Patents

Literature

204 results about "Hydrogen selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sensor instrument system including method for detecting analytes in fluids

ActiveUS8449824B2Novel and uniqueSimple designLaboratory glasswaresNanosensorsTransceiverHydrogen selectivity

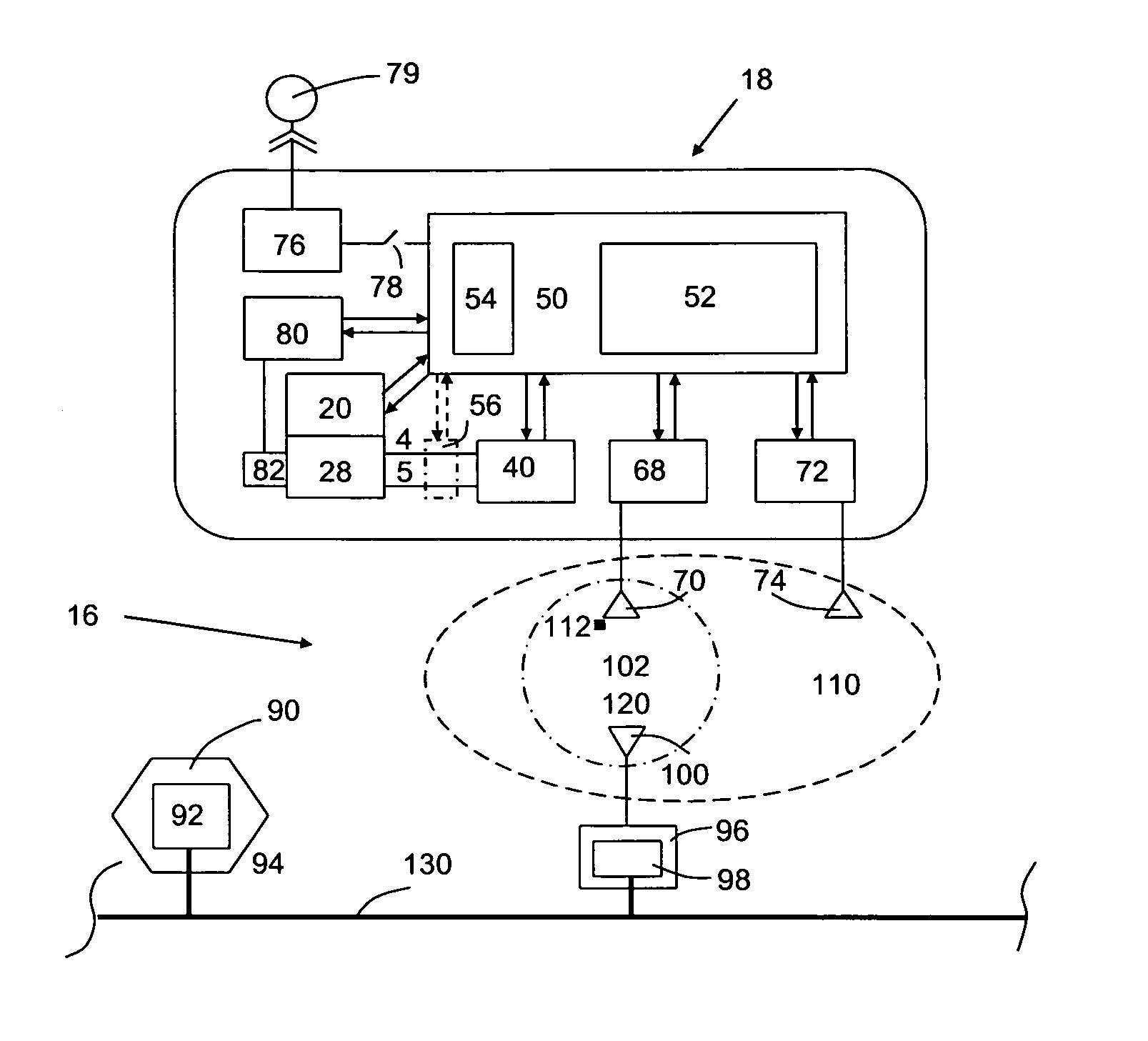

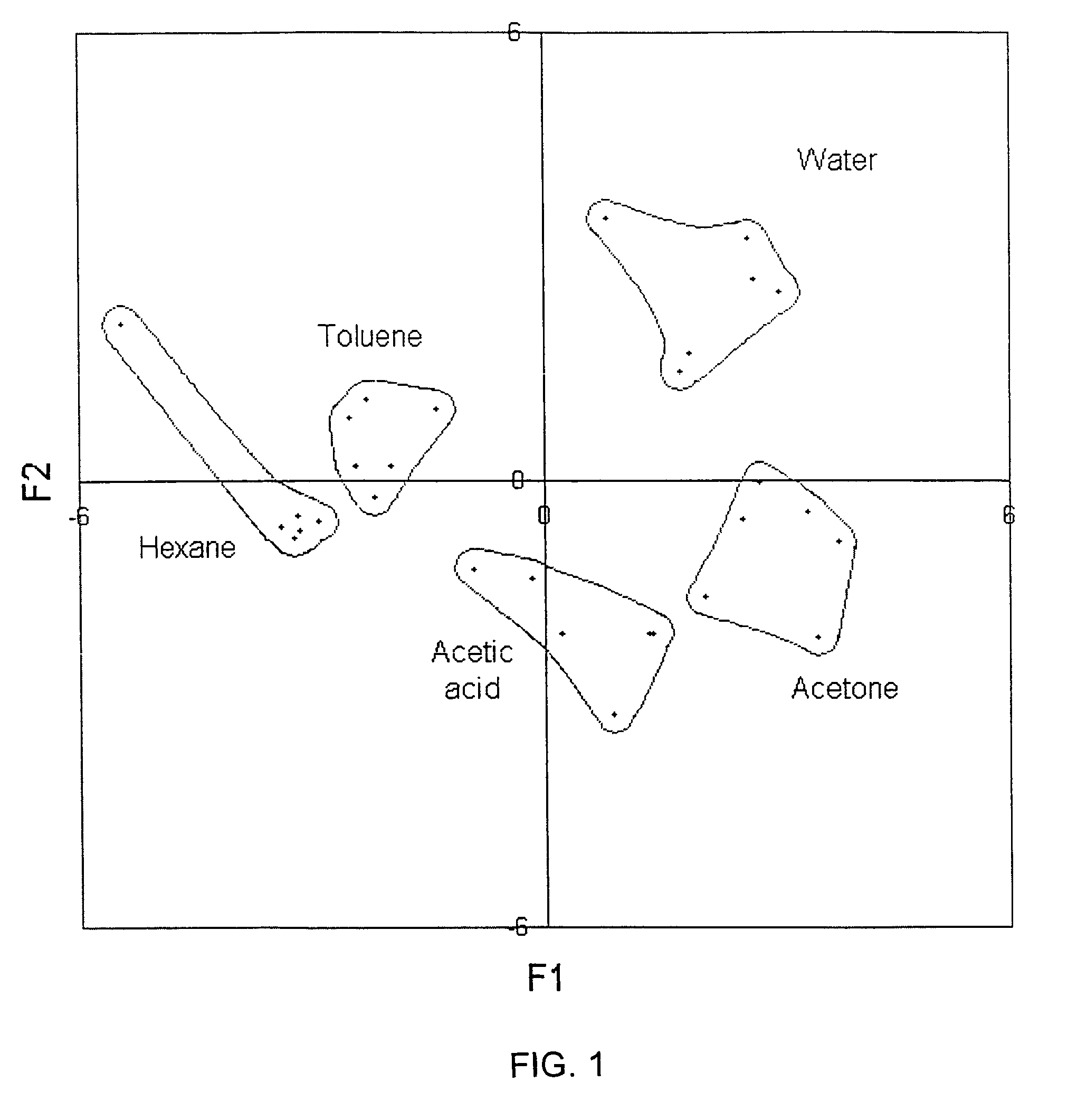

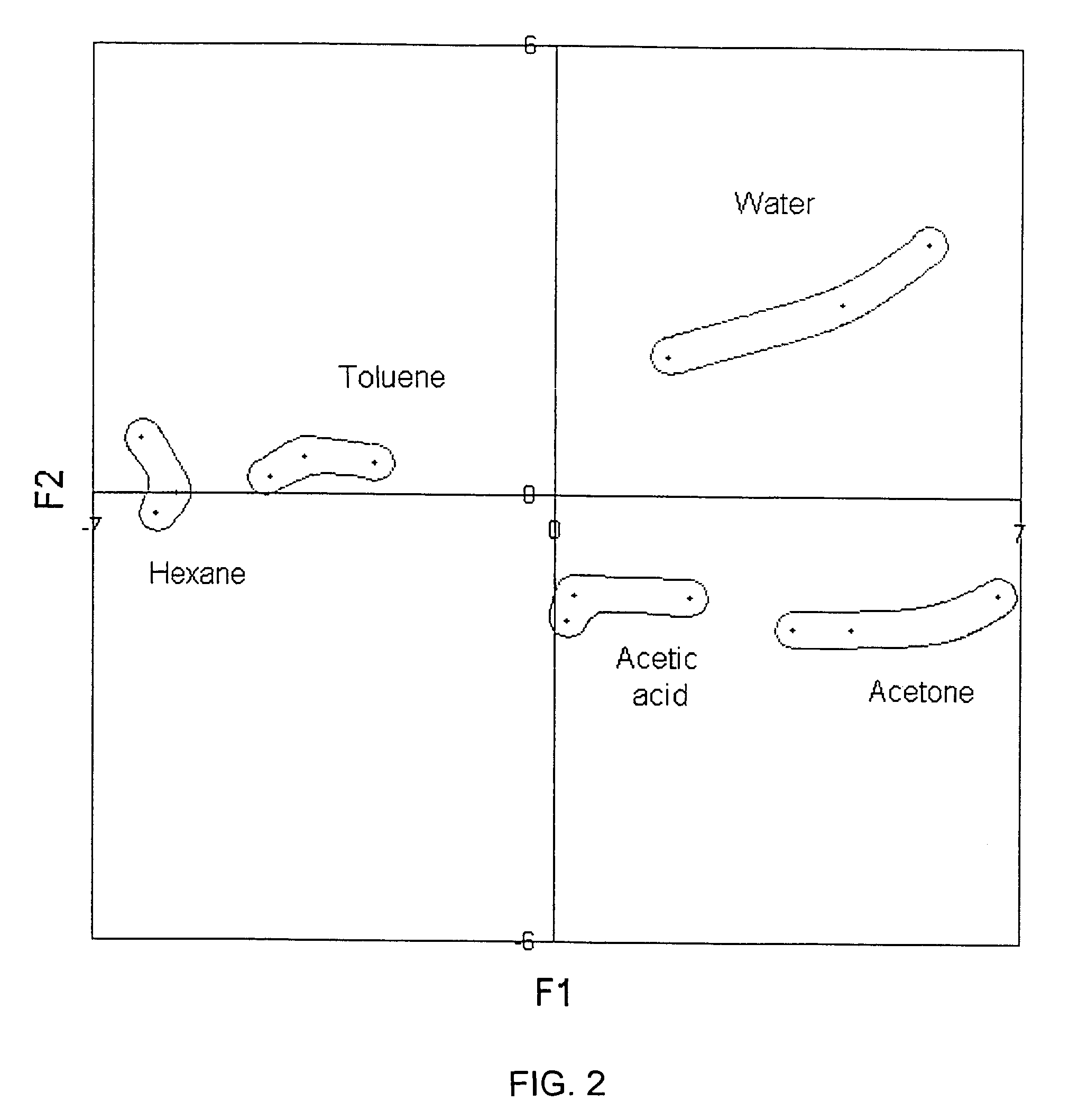

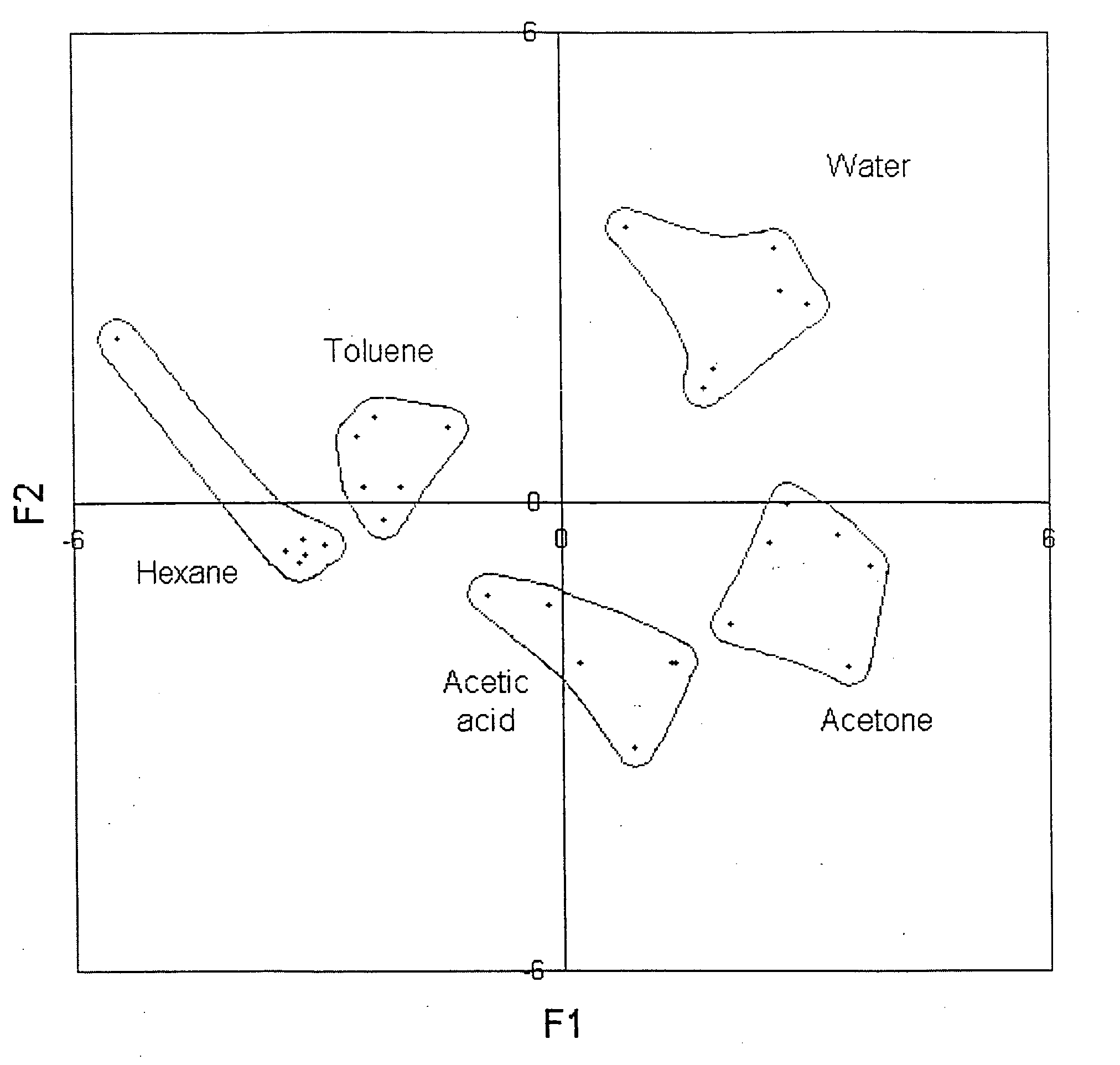

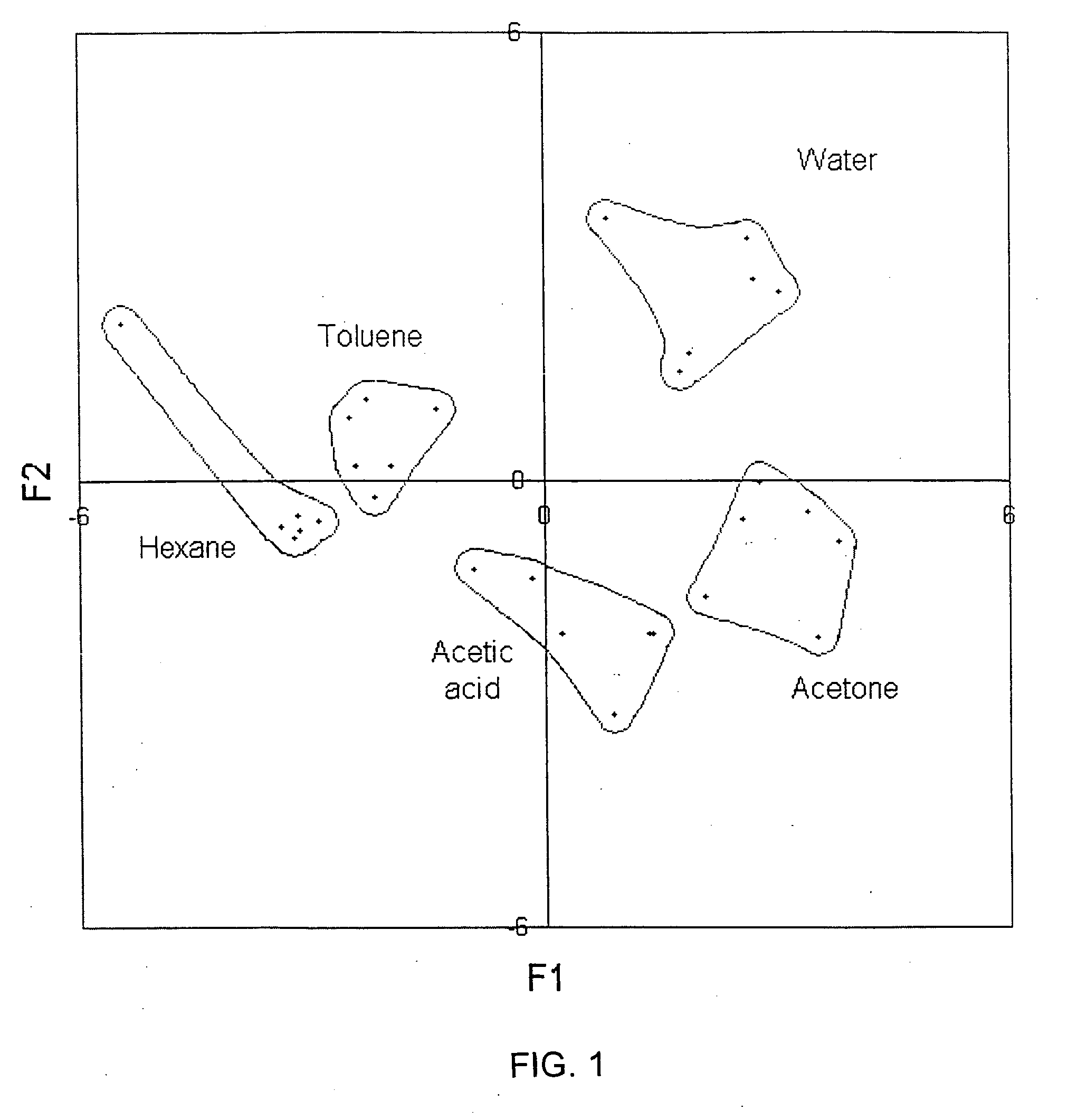

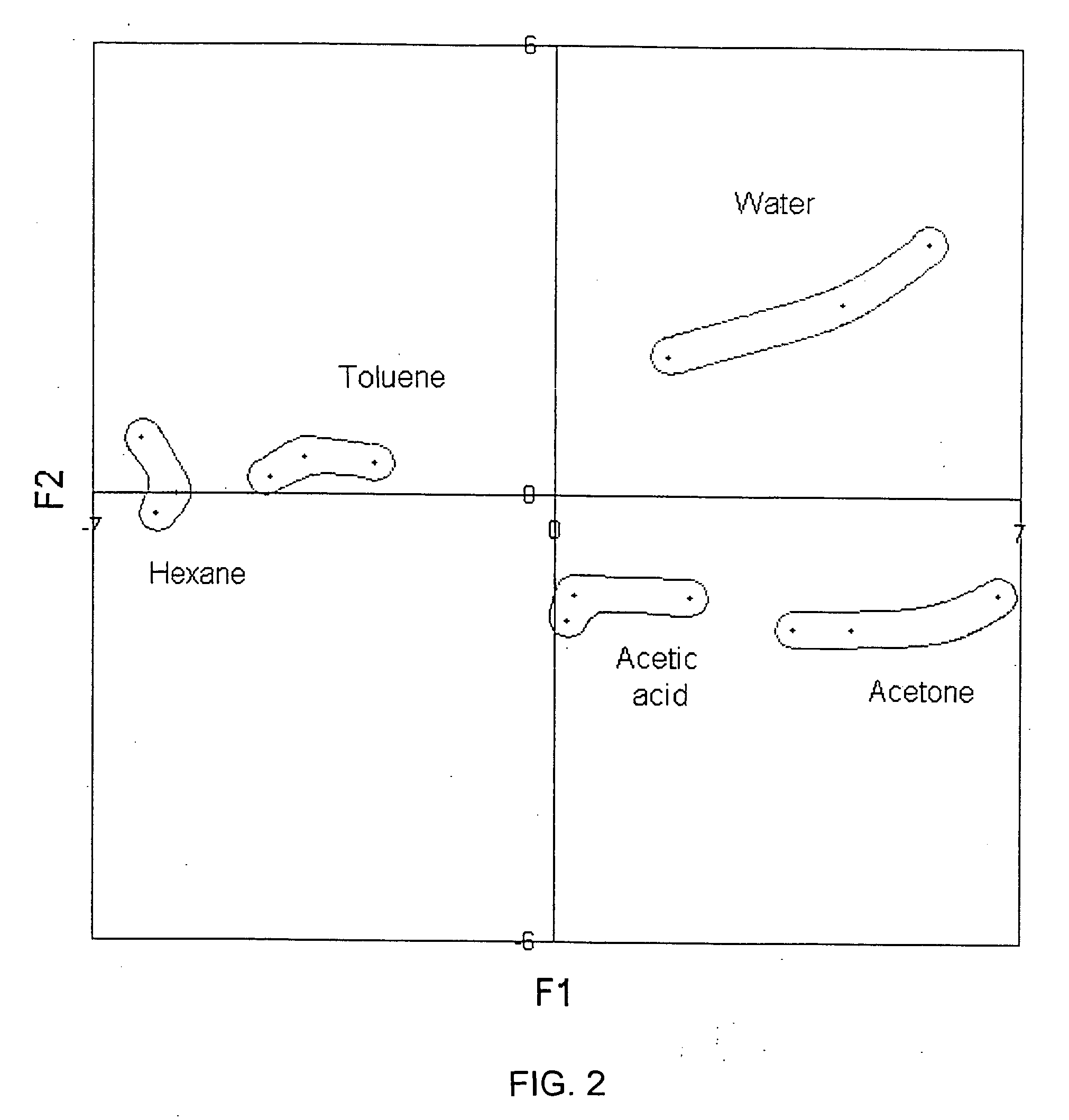

A sensor instrument system for detecting and identifying analytes in fluids of a region contains a local sensor instrument and remote central station. The instrument includes a core technology employing a single sensor having two electrodes operated by an electrical frequency sweeping to generate two sets of patterned electrical information from a single measurement, a data transmission module and a GPS receiver module. The central station connects to a network means connected to a plurality of local receiving sites equipped with including the respective transceivers, so that the local analyte electrical information and geographic position information transmitted by the instrument can be wirelessly and remotely received and processed by the central station. The core technology further includes a reference sensor for eliminating background influence, a temperature programming to control adsorption and desorption of analytes, and usage of all kinds of adsorbent materials having chemical selectivities including the hydrogen selectivity to enhance detection and identification of analytes in fluids.

Owner:SUN YIZHONG

Sensor instrument system including method for detecting analytes in fluids

ActiveUS20090261987A1Improves analyte detectionEasy to identifyElectric signal transmission systemsLaboratory glasswaresTransceiverDesorption

A sensor instrument system for detecting and identifying analytes in fluids of a region comprising a local sensor instrument and remote central station. The instrument is comprised of a core technology employing a single sensor having two electrodes operated by an electrical frequency sweeping to generate two sets of patterned electrical information from a single measurement, a data transmission module and a GPS receiver module. The central station connects to a network means connected to a plurality of local receiving sites equipped with including the respective transceivers, so that the local analyte electrical information and geographic position information transmitted by the instrument can be wirelessly and remotely received and processed by the central station. The core technology is further comprised of a reference sensor for eliminating background influence, a temperature programming to control adsorption and desorption of analytes, and usage of all kinds of adsorbent materials having chemical selectivity including the hydrogen selectivity to enhance detection and identification of analytes in fluids.

