A kind of sulfide electrolyte and preparation method thereof

A sulfide electrolyte and high-quality technology, which is applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of poor air stability, avoid contact reaction, avoid moisture reaction, and facilitate transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

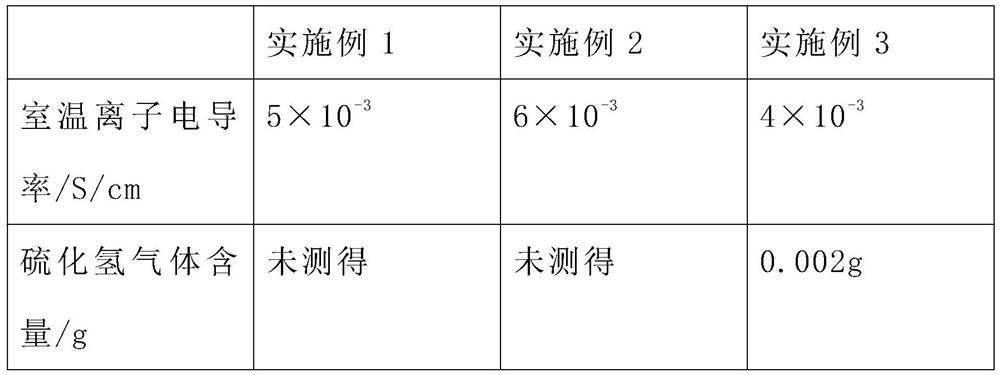

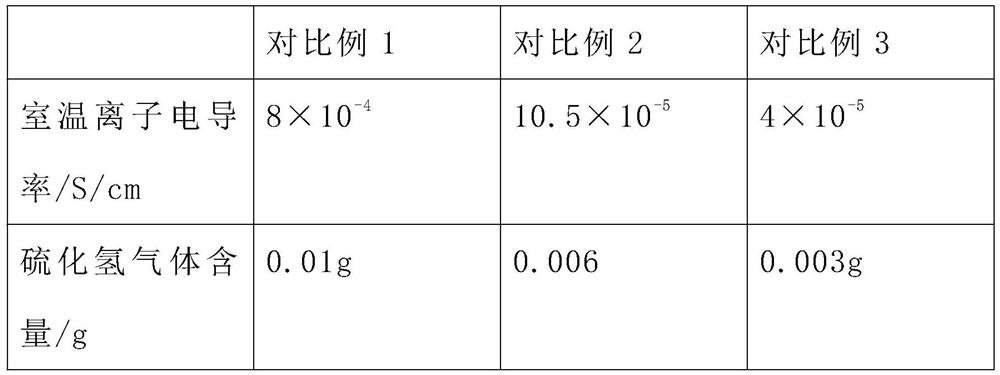

Embodiment 1

[0034] Under nitrogen protection, the molar ratio is (4-x): (1-x): x: 4 to get raw materials lithium sulfide, germanium sulfide and sulfur M, wherein x=0.6; wherein M is P; lithium sulfide, Pour germanium sulfide and phosphorus sulfide into a ball mill tank, and ball mill and mix for 4 hours under nitrogen protection to obtain ball abrasive; then add silicon microcrystals with 1% of the mass of the ball abrasive to the ball mill, stir and mix for 10 minutes, and then Under the conditions, the green body is pressed into tablets to obtain a green body; then the green body is moved into a microwave heater, and under the condition of nitrogen protection, under the condition of a microwave power of 200W, it is heated to 250°C, and after heat preservation and heat treatment for 1 hour, it is cooled and discharged. The product sulfide electrolyte is obtained. By controlling the microwave heating power and holding temperature, the crystallized Li in the product sulfide electrolyte can...

Embodiment 2

[0036] Under nitrogen protection, the molar ratio is (4-x): (1-x): x: 4 to get raw materials lithium sulfide, germanium sulfide and M sulfide, wherein x=0.8; wherein M is Zn; lithium sulfide, Pour the germanium sulfide and zinc sulfide into a ball mill jar, and ball mill and mix them for 5 hours under the protection of nitrogen to obtain a ball mill; then add silicon microcrystals with 2% mass of the ball mill to the ball mill, stir and mix for 12 minutes, and then mix them under a pressure of 300 MPa Under the conditions, the green body is pressed into tablets to obtain the green body; then the green body is moved into the microwave heater, under the condition of nitrogen protection, and the microwave power is 300W, heated to 300 ° C, heat preservation and heat treatment for 2 hours, cooled, and discharged. The product sulfide electrolyte is obtained. By controlling the microwave heating power and holding temperature, the crystallized Li in the product sulfide electrolyte can...

Embodiment 3

[0038] Under nitrogen protection state, the molar ratio is (4-x): (1-x): x: 4 to get raw materials lithium sulfide, germanium sulfide and sulfur M, wherein x=1.0; wherein M is Ga; lithium sulfide, Pour the germanium sulfide and gallium sulfide into a ball mill jar, and ball mill and mix them for 6 hours under the protection of nitrogen to obtain a ball mill; then add silicon microcrystals with 3% mass of the ball mill to the ball mill, stir and mix for 15 minutes, and then mix them under a pressure of 350 MPa Under the same conditions, the green body was pressed into tablets to obtain the green body; then the green body was moved into a microwave heater, and under the condition of nitrogen protection, under the condition of microwave power of 400W, heated to 350°C, heat preservation and heat treatment for 3 hours, cooled, and discharged. The product sulfide electrolyte is obtained. By controlling the microwave heating power and holding temperature, the crystallized Li in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com