Patents

Literature

1099results about "Alkali/ammonium soap compositions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soaps Produced from Oil-Bearing Microbial Biomass and Oils

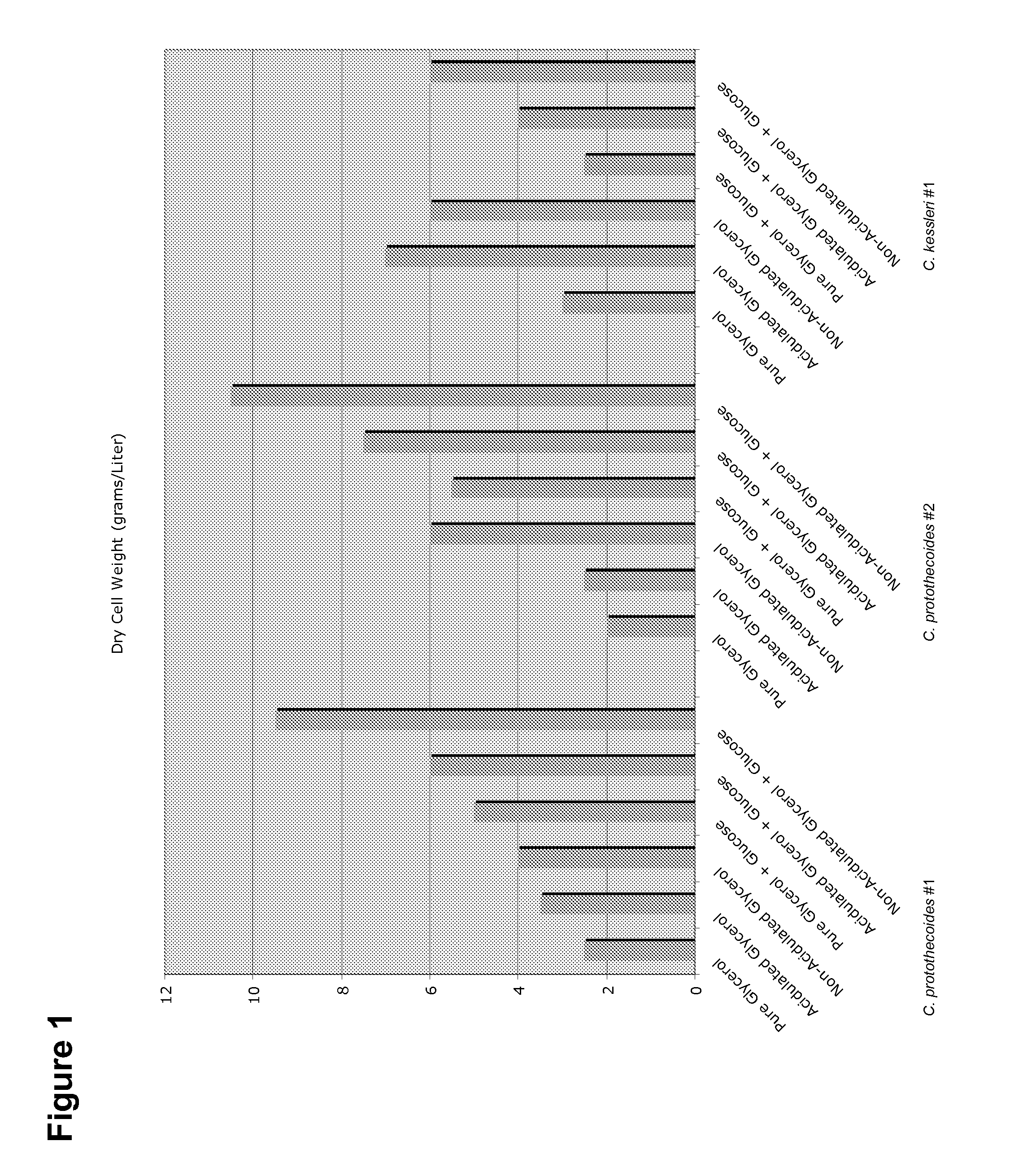

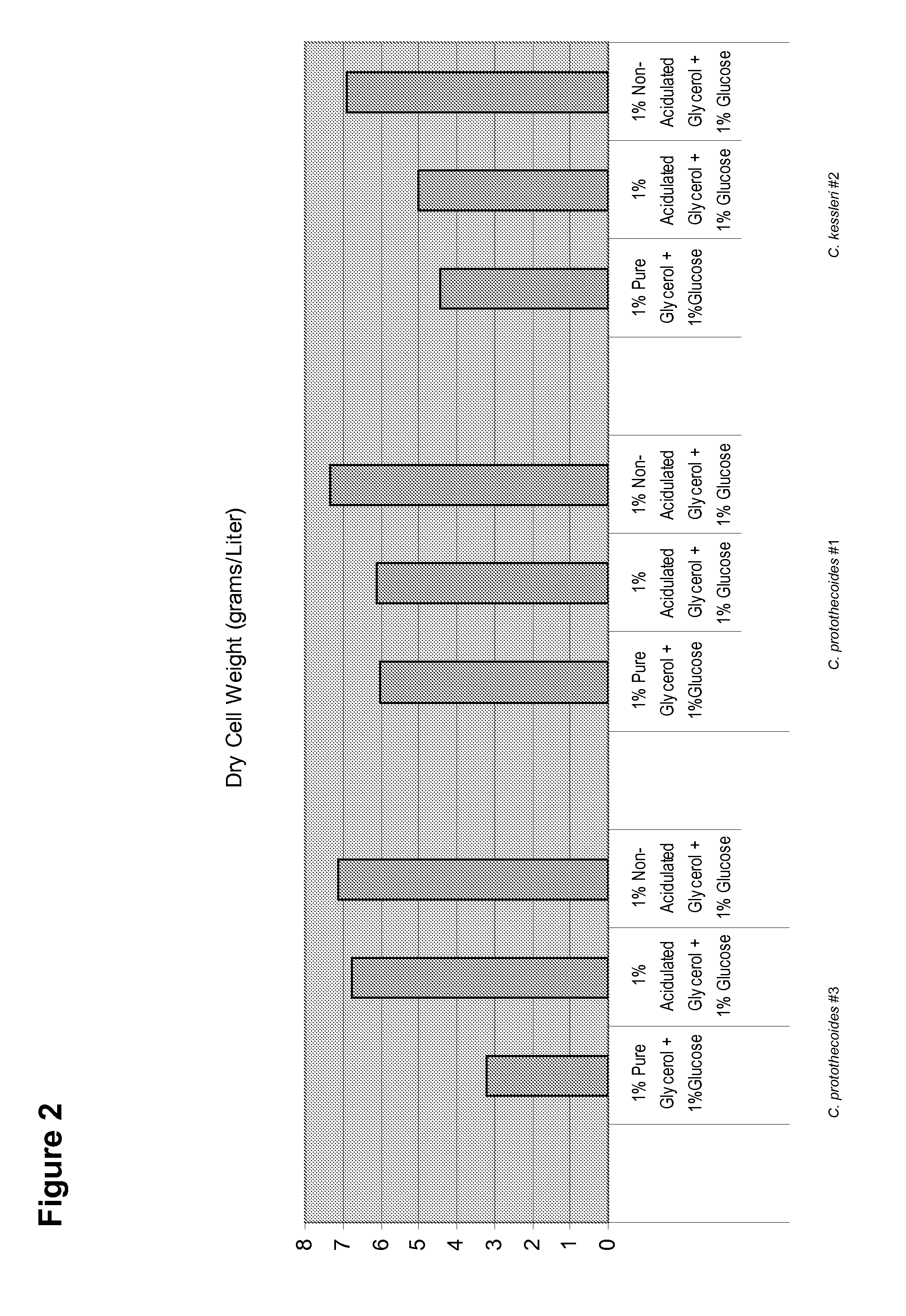

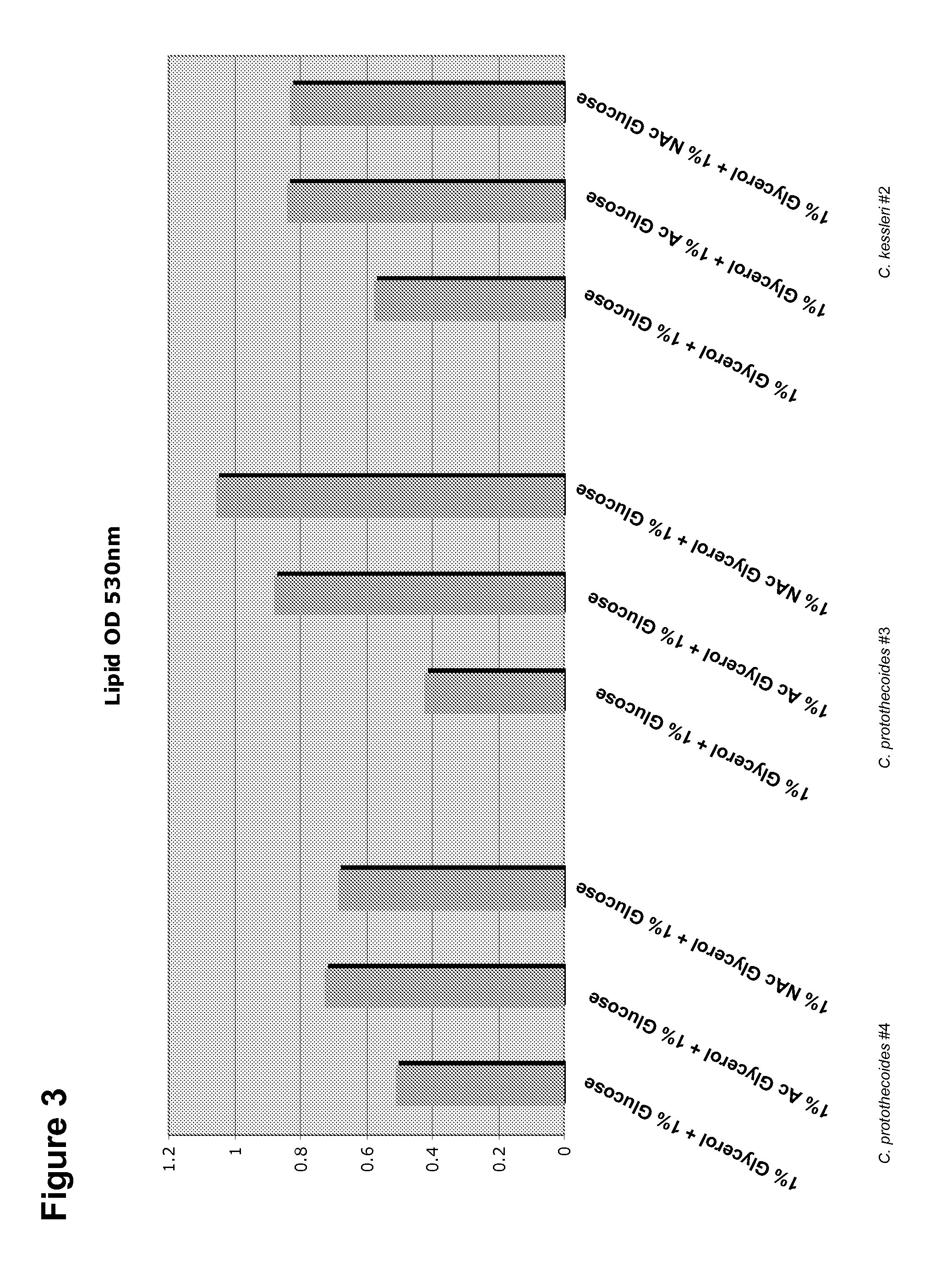

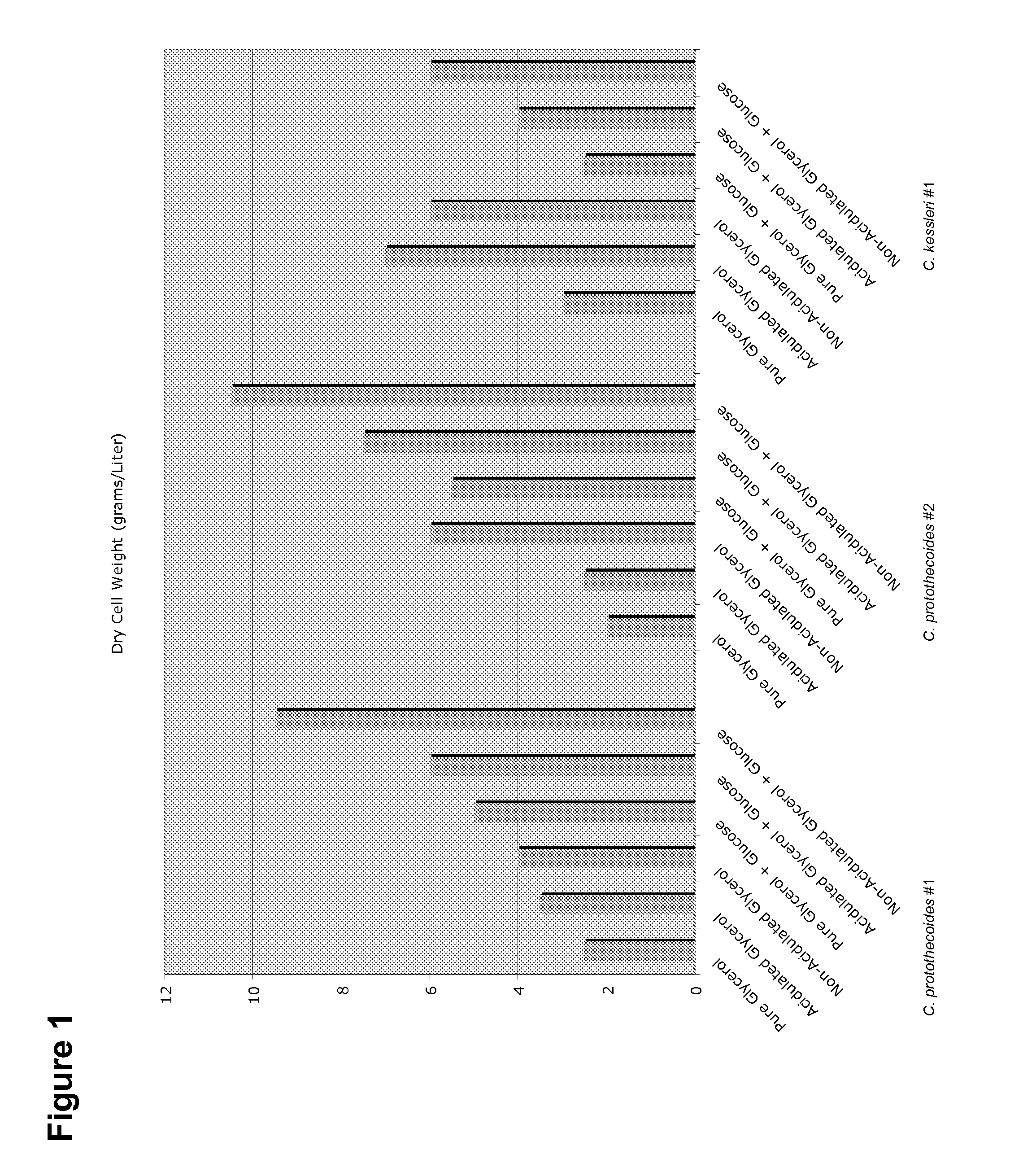

ActiveUS20090305942A1Improve efficiencyLow costSoap detergents with organic compounding agentsBiofuelsMicroorganismMicrobial oil

