Hand-made cold process soap and preparation method thereof

A cold soap making and manual technology, applied in the direction of chemical instruments and methods, skin care preparations, alkali soap/ammonium soap composition, etc., can solve the problems of large loss of spices, soap body pollution, taste variation, etc., to achieve non-volatile Black, save the amount of use, avoid the effect of taste variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

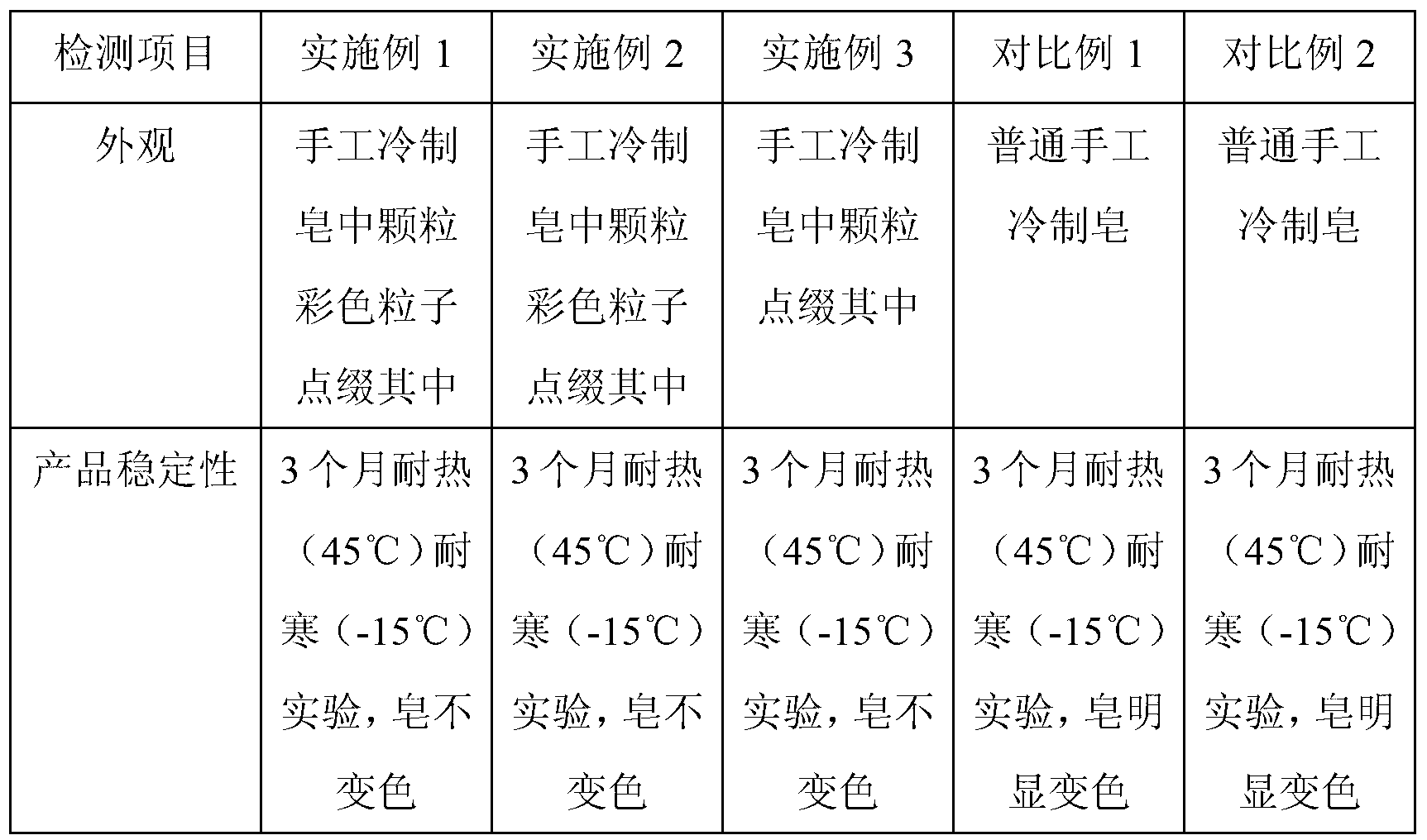

Examples

Embodiment 1

[0039] (1) Weigh each component according to the soap base formula in Table 1 below;

[0040] (2) Add avocado oil, coconut oil, olive oil, palm oil, and shea butter into the reactor, stir evenly (stirring speed 40rpm), raise the temperature to 30-40°C, and keep the temperature constant for use;

[0041] (3) Add aqueous sodium hydroxide solution at a temperature of 30-40°C to the solution in step 2), and stir rapidly (30-50rpm) until the soap becomes thicker and the viscosity of the soap is 6000mPa.s-8000mPa.s;

[0042](4) Add 2 parts by weight of encapsulated particles into the soap solution obtained in step (3), and stir evenly; the wall thickness of the encapsulated particles used is 0.25-0.35mm, and the capsule core of the encapsulated particles occupies the entire capsule 30-40% of the weight of the particles, and the particle size of the encapsulated particles is 0.5-0.8mm. The capsule wall is made of cellulose acetate butyl, and the capsule core is rose extract.

[004...

Embodiment 2

[0045] (1) Weigh each component according to the formula in Table 1 below;

[0046] (2) The rest of the steps are basically the same as in Example 1, the difference is that the encapsulated particles added in step (4) is 1.5 parts by weight, the wall thickness of the encapsulated particles used is 0.35-0.45mm, and the capsule core of the encapsulated particles is Accounting for 40-50% of the weight of the whole encapsulated particle, the particle diameter of the encapsulated particle is 0.8-1mm. The capsule wall is made of polyoxyethylene, and the capsule core is composed of VE oil, rose essential oil, oil-soluble rosemary extract and red pigment accounting for 1 wt% of the capsule core material in a mass ratio of 1:1:1.

Embodiment 3

[0048] (1) Weigh each component according to the formula in Table 1 below;

[0049] (2) The rest of the steps are basically the same as in Example 1, except that the encapsulated particles added in step (4) is 1.3 parts by weight, the wall thickness of the encapsulated particles used is 0.41-0.5 mm, and the capsule core of the encapsulated particles is Accounting for 35-45% of the weight of the whole encapsulated particles, the particle size of the encapsulated particles is 0.6-0.8mm. The capsule wall is made of butyl cellulose acetate, and the capsule core is made of hyaluronic acid aqueous solution with a mass fraction of 0.02% and angelica extract, and the mass ratio of the two is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com