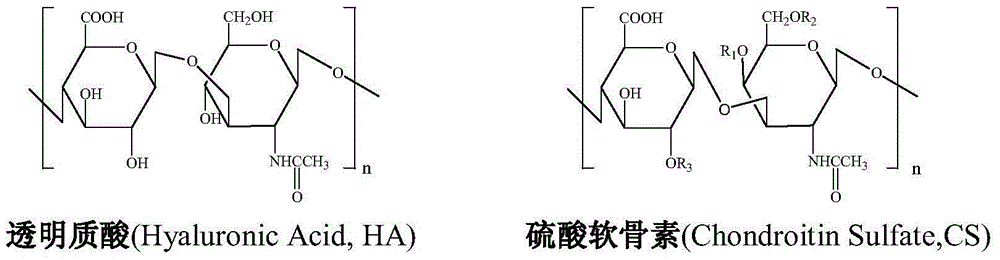

Combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap

A chondroitin sulfate and collagen peptide technology, applied in the fields of chondroitin sulfate, bone meal feed and soap co-production, hyaluronic acid, and collagen peptides, can solve problems such as hidden dangers of ethanol safety, achieve significant economic benefits and increase profit margins Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

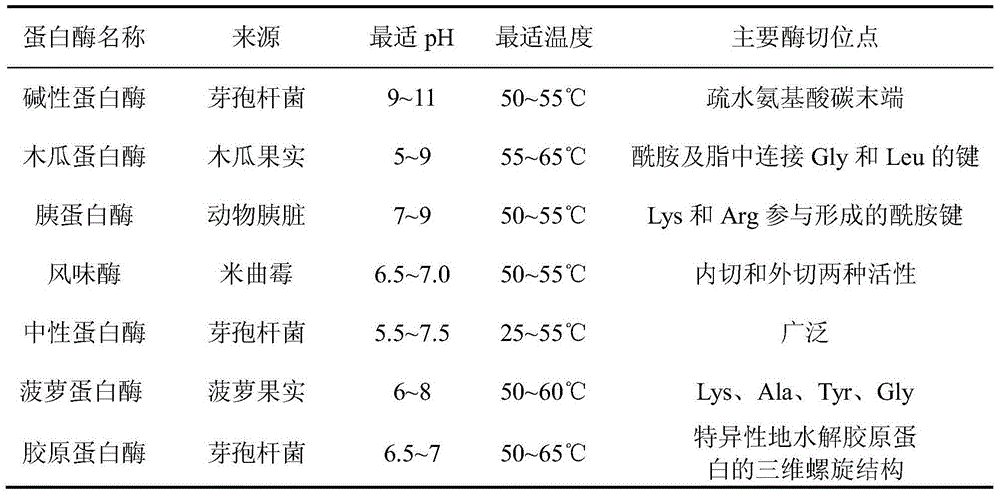

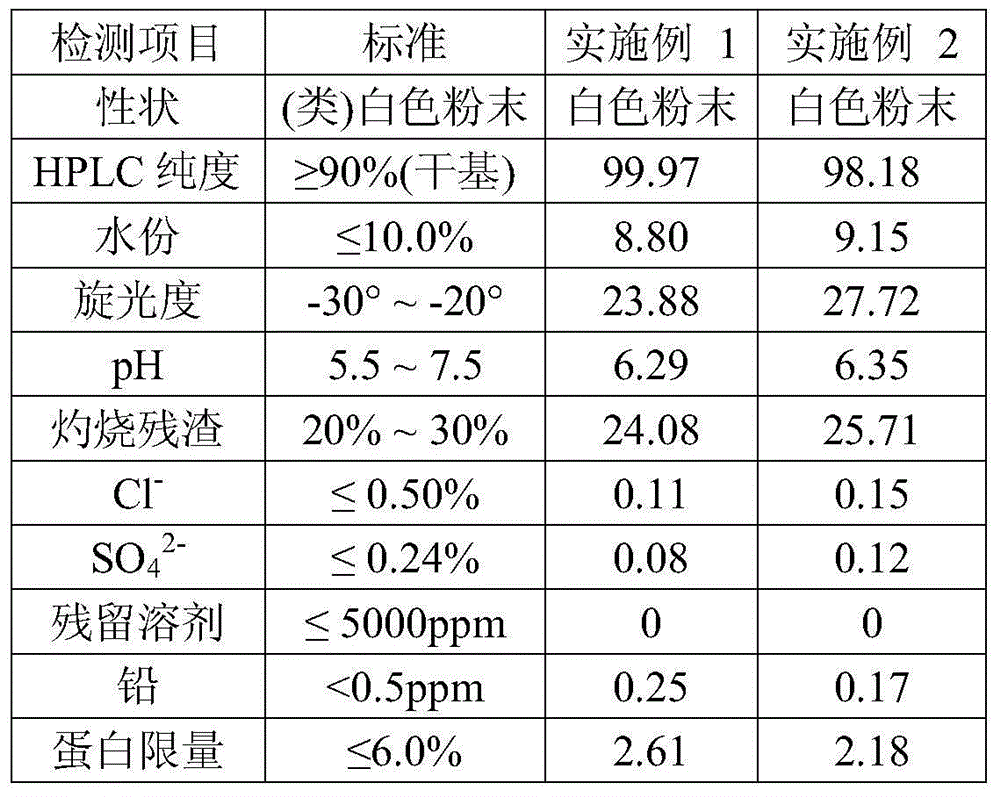

[0070] Crush 1000kg of shark cartilage (including wing bones, vertebrae and skulls), add 4000kg of distilled water, raise the temperature to 75°C, keep it for 1h, cool down to 55°C, adjust the pH to 8.0 with 400g / L NaOH solution, and then add 1×10 9 U complex protease A, hydrolyze at 55°C for 2 hours; adjust the pH to 7.0, then add 4.0×10 8 U complex protease B, hydrolyze at 52°C for 4h; adjust the pH to 6.5 with hydrochloric acid, raise the temperature to 80°C, and keep for 0.5h to inactivate the enzyme. After the enzymolysis is completed, the enzymolysis solution is filtered with a plate-and-frame leaf filter while it is hot, and the filtrate and bone residue-denatured protein complex are obtained respectively. The bone residue-denatured protein complex was vacuum dried and pulverized to obtain 348 kg of bone residue-denatured protein complex powder. After adjusting the pH of the filtrate to 5.0 with hydrochloric acid, put it into a special adsorption resin column for glyco...

Embodiment 2