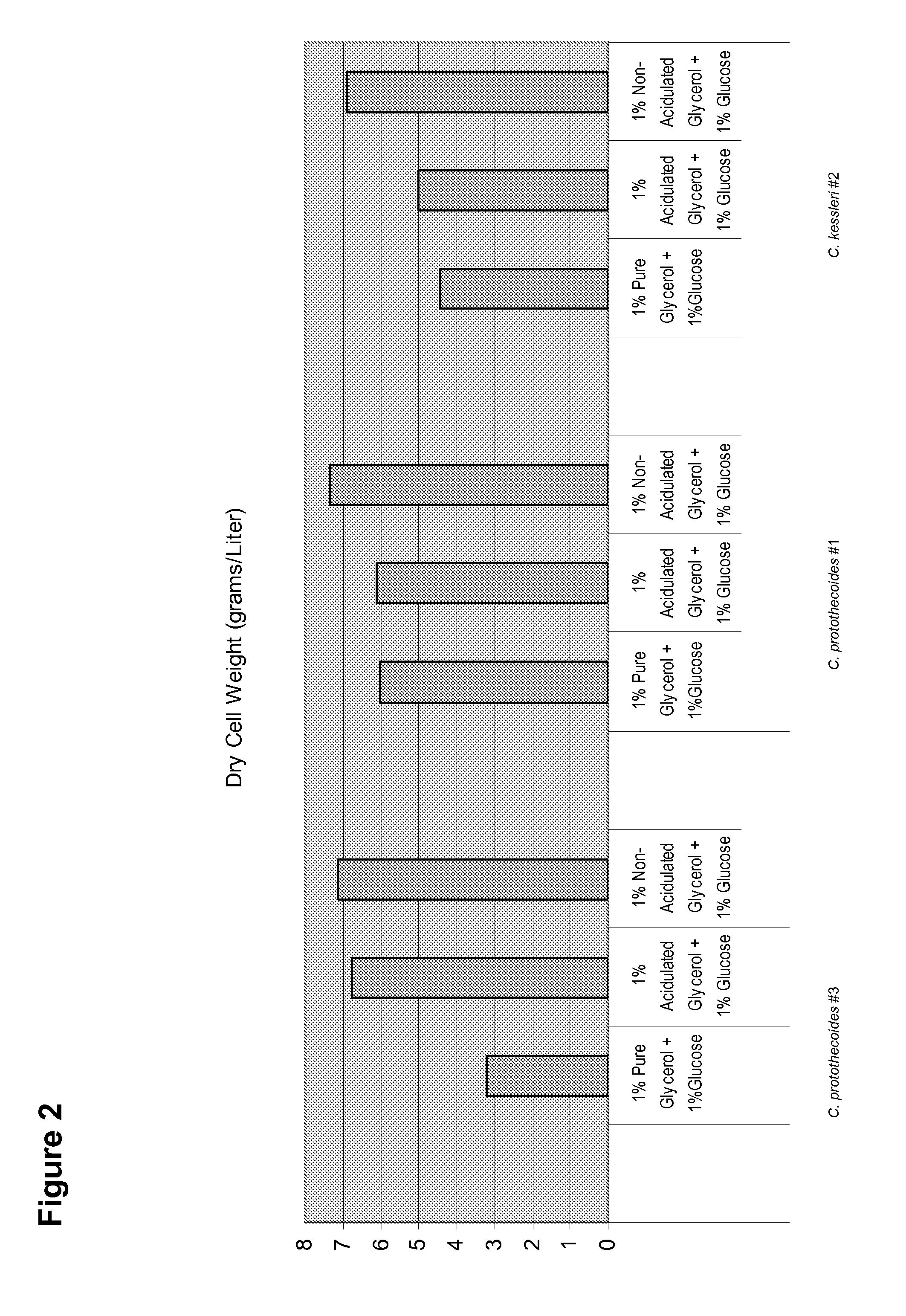

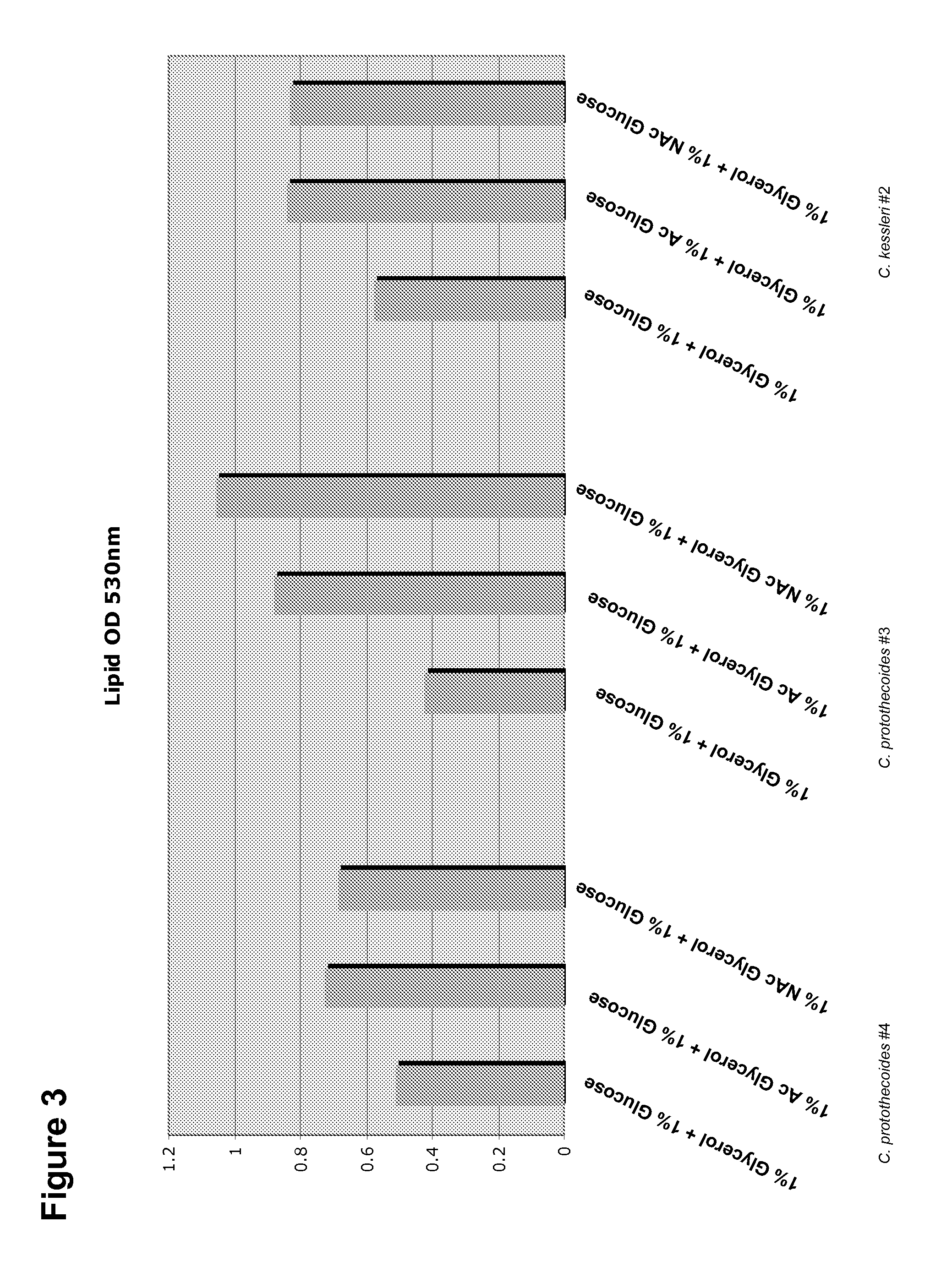

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

Soaps produced from oil-bearing microbial biomass and oils

ActiveUS8119583B2Low costImprove efficiencySoap detergents with organic compounding agentsCosmetic preparationsMicrobial oilGlycerol

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

Skin cleansing composition for removing ink

InactiveUS6265363B1Easy to cleanEfficient removalInorganic/elemental detergent compounding agentsCosmetic preparationsAlcoholStain

A skin cleansing composition suitable for removing ink and other stains from the hands and arms of a user includes an effective amount of a low molecular weight alcohol having from one to twelve carbon atoms and an effective amount of a peroxide releasing agent, e.g., a percarbonate salt, preferably sodium percarbonate, such that together, the alcohol and percarbonate salt provide a synergistic reaction that effectively removes ink from the skin of the user. Other additives such as fillers, abrasives, and detergents may be employed to provide further cleansing action.

Owner:GOJO IND INC

Natural cooling-making soap and low-temperature soap-making process

InactiveCN101649262AIncreased sensitivitySolve the problem of not moisturizingAlkali/ammonium soap compositionsAqueous sodium hydroxideDistilled water

The invention relates to a low-temperature soap-making process of natural cooling-making soap, which belongs to a washing article and a making process thereof. The cooling-making soap is made of the following raw materials in proportion by weight at low temperature: 20-28 distilled water, 60-71 base grease, 6-12 sodium hydroxide, essential oil accounting for 0.5-1.5 percent of the total weight ofthe distilled water, the base grease and the sodium hydroxide, and Chinese medicine accounting for 1.5-2.5 percent of the total weight of the distilled water, the base grease and the sodium hydroxide.The making process comprises the following steps: firstly, weighing the raw materials; secondly, adding the sodium hydroxide into the distilled water; thirdly, adding the base grease into a stainlesscontainer, heating by separating from water; fourthly, after reducing the temperature of the sodium hydroxide solution and the base grease solution, slowly pouring the sodium hydroxide solution intothe base grease solution, and completely stirring uniformly; fifthly, adding the essential oil and the powder of the Chinese medicine, and stirring uniformly; sixthly, pouring the liquid mixture intoa mould, demoulding, and standing thus obtaining the soap. The invention solves the problem of poor washing effect of the washing soap produced by the prior art.

Owner:王硕

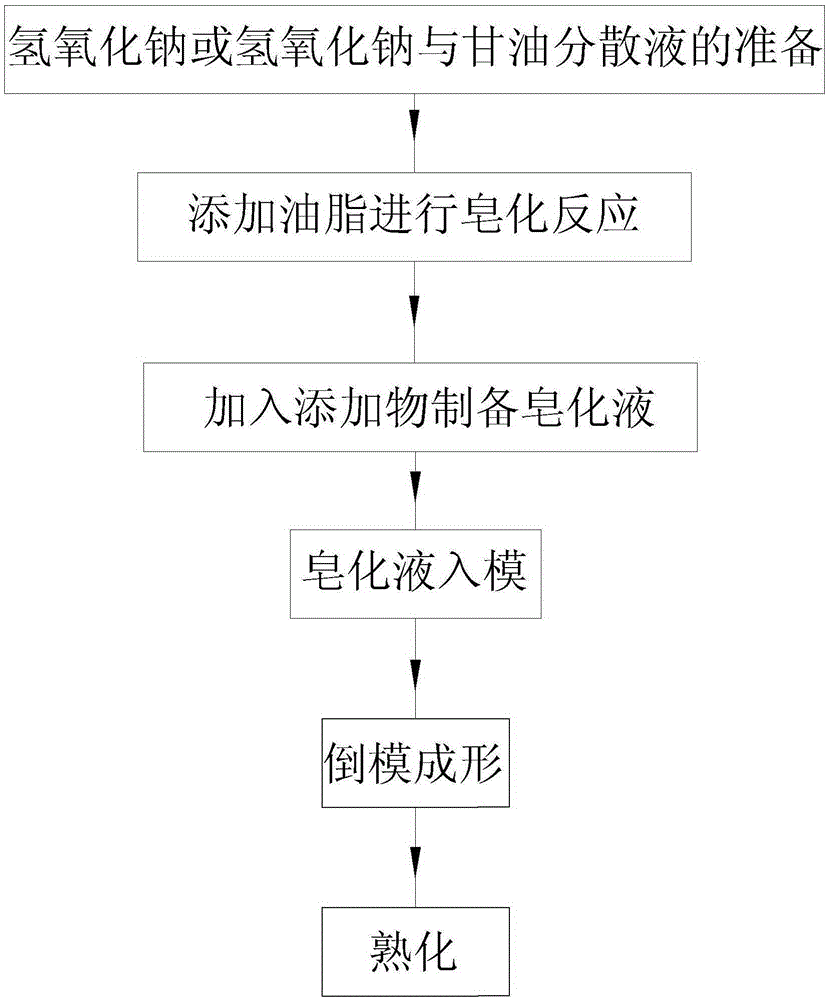

Preparation method of cold-formed soap

ActiveCN105400617AAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Camellia facial soap

InactiveCN102517174AAvoid harmModerate glycerin contentCosmetic preparationsToilet preparationsWater bathsOil and grease

The invention relates to camellia facial soap, which belongs to the field of washing products. The camellia facial soap is mainly and technically characterized by comprising the following main raw materials: 24-32g of camellia oil, 12-15g of coconut oil, 12-15g of palm oil, 12-15g of sweet almond oil, 20-23g of deionized water, 9-11g of NaOH and 2-3g of floral essential oil. A preparation method for the camellia facial soap comprises the following steps of: (1) putting the raw materials in a water bath container and stirring and mixing into liquid mixed oil; (2) slowly and completely dissolving the NaOH by using the deionized water; (3) slowly adding the liquid mixed oil into NaOH solution and completely mixing the liquid mixed oil with the NaOH solution; (4) adding the essential oil, andevenly stirring; (5) pouring into a mould and standing for 24-48 hours; and (6) demoulding after liquid soap is solidified, and putting in a cool ventilated place for 4-8 weeks for use. The camellia facial soap manufactured by the preparation method disclosed by the invention has proper glycerol content and good molding performance, has a face cleaning effect, a face protection effect, a disinfecting effect and a sterilization effect, has low requirements on production conditions and is low in production cost.

