Spray head cleaning and maintaining method and apparatus for digital spraying machine

A digital inkjet and nozzle technology, applied in printing and other directions, can solve the problems of inconvenient operation, unreasonable installation, poor maintenance effect, etc., and achieve the effect of simple structure, low production cost and good maintenance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

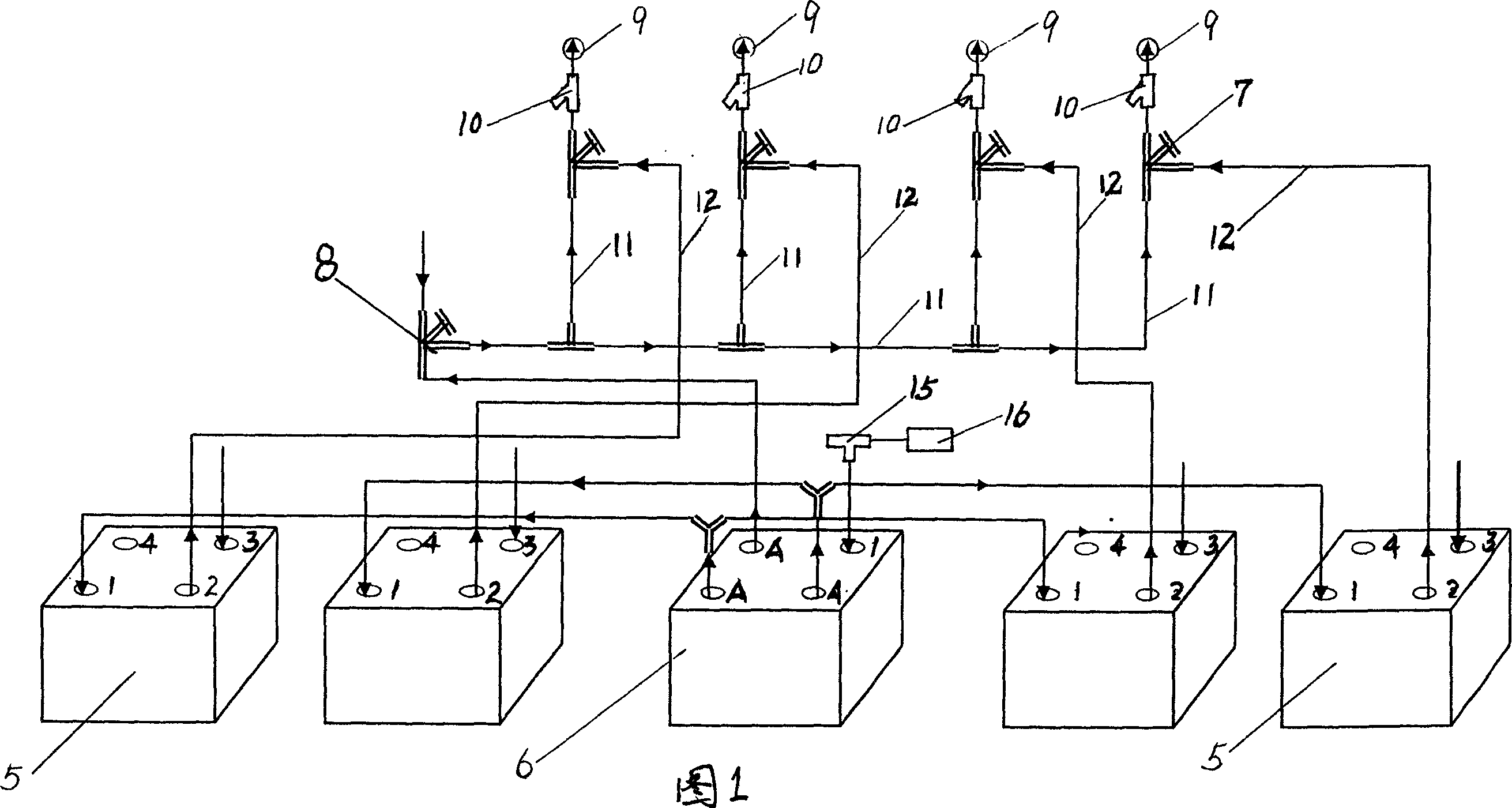

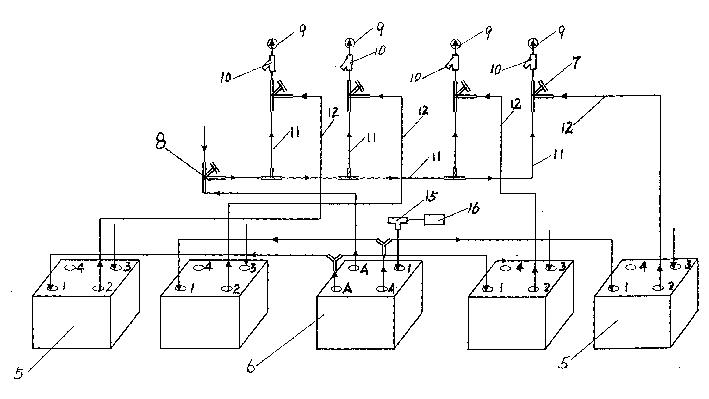

[0027] Embodiment 1: The cleaning and maintenance device of the patent of the present invention mainly includes three circuits: an ink circuit, a cleaning liquid circuit and an air circuit. One is the described ink circuit, which specifically can include: the ink in the main ink bottles of each color passes through the liquid flow pump and the ink filter, injects the ink of this color into the ink supply bottles 5 of each color as required, and in the ink supply A valve body 7 is also arranged between the bottle 5 and the spray nozzle 9, and this valve body can adopt a common three-way valve. One way of the three-way valve can allow ink to enter, and the other way can allow air to enter or cleaning liquid to enter.

[0028] The second is the cleaning liquid circuit: the cleaning liquid bottle is passed through the liquid flow pump and the cleaning liquid filter, and the cleaning liquid is connected to each nozzle 7 through the pipeline; between the cleaning liquid filter and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com