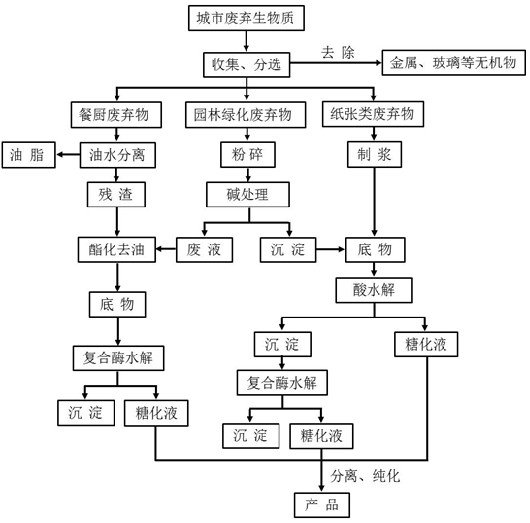

Multi-stage hydrolysis and saccharification method of urban waste biomass resources

A waste biomass and waste technology, applied in the direction of chemical recovery, fermentation, etc., can solve the problems of small application range, variable structure, complex biomass components, etc., to optimize the process route, reduce secondary pollution, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

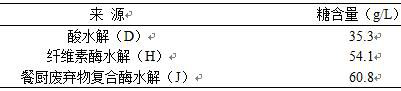

[0029] Example 1: Carry out multi-stage hydrolysis and saccharification of urban waste biomass resources according to the following steps

[0030] (1) Classify and collect 100g of leaves and branches, catering waste, and waste A4 paper to remove metal and glass impurities; dry leaves and branches at 80°C for 24 hours, and crush them through a 100-mesh sieve; gravitational sedimentation of food waste initially removes grease , to obtain the mixture; the A4 paper was crushed into cotton wool, and 300 mL of water was added to stir to make a pulp liquid;

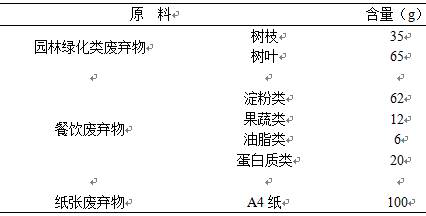

[0031] Table 1 Raw material component analysis (I)

[0032]

[0033] (2) Add 500mL 0.5% NaOH to the garden waste powder, place it in an XO-SM100 ultrasonic microwave reaction system for 2 hours, the ultrasonic frequency of the instrument is 20KHZ, the microwave frequency is 1000MHZ, and the reaction temperature is 50°C. After the treatment is completed, centrifuge at 3000g for 5min to collect the precipitate and waste liquid...

Embodiment 2

[0040] Example 2: Carry out multi-stage hydrolysis and saccharification of urban waste biomass resources according to the following steps

[0041] (1) Classify and collect 100g of lawn and green belt pruning waste, catering waste, and discarded newspapers, and remove metal and glass impurities; lawn and green belt pruning waste should be dried at 80°C for 24 hours, and pulverized by a grinder through a 100-mesh sieve; Gravity settling of the waste preliminarily removes grease and obtains a mixture; the waste is cut and the paper is crushed into cotton wool, and 400mL of water is added to stir to make a pulp liquid;

[0042] Table 3 Raw material component analysis (Ⅱ)

[0043]

[0044] (2) Add 500mL 0.5% KOH to the lawn and green belt pruning waste powder, place it in an XO-SM100 ultrasonic microwave reaction system for 2 hours, the ultrasonic frequency of the instrument is 20KHZ, the microwave frequency is 1000MHZ, the reaction temperature is 50°C, and centrifuged at 3000g ...

Embodiment 3

[0051] Example 3: Carry out multi-stage hydrolysis and saccharification of urban waste biomass resources according to the following steps

[0052] (1) Classify and collect waste tree trunks, leaves and sawdust for greening, catering waste, and waste packaging cartons, each 500g, to remove metal and glass impurities; leaves and branches are dried at 80°C for 24 hours, and pulverized through a 100-mesh sieve; Preliminary sedimentation to remove grease to obtain a mixture; discarded packaging cartons are broken into cotton wool, and 500 mL of water is added to stir to make a pulp liquid;

[0053] Table 5 Raw material component analysis (Ⅲ)

[0054]

[0055] (2) Add 2500mL 0.5% NaOH to the landscaping waste powder, place it in an XO-SM100 ultrasonic microwave reaction system for 2 hours, the ultrasonic frequency of the instrument is 20KHZ, the microwave frequency is 1000MHZ, and the reaction temperature is 50°C. After the treatment is completed, centrifuge at 3000g for 5min and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com