Owner:郴州邦尔泰苏仙油脂有限公司

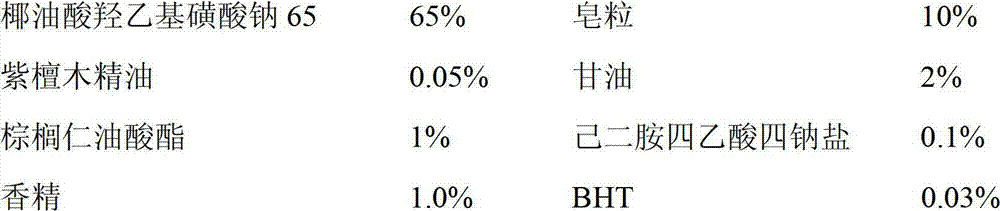

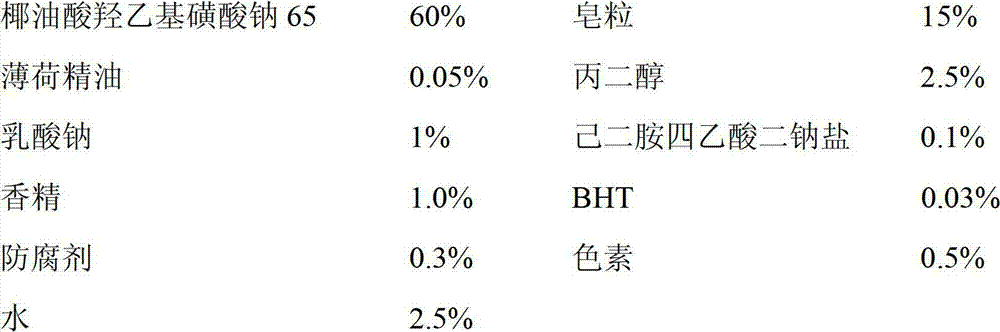

Multifunctional perfumed soap

ActiveCN102776087ALess irritatingMeet different functional requirementsSurface-active non-soap compounds and soap mixture detergentsSkin careHydrogenIrritation

The invention discloses multifunctional perfumed soap, which contains the following components by weight percent: 40-80 percent of surfactant, 10-25 percent of soap grains, 0.001-0.1 percent of essential oil, 0.5-5 percent of moisture preserving agent, 0.1-5 percent of skin protecting agent and 0.05-0.5 percent of chelating agent. The multifunctional perfumed soap provided by the invention has the advantages that since the surfactant is used for replacing most part of soap grains, the pH (potential of hydrogen) value is close to neutral and the irritation is less; and since the essential oil is added, the different functional demands of users are met.

Owner:广东名臣日化有限公司

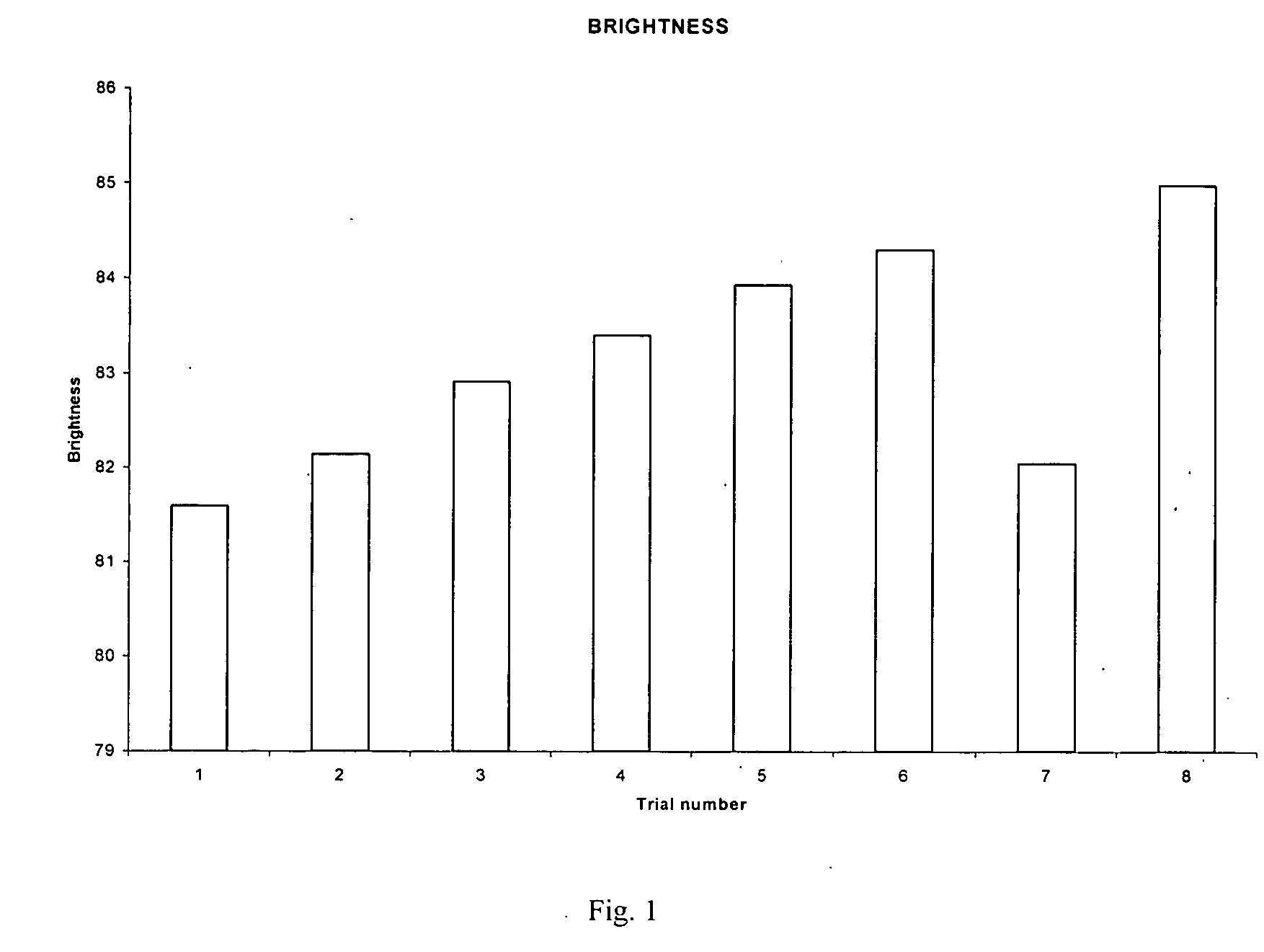

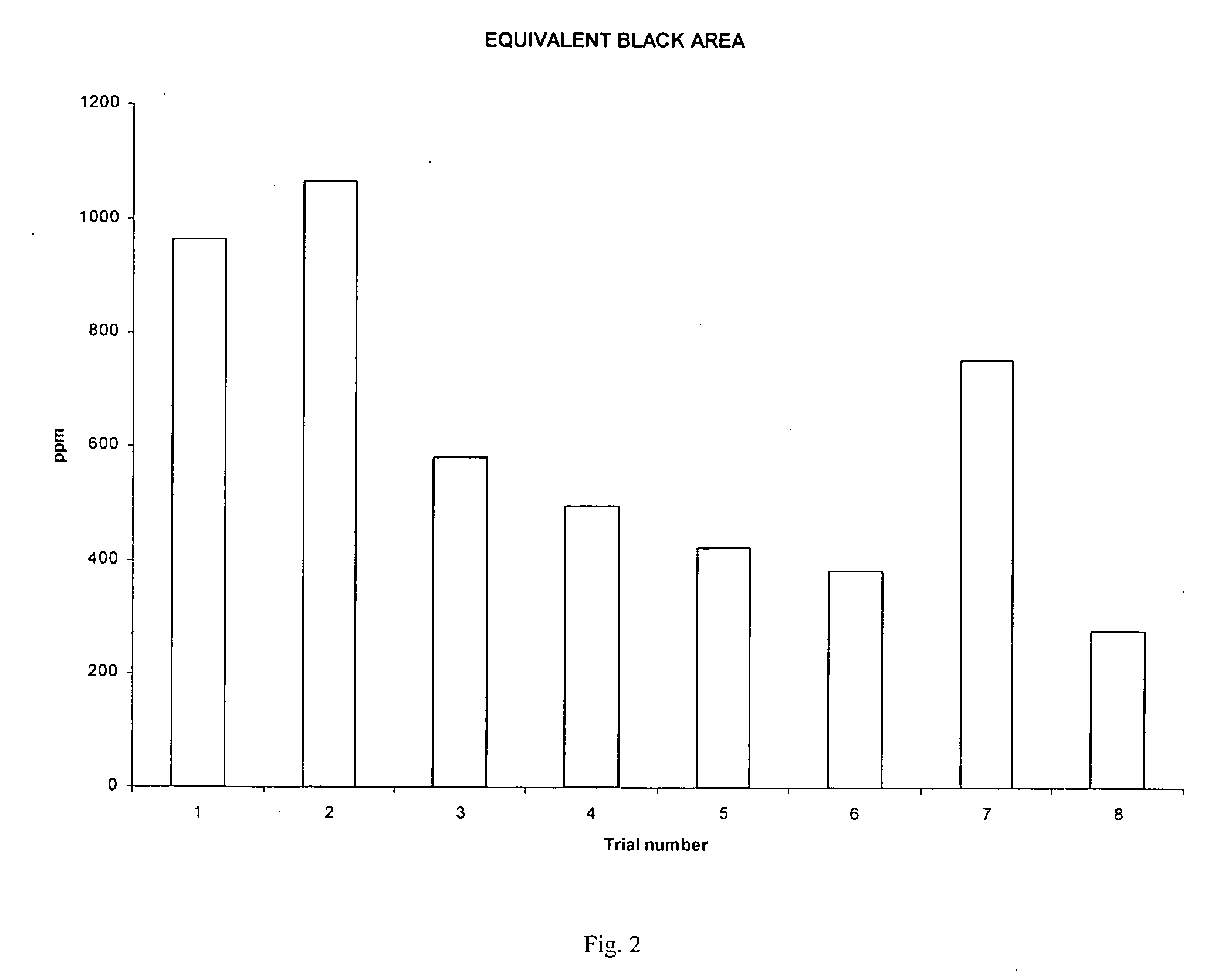

Method for enzymatic deinking of waste papers, the waste papers so treated and the treating composition

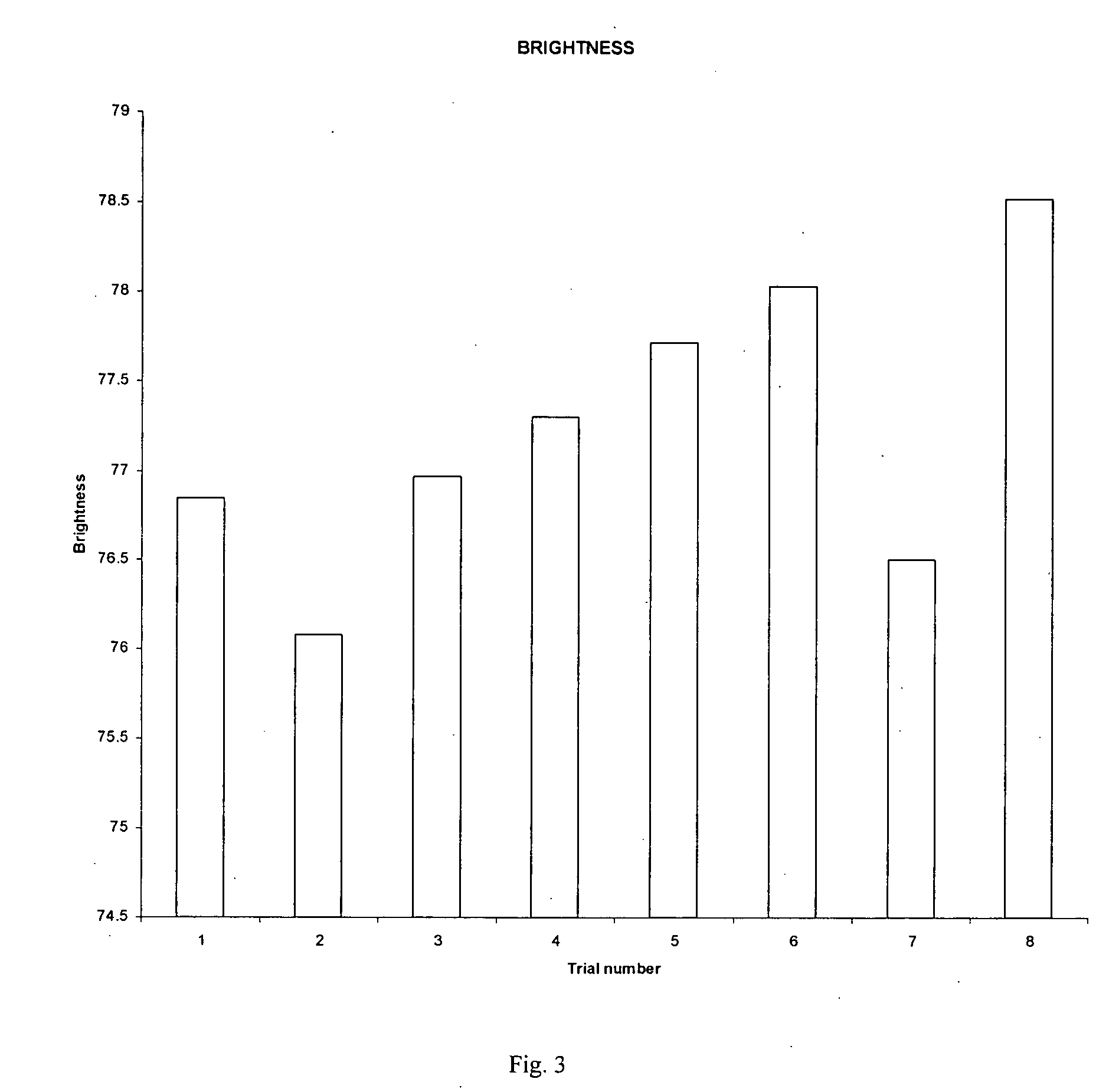

ActiveUS20060102299A1Prolonged actionIncrease brightnessPaper recyclingCellulose treatment using microorganisms/enzymesDeinkingPaper sheet

