Process for simultaneously extracting pigments, saponins and polysaccharides of sapindus, and preparation and application of saponins of sapindus

A sapindus saponin and extraction process technology, applied in skin care preparations, alkali soap/ammonium soap compositions, cosmetic preparations and other directions, can solve problems such as low yield, product precipitation, solvent residues, etc. The method is simple, easy to promote and apply, and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

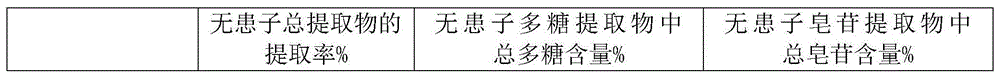

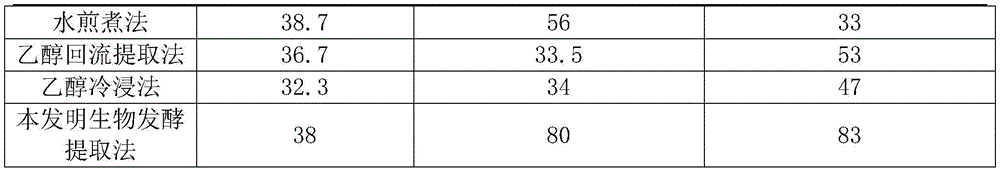

Examples

Embodiment 1

[0039] A simultaneous extraction process of Sapindus chinensis pigment, saponin and polysaccharide, comprising the following steps:

[0040] Step (1), the preparation of the total extract of Sapindus chinensis: crush the dry fruit peel of Sapindus chinensis to 20-40 mesh, decoct it with distilled water at 60°C, the volume ratio of distilled water to the dry fruit peel powder of Sapindus chinensis is 3:1, decocting repeatedly 3 times, decocting for 2 hours each time, filtering, merging the filtrate, concentrating under reduced pressure, drying to obtain the total extract of Sapindus chinensis;

[0041] Step (2), the preparation of Sapindus polysaccharide:

[0042] Soak the macroporous adsorption resin in ethanol for 24 hours, remove impurities, activate, and pack into a column; dissolve the total extract of Sapindus chinensis in distilled water, and make a relative density of 1.02g / cm 3 solution, filter, get the filtrate on the macroporous adsorption resin column, the sample v...

Embodiment 2

[0046] A simultaneous extraction process of Sapindus chinensis pigment, saponin and polysaccharide, comprising the following steps:

[0047] Step (1), the preparation of the total extract of Sapindus chinensis: crush the dry fruit peel of Sapindus chinensis to 20-40 mesh, decoct it with distilled water at 80°C, the volume ratio of distilled water to the dry fruit peel powder of Sapindus chinensis is 5:1, decocting repeatedly 5 times, decocting for 3 hours each time, filtering, merging the filtrate, concentrating under reduced pressure, drying to obtain the total extract of Sapindus chinensis;

[0048] Step (2), the preparation of Sapindus polysaccharide:

[0049] Soak the macroporous adsorption resin in ethanol for 23 hours, remove impurities, activate, and pack into a column; dissolve the total extract of Sapindus chinensis in distilled water, and make a relative density of 1.20g / cm 3 solution, filter, get the filtrate on the macroporous adsorption resin column, the sample v...

Embodiment 3

[0054] A simultaneous extraction process of Sapindus chinensis pigment, saponin and polysaccharide, comprising the following steps:

[0055] Step (1), the preparation of the total extract of Sapindus chinensis: crush the dried fruit peel of Sapindus chinensis to 20-40 mesh, and decoct it with distilled water at 70°C, the volume ratio of distilled water to dried fruit peel powder of Sapindella chinensis is 4:1, decocting repeatedly 4 times, decocting for 2.5 hours each time, filtering, merging the filtrate, concentrating under reduced pressure, drying to obtain the total extract of Sapindus chinensis;

[0056] Step (2), the preparation of Sapindus polysaccharide:

[0057] Soak the macroporous adsorption resin in ethanol for 25 hours, remove impurities, activate, and pack into a column; dissolve the total extract of Sapindus chinensis in distilled water, and make a relative density of 1.1g / cm 3 The solution, filter, get the macroporous adsorption resin column on the filtrate, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com