Owner:SUN YIZHONG

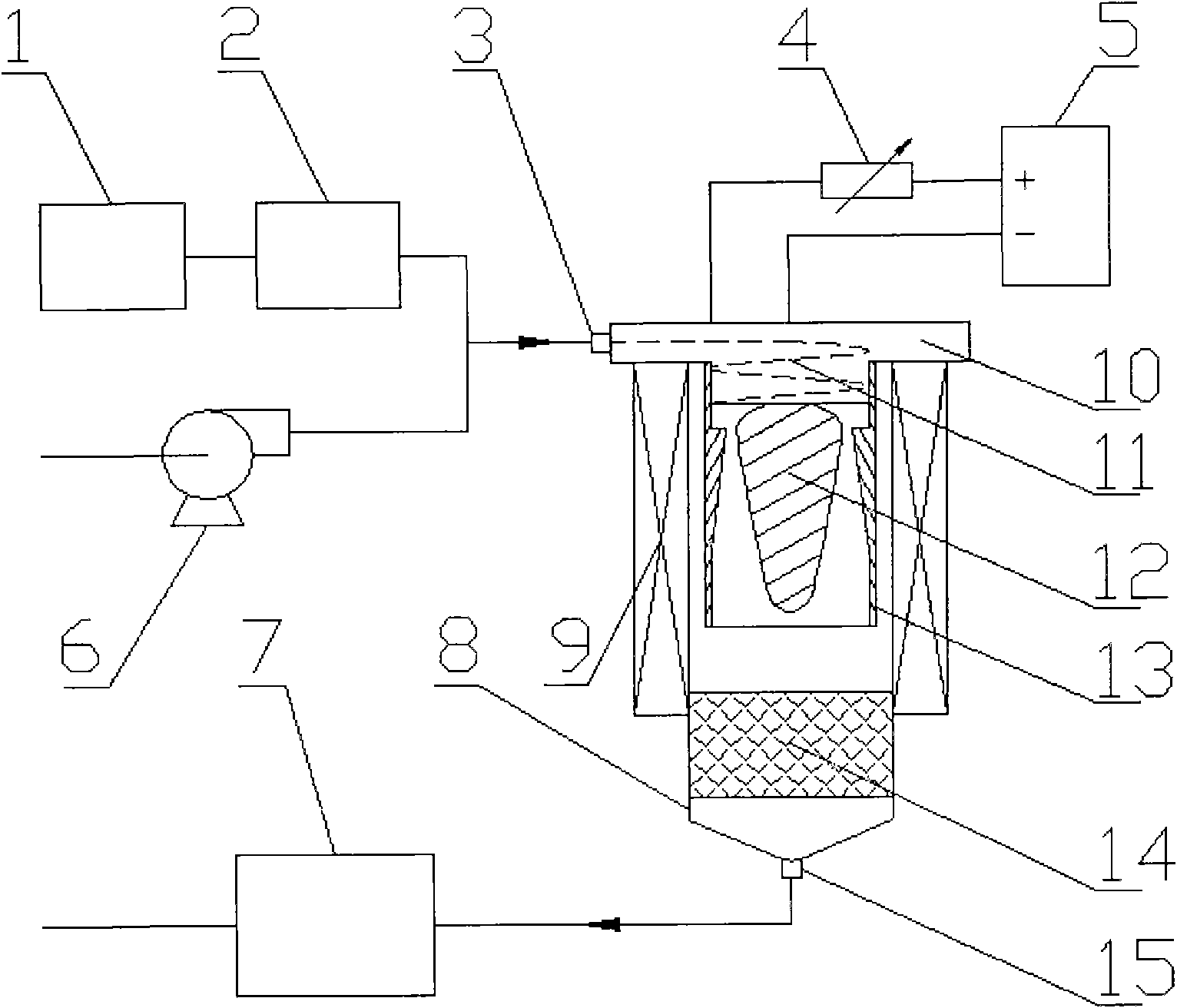

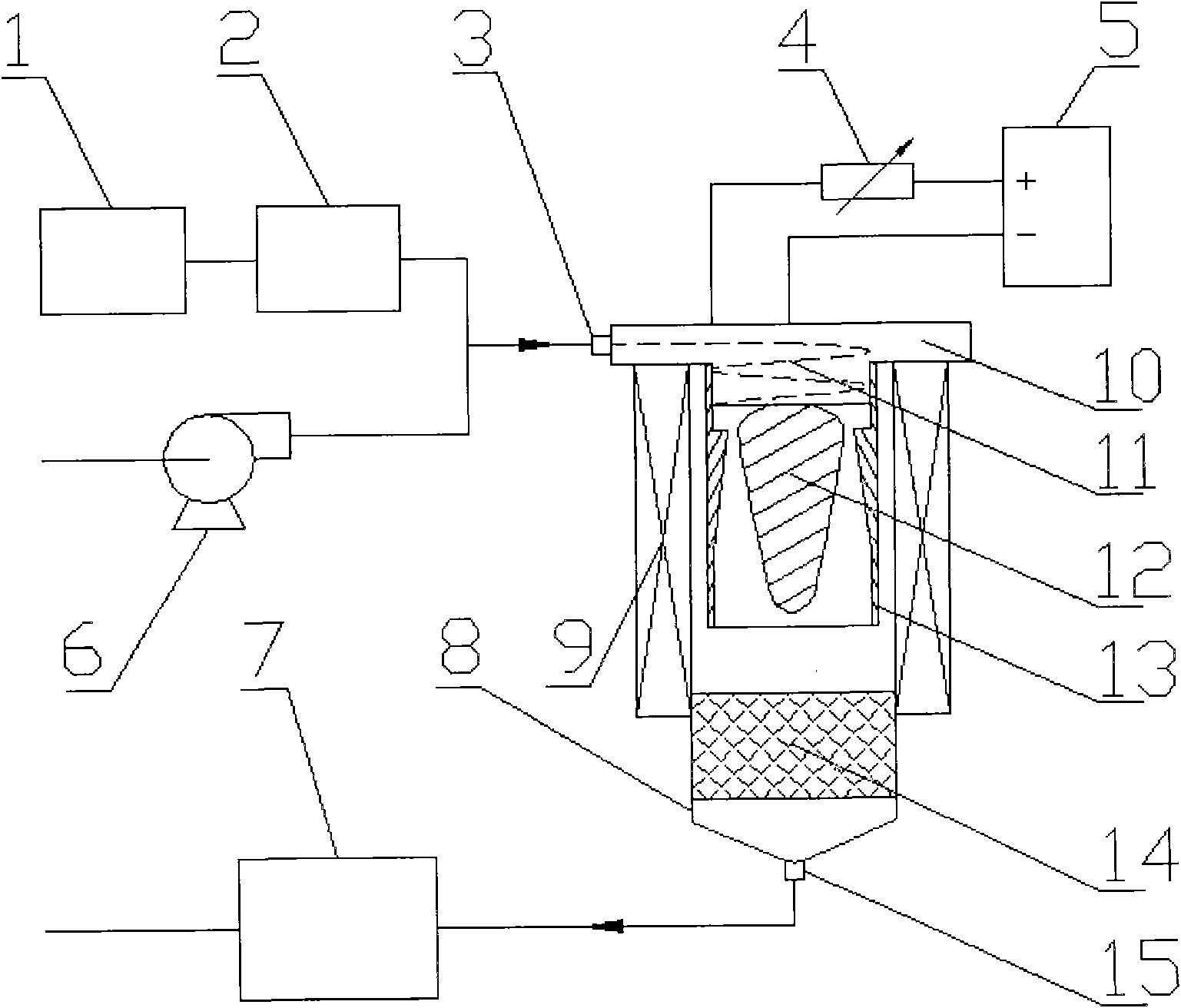

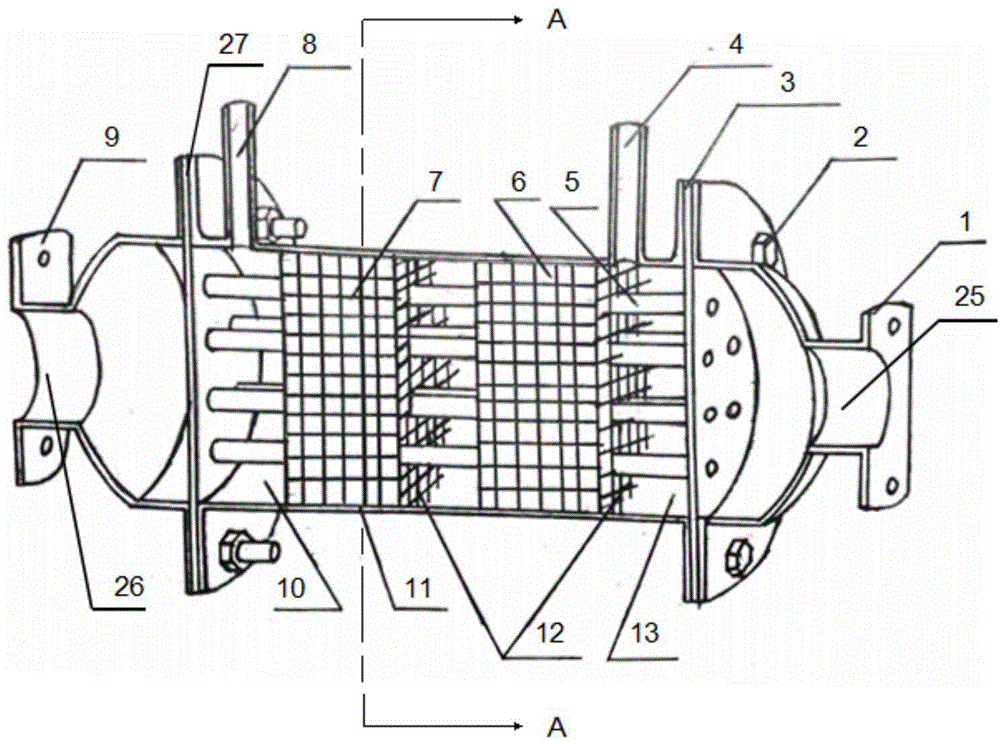

Hydrogen production device through reforming methane by using collaborative drive rotation sliding arc discharge plasma

ActiveCN101844744ALarge amount of processingGreatly increase throughputHydrogenHydrogen selectivityHigh-voltage direct current

The invention relates to a low-carbon hydrocarbon hydrogen production device, in particular to a hydrogen production device through reforming methane by using collaborative drive rotation sliding arc discharge plasma. The device comprises a reactor with a reaction hood and an insulated base. The electrode of the reactor is arranged on the insulated base and is connected with a high-voltage DC power supply. A reactor outlet is arranged on the reaction hood. One end of a mixed gas pipeline is connected with a gas inlet on the external side of the insulated base and the other end of the mixed gas pipeline is connected with an air pump and a methane gas source. The electrode comprises a conical internal electrode and a tubular external electrode, wherein the internal electrode is arranged in the center of the insulated base and the external electrode is arranged around the internal electrode. A spiral gas flow passage is arranged in the insulated base. The invention has the advantages that the effect of hydrogen production through methane reformation can be greatly improved, the methane conversion rate is higher, the hydrogen selectivity is higher, the energy consumption is lower and the methane treatment capacity is larger; and the device is simple, the cost is low and the device is particularly suitable for medium and small scale hydrogen production through methane reformation.

Owner:ZHEJIANG UNIV

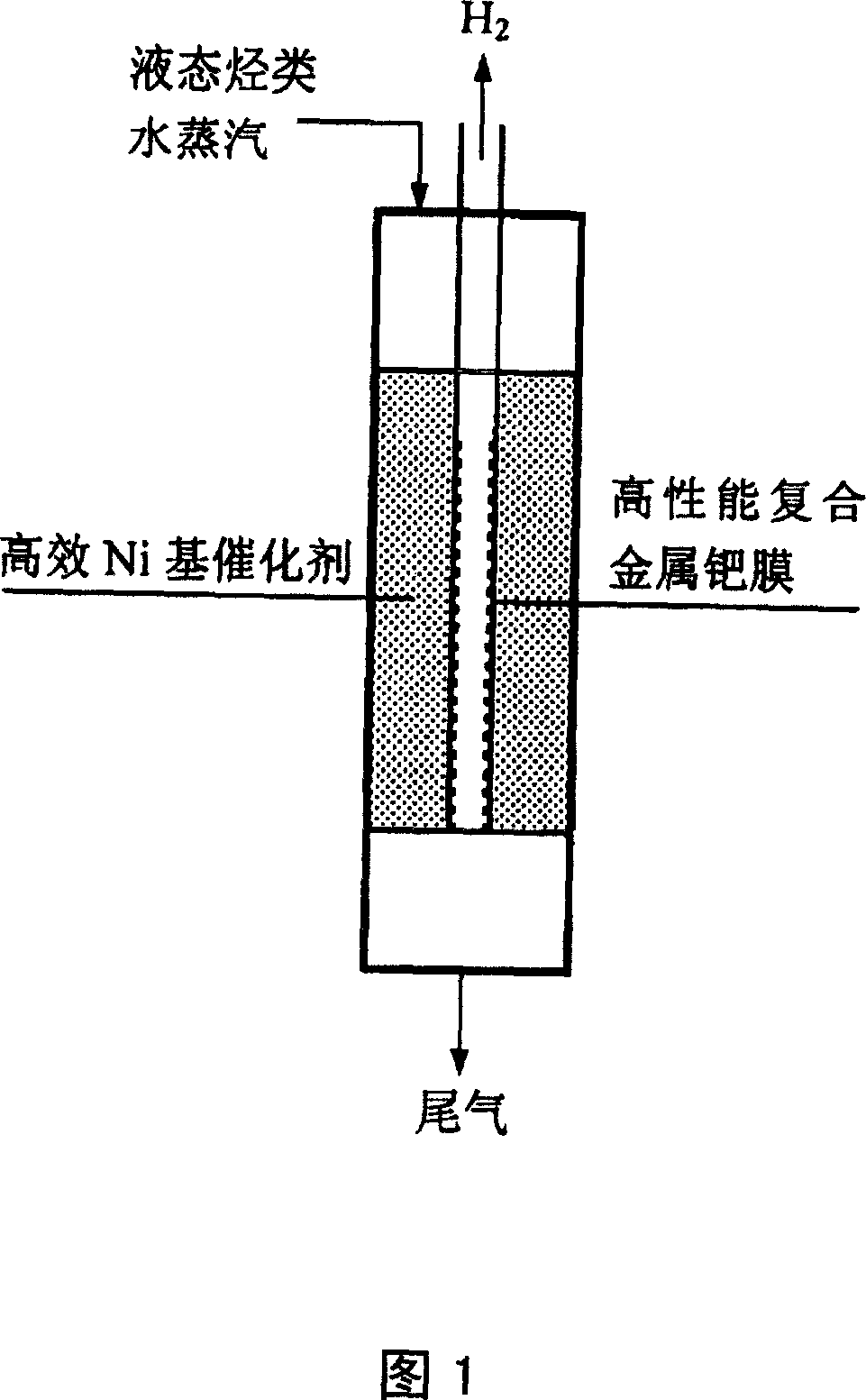

Process of preparing high purity hydrogen with liquid hydrocarbon in a palladium film reactor

The process of preparing high purity hydrogen with liquid hydrocarbon in a palladium film reactor adopts Ni base catalyst with high activity at low temperature to obtain liquid hydrocarbon converting rate near 100 % at the conditions of 450-550 deg.c temperature and carbon space velocity as high as 30,000 / hr, and uses high performance composite metal palladium film simultaneously at the conditions of 500-600 deg.c temperature and carbon space velocity as high as 2000 / hr for timely separating hydrogen generated through water vapor reformation of liquid hydrocarbon to avoid methanation reaction, so as to obtain methane selectivity lower than 3 % and hydrogen selectivity higher than 97 % and obtain high pure hydrogen in the permeation side of the palladium film. The present invention has low hydrogen producing cost and may be used widely in hydrogen refilling station and small dispersed power station.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

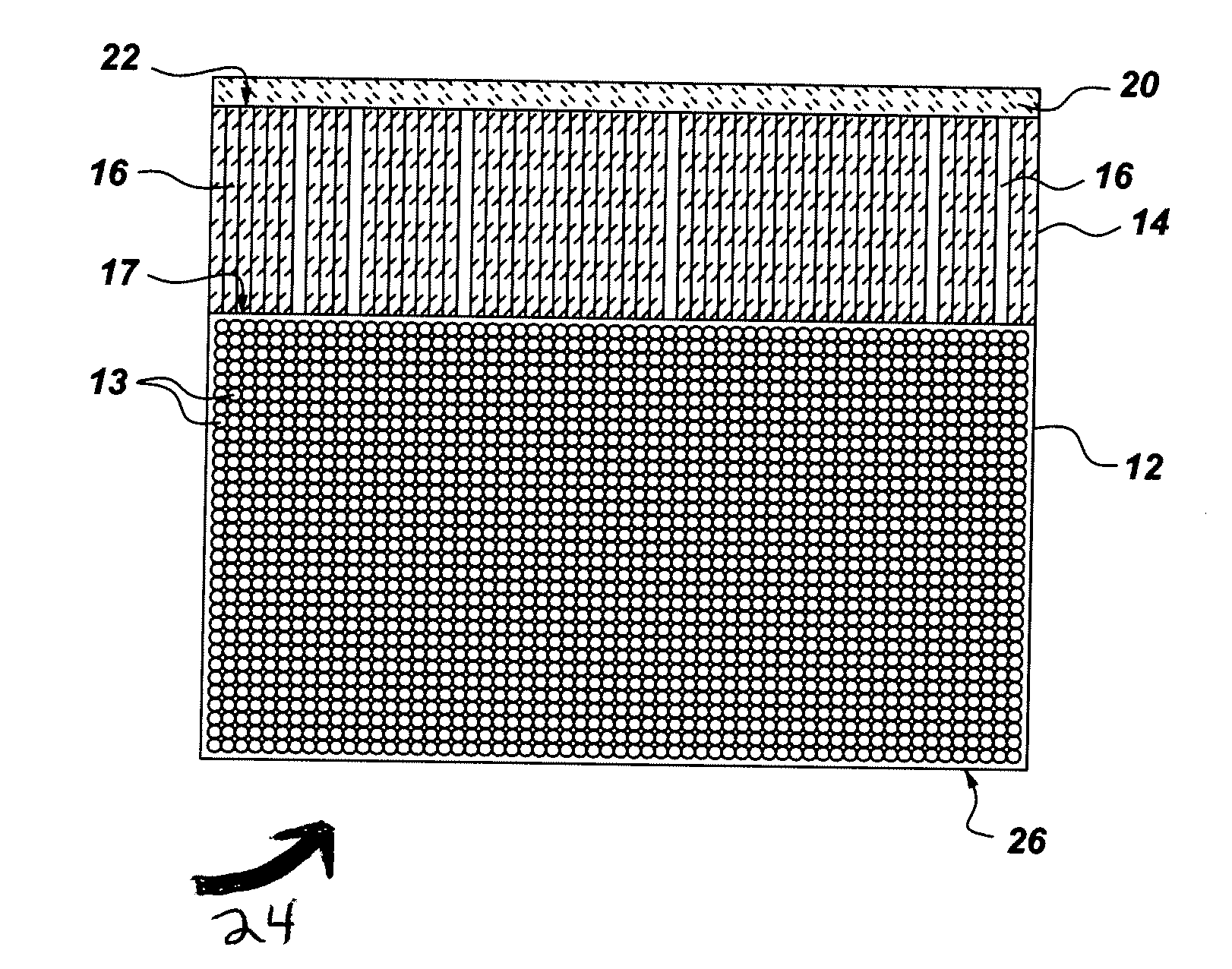

Membranes suitable for gas separation, and related articles and processes

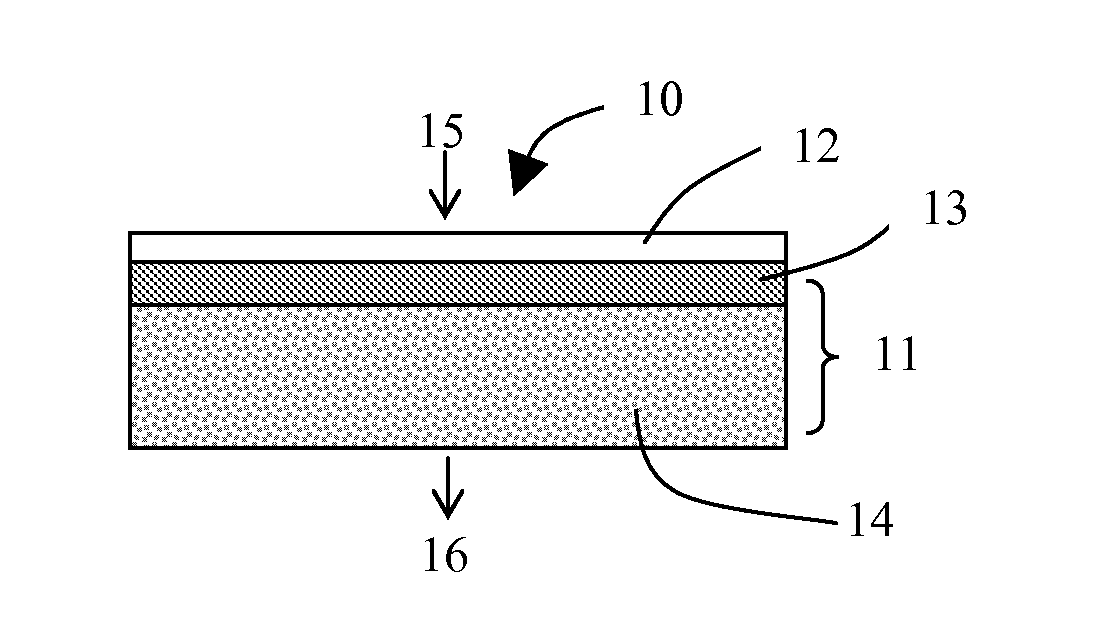

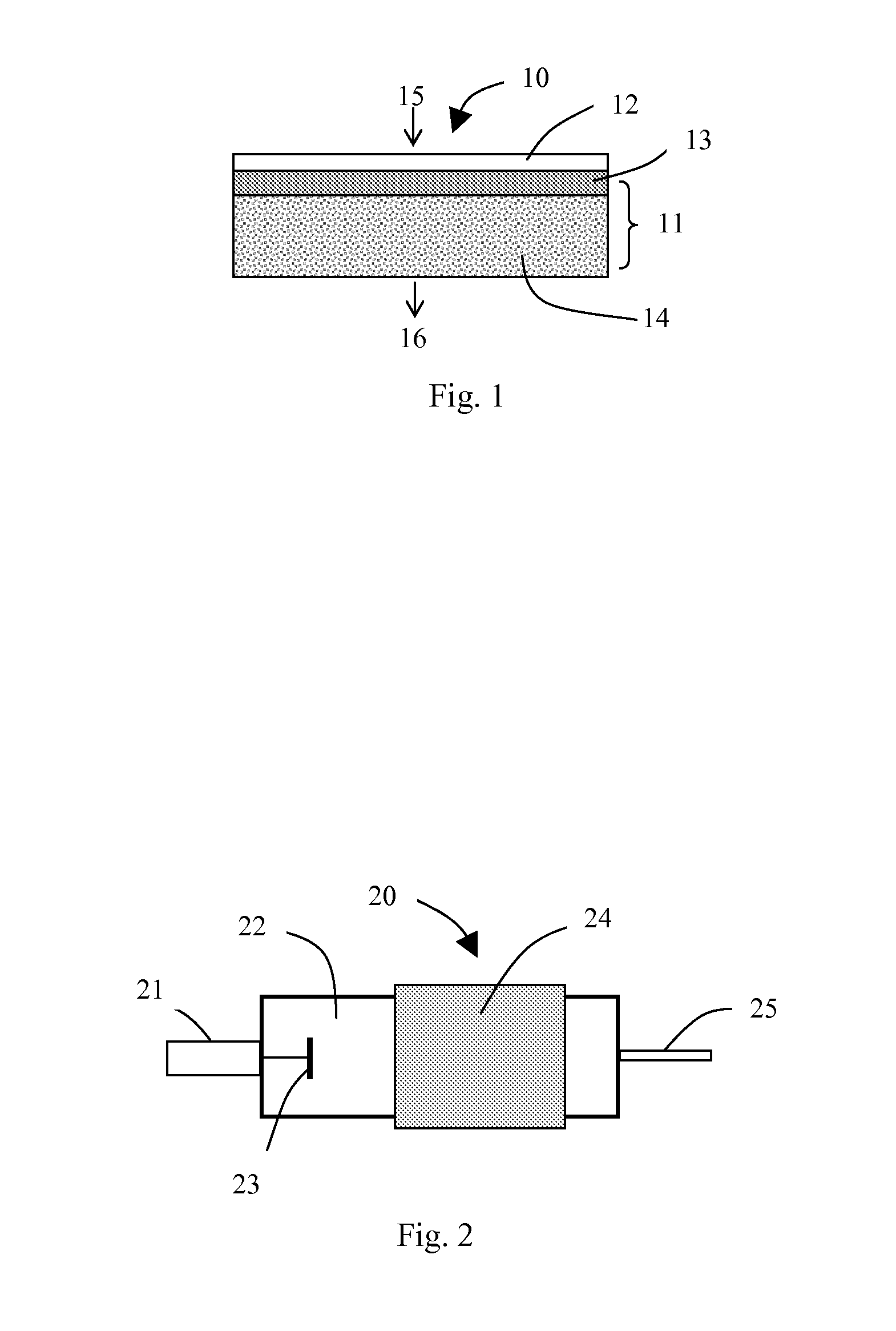

ActiveUS20110030382A1High selectivityCombustion enginesGas turbine plantsPorous substratePower station

A porous membrane structure is disclosed, which includes a porous substrate, a mesoporous, aluminum oxide layer disposed on the substrate; and a relatively thin, continuous, microporous barrier layer disposed on the mesoporous aluminum oxide layer, also formed from aluminum oxide. The membrane is capable of improving hydrogen selectivity within a gas stream, e.g., a synthesis gas composition. Membrane supports containing these structures are also described, as well as gas separation modules, and related processes. Power plants which incorporate the gas separation modules are also disclosed herein.

Owner:AIR PROD & CHEM INC

Biomass carbon-base material high-load nano-metal catalyst, as well as preparation method and application thereof

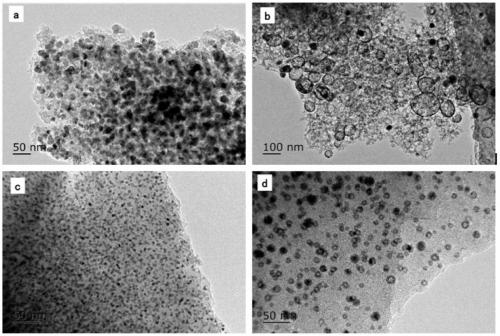

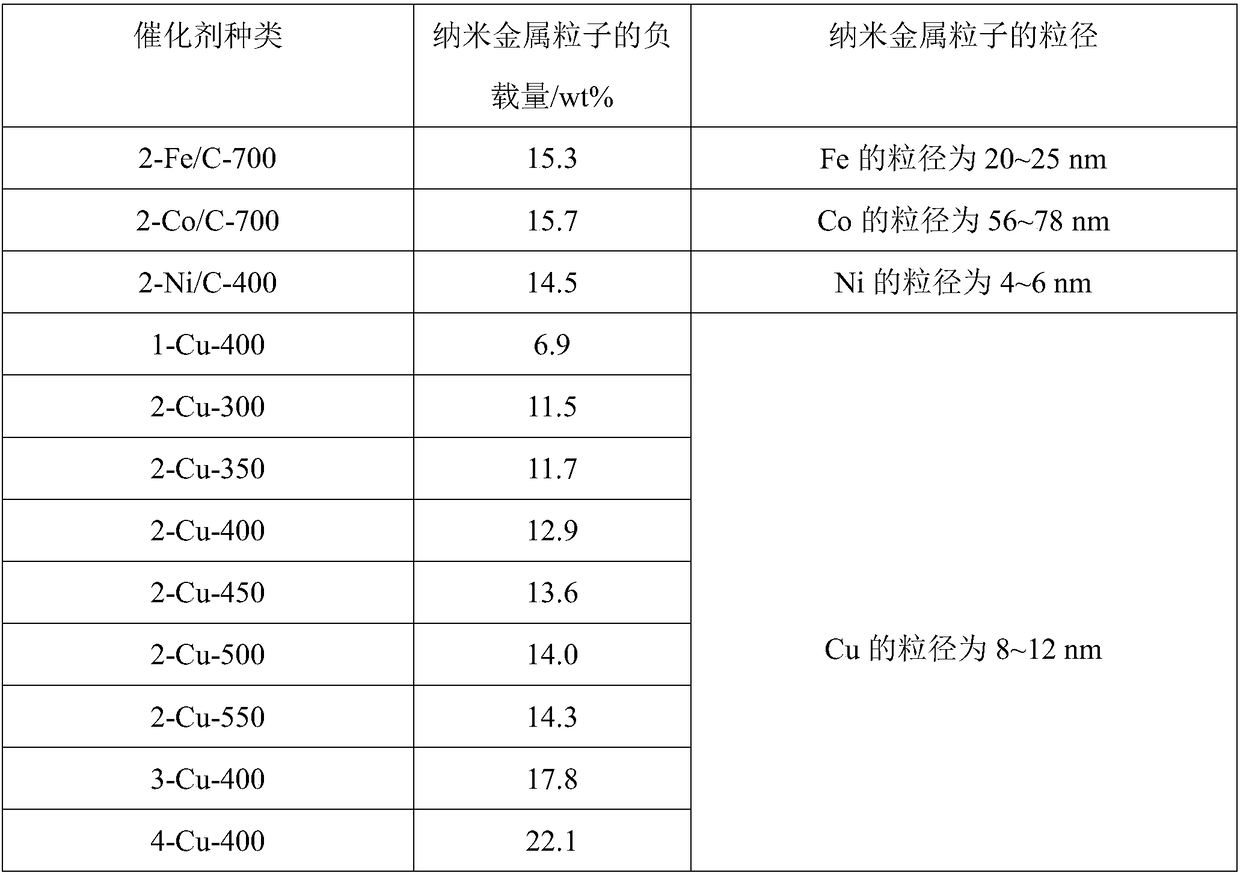

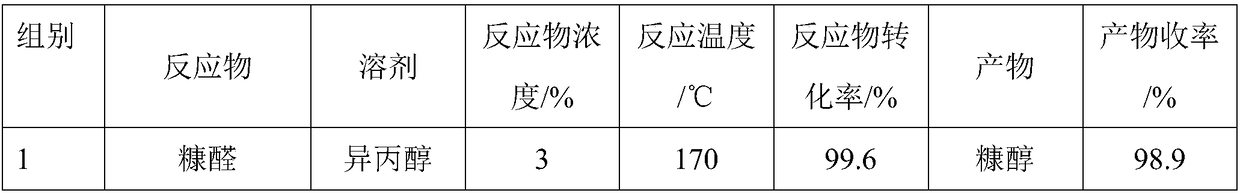

ActiveCN109364922ARaw greenEasy to makeMaterial nanotechnologyCatalyst carriersSimple componentCopper nitrate

