FCC (fluid catalytic cracking)-gasoline hydro-pretreating catalyst and method for preparing same

A gasoline hydrogenation and catalyst technology, which is applied in the treatment of hydrocarbon oil and petroleum industry, etc., can solve the problems of affecting the service life of the catalyst, the pores are easy to gel and block, and the gel capacity needs to be further developed, so as to improve the utilization rate and strengthen the The effect of improving gel ability and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

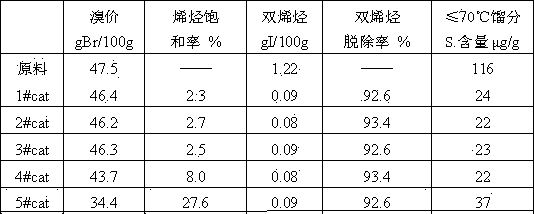

Embodiment 1

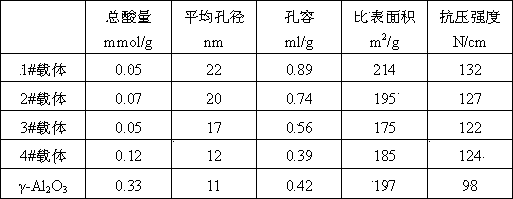

[0032] Add 92.9g of pseudo-boehmite, 12.3g of metatitanic acid, and 25.0g of magnesium oxide into a mortar and stir evenly, then add 2.5g of ethylene glycol, 1.0g of sesame powder and appropriate amount of distilled water, stir and roll evenly, and then squeeze. Forming, drying at 100℃ for 5h, then raising the temperature to 700℃, roasting in the air for 2h, and then passing in 2% ammonia solution, the volume ratio of ammonia vapor to air is 3:10, and keeping it at 600℃ for another 2h , And then stop adding ammonia solution, and continue roasting in the air at 700℃ for 1h to obtain Al 2 O 3 -TiO 2 -MgO carrier. The carrier is weakly acidic, with an average pore diameter of 22nm, a pore volume of 0.89ml / g, and a specific surface area of 214m 2 / g, the bulk density is 0.82g / ml, the crushing strength is 132N / cm, and the carrier is named 1# carrier.

Embodiment 2

[0034] Add 107.1g of pseudo-boehmite (water content 30%, the same below), 18.4g of metatitanic acid, and 10.0g of magnesium oxide into a mortar and stir evenly, then add 3.5g of starch, 3.0g of sesame powder and an appropriate amount of distilled water. After stirring and rolling evenly, extrusion molding, drying at 150°C for 3 hours, then raising the temperature to 500°C and roasting in air for 4 hours, and then passing in 2% aqueous ammonia solution. The volume ratio of ammonia vapor to air is 4:10. At 500℃, keep constant temperature for 3h, then stop adding ammonia solution, and continue roasting at 500℃ in air for 2h to obtain Al 2 O 3 -TiO 2 -MgO carrier. The carrier is weakly acidic, with an average pore diameter of 20nm, a pore volume of 0.74ml / g, and a specific surface area of 195m 2 / g, the bulk density is 0.75g / ml, the crushing strength is 127N / cm, the carrier is named 2# carrier.

Embodiment 3

[0036] Add 85.7g of pseudo-boehmite, 24.5g of metatitanic acid, and 20.0g of magnesium oxide into a mortar and stir evenly, then add 3.0g of diethylene glycol, 2.0g of sesame powder and a suitable amount of distilled water, stir and roll evenly and then squeeze Molding, drying at 130°C for 4h, then raising the temperature to 600°C and roasting in the air for 3h, and then passing in 2% ammonia solution. The volume ratio of ammonia vapor to air is 3.5:10, and the temperature is kept at 700°C for another 2h , And then stop adding ammonia solution, continue roasting in air at 600℃ for 2h to obtain Al 2 O 3 -TiO 2 -MgO carrier. The carrier is weakly acidic, with an average pore diameter of 17nm, a pore volume of 0.56ml / g, and a specific surface area of 175m 2 / g, the bulk density is 0.87g / ml, the crushing strength is 122N / cm, and the carrier is named 3# carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com