[0078] Soak 1000kg of bovine and pig cartilage (including nasal bone, larynx and trachea) in water to soften it, then crush it, add 5000kg of distilled water, raise the temperature to 80°C, keep it for 2h, remove the upper layer of bone oil, cool down to 55°C, and adjust with NaOH pH to 8.5, then add 1.4×10 9 U complex protease A, hydrolyze at 55°C for 2h; adjust the pH to 7.0, then add 6.0×10 8 U complex protease B, hydrolyze at 50°C for 5h; adjust the pH to 6.5 with hydrochloric acid, raise the temperature to 80°C, and keep for 0.5h to inactivate the enzyme. After the enzymolysis is completed, the enzymolysis solution is filtered with a plate-and-frame leaf filter while it is hot, and the filtrate and bone residue-denatured protein complex are obtained respectively. The bone residue-denatured protein complex was vacuum dried and pulverized to obtain 121 kg of bone residue-denatured protein complex powder. After adjusting the pH of the filtrate to 5.0 with hydrochloric acid...

Embodiment 3

[0094] Other operating steps are all the same as in Example 2, the difference is that the raw materials used are replaced with various ingredients shown in Table 5, and the theoretical and actual yields of chondroitin sulfate and collagen peptides are calculated respectively, from the table It can be seen from the figure that the yield of chondroitin sulfate and collagen peptide prepared by the present invention is close to the theoretical yield and the yield is high.

[0095] Table 5 Theoretical and actual yields of chondroitin sulfate and collagen peptides from different raw materials

[0096]

[0097] Note: The actual yield of chondroitin sulfate above refers to the yield after removing hyaluronic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com