The invention discloses a biomass carbon-based material high-load nano-metal catalyst, as well as a preparation method and application thereof. The catalyst is prepared by soaking shaddock peel powderin a nitrate solution having a certain concentration, drying and calcining, metal simple component serves as the active component, and organic carbon serves as the carrier; the nitrate is ferric nitrate, cobalt nitrate, nickel nitrate or copper nitrate; and the metal simple component is iron, cobalt, nickel or copper. The catalyst has the characteristics of environment-friendly raw materials, simple preparation process and high hydrogenation selectivity, has a good effect when being applied to a hydrogenation reaction of biomass derivatives, for instance, the furfuryl alcohol yield at a relatively low temperature of 170 DEG C can be 98,9 percent when the furfuryl alcohol is prepared by a furfuryl alcohol selective hydrogenation reaction.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

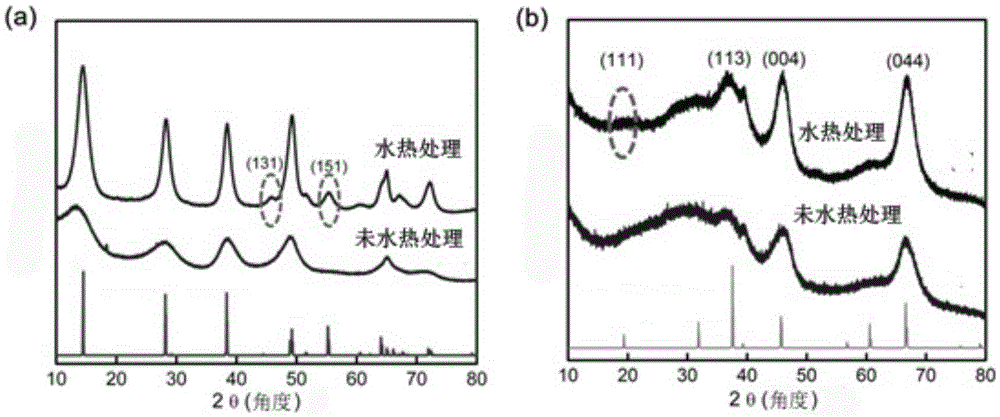

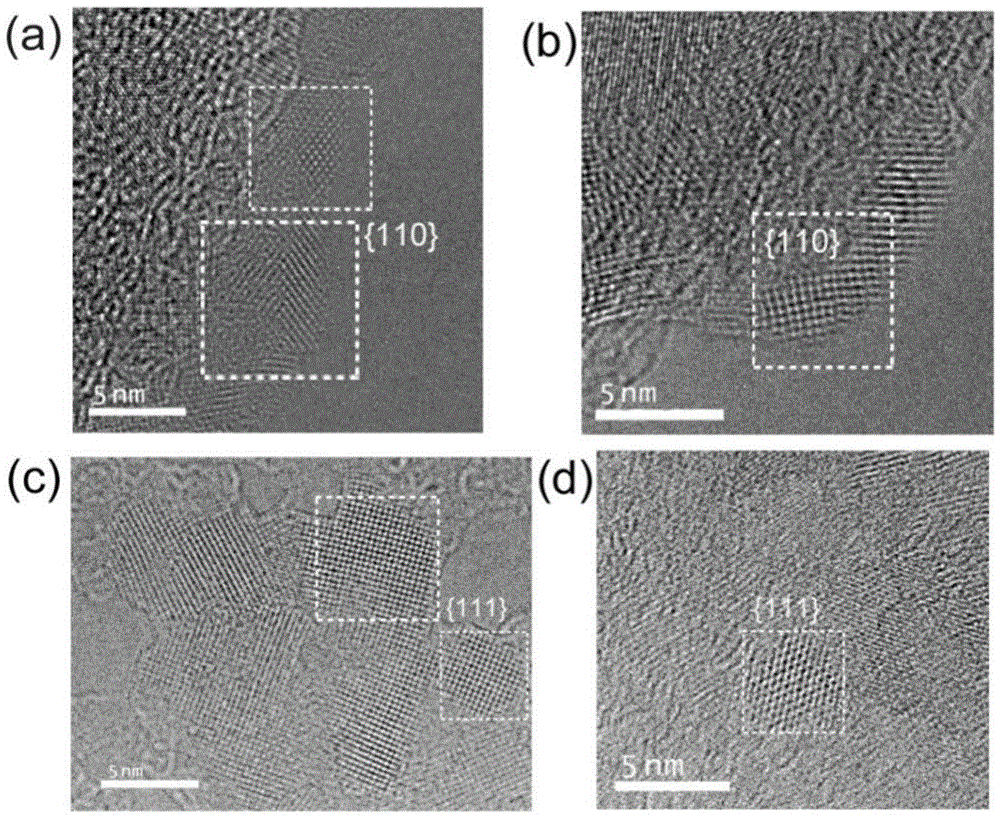

Light hydrocarbon sweetening catalyst based on aluminum oxide crystal face regulation and control and preparation method of light hydrocarbon sweetening catalyst

ActiveCN105618073AHigh activityHigh selectivityCatalyst carriersHydrocarbon by hydrogenationHigh activityHigh selectivity

The invention provides a light hydrocarbon sweetening catalyst based on aluminum oxide crystal face regulation and control and a preparation method of the light hydrocarbon sweetening catalyst. The light hydrocarbon sweetening catalyst is prepared by taking gamma-aluminum oxide after hydro-thermal treatment regulation and control as a carrier and nickel and molybdenum and active metals. The light hydrocarbon sweetening catalyst provided by the invention is a high-activity and high-selectivity catalyst, can be used for catalyzing thiol and alkadiene in light hydrocarbon to act to generate large-molecular sulfide, can be also used for catalyzing selective hydrogenation saturation of diolefin, is high in sweetening activity and high in diolefin hydrogenation selectivity when being compared with a conventional catalyst and is long in circulation period and relatively good in industrial application prospect as active components are not lost and low in probability of inactivation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

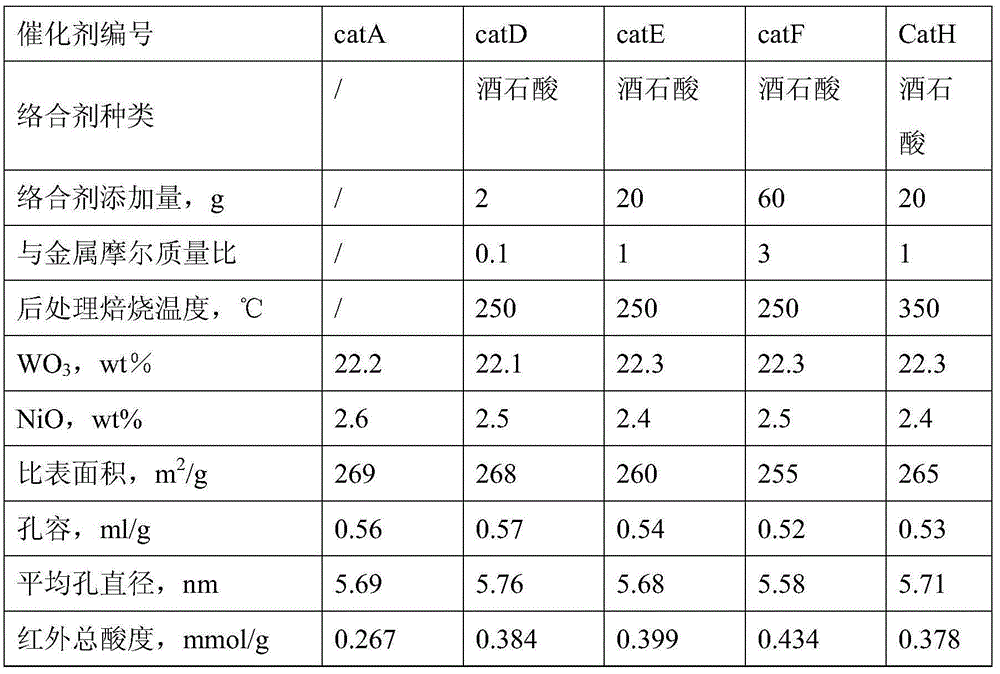

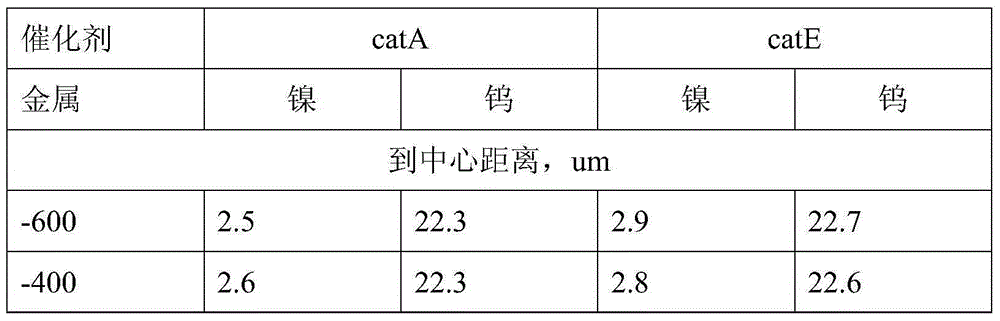

Preparation method for after-treatment hydrocracking catalyst

ActiveCN105195231AHigh selectivityVersatilityOrganic-compounds/hydrides/coordination-complexes catalystsAfter treatmentAlcohol

The invention discloses a preparation method for an after-treatment hydrocracking catalyst. The method includes the steps that 1, a hydrocracking catalyst carrier is prepared; 2, the catalyst carrier is steeped in steeping liquid containing active metal components and then dried and calcined at low temperature; 3, after matter capable of changing the arrangement of active metals is dissolved in a solvent according to a certain proportion, the catalyst obtained from the step 2 is steeped in the mixture; 4, materials obtained from the step 3 are dried and calcined for 1-10 hours at the low temperature of 150-400 DEG C, and the final after-treatment hydrocracking catalyst is obtained. The matter capable of changing the arrangement of the active metals is one or more of a phosphoric acid complexing agent, an alcohol amine complexing agent, an aminocarboxylic acid complexing agent, a hydroxy carboxylic acid complexing agent, an organic phosphonic acid complexing agent and a polyacrylic acid complexing agent. The after-treatment hydrocracking catalyst prepared through the method is higher in hydrogenation activity and hydrogenation selectivity, higher in selectivity for middle distillate, and suitable for treating the hydrocracking catalysts composed of various different metals.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Nano carbon material modified copper base catalyst and its preparing method

InactiveCN1586718AHigh activityHigh hydrogen selectivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogen selectivityWater vapor

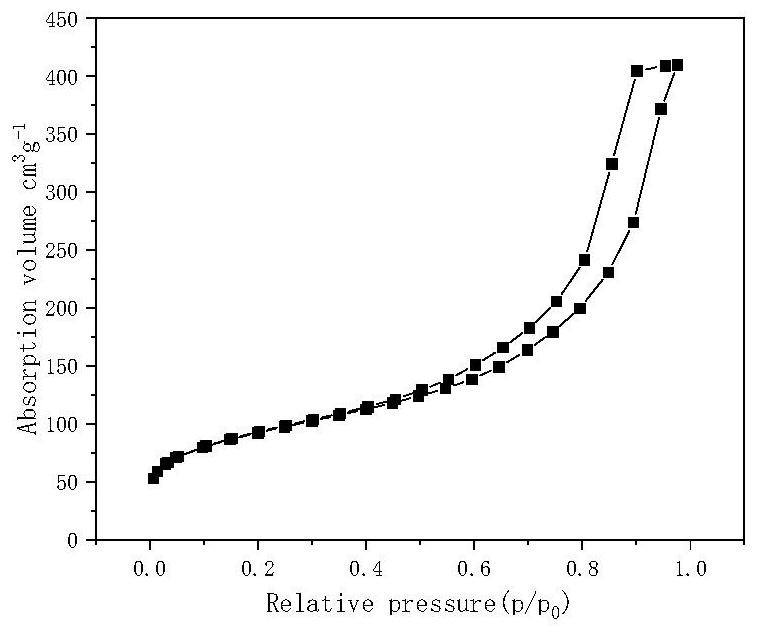

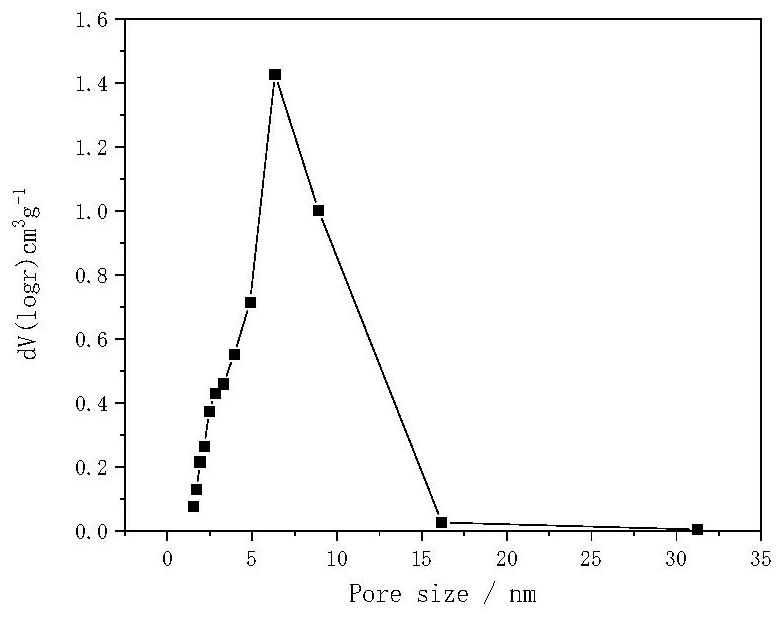

The present invention belongs to the field of chemical technology, and especially one kind of copper base catalyst with nanometer carbon material as co-catalyst for vapor reformation of methanol to prepare hydrogen and its preparation process. The catalyst is prepared through the process including the steps of: compounding 0.1 M solution of Cu / Zn / Al nitrate; compounding 0.1 M solution of sodium carbonate, dropping the 0.1 M solution of Cu / Zn / Al nitrate and 0.1 M solution of sodium carbonate in the same rate into reactor with nanometer carbon material for co-precipitation under strong stirring and 60 deg.c to obtain carbonate coprecipitate containing nanometer carbon material; washing, drying, roasting, etc. The prepared catalyst has unique porous structure of great specific surface area, high low temperature activity and high hydrogen selectivity, and may be used in preparing reformed product with hydrogen content up to 75 % and CO content lower than 0.1 %.

Owner:FUDAN UNIV

Cu-Zr catalyst for steam reforming of methanol to prepare hydrogen and its prepn

InactiveCN1772378ACtiveSelectiveHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrogen selectivity

The present invention discloses one kind of Cu-Zr catalyst for steam reforming of methanol to prepare hydrogen and its preparation process. The catalyst without Zn and Al components contains CuO10-80 mol%, ZrO2 20-90 mol% and MOx 0-20 mol%, where M is one of Ce, La, Fe, Y and Mn. The Cu-Zr catalyst is used for steam reforming of methanol to prepare hydrogen, and has high activity, high hydrogen selectivity and very high stability. Specifically, it has conversion rate in steam reforming of methanol of 90-99 %, hydrogen selectivity of 95-99 % and CO content in the product lower than 0.5 %.

Owner:FUDAN UNIV

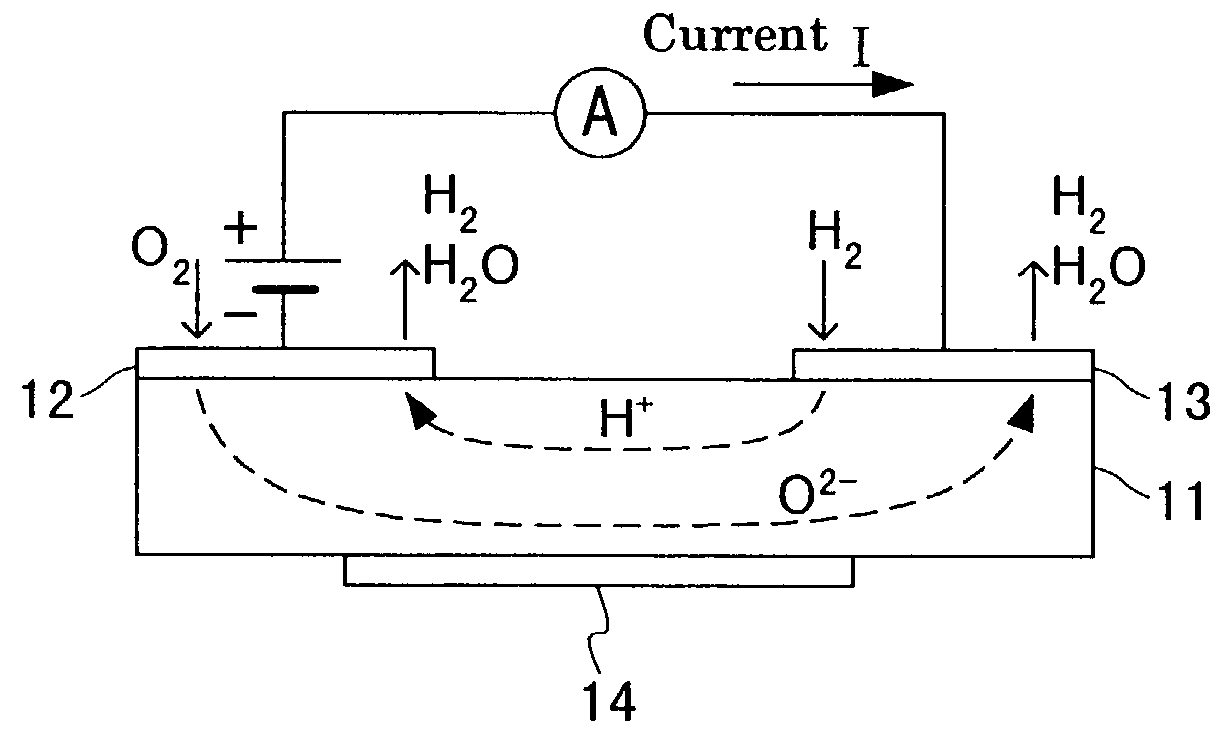

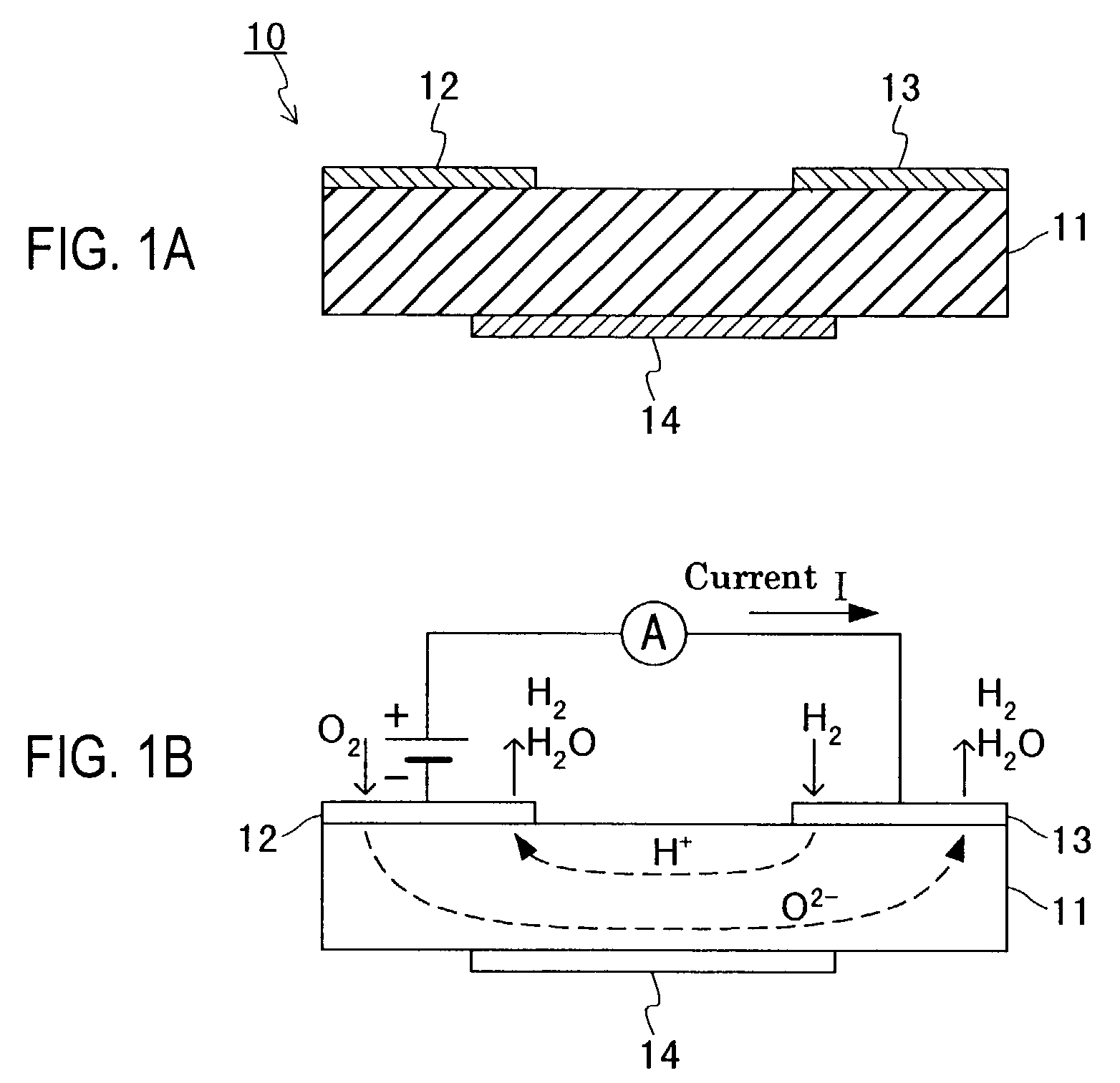

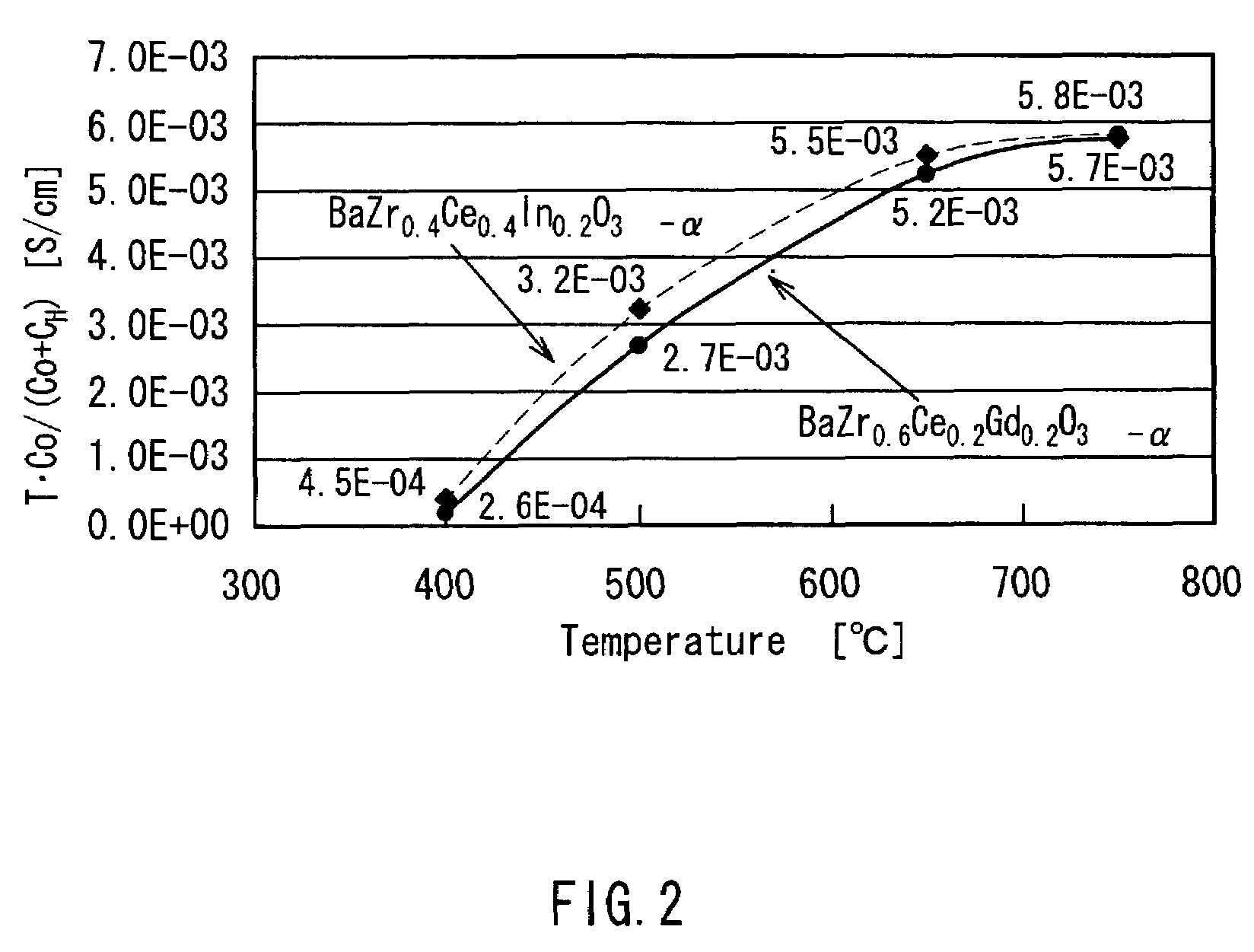

Hydrogen sensor, hydrogen sensor device and method of detecting hydrogen concentration

InactiveUS7235171B2High hydrogen selectivityGood responsiveness in detectionWeather/light/corrosion resistanceVolume/mass flow measurementHigh concentrationHydrogen concentration

A hydrogen sensor includes a solid electrolyte made of a barium cerium oxide, and a first electrode and a second electrode that are formed on the surface of the solid electrolyte. The first and the second electrodes are made of a material having a catalytic effect with respect to an oxidation reaction of hydrogen and are made of the same material. Thus, the hydrogen sensor can be inexpensive and has good hydrogen selectivity and responsiveness to detection, and thus it is possible to measure hydrogen in a high concentration region.