The present invention relates to a deinking composition and a method of deinking wastepaper by using a mixture of enzymes that act on constituents of all three waste paper components involved in ink retention on final pulp. The first component represents substrates located on the surface and in the internal waste paper structure. The second component represents substrates located in the interface between paper and ink, usually formed by coatings or size-press (starch containing or not) applied layers. The third component represents substrates located in the ink and / or toner compounds. This method provides improved performance in relation to conventional methods, or current deinking with enzymes, which acts on a limited number of substrates involved in ink retention on final pulp.

Owner:TRI TEX

Pure natural plant perfumed soap and preparation method thereof

InactiveCN102329702ATo promote metabolismFormed earlySoap detergents with organic compounding agentsAlkali/ammonium soap compositionsPremature agingWrinkle skin

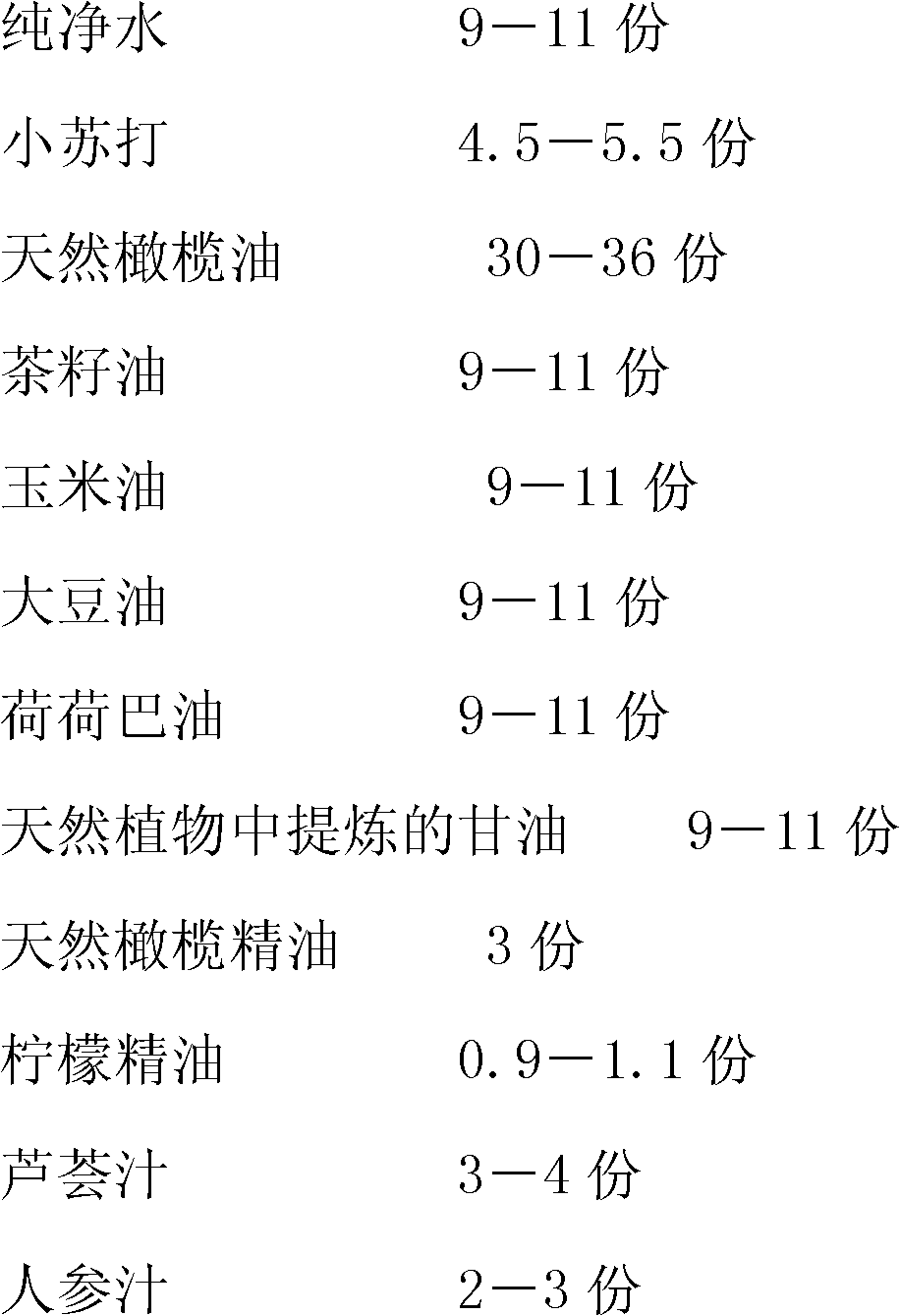

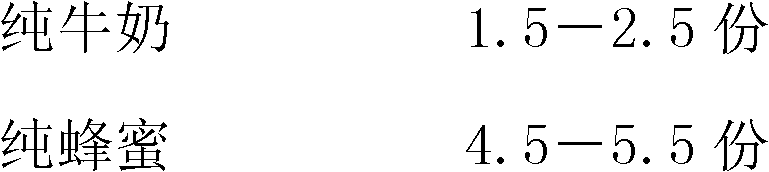

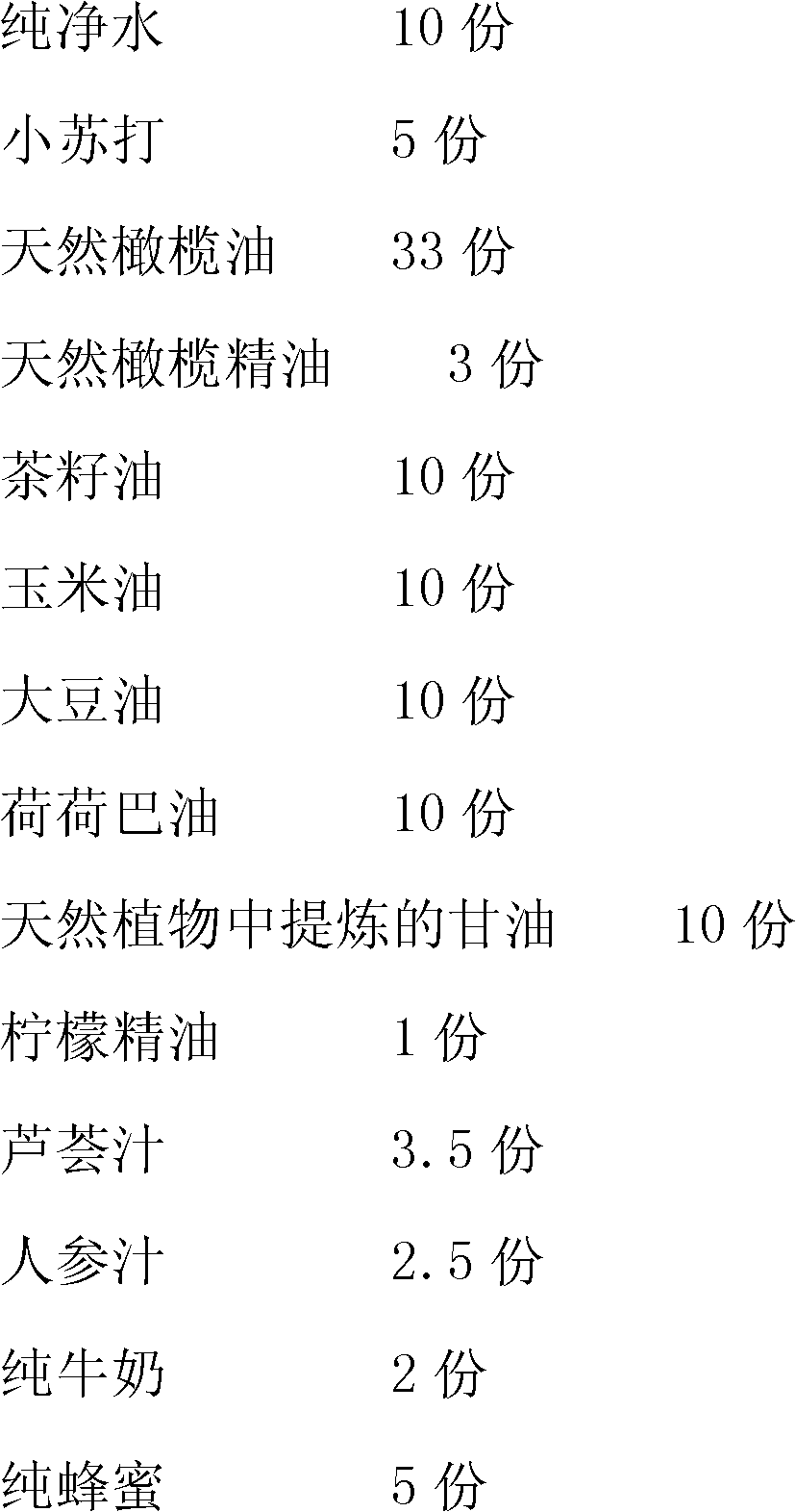

The invention relates to pure natural plant perfumed soap. The pure natural plant perfumed soap is prepared from the following raw materials in parts by mass: 9-11 parts of purified water, 4.5-5.5 parts of baking soda, 30-36 parts of natural olive oil, 9-11 parts of tea seed oil, 9-11 parts of corn oil, 9-11 parts of soybean oil, 3 parts of Jojo natural olive essential oil, 9-11 parts of Jojoba oil, 9-11 parts of glycerin extracted from natural plants, 0.9-1.1 parts of lemon essential oil, 3-4 parts of aloe juice, 2-3 parts of ginseng juice, 1.5-2.5 parts of pure milk and 4.5-5.5 parts of pure honey. The pure natural plant perfumed soap provided by the invention has the beneficial effects that the pure natural plant perfumed soap has certain bacteriostatic action, and can significantly improve whelk and dermatitis; multiple natural nutriments in camellia oil and Jojoba oil can provide sufficient nutrients and water for skin, thus skin is moisturized and has luster and good elasticity;and after bath, perfume is maintained on skin, skin metabolism can be accelerated, the formation of wrinkle and cell premature aging can be effectively prevented and stoped, and youth and luster can be restored, thereby achieving the effects of nourishing and whitening skin.

Owner:HANGZHOU NORMAL UNIVERSITY

Laundry product

InactiveUS20060019866A1Overcome disadvantagesProvide benefitsAnionic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsWater solubleLaundry

A unit dose fabric treatment system comprises (a) a water soluble container and (b) a liquid fabric treatment composition disposed in the water soluble container, the fabric treatment composition comprising two or more alkali metal fatty acid soaps derived from unsaturated fatty acid soaps formed from fatty acids having a iodine value greater than 20; and saturated fatty acid soaps formed from saturated fatty acids having an iodine value less than 5.

