A kind of preparation method of graphene coating protection metal lithium microsphere

A graphene coating, metal lithium technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as unfavorable application of lithium ion batteries, and achieve the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

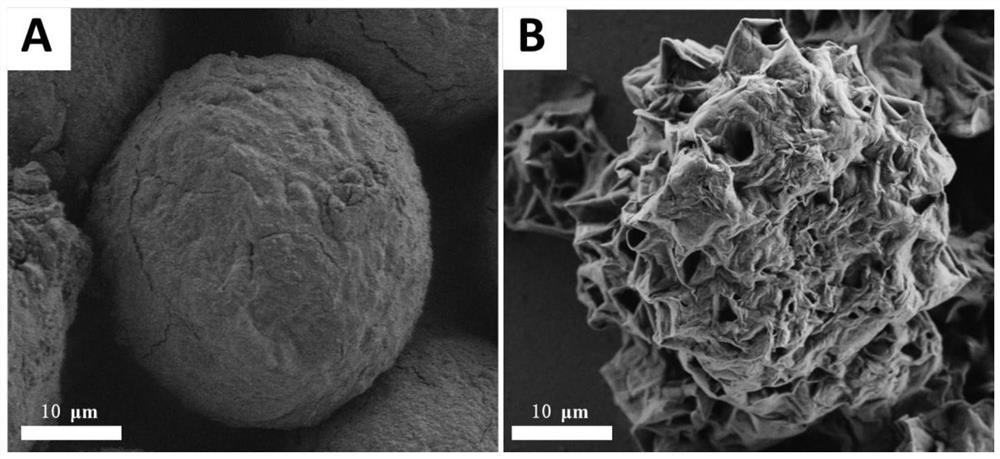

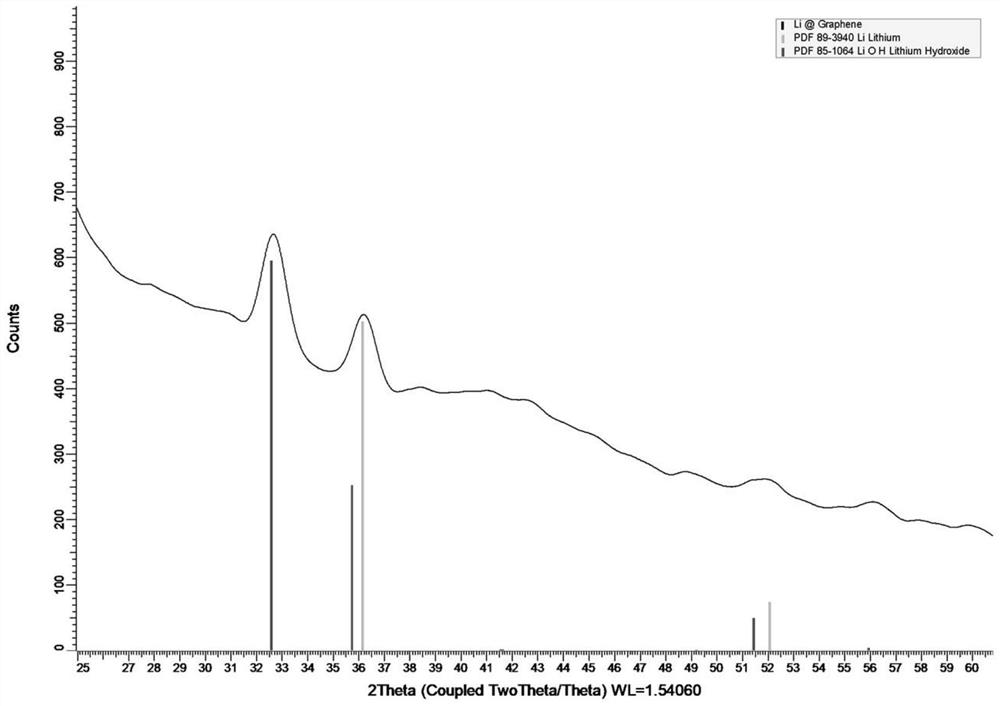

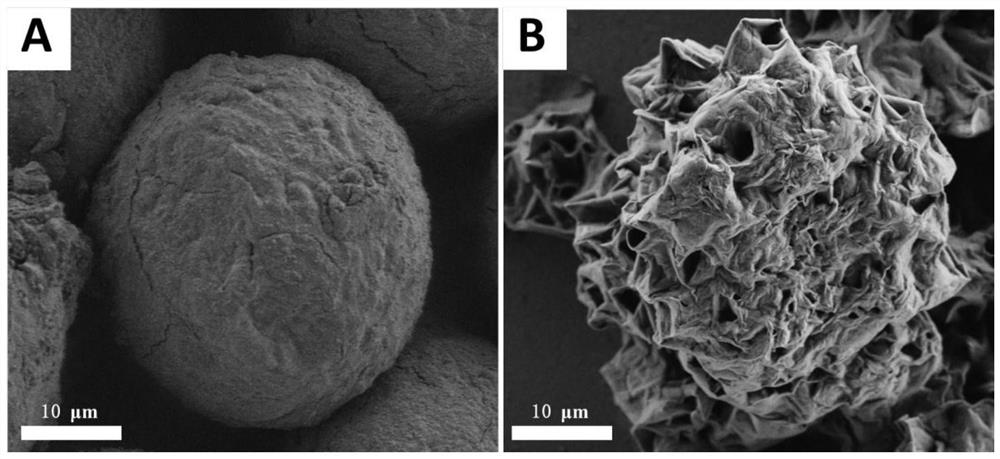

[0020] A preparation method for graphene-coated and protected metal lithium microspheres, comprising the steps of:

[0021] S1. Weigh 80-90mg of lithium metal, add it to 25-35ml of inert solvent, heat the lithium metal in the inert solvent to melt the lithium metal, and disperse it by high-shear stirring to make the molten lithium metal in the inert solvent Micron-sized particles are formed, and then the temperature is lowered to solidify the lithium metal to form a lithium metal microsphere dispersion;

[0022] S2, take by weighing 50~60mg of surface carboxyl-modified graphene after sand milling treatment, join in the inert solvent of 25~35ml, then, carry out ultrasonic dispersion treatment 5~10min, form uniform and stable graphene dispersion liquid;

[0023] S3. Mix the metal lithium microsphere dispersion in step S1 and the graphene dispersion in step S2, fully stir for 30-40 minutes, filter and separate the inert solvent or evaporate and dry it to prepare graphene-coated a...

Embodiment 2

[0028] A preparation method for graphene-coated and protected metal lithium microspheres, comprising the steps of:

[0029] S1. Weigh 80-90mg of lithium metal, add it to 25-35ml of inert solvent, heat the lithium metal in the inert solvent to melt the lithium metal, and disperse it by high-shear stirring to make the molten lithium metal in the inert solvent Micron-sized particles are formed, and then the temperature is lowered to solidify the lithium metal to form a lithium metal microsphere dispersion;

[0030] S2, take by weighing 50~60mg of surface hydroxyl-modified graphene after sanding treatment, join in the inert solvent of 25~35ml, then, carry out ultrasonic dispersion treatment 5~10min, form uniform and stable graphene dispersion liquid;

[0031] S3. Mix the metal lithium microsphere dispersion in step S1 and the graphene dispersion in step S2, fully stir for 30-40 minutes, filter and separate the inert solvent or evaporate and dry it to prepare graphene-coated and pr...

Embodiment 3

[0034] A preparation method for graphene-coated and protected metal lithium microspheres, comprising the steps of:

[0035] S1. Weigh 80-90mg of lithium metal, add it to 25-35ml of inert solvent, heat the lithium metal in the inert solvent to melt the lithium metal, and disperse it by high-shear stirring to make the molten lithium metal in the inert solvent Micron-sized particles are formed, and then the temperature is lowered to solidify the lithium metal to form a lithium metal microsphere dispersion;

[0036] S2. Weigh 50-60 mg of epoxy-modified graphene on the surface after sanding treatment, add it to 25-35 ml of inert solvent, and then perform ultrasonic dispersion treatment for 5-10 minutes to form a uniform and stable graphene dispersion;

[0037] S3. Mix the metal lithium microsphere dispersion in step S1 and the graphene dispersion in step S2, fully stir for 30-40 minutes, filter and separate the inert solvent or evaporate and dry it to prepare graphene-coated and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com