Owner:PANASONIC CORP

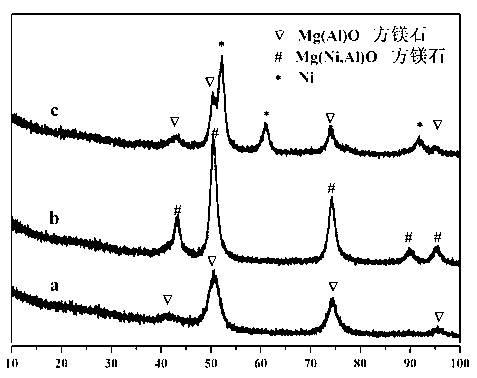

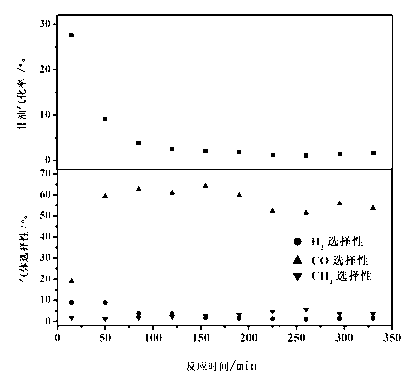

Hydrotalcite loaded nickel catalyst as well as preparation method and application thereof

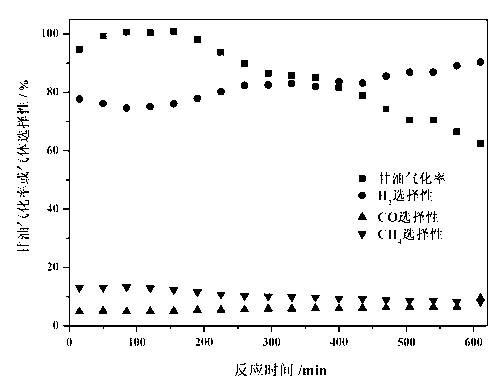

InactiveCN103071504ARaw materials are readily availableLow priceHydrogenMetal/metal-oxides/metal-hydroxide catalystsNickel catalystMixed oxide

The invention discloses an Mg-Al mixed oxide loaded nickel glycerol steam reforming catalyst as well as a preparation method and an application thereof, and belongs to the technical field of catalyst preparation. The preparation method comprises the following steps: taking an Mg-Al mixed oxide (Mg(Al)O) as a carrier and metal nickel as an active component, preparing Mg(Al)O in such a way that Mg-Al hydrotalcite (MgAl-LDH) is calcined at a temperature of 400-800 DEG C, wherein the catalyst comprises the following components by mass percent: 15-25% of Ni and 85-75% of Mg(Al)O, and loading Ni on the carrier by an impregnation method. The preparation method is simple, the raw materials are easy to obtain, and the prepared catalyst is used for hydrogen production from steam reforming of glycerol, and has the advantages of high glycerol gasification rate, good hydrogen selectivity, low selectivity of byproducts (CO and CH4), stable performance of the catalyst and the like.

Owner:FUZHOU UNIV

Sensor instrument system including method for detecting analytes in fluids

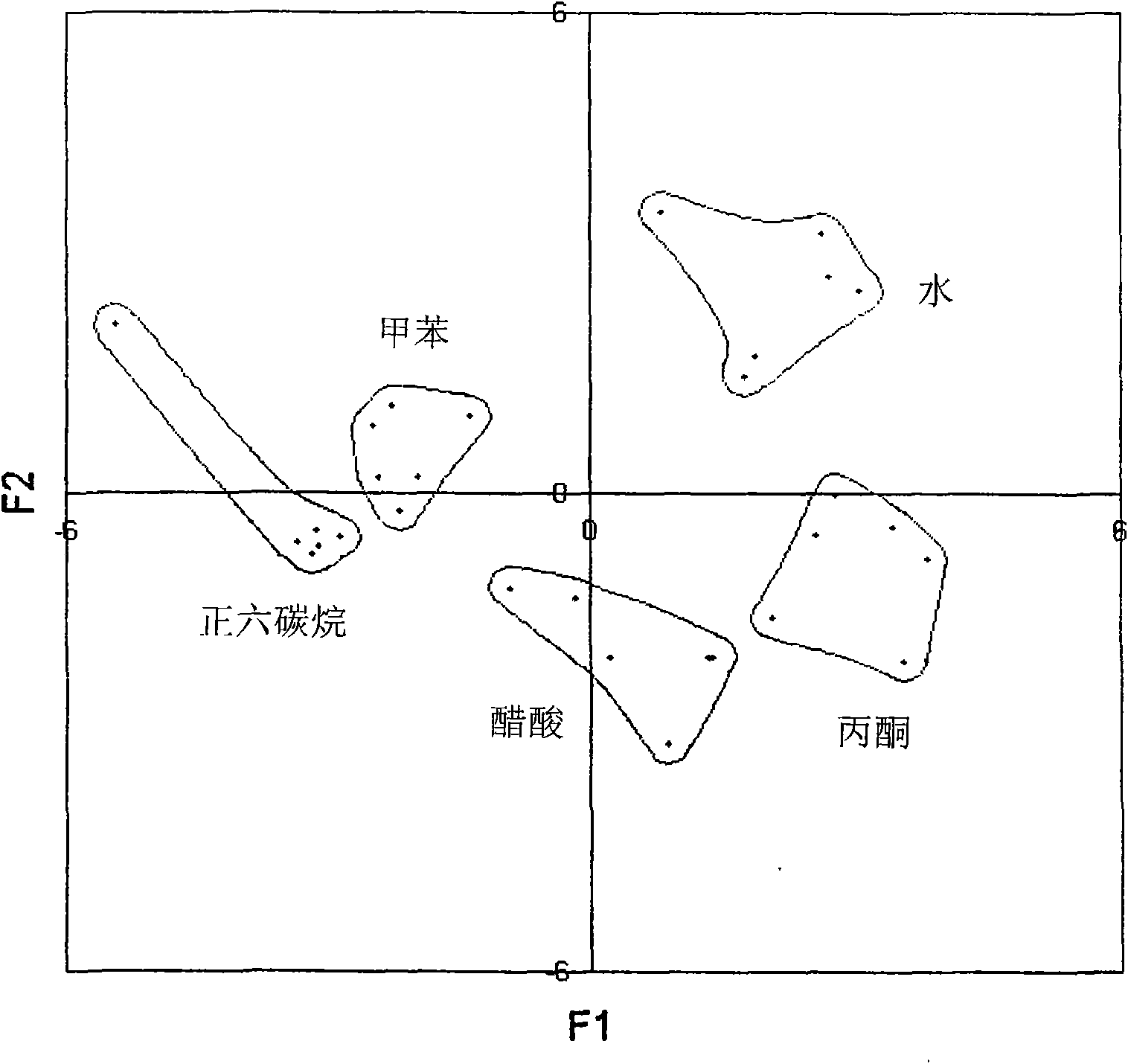

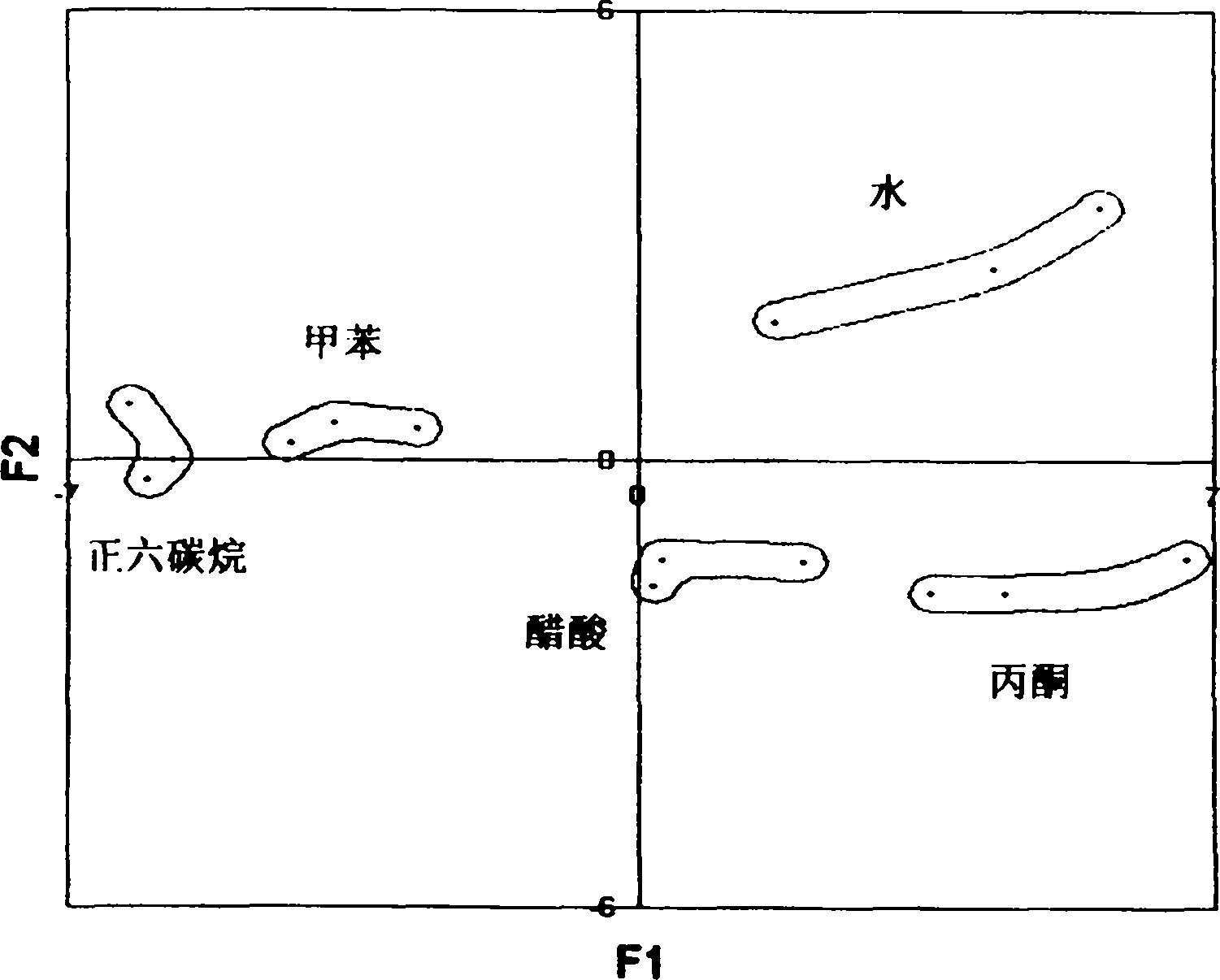

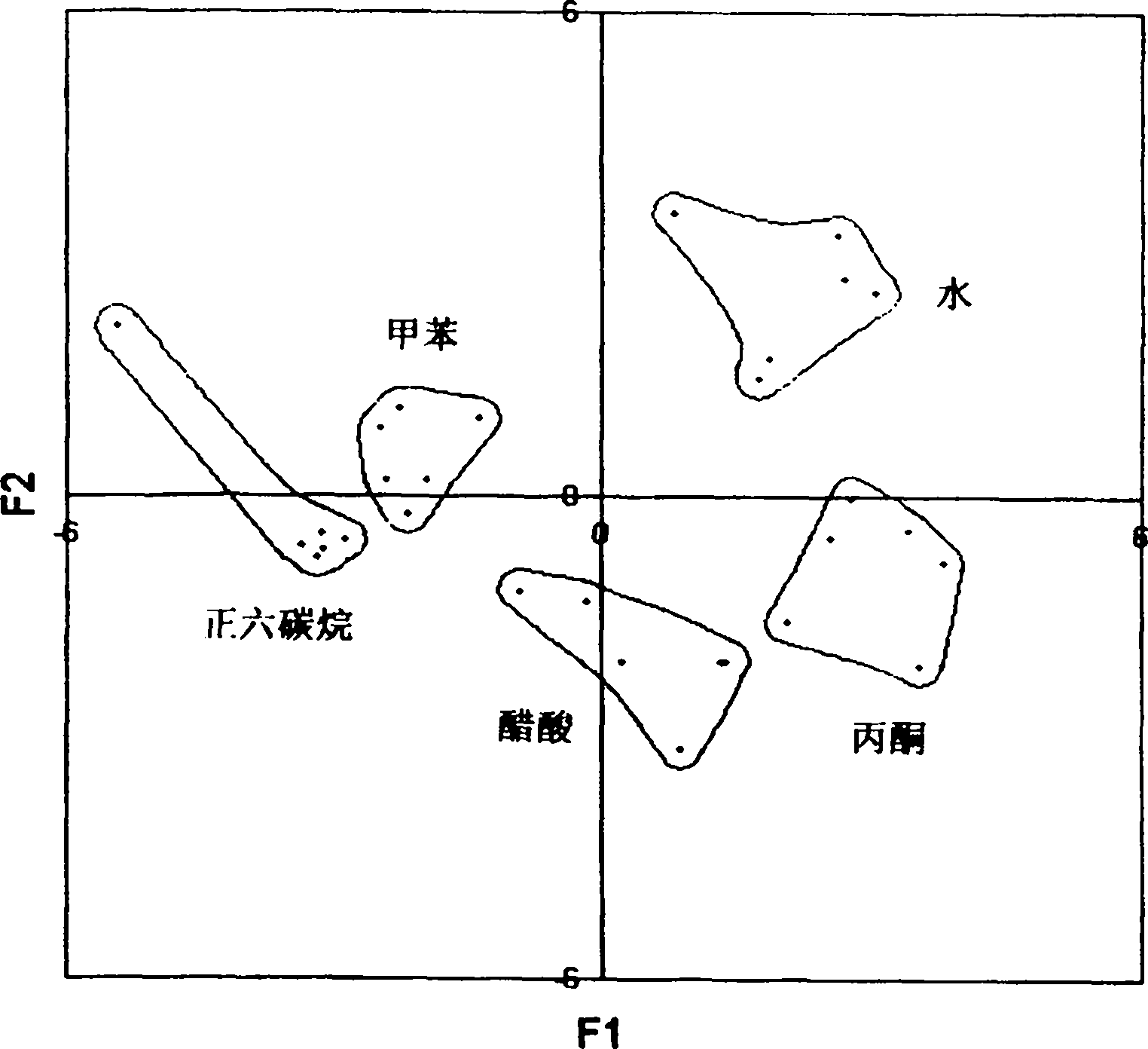

ActiveCN101581685ADetectableTo achieve the purpose of identificationMaterial resistanceTransceiverDesorption

A sensor instrument system and a method for detecting and identifying analytes in fluids of a region comprising a local sensor instrument and remote central station are disclosed. The instrument is comprised of a core technology employing a single sensor having two electrodes operated by an electrical frequency sweeping to generate two sets of patterned electrical information from a single measurement, a data transmission module and a GPS receiver module. The central station connects to a network means connected to a plurality of local receiving sites equipped with including the respective transceivers, so that the local analyte electrical information and geographic position information transmitted by the instrument can be wirelessly and remotely received and processed by the central station. The core technology is further comprised of a reference sensor for eliminating background influence, a temperature programming to control adsorption and desorption of analytes, and usage of all kinds of adsorbent materials having chemical selectivity including the hydrogen selectivity to enhance detection and identification of analytes in fluids.

Owner:孙一慧 +1

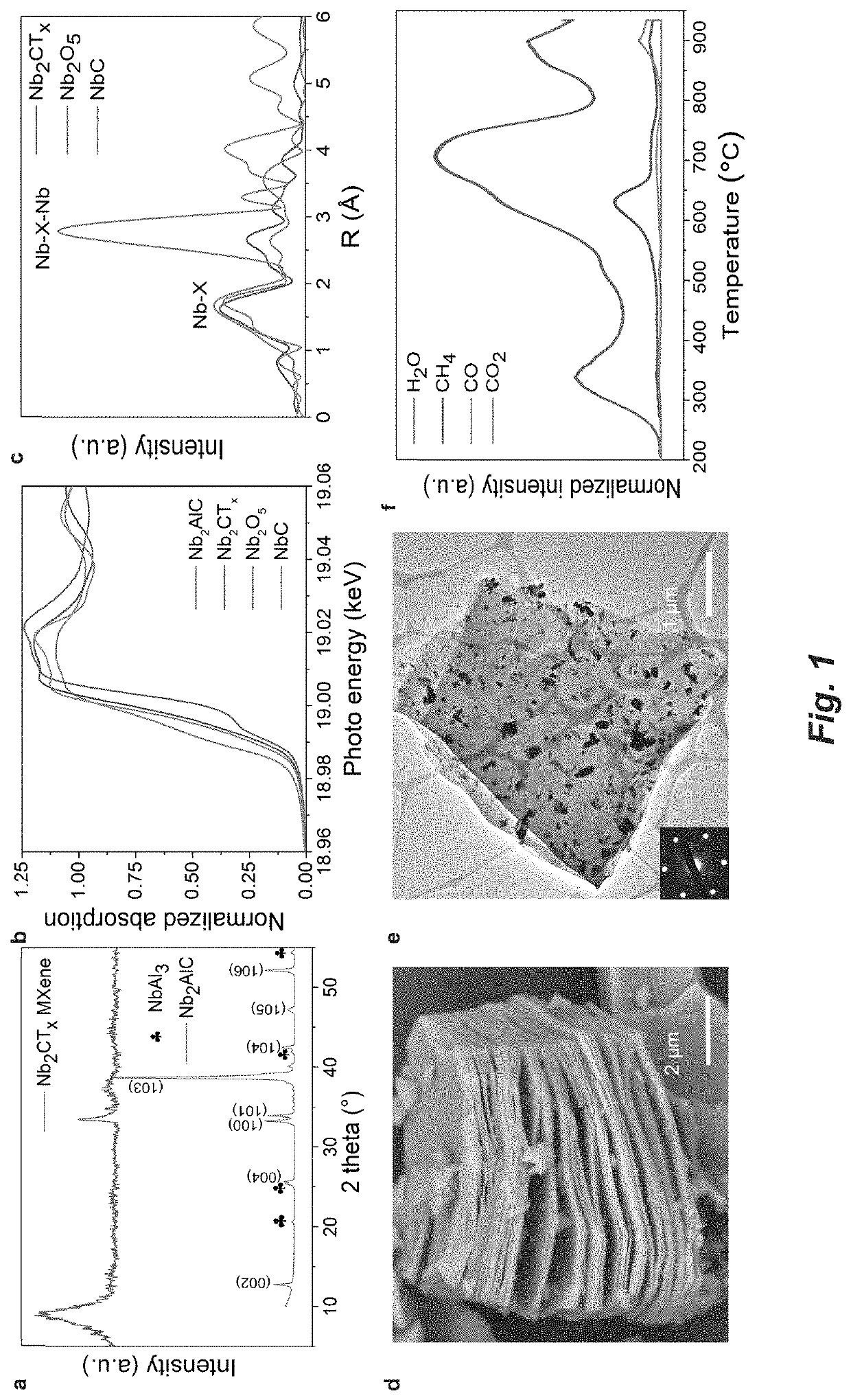

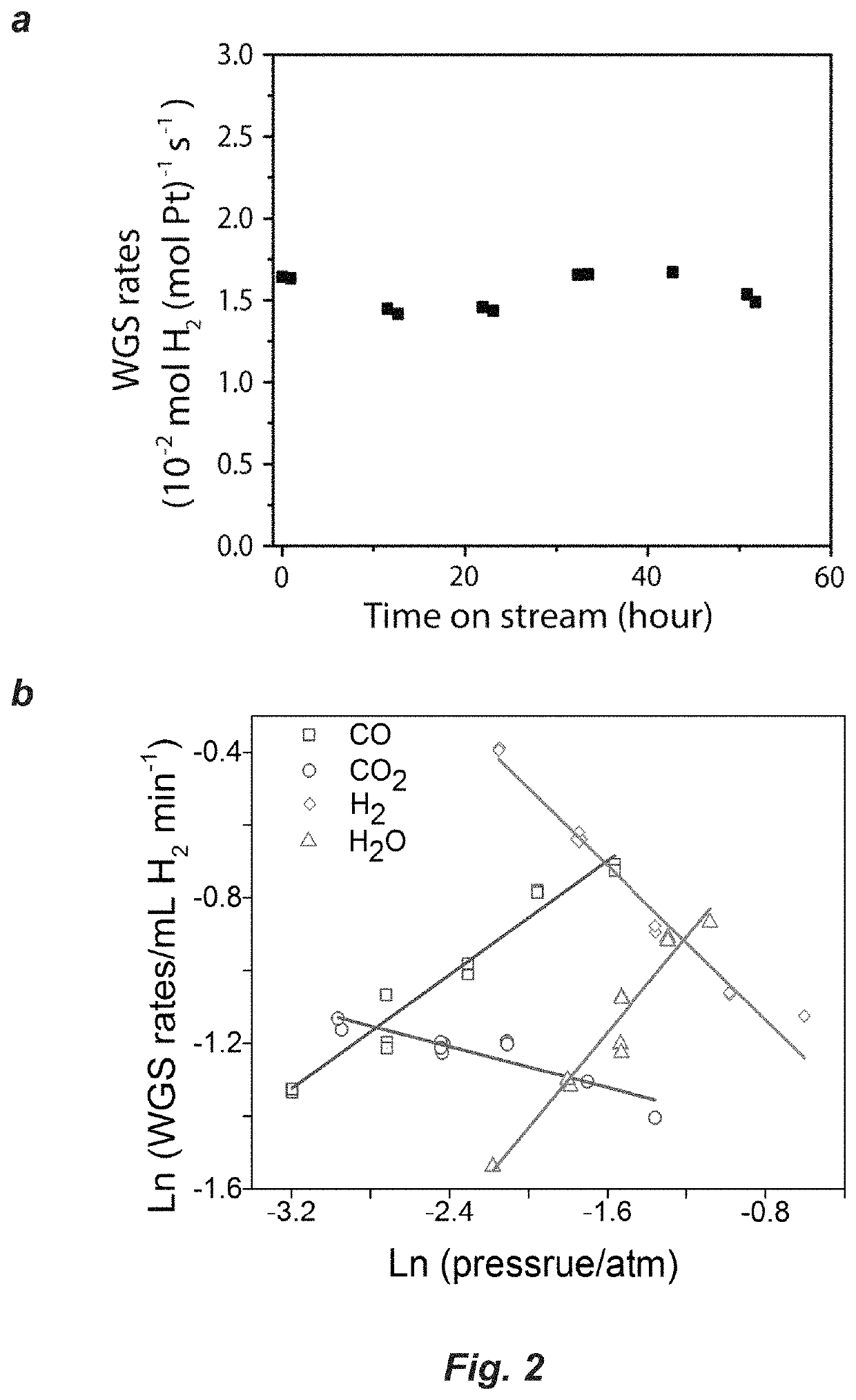

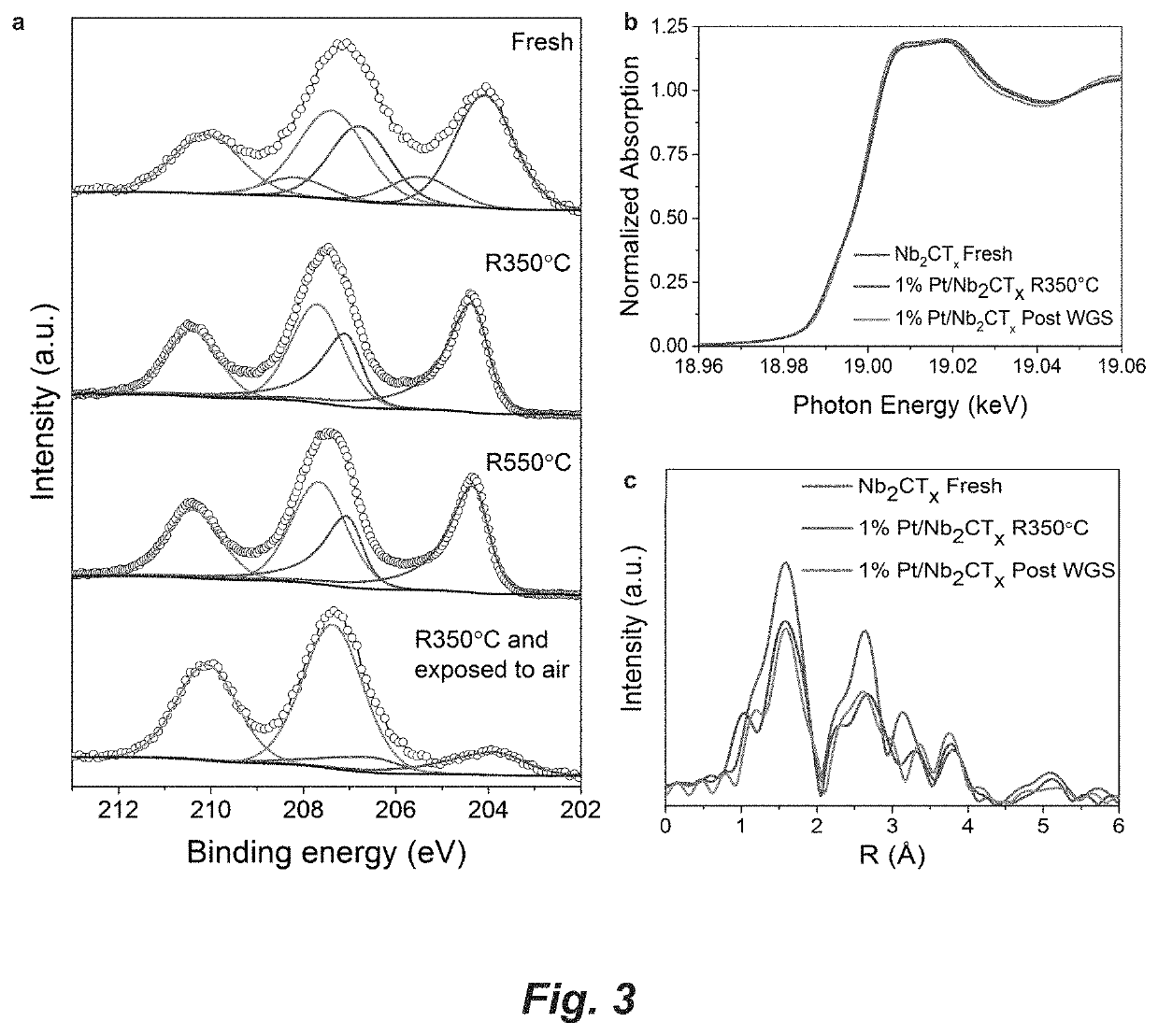

Two-dimensional metal carbide catalyst

ActiveUS10967363B1High rate and stabilityHigh temperature without loss of activityMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

Metal-support interaction offers electronic, geometrical and compositional effects to tune and maneuver catalytically active sites. Here we report the first example of a reactive metal support interaction (RMSI) between Pt and various MXenes, which are two-dimensional (2D) metal carbides, nitrides, or carbonitrides. The invention thus provides intermetallic Pt / MXene nanoparticle catalysts comprising platinum and MXene moieties. Pt3Ti and Pt3Nb intermetallic nanoparticle catalysts were prepared by RMSI of Pt nanoparticles supported on Ti3C2 and Nb2C MXenes. The intermetallic structures were verified by XAS, ARSTEM, and XPS. Experimental analysis showed that the extent of alloy formation is temperature dependent. Kinetics analysis revealed that in contrast to Pt / Al2O3, Pt supported by Nb2CTx exhibits weaker CO adsorption and the alloy-MXene interface shows enhanced ability of H2O dissociation for a water gas shift (WGS) reaction at 300° C. The catalysts also show improved selectivity and stability for alkane dehydrogenation compared to Pt.