Owner:CONOPCO INC D B A UNILEVER

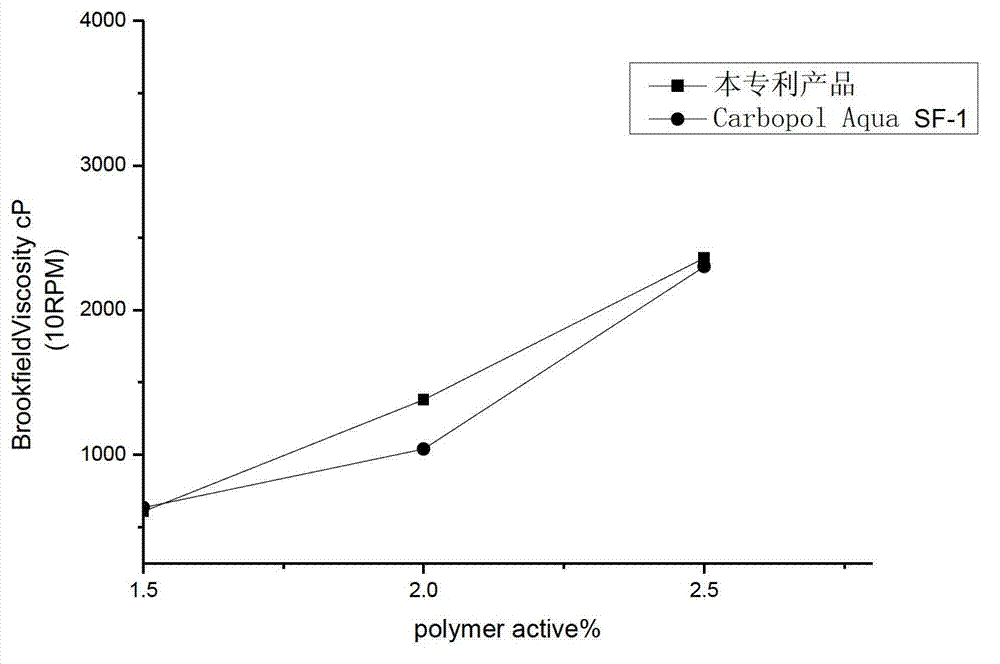

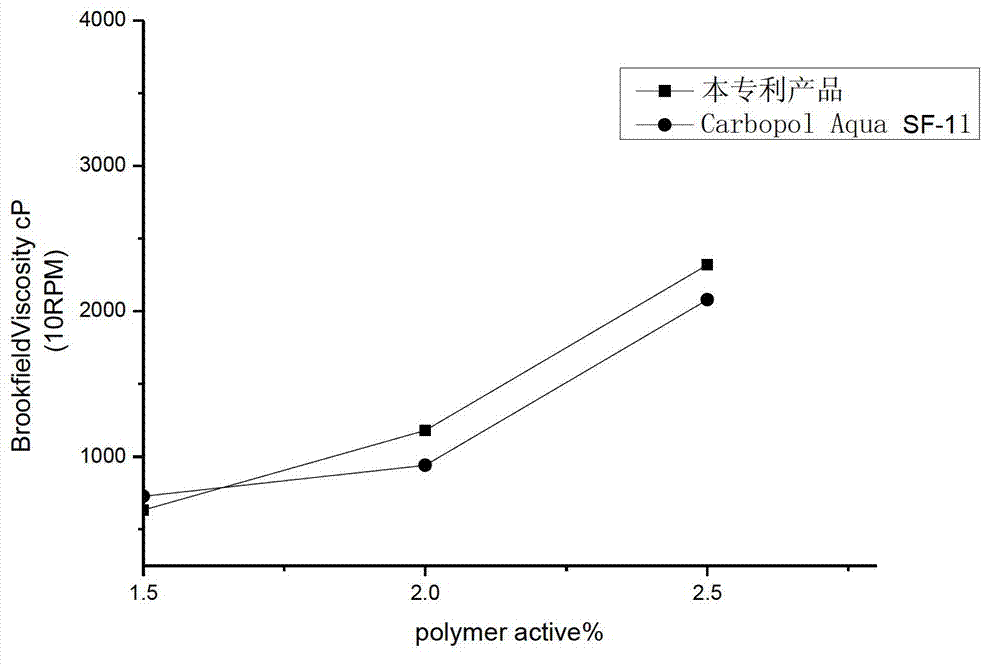

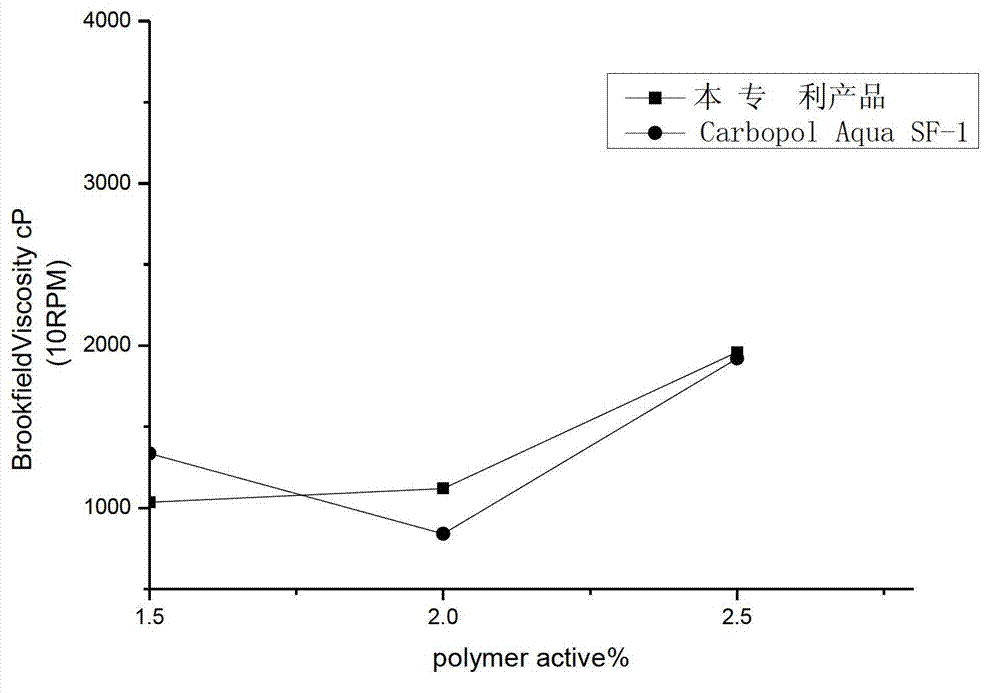

Polymer latex and application thereof

InactiveCN102863594AOmit demulsificationEasy to pumpTransportation and packagingSurface-active non-soap compounds and soap mixture detergentsPolymer sciencePhosphoric acid

The invention discloses a polymer latex which can be obtained by the reaction among alpha, beta-vinyl unsaturated carboxylic acid monomer (I) and or acid monomer with sulfonic acid, phosphoric acid or hypophosphorous acid, alpha, beta-vinyl unsaturated monomer (II), hydrophilic unsaturated crosslinking monomer or bifunctional and multifunctional vinyl unsaturated crosslinking monomer (III-VI), nonionic vinyl or acryl surface active agent (VII), anionic emulsifier, initiator, and chain transfer agent, wherein the polymer latex can be used for forming into a binary system in a surface active agent composition. Due to the unique crosslinking nodes in the polymer latex, the polymer latex can be used in various fields even under the low-pH and high-salt content severe environment such as the cosmetics, the medicines, the emulsion paint, and the effective and high-efficiency thickening agent and suspending agent in cleaning composition.

Owner:JIANGSU FEIXIANG CHEM

Method for preparing beautifying perfumed soap

The invention relates to the field of cleaning products, in particular to a method for preparing beautifying perfumed soap. The beautifying perfumed soap comprises the following components in parts by mass: 6-7 parts of olive oil, 1 part of palm oil, 1 part of sodium hydroxide, 4-5 parts of water and 0.065-0.26 part of pearl powder or essential oil, wherein the olive oil, the palm oil, the sodium hydroxide and the water are used as main raw materials; and the pearl powder and the essential oil are used as auxiliary raw materials for adding as required. The method comprises the following steps of: filling olive oil and palm oil into a stainless steel container or a heat resistant glass container, heating by insolating water and cooling to 45-50 DEG C; slowly adding sodium hydroxide into water; after the sodium hydroxide is completely dissolved into water, cooling to 40-50 DEG C; slowly pouring an alkali solution into a container loaded with oil and rapidly stirring until soap liquid is thick; adding the pearl powder and the essential oil and uniformly stirring; pouring the stirred soap liquid into a die and demoulding after 24 hours; and then placing the soap liquid at normal temperature environment for saponifying for 4-8 weeks. The handmade soap prepared by the invention has the advantages of high grade of adopted grease, simple and safe preparation process and no any additive and can be used for washing the face and the hair and bathing; and because glycerol is still retained in the perfumed soap, the beautifying perfumed soap not only can have the effect of cleaning but also can protect the skin and hair.

Owner:朱鹏龙

Hair-washing handmade soap and preparation method thereof

InactiveCN104312788APrevent regenerationRetain nutrientsHair cosmeticsAlkali/ammonium soap compositionsHair rootsAdditive ingredient

The invention discloses a hair-washing handmade soap and a preparation method thereof. The hair-washing handmade soap is prepared from the following components in percentage by weight: 26-40% of palm oil, 20-30% of fleece-flower root and olive infused oil, 13-20% of coconut oil, 6.6-10% of caster oil, 9-12% of NaOH, 0.8-1.2% of natural perfume (fresh ginger essential oil) and the balance of deionized water. By using full-natural vegetal oil as a raw material, the soap which is purely manually cold-prepared is free of soap base and any chemical additives, and all materials are naturally saponified at normal temperature, so that the nutritional components of the raw materials are integrally reserved. Fleece flower root and fresh ginger essential oil type natural perfume hair-washing handmade soap contains the nutritional components such as rich lecithin of fleece flower roots to nourish hair roots and promote hair melanogenesis, so that the hair is easy to comb and pitch-black and bright. Fresh gingers have the functions of relieving exterior syndrome by dispersion. Externally used fresh gingers can be used for increasing blood circulation of head, stimulating hair follicles to open, promoting metabolism of hair, activating hair follicle tissues, preventing alopecia, regenerating hair and the like.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

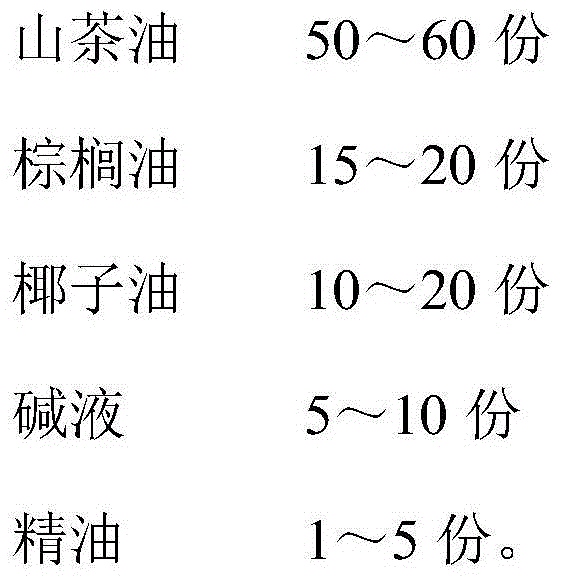

Handmade camellia oil soap and preparation method thereof

InactiveCN104388213AModerate hardnessEasy to storeSkin careAlkali/ammonium soap compositionsCoconut oilHardness

The invention relates to handmade camellia oil soap and a preparation method thereof. The handmade camellia oil soap is prepared from the following raw materials in parts by mass: 40-80 parts of camellia oil, 1-30 parts of palm oil, 1-30 parts of coconut oil, 5-30 parts of an alkaline solution and a proper amount of essential oil. The handmade camellia oil soap disclosed by the invention is simple in preparation process, diversified in product shape, flavor and color, moderate in hardness, convenient to store, durable in use, quite high in practicability and quite high in economic efficiency; the method disclosed by the invention is simple in preparation process, easy to implement, high in production efficiency, high in safety and capable of rapidly and efficiently preparing the handmade camellia oil soap which is good in cleaning, wetting and nourishing effects, moderate in hardness and durable in use.

Owner:HANGZHOU CHOISUN BIO TECH CO LTD

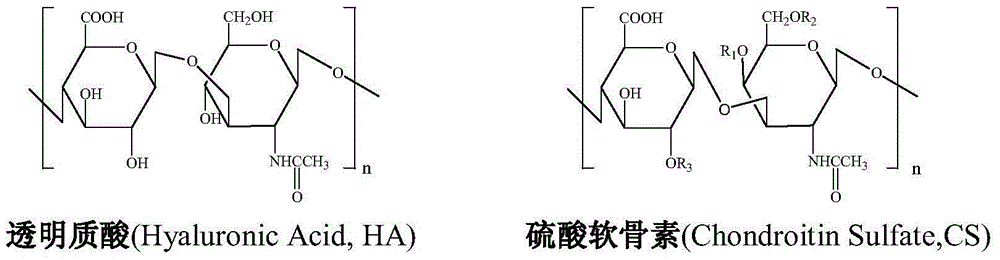

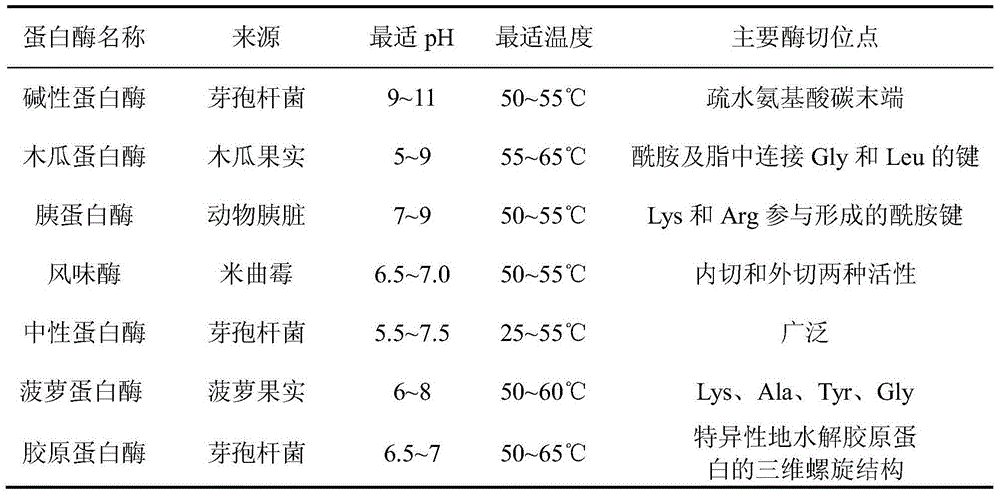

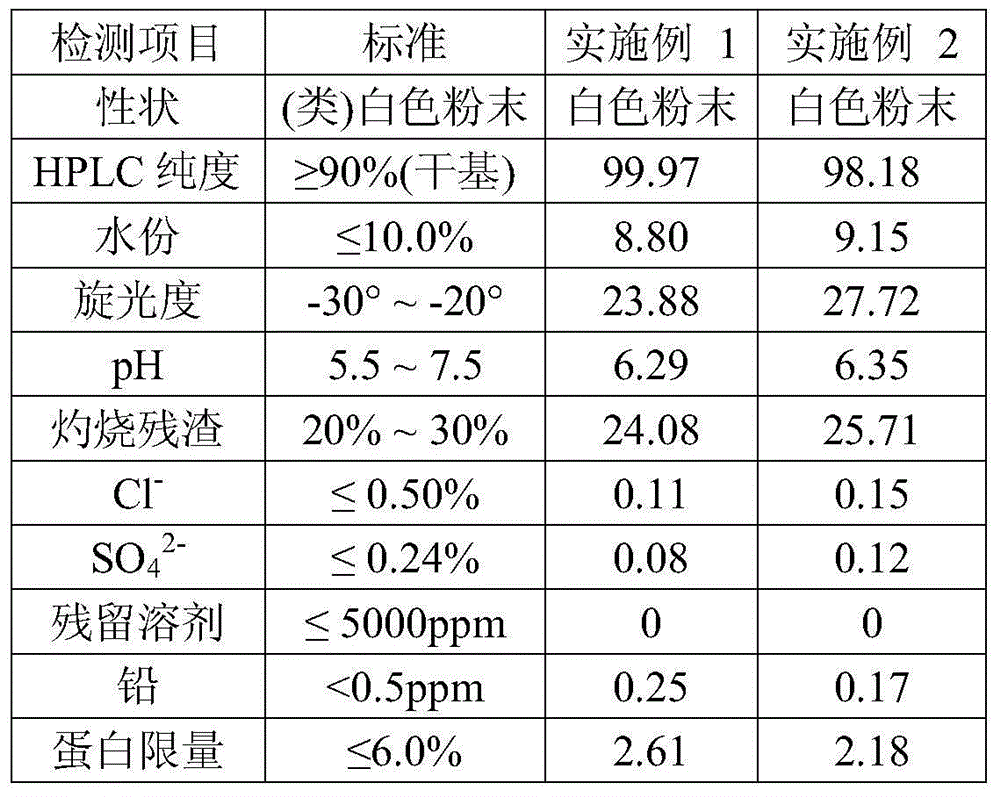

Combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap

ActiveCN104531817ARealize simultaneous hydrolysisEmission reductionConnective tissue peptidesCutting soapResource utilizationHydrolysate

