Handmade soap containing tea residue extract and preparation method of handmade soap

A technology of extract and handmade soap, which is applied in the field of handmade soap containing tea dregs extract and its preparation, can solve the problems of inaccurate handmade soap preparation process and insufficient variety of handmade soap, so as to reduce garbage, improve quality, and improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

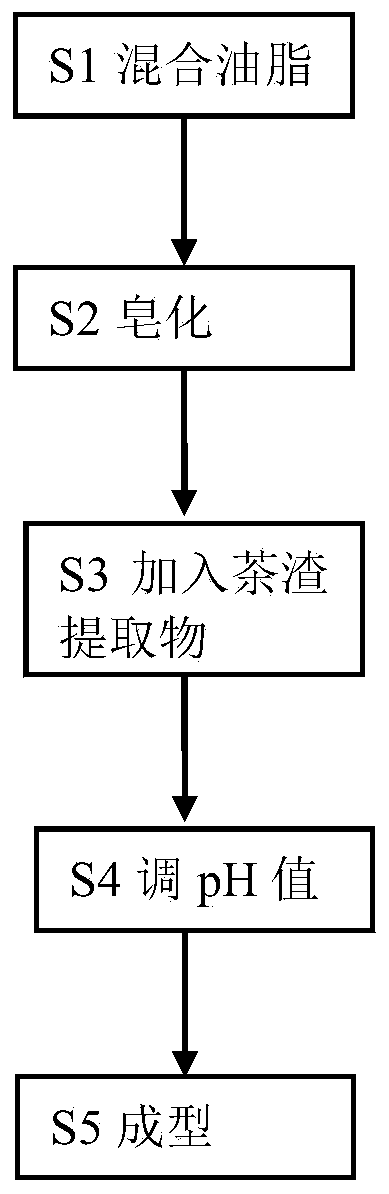

Method used

Image

Examples

Embodiment 1

[0043] Contain the handmade soap of tea residue extract in the present embodiment, and the raw material formula of handmade soap comprises by weight: 200 parts of mixed oil, 28 parts of NaOH, 42 parts of distilled water and 3-5 parts of tea residue extract, mixed oil is tea seed Oil: rapeseed oil: palm oil in a mixture of 5:1:4 by weight. Wherein the tea residue extract is the alcohol-soluble tea polyphenol extract obtained by extracting the tea residue of Wuyi rock tea with ethanol, and the extraction process of the tea residue extract includes: A1, after drying the tea residue of Wuyi rock tea, crushing Obtain tea residue powder; A2, mix the tea residue powder obtained in step A1 and the ethanol solution with a concentration of 80% according to the ratio of material to liquid ratio of 1:7, wherein the tea residue powder is 100g, and the ethanol solution is 700g. Extract for 30 minutes; A3, filter the solution extracted in step A2, and the filtered solution is the tea dregs e...

experiment example 1

[0062] Experimental Example 1 Effect of Water Bath Temperature on Total Alkali Content of Finished Handmade Tea Soap

[0063] In order to understand the influence of water bath temperature on the total alkali content of handmade soap during saponification, three experimental groups were designed, and the mixed oils were placed in water bath temperatures of 40°C, 50°C and 60°C, and other preparation steps were the same as in Example 1. .

[0064] The graph presents a V shape with a large angle; when the saponification water bath temperature is around 50°C, the detected total alkali value is the lowest; the total alkali detected on both sides is higher than that in the middle. It can be seen that: around 50°C is the best water bath temperature for handmade tea soap.

experiment example 2

[0066] In order to understand the influence of stirring time during saponification on the total alkali content of handmade soap, three experimental groups were designed, stirring for 2h, 3h and 4h when adding sodium hydroxide solution respectively, and other preparation steps were all the same as in Example 1.

[0067] See attached Figure 5 As shown, it is found that along with the stirring time prolonging, the measured value of the total alkalinity is in a downward trend, which is consistent with the fact that the longer the stirring time is, the more complete the saponification is, and the total alkalinity reaches a minimum value approximately around 3h. Therefore, the stirring time is about 3h as the optimum stirring time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com