Scrub soap and preparation process and formula thereof

A kind of scrub soap, the technology of making technology, applied in the direction of soap solution manufacturing, chemical instruments and methods, forming soap, etc., to achieve the effect of protecting the environment, increasing economic benefits, and good maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

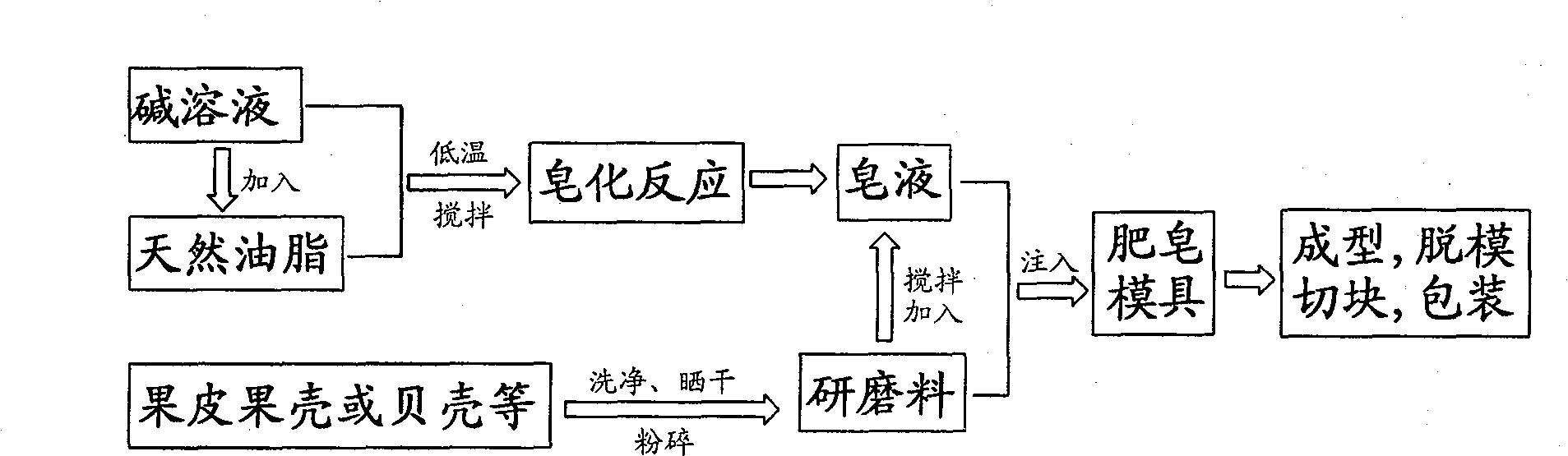

Method used

Image

Examples

Embodiment 1

[0010] Example 1: Pineapple Detox Scrub Soap

[0011] Fresh pineapple peel is washed, dried in the sun, crushed, and passed through a 20-100 mesh sieve to obtain natural pineapple peel particle frosting material, which is set aside. Weigh 200g of coconut oil, 300g of olive oil, 150g of wheat germ oil, 150g of rice bran oil, 100g of evening primrose oil and 100g of cocoa butter into a glass beaker or stainless steel pot, heat in a water bath until all the oils are melted, and cool to 10 Between -50°C. Slowly add 300ml-3000ml of 5%-50% NaOH solution to the above oil under stirring, keep the reaction temperature not exceeding 50°C, and stir for 5-30min until the soap becomes thick. 0.1%-5% of the natural pineapple peel granule scrub material, stir evenly and pour it into the soap mold, leave it for 1-3 weeks until the soap liquid is formed, then demould, cut into pieces, and pack. Before packaging, you can also draw, engrave, or inlay various text patterns on the scrub soap to ...

Embodiment 2

[0012] Example 2: Buckwheat descaling scrub soap

[0013] Take fresh buckwheat husks and dry them in the sun, crush them through a 40-200 mesh sieve to obtain buckwheat husk frosting materials, and set them aside. Weigh 200g of coconut oil, 150g of olive oil, 150g of wheat germ oil, 150g of macadamia nut oil, 150g of almond oil, 100g of evening primrose oil and 100g of tallow into a glass beaker or stainless steel pot, and heat in a water bath until all the fats are melted , cooled to between 10-50°C. Slowly add 10-40% Na with stirring 2 CO 3 Put 200ml-2000ml of the solution into the above-mentioned oil, keep the reaction temperature not exceeding 50°C, and at the same time fully stir for 20-100min until the soap becomes thick, and add about 0.5%-5% of the total weight of the saponified solution. , Stir well and pour it into the soap mold, leave it for 3-8 weeks until the soap liquid is formed, then demould, cut into pieces, and pack. Before packaging, you can also draw, e...

Embodiment 3

[0014] Example Three: Citrus Anticancer Scrub Soap

[0015] Take fresh citrus fruit peels such as orange peels, tangerine peels, lemon peels or grapefruit peels, wash, dry and pulverize through a 60-200 mesh sieve to obtain citrus fruit peel granule scrubbing materials for future use. Weigh 150g of coconut oil, 150g of olive oil, 150g of palm oil, 150g of almond oil, 100g of jojoba oil, 100g of wheat germ oil, 100g of soybean oil and 100g of lanolin into a glass beaker or a stainless steel pot, and heat in a water bath until all The grease is melted and cooled to between 10-50°C. Slowly add 300ml-3000ml of 5-50% KOH solution dropwise to the above oil under stirring, keep the reaction temperature not exceeding 50°C, and at the same time fully stir for 3-30min until the soap becomes thick, add about One or several mixtures of 1%-6% citrus fruit peel scrub materials, stir well and pour into soap molds, leave it for 2-4 weeks until the soap liquid is formed, then demould, cut int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com