catalyst is 1.9wt%.

[0077] The difference between the preparation method of sample 4# and the preparation method of sample 1# is that the solid content of the organosilicon sol is 38wt%, the average particle size of the nano-silica in the organosilicon sol is 20nm, and the surface of the nano-silicon oxide particles is mainly acetyl 6.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com