Biomass carbon-base material high-load nano-metal catalyst, as well as preparation method and application thereof

A biomass carbon and nano-metal technology, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve problems such as cumbersome preparation process, and achieve simple preparation process. , the effect of high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

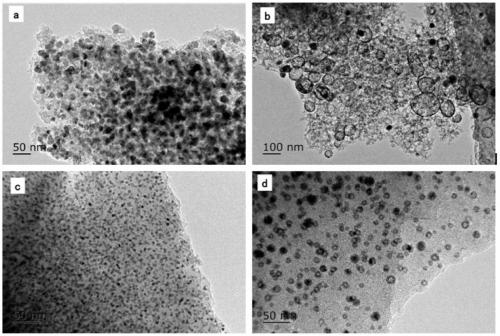

[0026] The preparation of embodiment 1 catalyst

[0027] (1) Remove the yellow outer skin of the pomelo peel, cut the white part into strips, and freeze-dry it in a vacuum freeze dryer for 48 hours. After the freeze-drying is completed, put it into a crusher and crush it into powder to obtain pomelo peel powder .

[0028] (2) Weigh iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) 0.868g, cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) 0.741g, nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.378g, copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 (2) 0.228g, 0.456g, 0.684g, 0.912g, the above-mentioned nitrate crystals are dissolved in the deionized water of 15mL respectively, obtain the iron nitrate solution that concentration is 0.14mol / L respectively (the concentration of iron ion is 8 * 10 -3 g / mL), concentration is 0.17mol / L cobalt nitrate solution (concentration of cobalt ion is 1×10 -2 g / mL), the concentration is the nickel nitrate solution of 0.087mol / L (the conc...

Embodiment 2

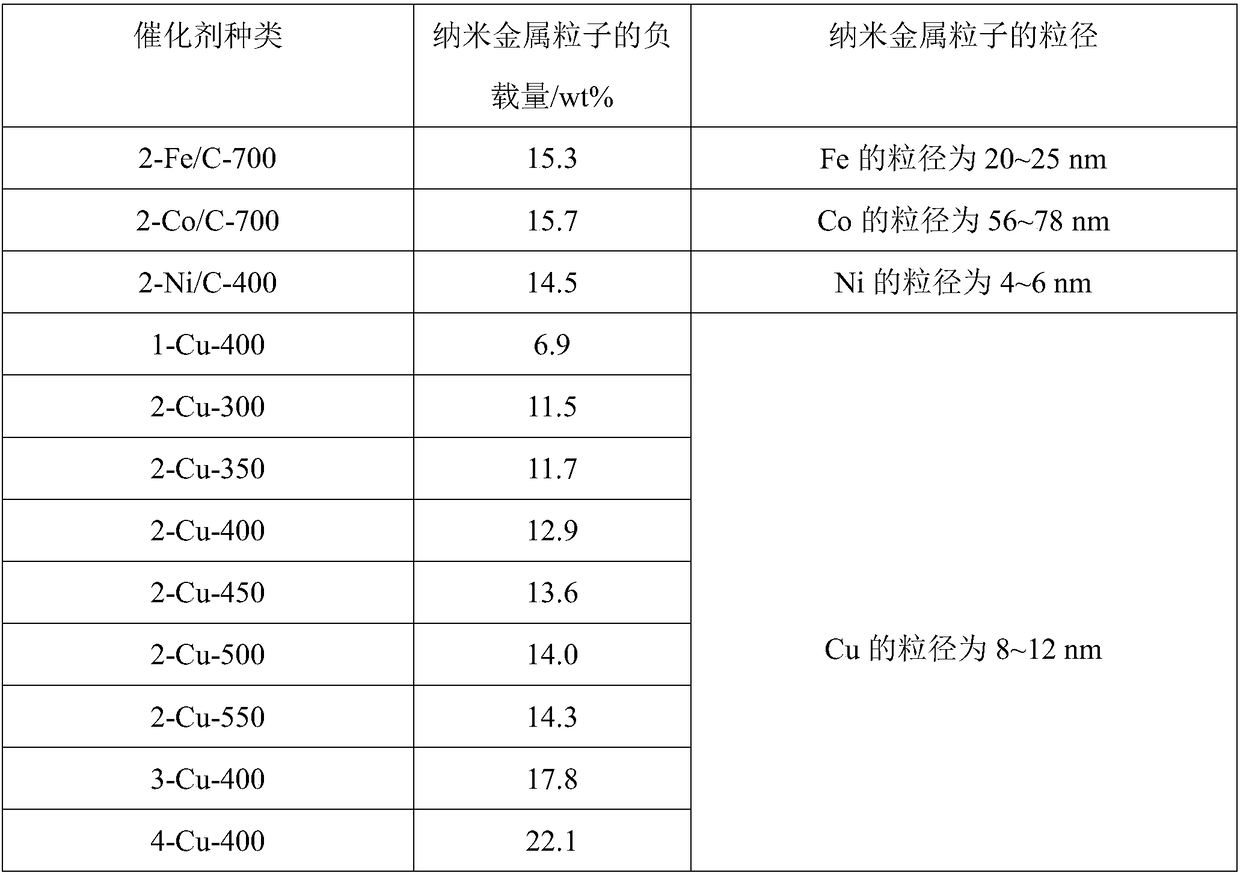

[0034] Embodiment 2 uses different catalysts to carry out furfural hydrogenation reaction

[0035] Get furfural 0.6g, catalyzer 0.1g, Virahol 20mL is put into the autoclave of 50mL, with H 2 Replace the air in the kettle 5 times, fill with H 2 Pressurize to 2MPa, seal the reactor. Turn on the magnetic stirrer (700rpm), raise the temperature of the reactor to 170°C in 30 minutes, and start the timing reaction. The reaction time is 3 hours, and the product furfuryl alcohol is obtained. The product is quantitatively analyzed by gas chromatography, and the conversion rate of raw materials and product yield are calculated. . The results are shown in Table 2.

[0036] Table 2 uses different catalysts to carry out the result of furfural hydrogenation reaction

[0037] group

Embodiment 3

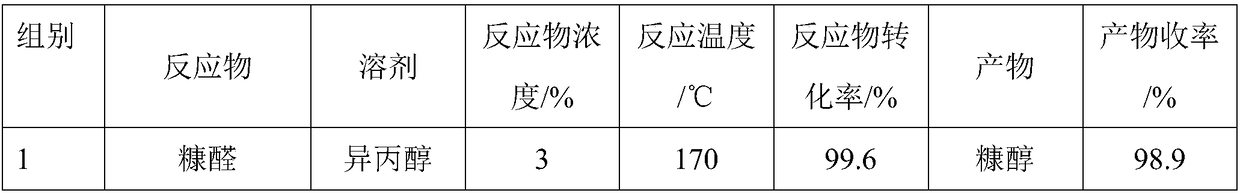

[0038] The hydrogenation reaction of embodiment 3 different biomass derivatives

[0039] With reference to the method of Example 2, investigate the catalytic effect of using catalyst 2-Cu-400 to carry out hydrogenation reaction of different biomass derivatives, wherein, the reaction conditions are as follows: the amount of catalyst 2-Cu-400 is 0.1g, and the amount of solvent is 20mL , H 2 The pressure is 2MPa, the reaction time is 3h, and the stirring speed is 700rpm. Quantitative analysis of the product was carried out by gas chromatography, and the conversion rate of the raw material and the yield of the product were calculated. The results are shown in Table 3.

[0040] Table 3 The results of hydrogenation reaction of different biomass derivatives using catalyst 2-Cu-400

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com