Owner:IOWA STATE UNIV RES FOUND +1

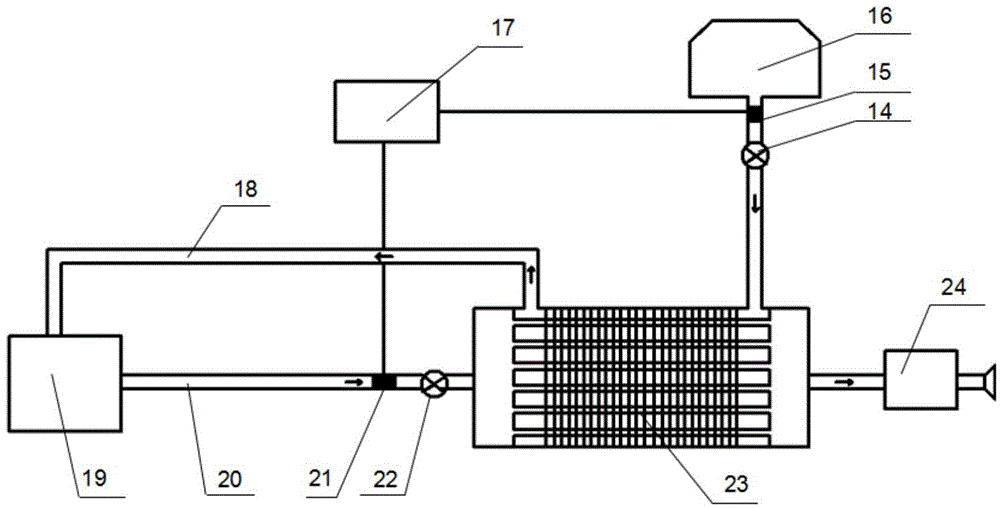

Vehicle-mounted hydrous ethanol low-temperature reforming hydrogen production method and device and application system

ActiveCN104555923AImprove heat transfer efficiencyAchieve mutual synergyHydrogenEnergy inputHydrogen selectivityFuel oil

The invention discloses a vehicle-mounted hydrous ethanol low-temperature reforming hydrogen production method and device and an application system. The method comprises the following steps: reforming hydrous ethanol into hydrogen-rich gas by virtue of two-stage catalysis by utilizing automobile engine waste heat, and introducing the hydrogen-rich gas into the automobile engine to perform the mixed combustion process with fuel oil. According to the device and application system, large catalyst contact surface area is generated by utilizing a two-stage honeycomb titanium mesh structure, and miniaturization of a reforming hydrogen production device is promoted, so that vehicle-mounted online hydrogen production is possible. According to the two-stage catalysis structure, the mutual synergistic effect of the catalyst is achieved, and the problems that the ethanol conversion efficiency is low, the hydrogen selectivity is low and the like due to use of a single catalyst are solved; and moreover, in a low-temperature environment, according to the mutual synergistic effect of basic catalysts, the sintering and carbon deposit problems of the catalyst are solved, and the service life of the catalyst is prolonged. By utilizing the automobile tail gas waste heat, the automotive online hydrogen doping aim is achieved, the combustion efficiency of fossil fuel is improved, and the emission amount of harmful substances of the automobile engine is reduced.

Owner:WUHAN UNIV OF TECH

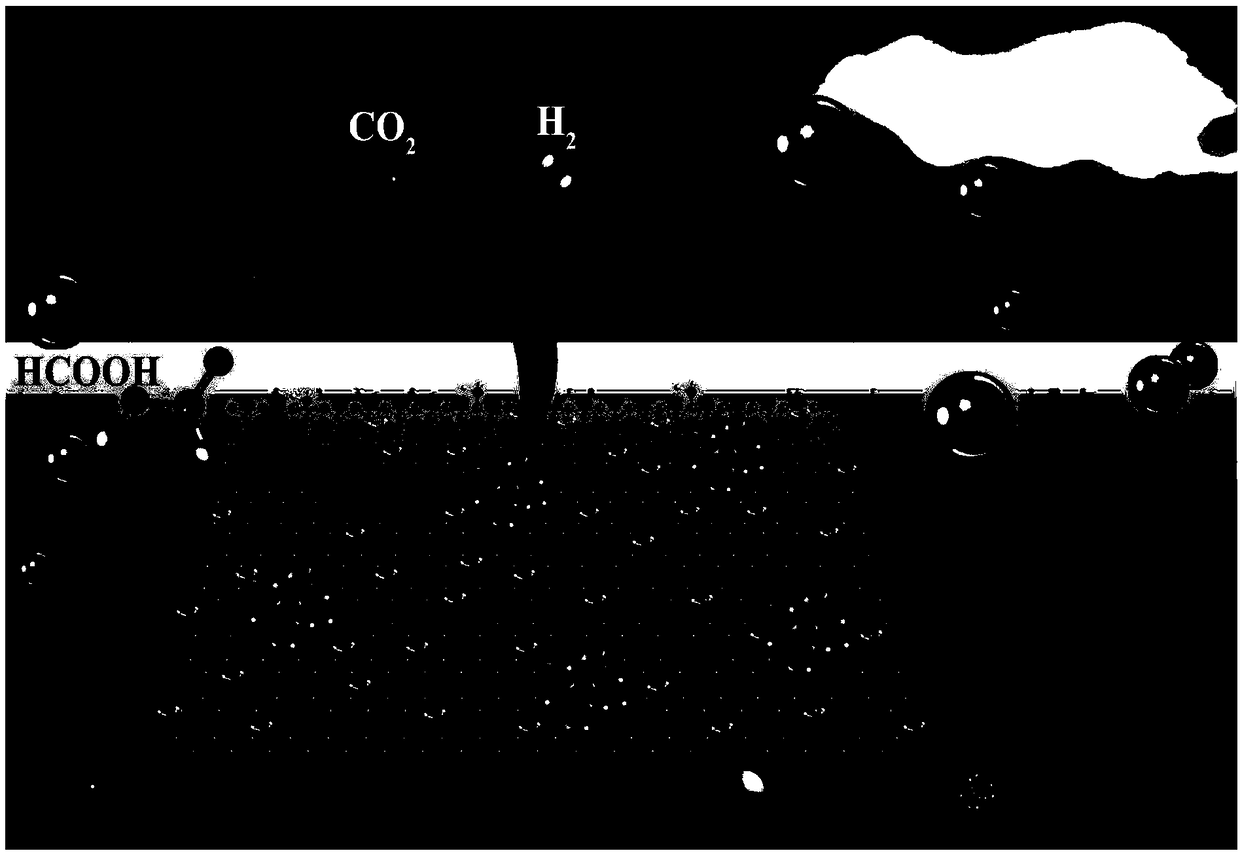

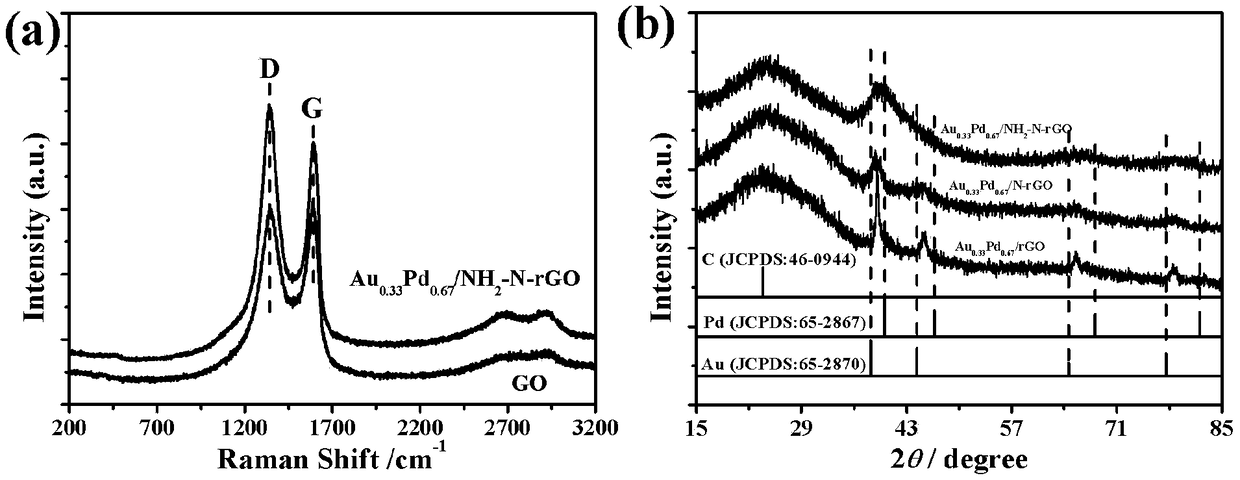

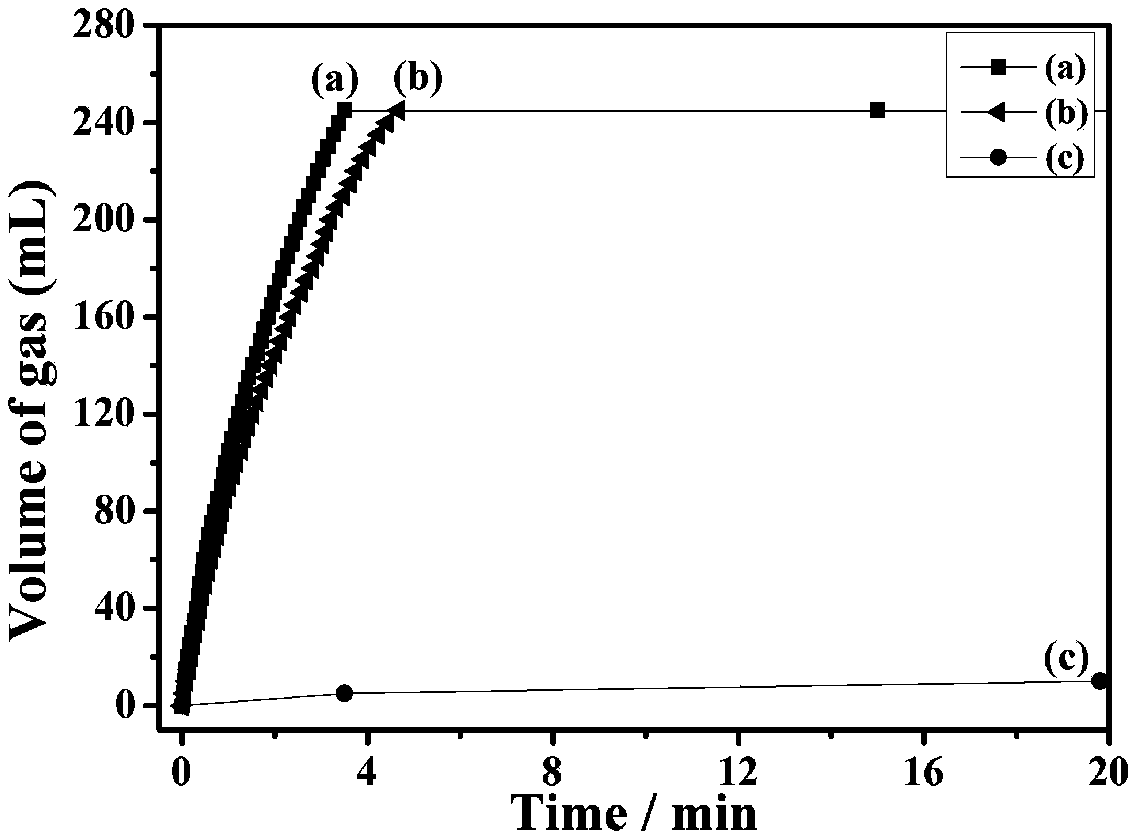

Functional graphene loaded gold palladium nano-catalyst as well as preparation and application thereof

InactiveCN108855185AShort synthesis timeHigh catalytic activityHydrogenPhysical/chemical process catalystsNano catalystHydrogen selectivity

The invention provides a functional graphene loaded gold palladium nano-catalyst as well as preparation and application thereof. A one-step fast reduction method is used; a functional graphene loadedgold palladium nano-catalyst is fast synthesized at room temperature; the advantages that the synthesis time is short, the operation is simple and convenient, and the like are realized; the dispersionperformance of gold palladium nanometer particles on graphene carriers (NH2-N-rGO) modified by -NH2-N is obviously improved; the particle dimension (0.3 to 2.8nm) of metal NPs is effectively reduced;the synthesized AuPd / NH2-N-rGO catalyst is used for catalyzing methanoic acid water solution for room temperature decomposition for hydrogen preparation. The catalyst still has high catalysis activity under the condition of no additive existence; the conversion rate is 100 percent; the hydrogen selectivity is 100 percent; the circulation stability is high; the catalysis activity is high.

Owner:JILIN UNIV

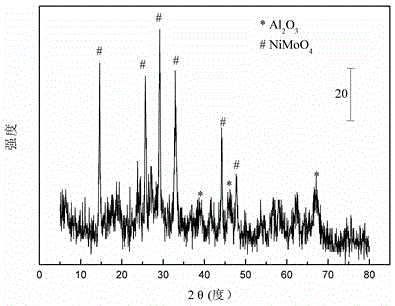

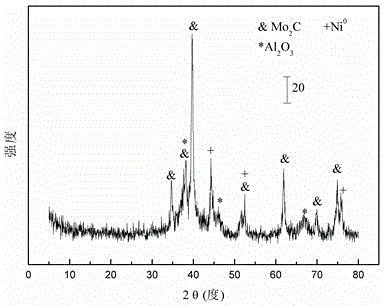

Nickel-molybdenum carbide composite catalyst for preparing synthesis gas through dry reforming of methane

InactiveCN105107515AImprove thermal stabilityInhibit migrationHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogen selectivityCarbonization

The invention relates to a nickel-molybdenum carbide composite catalyst for preparing a synthesis gas through dry reforming of methane, and aims at solving the problem that catalyst deactivation is caused by the situation that active components in the conventional nickel-based catalyst and molybdenum-based catalyst are easy to oxidize and sinter during the process of preparing the synthesis gas through dry reforming of methane. The preparation method of the nickel-molybdenum carbide composite catalyst comprises the following steps: a nickel molybdenum oxide precursor is synthesized through a one-step synthesis urea combustion method by adopting the double components, namely nickel and molybdenum; the virgin gas is subjected to dry reforming through methane, and an Ni-Mo2C composite structure is compounded in situ; carbonization-oxidation circulation of Mo2C is established during the process of dry reforming of methane at the same time, so as to obtain the nickel-molybdenum carbide composite catalyst which is sintering-resistant, oxidation-resistant and stable in structure. According to the nickel-molybdenum carbide composite catalyst, the stability and hydrogen selectivity of the process of preparing the synthesis gas through dry reforming of methane are improved; the chemical composition of the catalyst provided by the invention is Nia (Mo2C)b (Al2O3 )c in which the a is 0.09-0.19, the b is 0.03-0.10 and the c is 0.75-0.88.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Lanthanum calcium iron cobalt calcium titanium ore type catalyst for oxidizing and reforming ethanol and method for preparing catalyst

InactiveCN102941099AHigh catalytic activityImprove stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogen selectivityEvaporation

The invention discloses a lanthanum calcium iron cobalt calcium titanium ore type catalyst for oxidizing and reforming ethanol and a method for preparing the catalyst. The chemical formula of the catalyst is La1-xCaxFe1-yCoyO3, wherein the x is in a range of 0.1 to 0.5, and the y is in a range of 0.1 to 0.5. The method for preparing the catalyst includes that corresponding metal salt is dissolved in deionized water according to a molar ratio of metal ions to be prepared into a salt solution, citric acids are added according to a molar ratio of the citric acids and the metal ions, citric acids and polyethylene glycol 400 are added in a salt solution according to a molar ratio of the citric acids and the polyethylene glycol, uniform complexes are obtained after stirring, and then the complexes are subjected to evaporation concentration, drying and calcining to obtain the lanthanum calcium iron cobalt calcium titanium ore type catalyst. The lanthanum calcium iron cobalt calcium titanium ore type catalyst for oxidizing and reforming ethanol and the method for preparing the catalyst have the advantages that the manufacture process is simple, and the obtained catalyst has good reactivity and high hydrogen selectivity, and excellent stability and anti-carbon deposition capabilities simultaneously.

Owner:TIANJIN UNIV

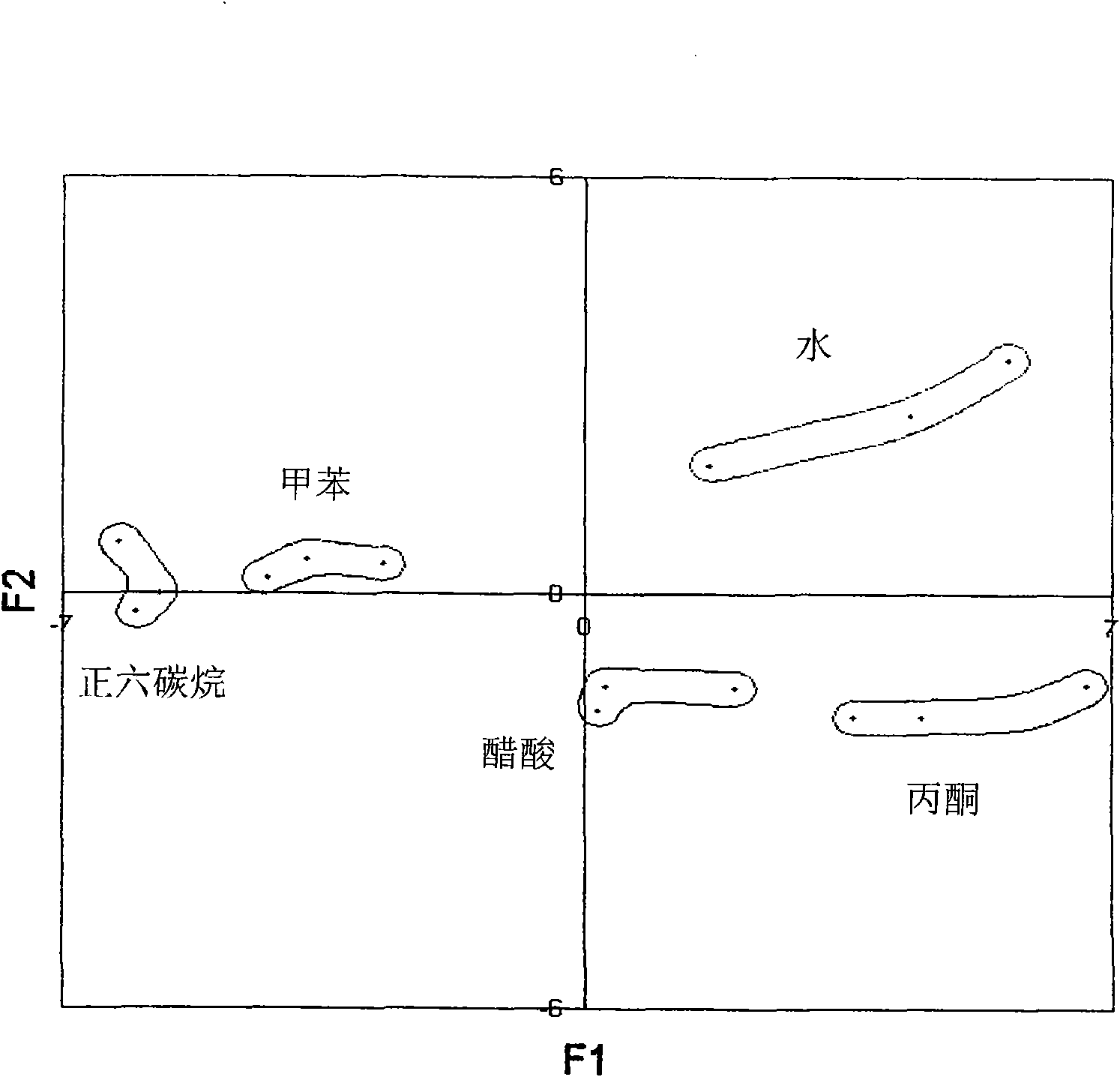

Sensor instrument system including method for detecting analytes in fluids

ActiveCN103293198AReduce manufacturing costOverall small sizeMaterial resistanceDesorptionHydrogen selectivity

A sensor instrument system and a method for detecting and identifying analytes in fluids of a region comprising a local sensor instrument and remote central station are disclosed. The instrument is composed of a core technology employing a single sensor having two electrodes operated by an electrical frequency sweeping to generate two sets of patterned electrical information from a single measurement. The instrument further includes a data transmission module and a GPS receiver module. The central station is connectd with a plurality of local information sites which can wirelessly transmit and receive information in different areas in the region, so that information transmitted by the sensor instrument can be received by the central station through the local sites. The core technology further comprises a reference sensor for eliminating background influence, a temperature programming to control adsorption and desorption of analytes, and usage of all kinds of adsorbent materials having chemical selectivity including the hydrogen selectivity to enhance detection and identification of analytes in fluids.