The invention discloses a combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap. The method mainly comprises the process steps that animal cartilage is soaked with water and smashed to obtain cartilage powder, the cartilage powder undergoes protease enzymolysis and then is adsorbed by resin, adsorbed enzymatic hydrolysate is collected, the resin undergoes gradient elution through a NaCl aqueous solution, and eluants undergo desalination, concentration, sterilization and drying to obtain finished products of the hyaluronic acid and chondroitin sulfate; the adsorbed enzymatic hydrolysate undergoes decoloration, anion and cation exchange resin mixed column treatment, nanofiltration purification, concentration, sterilization and drying to manufacture finished products of the collagen peptide; grease undergoes extraction saponification to manufacture the soap; denatured protein-bone dreg compounds and other materials are mixed to manufacture the fodder. According to the combined production method, by utilizing the process of resin adsorption-spray drying, highly-intensified resource utilization of cartilage is achieved, energy saving and emission reduction are achieved, and the economic benefit and the social benefit are remarkable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Traditional Chinese medicine perfumed soap for removing acne and preventing skin allergy

InactiveCN102391919ADermatological disorderAlkali/ammonium soap compositionsSide effectViral infectious disease

The invention provides medicated soap for aiding in preventing and treating acne, eliminating cosmetic allergy and thoroughly removing remaining cosmetic from face, which has the effects on resisting bacteria, diminishing inflammation, promoting blood circulation of skin, preventing skin allergy and the like. The medicated soap has a faint scent and abundant foam, is convenient in use without side effect, can be used for cleaning skin and washing hands normally, and can prevent many kinds of bacterial and viral infectious diseases.

Owner:许扬

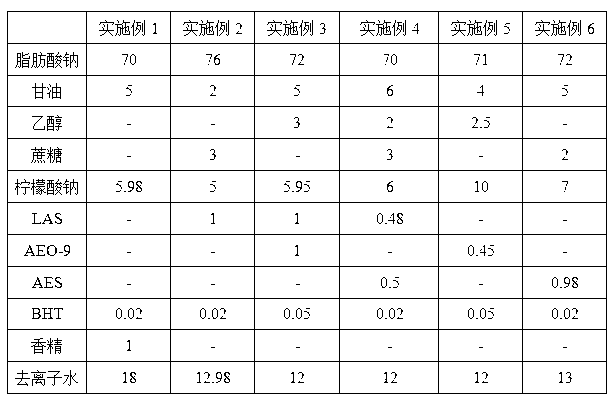

Transparent soap

InactiveCN103013715AHigh transparencyHigh hardnessSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsActive agentFatty acid

The invention discloses a transparent soap, which is mainly prepared by fatty acid, a transparent reagent, sodium citrate, a surfactant and deionized water, wherein the content of sodium citrate based on weight is 0.1-15%. The transparent soap has appropriate hardness and transparency; and the washing capability is not influenced by calcium ions and magnesium ions when in use.

Owner:GUANGDONG PENGJIN INDUSTRY CO LTD

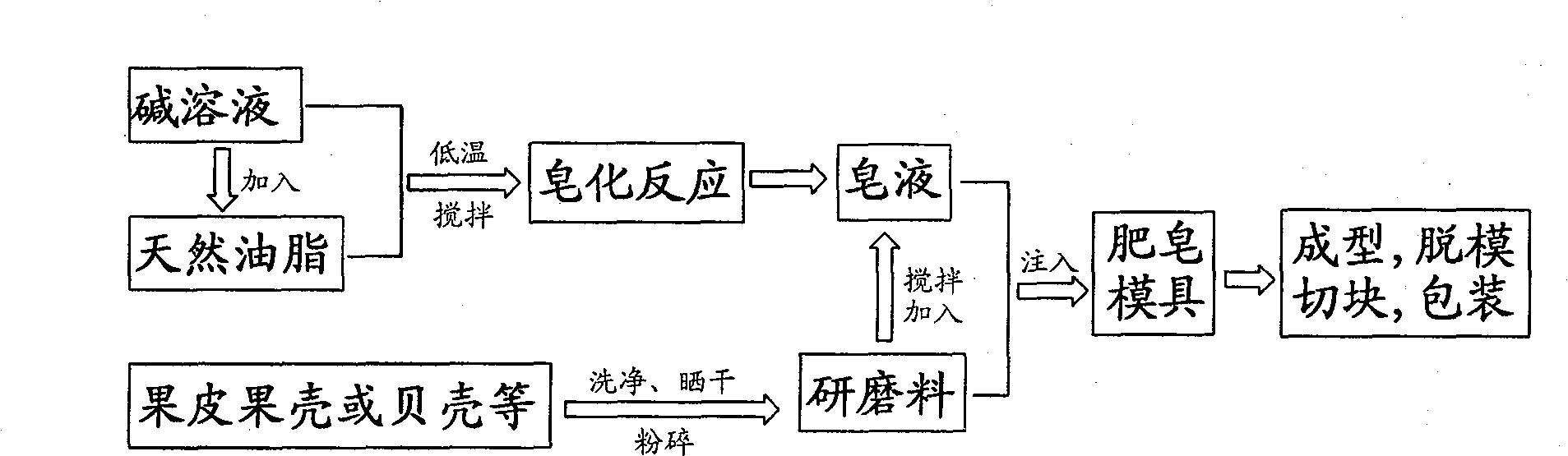

Scrub soap and preparation process and formula thereof

InactiveCN102041205AImprove maintenance effectNo adverse effectsShaping soapAlkali/ammonium soap compositionsOyster shellsBULK ACTIVE INGREDIENT

The invention discloses a solid cleaning product, which is prepared by the following steps of: grinding natural plant peel, pericarp, husk and shell materials such as shells, durian shells, litchi pericarp, oyster shells, pineapple peels, buckwheat husks, aloe peels, orange peels and cinnamon bark into particles with 20 to 600 meshes serving as scrub materials, and adding one or more scrub materials into a soap base by adopting low temperature saponification technology to prepare the scrub soap. In the process of preparing the scrub soap, surfactants and chemical additives are not added at all, and byproducts are not generated at all, so the scrub soap cannot have any adverse effect on the skin and environment. The pericarp, husk or shell scrub material in the scrub soap can peel off or remove dead skin cells, contains rich natural active ingredients such as polysaccharides, vitamins, tartaric acid and pectin, which have good effects of sterilizing, beautifying, moistening, repairing and resisting ageing on the skin, and has great market application prospect.

Owner:王世范

Technology for ultrasonically producing cold soap

InactiveCN102994280AShort reaction timeLow production costSoap detergents with other compounding agentsAlkali/ammonium soap compositionsEngineeringSOAP

Owner:吴妙娴 +1

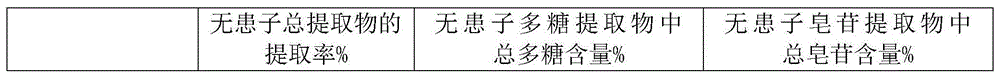

Process for simultaneously extracting pigments, saponins and polysaccharides of sapindus, and preparation and application of saponins of sapindus

The invention relates to a process for simultaneously extracting pigments, saponins and polysaccharides of sapindus, and preparation and application of the saponins of the sapindus, and belongs to the technical field of medicine and chemical engineering. The process includes extracting total extracts of the sapindus from dry fruit peel of the sapindus by the aid of a decocting method, dissolving the total extracts in water to obtain samples, feeding the samples to macroporous adsorption resin, eluting the macroporous adsorption resin by distilled water at first, collecting eluent, removing proteins by the aid of a dialysis method, and concentrating and drying the eluent to obtain polysaccharide extracts of the sapindus; eluting the macroporous adsorption resin with 4-5 retention volumes by the aid of 40% ethanol, then eluting the macroporous adsorption resin by the aid of 80% ethanol, collecting eluent and concentrating and drying the eluent to obtain saponins extracts of the sapindus; eluting the macroporous adsorption resin by the aid of 95% ethanol, collecting eluent and concentrating and drying the eluent to obtain pigment extracts of the sapindus. Active dry yeast is inoculated in the saponins extracts of the sapindus after the saponins extracts of the sapindus are dissolved in water, then the saponins extracts of the sapindus are fermented and are concentrated and dried to obtain the saponins of the sapindus. The process, the preparation and the application have the advantages of simplicity in preparation method, low cost, one-step reaction, environmental protection, high efficiency and easiness in popularization and application.

Owner:陈琳仁

Preparation method for manually ground soap

InactiveCN103756817AImprove processing efficiencySolve the low saponification rateShaping soapAlkali/ammonium soap compositionsSolubilityMineralogy

The invention discloses a preparation method for a manually ground soap, which comprises the following steps: after a soap base is prepared, feeding the soap base into a three-roller mill to carry out primary grinding so as to obtain a flaky soap base; detecting the pH of the flaky soap base obtained after primary grinding and if the pH value is greater than 9, adding weak acid into the flaky soap base obtained after primary grinding to regulate the pH value; after the weak acid is added, carrying out grinding again, confirming that the pH value is reduced into the use range, and feeding the soap base subjected to pH value regulation into a soap plodder for extrusion molding; after extrusion molding, printing by a soap cold printing machine to obtain the manually ground soap and packaging to obtain the finished product. According to the invention, the pH value of the soap is regulated in the grinding process, thus, after the soap preparation process is finished, the obtained manually ground soap can be immediately used; in the grinding process, all or most of soap crystal phases are transformed into beta crystal phases by grinding and pressing through mechanical force, thus, compared with an unground soap, the prepared soap has high solubility, strong foaming capacity and fine washing feeling.

Owner:夏程

Natural hand-made soap component, and its manufacturing method

InactiveCN1850955APromote regenerationPromote blood circulationAlkali/ammonium soap compositionsGLYCYRRHIZA EXTRACTChinese licorice

The invention discloses a natural perfumed soap constituents and the manufacture method that includes mixing extract, 30% NaOH solution, unilateral essential oil, and vegetable basal oil. The mixing extract is made up from ginseng, liquorice, mung bean, white batryticated silkworm, kaempferia galamga, corn mint, ledebouriella root, ligusticum, and abnormal fruit of Chinese honeylocust, radix trichosanthis, and Japanese ampelopsis. The vegetable basal oil includes olive oil, coconut oil, palm oil, wheat germ oil, fructus rosae oil, shea butter, and rice bran oil. It has the advantages of enhancing skin immunity, activating blood circulation and cell regenerating.

Owner:JINAN MAKA COSMETICS CO LTD

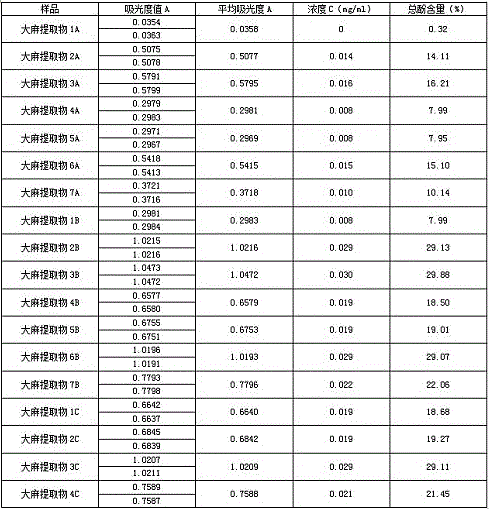

Composition containing cannabis sativa extract and application thereof in cleaning articles

The invention discloses a composition. The composition consists of cannabis sativa extract and auxiliary materials acceptable in the field of the cleaning articles. The cannabis sativa extract contains cannabinoid substances. The invention also discloses an extracted part of cannabis sativa in the cannabis sativa and an applicable preparation method, a gross proportion of the cannabis sativa extract in the cleaning articles, a constitution of auxiliary materials of the cleaning articles and a product form of the cleaning articles. A novel composition is provided for the field of the cleaning articles, and a new type of cleaning product is provided for consumers.

