Thin shell type catalyst and preparation method thereof

A catalyst and thin-shell technology, applied in the field of thin-shell catalysts, can solve the problems of shell precious metal loss and easy wear, and achieve the effect of excellent activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

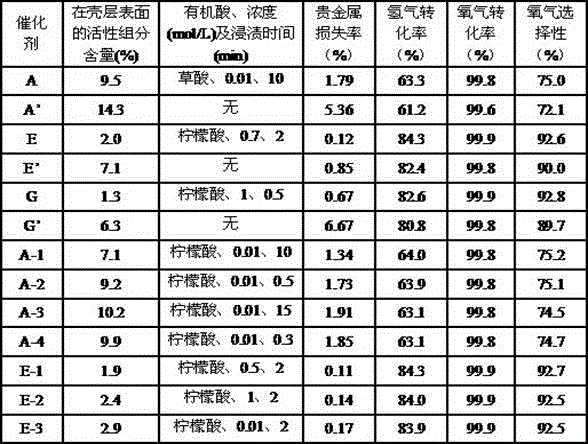

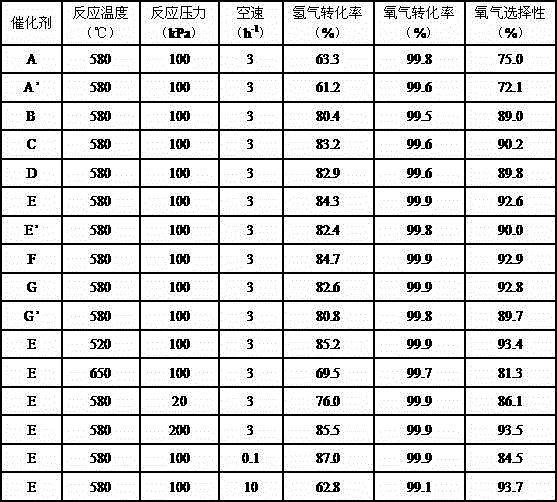

Examples

Embodiment 1

[0034] Put 10 grams of small spherical particle thin-shell carrier AI whose core is mullite, thin shell is γ-alumina, and the shell thickness is 0.21 mm, into 50 mL of oxalic acid aqueous solution with a concentration of 0.01 mol / L for 10 min. Afterwards, the pellets were filtered out, and dried in an oven at 120° C. for 14 hours to obtain the thin-shell carrier AII.

[0035] Dissolve ammonium chloroplatinate in water to prepare a solution. Put the thin-shell carrier AII impregnated with oxalic acid into 40mL ammonium chloroplatinate solution for impregnation, then dry at 90°C for 24 hours, then bake at 400°C for 20 hours, and cool to room temperature to obtain a non-uniform distribution of Pt in the shell The thin-shell catalyst A. Elemental analysis showed that the mass fraction of Pt in the catalyst was 0.0502%.

[0036] The attrition rate of the thin-shell catalyst A was determined to be 0.80% according to the method of the standard HG / T 2976-1999, and the mass fraction ...

Embodiment 2

[0045] Put 10 grams of small spherical particle thin-shell carrier BI whose core is silicon carbide, thin shell is δ-alumina, and shell thickness is 0.33 mm into 50 mL of tartaric acid aqueous solution with a concentration of 0.05 mol / L for 8 minutes. After dipping The pellets were filtered out and dried in an oven at 100°C for 20 hours to obtain the thin-shell carrier BII.

[0046] Dissolve triruthenium dodecacarbonyl in water to prepare a solution. The thin-shell carrier BII impregnated with tartaric acid was immersed in 40 mL of triruthenium dodecacarbonyl solution, then dried at 100°C for 2 hours, then calcined at 300°C for 24 hours, and cooled to room temperature to obtain Ru in the shell. Evenly distributed thin-shell catalyst B. Elemental analysis showed that the mass fraction of Ru in the catalyst was 0.688%.

[0047] The attrition rate of the thin-shell catalyst B was determined to be 0.46% according to the method of the standard HG / T 2976-1999, and the mass fractio...

Embodiment 3

[0051] Put 10 grams of thin-shell carrier CI with spinel as the inner core, θ-alumina as the thin shell, and a shell thickness of 0.35 mm into 50 mL of citric acid aqueous solution with a concentration of 0.20 mol / L for 6 min. After impregnation, the pellets were filtered out and dried in an oven at 100°C for 5 hours to obtain the thin-shell carrier CII.

[0052] Dissolve ammonium hexachloroosmate in water to make a solution. Put the thin-shell carrier CII impregnated with citric acid into 40mL ammonium hexachloroosmate solution for impregnation, then dry at 100°C for 15 hours, then bake at 500°C for 8 hours, and cool to room temperature to obtain Os in the shell Non-uniformly distributed thin-shell catalyst C. Elemental analysis showed that the mass fraction of Os in the catalyst was 0.3040%.

[0053] The attrition rate of the thin-shell catalyst C was determined to be 0.27% by the method of the standard HG / T 2976-1999, and the mass fraction of Os in the catalyst with the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com