Owner:孙一慧 +1

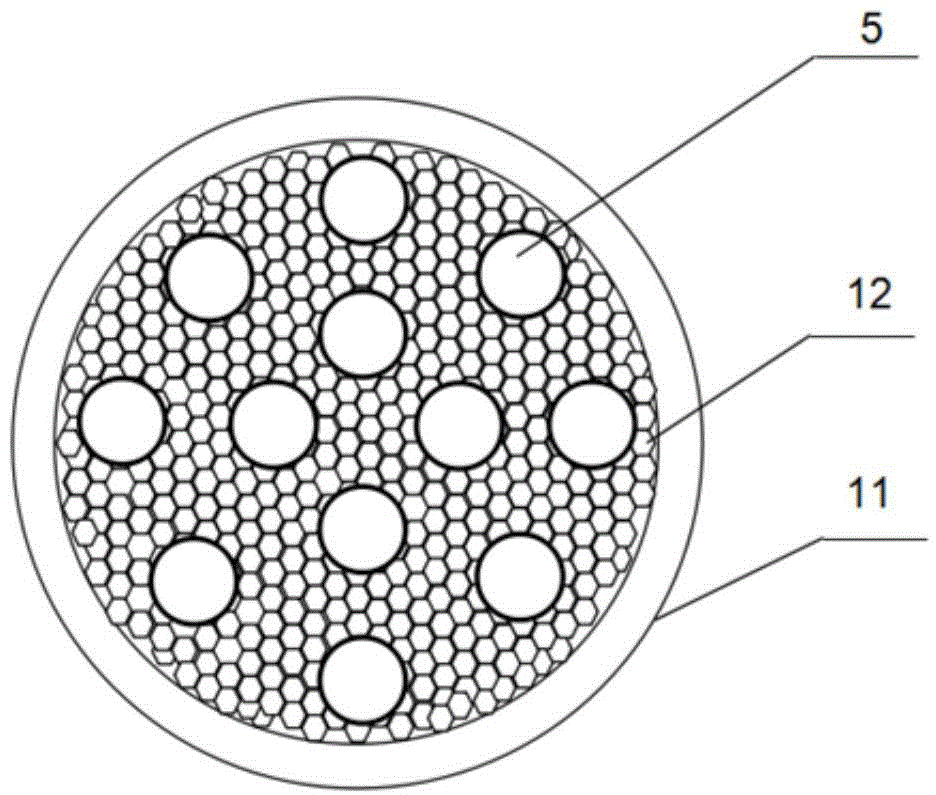

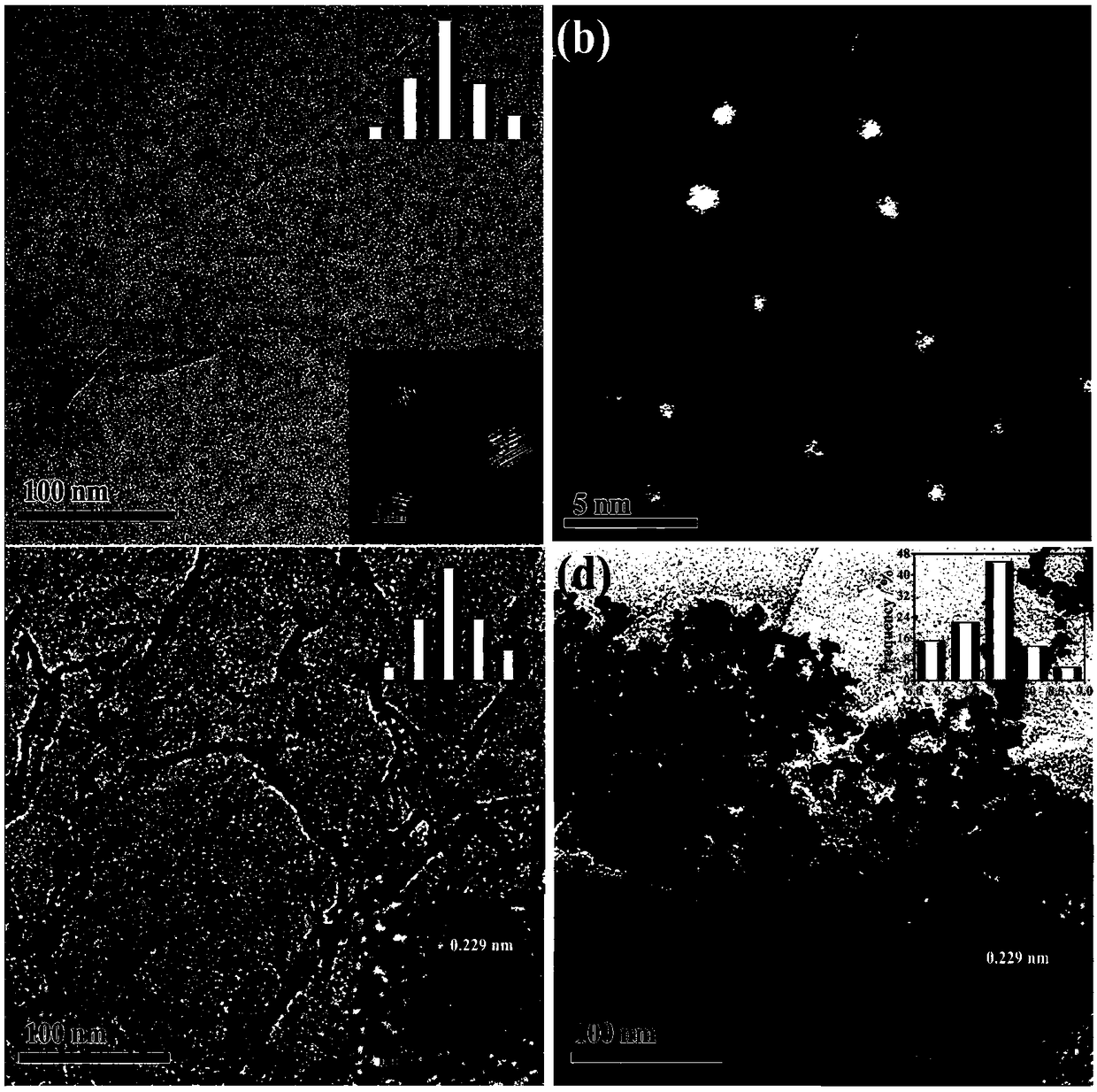

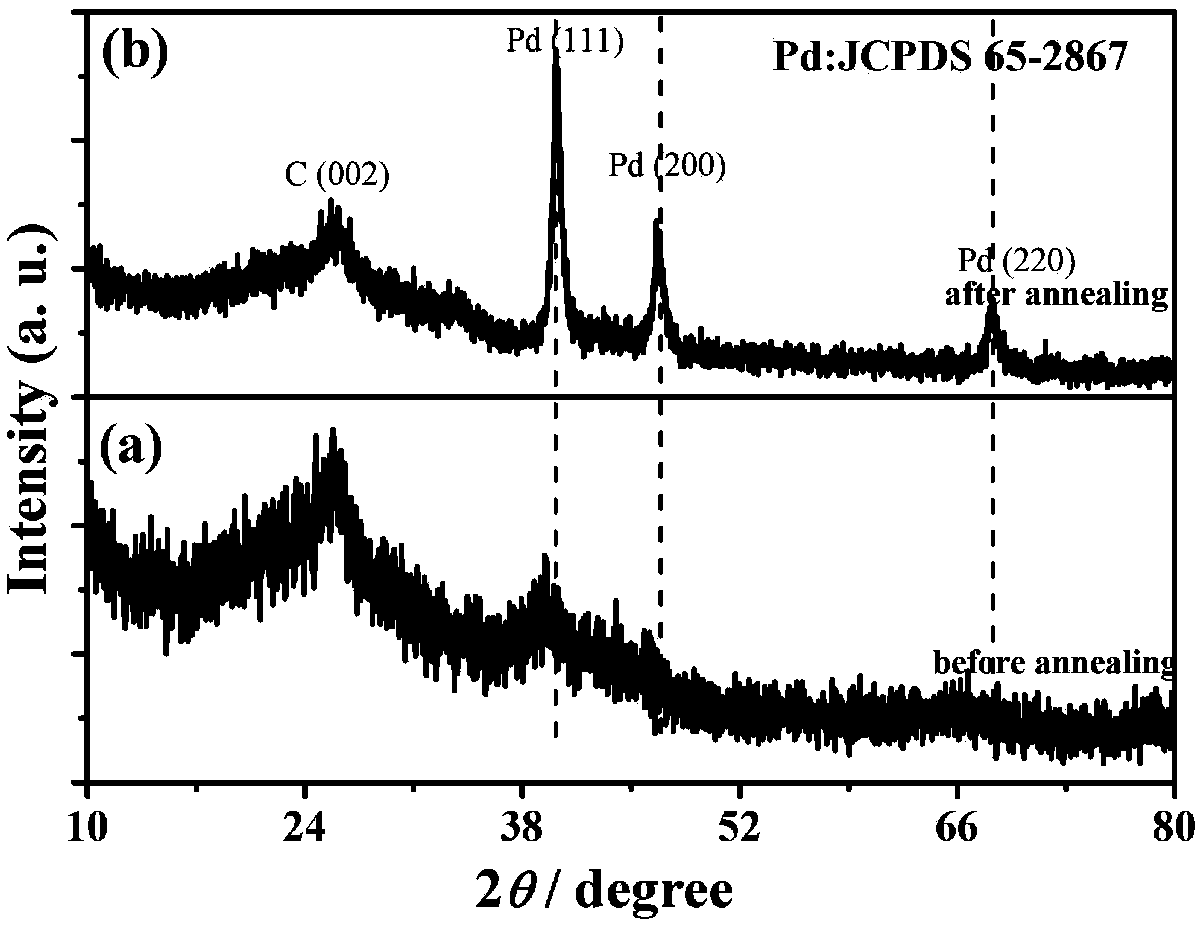

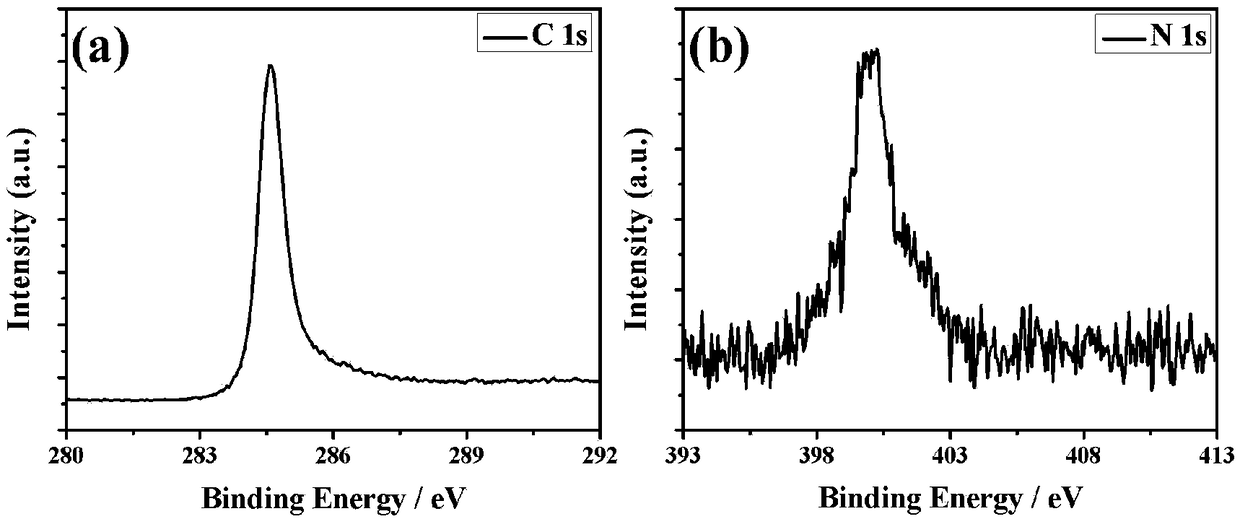

Functionalized carbon nanotube loaded palladium nano-catalyst and preparation and application thereof

ActiveCN108126695AHigh catalytic activityHigh activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsDispersityNano catalyst

The invention relates to a functionalized carbon nanotube loaded palladium nano-catalyst and preparation and application of the functionalized carbon nanotube loaded palladium nano-catalyst. The functionalized carbon nanotube loaded palladium nano-catalyst is characterized in that the functionalized carbon nanotube loaded palladium nano-catalyst is synthesized through a one-step rapid reduction method, and the application of the functionalized carbon nanotube loaded palladium nano-catalyst to preparation of hydrogen by catalyzing an aqueous solution of formic acid. The functionalized carbon nanotube loaded palladium nano-catalyst has the beneficial effects that the functionalized carbon nanotube loaded palladium nano-catalyst is synthesized through the one-step rapid reduction method at the room temperature, the functionalized carbon nanotube loaded palladium nano-catalyst has the advantages of short synthesis time, convenient operation and the like, the dispersity of palladium NPs onan F-CNTS substrate is obviously improved, and the particle size of the metal NPs is reduced; the synthesized Pd / F-CNTS catalyst is used to catalyze the aqueous solution of formic acid to decompose and make hydrogen at the room temperature, and the catalyst still keeps very high catalytic activity, 100% conversion rate, 100% hydrogen selectivity and better cycling stability without any additive.

