Preparation method of cold-formed soap

A technology of cold-processed handmade soap and saponification liquid, which is applied in the field of preparation of cold-processed handmade soap. It can solve the problems of poor molding of handmade soap, failure of preparation, and solidification of soap liquid in saponification reaction speed, and achieve effective control of saponification reaction speed and saponification. The effect of speeding up the reaction process and speeding up the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

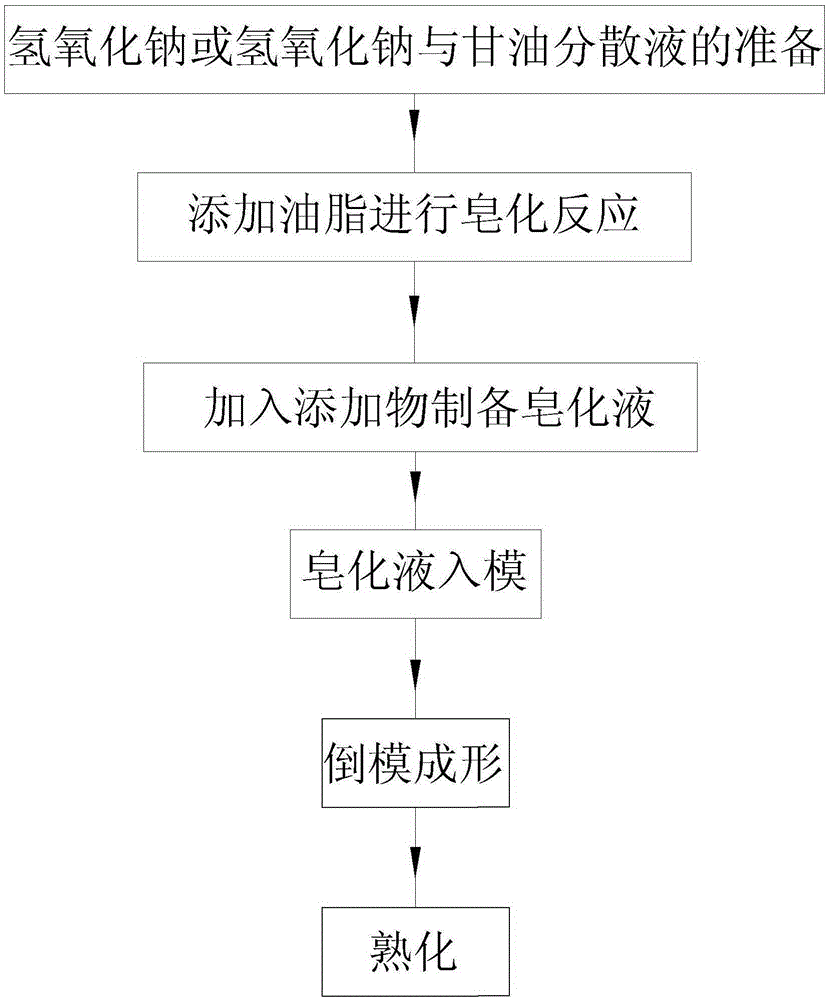

[0037] Such as figure 1 Shown, the preparation method of the present embodiment cold handmade soap comprises the following steps:

[0038](1) By weight, 7 parts of sodium hydroxide were added to 10 parts of glycerin, and sheared and emulsified at a speed of 1000 rpm for 0.5 minutes to make a sodium hydroxide glycerin dispersion;

[0039] (2) Mix the sodium hydroxide glycerin dispersion obtained in step (1) with 100 parts of coconut oil, and shear and emulsify at a speed of 1000 rpm for 0.5 minutes at 20° C.;

[0040] (3) Close the shearing emulsifier, add 0.1 part of milk powder, 0.1 part of lavender essential oil and 0.1 part of vitamin E to the mixed solution obtained in step (2), and stir at a speed of 100 rpm for 0.5 minutes to obtain a saponified solution;

[0041] (4) inject the saponified solution obtained in step (3) into the mould, mold it after 1 day, and then ripen it in 10 days.

Embodiment 2

[0043] The preparation method of the present embodiment cold handmade soap comprises the following steps:

[0044] (1) By weight, 14 parts of sodium hydroxide were added to 20 parts of glycerin, and sheared and emulsified for 2 minutes at a speed of 5000 rpm to make a sodium hydroxide glycerin dispersion;

[0045] (2) Mix the sodium hydroxide glycerin dispersion obtained in step (1) with 100 parts of sweet almond oil, and shear emulsify at 40° C. at a speed of 5000 rpm for 2 minutes;

[0046] (3) Close the shearing emulsifier, add 5 parts of traditional Chinese medicine powder, 1 part of rose essential oil and 1 part of propolis to the mixed solution obtained in step (2), and stir for 2 minutes at a speed of 300 rpm to obtain a saponified solution;

[0047] (4) inject the saponified solution obtained in step (3) into the mould, mold it after 3 days, and then ripen it in 10 days.

Embodiment 3

[0049] The preparation method of the present embodiment cold handmade soap comprises the following steps:

[0050] (1) By weight, 10 parts of sodium hydroxide are added to 15 parts of glycerin, and shear emulsified for 1 minute at a speed of 3000 rpm to make a sodium hydroxide glycerin dispersion;

[0051] (2) Mix the sodium hydroxide glycerin dispersion obtained in step (1) with 100 parts of rosehip oil, and shear emulsify at 30° C. at a speed of 2000 rpm for 0.5 to 2 minutes;

[0052] (3) Turn off the shear emulsifier, add 2 parts of matcha powder, 0.5 part of tea tree essential oil and 0.5 part of honey to the mixed solution obtained in step (2), and stir at a speed of 200 rpm for 1 minute to obtain a saponified solution;

[0053] (4) inject the saponified solution obtained in step (3) into the mould, mold it after 2 days, and then ripen it in 7 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com