Owner:HANYI BIO TECH CO LTD

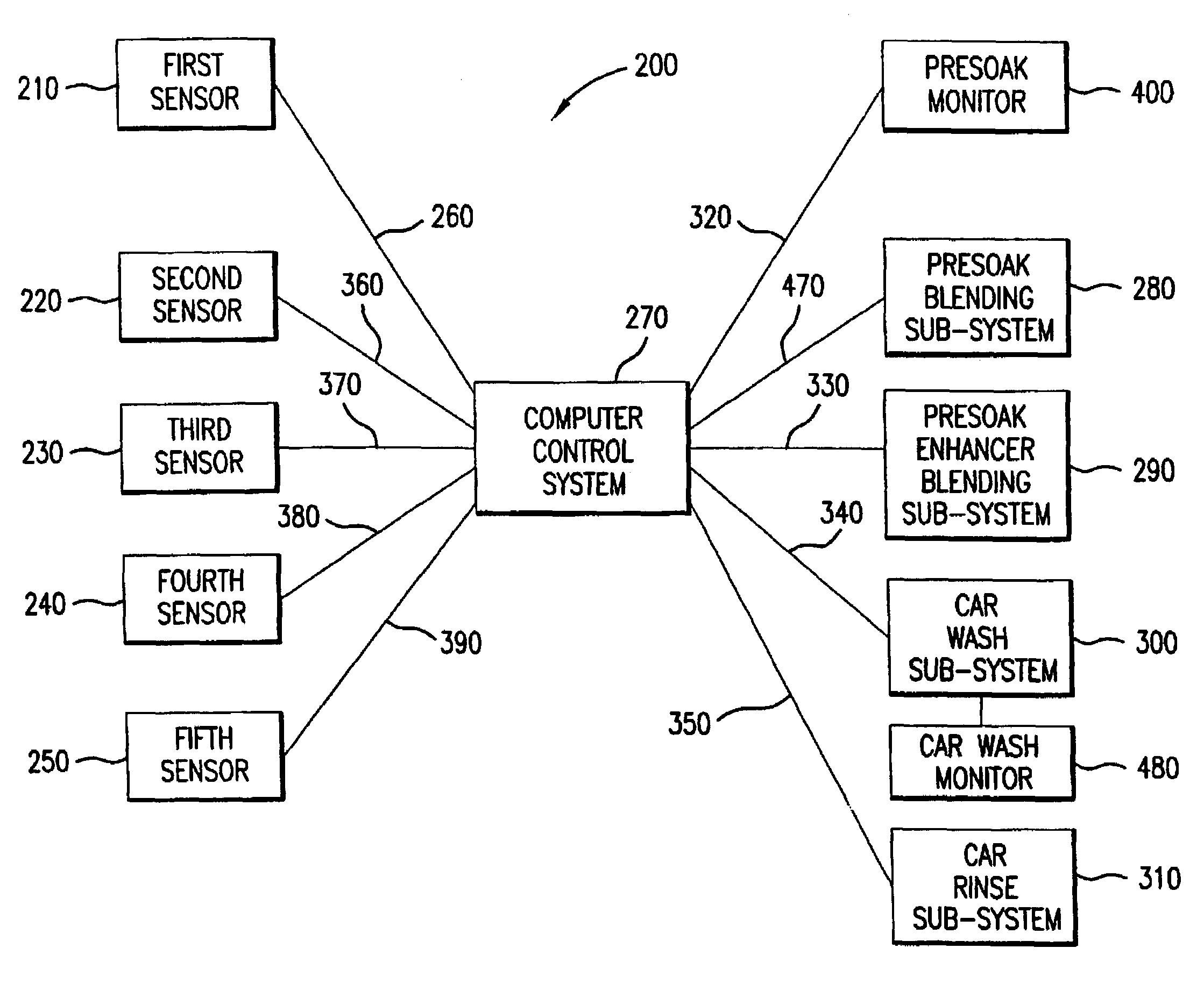

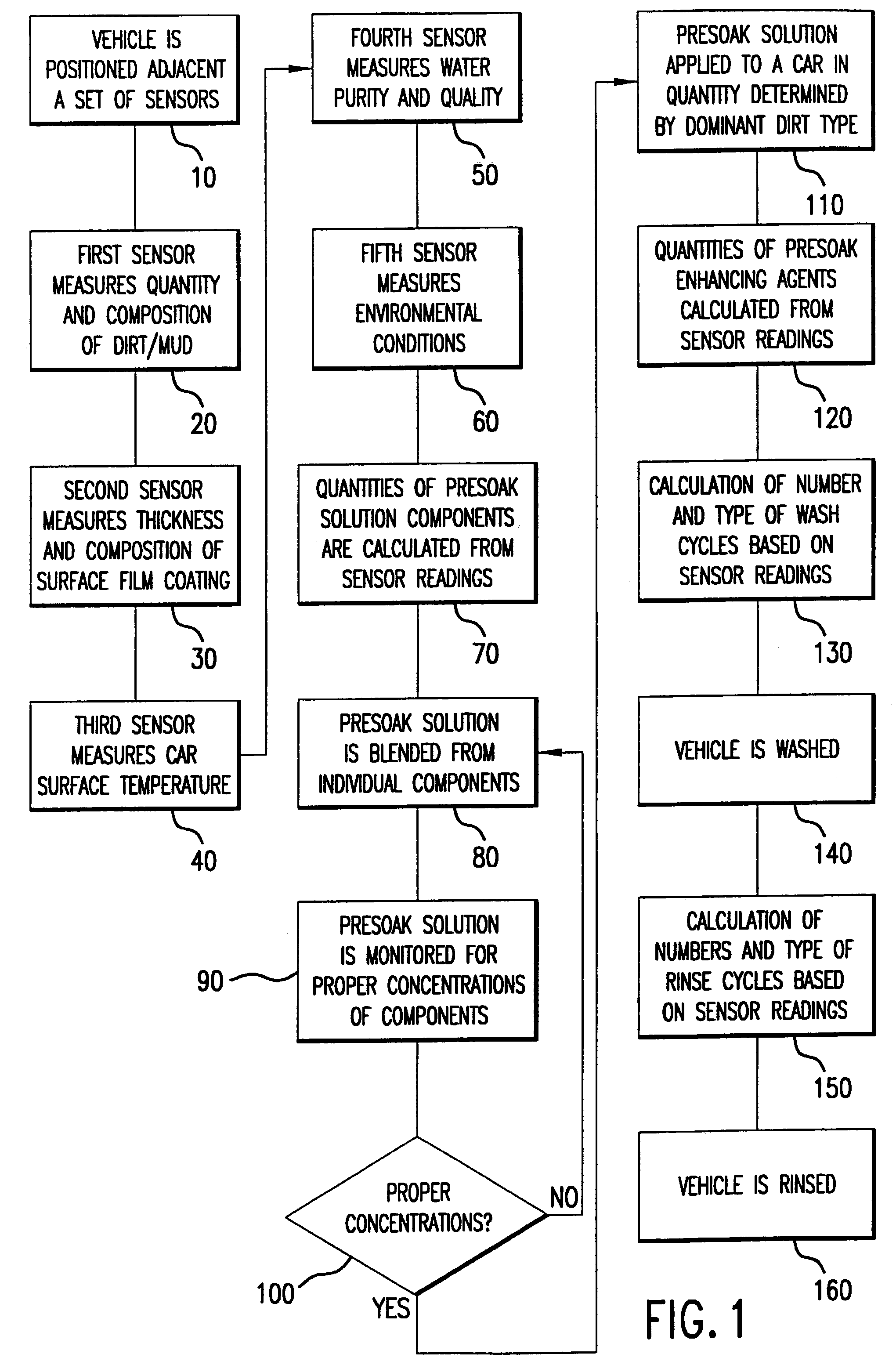

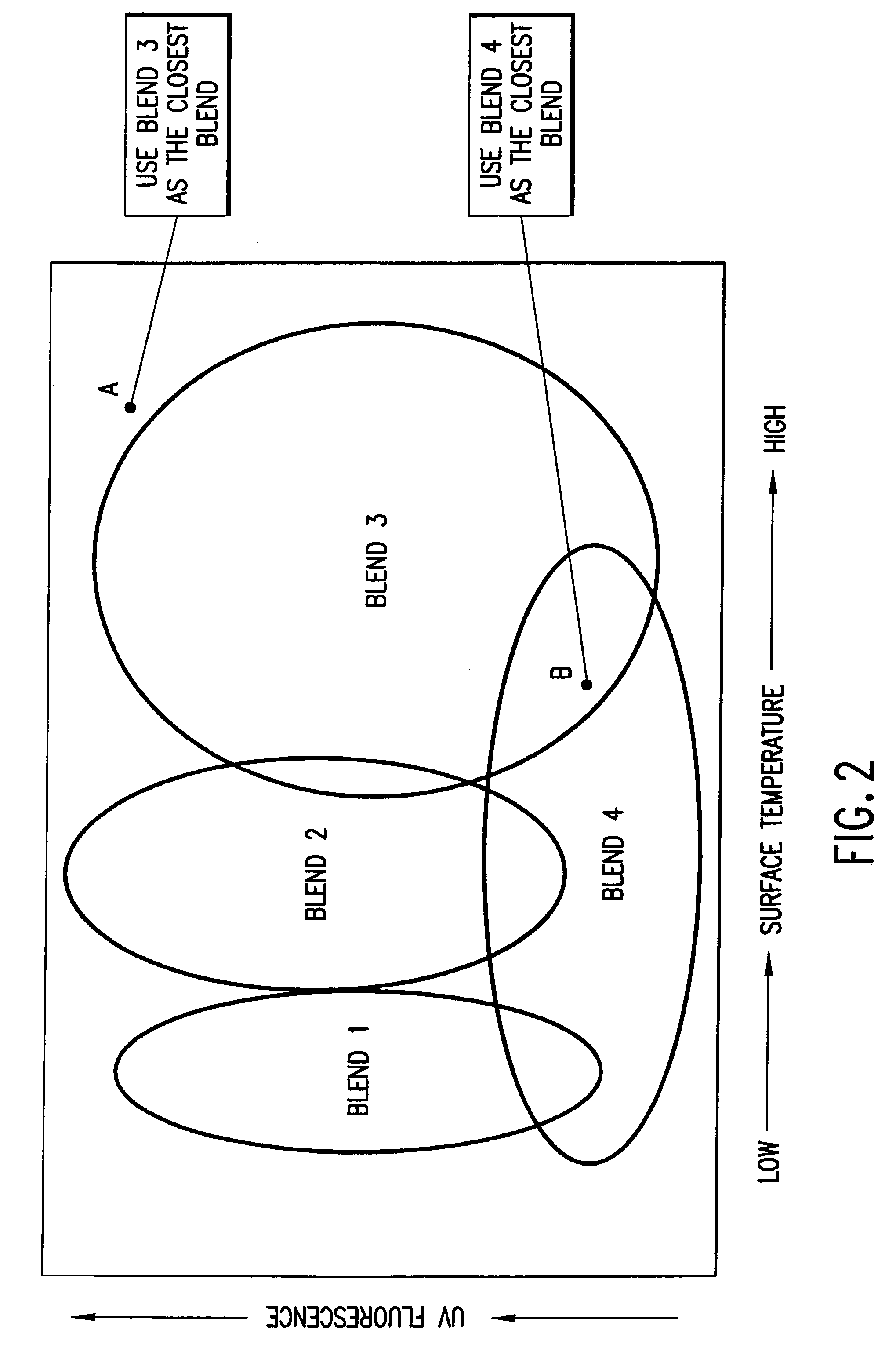

Customizable vehicle wash blending system and method

ActiveUS7045021B2Detergent mixture composition preparationCleaning apparatus for vehicle exteriorsHybrid systemEngineering

A customizable car wash blending and method is provided. The method includes the steps of positioning a vehicle adjacent a set of sensors (step 10), measuring a variety of parametric data relating to macroscopic debris and surface film formed on a surface of the vehicle, calculating the quantity of presoak components to be added to a presoak solution (step 70), blending the presoak solution (step 80), and applying the presoak solution to the vehicle (step 110). Quantities of presoak enhancing agents are also calculated from the sensor readings (step 120) along with the calculation of the number and type of wash cycles required for the vehicle (step 130).

Owner:UNITEC INC

Natural hand soap and preparation method thereof

InactiveCN105219553ADecontaminationHas the effect of skin care, freckle removal and moisturizingAntibacterial agentsSkin careGleditsia triacanthosGLYCYRRHIZA EXTRACT

The invention discloses a natural hand soap and a preparation method thereof. The natural hand soap comprises the following raw materials in parts by weight: 30-40 parts of sapindus mukorossi, 10-20 parts of Chinese honey locust, 3-6 parts of anthemis nobilis, 9-14 parts of liquorice, 5-8 parts of almond, 10-15 parts of olive oil, 10-15 parts of palm oil, 5-15 parts of sodium hydroxide, 5-10 parts of purified water, 10-20 parts of a plant extract sterilizing agent and 5-10 parts of a flavouring agent. The natural hand soap prepared by adopting the preparation method has the functions of decontaminating, protecting skin, removing freckles, preserving moisture and sterilizing, is a natural and harmless hand soap, and further has an extensive economical value.