Owner:JILIN UNIV

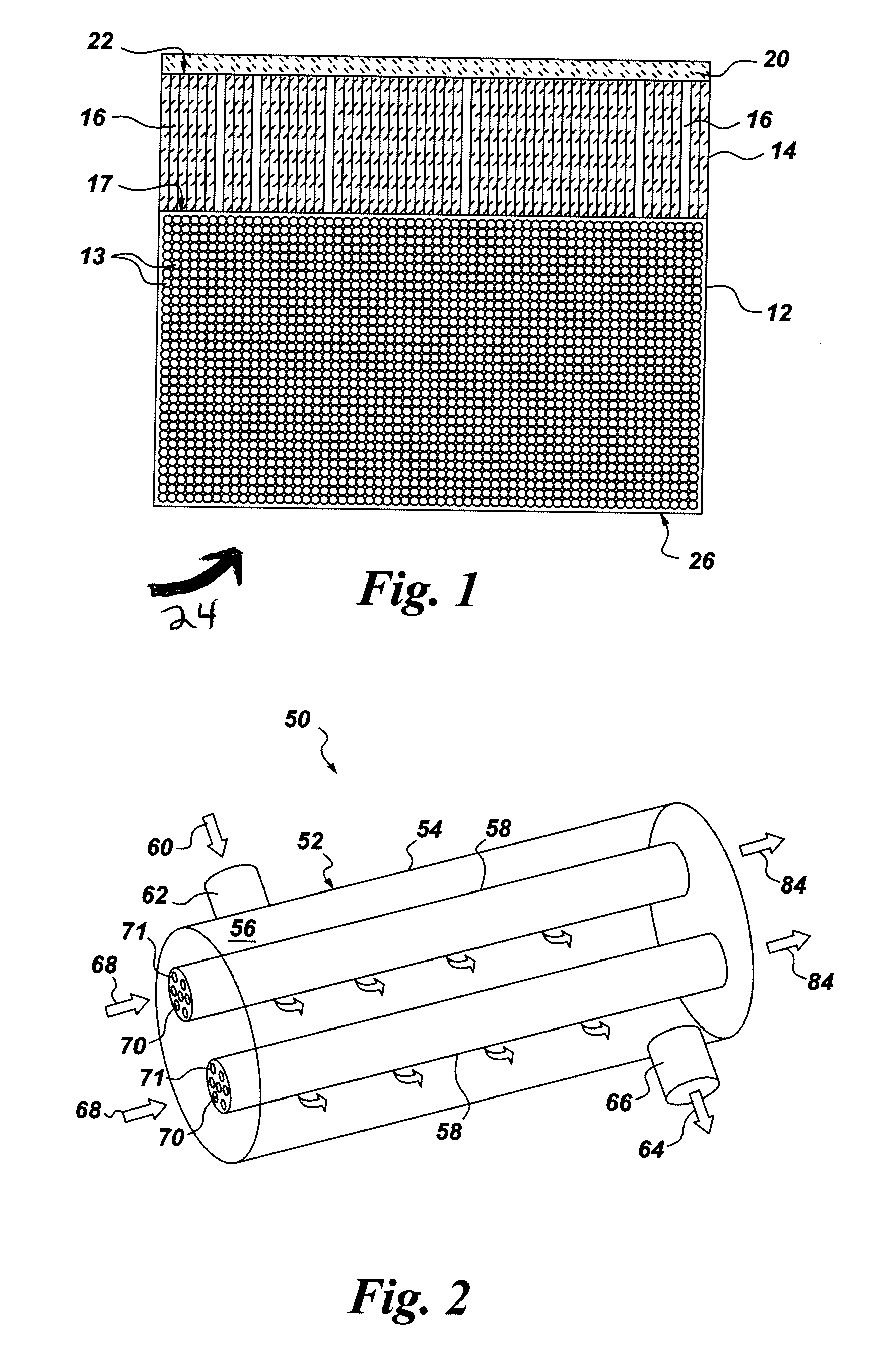

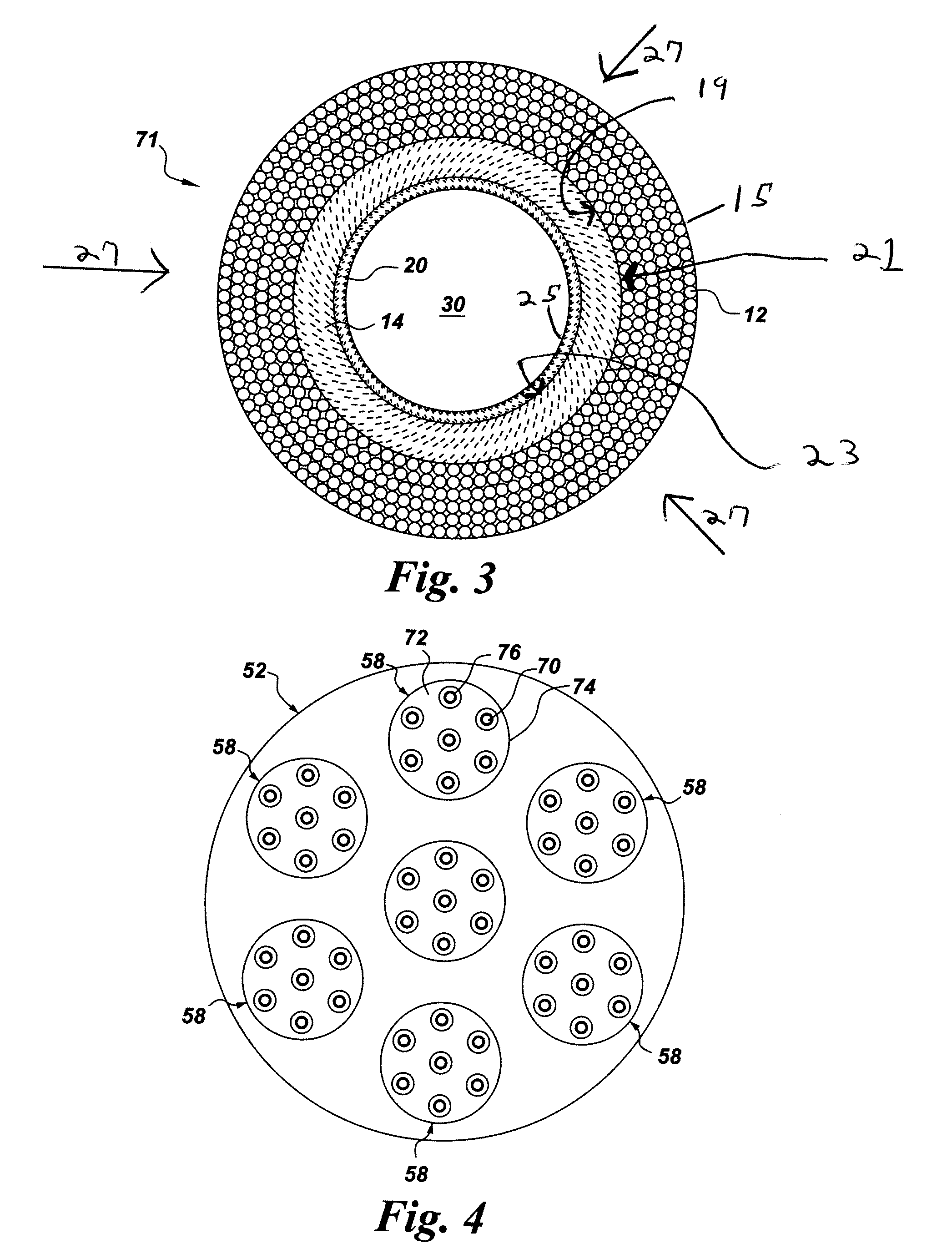

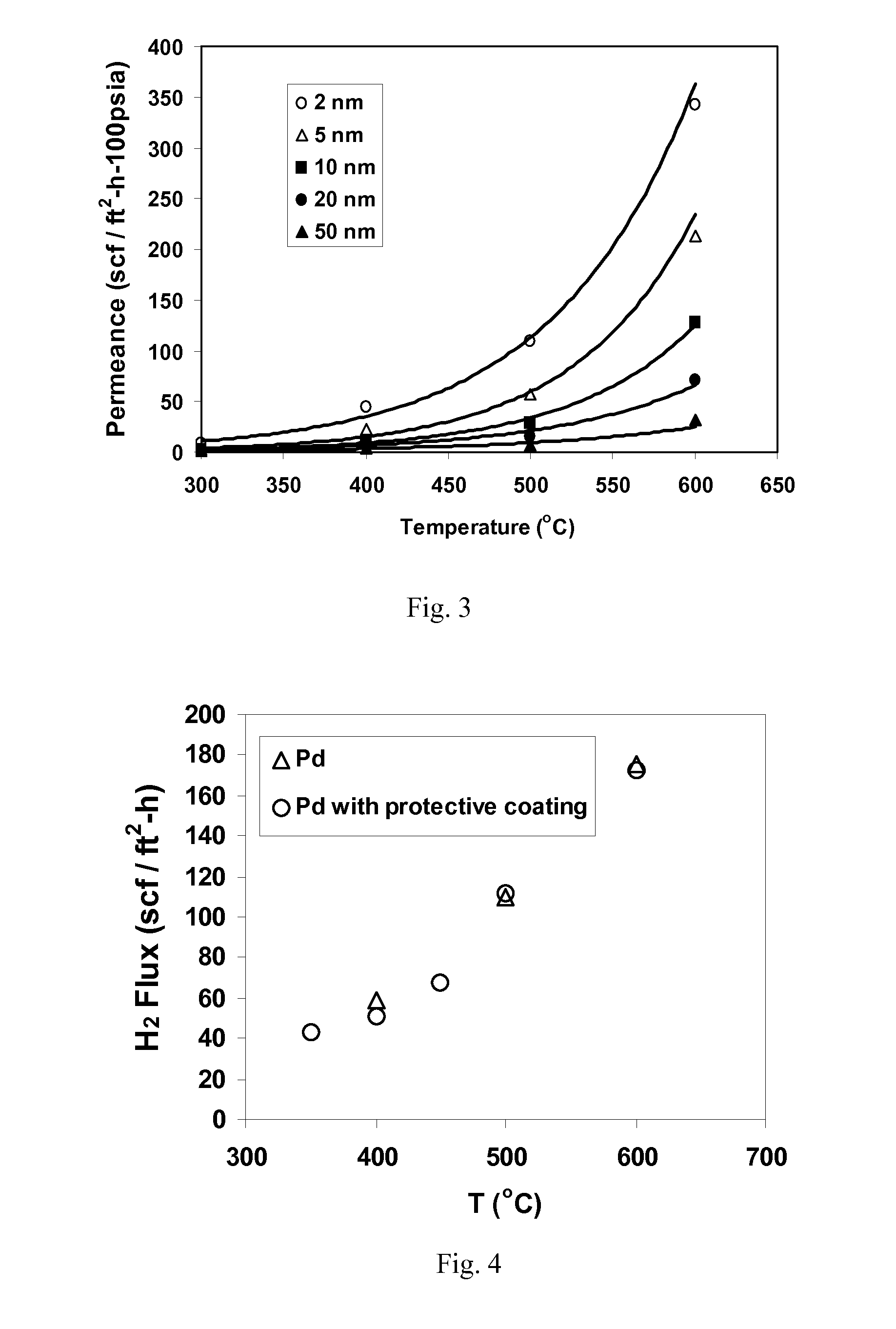

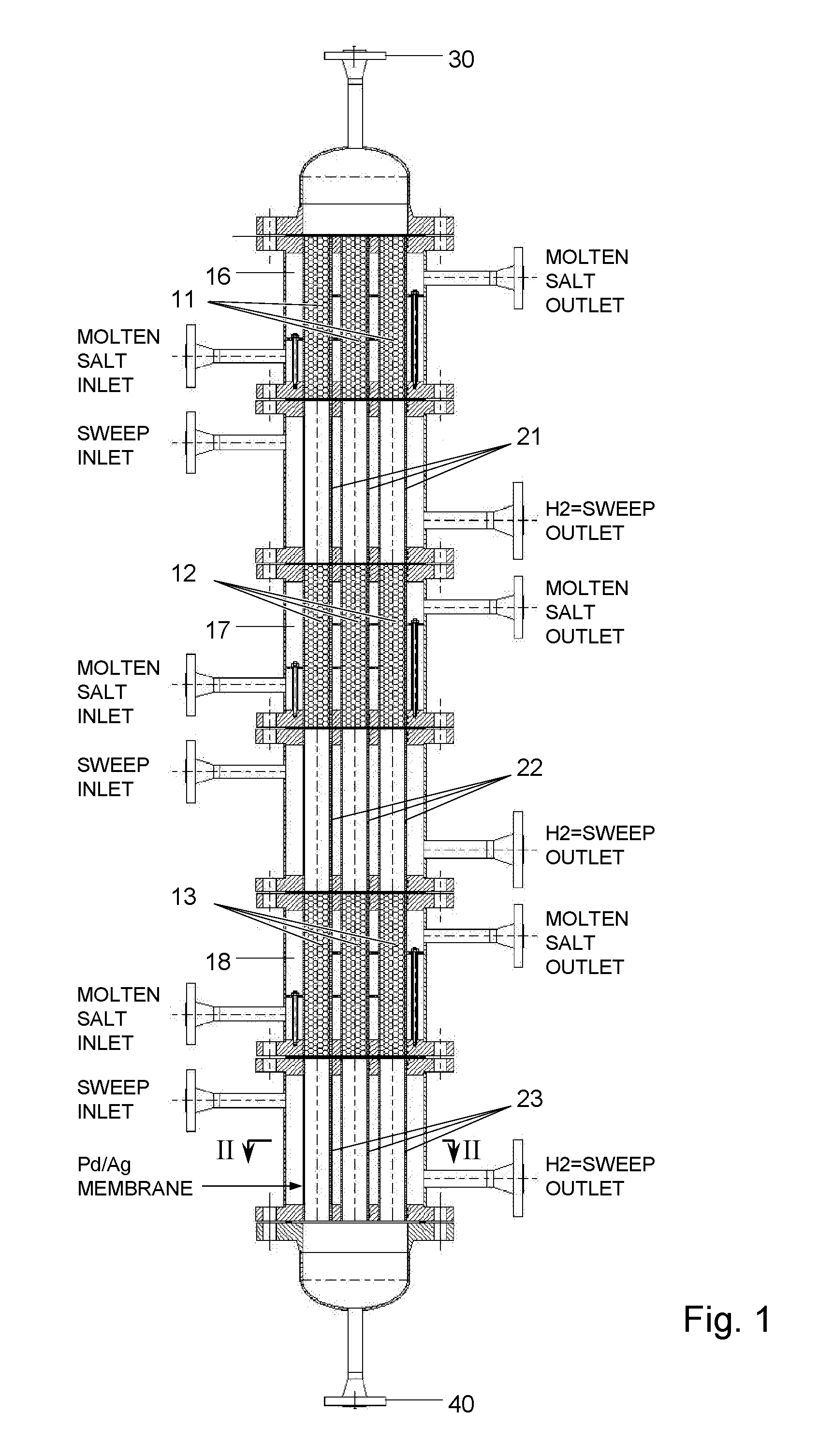

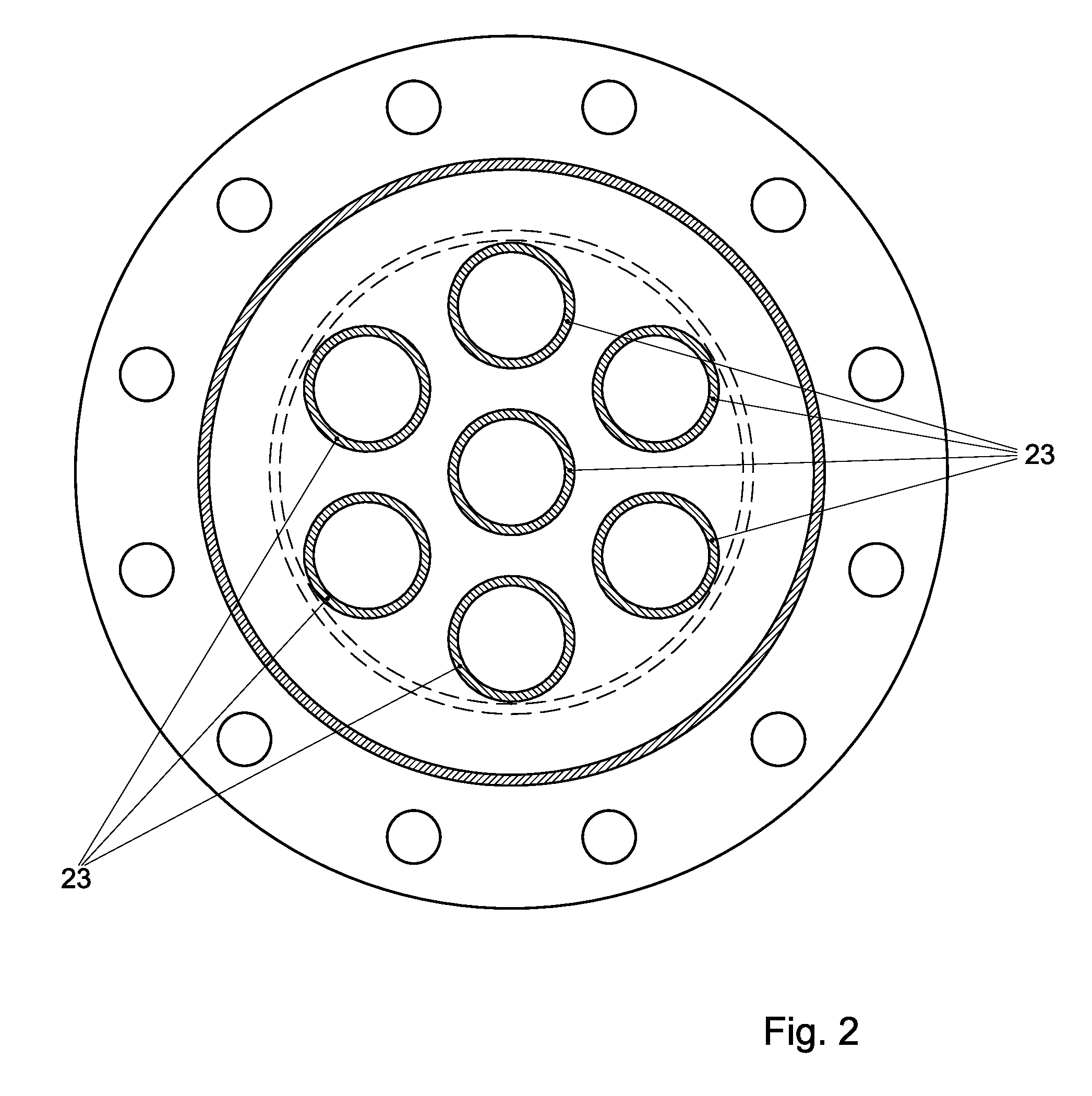

Steam methane reforming reactor with hydrogen selective membrane

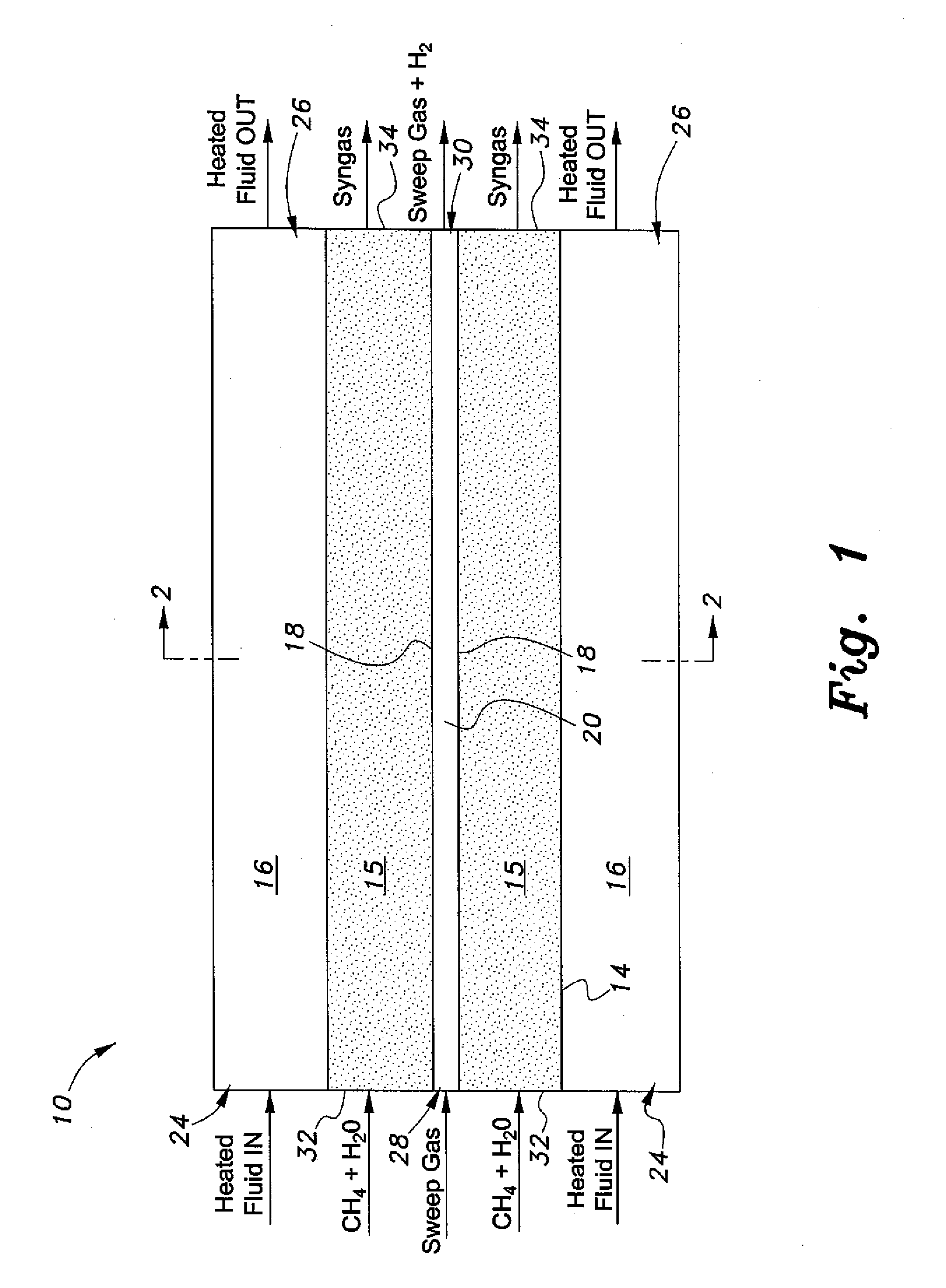

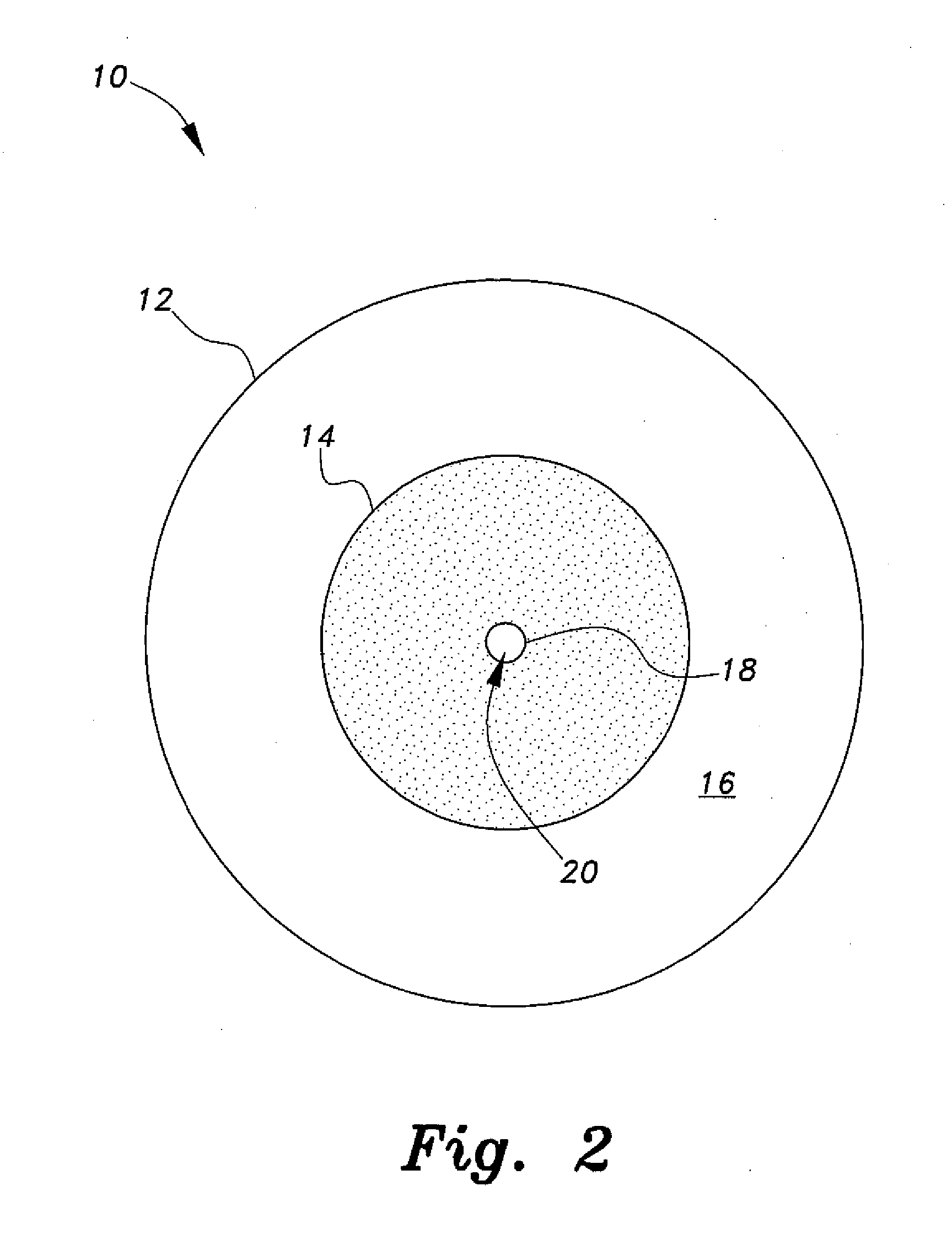

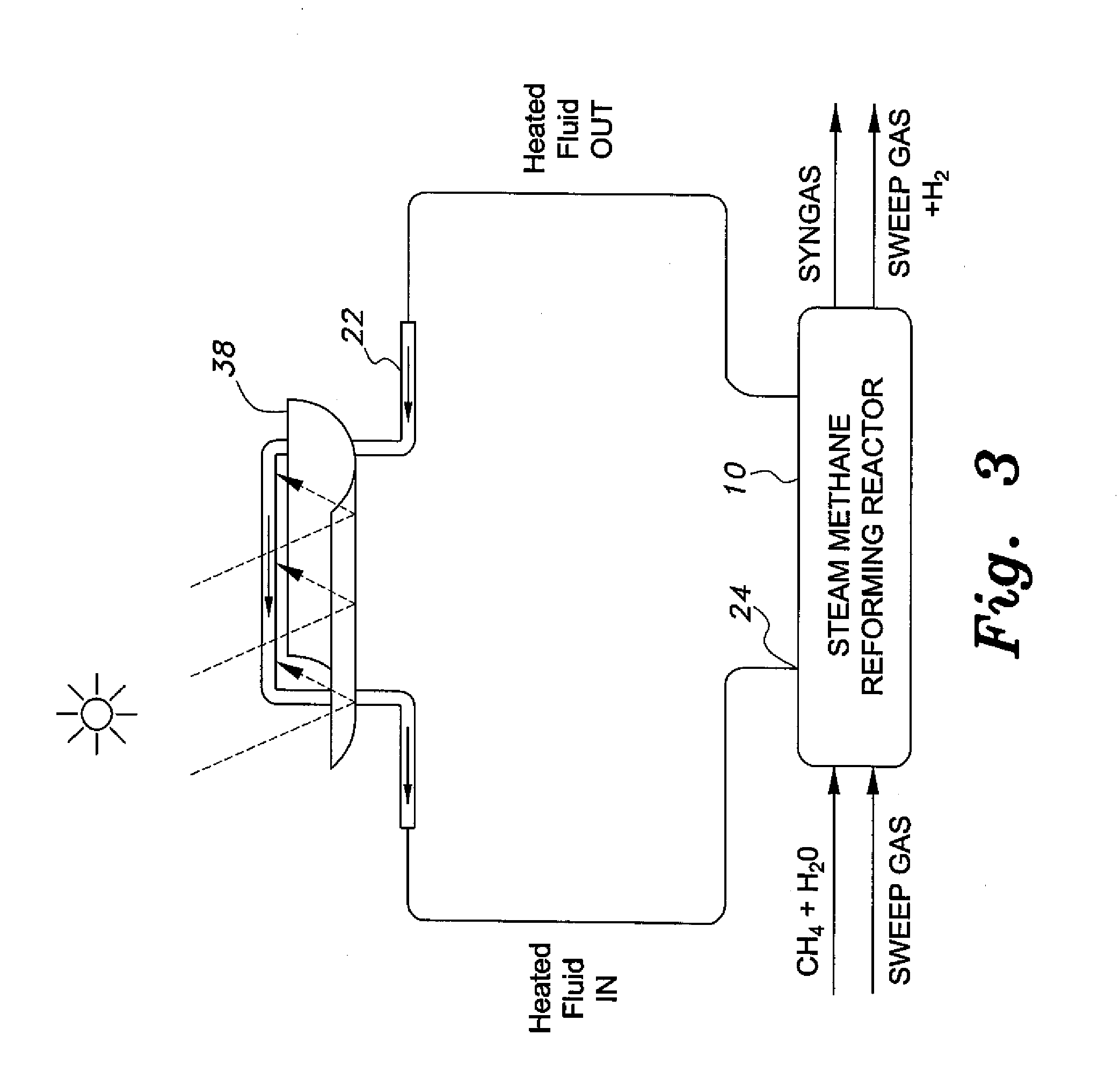

InactiveUS20160340187A1Readily apparentHydrogenChemical/physical/physico-chemical stationary reactorsHydrogenHydrogen selectivity

The steam methane reforming reactor includes a substantially cylindrical housing or shell and a tube disposed concentrically within the substantially cylindrical shell. The tube includes one or more catalysts. A hydrogen selective membrane extends through a central portion of the tube. The hydrogen selective membrane can be formed from a hydrogen selective material such as a palladium alloy. The membrane defines a central passage or permeate zone. A feed zone including the catalyst extends around the permeate zone. A sweep gas, such as air, nitrogen or the like, may be injected in the permeate zone, via an inlet, and pass through the permeate zone, exiting via an outlet. An annular heated fluid passage is defined between an outer surface of the tube and an inner surface of the substantially cylindrical housing or shell. A heating medium may be injected into the heated fluid passage to pass therethrough.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

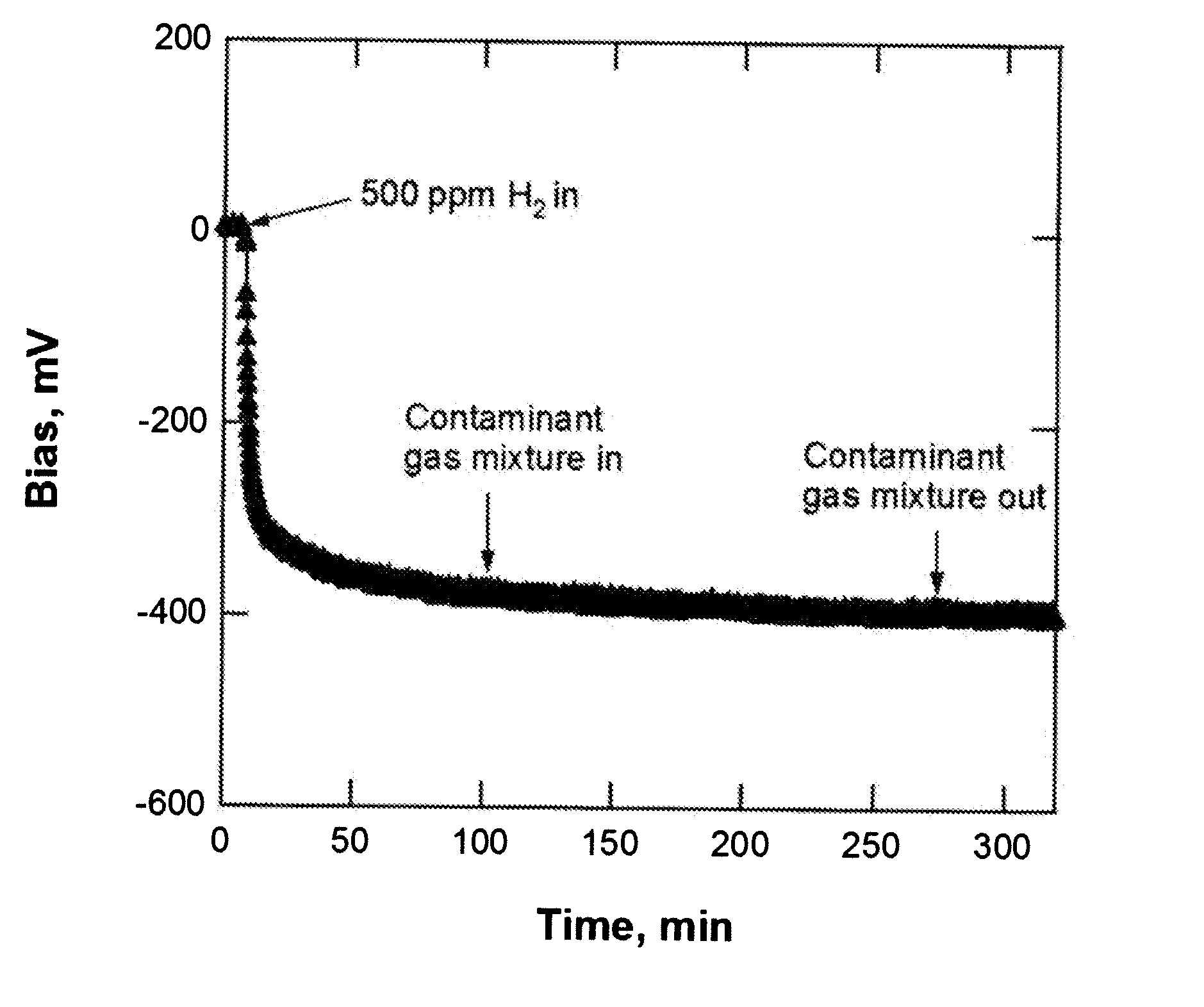

Hydrogen selective protective coating, coated article and method

ActiveUS20120325087A1Improve hydrogen permeabilitySemi-permeable membranesIsotope separationPollutantCermet

Hydrogen selective coatings, coated articles and methods for their formation and for hydrogen separation or purification. The coatings are formed by atomic layer deposition of suitable metal oxides with desirable hydrogen activation energy or hydrogen flux, e.g., silicon dioxide, and can be borne on a nonporous, thin-film metal or cermet substrate, e.g., a palladium sheet or layer. The coated substrate may include a porous support for the sheet or layer. The coated article may be used as a purification membrane and the coating can protect the metal layer from contaminants in the gas or process stream from which hydrogen is being purified. In some embodiments, the coated article can provide such protection at elevated temperatures in excess of 300° C.; and in other embodiments, can provide protection at temperatures in excess of 600° C. and even in excess of 800° C.

Owner:T3 SCI

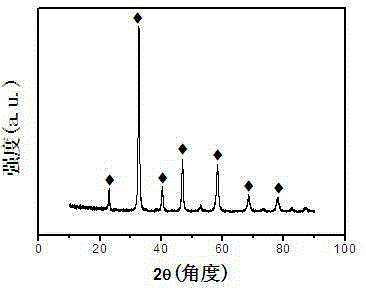

Ceramic catalyst taking red mud waste residues as carrier as well as preparation method and application thereof

ActiveCN111138167AAvoid secondary pollutionSolve the shortageCatalyst carriersHydrogenAluminium industryPtru catalyst

The invention discloses a ceramic catalyst taking red mud waste residues as a carrier as well as a preparation method and an application thereof. According to the catalyst, ceramic spherical particlesprepared from polluting red mud waste residues discharged when aluminum oxide is extracted in the aluminum production industry, aluminum source powder and a forming agent solution are used as carriers, molybdenum oxide is used as a catalytic active component, and zirconium oxide is used as a cocatalyst. The preparation method comprises the following steps: preparing a ceramic spherical particle carrier from red mud waste residues, aluminum source powder and a forming agent solution through crushing, burdening, granulating, forming, calcining and other processes; dipping the ceramic sphericalparticle carrier in an active component and co-catalytic ion precursor composite solution; drying the carrier, and roasting the carrier to obtain the ceramic-based reforming hydrogen production catalyst. The reforming hydrogen production catalyst not only can realize resource utilization of industrial waste residue red mud, but also is high in H2 selectivity of reforming formaldehyde to produce hydrogen at a low temperature, is simple in preparation process, and has a wide market application prospect.

Owner:南京环福新材料科技有限公司

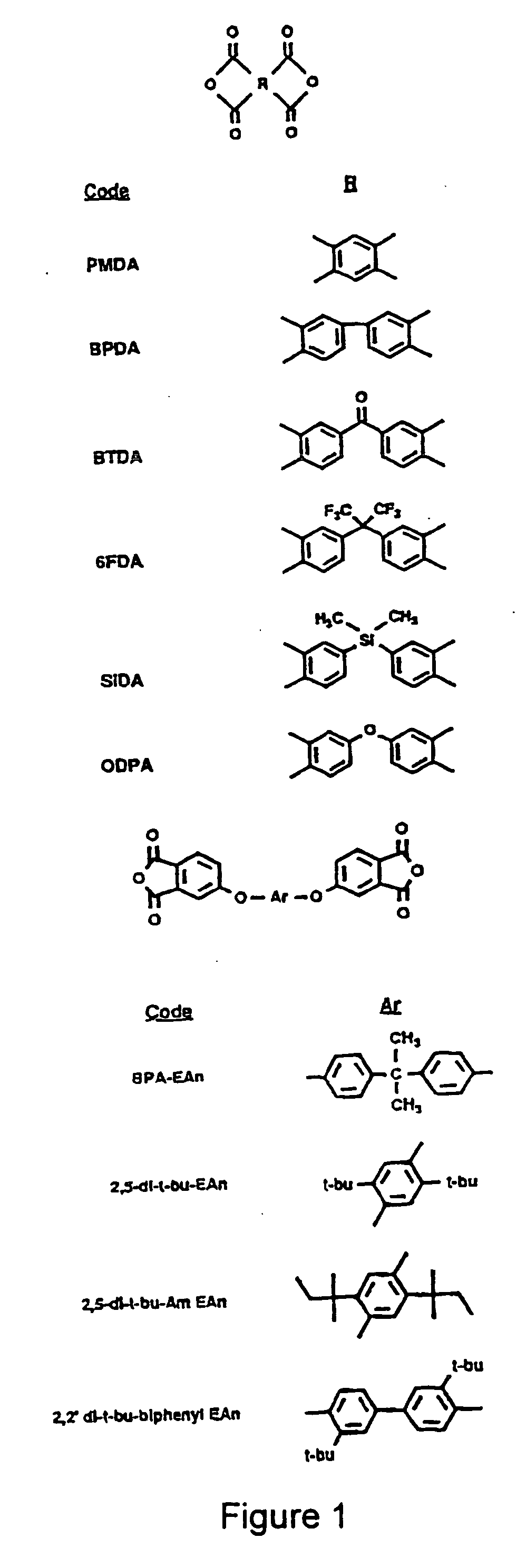

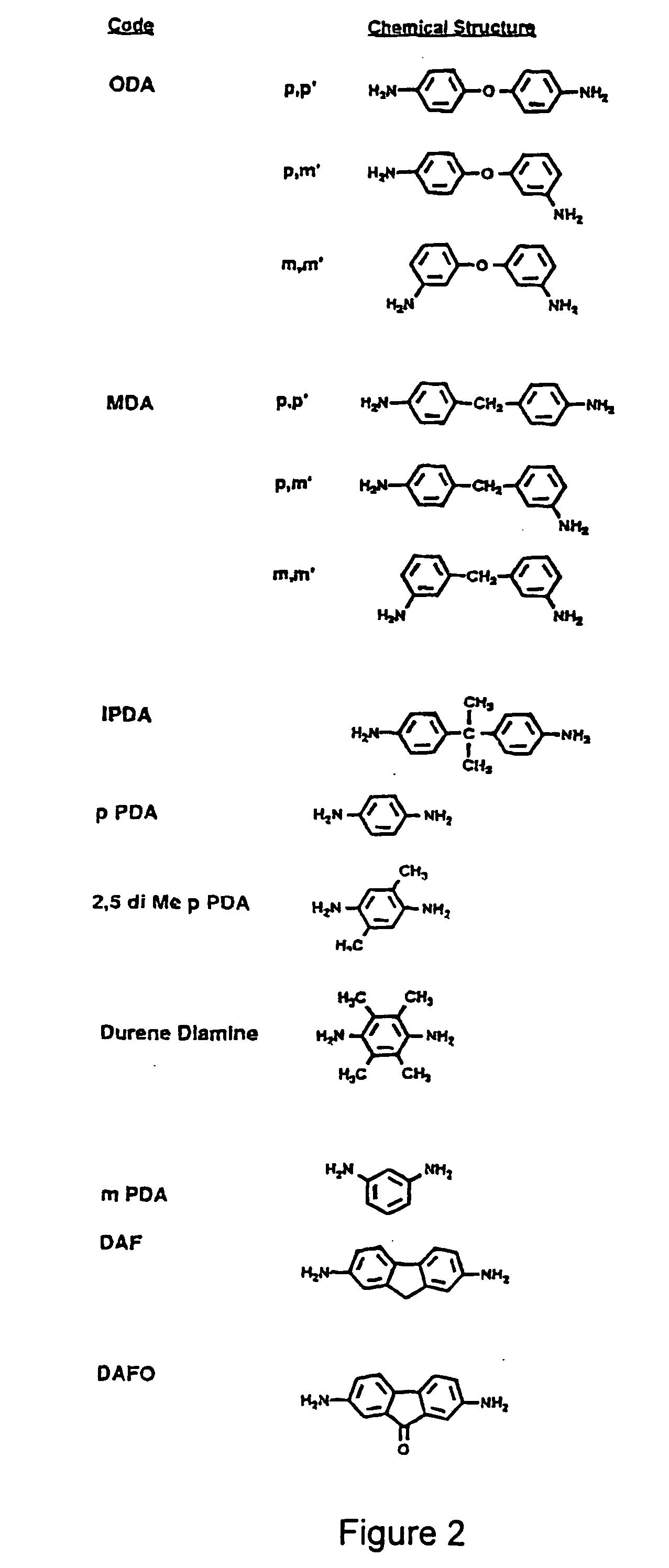

Mis-based sensors with hydrogen selectivity

InactiveUS20060196246A1Reduced responseRemarkable effectAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansHydrogenHydrogen selectivity

The invention provides hydrogen selective metal-insulator-semiconductor sensors which include a layer of hydrogen selective material. The hydrogen selective material can be polyimide layer having a thickness between 200 and 800 nm. Suitable polyimide materials include reaction products of benzophenone tetracarboxylic dianhydride 4,4-oxydianiline m-phenylene diamine and other structurally similar materials.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY +1

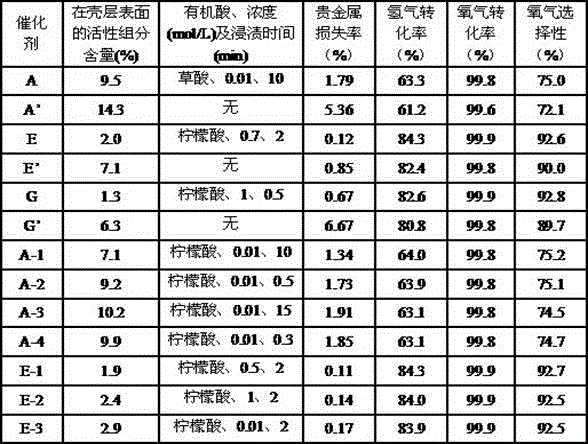

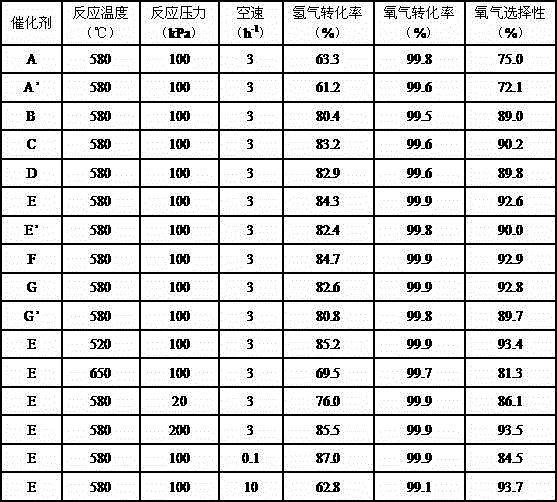

Thin shell type catalyst and preparation method thereof

ActiveCN104437473AImprove dispersionMolecular sieve catalystsHydrocarbonsThin shellsHydrogen selectivity

The invention relates to thin shell type catalyst of which the active ingredients are non-uniformly distributed in the shell layer. The problem in the prior art that precious metals in the shell layer are lost because the shell layer of the thin shell type catalyst is worn is mainly solved. With the adoption of the technical scheme, the thin shell type catalyst of which the active ingredients are non-uniformly distributed in the shell layer comprises an inert carrier core, and a porous material shell layer bound to the core, wherein at least one platinum metal active ingredient is loaded to the shell layer; and the content of the platinum metal active ingredients on the surface of the shell layer is lower than the content at the inner side of the shell layer. The problem is well solved, and the catalyst can be used for hydrogen selectivity oxidizing reaction in the process of producing unsaturated hydrocarbons through dehydrogenation of aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

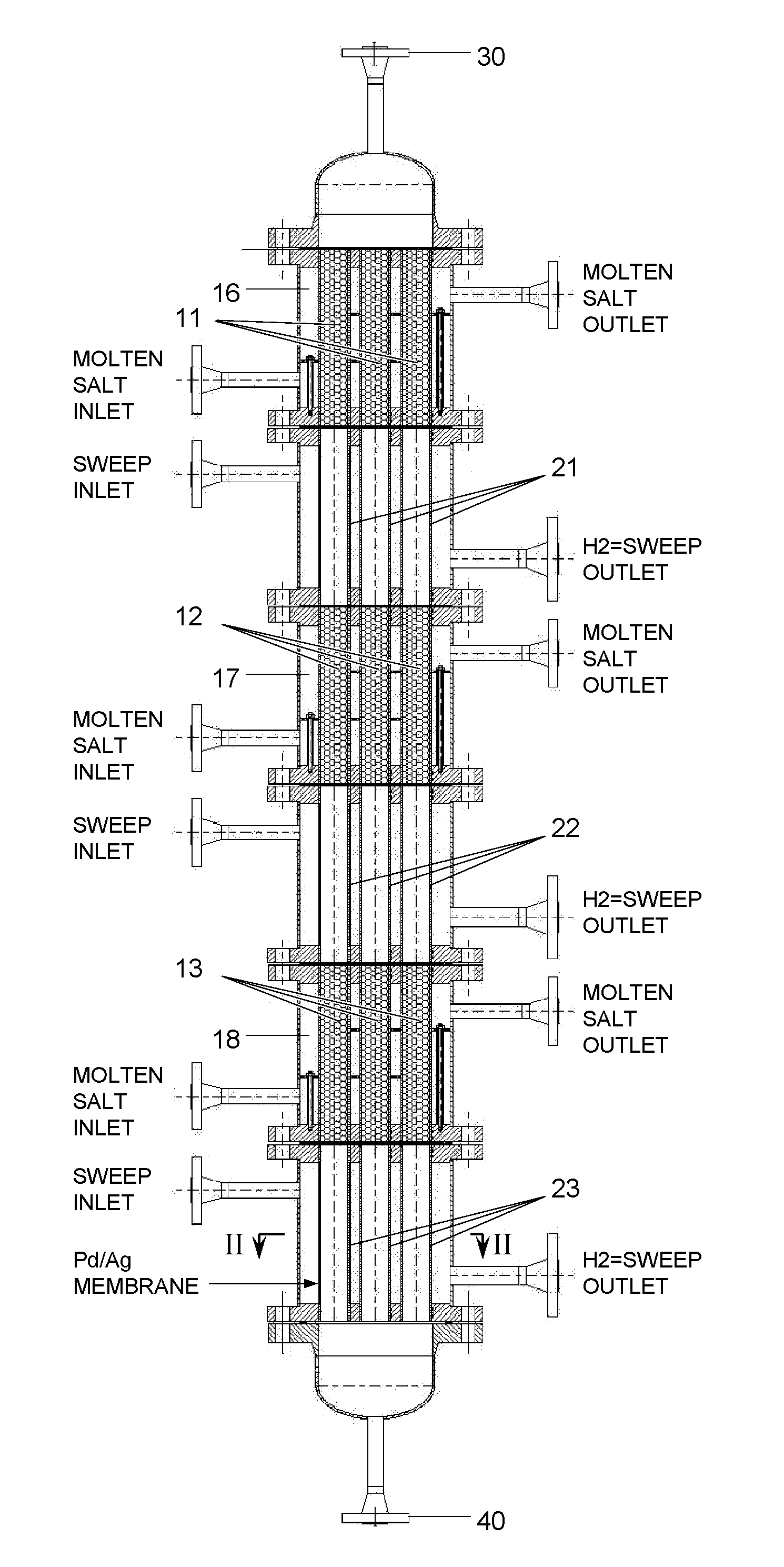

Method and system for the production of hydrogen

Disclosed is a process for the production of hydrogen in a reactor system comprising a steam reforming reaction zone comprising a reforming catalyst and a membrane separation zone comprising a hydrogen-selective membrane. The process involves a reaction system of so-called open architecture, wherein the reforming zone and the membrane separation zone operate independently of each other. The invention provides the heat for the reforming reaction through heat exchange from liquid molten salts, preferably heated by solar energy.