Owner:GUANGXI UNIV

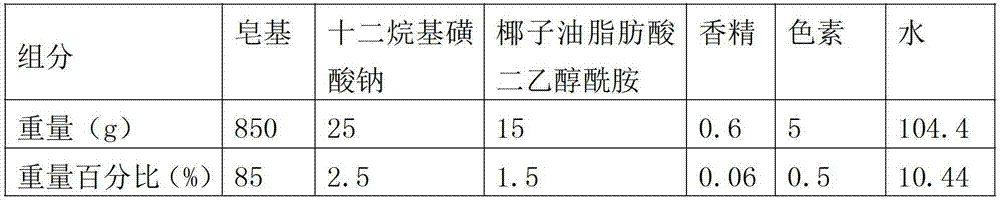

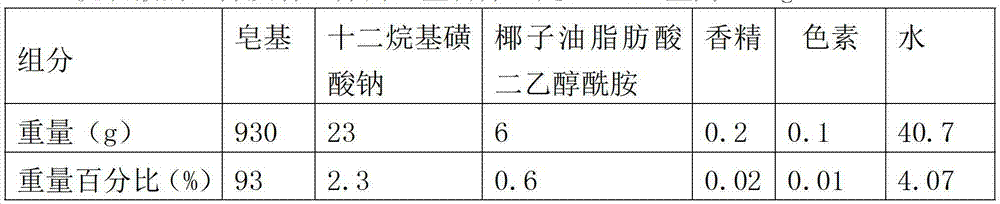

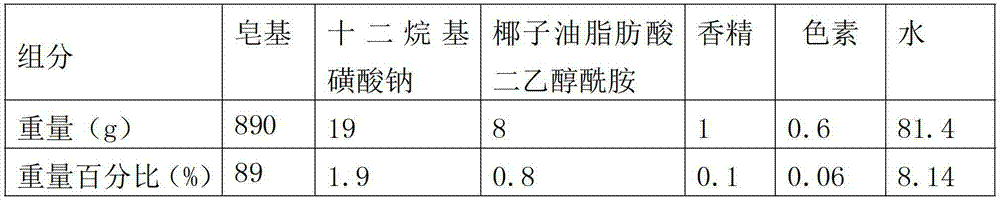

Liquid laundry detergent and preparation method thereof

InactiveCN103205332AStrong decontaminationImprove cleanlinessSurface-active non-soap compounds and soap mixture detergentsAlkali/ammonium soap compositionsLiquid laundry detergentDodecylsulfonic acid

The invention discloses liquid laundry detergent. The liquid laundry detergent comprises the following components in percentage by weight: 85 to 95% of soap base, 1.5 to 2.5% of sodium dodecyl sulfate, 0.5 to 1.5% of cocoanut fatty acid diethanolamide, 0.01 to 0.5% of essence, 0.01 to 0.5% of pigment, and the balance of water. A preparation method of the liquid laundry detergent comprises the following steps of: a, mixing the components of the liquid laundry detergent in proportion; b, stirring and heating to 80 to 85 DEG C; and c, cooling to obtain a finished product of the liquid laundry detergent. According to the liquid laundry detergent and preparation method provided by the invention, the prepared liquid laundry detergent has the characteristics of high detergency and mild performance.

Owner:武汉创新资源环保循环有限公司

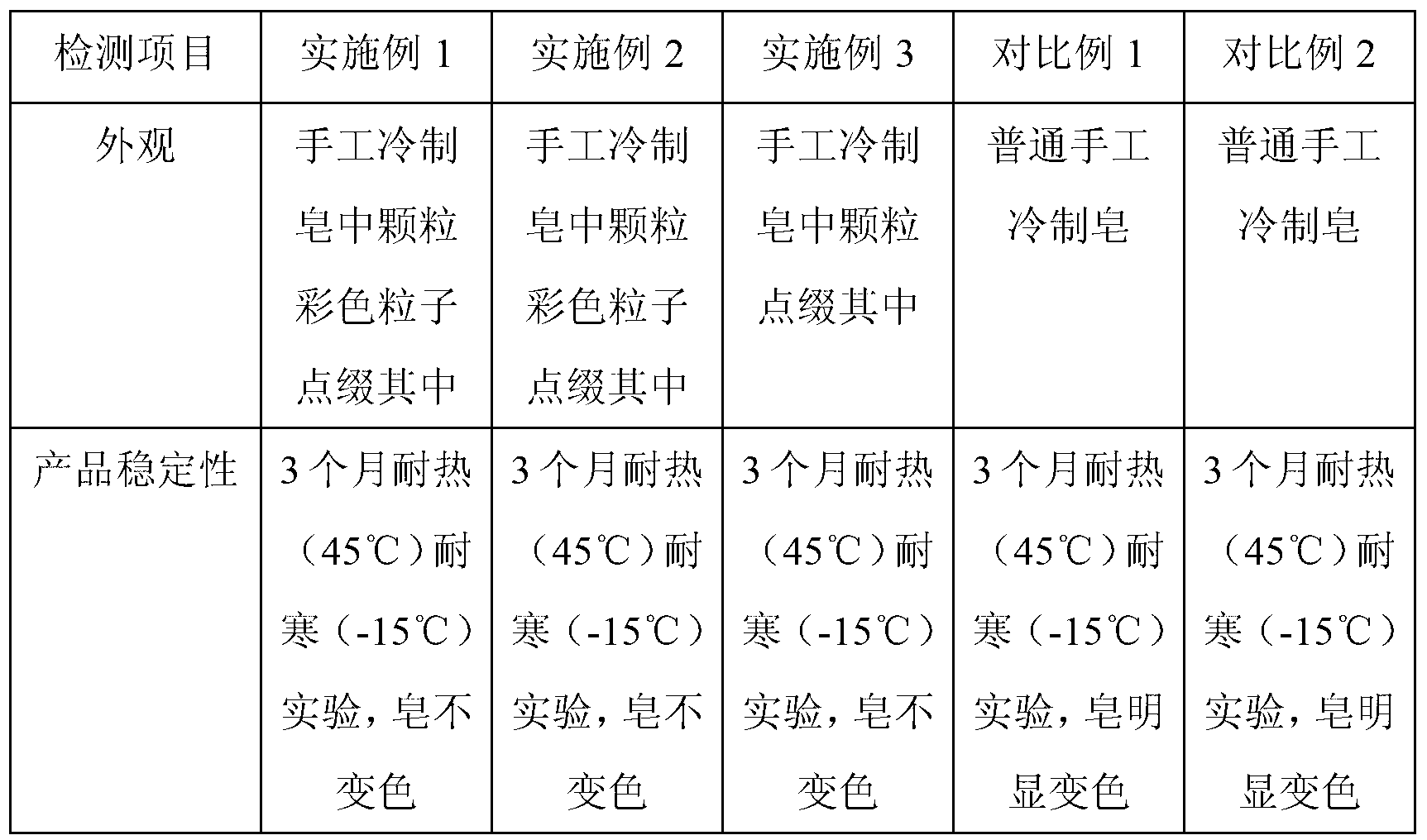

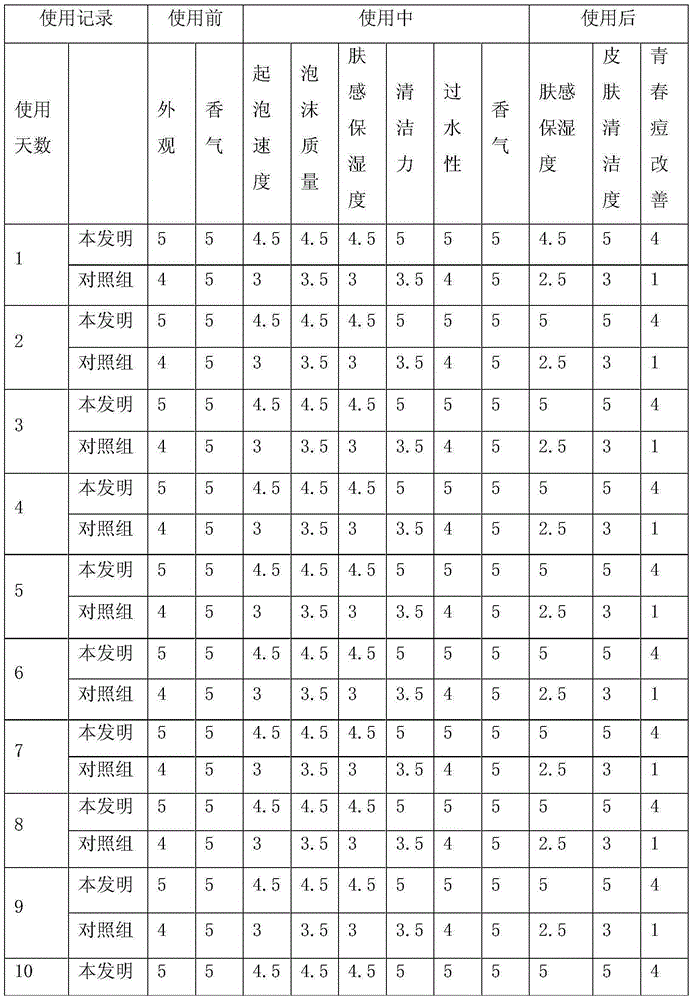

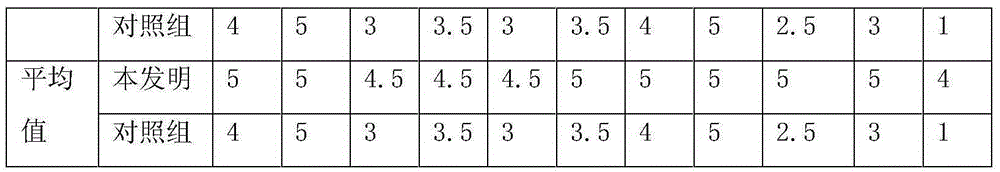

Hand-made cold process soap and preparation method thereof

ActiveCN103224848APrevent spoilageNot easy to change the tasteDetergent materialsSkin careCoconut oilAvocado Oil

The invention provides a hand-made cold process soap and a preparation method thereof. The hand-made cold process soap comprises 1-2% by weight of encapsulation particles, wherein the encapsulation particles have a capsule wall and a capsule core. A soap base formula of the hand-made cold process soap comprises the following components, by weight, 5-20 parts of avocado oil, 5-20 parts of coconut oil, 5-20 parts of olive oil, 5-20 parts of palm oil, 5-20 parts of shea butter oil, 5-15 parts of sodium hydroxide, and 10-35 parts of water. According to the hand-made cold process soap, the function components, or perfume or other substances are wrapped in the microcapsules, such that direct contact of the function components, the perfume and other substances, and the alkaline environment of the hand-made cold process soap can be avoided so as to effectively solve problems of easy failures and volatilization of nutrients, perfume, and other substances, and easy deterioration of the hand-made cold process soap.

Owner:厦门诚享东方股份有限公司

Skin-whitening and moisturizing soap and preparation method thereof

InactiveCN103468440AMoisturize the skinSuitable for useSkin careAlkali/ammonium soap compositionsBiotechnologyTea Tree extract

The invention discloses a skin-whitening and moisturizing soap, belonging to the field of sanitary products. The soap is composed of the following components by mixing in parts by weight: 1-2 parts of sodium hydroxide, 3-5 parts of pure water, 15-20 parts of coconut oil, 8-12 parts of olive oil, 8-12 parts of almond oil, 8-12 parts of tea seed oil, 0.5-1 part of plant extracts, 0.5-1 part of propolis, and 0.5-1 part of plant essential oil. The plant extracts include a geranium extract, an aloe extract, a tea tree extract, an angelica extract and a licorice extract, and the plant essential oil refers to citric acid essential oil and lavender essential oil. The soap disclosed by the invention has the effects of moisturizing the skin and preventing the precipitation of melanin, and the soap is natural, non-irritant, simple to make and convenient to use.

Owner:上海超领日化产品有限公司

Tea-seed-oil acne-removing facial soap

ActiveCN105316135AReduce stimulationDamage suppressionAntipyreticAnalgesicsPeppermintsScutellariae radix

The invention provides a tea-seed-oil acne-removing facial soap. The tea-seed-oil acne-removing facial soap comprises the following ingredients in parts by weight: 1.5-3 parts of tea seed oil, 2-5 parts of a camellia seed extract, 19-21 parts of stearic acid, 7-10 parts of lauric acid, 3-5 parts of sodium hydroxide, 4-6 parts of allantoin, 0.1-0.4 part of borneol, 0.8-1.1 parts of a peppermint aqueous extract and 1-4 parts of a scutellaria root aqueous extract. The tea-seed-oil acne-removing facial soap is rich in various essence ingredients, such as tea saponin, squalene, vitamin E and other antioxidant ingredients, is strong in saponification, and has the strong effects of moistening skin, diminishing inflammation, relieving itching, cleaning and removing acne.

Owner:CHONGQING HUPO TEA OIL CO LTD +1

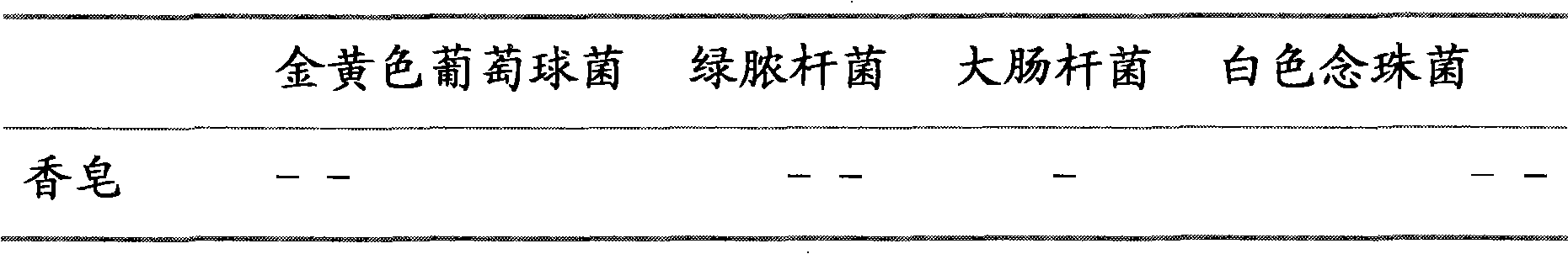

Antibacterial soap and preparation method thereof

InactiveCN102329703AEfficient removalEfficient killingAlkali/ammonium soap compositionsEscherichia coliStaphylococcus aureus

The invention discloses antibacterial soap which is characterized by comprising the following raw material components: 5-15% of coconut oil, 10-20% of palm oil, 3-10% of olive oil, 15-30% of beef tallow, 5-15% of sodium hydroxide, 2-8% of liquorice water extract, 1-3% of sodium dodecyl benzene sulfonate and 3-8% of titanium dioxide. The antibacterial soap obtained in the invention can be directlyapplied to the skin to effectively eliminate and kill bacteria on the skin and can resist staphylococcus aureus, Pseudomonas aeruginosa, escherichia coli and Candida albicans simultaneously.

Owner:NINGXIA MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com