Owner:STAMICARBON ACTING UNDER THE NAME OF MT INNOVATION CENT

Catalyst for preparing methyl glycolate through hydrogenation of dimethyl oxalate and synthesis method and application of catalyst

ActiveCN111921547ALow costThe synthesis method is simplePhysical/chemical process catalystsOrganic compound preparationNickel saltPtru catalyst

The invention discloses a catalyst for preparing methyl glycolate through hydrogenation of dimethyl oxalate. The catalyst can be synthesized by two methods, the first method is that nickel salt and phosphate are simultaneously loaded directly through a co-deposition precipitation method to synthesize the catalyst containing different components of Ni and NiP at the same time; according to the second method, a catalyst intermediate containing Ni is synthesized through a deposition and precipitation method, and then the catalyst containing different components of Ni and NiP at the same time is synthesized through a secondary impregnation or programmed heating phosphate decomposition method. The catalyst is a non-noble metal catalyst, is low in cost and simple in synthesis method, and has thecharacteristics of good activity, high conversion rate, high selectivity, good stability and environmental friendliness in the reaction of selectively preparing methyl glycolate by hydrogenating dimethyl oxalate.

Owner:ZHEJIANG NORMAL UNIVERSITY

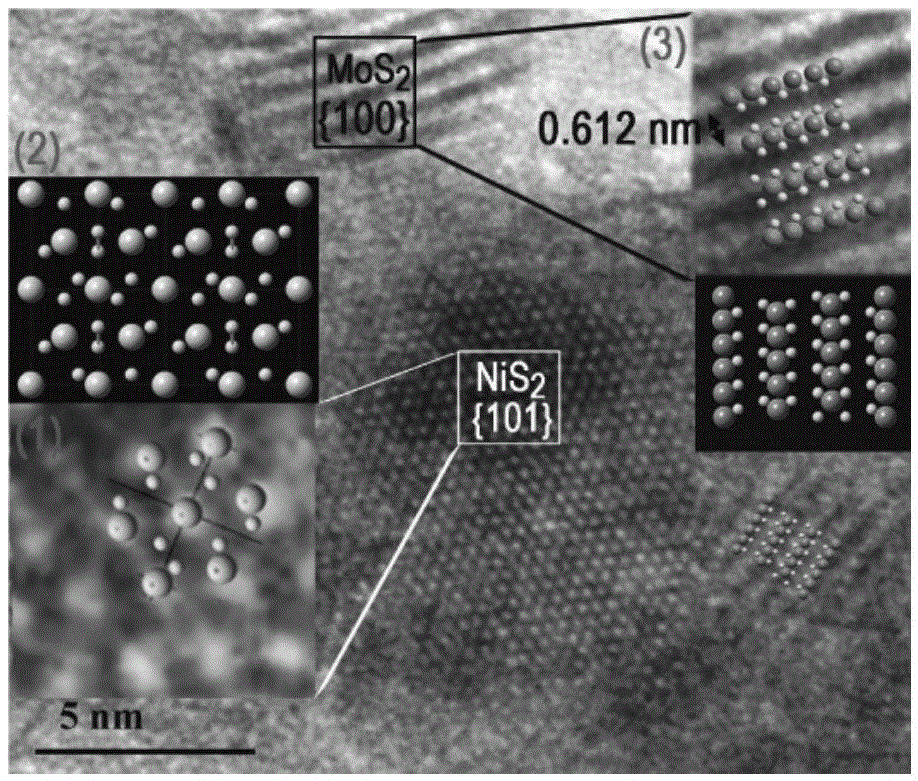

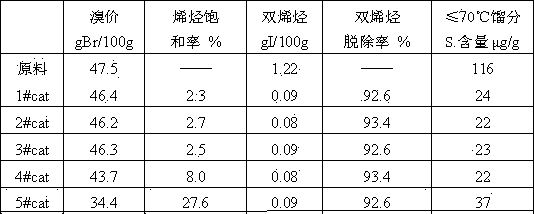

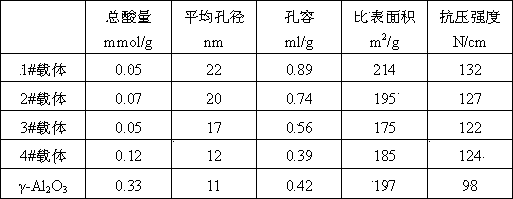

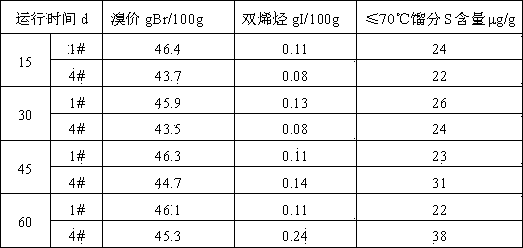

FCC (fluid catalytic cracking)-gasoline hydro-pretreating catalyst and method for preparing same

InactiveCN103372450AMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentPtru catalystHydrogen selectivity

The invention relates to an FCC (fluid catalytic cracking)-gasoline hydro-pretreating catalyst and a method for preparing the FCC-gasoline hydro-pretreating catalyst. The FCC-gasoline hydro-pretreating catalyst is a supported catalyst prepared by impregnating an Al2O3-TiO2-MgO composite oxide which servers as a carrier with Ni, Mo and Co, wherein the active components of the FCC-gasoline hydro-pretreating catalyst are distributed like an eggshell. The Al2O3-TiO2-MgO composite oxide which servers as the carrier comprises 10-20% by weight of TiO2, 10-15% by weight of MgO and the balance of Al2O3. The carrier is weakly acidic, has the average pore size distribution of 17-22nm, the pore volume of 0.56-0.89ml / g, the specific surface area of 175-214m<2> / g, the bulk density of 0.75-0.87g / ml and the anti-crushing strength of 120N / cm or higher. The FCC-gasoline hydro-pretreating catalyst provided by the invention comprises 4.8-7.2% by weight of NiO, 3.1-4.5% by weight of MoO3 and the balance of CoO. The FCC-gasoline hydro-pretreating catalyst presents good bis-olefin removal activity, small-molecule sulfur removal activity and bis-olefin hydrogenation selectivity when being used for treating the FCC gasoline under the condition that the temperature is 80-130 DEG C, the pressure is 1.0-2.0Mpa, the space velocity is 2-5h<-1> and the critical hydrogen and oil volume ratio is 400:1. In addition, the FCC-gasoline hydro-pretreating catalyst has strong gumming resisting capacity and quite long service life.

Owner:WUHAN KELIN FINE CHEM

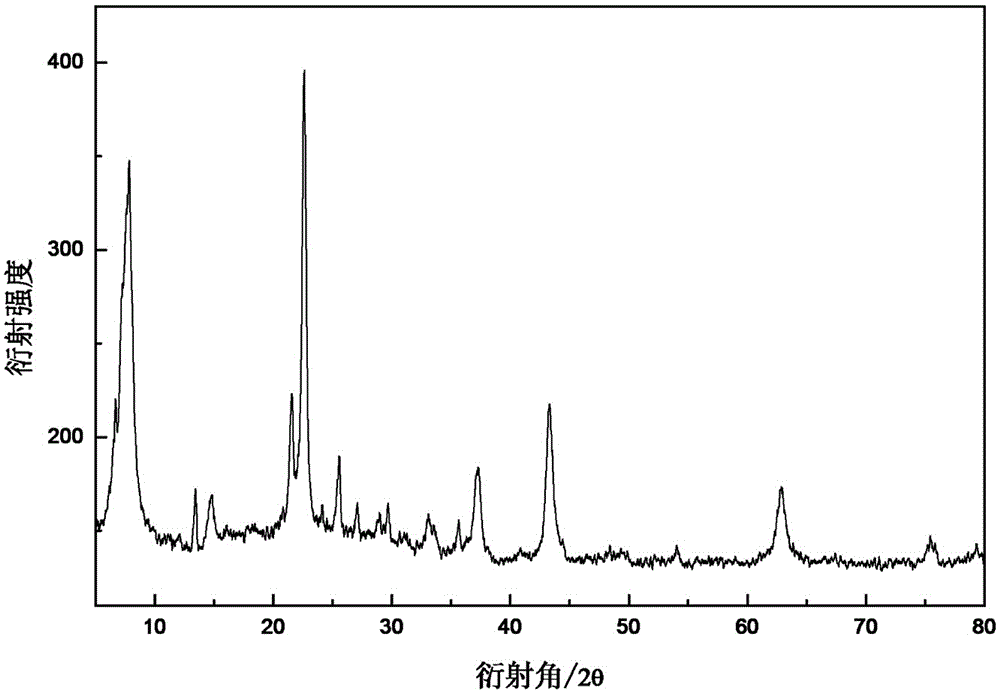

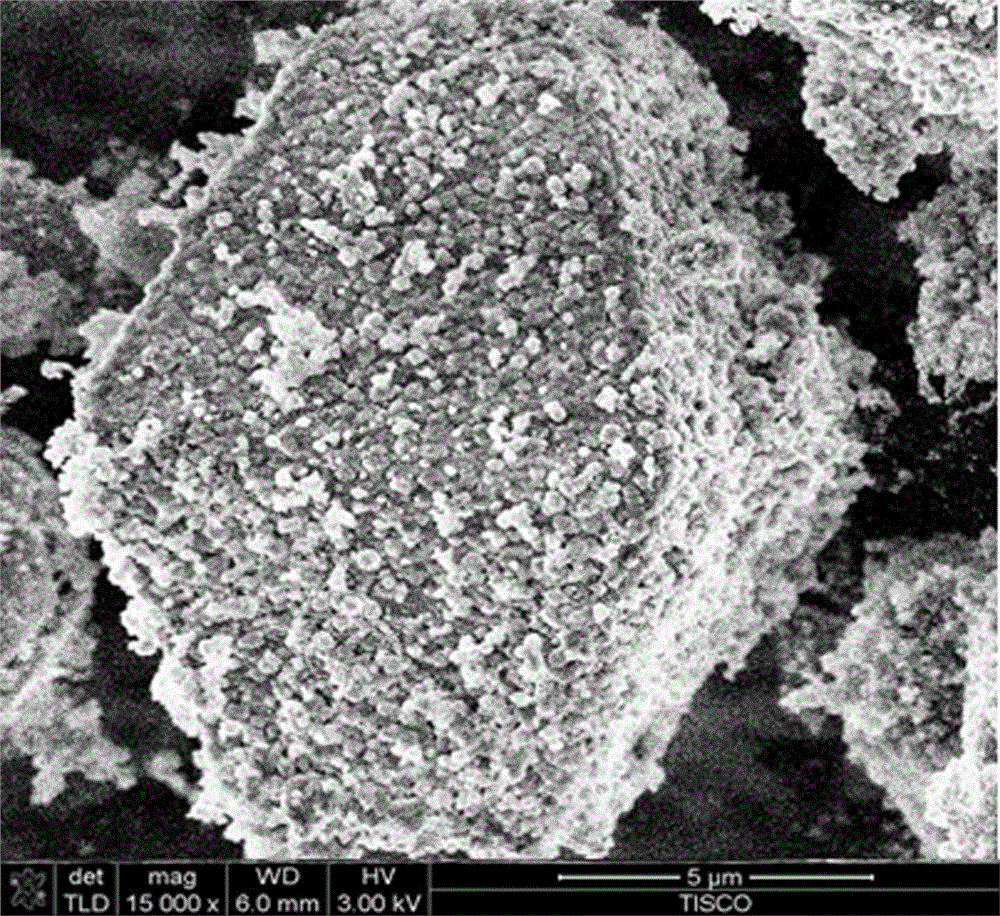

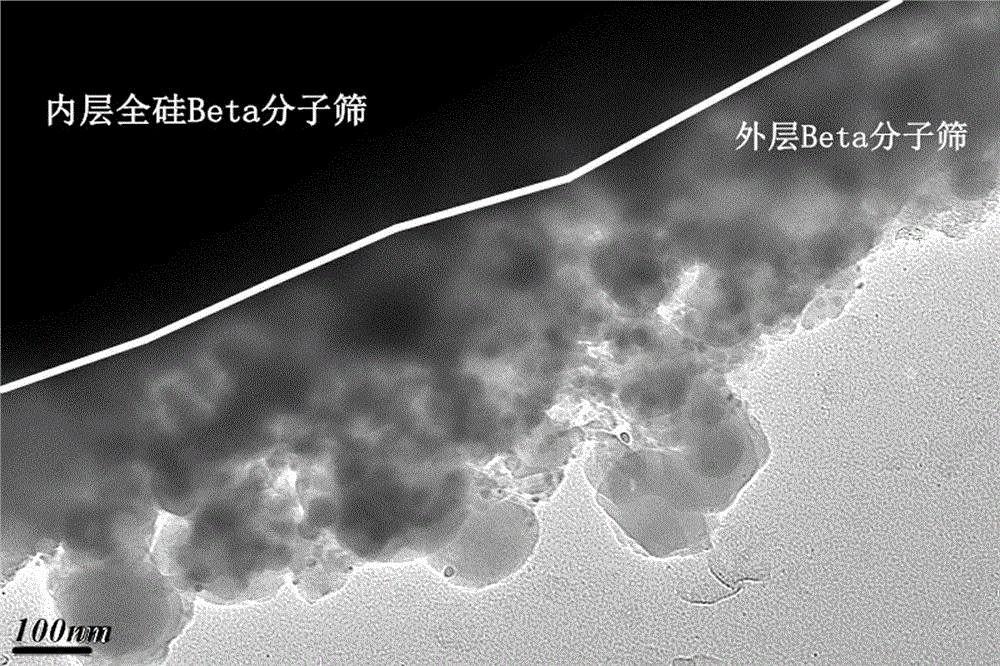

Core-shell structured Beta molecular sieve and preparation method thereof

ActiveCN105013527AEfficient use ofMake up for deficienciesHydrogenMolecular sieve catalystsMolecular sieveHydrogen selectivity

A core-shell structured Beta molecular sieve comprises 70-75wt% of an inner layer Beta molecular sieve core structure and 25-30wt% of an outer layer Beta molecular sieve shell structure wrapped outside the surface of the core structure, total silicon Beta molecular sieve is adopted as the carrier of the inner layer Beta molecular sieve to support copper and / or iron oxide, the copper and / or iron oxide accounts for 3-8% of the mass of the total silicon Beta molecular sieve, the surface of the inner layer Beta molecular sieve is connected with a poly(diallyldimethylammonium chloride) group, and 10-15% of nickel oxide is supported on the outer layer Beta molecular sieve. The core-shell structured Beta molecular sieve utilizing synergism of inner and outer double-layer molecular sieves and supported metal elements has high catalysis activity, and has the advantages of great improvement of the selectivity of a target product hydrogen, and very high ethanol conversion rate and hydrogen selectivity as an ethanol steam reforming hydrogen production catalyst.

Owner:TAIYUAN DACHENG ENVIRONMENTAL ENERGY CHEM TECH

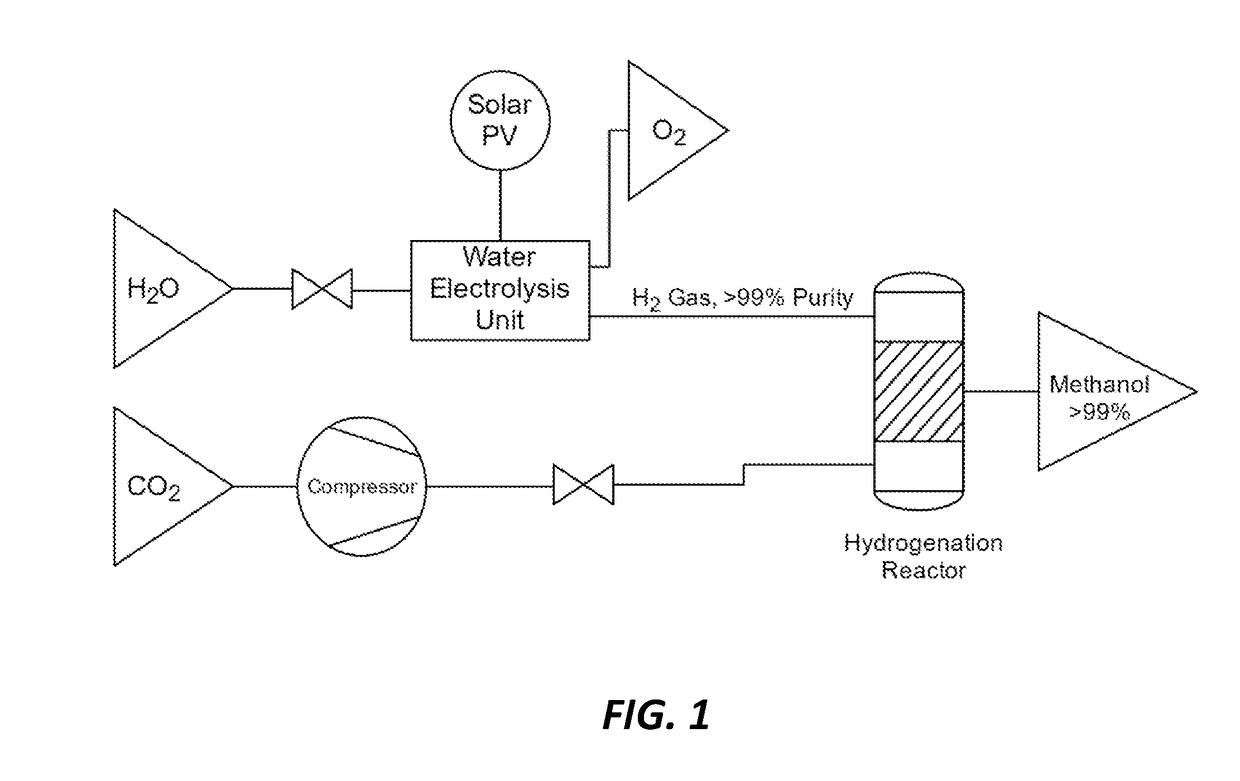

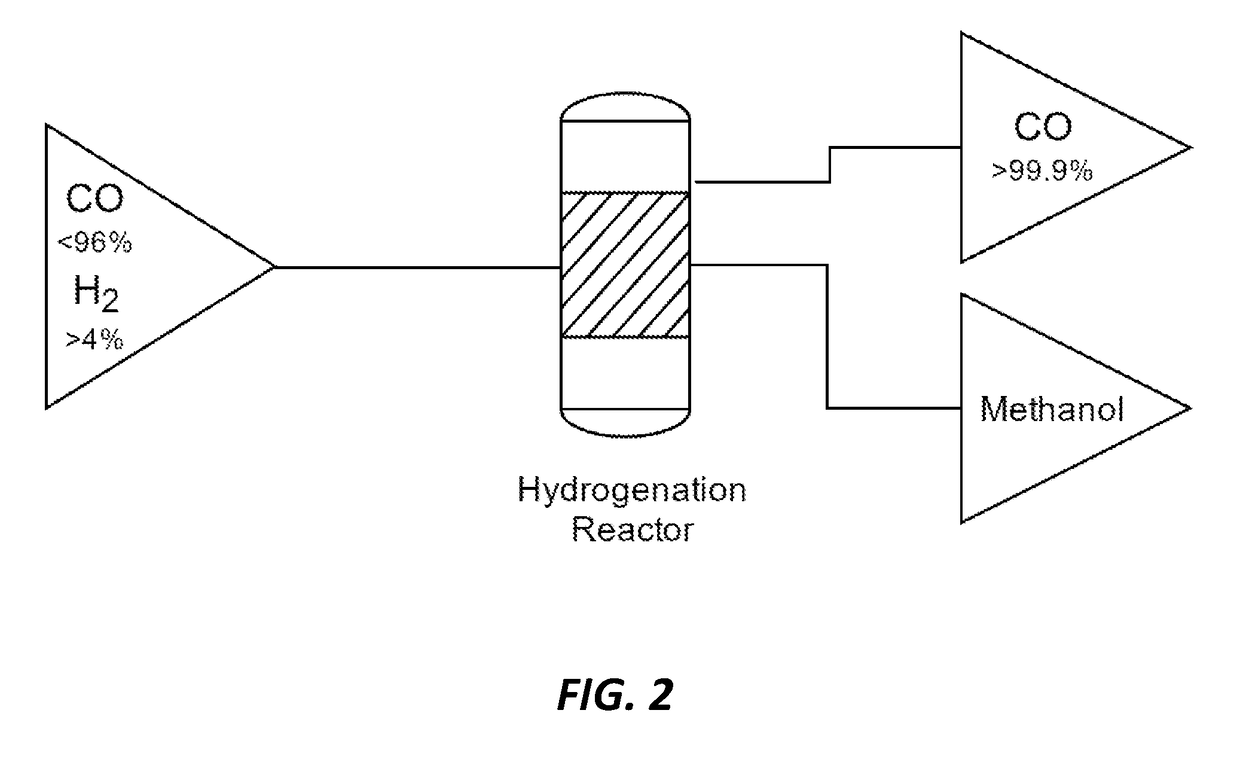

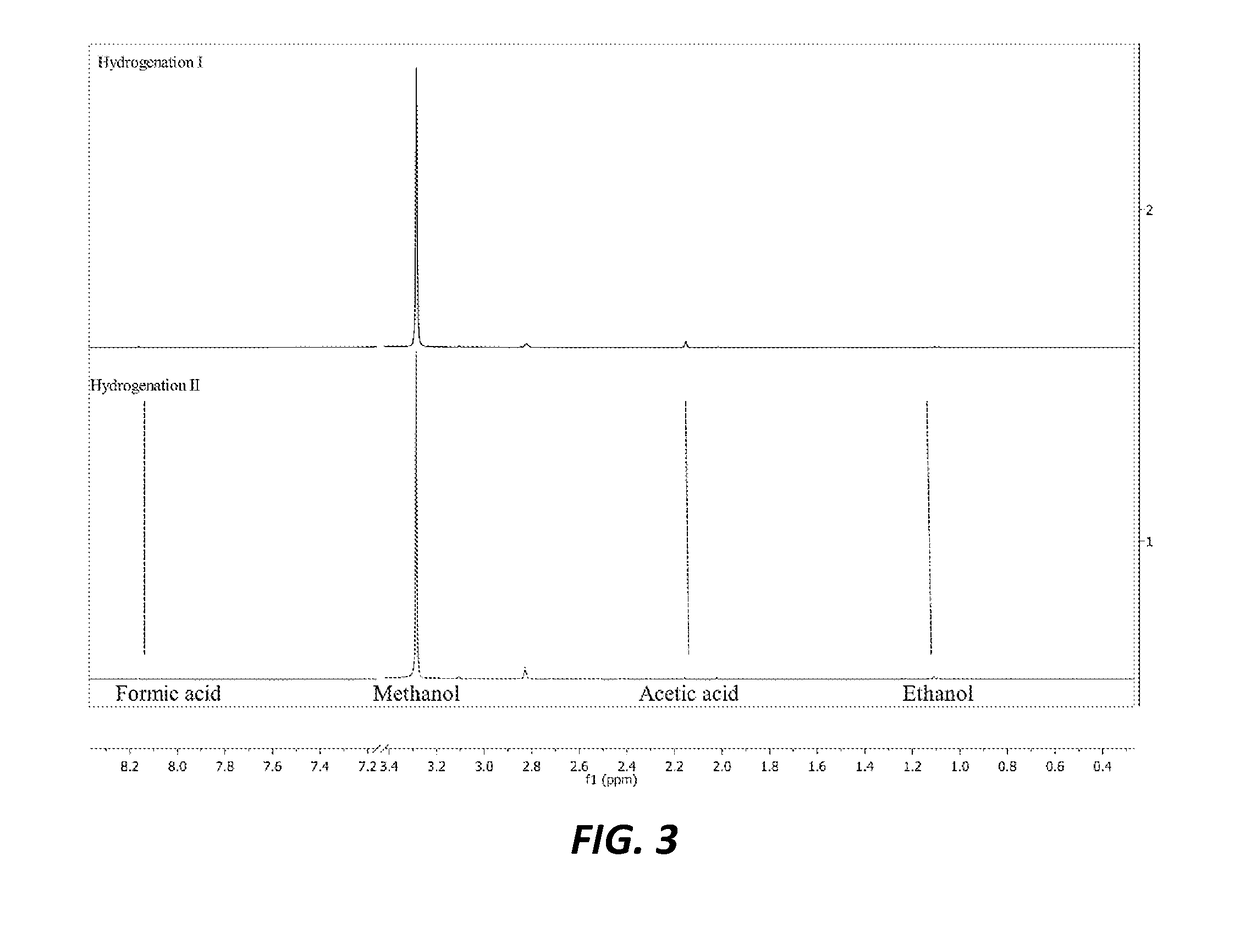

Methods and catalysts for the selective production of methanol from carbon dioxide and hydrogen gas for chemical synthesis and gas purification

ActiveUS20180362426A1Low costHigh surface area supportProductsReagentsChemical synthesisHydrogen selectivity

Catalysts and methods for the selective conversion of carbon dioxide and hydrogen into methanol using heat and high pressure in a hydrogenation reactor are disclosed. Key to this process are catalysts, which are comprised of multimetallic, aluminum oxide-supported nanoparticles. In some embodiments of the invention, the catalytic nanoparticles are made from mixtures of zinc and copper, or mixtures of palladium and copper, in different stoichiometric equivalents. In others, stoichiometric additives or dopants are added in order to improve the rate of product formation, improve selectivity, or allow for flow configurations. Methods for the use of these catalysts for the synthesis of methanol, and for the purification of CO2, H2, or CO gas streams by transforming contaminants into liquid methanol are also described.

Owner:AIR CO HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com